Influence of temperature on thermal relaxation of exchange bias field in CoFe/Cu/CoFe/IrMn spin valve∗

2021-10-28XianJinQi祁先进NiNaYang杨妮娜XiaoXuDuan段孝旭andXueZhuLi李雪竹

Xian-Jin Qi(祁先进) Ni-Na Yang(杨妮娜) Xiao-Xu Duan(段孝旭) and Xue-Zhu Li(李雪竹)

1Engineering Research Center of Metallurgical Energy Conservation and Emission Reduction,Ministry of Education,Kunming University of Science and Technology,Kunming 650093,China

2State Key Laboratory of Complex Nonferrous Metal Resources Clean Utilization,Kunming University of Science and Technology,Kunming 650093,China

Keywords: exchange bias field,spin valves,temperature,thermal relaxation

1. Introduction

In 1986, Grunberget al.[1]found that in the Fe/Cr/Fe sandwiched structure, exchange coupling between Fe layers occurs through the Cr layer, and when the Cr layer thickness is appropriate value,antiferromagnetic coupling is present between the two Fe layers. In 1988, Baibichet al.[2]reported that at a low temperature (4.2 K) with an outfield of 20 kOe(1 Oe=79.5775 A·m−1), the resistance of Fe (3.0 nm)/Cr(0.9 nm) multilayered film prepared by molecular beam epitaxy is increased by 50%, far exceeding the anisotropic magnetoresistance(about 0.2%)of the pure Fe layer.This is called the giant magnetoresistance(GMR)effect,which has attracted attention because of its wide application prospects in highdensity readout heads and magnetic storage devices (such as hard disks).[3–6]Therefore,the recording density of computer hard disks and the data reading speed of magnetic heads are greatly increased, which allows the hard disk capacity to be increased while their sizes are reduced. Because the exchange bias principle in ferromagnetic/antiferromagnetic systems has important applications in GMR heads, non-volatile memory,and magnetic transducers for high-density magnetic recording,materials with exchange coupling effects,such as spin valves and tunnel junctions,have been extensively investigated.[7–11]

The magnetic electronic devices,when being used, must be able to withstand high temperatures or magnetic fields,which reduces the size of the exchange bias field of the devices and also restricts their performances. The thermal stability of an exchange bias greatly influences the reliability of magnetic electronic device. For example, after being treated at 250°C,the FeMn nailing spin valve multilayered film loses the nailing effect of its antiferromagnetic layer,and the GMR may even disappear.[12]In the IrMn nailing spin valve multilayered film,after about 100-°C temperature treatment,it was found that the nailing effect of IrMn antiferromagnetic layer is weakened, and exchange bias field is reduced.[13]Therefore,a study of the thermal–magnetic stability of the exchange bias will help design and use magnetic electronic devices. In addition,the study of thermal relaxation of an exchange bias field will reveal the nature of the exchange bias.

This paper focuses mainly on the influence of temperature on the structure and magnetic properties of spin valve.The relationship between temperature and exchange bias field is analyzed through modeling.At the same time,the characteristics of thermal relaxation of spin valve multilayered film are studied,and the thermal relaxation phenomenon is reasonably analyzed.

2. Experimental process

CoFe/Cu/CoFe/IrMn spin valve was prepared on a silicon substrate by high-vacuum magnetron sputtering (Japan vacuum MPS-4000-HC2). The structure and thickness of the spin valve was Ta(5 nm)/Co75Fe25(5 nm)/Ir20Mn80(12 nm)/Ta(8 nm). To prevent the sample from being oxidized in the air,an 8-nm-thick Ta layer was deposited on the IrMn layer as a protective layer. During sputtering,the background vacuum degree was higher than 5×10−7Pa.High-purity argon gas was used for sputtering,the air pressure was 7×10−2Pa,the sputtering power was 120 W, and the growth rate was controlled at 0.03 nm/s–0.12 nm/s. During deposition,an external magnetic field of 100 Oe was applied parallel to the film surface to induce an easy magnetization direction.

An HH10 VSM was used to measure hysteresis loops at room temperature. The magnetic field was applied parallel to the film surface,and the positive field direction was parallel to the external field direction added during deposition. The magnetic field scanning range was from−800 Oe to 800 Oe,and the scanning speed was 3 Oe/s. The texture of the film was studied with a D8-Advance XRD,and the interface roughness was studied by AFM.

During the thermal relaxation of spin valve,the magnetic field was swept from the forward saturation field to the reverse saturation field,and then remained under the reverse magnetic field with an absolute value greater than 200 Oe–300 Oe.After holding for a certain time,the magnetic field was swept from the reverse saturation field to the forward saturation field.During magnetic field conversion, the back branch curve of the hysteresis loop can be measured. When there is no hold time in the forward saturation field, the front hysteresis loop can be measured by sweeping directly from the forward field to the reverse field. A second residence was then performed at a magnetic field in a range of 200 Oe–300 Oe in the reverse saturation field. The effect of temperature on the thermomagnetic properties of the exchange bias field of the spin valves was studied by the time accumulation method.

3. Results and discussion

3.1. Effect of temperature on structure of spin valves

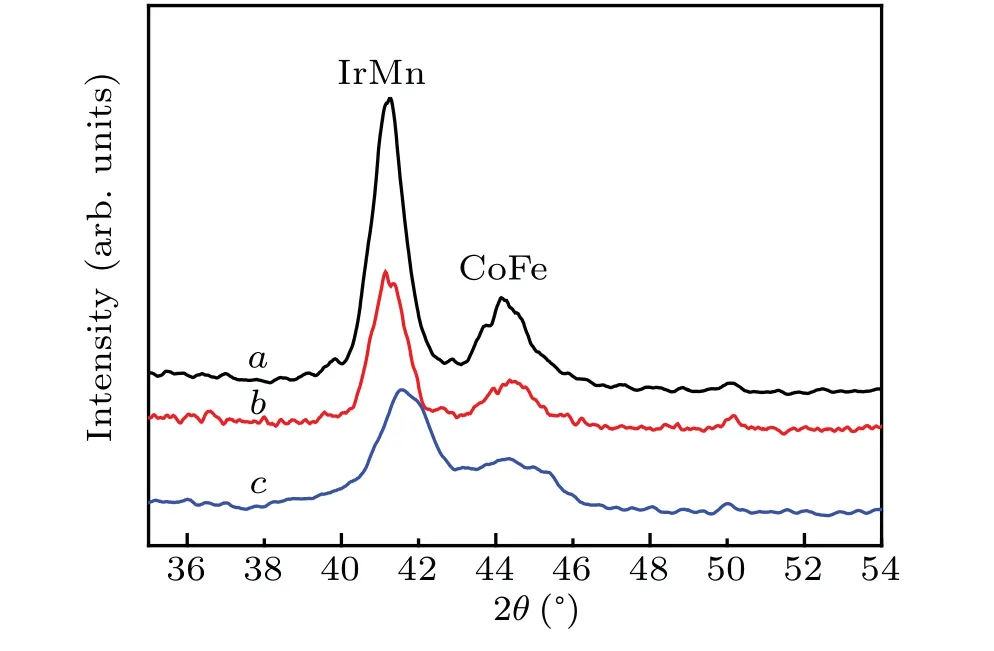

Figure 1 shows the x-ray diffraction (XRD) pattern of the CoFe/Cu/CoFe/IrMn spin valve film at room temperature,150°C,and 275°C and IrMn has a good(111)direction texture. When the temperature increases to 150°C,the peak intensity of IrMn(111)decreases(curveband curvecin Fig.1).When the temperature reaches 275°C, the diffraction peak shifts towards a higher 2θvalue, possibly because of chemical diffusion and strain-relief.[14,15]

Fig.1. XRD patterns of spin valves at room temperature(curve a),150 °C(curve b),and 275 °C(curve c).

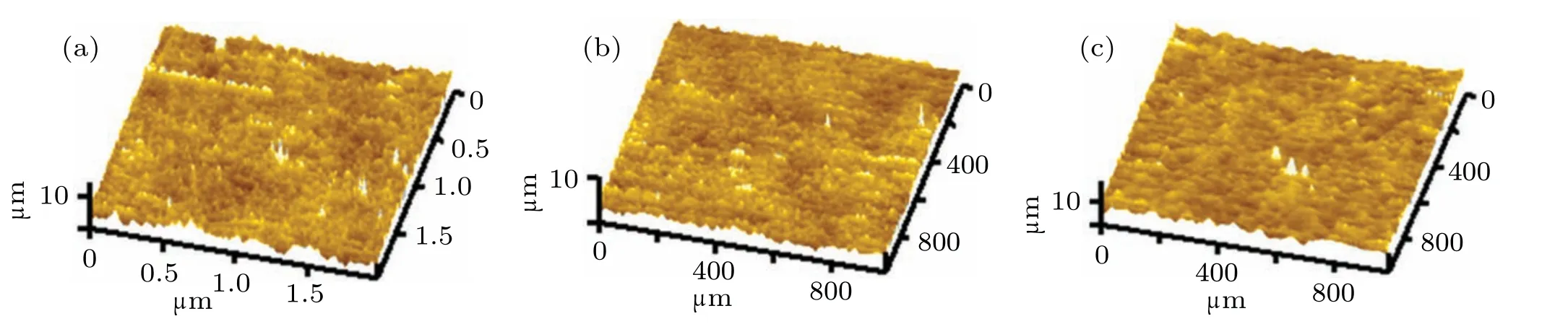

To further investigate the effect of temperature on the structure of the spin valve multilayered film, the surface/interface morphologies are studied by using AFM. It is generally believed that multilayered film deposited by magnetron sputtering is continuous and coherent at a certain thickness when it is deposited continuously at the same pressure.In this way,when the interface is not far away from the surface,the surface morphology is approximately the same as the interface morphology.[16]The ferromagnetic/antiferromagnetic interface in the bilayer film studied in this paper is 20 nm away from the surface. Thus, it is likely that the surface roughness of the sample can indirectly reflect the interfacial roughness between IrMn and CoFe layers.

The AFM images are shown in Fig.2,where figures 2(a),2(b), and 2(c) show the three-dimensional topograph of the sample at room temperature, 150°C, and 275°C, respectively. The correspondingRrmsroughness of the sample is 0.542 nm, 0.791 nm, and 1.078 nm, respectively. The surface/interfaceRrmsincreases with the temperature rising after the spin valve has been heated.This is consistent with the conclusion obtained by Chenet al.,[17]in which the roughness of NiFe/FeMn bilayer increases with the temperature rising.

Fig.2. AFM images of spin valve at(a)room temperature,(b)150 °C,and(c)275 °C.

3.2. Effect of temperature on magnetic properties of multilayer spin valve film

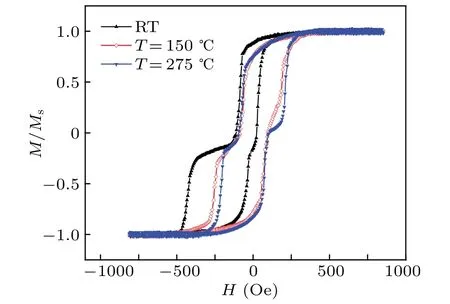

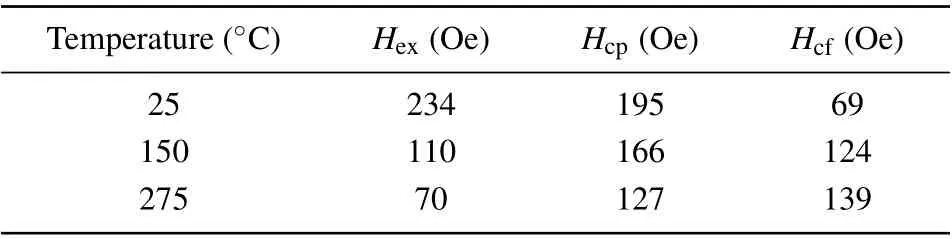

Figure 3 shows that the shape of the hysteresis loop of the CoFe/Cu/CoFe/IrMn spin valve changes greatly with the increase of temperature.Hex=(Hc1+Hc2)/2(Hc1is the value of the forward branch of the hysteresis loop deviating from the zero field,andHc2is the value of the backward branch of the hysteresis loop deviating from the zero field.) shows that the exchange bias field decreases as the temperature increases(specific data are given in Table 1). The coercive force of the pinned layer and the free layer can be obtained from the formula,Hc=(Hc1−Hc2)/2. The coercivity of the nailed layer decreases at higher temperatures, while the coercivity of the free layer increases as the temperature increases(specific data are listed in Table 1).

Fig.3. Hysteresis loops of samples at Tm =room temperature(RT),150 °C,and 275 °C.

Table 1. Values of spin valve exchange bias field, pinning layer, and free layer coercivity at three different temperatures.

According to the XRD pattern(Fig.1), IrMn has a good(111) directional texture after it has been heated at different temperatures,showing that the multilayered spin valve experiences exchange bias after having been heated. However,upon increasing the heating temperature,the IrMn(111)directional texture is weakened,which reduces the pinning effect of IrMn and the spin valve exchange bias field as well.

Roughness is also an important factor that affects exchange bias.[17–19]Generally, the exchange bias field decreases upon increasing the roughness;[20,21]therefore,the increased surface/interface roughness after heating at 150°C and 275°C is another major reason for the reduction in the multilayer exchange bias field of the spin valves.

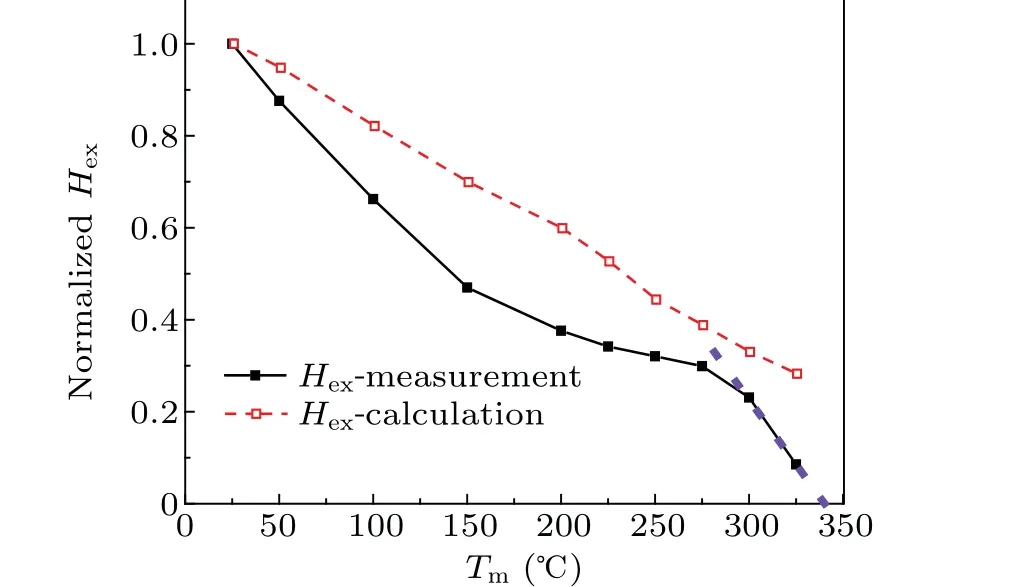

The relationship between the temperatureTmand exchange bias fieldHexfor the spin valve is shown in Fig. 4,whereHexis normalized.Hexdecreases monotonically with temperature increasing, which has already been found in many thin films of exchange coupled systems, such as CoFe/IrMn exchange-coupled bilayer[22]and(CoFe, Co, and NiFe)/Cu/CoFe/IrMn spin valves.[23]The cutoff temperature of thin film can be determined by the linear extrapolation of the exchange bias and temperature plot,and this method shows that the cutoff temperature of the CoFe/Cu/CoFe/IrMn spin valve is about 340°C.

Fig.4. Measured and calculated variation of exchange bias field(Hex)with temperature of pinning layer in a spin valve.

In general, when the temperature is room temperature(Tm),the relation of the exchange bias field with the exchange coupling constant and the saturated magnetic moment can be written as[24]

whereHex(Tm) is the exchange bias field atTm,J(Tm) is the interface exchange coupling constant atTm,Msp(Tm)is the saturation magnetic moment of the pinned ferromagnetic layer atTm, andtFis the thickness of the pinned ferromagnetic layer of the spin valve.

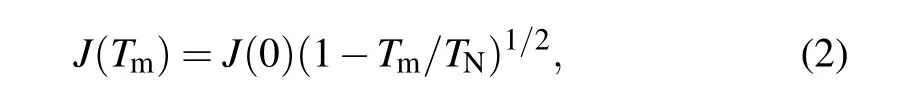

The relationship betweenJandTmcan be written as[25,26]

whereJ(0) is the exchange bias constant between ferromagnetism and antiferromagnetism at 0 K,andTNis the Nell temperature.

According to Eqs. (1) and (2), the equation representing the effect of the size ofHexbecomes

According to formula(3),the relation betweenHexandTmis fitted as shown by the dotted line in Fig. 4, which indicates that there is a slight deviation between the fitted data and the experimental data. This is mainly because changes in the microstructure,such as grain size and texture,are not considered in the fitting formula. However, in the actual processes, increasing the temperature will affect the microstructure(Fig.1).

Figure 5 shows the coercivity of the free layerHcfversustemperature and the saturation magnetic momentMspversustemperature of the spin valve multilayered film. The change in the coercivity withTmof the free layer in spin valve is nonmonotonic, and the maximum value appears atTm=225°C.This phenomenon has also been observed in exchange-coupled NiFe[27]and CoFe films.[28,29]

Fig. 5. Coercivity of the free layer (Hcf) and saturation magnetic moment(Ms)versus temperature of the spin valve multilayered film.

When the temperature is lower than 225°C,bothTmandHcfincrease, mainly because of the phase transition of the CoFe free layer. In general,when CoFe is deposited on the Cu layer,an fcc structure forms easily.[30]In this study,the CoFe free layer deposited on the Ta seed layer may form a partial bcc structure. As the temperature increases, some CoFe with a bcc structure changes into an fcc structure, which increases the fcc phase in the CoFe free layer. Because fcc phase is harder than bcc phase,Hcfincreases withTmincreasing when the temperature is lower than 225°C.

When the temperature is higher than 225°C,Tmincreases andHcfdecreases. This is mainly due to the decline in the texture direction of CoFe(111) in the free layer at elevatedTm(Fig. 1), resulting in a less-anisotropic material.[31]In addition, the transition from a bcc structure to an fcc structure of the CoFe free layer may terminate at about 225°C. For these two reasons,Hcfdecreases asTmincrease at temperatures greater than 225°C.

Fig.6. Normalized coercivity Hcp varying with temperature in nailed layer.

Figure 6 shows the variation in the coercivity of the nailing layerHcpwith temperatureTm. The normalized coercivityHcpof the nailed layer decreases monotonically with the temperature increasing,which is consistent with the Lam Yet al.’s result,[32]who studied the influence of temperature on the coercivity of NiMn/CoFe/NiMn film.

3.3. Effect of temperature on thermal relaxation of multilayer spin valve film

The effect of temperature on the thermal relaxation of the spin valve is studied by placing the samples in a reverse saturated field for different times. Figure 7 shows the variations of multilayered film exchange bias field with residence time in the reverse saturation field of the spin valves at different temperatures. As can be seen from Fig.7, when the temperature is lower than 200°C the exchange bias field decreases as the residence time increases At the beginning of the negative saturation field,the exchange bias field decreases first faster,and then slowly gradually. When the temperature is higher than 200°C,the exchange bias field remains unchanged as the residence time increases.

Fig. 7. Curves of spin valve multilayered film exchange bias field (Hex)versus residence time in reverse saturation field(tsat)at(curve a)room temperature, (curve b) 50 °C, (curve c) 100 °C, (curve d) 150 °C, (curve e)200 °C,(curve f)250 °C,(curve g)275 °C,and(curve g)300 °C.

When the temperature is lower than 200°C,the exchange bias field of the spin valves decreases with the residence time increasing because the magnetic moments in some regions of the antiferromagnetic layer are reversed due to the thermal activation across the energy barrier.[33–35]When the applied magnetic field is scanned from the forward saturation to the reverse saturation,the magnetic moment direction of the ferromagnetic layer is parallel to the direction of the external magnetic field, for the Zeeman energy produced by the external magnetic field is greater than the exchange coupling energy between ferromagnetism and antiferromagnetism. However,the anisotropy of the antiferromagnetic layer is greater than that of the Zeeman energy generated by the external magnetic field. Therefore, the magnetic moment of the antiferromagnetic layer does not change with the direction of the external magnetic field but remains in its original direction.At this time, the system is in a metastable state. When the CoFe/Cu/CoFe/IrMn spin valve multilayered film is still in the reverse saturation field,the magnetic moment of antiferromagnetism begins to reverse due to exchange coupling between strong ferromagnetism and strong antiferromagnetism. The anisotropy energy of the antiferromagnetic layer decreases with the reversal of the magnetic moment,which weakens the pinning effect of the antiferromagnetic layer.With the increase of the residence time of CoFe/Cu/CoFe/IrMn in the reverse saturation field,more magnetic moments in the antiferromagnetic layer are reversed by thermal activation across the energy barrier distribution. Finally,the multilayer film exchange bias field of the spin valve decreases with the increase of the residence time in the reverse saturation field.

At each temperature below 200°C, at the beginning of the negative saturation field,Hexdecreases first faster and then slowly gradually because the smaller antiferromagnetic (AF)domain barrier is lower. The smaller AF domains are reversed more easily than the larger ones.[36]The number of small domains with low energy barriers in the antiferromagnetic layer decreases with residence time increasing at each temperature.In addition, magnetic domain nucleation and domain growth occur during inversion. Under a negative saturation field, vacancies and crystal defects are generated in the thin film,and the magnetic domain nucleation process is more likely to occur near crystal defects.[37]With the film’s residence time in the negative saturation field increasing, the number of defects available for nucleation gradually decreases in comparison with the number of initial nucleation defects. Thus, at the beginning of the residence in a negative saturation field,at each temperature,Hexbegan to decrease first faster and then slowly gradually.

When the temperature is higher than 200°C, the exchange bias field does not change with the residence time increasing, which is mainly because the high temperature increases the energy barrier of magnetic moment inversion in some regions of the antiferromagnetic layer and narrows the overall energy barrier distribution. During residence in a reverse saturation field, the exchange coupling energy between the ferromagnetic layer and the antiferromagnetic layer cannot overcome the energy barrier of the antiferromagnetic moment reversal, because the energy barrier of the moment reversal of each part of the antiferromagnetic layer is relatively large. That is to say, the magnetic moment of the antiferromagnetic layer does not flip when the residence time in the reverse saturation field increases. Therefore, when the temperature is greater than 200°C,the exchange bias field of the spin valve does not change at a longer residence time.

It can be seen from Fig.7 that temperature speeds up the thermal relaxation ofHexin the exchange bias field, that is,the increase of temperature quickens the decrease ofHex. The distribution of the energy barrier determines AF domain inversion, and the mechanism of AF domain inversion is different at different temperatures.[38]When the temperature is relatively low, the magnetic domain of AF layer is reversed uniformly. The energy barrier is fairly wide. To achieve a reversal,all domains must simultaneously cross the highest energy barrier. This reversal pattern must therefore be powerful enough.As the temperature increases,the reversal mechanism changes from uniform inversion to the inversion in the helical domain form. The energy barrier distribution of the inversion in the spiral domain form is relatively narrow,so it is easier to realize the inversion. As the temperature increases, the number of reversals increases due to the helical domains formed by magnetic domains.[36,38]So this speeds up the decrease ofHex. Therefore,the temperature increase can quicken the thermal relaxation of the spin valve exchange bias fieldHex.

4. Conclusions

The effect of temperature on the thermal relaxation of CoFe/Cu/CoFe/IrMn spin valve in an exchange bias field is studied. The results show that the temperature affects the structure and magnetic properties of CoFe/Cu/CoFe/IrMn. As the temperature increases,the texture of IrMn(111)decreases,the surface roughness and interface roughness increase, and the exchange bias field decreases. When the temperature is lower than 200°C,the exchange bias field decreases with residence time increasing, and when the temperature is greater than 200°C, the exchange bias field is basically unchanged though the residence time increases.

猜你喜欢

杂志排行

Chinese Physics B的其它文章

- Physical properties of relativistic electron beam during long-range propagation in space plasma environment∗

- Heterogeneous traffic flow modeling with drivers’timid and aggressive characteristics∗

- Optimized monogamy and polygamy inequalities for multipartite qubit entanglement∗

- CO2 emission control in new CM car-following model with feedback control of the optimal estimation of velocity difference under V2X environment∗

- Non-peripherally octaalkyl-substituted nickel phthalocyanines used as non-dopant hole transport materials in perovskite solar cells∗

- Dual mechanisms of Bcl-2 regulation in IP3-receptor-mediated Ca2+release: A computational study∗