Review of in-space assembly technologies

2021-10-25ZhihuiXUEJinguoLIUChenchenWUYuchuangTONG

Zhihui XUE ,Jinguo LIU ,Chenchen WU ,Yuchuang TONG

a State Key Laboratory of Robotics,Shenyang Institute of Automation,Chinese Academy of Sciences,Shenyang 110016,China

b Institutes for Robotics and Intelligent Manufacturing,Chinese Academy of Sciences,Shenyang 110169,China

c University of Chinese Academy of Sciences,Beijing 100049,China

KEYWORDS In-situ resource utilization;In-space assembly;Modular;On-orbit servicing;Space robots

Abstract With the rapid development of space technology and the increasing demand for space missions,the traditional spacecraft manufacturing,deployment and launch methods have been unable to meet existing needs.In-space assembly (ISA) technologies can effectively adapt to the assembly of large space structures,improve spacecraft performance,and reduce operating costs.In this paper,the development and technologies for ISA are reviewed.ISA is classified from multiple angles,and the research status of ISA is shown clearly through the visual mapping knowledge domain.Then the development status of autonomous robot assembly in the United States,Europe,Japan,Canada and China is reviewed.Furthermore,the key technologies of ISA are analyzed from three aspects:assembly structure design,robot technologies and integrated management technologies.ISA technologies are still facing major challenges and need to be further explored to promote future development.Finally,future development trends and potential applications of ISA are given,which show that ISA will play a vital role in human space exploration in the future.

1.Introduction

Since the beginning of the space program,the spacecraft has been built,integrated and tested on the ground before launch,and retired at the end of its life.1For spacecraft operating in orbit,they often face problems such as high maintenance costs,aging equipment functions,and limited fuel life.2How to ensure a more durable and stable orbital operation of spacecraft in a complex space environment at a lower cost,and achieve the goal of a lunar/Mars plan to establish a safe and cost-effective extraterrestrial base have become the current research focus in the field of space technology.

With the exception of the international space station (ISS),currently all spacecraft are transported to orbit as an integral unit through one launch.In the traditional launch mode,the spacecraft design must meet the following conditions:the mass constraints of the selected launch vehicle,the volume constraints of the launch vehicle fairing and the load constraints imposed by the launch environment.3,4It is obviously unrealistic to use traditional launch methods for structures with large volumes(diameter greater than 15 m or size greater than 20 m,such as large space telescopes,large space habitats).With the improvement of spacecraft performance,the cost of payload development and launch are increasing in this method as well as the complexity of the structure.At the same time,another consequence of this approach is technology obsolescence due to the long-term ground construction and verification process.1,5

Since the 1970s,many international scientific research institutions have begun to study techniques for constructing large structures in space.6NASA was the pioneer of ISA.Due to its application of advanced lightweight structures and experience gained from ISA of international space station and Hubble Space Telescope,NASA immediately began to study the technology of building large structures in space.As the range of spacecraft activities continues to expand into deep space,as well as the trend of networking,integration,and intelligence of space systems,astronaut extravehicular activities have been difficult to apply to large-scale,high-precision,and high-risk ISA tasks.

The application of ISA technologies enables the payload to be fully deployed and utilized which greatly expands the design selection of spacecraft.Meanwhile,ISA provides new upgrade and maintenance functions for the design and manufacturing of spacecraft,and increases the possibility of building large structures in the space environment.7,8In the future,ISA technologies can be used to create fixed structures such as space infrastructure,gas stations,space manufacturing facilities,space tourism complexes,and asteroid mining stations.9Developing a strong and sustainable way of ISA will become the key to human space exploration.

ISA is defined as the assembly activities completed in the target orbit and extraterrestrial space (such as:Low Earth Orbit,Geostationary Orbit,Cis-Lunar Space,Mars Orbit,Mars Surface,Lunar Space and interstellar space),which is to assemble modules in space in order to form a larger functional element,or to recombine one or more structures after separation.In this process,these modules can be combined using their own power and propellant,or they can be assembled from separate spacecraft.10

This paper reviews development and technologies of ISA from seven parts.Section 1 presents the background and significance of the development of ISA.Section 2 classifies the form of ISA from multiple angles.Section 3 analyzes the main research institutions and research hotspots by drawing mapping knowledge domain through visual analysis.Section 4 introduces the development status of the autonomous assembly by space robots in several major countries.Section 5 introduces the key technologies of ISA in detail from three aspects of assembly structure design,robot technologies,and integrated management technologies,and points out the technical challenges in the assembly process.Section 6 points out the future development trend of ISA.Section 7 summarizes the results of the entire review and proposes future prospects.

2.Classification of ISA

2.1.Classification according to the complexity of assembly

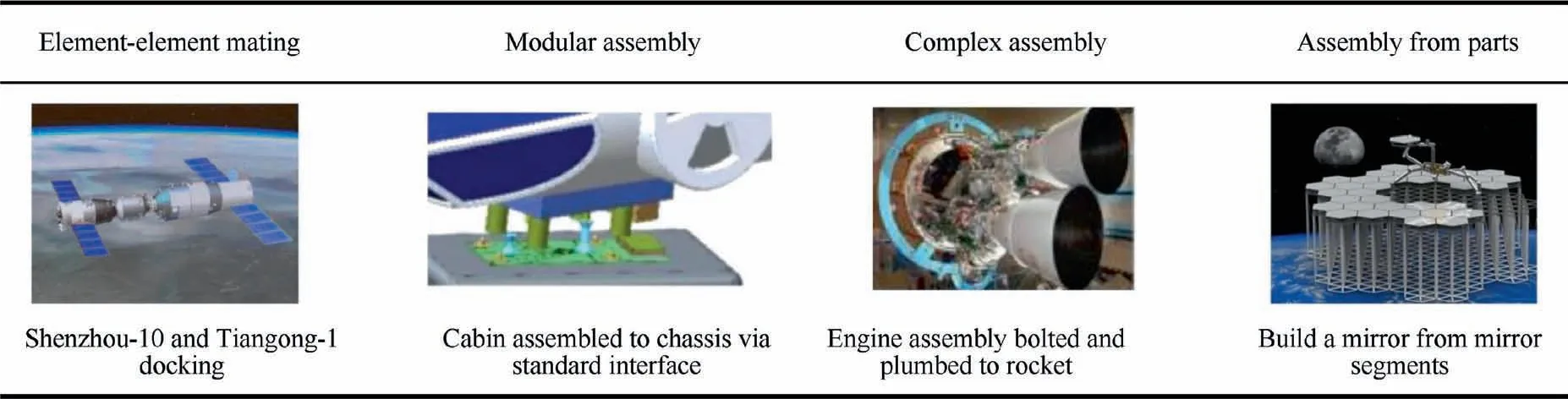

According to the complexity of the assembly,the ISA task of the spacecraft is divided into four levels.11,12As shown in Fig.1:1)Mating between elements:Two or more independent spacecraft are assembled into a larger space structure and assembled in space with the lowest complexity.2) Modular assembly:Docking and assembly of cabins or modules to make it an independent spacecraft or to expand and reconstruct its functions.3) Complex assembly of components:An assembly of components involves an assembly sequence,which requires a lot of operation and interaction to connect.4) Assembly from parts:Assembly from initial parts to components needs to go through multiple assembly stages,which is similar to building a computer from the power supply,heat sink and other parts,such as building a truss from a structural member,or installing a mirror segment and alignment on a structural frame mechanism.

Fig.1 Task level division of ISA.11,12

2.2.Classification according to the assembly positions

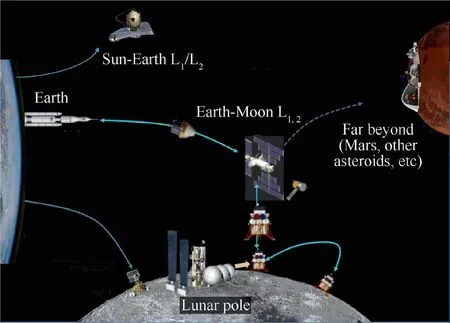

ISA can be carried out on the target orbits and in the interstellar space to complete the overall goal of scientific exploration and space dwelling,13,14as shown in Fig.2.Assembly on the target orbits is known as on-orbit assembly (OOA).Eckersley et al.15defined OOA as the connection,movement,separation(and possible reconnection) of objects.OOA is developing from low-Earth orbits to further orbits.The ISS assembled on the Low Earth orbit (LEO) and the telescopes assembled on the Sun-Earth Lagrangian Point are good examples.Moreover,establishing the Deep Space Gateway on the cis-lunar space can not only perform lunar missions,but also transport spacecraft to Mars as well as other deep space destinations.Assembly in interstellar space includes assembly on the surface of the moon,Mars,and other asteroids,and is committed to achieving in-situ resource utilization (ISRU) on the surface of the planet,such as building a fuel plant on the surface of the moon,an infrastructure on the surface of Mars,and a mining station on other asteroids for deep space exploration in the future.

Fig.2 Schematic diagram of ISA positions.13,14

2.3.Classification according to the assembly implementation

ISA can be done by astronauts or robots.Technologies for assembling spacecraft in space have developed for decades.So far,these efforts have mainly been made by astronauts performing tasks.16Strict manual assembly outside the cabin has become impractical due to limitations of the assembly structure size,the outer space environment and the astronaut’s own conditions.17,18According to the different assembly tools used,ISA technologies of the space structure can be divided into:1) manual assembly by astronauts with assembly assistance,and 2) autonomous assembly by space robots.The following will mainly introduce its development and technology according to the implementation of space assembly technology.

2.3.1.Manual assembly by astronauts with assembly assistance

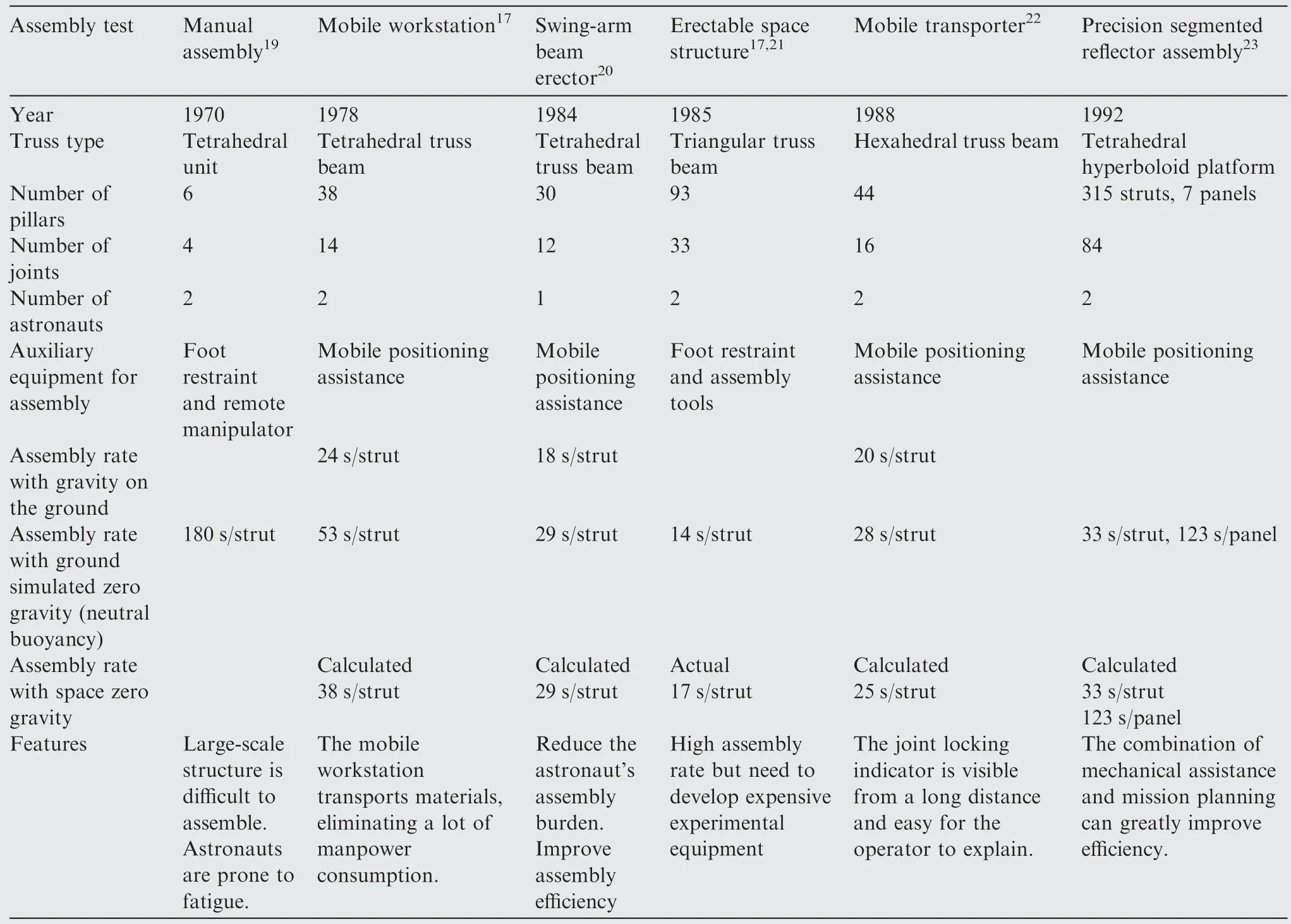

The manual assembly technologies by astronaut represented by the United States and Russia,mainly use space shuttle or spacecraft to send astronauts into space,and then complete the assembly task through astronauts wearing extravehicular space suits.The technologies of the United States and Russia have become mature.From the 1970s to the early 1990s,the Langley Research Center (LaRC) conducted a series of research on the manual assembly of large space structures.These studies were conducted under three environmental conditions:ground gravity,ground simulated zero gravity,and space zero gravity.Table 1 shows the comparison of assembly tests when using different auxiliary equipment,6including manual assembly of tetrahedral structural units,19mobile workstation assembly of tetrahedral truss beams,17swingarm beam erector,20construction of erectable space structure,17,21mobile transporter,22precision segmented reflector assembly.23The following conclusions were finally concluded by a series of manual assembly studies:(1)Using mobile workstation and swing-arm beam erector to assist astronaut assembly can reduce astronaut fatigue.(2) Mission planning can reduce the spare time of astronauts during assembly and improve the efficiency.(3) The use of human and robotassisted deployable construction methods can mitigate cost and risk issues,and achieve the versatility of the spacecraft structure.On this basis,Heard et al.17gave a comparison of the rates of three different ISA methods:strict manual assembly,mobile workstation assembly and automatic machine assembly.In addition,since the 1970s,on-orbit servicing by astronauts,such as maintenance of Skylab and the Solar Maximum Mission satellite,the ISS and the Hubble Space Telescope (HST) have laid the foundation for the development of space assembly technology.24

Table 1 Comparison of space structure for astronaut manual assembly.

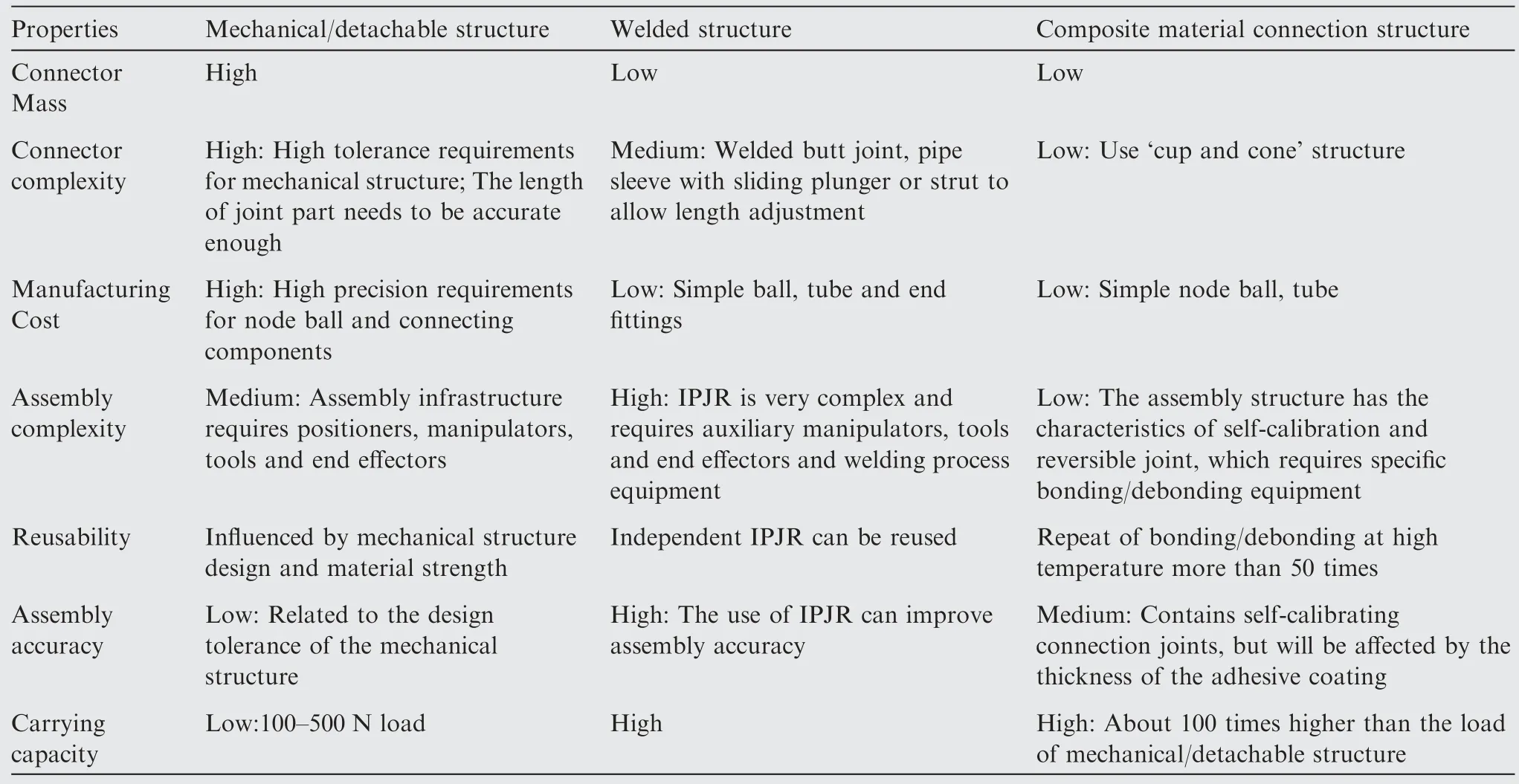

Table 2 Comparison of different connection structuresy.43,133

2.3.2.Autonomous assembly by space robots

With the development of ISA,in addition to space remote control robots,18,25researchers began to work on fully autonomous space robot systems for autonomous assembly.The space autonomous assembly robot includes onboard robotics,free-flying assembly agents,and persistent assembly platforms,26as shown in Fig.3.

Fig.3 Classification of autonomous assembly robots.26

3.Literature analysis

This section analyzes ISA from the perspective of literature.The search was performed in the database of Web of Science core set with ‘‘in-space assembly”or ‘‘on-orbit assembly”or‘‘in-space manufacturing”as the search subject,using the search formula ‘‘(assembly or manufactur *) and (space or orbit) and robot”.The time span is 1990–2020 and the document type is (Article OR Review).After searching,a total of 517 related search results were obtained.The date of data acquisition is February 27,2020.

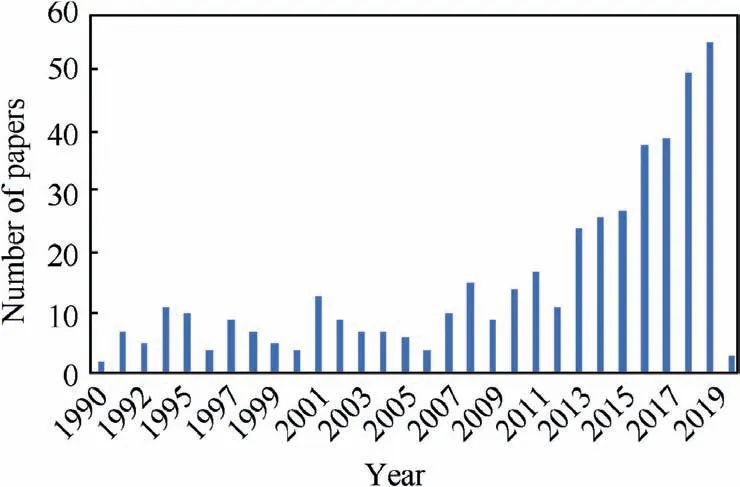

Fig.4 shows the number of related papers published in 1990–2020.Through the analysis of the trend of the number of published articles,we can understand the changes in the research focus in this field.It can be observed that the number of papers published increased gradually between 1990 and 2020.From 1990 to 2012,the number of papers remained basically the same,but since 2013,the number of papers has increased significantly.It shows that the in-space assembly technologies have good progress prospects.

Fig.4 Number of papers over time.

3.1.Research subjects of ISA

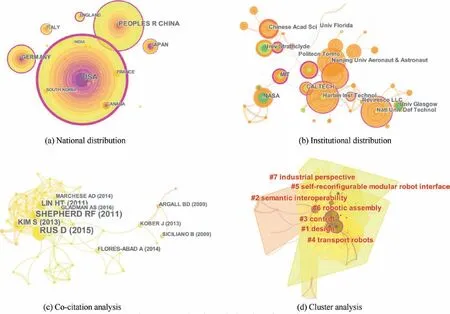

In this paper,517 samples are analyzed by using the visualization software of CiteSpace 5.5.R2 based on Java platform to draw the mapping knowledge domain.Through the analysis of the distribution of countries and institutions,we can understand the research subjects in this direction,as shown in Fig.5(a).The size of the node circle indicates the contribution rate of the country in the related research field,and the centrality of the node represents its importance in the map.Through visual analysis,it can be clearly seen that in the field of ISA,countries such as USA,CHINA,GERMAN,and JAPAN have made significant contributions.The institutions that conduct in-depth research on ISA technology include:National University of Defense Technology,Harbin institute of technology,Chinese Academy of Sciences,NASA,etc.,as shown in Fig.5(b).Through literature co-citation analysis,Fig.5(c)shows the scientists who have made outstanding contributions in this field,such as Shepherd RF,Rus D,Kim S and others.At the same time,the literature co-citation analysis can indicate the development process in this field.

3.2.Research hotspots of ISA

Clustering analysis with key words shows that in-space assembly belongs to an interdisciplinary field and involves many research fields.Among them,the hot research directions that researchers are interested in are:design,self-reconfigurable modular robot interface,semantic interoperability and so on,as shown in Fig.5(d).Among them,modular reconfigurable,human-robot interaction and other characteristics of space assembly robots represent the current development direction.

Fig.5 Mapping knowledge domain analysis.

4.Research status of ISA

With the continuous expansion of the application field of space technology,the increasing diversification of the operation orbit,and the continuous complexity of the assembly structures,all countries are actively carrying out the research of ISA technologies and developing their own ISA technologies.OOS have set the stage for the development of ISA.Countries represented by the United States,Europe,Japan,Canada,and China have launched a series of space assembly experiments.

4.1.Research status in the United States

Since the early 1990s,the United States has begun research on autonomous space assembly technology.The early ISA mainly relied on rendezvous and docking.There are many explorations in the United States.For example,the United States successfully demonstrated Apollo,which was used for the automatic guidance,navigation and control functions of rendezvous and docking,as well as Shuttle27that demonstrated rendezvous and capture of various types of spacecraft for the assembly of spacecraft,such as the ISS.However,these rendezvous and docking were all completed by astronauts.After that,the United States carried out the research of autonomous rendezvous and docking between modules.At the same time,Due to certain limitations of astronaut assembly,low quality,large-area space truss structure is the primary candidate for structure selection in space assembly.The assembly of the ISS and the orbital maintenance and system upgrades of the HST have set a precedent for ISA.28,29

XSS.Beginning in the late 1990s,the US Air Force Research Laboratory built a series of low-cost microsatellites,the most representative of which was the‘‘Experimental Satellite System”(XSS)program.In January 2003,the first XSS-10 was launched.After that,the practice of a series of demonstration test satellites XSS-11 (Fig.6) and XSS-12 provided valuable experience for the development of independent assembly technology in the United States.24

Skyworker.NASA launched a plan for ‘‘Exploratory Research and Technology of Space Solar Energy”,and planned to achieve space verification of the 10 MW system in 2020.The Robotics Laboratory at Carnegie Mellon University in the United States collaborated with NASA to design a robot system called Skyworker(Fig.6)for on-orbit assembly,inspection,and maintenance tasks.It has the ability to move autonomously and to move loads autonomously.Its coverage reaches several kilometers,and its load capacity can reach ton level to realize large-scale space structures,especially the assembly of space solar power stations.30,31

DART.In 2001,the Demonstration for Autonomous Rendezvous Technology (DART) introduced by NASA (Fig.6)was initiated by the Orbital Science Corporation (OSC).32The mission goal of DART is to demonstrate the hardware and software technologies required for autonomous rendezvous in orbit,including testing the main performance of sensors,computers,propulsion systems and related software installed on DART.DART uses advanced video guidance sensors to provide communication when approaching the target satellite.Although the task could not be successfully completed,the autonomous rendezvous technology verified by it played an important role for Orbital Express.33

Fig.6 Typical representatives of development of American in-space assembly.

SUMO.Spacecraft for the Universal Modification of Orbits (SUMO)34was a risk reduction program for advanced maintenance spacecraft,which was executed by the Naval Space Technology Center.Developed in 2005,the purpose of this program is to demonstrate the integration of machine vision,robotics,machinery and autonomous control algorithms to achieve OOA,removal of orbital debris,docking with customer satellites and orbital maneuver.SUMO is a modular spacecraft consisting of a high-performance propulsion module and a payload module containing autonomous rendezvous and grab systems (Fig.6).The payload module includes three 7-DOF (7-DOF) universal robotic arms,a variable baseline machine vision system,and a toolbox with multiple end effectors.SUMO could disassemble and install ORUs and supplement propellant and pressure agent.

Orbital Express.The ‘‘Orbital Express”35,36(Fig.6) sponsored by the Defense Advanced Research Projects Agency(DARPA) was initiated in March 2007.ASTRO,the service satellite,can independently capture and dock the target satellite NEXTSat,and replace the modules.While NEXTSat,the target satellite,is responsible for simulating the faulty satellite and the orbital storage platform.The mission successfully demonstrated robot satellite service activities and some activities to replace the orbital replacement unit (ORU) for the first time.During the approximately four-month mission,Orbit Express confirmed that the key technologies required for satellite services had been already in place.The success of the‘‘Orbital Express”showed that the United States had taken the lead in the world in autonomous assembly.

The Notional Missions.NASA reported the Notional Missions design concept proposed by the GSFC R&D team in 2010.12Its purpose is to investigate unsampled areas in the space for trade in satellite services.These tasks include:GEO Supersync(NM1),GEO Refueling(NM2),LEO Refurbishing(NM3),Earth-Moon L1 (EML1) Robotic Assembly (NM4),Highly Elliptical Orbit (HEO) Refurbishing (NM5),and Sun-Earth L2 (SEL2) Human/Robotic Assembly (NM6).24Among them,the main tasks of NM3 and NM5 are on-orbit refurbishment and upgrade,and the main tasks of NM4 and NM6 are ISA.

The main goal of NM4 is to develop a servicer design concept for assembling a Thirty-Meter Space Telescope (TMST)on Earth-Moon L1.Its flight part includes Robotic Telescope Construction Servicer (RTCS) and 11 Barges,which are mainly used to carry assembled parts to create TMST and robot modules.The RTCS system consists of two robotic arms,the long arm is used to capture and transfer large components docked,while the short arm is used for smart work such as structural assembly (Fig.6).The main goal of NM6 is to develop a Servicer design concept for human–machine collaboration to assemble a large observatory on Sun-Earth L2 (SEL2).NM6 is scheduled to be launched in 2035.The NM6 flight segments include the Human and Robotic Telescope Construction Servicer (HRTCS),four Modular Propulsion System and Telescope (MPST) elements,a human habitation facility,an airlock,and the Orion crew module(Fig.6).24The four MPST units will be launched in sequence and actively rendezvous and dock with HRTCS.The research focus of NM6 is the design of HRTCS.HRTCS has two 20 m robotic arms for parking activities and large-scale assembly tasks and six Robot Mounting Points (RMPs).Therefore,it is possible to provide platform support for the robot and human construction of the observatory,as well as robot tools and vibration holding parts for the reconfigurable robot arm.MPST is a spacecraft bus used to transport observatory components to SEL2,while Orion spacecraft is used to transport crews to SEL2 orbit.The main task of assembling the observatory will be completed by astronauts under the guidance of the ground control center through 17 EVAs in collaboration with robots.When the assembly is completed,HRTCS will be separated and continue to serve on orbit.

eXCITe.The DARPA of the United States Started the‘‘Phoenix Project”in 2011,37which aimed to recycle the components of failed satellites in GEO orbit and realize on-orbit assembly of the new spacecraft system by using space robot technology.The plan first proposed ‘‘Satlets”.38That is to say,modular satellite was designed based on cell morphology.In addition,standardized interface and replaceable satellite architecture were adopted to realize low-cost and standardized mass production of modular satellite.In December 2018,the‘‘Experiment for Cellular Integration Technologies”(eXCITe)composed of 14‘‘Highly Integrated Satellites”(HISat)entered the sun synchronous orbit to carry out the third test of onorbit verification,the schematic diagram of its on-orbit flight is shown in Fig.6.HISat is a single unit,just like a human embryonic cell,which can self-differentiate as needed to become any tools it needs.

Robonaut 2.Since 2011,Robonaut 2(Fig.6),developed by NASA and General Motors(GM),has become the first humanoid robot in space.39,40The robot has advanced mechanical control technology,sensitive sensors and visual technology,which are used to assist astronauts to complete sporadic work and maintenance tasks in the international space station after Robonaut.Ground tests have demonstrated the robot’s ability to carry out different tasks,including the assembly of truss structures.41In the future,it will be planned to replace astronauts to accomplish extra-vehicular activities(EVA)and other space missions.

SpiderFab.In addition to research on autonomous assembly robots,the United States has also developed in-space manufacturing in recent years.‘‘SpiderFab”was a concept of inspace manufacturing system proposed by American Tether Infinite Company in 2012 to overcome the launch limitation of the launch vehicle and change the development and deployment of spacecraft.42SpiderFab uses its own 3D printing heads and materials to manufacture specific spatial structural units on orbit and assemble them to form large space systems such as huge radio antennas,solar arrays or solar sails.It is planned to realize autonomous assembly in space in 2024.Fig.6 shows the concept diagram of SpiderFab fabricating parabolic reflector.

SALSSA.In 2015,NASA’s Space Technology Mission Directorate (STMD) sponsored a small study to investigate and determine the technology required for the space assembly of large structural system Architectures(SALSSA),43and identified its focus applications3including:1)Solar electric propulsion(SEP),44–47the conceptual rendering is shown in Fig.6.2)Next-generation large space telescope.3) Multi module vehicles;4) Space aggregation facilities;5) Planetary surface systems.

Tipping Point Program.At the end of the same year,STMD‘‘Tipping Point Program”took advantage of the growing interest and capabilities of the commercial sector to develop robot ISA capabilities.STMD dedicated to promoting ISA assembly performance,including improvements Longdistance manipulation,reversible precision connection,power/data/mechanical connection interface,functions required for robot assembly and additive manufacturing.48The project includes:1) Archinaut:multifunctional space robot precision manufacturing and assembly system (Made in Space,Inc.),2) Commercial In-space Robotic Assembly and Services(CIRAS):public private partnership for the manufacture and assembly of space robots for spacecraft and space structures (Orbital ATK),and 3) Dragonfly:On-orbit robot installation and reconfiguration of large solid-state RF reflectors (Space Systems Loral (SSL)).49

Among them,the core of Archinaut(Fig.7(a))is to extend the tradition of research and development to realize space manufacturing,assembly,automation,recycling,In-situ resource utilization (ISRU) and the vision of the next generation of space habitat,that is,all aspects of the habitat are assembled and integrated in space.Archinaut will use the 3D printing technology and the ‘‘Additive Manufacturing Facility”(AMF) that have been verified on the ‘‘International Space Station”for in-space manufacturing.25,50Archinaut is now renamed OSAM-2,a manufacturing system that can significantly reduce risks and costs.51CIRAS (Fig.7(b)),started in October 2016,included demonstrations of robot reversible connection methods for mechanical and electrical connections,feasible concepts for verifying the geometry of space assembly,and demonstration of repeatable module interfaces for space structure assembly.In the future,it will be used for robot assembly,repair,maintenance and refurbishment capabilities,and the reuse of spacecraft modules,such as assembling truss and connecting solar panel modules.50,52Dragonfly53(Fig.7(c)) will assemble and reconstruct large solid RF reflector on orbit to demonstrate the in-space assembly technologies of autonomous antenna,and change the assembly modes of existing satellites.In September 2017,the‘‘Dragonfly”project successfully completed the ground demonstration test by using a 3.5 m robotic arm system to assemble a large antenna reflector for the ground simulation satellite.The next step is to apply these capabilities to on-orbit operations,drive the in-space assembly of geosynchronous satellites,improve satellite performance by assembling larger antennas,and improve mission flexibility by moving or replacing satellite antennas.

Fig.7 Tipping Point Program.50,52

Restore-L.NASA’s Restore-L flight program,launched in 2016,is based on the collective history of spacecraft and hardware in-space assembly,repair,refueling and maintenance.54,55These technologies are essential for future construction of space infrastructure.In April 2020,Restore-L was renamed On-orbit Servicing,Assembly and Manufacturing mission 1(OSAM-1).OSAM-1 is led by NASA’s Exploration &Inspace Services (NExIS) project in Goddard and is currently being implemented in collaboration with Maxar Technologies.The OSAM-1 spacecraft and its attached space infrastructure dexterous robot Space Infrastructure Dexterous Robot (SPIDER) will refuel satellites in space,assemble communication antennas and manufacture beams (Fig.6).56During the ground demonstration phase of NASA’s Tipping Point Program,SPIDER was previously known as the ‘‘Dragonfly”.It will assemble seven components to form a functional 3-meter communications antenna.57

Hive.In February 2018,NASA announced that through the‘‘Hive”project,it would study the feasibility of using intelligent unit modules to self-assemble into a variety of spacecraft platforms on demand.‘‘The Aerospace Corporation Hive”58(Fig.6) is based on a mass-produced cube that can rotate a‘‘face”while connecting to other hive units.Hive ‘‘unit”has the ability of self-assembly and reassembly on orbit,which depends on the improvement of functional requirements,and can improve the flexibility of space systems.

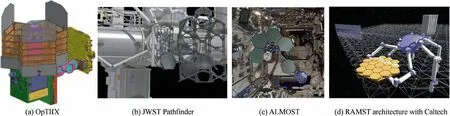

Large Space Telescope.For the assembly of large space telescopes,in the early 1990s,NASA conducted extensive technical development of the far-infrared space telescope with a diameter of 20 m,and finally formed a precision segmented space telescope reflector.59,60NASA is currently demonstrating the capabilities of ISA on various mission platforms,such as the Optical Testbed and Integration on ISS eXperiment(OpTIIX) (Fig.8(a)),a small 1.5-meter optical telescope installed on the International Space Station,which main goals include demonstration of telescope assembly technology and end-to-end optical system technology,61and ground test project James Webb Space Telescope (JWST) Pathfinder (Fig.8(b)),which will provide an opportunity for people and robots to coordinate in space assembly.62The large-aperture telescope ALMOST obtained by independent assembly of electromagnetic formation flight (EMFF) on ISS (Fig.8 (c)),is initiated by MIT,NASA Goddard Space Flight Center (GSFC),and Aurora Flight Sciences.63,64Its goal is to demonstrate the assembly of space robots with precise and potentially flexible structures under microgravity conditions.In addition,Lee et al.65of Caltech proposed an architecture and conceptual design of a robot-assembled modular space telescope(RAMST),which can be used for assembly in Earth orbit and operation at Lagrange point 2 in the Sun and Earth.Notable features of the RAMST architecture include the use of modular deployable structures,general-purpose robotics,advanced metrology,and formation flight options.The multi-arm robot hexbot moves on the main frame structure to perform its assembly and maintenance tasks (Fig.8(d)).These tasks include transporting the truss and mirror modules on the partially assembled main mirror structure,positioning and aligning the modules for assembly,removing,and installing components.

Fig.8 Research on assembly of large telescopes.61–63,65

At this stage,the United States will continue to conduct research and testing on the International Space Station to solve exploration challenges and assess the potential of lunar resource development standards.It plans to construct a Deep Space Gateway (DSG) to perform missions on the moon and start deep space transportation and assembly,such as using Deep Space Gateway (cis-Lunar orbit) to assemble a large observatory (Fig.9).66,67

Fig.9 Using the Deep Space Gateway (cis-Lunar orbit) to assemble a large observatory.66

Other autonomous assembly robots are also under research,such as RoboSimian (Fig.10),an experimental truss assembly robot originally developed by JPL for DARPA,which successfully demonstrated the fully autonomous assembly process of six trusses.68This research solved the problem of using autonomous robots to assemble modular components in space to construct large space structures (about 100 m).

Fig.10 Autonomous assembly with JPL’s RoboSimian robot.68

Sun shade/Star Shade.In the next few decades,occultation will be the key method to image the extraterrestrial planets directly.The combination of telescope and star shadow can suppress starlight,thus providing the high contrast and high sensitivity required for imaging exoplanets with reflected light.69Recent research on the detection mission Exo-S using the star shade provides a conceptual discussion of how the star shade works (Fig.11).70,71The Multi-Limbed Robot can assemble the perimeter truss module,fill the inner area of the shade,and carry out quality inspection and control.

Fig.11 Exo-S mission for occultation detection.70

4.2.Research status in Europe

ERA.The typical European Robotic Arm (ERA)72,73was designed and assembled by Airbus Defence and Space Netherlands.The robotic arm has 7 degrees of freedom(Fig.12(a)).It was connected to the Russian cabin section of the ISS and mainly used for the installation and deployment of solar panels,replacement of solar panels,and astronaut EVA assistance.

OLEV.European Orbital Life Extension Vehicle(OLEV)74includes ConeXpress-OLEV (CX-OLEV) (Fig.12(b)) and SMART-OLEV (Fig.12(c)).

Fig.12 Related Research from ESA.73–74,76

CX-OLEV,74,75funded by ESA and Orbital Recovery Ltd(ORL),was launched by Ariane as the main vehicle in 2008.Dutch Space built ConeXpress OLEV based on the payload adapter,which was used by Ariane 5 launcher for each mission.A ‘cone-rod’ docking mechanism was used to dock with geostationary communications satellites,which could operate as an orbital‘tug’to provide propulsion,navigation and guidance for the satellite.SMART-OLEV is a technical test platform developed by ESA to prove the use of electric propulsion for interplanetary orbit transfer maneuvers.Since 2010,it has provided services to geostationary communication satellites that have suffered from propellant depletion.76

ROTEX77,78manipulators adopted Light Weight Robots79(Fig.13)developed by the German Aerospace Center DLR,which was an attempt by Germany to participate in space automation and robot activities.The design concept of DLR’s light weight robots is to achieve a kind of manipulator that is similar to the motion control of human arms.It needs to be able to manipulate objects as indirectly as possible with humans in an unknown and constantly changing environment.

Fig.13 DLR’s operational light-weight robot.79

After the end of ROTEX,DLR carried out further research on this basis,which was later known as Experimental Servicing Satellite (ESS).80The ESS applied robotic technology to solve the problem of serving non-cooperative targets in or near geostationary orbit.On the basis of ROTEX,the ROKVISS high-performance space light robot technology experiment carried out flight verification on the highly integrated modular robot joints in 2005.This verification demonstrated various control modes,evaluated the performance and dynamic parameters of robot joints in a long time,so as to get rid of large and expensive anti-radiation components and achieve high integration in space.79,81This was essential for autonomous assembly technology.

In addition,in 2010,Germany launched the Intelligent Building Blocks for On Orbit Satellite Servicing and Assembly(iBOSS),82,83as shown in Fig.14.This in-space manufacturing spacecraft project carried out key technologies ground test in 2018.It is a reconfigurable spacecraft that uses standardized interfaces and modular design and manufacturing for onorbit service and assembly.The goal of iBOSS is to significantly reduce the cost of satellite maintenance through standardization and modularization,which will be used to study the technologies of assembling intelligent modular cubes into modular reconfigurable spacecraft.

Fig.14 The intelligent Building Blocks (iBOSS).82,83

AAReST.Surrey Space Centre(SSC)has collaborated with the California Institute of Technology,Jet Propulsion Laboratory(JPL)and Indian Institute of Space Science and Technology (IIST) to carry out Autonomous Assembly of the Reconfigurable Space Telescope (AAReST) mission.15A launch is expected in 2020(Fig.15)).The main mirror consists of 10 cm diameter circular mirrors,which is used to demonstrate some key technologies of low-cost on-orbit assembly(including close rendezvous and docking) and reconstruction of space telescopes based on multi-mirror components.84,85When the initial calibration and imaging requirements are met,the two mirror segments carried by the independent Cubesats equipped with the propulsion system will be separated from the mirror group,perform orbital manipulation to reposition themselves in a new position in the array.

Fig.15 AAReST Mission Concept.15

GOAT.Surrey Satellite Technology Ltd(SSTL)conducted an internally funded study to explore the broad significance of using small satellites to construct large telescopes on orbit.This research introduced the point design of a 25 m sparse aperture (ring) telescope.The system is assembled in space by several small components which are launched separately to form larger instruments.86The mission architecture is shown in Fig.16,where the Hub-Sat modules with multiple manipulators can not only help the final telescope assembly,but also help to connect Hub-sat components with each other.

Fig.16 Conceptual 25 m primary diameter modular GOAT telescope.86

NSTP-2.Surrey Satellite Technology Ltd (SSTL) successfully completed a study of the British National Space Technology Programme (NSTP-2),aiming to develop guidance navigation and control (GNC) and sensor architecture for future low-cost rendezvous and docking tasks (including inspace assembly).The research used the cooperative satellite spacecraft rendezvous and docking mission demonstrator of micro-satellites (active chaser and passive target),which involved formation flight,rendezvous and docking and other tasks.87The results so far show that such a GNC model and mission demonstrator are feasible.

Jackson et al.88of the University of Surrey proposed an innovative design of a small space robot based on intelligent robot technology and low-cost small satellites.The robot has a three-link manipulator with five degrees of freedom,which can be used for space assembly.The feasibility of ISA was analyzed,and the trade-off between manipulator structure and basic spacecraft size was given.

4.3.Research status in Japan

JEMRMS.JEMRMS,a Japanese experimental cabin remote manipulator developed by Japan Aerospace Exploration Agency (JAXA),89,90is composed of a Main Arm (MA) and a Small Fine Arm (SFA) connected in series.JEMRMS was installed in the Japanese experimental cabin section of the international space station (Fig.17).91The SFA is positioned by the MA to complete a series of fine operations,which are used to support maintenance tasks in the corresponding area of the space station,so as to reduce the workload of extravehicular activities of astronauts and accumulate experience for Japan’s ISA.

Fig.17 JEMRMS installed on ISS.91

ETS-VIII.Japan’s ETS-VII92,93was launched in 1997,used to verify a series of tasks of the control on-orbit service,such as relative motion,docking,orbit operation,replacement of equipment.ETS-VII proved the feasibility of ORU exchange.ETS-VIII94–96(Fig.18),launched in December 2006,is an advanced technology demonstration satellite designed to develop and verify the world’s largest geostationary satellite bus technology.ETS-VIII was equipped with two LDR modules,each consisting of 14 hexagonal modules.This antenna is the first deployable antenna designed in modularity in the world.Each module has a deployable truss structure.After deployment,each reflector forms a parabola and an expanded metal mesh (19 m×17 m).The successful deployment of the antenna verifies the feasibility of the antenna modular design.

Fig.18 Artist’s view of ETS-VIII spacecraft in orbit.96

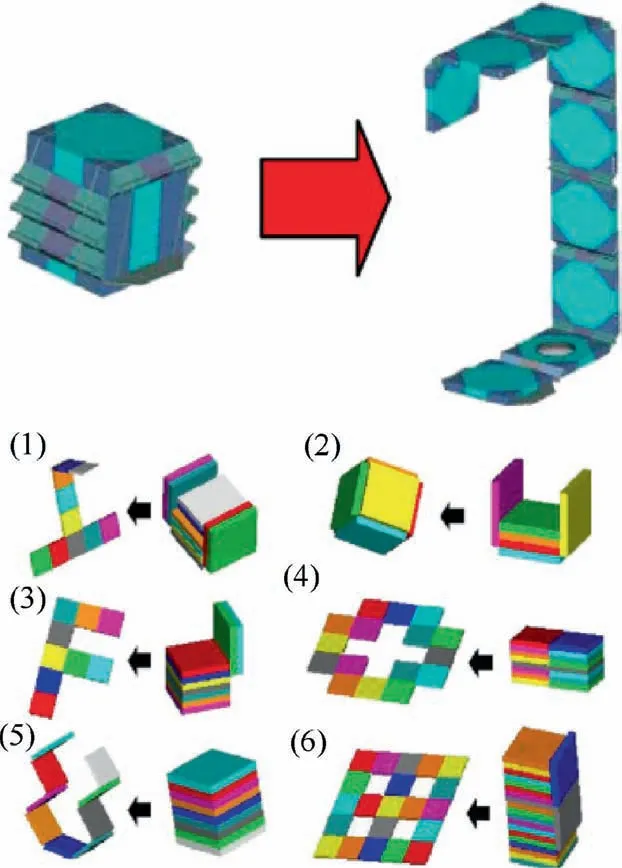

PETSAT.Japan has also conducted research on the assembly of reconfigurable modular structures.Japan’s Panel Extension Satellite (PETSAT) program97,98was developed in 2003,with a plan of 5 years.As a cellular satellite with modular and reconfigurable features,the PETSAT project designed a satellite panel with a side length of 350 mm and a thickness of 50 am,which was connected with reliable hinge and lock pin of connection mechanism,and can select an appropriate panel and connection mode according to different tasks.The characteristics of the satellite are driven by multiple tasks and can be mass-produced,which not only reduces the cost but also improves the reliability of the system.In the orbit state,through the connection mechanism on the panel,the satellite function can be realized,the ground test of the whole satellite system can be avoided,and the cost can be saved.Various modular configurations of PETSAT satellite are shown in Fig.19.

Fig.19 Various modular configurations of PETSAT satellite.97,98

4.4.Research status in Canada

During the construction of the ISS,the Shuttle Remote Manipulator System (SRMS) and the Space Station Remote Manipulator System (SSRMS) developed by the Canadian Space Agency (CSA) played important roles in the assembly and maintenance of the ISS.12SRMS99is a special manipulator with 6 degrees of freedom,15.2 m length and Φ0.38 m diameter(Fig.20(a)).The famous application of SRMS is five repairs for HST.In the mid-1990 s,in order to support the construction of the ISS,CSA began to improve the carrying capacity and assembly accuracy of the manipulator,and finally formed the Space Station Remote Manipulator System(SSRMS) (Fig.20(b)).The maximum operating capacity of SSRMS100can reach 116,000 kg,which is higher than that of SRMS,and the operating accuracy can reach 6.4 mm.In addition to SSRMS,Special Purpose Dexterous Manipulator(SPDM)(Fig.20(c))and Mobile Remote Servicer Base System(MBS)have been developed to form the Mobile Servicing System (MSS).Then,the MSS is connected to the main truss of the ISS via a Mobile Transport (MT).

Next-generation Canadarm (NGC)101(Fig.20(d)) is also under development to support both low earth orbit and deep space missions.The NGC consists of two manipulators:a large manipulator arm with a range of 15 m,and a small manipulator arm with a range of 2.6 m.It adopts the function of a new telescopic arm.The big arm can be used to fold and install the small spacecraft in the future.The small arm can help the satellite operate accurately.

Fig.20 Related Research in Canada.12,99–101

4.5.Research status in China

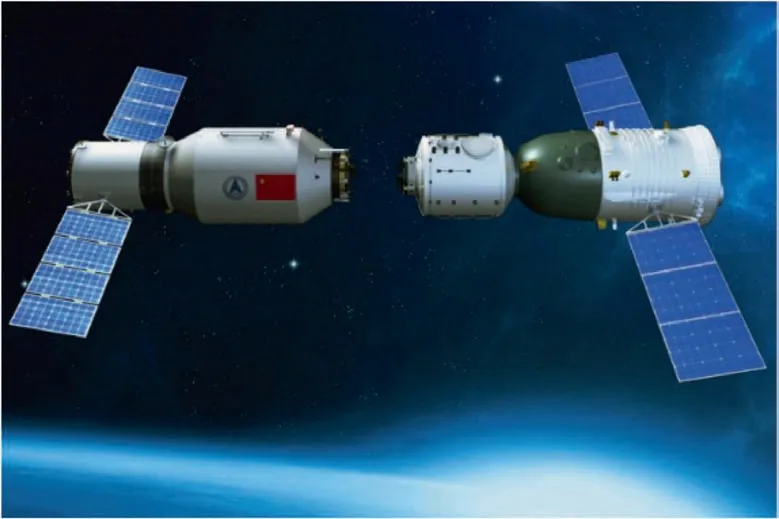

The early research on space exploration robots in China began in the 1990s,and the in-depth research on space robots began in 2000.Currently,the ongoing in-space assembly exploration is China Manned Space Engineering(CMSE),whose goal is to establish a large national space laboratory with long-term human participation.102The docking of China’s manned spaceflight series,such as the Shenzhou series of spacecraft docked with Tiangong 1 and Tiangong 2,provided the foundation for the construction of the Chinese space station.103As shown in Fig.21,it is a conceptual diagram of the docking of Shenzhou 8 and Tiangong 1.CMSE will be implemented in two stages,namely the space laboratory and the space station.104Among them,the Chinese Space Station Remote Control Manipulator System (CSSRMS) is an important tool to complete aerospace missions such as on-orbit assembly,maintenance,operation assistance,load support and astronaut onorbit support,which is a dual arm setup.CSSRMS(Fig.22)is composed of the Module Manipulator(CMM)and the Experiment Module Manipulator (EMM).Its core components are modular in design and can work together.102,105Robot astronaut (Fig.23) of Harbin Institute of Technology (HIT) has been developed to replace astronauts to complete extravehicular activities and perform fine operations.It has highly integrated flexible manipulator joints,modular and multi-sensor smart hand fingers,binocular target tracking technology based on embedded microprocessor,and telepresence remote control operation technology with touch feedback.102,106

Fig.21 Artistic rendering of docking between Tiangong 1 and Shenzhou 8.103

Fig.22 CMM and EMM independently working on experimental module.102

Fig.23 Robot astronaut of HIT.102

On October 24,2017,China’s Changchun Institute of Optics,Fine Mechanics and Physics (CIOMP) and UK’s University of Surrey (UoS) led the launch of the ultra-large aperture in-space assembly project.The project would work together to develop a 10 m horizontal aperture space telescope(Fig.24),12,107and study the robots and automation key technologies required for assembly.

Fig.24 Future-Generation Space Telescope.108

In addition,numerous experimental studies of space assembly are also underway.Zhang et al.108of Harbin Institute of Technology,designed a self-reconfigurable multi-arm space robot system for on-orbit service (Fig.25(a)).The robot can be combined into a variety of configurations such as freeflying three-arm system,compounded single-foot dual-arm system,compounded dual-foot single-arm system,and compounded single-foot single-arm system and will be used for future space maintenance.Tang et al.109proposed a new space truss crawling robot based on the bionic principle,which was used to assemble space truss structures(Fig.25(b)).The system is composed of multi-articulated legs and adhesive microstructures imitating gecko.Crawling experiments were carried out through simulation and experiment of low gravity environment to verify the feasibility of the robot’s motion function.Jiang et al.110proposed a new type of assembly robot(Fig.25(c)) with a circular moving base and 9 DOFs retractable robotic arms in order to realize the in-space assembly and maintenance of space telescopes.It can not only be operated in an autonomous mode but also be controlled remotely.This robot used time-optimal trajectory planning based on genetic algorithm to achieve efficient assembly,which had the advantages of large working space and small size.

Fig.25 Research on related autonomous robots.108–110

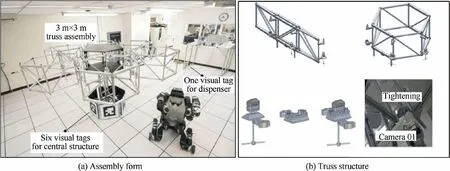

Cheng et al.111of the China Academy of Space Technology proposed a multi-robot collaborative assembly mode with an additional space manipulator arm and a free-flying robot for large space solar power plants,and optimized the assembly sequence and route.Liu et al.112of Shenyang Institute of Automation,Chinese Academy of Sciences designed a compact,light-weight,five degree of freedom multi-functional end effector,which can realize the automatic docking of the quick isolator of the refueling pipeline through a single mechanical arm and improve the docking efficiency.Zhang et al.113proposed a caging-pair method for space objects that do not have graspable features,which has the inherent advantages of high robustness and reliability.Besides,he also proposed an adaptive robust decoupling control of multi-arm space robots using time-delay estimation technique,which has been proved to be simple and effective114.Lu et al.,115Nanjing University of Aeronautics and Astronautics,designed a series of collaborative modular components with special connectors for large-scale spatial structure assembly,and developed an automatic assembly strategy based on camera vision measurement to complete the assembly task.A framework structure can be assembled from seven modular components,six of which need to be assembled around a central component.The whole assembly process is completed by the grab operation of the mechanical arm and the rotation and cooperation of the platform.Liu and others from Harbin Institute of Technology conducted research on multi-arm cooperative capture,106end effectors,116,117and dexterous hand.118Guo et al.119proposed a hierarchical planning method for the assembly sequence of large space truss structures.Hu120of Zhejiang University studied the design and dynamics of spatial extensible structures.Fu et al.121of the University of national defense science and technology proposed a modular measurement and control system for small satellites.Chen et al.122of Beijing University of Posts and Telecommunications proposed a rolling strategy for a dual-arm space robot based on friction control to capture rolling targets.This strategy can reduce the target speed while maintaining basic attitude stability.

5.The key technologies of ISA

ISA covers a wide range of technologies.In the Space Science and Technology (S&T) Cooperation Forum composed of US government partners,a number of scientific and technological cooperation subject areas including autonomous or semiautonomous in-space assembly have been identified to develop a government roadmap for the work of ISA,determine a strategic framework,and assess the required capacity requirements.1,62,123According to the capacity requirements of ISA,the following key technologies are summarized,as shown in Fig.26.

Fig.26 Overview of ISA key technologies.

5.1.Assembly structure design

5.1.1.Modular design of structural unit

(1) Module division and design technology

W.D.Nadir defined modularity as ‘‘integrating the functions of the system into various modules,minimizing the coupling between modules and maximizing the cohesion between modules”,and it is the standardization of the interface between design elements and the reuse of functional units.10,124The concept of modular spacecraft embodies the idea of standard interface and division of functional units.The module division of the spacecraft is the first step of the modular design task,and it is also an extremely critical step.Whether the module division can be reasonably carried out will have a direct impact on the function realization and technical cost of the later spacecraft development.The modular design of the components expands the initial design space,improves the reusability and sustainability of the system,and reduces development costs and mission risks.11The design of the module should be easy for the robot to manipulate and assemble,and it should be adjustable to meet the design accuracy and stability requirements.The best example is the HST,which is much more capable after maintenance than during launch due to technology upgrades and the installation of ORU.The research on deployable truss units is also a good example.125More mature technologies include deployable subsystems,such as the JWST structure,or inflatable components,such as the Bigelow Scalable Mobile Module(BEAM)on the International Space Station.126

(2) Design technology for standard interfaces

The interface is the link between the modules,and the channel for the transmission of matter,energy and information between the modules.It is mainly divided into mechanical interface,power interface,thermal control interface,and data interface.Mechanical interface provides fixation for the module and complete sealing function for other interfaces.When designing the module,it is necessary to standardize the mechanical structure,shape,size,installation direction,installation position and installation accuracy of the module interface.Similar to the ‘‘plug-and-play”architecture of the computer industry,the modular design must be used in conjunction with standard interfaces in order to realize all the functions of on-orbit upgrade.47

5.1.2.Module aggregation and assembly design

(1) Design technology for assembly platform layout

The configuration layout of the assembly platform will affect its mission capability.Large-scale facilities have problems with accuracy checking and coupled vibration during assembly.The optimization of the structure of the assembly structure involves the size,shape and topology of the structure,so it plays a vital role in the assembly process.Daxini and Garcia127,128reviewed the structural optimization methods and pointed out the problems of traditional parametric shape optimization techniques,(such as finite element,boundary element and other grid-based numerical tools),and the advantages of using the meshless method for structural analysis.

(2) Connection technology for assembly structure

The connection technology of assembly and deployment structure has been widely studied.The more traditional method of assembling space structures uses mechanical joints,which are designed to be compatible with astronauts (Fig.27(a)) or robots (Fig.27(b)).43,129–132But some new joints designed for ISA are needed to improve the micro-dynamic stability of the connection structure.In addition to the traditional mechanical connection interface,the connection method of electron beam welding and composite materials is the hotspot of current research (Fig.27(c)).In order to reduce maintenance costs and increase service life,certain structural units should have reversible standard interfaces,electrical and fluid connections,and the ability to connect auxiliary tools.What’s more,they should have the ability to disconnect structural,electrical and fluid connections without damaging other system components.In the process of structural assembly,some additional requirements are put forward for the assembly agent:1)the connecting parts shall not deform within their service life.2)The thermal load must be considered in the process of assembly and operation.3) Various connection methods must be available,including but not limited to locking,welding,tightening and bonding.126LaRC is investing in an internal technical activity called RAMSES,which focuses on the development of modular assembly technology using innovative and stable reversible connection methods.48Some companies in the Small Business Innovation Research (SBIR) program are working to improve the capability of reversible precision connections and mechanical/power/data connections required by ISA.Meyer et al.133studied reversible bonding for assembly and disassembly of reconfigurable space structures,and conducted a study of the reversible bonding strength based on the interchain transesterification reaction between two desulfurized bonds.It showed the feasibility of using ATSP as an adhesive for reversible bonding in space assembly.Based on the above research,Table 2 compares the characteristics of the assembly structure using the traditional mechanical connection interface,electron beam welding and composite material connection.

Fig.27 Mechanical joints.43,133

(3) Interoperability of different systems

System interoperability refers to the ability of two systems to work normally on the interface,including hardware and software interoperability.In order to accommodate visiting spacecraft and accommodate interaction with other (TBD)associated systems,standard protocols and ports are required.1,62

(4) Docking and berthing technology of modules

The docking and berthing technology of modules includes any rendezvous and proximity operation,which involves attitude control,sensing,and mechanical interface.Many missions in the past27have proven this achievement and will continue to work in this area.With the advancement of hybrid propulsion systems,sensors and spacecraft control algorithms,docking and berthing technology of modules will be an important support for ISA.134

5.2.Robot technologies

In order to enable the robot to assemble and transport the structure,the power and signal lines between the robot and the astronaut must be secured.Autonomous robot technologies will provide greater operational processing capabilities in harsh space environments to expand the capabilities of astronauts.Although a lot of research has been conducted on autonomous assembly by space robots,135–137there are still a series of challenges in the assembly process,126,138as shown in Table 3.

Table 3 Related robot technologies and challenges of ISA.126,138

Table 4 Potential future applications of ISA.11,48,218

Facing the future challenges and goals of space robots,it is urgent to develop the advanced technology of space robots,especially to integrate artificial intelligence,develop wireless communication or power transmission,multi-modal perception human-robot interaction,etc.

Autonomously assembled robots need to have certain autonomous decision-making capabilities.Through the intelligent system,the state and surrounding environment can beknown by sensors and memory.These data can be used to execute decisions according to predetermined rules,including planning,rendezvous,object recognition,pose estimation,docking,task execution,fault diagnosis and exception resolution.136For example,CIMON,12,139the first artificial intelligence robot on the ISS (Fig.28),whose main purpose is to prove the benefits of human-robot collaboration in space,and to reduce the workload of astronauts.This kind of AI technology is being developed continuously,which can help astronauts complete complex space missions in the future.

Fig.28 The first flight AI robot on ISS.12

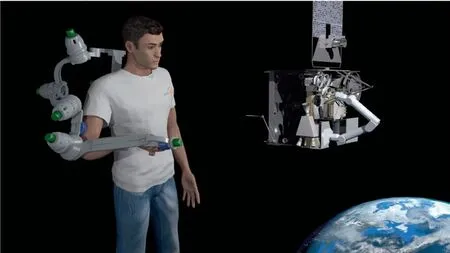

For space robots that use a teleoperation system based on human-robot interaction,effective use of multiple sensory modes,multiple display methods and communication channels can enhance situational awareness.The United States,Germany,Russia and other countries have done a series of studies on this.In 2012,NASA initiated the special project of surface telerobotics,which focused on how to improve the efficiency of astronauts in the operation of teleoperating planet surface robots.140The ROSCOSMOS and DLR jointly carried out KONTUR projects.141–143In the early stage of the project,DLR developed a spacecraft level force feedback manipulator for on-orbit teleoperation.Fig.29(a)shows that astronauts use the force feedback manipulator for teleoperation.A series of experiments were carried out through the force feedback controller,including:non-contact tracking and targeting tasks,astronauts teleoperated ground robots to shake hands and toast with people,astronauts and ground operators controlled the robot together to complete the two-arm cooperation(Fig.29(b)).These experiments prove the feasibility and effectiveness of remote presentation and force feedback during orbit-to-ground teleoperation.METERON,144,145initiated by ESA and cooperated with DLR,NASA and Roscosmos,studied the perception and operation ability of astronauts’ teleoperation in microgravity environment,146tested and evaluated the communication performance between the ground and the space station,and carried out assembly,maintenance and verification experiments for teleoperation of ground robots.Fig.29(c) shows that the ground robot is teleoperated by the astronauts to plug and unplug the interface.Fig.29(d) shows that the ground robot is installing antenna.

Fig.29 Teleoperation experiments.143,144

Increasing situational awareness needs to start from both the remote operator and the robot.Kazanzides et al.16,147–149of Johns Hopkins University (JHU) have implemented a virtual model based on video images to enhance the situational awareness of the operator.The framework is implemented on the main console of the improved Da Vinci surgical robot(Fig.30),which can provide operators with immediate visual feedback and motion guidance,and reduce the delay of teleoperation control.By combining the images obtained from the enhanced virtual system with the 3D model of the robot workspace and objects in the local environment,the teleoperator can be more flexible in choosing a viewpoint that is conducive to accomplishing a given task.Satellite Servicing Projects Division (SSPD) has studied the use of virtual reality (VR)and augmented reality(AR)systems to visualize models during the design and test phases and improve the situational awareness of remote operators during the operational phase of robotic tasks.13James et al.150studied an exoskeleton wrist design based on a composite visualization method (Fig.31).Range of motion and ergonomic compatibility can be verified in the same virtual workspace.Tactile system provides additional information channels to teleoperators in the form of force feedback,which can further improve the situational awareness ability.Liu et al.151proposed a tactile-based teleoperation solution for space exploration,which used a hybrid master–slave mapping method that combined the advantages of rate control and variable scale factor position mapping to achieve accurate and effective teleoperation.

Fig.30 JHU Da Vinci main console.16

Fig.31 Exoskeleton design.150

In addition to assisting astronauts with multimodal situational awareness,the multi-sensor fusion technology applied to robots also plays a key role in ISA.For example,ROTEX,the first in-cabin space robot,made full use of multi-sensor fusion technology.A multi-sensor intelligent gripper is installed at the end of the gripper.The gripper includes a six-dimensional wrist force sensor,a tactile sensor array,nine infrared ranging sensors and a pair of micro stereo cameras.152In addition,the working space of the robot also has a pair of cameras.

5.3.Integrated management technology

Assembly management technology is a comprehensive controller that coordinates,manages,and controls the assembly of various subsystems.It is the main component that improves the reliability,survivability,and cost performance of the assembly system.

5.3.1.Assembly dynamics and control technology

ISA is one of the most promising technologies for the construction of large-scale space structures in the future.The assembly process will show different dynamic characteristics with the increase of the number of structural units and the installation sequence.The construction of a space structure with ISA involves many dynamic and control problems,such as the transportation and assembly of each assembly module,the attitude adjustment of spacecraft and the overall stability of the assembly structure,parameter identification,153,154vibration suppression,error compensation control.

During the in-space assembly process based on module docking,the mass distribution of the combined spacecraft will change with the movement of the manipulator,fluid transmission and other operations.Therefore,in the process of dynamic modeling,the time-varying characteristics of mass distribution should be considered to establish the attitude motion model of combined spacecraft.The change of moment of inertia caused by the assembly process also brought challenges to the parameter identification.For such a timevarying system,the large-scale variation of the parameters and the uncertainty of the variation law make the attitude control of spacecraft become a major difficulty.In addition,during the docking process of the spacecraft modules,the disturbing force caused by the contact and collision between the end-effector and the target object may cause the wobble of the spacecraft components and the change of the pose,or even eject the target object.In order to reduce the influence of this disturbance force,the compliant control based on ISA has become a research hotspot.In the process of rendezvous and docking of modern spacecraft,the traditional control method of rigid spacecraft is no longer applicable because of carrying large flexible solar electromagnetic panels and antennas.Cooperative control of multiple flexible spacecraft has become a hot research topic.There have been many studies on ISA based on modules docking.Buckner and Lampariello155proposed a robust model predictive controller based on linear tube for rendezvous maneuver of free-tumbling satellite,which would ensure the feasibility and stability of the predefined uncertainty in the target motion.Okasha et al.156developed a control algorithm for autonomous assembly of multiple satellites based on the closed form analytical solution of the relative motion equation in general Kepler orbit.Du and Li157studied a distributed coordinated attitude control strategy,which can asymptotically achieve attitude synchronization and suppress the vibration caused by flexible appendages.Hu et al.158,159proposed a new distributed controller based on artificial potential field for the autonomous assembly of a group of flexible spacecraft in orbit,so that the flexible spacecraft could be assembled autonomously without collision between components.Besides,the collision-free assembly control law of multiple flexible spacecraft based on the potential field that they studied could successfully complete the assembly task.Chen et al.160,161proposed a composite controller which combines output consistency controller and collision avoidance controller into a group of hub-beam systems to realize the assembly task of spacecraft flexible accessories and suppress vibration.Moreover,he also proposed a distributed control law with disturbance observer for the autonomous assembly of flexible spacecraft formations.This method can make the large flexible space structure achieve the desired configuration while avoiding collision between components.Wei et al.162considered collision constraints and obstacle avoidance issues,and proposed a multistage control strategy to achieve collision-free docking between the chaser spacecraft simulator and the spinning target spacecraft simulator.

For the modular assembly of large space structures,the dynamics and control are more complicated.Vibration suppression and elimination of cumulative errors in the assembly process are also indispensable parts.The dynamic modeling and control of the ISA structure needs to consider the structural characteristics,such as large scale,complex system,low stiffness,strong nonlinearity.Besides,the impact of the complex environment in the service process and the structural changes under the external load should also be considered.With the increase of the modules,the flexibility of the whole system structure becomes more and more large.The nonlinear problem of the connection has become an important part that cannot be ignored to affect the dynamic characteristics of the structure.The traditional centralized control strategy is also facing challenges.The existing dynamic analysis method and control strategy of the central rigid body plus flexible accessories are no longer applicable,and the full flexible dynamic analysis method163needs to be established.Wasfy and Noor164comprehensively discussed the dynamic modeling of flexible spacecraft,the mutual coupling between flexible components and ground tests,and other issues,which created a good theoretical basis for the subsequent research.164Aiming at dynamics and control of assembly structures,decentralized control strategy165–168is a strategy to dismantle large system control problems into independent control problems of several subsystems.In recent years,it has been widely used in the active control field of large-scale space structure because of its advantages of low complexity and high reliability.In addition,there are also distributed control strategies169,170for large-scale structure.The difference between them is that the distributed control strategy considers the measurement information in a certain range around the subsystem when designing the subsystem controller.Distributed control strategy sets the information interaction between the controllers to form the distributed collaborative control network,which can further improve the reliability and fault tolerance of the control system.

5.3.2.Metrology and assembly operation management technologies

In the process of assembling the space structures,how to complete the assembly work efficiently,safely and reliably becomes a major challenge in the process of ISA.It is necessary to plan the assembly sequence and path reasonably,improve the assembly accuracy,verify the assembly technology,and deal with the unexpected situations in the assembly process in time.

(1) Assembly sequence and path planning techniques

Assembly planning is a pre-determined in-space assembly plan,which is mainly based on the constraints of external environmental factors,and considers the performance of the assembly operation body.According to the content of the task,assembly planning needs to reasonably arrange and plan all the decisions and behavior sequences required by the task body to complete the task.There are a series of challenges in the assembly sequence planning.171In addition to planning complex assembly tasks,there are unforeseen problems in the process of operation.Whether it can successfully perform the planned tasks depends on the appropriate assembly sequence.

The early work of computer-aided assembly sequence planning is based on graph search theory,but all sub-assembly and disassembly operations must be formulated.Although these methods can find the globally optimal solution,they can’t quickly find high-quality solutions for complex structures.172The distributed algorithm is only suitable for the assembly of the specific structure under consideration,such as the uniform distribution and parallelization demonstration of large truss structures.173,174Lindsey and Kumar175proposed a distributed construction algorithm that solved the problem of using standard parts and simple fasteners to construct truss structures.This algorithm allows multiple robots to assemble the structure only according to the specified blueprint.The enumeration construction assembly sequence176is limited by the number of assembly parts and the algorithm search space.In addition,the application of some intelligent methods such as expert system177and genetic algorithm178in assembly sequence planning has attracted more and more attention.Recent research has developed towards multi-robot assembly,179such as the assembly robot for truss climbing,180the robot for automatic ordering of tasks,181and group assembly robot inspired by termites.182In Ref.183,an adaptive method based on reinforcement learning (RL) was proposed for manipulating,transporting parts and assembling 3-D structures in quadrotor assembly and moderately constrained and dynamic environments.

In trajectory planning,it is important to carefully plan and analyze the trajectory of the robot to ensure that singularities do not appear within the limits of robot operation,because it is very difficult to recover from a dilemma with a huge load.16The traditional inverse kinematics solution should be generalized to meet various constraints,such as interference minimization,complex external layout,collision avoidance,184minimum cost,and trajectory optimization.Kruse and Newman et al.185–187determined the acceptable trajectory by evaluating various constraints of robot motion,including singularity and speed,acceleration and joint load limits.Zhang and Liu188considered the location of the foundation parking as an optimal parameter to develop a more comprehensive and effective motion planning strategy.She et al.189considered the structural vibration caused by the flexible connection and the topological constraints in the assembly process,and studied the planning of ISA task.Tong et al.190proposed a 3D space obstacle avoidance algorithm based on neural network,which greatly reduced the time and distance in path planning.In addition,she also proposed a weighted additional deviation velocity method based on gradient projection (GP-WADV) to solve the obstacle avoidance problem of redundant manipulators with known end effector trajectories.191

(2) High-precision assembly technology

For the high-precision assembly technology of space structures,current research is devoted to reducing the complexity of structural systems,and improving the accuracy of assembled parts through robotic fixtures and welding.There are many methods such as the development of multi-functional and reconfigurable Intelligent Precision Jigging Robot (IPJR) that can support and accurately position structural elements when welding structural elements.48,192,193For high-precision assembly technology,the intersection of many sub-fields is needed,including sensor fusion,optimal estimation algorithm,error detection and correction.In achieving high-precision metrology,laser-based metrology systems are more and more attractive.194Dorsey et al.43introduced a new in-space assembly mode that combined reusable and multi-purpose in-space IPJRs with low-precision structural components that are connected by on-orbit welding.This model can be easily extended to in-space repair,refurbishment and manufacturing,thereby laying the foundation for precise space systems.An experiment conducted in the Jet Propulsion Laboratory (JPL) of NASA proved that a pair of cooperative robots can ensure the accuracy by using high rigid motion to accurately assemble beams.195,196

(3) Modeling simulation and verification technology

In order to ensure the safety and reliability of the spacecraft designed based on ISA,it is necessary to conduct ground verification first,implement hardware-in-the-loop modeling and operation simulation of the module assembly operation,and finally complete the on-orbit verification.48In order to simulate on-orbit conditions,especially the effects of microgravity,verification can be performed in a free-floating environment or software can be used to compensate for the limitations of fidelity in low-gravity facilities.197Air floatation method,water floatation method,suspension method,moving trolley method,hardware-in-the-loop and other methods can be used for verification.198Ueno et al.199developed autonomous collaborative robots for orbital assembly of large space structures and multi-robot ground test stands for verifying the feasibility of assembly and maintenance of autonomous multi-robot systems.

(4) Performance evaluation and health management

The assembly process is required to be able to handle a variety of problems,including cutting and forming parts as needed,solving assembly errors,task assignment,and handling unexpected events.200In the entire assembly process,it is necessary to build an assembly performance evaluation and health management system with accuracy,stiffness,efficiency,and cost as the goals,to solve the problems of comprehensive assessment of assembly objects and health management.

5.3.3.Astronaut life support technology

Astronaut life support technology includes two aspects.On the one hand,it is necessary to ensure the life safety of astronauts.On the other hand,the need for flexibility and comfort of astronauts in space must also be considered.The radiation in space and the microgravity environment will adversely affect the musculoskeletal and cardiopulmonary systems of astronauts.Establishing artificial gravity vehicles (AGV) through in-space assembly technologies can reduce the harm of microgravity.126It is also the key of life support technology to realize safe human–machine cooperation during assembly task.Humans and robots can improve productivity by sharing workspace and cooperating closely.The strategies to achieve safe human–machine cooperation can be divided into two categories:the pre-collision processing which can predict and prevent the forthcoming collision201–205and the post-collision processing which can reduce the impact/injury after the accidental human–computer collision.206,207

5.3.4.Adaptive technology of system and environment

The accuracy of electronic components of spacecraft,the degradation and deformation of assembly materials and motion pairs in microgravity,strong radiation and large temperature difference environment are major challenges of ISA technologies.Solving the problems of long life and reliability of assembly structures requires the development of adaptive technology for systems and environments.At the same time,the assembly system also needs to adapt to the assembly environment and be able to assemble on the planet surface(such as Mars,Moon).

6.Future development trends

6.1.In-space manufacturing and assembly of large space structures

As human exploration of space continues to a surpass Earth’s orbit,the in-space manufacturing and assembly of large space structures are essential for human sustainable exploration.Future construction of large spatial structures such as telescopes,star shades,large fuel warehouses,or long-term habitats will rely on ISA.SALSSA has high requirements for assembly accuracy and cost,whose goal is to achieve a new comprehensive spatial assembly model,43including four key capability areas3:assembly and construction,service and maintenance,reuse,renovation and recycling and on-site Infrastructure.In recent years,the development of space additive manufacturing technology208will change the in-space manufacturing capacity of spacecraft,help to realize the integration of in-space manufacturing,assembly and deployment,reduce the geometric constraints of spacecraft modules,the cost and cycle of development and launch.In 2015,NASA and Made in Space conducted the second microgravity 3D printing test at the ISS,and successfully printed the wrench tool,209which also marked a breakthrough in the on-orbit 3D printing process method in the microgravity environment.There has been great progress in material forming and mechanical problems in space microgravity and high vacuum environments as well.208New carbon nanotube composite materials,210‘‘digital materials”211have laid a foundation for the integrated development of in-space manufacturing,assembly and lightweight design of large space structures.In the future,ISRU will be implemented for deep space exploration.212A series of challenges related to thermal deformation,material properties and product pollution need to be solved.

6.2.Coordination of multi-people and multi-robot

Past efforts have made space assembly technology develop continuously and become an application with great potential for space exploration in the future.However,in a short time,the realization of space assembly technology still needs the participation of human beings,especially in the assembly process of large-scale space structures,human–machine coordination can improve the assembly efficiency,increase the flexibility of the assembly process and ensure the assembly quality.For example,Gao et al.213designed a free flying robot (AAR-2)for the Chinese Space Station.It has a clear environmental awareness and artificial intelligence,and can complete certain specific tasks under the control of astronauts or autonomously.In addition,for human–machine coordination,he also proposed a parallel network based on hand detection and posture estimation for human–computer interaction.137,214In the future,the coordination of multi-person and multi-robot will play an important role.

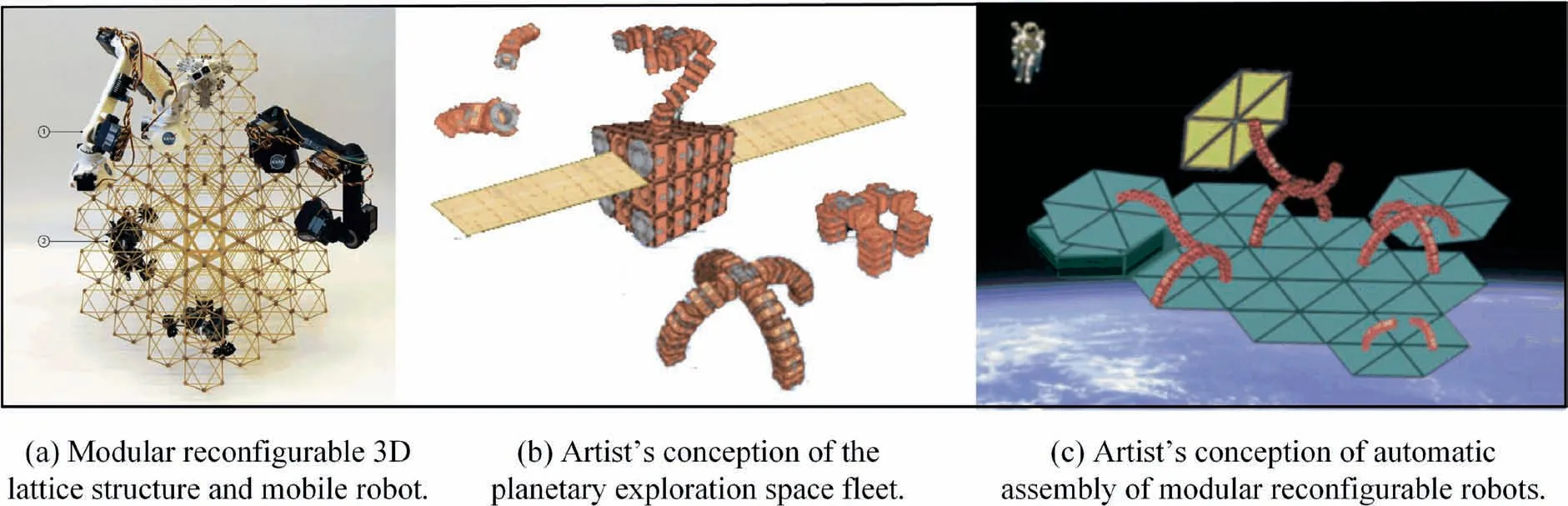

6.3.Modular reconfigurable spacecraft to achieve autonomous assembly

Compared with the traditional spacecraft,modular reconfigurable spacecraft has more advantages in design,manufacturing,deployment and usage.It will become a new type of spacecraft that can respond to the operational requirements more quickly,flexibly,reliably and less cost-effectively.Many large structures,such as large telescopes,large (megawatt)solar cell arrays,can benefit from the in-space assembly of lightweight structural elements and modular units.3,47The NASA Automated Reconfigurable Mission Adaptive Digital Assembly Systems (ARMADAS) mission will develop and demonstrate the automatic assembly of ‘‘digital materials”and structures based on building blocks,as shown in(Fig.32(a)).215,216In the future,Mars surface vehicle,moon outpost,planetary exploration space fleet(Fig.32(b))realized by reconfigurable spacecraft can be used for deep space exploration.5

Fig.32 Modular reconfigurable spacecraft to achieve autonomous assembly.5,215,217

In addition,for large structures composed of modular components,reconfigurable space assembly robots also have a broad development prospect (Fig.32 (c)).217The reconfigurable robot can be reconstructed or decomposed according to the needs to optimize the shape.Its operation is more flexible,fault adaptability is strong,launch cost is low,and it can better meet the assembly requirements of large space structure.

6.4.Future applications