Loose Sand Cemented by Microbial Cementitious Material:Composition, Microstructure and Mechanical Properties

2021-09-15ZHANQiweiWANGShugangLIUBaoyaPANZhihongYUXiaoniuQIANChunxiang

ZHAN Qiwei, WANG Shugang, LIU Baoya, PAN Zhihong,YU Xiaoniu, QIAN Chunxiang

(1. School of Civil Engineering and Architecture, Jiangsu University of Science and Technology, Zhenjiang 212100, China; 2. Guangdong Provincial Key Laboratory of Building Energy Efficiency and Application Technologies, Guangzhou University, Guangzhou 510006, China; 3.Training Base, PLA Army Engineering University, Xuzhou 221004, China; 4. Department of Civil and Environmental Engineering, Nanyang Technological University, Singapore City 639798, Singapore; 5. College of Materials Science and Engineering, Southeast University, Nanjing 211189, China))

Abstract: Through the influence of the dosage of culture solution and calcium source on hardness and compressive strength of samples, the formulation of microbial cementitious materials was optimized and defined. The influence of temperature on composition, microstructure and mechanical properties of loose sand cemented by microbial cementitious material was compared and analyzed systematically. With the increase of temperature, the performance of loose sand was improved remarkably. Calcite with cementitious properties could be induced at higher temperatures, but not at lower temperatures. When the temperature was 30 ℃,loose sand cemented by microbial cementitious material had more calcite and more dense structure. Moreover,hardness and compressive strength were also superior. The wind tunnel test showed that the wind erosion resistance was improved obviously and the mass loss was lower at high temperature. Engineering properties of loose sand cemented by microbial cementitious material was measured integrally. Through comparative analysis, engineering properties of loose sand were basically unchanged, and there was no negative effect on the later period use of sand.

Key words: loose sand; microbial cementitious material; calcite; microstructure; mechanical properties

1 Introduction

Microbial cementitious material has many advantages, such as fast, high efficiency, easy control and friendly environment, and it is expected to be applied to dust control, desert management, foundation reinforcement, slope stability and other fields[1-4]. In days to come, microbial cementitious materials will cause more and more attention[5,6].

As early as 1992, Kantzaset alpioneered a new process of consolidation sand by microbe induced calcium carbonate deposition[7]. Loose sand particles were cemented into a whole, and the porosity and permeability coefficient decreased by 50% and 90%, respectively. Cord-Ruwischet aldesigned the method of consolidation sandin situbased on urea decomposition by urea enzyme, and 1 meters of sand column was prepared avoiding the phenomenon of aggregation and crust formation at the top of sand column[8-10]. Whiffin found that microbial cementitious material was injected into loose particles, while the injector was test device. Under this process conditions,the cementation effect was uneven at different positions. With the increase of cementation times, the compressive strength increased gradually. The effect of urea hydrolysis rate on the strength of cemented body was investigated, and higher strength could be obtained with lower urea hydrolysis rate[11,12]. Harkeset alproved that culture solution, which was diluted by the low concentration of salt solution, could transfer easily in loose particles. Meanwhile, uneven distribution of culture solution was avoided by increasing injection times of culture solution[13,14]. In China, the first study of microbial cementitious material was carried out in 2004. Qianet aldemonstrated that microbial cementitious material could be used for heavy metal restoration, loose sand cementation and cracks selfrepairing of cement-based material[15-17]. At present,urinary enzyme microbial cementitious material had been investigated widely, but ammonia would be released during the cementing process, which had a negative impact on the ecological environment.

In my previous study, a new type of microbial cementitious material based on carbon dioxide capture and utilization was developed, and it could be used to cement sand in shallow layer, while the purpose of fugitive dust control was achieved successfully[18-20]. In this research, the formulation of microbial cementitious material was optimized through the influence of the dosage of culture solution and calcium source. The influence of temperature on composition, microstructure and mechanical properties was compared. Engineering properties of loose sand before and after cemented by microbial cementitious material were analyzed.

2 Experimental

2.1 Materials

Microbial cementitious material had two components: microbe and calcium source. Microbe was Paenibacillus mucilaginosus, which was purchased from the China Center of Industrial Culture Collection(CCIC). Cultivation of Paenibacillus mucilaginosus was conducted in sucrose culture (10 g of sucrose and 3 g of sodium hydrogen phosphate were dissolved in deionized water to 1 L, and the pH value was adjusted to about 7.0) at 35 ℃ for 72 h. The culture solution was kept at 4 ℃ for stock prior to use. The calcium source was calcium nitrate, which was obtained from commercial sources. Microbial cementitious material was prepared by mixing Paenibacillus mucilaginosus and calcium nitrate in a certain proportion.

The particle size distribution and chemical composition of loose sand were shown in Table 1 and Table 2. Loose sand cemented by microbial cementitious material was conducted in wind erosion plates with internal diameter of 20.0 cm and height of 2.0 cm. The geotextile with weak permeability was fixed at the bottom of the wind erosion plate, avoiding the loss of microbial cementitious material.

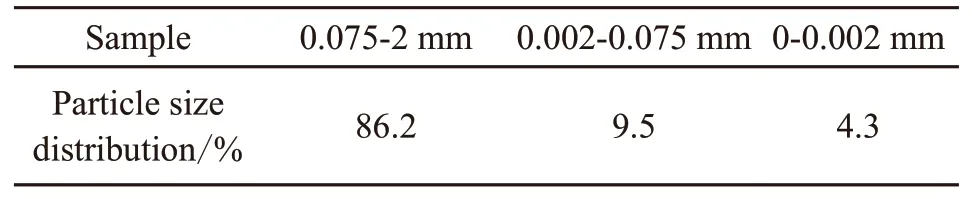

Table 1 Particle size distribution of loose sand

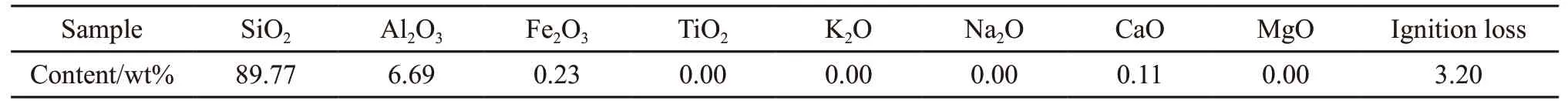

Table 2 Chemical composition of loose sand

2.2 Analysis of microstructure and mechanical properties

Calcium source was dissolved in the culture solution, and the above solution was sprayed evenly on the surface of the wind erosion plates. The reaction was performed at different temperatures for 120 h. Then,the samples were dried at 60 ℃ in an oven. Afterwards,the samples were released and characterized.

The composition was examined by XRD with Bruker D8-Discover diffractometer using graphite monochromatized high-intensity Cu Kα radiation (λ= 1.540 6 Å). Microstructure was studied by scanning electron microscopy (SEM) with a GENESIS 60S energy dispersive X-ray spectroscope spectroscopy.The accelerating voltage and spot size of the secondary electron detector were 20 kV and 4.0, respectively.Microstructure was further analyzed by transmission electron microscopy (TEM).

Loose sand was cemented into a cementation body with certain mechanical properties, and mechanical properties were characterized by measuring the hardness and compressive strength of cementation body. The hardness of the sample was measured by shore hardness test instrument. In order to improve the accuracy of the measurement, it was fixed on the special support. Meanwhile, the compressive strength of the sample was examined by electronic universal testing machine using displacement control method.Wind erosion resistance was carried out in a wind tunnel test machine with wind speed of 12 m/s, erosion angle of 0 degree and duration of 1 h.

2.3 Comparison of engineering properties

Engineering properties of loose sand, which contained permeability coefficient, compression coefficient, cohesion and internal friction angle, were tested referring to the existing national standards(GB/T50123-1999). Permeability coefficient was measured by constant water pressure penetration test.Compression deformation was obtained during the compression consolidation test. The shear strength wasthe ultimate strength, and it was the resistance to shear when a part of the soil sided against another part of the soil. The evaluation indexes of shear strength included cohesion and internal friction angle.

3 Results and discussion

3.1 Preparation of microbial cementitious material

3.1.1 Dosage of culture solution

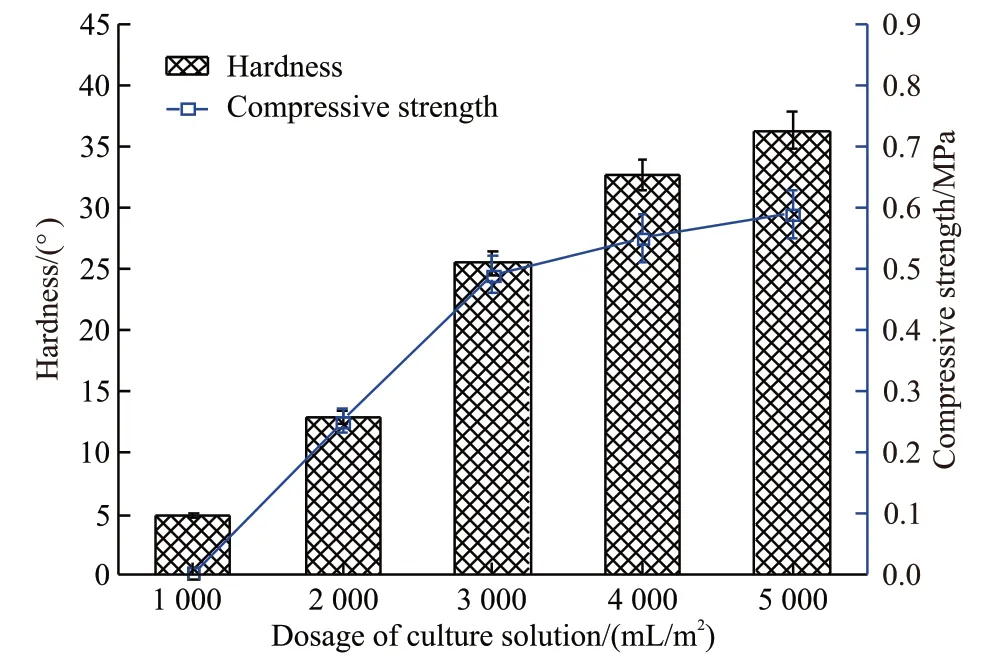

Sufficient amount of calcium source (500 g)was dissolved in the culture solution, and the above solution was sprayed evenly on the surface of the wind erosion plates. The reaction was performed at 25 ℃for 120 h. Then, the samples were dried at 60 ℃ in an oven. Afterwards, the samples were released and characterized. Influence of dosage of culture solution on hardness and compressive strength of samples was shown in Fig.1.

Fig.1 Influence of dosage of culture solution on hardness and compressive strength

It could be seen from Fig.1, the dosage of culture solution had a significant influence on hardness and compressivestrength of samples. With the increase of dosage of culture solution, the effect of reinforcement increased gradually. When the dosage of culture solutionwas1000, 2 000,3000,4000and5000 mL/m2,the hardness ofsampleswere 4.8°,12.8°,25.5°, 32.7° and 36.3°, while the compressive strength of samples were 0, 0.25, 0.49, 0.55, and 0.59 MPa,respectively. When the dosage of culture solution was 3 000 mL/m2, the increase range of hardness and compressive strength decreased obviously with the increase of the dosage of culture solution further.Therefore, the optimum dosage of culture solution was 3000 mL/m2.

3.1.2 Dosage of calcium source

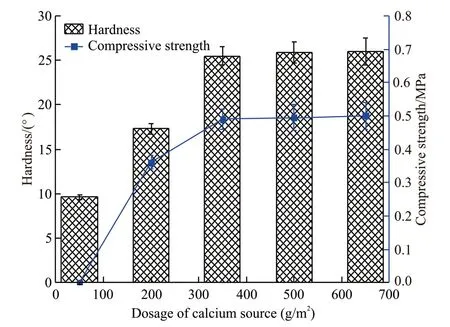

Different amount of calcium source were dissolved in the culture solution and sprayed evenly on the surface of the wind erosion plates. Influence of dosage of calcium source on hardness and compressive strength of samples was shown in Fig.2.

Fig.2 Influence of dosage of calcium source on hardness and compressive strength

Fig.2 showed that the hardness of samples with different amount of calcium source were 9.6°, 17.3°,25.5°, 25.9° and 26.0°, whereas compressive strength of samples were 0, 0.36, 0.49, 0.50 and 0.50 MPa,respectively. When the dosage of calcium source was lower than 350 g/m2, the hardness and compressive strength of samples increased with the increase of the dosage of calcium source. When the dosage of calcium source was higher than 350 g/m2, the hardness and compressive strength of samples had hardly changed.As a result, the appropriate dosage of calcium source was 350 g/m2.

According to the above research results, the optimal proportion of microbial cementitious material was: paenibacillus mucilaginosus culture solution(mL): calcium nitrate = 3 000:350(g/g), which was used to cement sand in 1 m2.

3.2 Influence of temperature on composition and microstructure

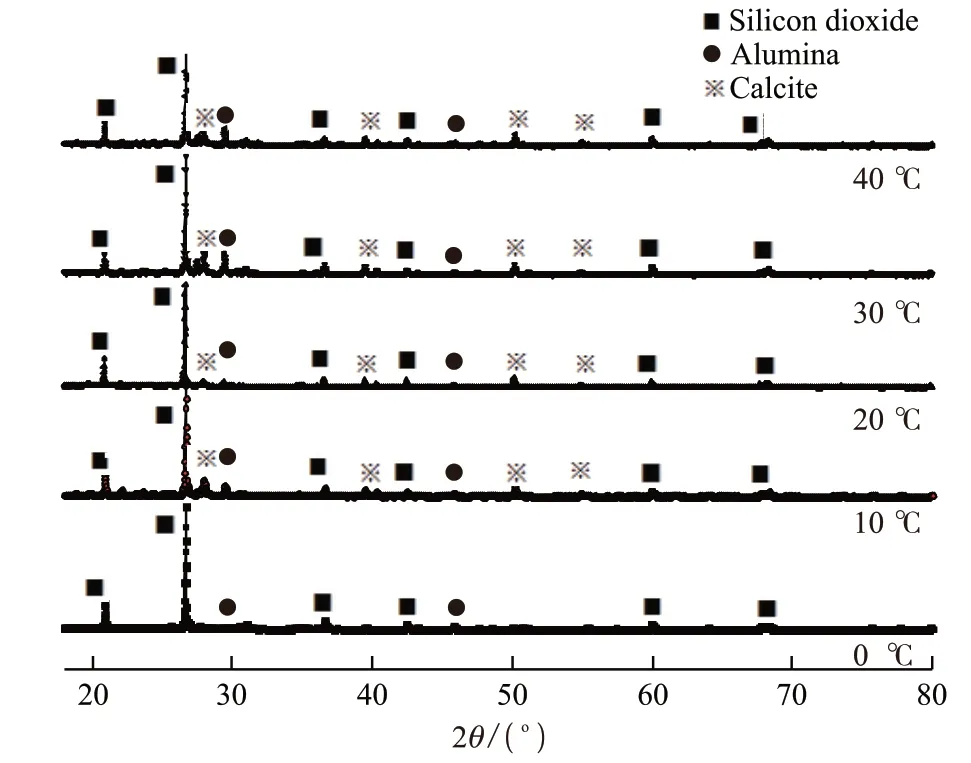

It was known to us, temperature was an important factor affecting the microbial growth, reproduction and enzyme activity. Influence of temperature on composition of samples was shown in Fig.3. XRD patterns indicated that temperature seriously influenced the composition of sand cemented by microbial cementitious material. When the temperature was 0 ℃,the samples were composed of silicon dioxide and alumina. When the temperature was higher than 10 ℃,the composition of the samples changed, and new components of calcite appeared. Microbes had strong temperature dependence, and they would be dormant at lower temperatures. Meanwhile, microbial induced mineralization could not be carried out, and new mineralization products could not be produced.Therefore, the composition of the sample had changed markedly at different temperatures.

Fig.3 XRD patterns at different temperatures

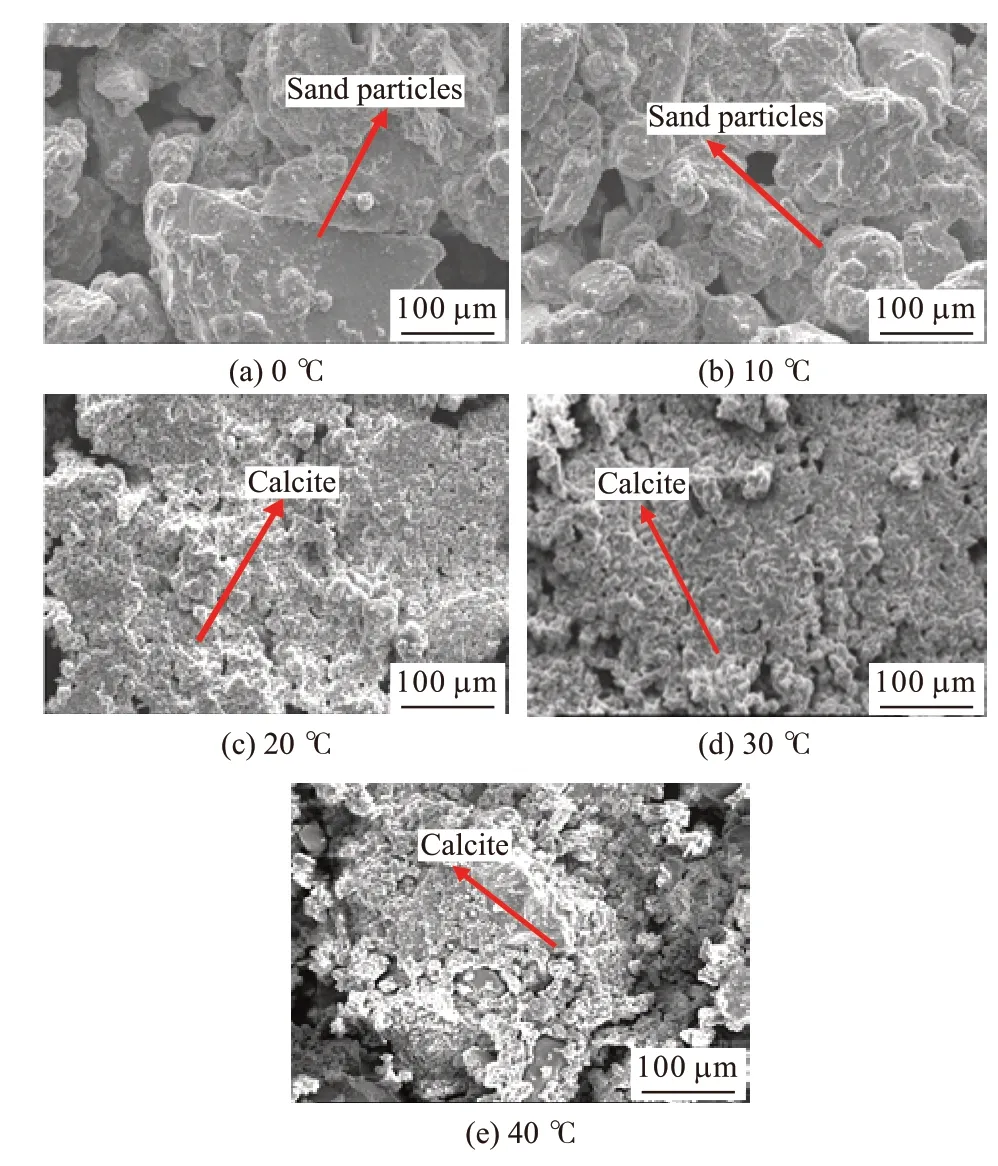

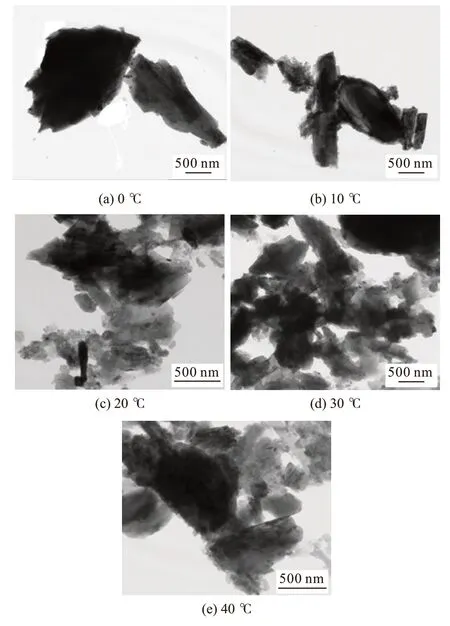

The microstructure of samples was studied by SEM and TEM in this paper. (Fig.4 and Fig.5).The structure of loose sand was gradually compact with the increase of ambient temperature. At ambient temperature of 0 ℃, microbes were dormant without deposits of mineralized products, and could not cement loose sand particles. At ambient temperature of 10℃, the growth of microbes was still limited, and the deposits of mineralized products are less; Therefore,the defects between particles were not fully filled,and the overall compactness was relatively poor. At ambient temperature of 20 ℃, microbes could grow normally with deposits of mineralized products, and the cementation effect of sand particles was improved significantly. At ambient temperature of 30 and 40℃, microbes could induce more mineralized products with denser structure. There was a lot of calcite on the surface and between the sand particles, which filled the defect and cemented the sand particles into a whole, forming a relatively dense structure. TEM images showed that there were fewer calcites prepared by microbial induced at ambient temperature of 0 and 10 ℃, which were simply accumulated in the gap between the sand particles, and it was impossible to make sand particles covered. At ambient temperature of 20, 30 and 40 ℃, there were more calcite prepared by microbial induced, which adhered tightly around the sand particles and almost completely covered the sand particles.

Fig.4 SEM images at different temperatures

Fig.5 TEM images at different temperatures

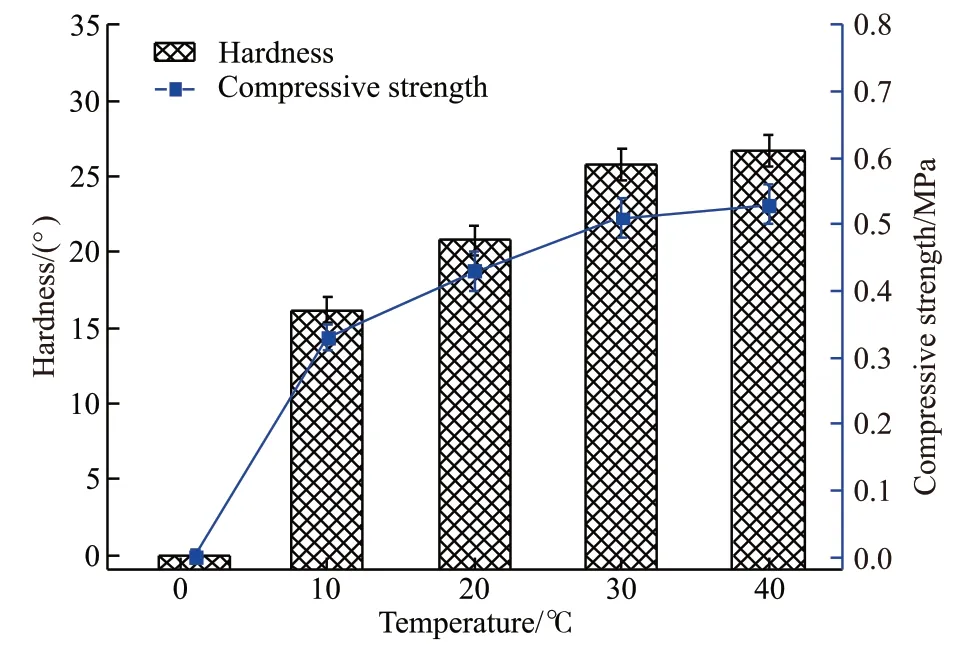

3.3 Influence of temperature on mechanical properties

Influence of temperature on hardness and compressive strength of samples was shown in Fig.6.Fig.6 indicated that temperature seriously influenced the hardness and compressive strength of samples. At different temperatures, the hardness of samples were 0°, 16.8°, 21.5°, 25.7° and 27.0°, while the compressive strength of samples were 0, 0.35, 0.44, 0.51 and 0.53 MPa, respectively. With the increase of the temperature,the cementing effect was improved, and the amount of calcite increased gradually. The optimum temperature of cementing sand by microbial cementitious material was about 30 ℃. When the temperature was 30 ℃, the mechanical properties of samples were superior. When the temperature was lower than 30 ℃, the cementing effect could be improved by increasing the amount of microbial cementitious material. In order to reduce costs, the amount of microbial cementitious material should be cut down when the temperature was higher than 30 ℃.

Fig.6 Influence of temperature on hardness and compressive strength

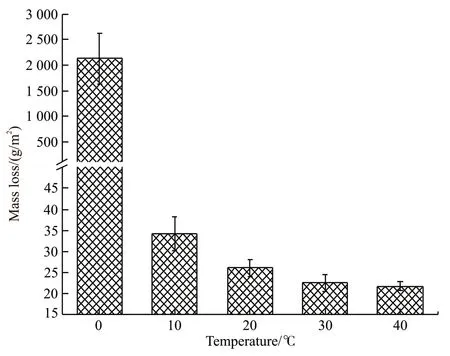

Influence of temperature on wind erosion resistance of samples was shown in Fig.7. From Fig.7,mass loss of samples at different temperatures was 2 231.0, 32.7, 25.6, 23.1 and 22.4 g/m2, respectively.At ambient temperature of 0 ℃, the mass loss of the sample was very large. The main reason was that there was no mineralized product and the sand was still in loose structure. With the increase of temperature,a large number of calcite was prepared by microbes induced, and the cementing effect of microbial cementitious material was superior. As a result, the mass loss of the samples decreased significantly by more than 98.5%.

Fig.7 Influence of temperature on wind erosion resistance

3.4 Engineering properties of sand

Microbial cementitious material could effectively consolidate loose sand particles and form a consolidation body with certain mechanical properties,thus achieving the purpose of sand consolidation and dust suppression. Compared with the traditional curing agent, microbial cementitious material had the characteristics of green environmental protection and no secondary pollution.

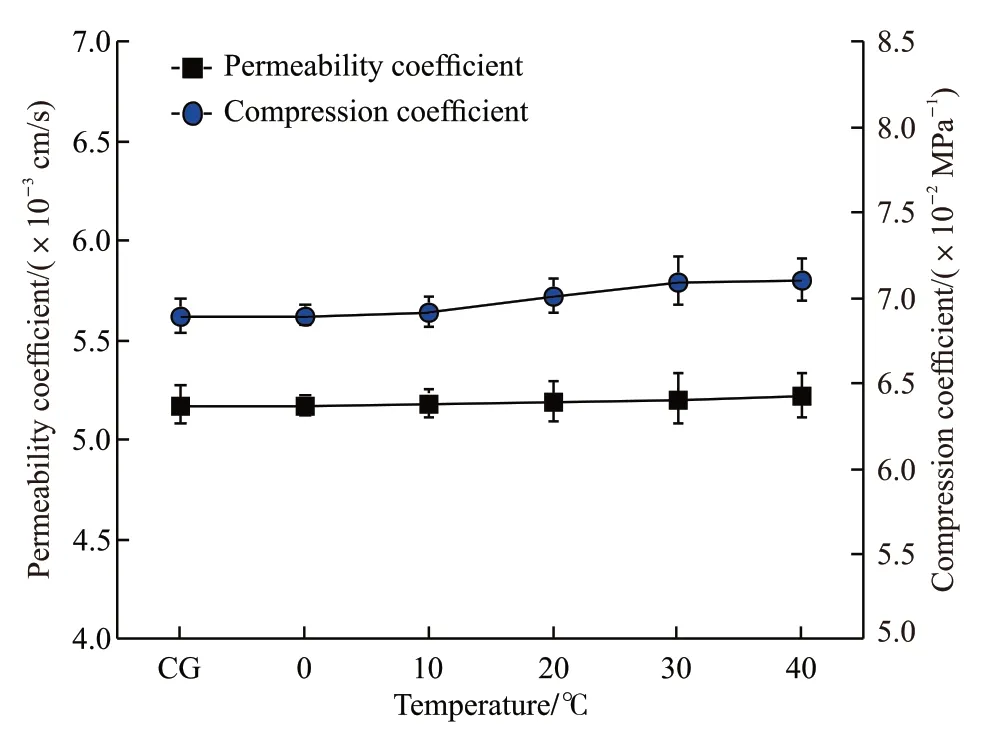

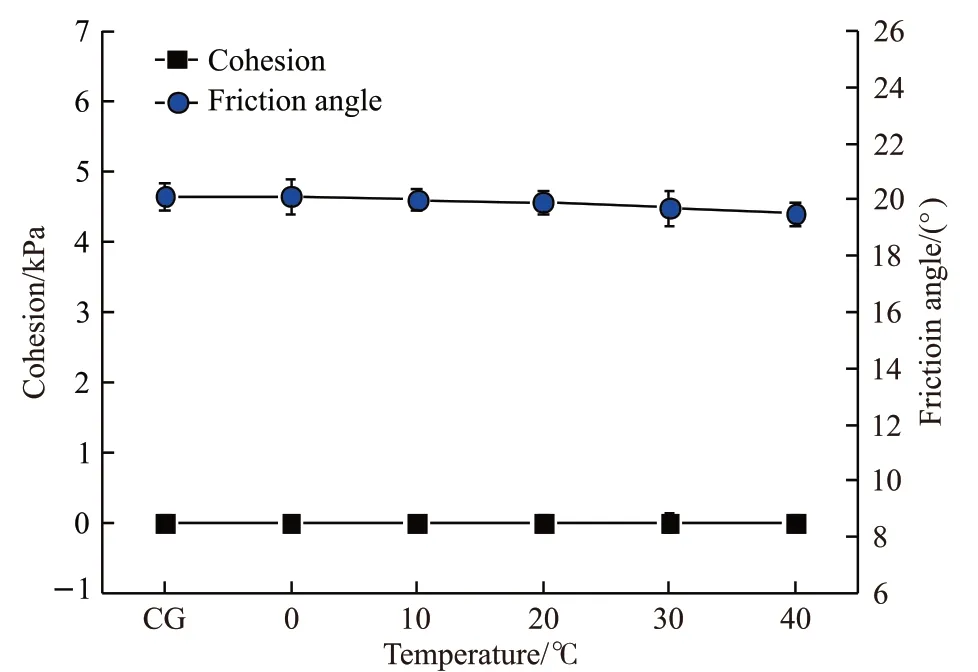

Engineering properties of sand cemented by microbial cementitious material were shown in Fig.8 and Fig.9. In general, the changes of engineering properties were not obvious. Permeability coefficient of sand before cemented was 5.18×10-3cm/s, while the maximum permeability coefficient of sand after cemented was 5.21×10-3cm/s. Permeability coefficient of sand after cemented by microbial cementitious material increased by 0.58%. Meanwhile, the maximum compression coefficient of sand increased by 2.89%, and the minimum friction angle of sand reduced by 1.99%. Furthermore, cohesion of sand remained unchanged at 0 kPa. Through comparative analysis,engineering properties of sand cemented by microbial cementitious material were basically unchanged, and there was no negative effect on the later period use of sand.

Fig.8 Influence of temperature on permeability coefficient and compression coefficient

Fig.9 Influence of temperature on cohesion and friction angle

4 Conclusions

The optimal proportion of microbial cementitious materials was: Paenibacillus mucilaginosus culture solution (mL): calcium nitrate (g) = 3 000:350, which was used to strengthen sandy soil in 1 m2. When the temperature was 0 ℃, the samples were composed of silicon dioxide and alumina. When the temperature was higher than 10 ℃, the composition of the samples changed, and new components of calcite appeared.With the increase of temperature, the amount of calcite deposits increased and the structure became more compact; The hardness and compressive strength of samples gradually improved, and the mass loss of the samples decreased significantly by more than 98.5%. The engineering properties of sand cemented by microbial cementitious material were basically unchanged, and there was no negative effect on the later period use of sand.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Mechanical Properties and Microstructure of Al2O3/SiC Composite Ceramics for Solar Heat Absorber

- Effect of Friction Stir Welding on Bulk Metallic Glasses

- Effects of Lay-up Types of Out-of-autoclave Prepregs on Preparation Quality of L-shape Composite Laminates

- Hypereutectic Al-Si Matrix Composites Prepared by In Situ Fe2O3/Al System

- Preparation of Heavyweight Ultra-high Performance Concrete Using Barite Sand and Titanium-rich Heavy Slag Sand

- Effects of Shale and CaO Incorporation on Mechanical Properties and Autogenous Deformation of Early-age Concrete