Response of grain-filling rate and grain quality of mid-season indica rice to nitrogen application

2021-05-23ZHANGJingZHANGYanyanSoNGNingyuanCHeNQiuliSUNHongzhengPeNGTingHUANGSongZHAoQuanzhi

ZHANG Jing,ZHANG Yan-yan,SoNG Ning-yuan,CHeN Qiu-li,SUN Hong-zheng,PeNG Ting,HUANG Song,ZHAo Quan-zhi

1 College of Agronomy,Henan Agricultural University,Zhengzhou 450046,P.R.China

2 Xinyang Agriculture and Forestry University,Xinyang 464001,P.R.China

Abstract Nitrogen is one of the important factors for high yield of rice. Apart from high yield,high quality has become the current urgent demand for rice production. Grain-filling stage is crucial for rice yield and quality formation. However,the effect of nitrogen on grain-filling characteristics and the relationship of grain-filling characteristics and rice quality of mid-season indica rice were still unclear. A field experiment was carried out to ascertain the critical grain-filling characteristics that contribute to rice milling quality,appearance quality and cooking and eating quality under nitrogen applications. The results showed that nitrogen applications prolonged the duration of superior and inferior grain filling. The mean grainfilling rate (Gmean ) and the maximum grain-filling rate (Gmax ) of the inferior grains were positively correlated with chalky kernel rate,chalkiness,and amylose content. The time reaching the maximum grain-filling rate (Tmax G) of the inferior grains was positively correlated with brown rice rate,milled rice rate,and head milled rice rate. Chalky kernel rate and chalkiness were negatively correlated with peak paste viscosity and breakdown viscosity. Less amylose content and more crude protein content were detected in nitrogen application of Liangyoupei 9 and Y Liangyou 2 both in 2016 and 2017. According to the correlation analysis,better cooking and eating quality of Y Liangyou 2 which had less amylose content might result from its higher Gmax and Gmean of inferior grain than that of Liangyoupei 9 in the treatments of nitrogen application. These results indicated that the prolonging grain-filling duration and increasing grain weight at the maximum grain-filling rate of inferior grains contributed to the improvement of milling quality,appearance quality,and cooking and eating quality of mid-season indica rice under appropriate nitrogen applications.

Keywords:mid-season indica rice,grain-filling rate,rice quality,nitrogen

1.lntroduction

Grain-filling is crucial for rice yield and quality.In this process,photosynthesis product is transported from the effective leaf (source) to grain (sink) through stem,starch is syntheszed and accumulated in grain as well(Wanget al.2003;Xiong 2011). The grains which are usually located on apical primary branches are called superior grains and flower earlier than the others on a panicle,resulting in earlier and faster grain filling,and higher grain fullness. By contrast,the grains which are usually located on proximal secondary branches on a panicle are called inferior grains (Yang 2010). Grain-filling process directly affects setting rate and grain weight,thus influencing the yield (Zhuet al.2018). Increasing nitrogen application promoted grain-filling rate and protein content,but decreased amylose content in grain (Xiong 2011).Nitrogen application significantly affected grain filling of superior and inferior grains (Zhaoet al.2007). The initial grain filling of superior grain without nitrogen application was earlier and faster than that under nitrogen application(Zhaoet al.2007). The duration of grain filling was significantly prolonged by elevating the amount of nitrogen fertilizer,and then decreasing the maximum grain-filling rate and increasing grain fullness (Duan 2018). Grainfilling degree was negatively correlated with chalkiness and chalky kernel rate of superior and inferior grains(Zhaoet al.2007). Unlike the significant decrease in chalkiness after topdressing nitrogen fertilizer at heading stage,there was no significant change in length-width ratio (Huet al.2016). To a certain extent,decreased content of amylose in rice grain caused a reduction of starch paste temperature,but protein content increased with the increase of nitrogen application,resulting in rice hardening and taste deterioration (Jinet al.2001;Gaoet al.2010;Zhanget al.2010). The viscosity properties of rice depending on the relative balance of protein content and amylose content were regulated by the amount of nitrogen application.

Grain-filling stage is important for rice yield and quality formation. Starch and protein,the final products of carbon and nitrogen metabolism,are the key factors affecting rice quality. To achieve high yield,high nitrogen input is an indispensable cultivation practice,especially for the super hybrid rice with greater panicle size (Yuan 2017). However,over application of N fertilizer is currently occuring in China,causing yield reduction of super rice cultivars (Tang 2003;Lianget al.2015;Liuet al.2018). This is partially attributed to mutual shading (Tanaka 1966),lodging (Duyet al.2004)and low grain filling (Liuet al.2018). Although many studies have been reported on the effect of nitrogen application on grain filling or rice quality,the relation between grain-filling characteristics of superior and inferior grains and grain quality of mid-season hybridindicarice is still unclear. Thus,we employed two elite varieties of mid-season hybridindicarice to investigate the influence of nitrogen on grain-filling characteristics,rice appearance quality,and cooking and eating quality,aiming to further clarify the responses of grain filling of superior and inferior grains and rice quality to different nitrogen applications.

2.Materials and methods

2.1.Experimental design

We conducted the same field experiment at Xinyang,Henan Province,China (34°34´N,115°33´E) each in 2016 and 2017. Soil properties at the experimental site were as follows:soil organic C 29.29 g kg–1,total N 1.00 g kg–1,available N 56.74 mg kg–1,available P 16.51 mg kg–1,available K 139.3 mg kg–1,and pH 6.41. Two representative cultivars of super rice breeding program,Liangyoupei 9 and Y Liangyou 2,were used in this experiment. They have achieved high yield and good rice quality in the previous studies (Lüet al.2000;Wuet al.2015). The total number of spikelets of Y Liangyou 2 was higher than that of Liangyoupei 9,while the grain weight of Y Liangyou 2 was a little lower than that of Liangyoupei 9 (Zenget al.2017;Liuet al.2018). Rice seeds were sown on April 12,and transplanted on May 13 at a hill spacing of 30 cm×20 cm with two seedlings per hill in 2016 and 2017.Nitrogen fertilizer was applied at 0 (N0),210 kg N ha–1(N14)and 390 kg N ha–1(N26). Each treatment replicated three times. The treatments were applied to 18 plots. Each plot was 4.5 m×7 m in size. Nitrogen fertilizer was applied as basal,tillering and panicle fertilizers with the ratio of 4:2:4.The total amount of nitrogen,phosphorus and potassium fertilizers was applied at the ratio of 2:1:2,calculated as N,P2O5and K2O. Phosphorus fertilizer was applied as basal in the form of calcium superphosphate. Half to half of potassium chloride fertilizer was applied as basal and panicle fertilizer,respectively. A 4–5-cm water layer over the soil surface was maintained during the pre-flowering period. A timely-drying paddy field was used to control inefficient tillers. Alternate wetting and drying irrigation was applied during the post-flowering period. The plots were irrigated to 2–3 cm shallow water layer after flowering and then dried off naturally,followed by the alternate wetting and drying treatment until 7 days before harvest.

2.2.Determination of grain-filling parameters

About 100 main-stem panicles headed on the same day were marked in each plot.Ten marked panicles were sampled randomly from each plot at one time,starting at 7 days after full heading at a 7-day interval until maturity.The first,fourth,fifth,and sixth grains located at the upper three branches and the first grain of the secondary branch in each panicle were collected as the superior grains,while the grains of the lower three branches and the secondary branch except the first grain were collected as the inferior grains. All the superior and inferior grains were oven-dried at 70°C for about 72 h to a constant weight. Grain-filling rate (i.e.,changes in grain weight with days after full heading) was fitted using Richards equation;and grainfilling parameters including initial grain-filling rate (GR0),time of reaching the maximum grain-filling rate (TmaxG),grain weight of the maximum grain-filling rate reaching(WmaxG),the maximum grain-filling rate (Gmax),and the mean grain-filling rate (Gmean) were calculated according to Zhuet al.(1988).

2.3.Determination of milling quality and grain shape of rice grain

Thirty-five plants were harvested at maturity stage in each plot. After being threshed and naturally dried,the seeds were stored for 3 mon for grain quality measurement. Milling quality including milled rice rate,head milled rice rate,and chalkiness and chalky rate were measured according to the GB/T 17891-1999 (1999) standard.

2.4.Determination of crude protein and amylose contents of rice grain

Crude protein was measured using Micro-kjeldahl Method.Amylose content was measured in accordance with the GB/T 15863-2009 (2009).

2.5.Determination of starch pasting viscosity of rice grain

Pasting properties of rice flour were measured using a Rapid Viscosity Analyzer (RVA 4500,Perten,Sweden),according to the American Society for Cereal Chemistry Operating Procedures (Baet al.2018). The RVA spectrum characteristic value was mainly represented by peak viscosity (PKV),hot paste viscosity (HPV),cool paste viscosity (CPV),breakdown viscosity (BDV=PKV–HPV),and setback viscosity (SBV=CPV–PKV) (Caoet al.2018).

2.6.Statistical analysis

Analysis of variance was conducted to detect difference in grain quality characteristics using SPSS 22.0 (IBM,USA).The least significant difference (LSD) at the 0.05 probability level was used to test the significantly difference of the means between the treatments. The correlations between grain-filling characteristics and rice quality were evaluated using Pearson’s correlation analysis.

3.Results

3.1.Grain-filling characteristics of superior and inferior grains

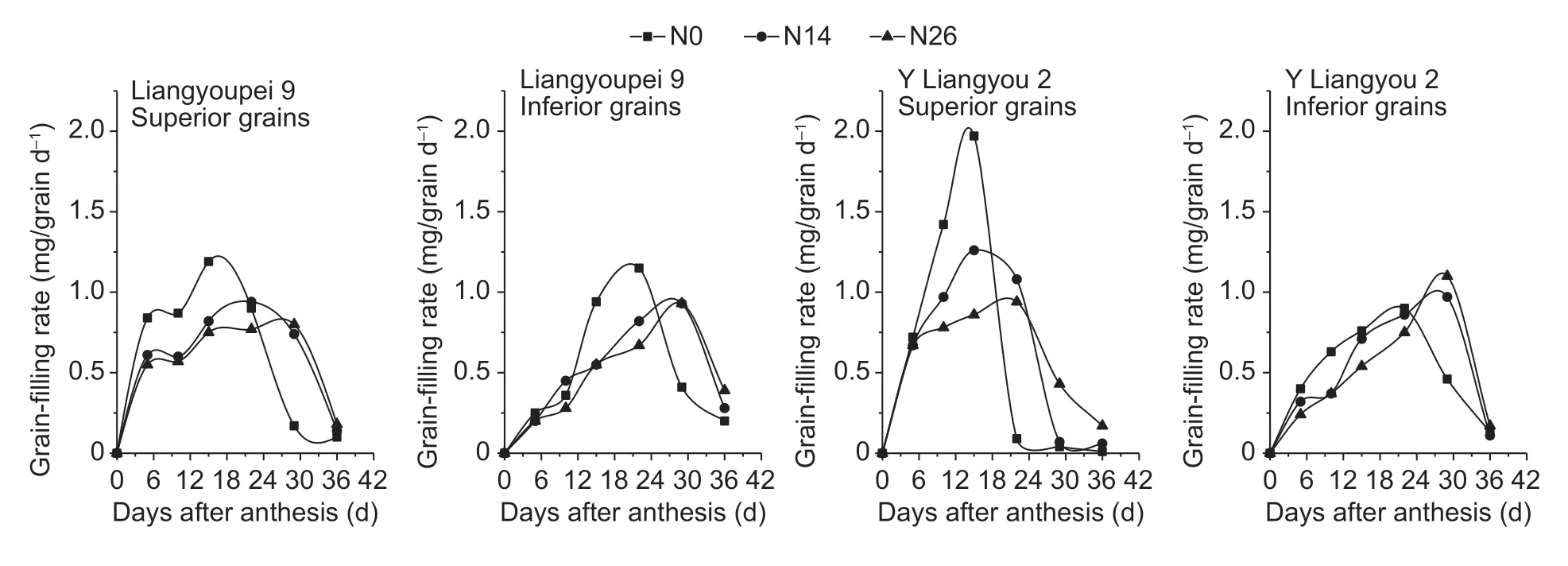

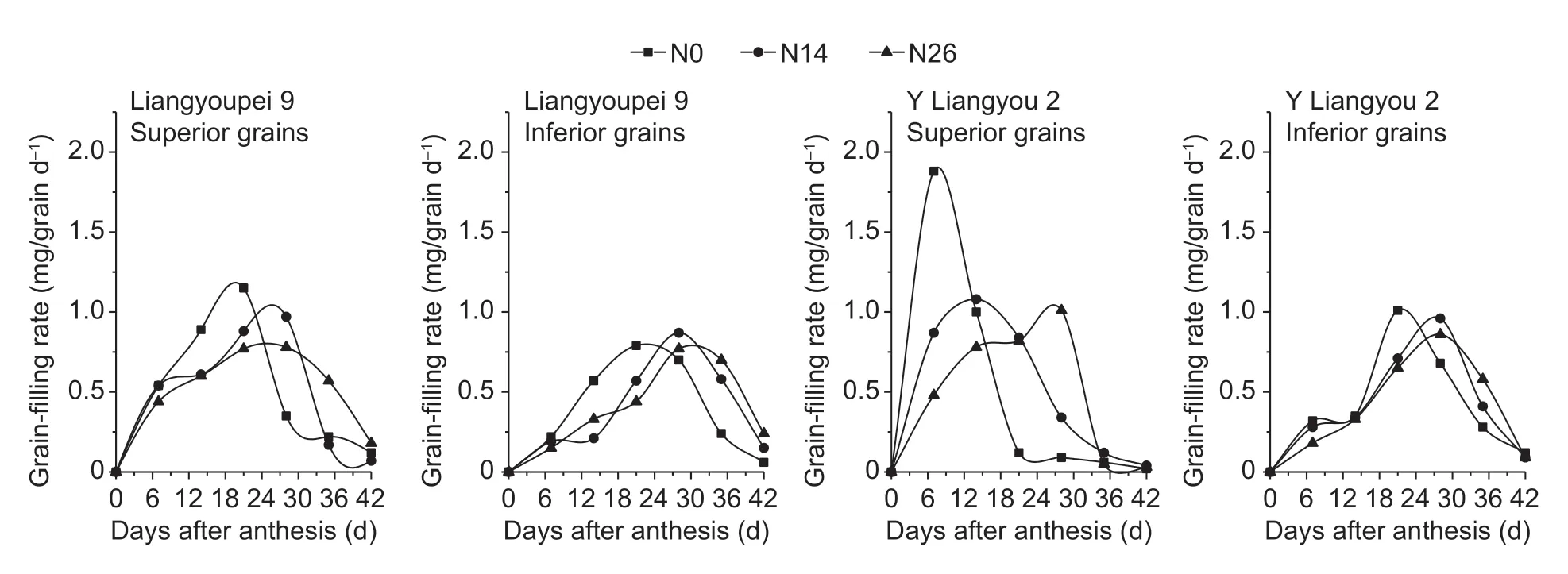

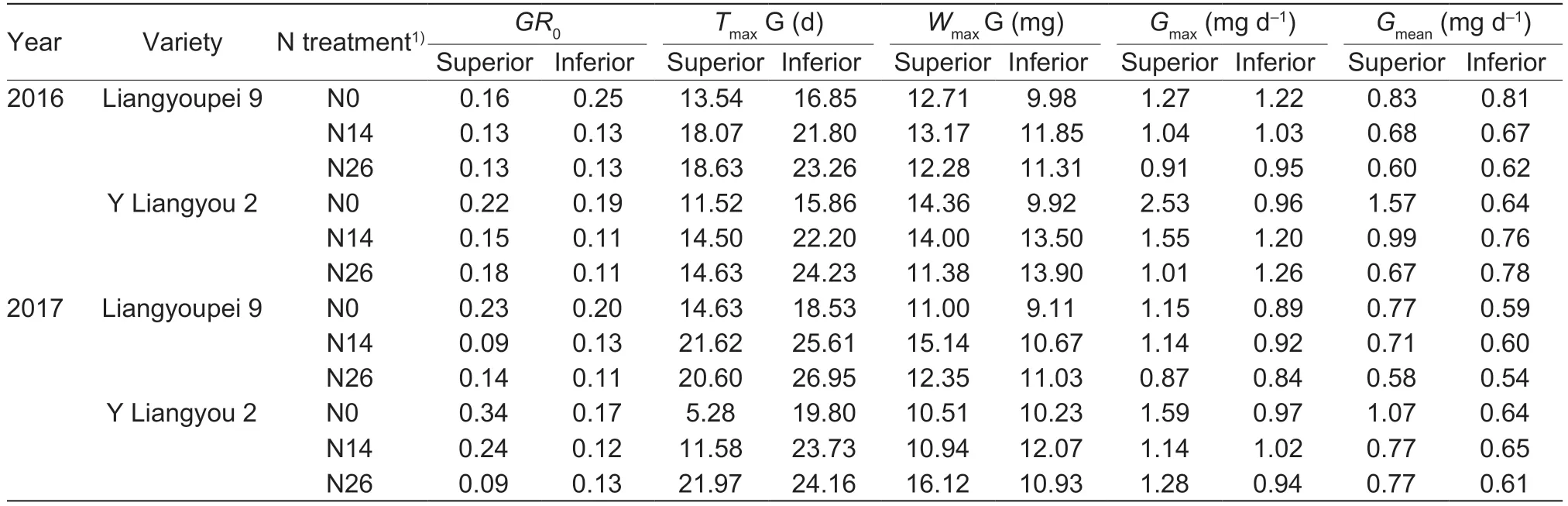

Grain-filling rates of superior grains and inferior grains were well fitted by the Richards equation (R2>0.995,P<0.001,date not shown) for two varieties in 2016 (Fig.1)and 2017 (Fig.2). During the 0–20 d of grain filling,nitrogen application caused decrease of grain-filling rate of Liangyoupei 9. However,at the late 10 d of grain filling,grain-filling rate in the N26 treatment was higher than that in N0 and N14.GR0of the superior grains of Y Liangyou 2 was higher than that of Liangyoupei 9 at 2016(Table 1). The highestGR0of superior or inferior grains was found in the N0 treatment.GR0of the superior grains of Y Liangyou 2 were higher than that of Liangyoupei 9 in the same nitrogen treatment except for that of Y Liangyou 2 in the N26 treatment in 2017,whilstGR0of the inferior grains of Liangyoupei 9 was higher than that of Y Liangyou 2 in the N0 and N14 treatments. The highestTmaxG was recorded in the inferior grains of Liangyoupei 9 in the N26 treatment,followed by those in the N14 treatment,which was 27.56 and 31.24% higher than that in the N0 treatment in 2016 and 2017,respectively. Time difference value ofTmaxG between the superior grains and inferior grains of Liangyoupei 9 was less than that of Y Liangyou 2,except for that of Y Liangyou 2 in the N26 treatment in 2017.WmaxG was the highest in the superior grains of Y Liangyou 2 in the N26 treatment in 2017,followed by those in Liangyoupei 9 in the N14 treatment in 2017. The superior grains of Liangyoupei 9 had a higherWmaxG than its inferior grains.Except in the N26 treatment in 2016,GmaxandGmeanwere higher in the superior grains than in the inferior grains. In the two tested varieties,superior grains in the N0 treatment had the highestGmaxandGmean. In addition,GmaxandGmeanwere higher in Y Liangyou 2 than in Liangyoupei 9. These results indicated that grain filling of the superior grains of Y Liangyou 2 started quicker,and reached the peak faster than that of Liangyoupei 9. The gap ofTmaxG between the superior and inferior grains was widened by high nitrogen application,especially for Y Liangyou 2.

3.2.Grain milling quality,appearance quality and amylose and crude protein contents

Fig.1 Dynamic change of grain-filling rate curve of superior and inferior grains under different nitrogen applications in 2016. N0,N14 and N26,0,210 and 390 kg N ha–1,respectively.

Fig.2 Dynamic change of grain-filling rate curve of superior and inferior grains under different nitrogen applications in 2017. N0,N14 and N26,0,210 and 390 kg N ha–1,respectively.

Table 1 The initial grain-filling rate (GR0 ),time reaching the maximum grain-filling rate (Tmax G),grain weight of the maximum grain-filling rate reaching (Wmax G),the maximum grain-filling rate (Gmax ),and the mean grain-filling rate (Gmean )

Milling quality contains brown rice rate,milled rice rate and head milled rice rate (Table 2). Milled rice rate was better in the N14 and N26 treatments than in the N0 treatment.Y Liangyou 2 had a higher brown rice rate,milled rice rate and head milled rice rate than Liangyoupei 9 in 2016 and 2017. For brown rice rate of Liangyoupei 9,there were 1.65 and 1.59% increase in the N14 treatment,and 1.66 and 3.02% increase in the N26 treatment,compared to the N0 treatment,in 2016 and 2017,respectively. Head milled rice rate increased with the increase of N application. For milling quality,significant differences were found between years and between N treatments for both varieties. The interaction of year and N treatment was also significant for head milled rice rate.

Appearance quality includes chalkiness,chalky kernel rate and length-width ratio(Table 2). Y Liangyou 2 had a bigger lengthwidth ratio than Liangyoupei 9. The effect of nitrogen application on length-width ratio was not significant. Chalkiness and chalky kernel rates were reduced under elevated N application for two varieties during two years. For Y Liangyou 2,there were 7 and 23.8%,10.7 and 35.5% decrease in chalkiness,and 6.9 and 16.4%,9.6 and 38.7% decrease in chalky kernel rate in the N14 and N26 treatments compared to the N0 treatment in 2016 and 2017,respectively. Variance analysis suggested that year,N treatment and their interaction had significant effects on chalkiness and chalky kernel rates.

The amylose content of Liangyoupei 9 was 37.5 and 44.3% higher than that of Y Liangyou 2 in the N0 treatment in 2016 and 2017,respectively. For Liangyoupei 9,amylose content decreased with elevated N application,which was 9.62 and 15.13%less in the N14 and N26 treatments than that in the N0 treatment,respectively,in 2016. Crude protein content increased with elevated N application. Statistically significant differences in crude protein content were found between years and between N treatments for both varieties.The interaction of year and N application was also significant for amylose and crude protein contents.

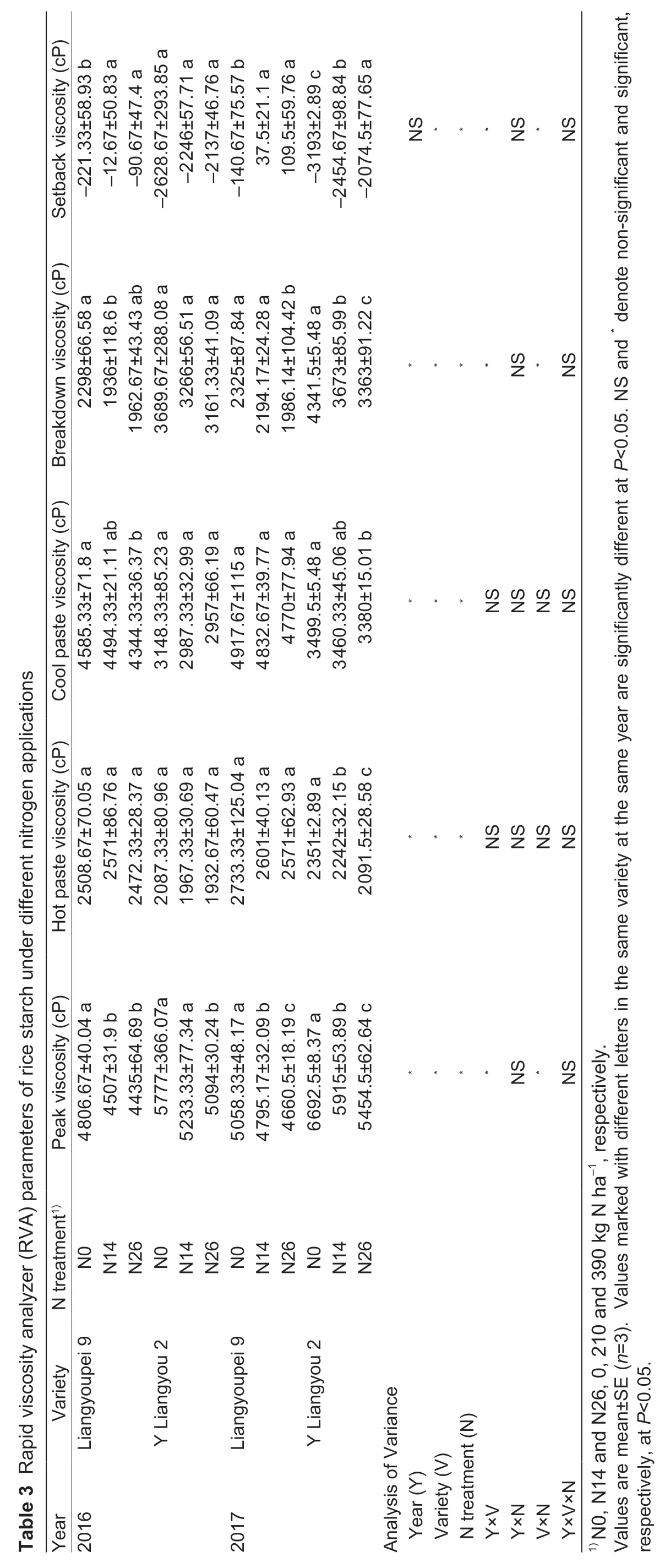

3.3.RVA parameters

Elevated N application decreased PKV and CPV in each year for both varieties when compared with those in the N0 treatment(Table 3). PKV,BDV and SBV of Y Liangyou 2 were higher than those of Liangyoupei 9.For Y Liangyou 2,there were 11.6 and 18.5% decrease of PKV,and 1.1 and 3.4%decrease of CPV in the N14 and N26 treatments compared to those in the N0 treatment in 2017,respectively. For both varieties,significant differences in PKV,HPV,CPV and BDV were found between years and between N treatments. The interaction of year and N application was not significant for PKV,HPV,CPV and BDV.

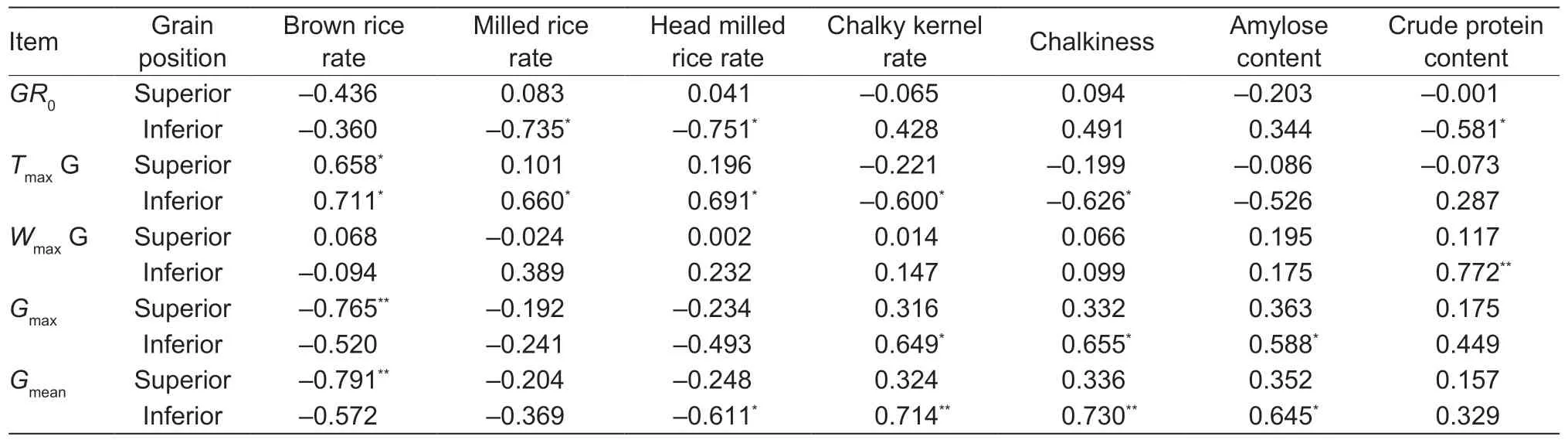

3.4.Correlations between grain-filling characteristics and rice quality

GR0of the inferior grains was significanlty negatively correlated with milled rice rate,head milled rice rate,and crude protein content (Table 4).TmaxG of the superior and inferior grains were both significanlty positively correlated with brown rice rate. In addition,TmaxG of the inferior grains was significantly negatively correlated with chalky kernel rate and chalkiness.WmaxG of the inferior grains was significanlty positively correlated with crude protein content,but not with milling quality.GmaxandGmeanof the superior grains were significantly negatively correlated with brown rice rate,but significantly positively correlated with chalky kernel rate,chalkiness and amylose content.

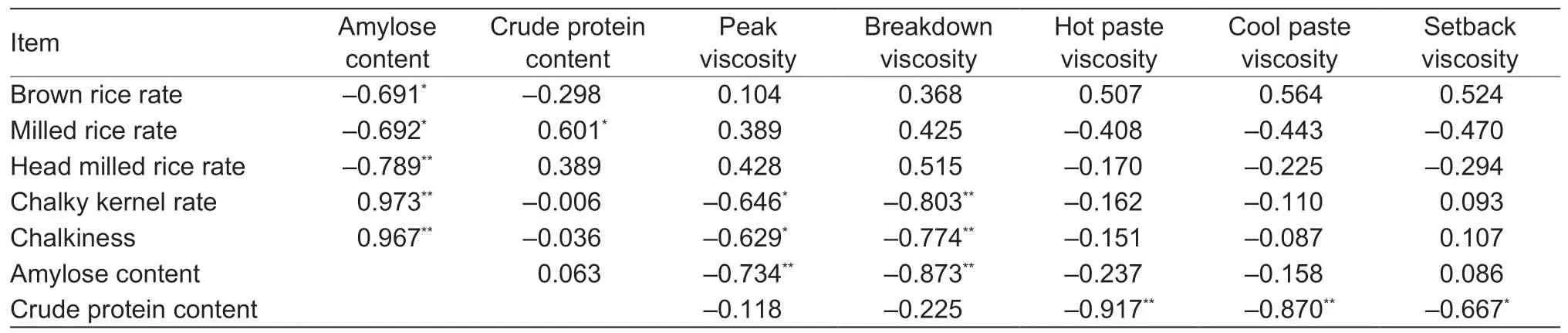

Brown rice,milled rice and head milled rice rates were significantly negatively correlated with amylose content,but not with crude protein content (Table 5). Chalky kernel rate and chalkiness were significantly positively correlated with amylose content,but not with crude protein content. Furthermore,chalky kernel rate and chalkiness were significantly negatively correlated with PKV and BDV.Amylose content was significantly negatively correlated with PKV and BDV. Crude protein content was significantly negatively correlated with HPV,CPV and SBV.

4.Discussion

4.1.Grain-filling of superior and inferior grain responses to nitrogen application

The number of effective panicles of Y Liangyou 2 and Liangyoupei 9 increased with the increase of nitrogen application,but both varieties achieved a higher grain yield under the nitrogen treatment of 210 kg ha–1than 0 or 390 kg ha–1(Zenget al.2017;Liuet al.2018). As a part of the same project,our results on yield were consistent with these studies (data not shown). Grain-fillingprocess affects rice yield because grain-filling characteristics determines grain weight to a great extent (Zhuet al.2018;Chenet al.2019). Apart from breed genetic factor,nitrogen application significantly affects grain-filling of rice (Zhaoet al.2007). Previous studies have certified that grain-filling rate decreased with the increase amount of nitrogen (Guet al.2001;Wanget al.2016). Our study found thatGmeanof the superior grains decreased,butTmaxG of the superior and inferior grains increased gradually,with elevated nitrogen application. Prior toTmaxG,grain-filling rate of the superior and inferior grains both decreased with the increase of nitrogen application. These results indicated that nitrogen application decreased the grain-filling rate of the superior and inferior grains,postponing the maximum time of grain filling and prolonging the effective grain-filling duration.This is because high nitrogen input increased nitrogen concentrations in plant tissue,which might bring about a high rate of nitrogen metabolism and result in enhancement of carbohydrate consumption and reduction of carbohydrate translocation to grain filling (Liet al.2010;Lianget al.2015). Furthermore,hull size is another factor contributing to grain weight.Unlike greater grain weight of the superior and inferior grains detected in the N14 treatment,lengthwidth ratio of brown rice was a little greater in the N26 treatment than that in the N14 treatment. Regrettably,the length and width of superior and inferior grains were not measured in this study. The influence of nitrogen on the size of superior and inferior grains needs to be investigated in future research.

Table 4 Correlation of rice grain-filling parameters with amylose and crude protein content,and rice milling quality in 2016 and 2017

Table 5 Correlation of rapid viscosity analyzer (RVA) profile values with amylose and crude protein content,and rice milling quality in 2016 and 2017

4.2.Responses of rice quality to grain filling and nitrogen application

Rice quality is determined by genetic and environmental factors (Senthilvelet al.2008). There are contradictory reports on the influence of nitrogen on rice quality (Zhouet al.2001;Xuet al.2005;Xionget al.2008;Ning 2011).In the present study,milling quality was improved by nitrogen application. This result was consistent with the finding of Jianget al.(2017). Chalkiness and chalky kernel rates decreased with elevated nitrogen application,which confirmed the results of Jinet al.(2001). DecreasingGR0and prolongingTmaxG of the inferior grains might contribute to the improvement of milling quality. ProlongingTmaxG and higherGmaxandGmeanof the inferior grains reduced the chalky kernel rate. However,the N26 treatment with excessive nitrogen application did not perform better than the N14 treatment. These results suggested that within a certain amount,nitrogen application induced milling and appearance quality improvement partial due to altering grain filling of the inferior grains.

The content and compose of amylum and protein were usually used to evaluate rice cooking and eating quality.Amylose and crude protein contents were significantly affected by nitrogen application.Nitrogen application increased crude protein in rice,but not amylose content.Liangyoupei 9 had a lower amylose content in the N26 treatment than in other treaments,which is similar to previous results (Taoet al.2016;Sunet al.2018). Amylose is moderated by both genes and environment (Zhanget al.2008,2009;Caoet al.2018),leading to the contrary results of Y Liangyou 2 in the N26 in 2016 and 2017. Appropriate nitrogen has been approved to maintain and improve rice quality. Low amylose level of starch was detected in the rice grown with nitrogen application (Singhet al.2011).Elevated nitrogen application decreased PKV,HPV,CPV,and BDV of starch (Guet al.2015). Zhouet al.(2002)and Wanget al.(2003) found that amylose content was negatively correlated with cooking and eating quality. They considered that low amylose content caused soft rice in a certain range. Otherwise,the taste of rice tended to be harder. Our results also confirmed that amylose content was negatively correlated with PKV and BDV,indicating that nitrogen application improved cooking and eating quality to some extent. Thus,it was apparent that Y Liangyou 2 had a better cooking and eating quality than Liangyoupei 9 because the inferior plants of the former had higherGmaxandGmeanthan those of the latter.

5.Conclusion

Nitrogen application improved rice milling,appearance and cooking quality by decreasing amylose content and increasing protein content. Moreover,the improvement of rice quality was mainly attributed to the prolonged effective duration of inferior grain filling and the subsequent increase in its grain weight. Inferior grain is of great significance to the improvement of gain quality of mid-seasonindicarice.

Acknowledgements

This work was supported by the National Key R&D Program of China (2016YFD0300505) and the Rice Industry Technology System of Henan Province,China (S2012-04-G02).

Declaration of competing interest

The authors declare that they have no conflict of interest.

杂志排行

Journal of Integrative Agriculture的其它文章

- Low glycemic index:The next target for rice production in China?

- Effects of different types of slow-and controlled-release fertilizers on rice yield

- Advancements in plant regeneration and genetic transformation of grapevine (Vitis spp.)

- Indica rice restorer lines with large sink potential exhibit improved nutrient transportation to the panicle,which enhances both yield and nitrogen-use efficiency

- Effects of nitrogen management on the ratoon crop yield and head rice yield in South USA

- Determining nitrogen status and quantifying nitrogen fertilizer requirement using a critical nitrogen dilution curve for hybrid indica rice under mechanical pot-seedling transplanting pattern