Magnesium matrix composite reinforced by nanoparticles–A review

2021-03-10NieWngDengHuWu

K.B.Nie,X.J.Wng,K.K.Deng,X.S.Hu,K.Wu

aState Key Laboratory of Advanced Welding and Joining,Harbin Institute of Technology,Harbin 150001,China

b College of Materials Science and Engineering,Taiyuan University of Technology,Taiyuan 030024,China

Received 26 December 2019;received in revised form 22 July 2020;accepted 4 August 2020

Available online 8 October 2020

Abstract Significant progress has been made in magnesium-based composites during recent decades,especially for the appearance of magnesium matrix composite reinforced by nanoparticles.The nanoparticles added not only exhibit a good strengthening effect,but also maintain the initial toughness of the matrix,effectively balancing the contradiction between the strength and plasticity in the traditional magnesium matrix composites.The magnesium matrix nanocomposites with excellent mechanical properties have pushed the development of magnesium matrix composites to a new stage.However,it is very difficult to disperse the nanoparticles in metal melt especially in magnesium melt which is different from other metal melts and dangerous during the cast processing.This means that the preparation of magnesium matrix nanocomposite is extremely challenging.Further,the magnesium matrix nanocomposites possess a distinctive characteristic in deformation behavior,strengthening and toughening mechanism due to their special size effect of nanoparticles.Accordingly,this review will focus on the new preparation technologies,deformation behavior,mechanical properties and strengthening and toughening mechanisms.The potential applications,development trends and future research ideas of magnesium matrix nanocomposite are also prospected.

Keywords:Magnesium matrix nanocomposite;Microstructure;Mechanical properties;Strengthening mechanism.∗Corresponding author.

1.Introduction

Light-weight magnesium which possesses extremely low density,good machinability and structural properties,can meet the requirements of energy saving and emission reduction in the transportation sector and other automotive application[1–3].However,there are still some bottlenecks in a target application for magnesium such as low elastic modulus and ductility,poor creep and abrasion resistance and high corrosion rate[4].To circumvent these limitations,the introduction of alloying elements or reinforcements to magnesium has been adopted in previous studies[5–8].In particular,the addition of particulate reinforcements to magnesium matrix has been proven to further improve the mechanical properties in addition to precipitation strengthening,grain refinement strengthening and solid solution strengthening contributed by alloying element[9–12].There are various types of particulate reinforcements available to prepare magnesium matrix composites(MMCs)such as carbides(SiC,TiC,B4C,ZrC),oxides(Al2O3,TiO2),borides(ZrB2,TiB2),nitrides(AlN,BN,ZrN,TiN)and metals(Ti,Cu,Mo,Ni)[12–15].It has been shown that the MMCs containing one or more traditional micron size particulate reinforcements and continuous magnesium matrix have outstanding advantages over monolithic magnesium,such as high strength,high modulus and wear properties[16–18].However,there is a high probability that the addition of micron size particulate reinforcements can easily leads to particle cracking and void formation in the ascast MMCs,which accelerates the failure during the following secondary processing.For more than a decade the appearance of magnesium matrix composite reinforced by nanoparticles has showed that the addition of nanoparticles not only exhibits a good strengthening effect,but also maintains the toughness of the initial matrix,thus push the development of magnesium matrix composites to a new stage.By adding less than 3vol%nanoparticles,comparable or even superior mechanical properties can be achieved in the magnesium matrix nanocomposites relative to traditional magnesium matrix composites[19,20],which better balance the contradiction between the strength and plasticity.

However,to fabricate the magnesium matrix nanocomposites with excellent mechanical properties,the main issue to be faced is the low wettability between the ceramic nanoparticles and molten magnesium matrix[21,22].It is extremely difficult to disperse the nanoparticles in metal melt especially in magnesium melt,because the magnesium melt is easier to burn relative to other metal melts,which is more dangerous during alloy melting.This means that the preparation of magnesium matrix nanocomposite is a huge challenge.The casting methodologies involving in either liquid based or solid based techniques[23–28]have been explored for preparing magnesium matrix composite containing nano-sized particle.Further,due to the special size effect of nanoparticles,there is also a distinctive characteristic in the grain refinement,the crushing of second phases,the improved distribution of reinforcement and the dynamic precipitation for the magnesium matrix nanocomposite during the secondary processing such as extrusion or rolling[29,30].Moreover,the relationship between the mentioned microstructure and corresponding strengthening and toughening mechanism of the magnesium matrix nanocomposite has been explored in some literatures[31].

The present work will focus in detail on the important progress of lightweight magnesium matrix composites reinforced by nanoparticles in the preparation,forming,performance and toughening mechanisms.The principles and applications of different preparation technologies for magnesium matrix composites reinforced by nanoparticles will be presented.The effect of different secondary processing methods on the microstructure and mechanical properties as well as the strengthening and toughening mechanisms will be also reviewed.The potential applications,development trends and future research ideas of magnesium matrix nanocomposite are also prospected.

2.Preparation of magnesium matrix composite reinforced by nanoparticles

In order to improve the strength of the magnesium,microsize ceramic particles have been introduced into magnesium matrix,but unfortunately,they severely degrade the plasticity and machinability of magnesium.In this situation,the low concentration of nanoparticles which have the potential to improve strength while maintaining or even improving the plasticity of magnesium,has been introduced to the magnesium matrix.However,it is difficult to disperse the nanoparticles uniformly in magnesium matrix due to the strong van der Waals force between the nanoparticles and the very poor wettability with the magnesium matrix[32].The commonly employed processing techniques to synthesize magnesium matrix nanocomposite includes ultrasonic vibration[33,34],the combination of ultrasonic vibration and semisolid stirring[35],disintegrated melt deposition(DMD)[6],in situ synthesis method[36],friction stir processing[37],powder metallurgy[38],etc.Among them,the ultrasonic vibration,the combination of ultrasonic vibration and semisolid stirring method and the DMD method are most widely used.

Fig.1.Two nanoparticle dispersion model.

2.1.Ultrasonic vibration

Solidification processing technologies,especially casting,is a cost effective to enable a high volume and net shape production of magnesium matrix nanocomposites.Because the van der Waals force between the nanoparticles is strong and the wettability between the magnesium and the nanoparticles is very poor,a reliable casting process which enables efficient dispersion of nanoparticles in magnesium melt is needed to develop high performance bulk magnesium matrix nanocomposites.In this situation,the ultrasonic vibration has been proven to be effective which combines the casting technologies with transient cavitation and acoustic streaming.The ultrasonic vibration can produce transient micro-hot spots of temperatures of~5000°C,which reach pressures above 1000 atm,and heating and cooling rates above 1010°C/s[39].Such strong impact coupling with local high temperatures can potentially clean the particle surface,break the nanoparticle clusters.

2.1.1.The theoretical feasibility of ultrasonic vibration

In order to simulate the theoretical feasibility of ultrasonic vibration on the dispersion of nanoparticles,two nanoparticles agglomeration model in metal was built by Yang[40].As shown in Fig.1,the attractive forces between two nanoparticles include Van der Waals force and capillary force.The two forces which were calculated based on the actual fabrication conditions were added together and then converted into pressure,which is the force required to separate two agglomerated nanoparticles.By comparing the calculated force with the numerically calculated ultrasonic cavitation pressure,for the nanoparticles with a diameter of 30nm,the acoustic cavitation pressure more than 6000 atm was much higher relative to the calculated force of 650 atm required to separate the two particles.The acoustic streaming can be also numerically simulated,which significantly affects the distributing of nanoparticles inside the melt.

Fig.2.Schematic of the cavitation and streaming effects for nanoparticle dispersion and wetting in metal melts[33].

Fig.2 shows the schematic of ultrasonic cavitation effect and acoustic stream effect for nanoparticle dispersion and wetting in metal melts[33].When the intensity of ultrasonic sound exceeds a certain limit,the state of the melt can be changed by the interactions between the ultrasonic sound and the melt[41].Once the high-intensity ultrasonic waves spread in the molten metal,a series of complex nonlinear phenomena such as acoustic cavitation and acoustic streaming effects can be generated in the melt[42].Acoustic streaming as a liquid flow resulting from acoustic pressure gradient can be used to disperse the nanoparticles from macroscopic aspect.Under cyclic high-intensity ultrasonic waves,lots of micro bubbles would form in the melt.These bubbles can expand during the negative pressure cycle and collapse to tiny bubbles during the positive pressure cycle,leading to transient micro“hot spots”.This effect called“acoustic cavitation”can produce an implosive impact and break up the clustered nano-size particles[43].Besides,the wettability between the particles and the matrix alloy can be enhanced by this strong impact coupling with local transient high temperatures[44].

2.1.2.The actual application of ultrasonic vibration

Fig.3 shows typical experimental setup of ultrasonic vibration.Theoretical calculations can be used to evaluate whether the ultrasonic equipment used meets the requirements for dispersing nanoparticles.Ultrasonic intensity I stands for the sound power per unit area,which can be expressed as in the melt[45]:

Fig.3.Schematic of experimental setup for ultrasonic vibration of magnesium melt.

whereρis the density of molten melt,c is the ultrasonic velocity,f is ultrasonic frequency of the ultrasonic generator,A is the amplitude of the horn during the ultrasonic treatment.Previous research has shown that when the ultrasonic intensity Iexceeds 80W cm−2,the cavitation effect is sufficient in the aluminum or magnesium melt[45,46].Since the density and viscosity of the magnesium melt is equivalent to that of water,whenρis 1.59g cm−3,it can be assumed that the propagation speed c of the ultrasonic wave in the magnesium melt is 1.5×103m s−1[47].Assuming that the ultrasonic processing power is about 20kHz,the titanium tool head and the magnesium melt are completely wetted.When the amplitude of the ultrasonic wave is 12 and 30μm,the ultrasonic intensity is 225 and 1400W cm−2,respectively[48],which is much higher than the required ultrasonic intensity of 80W cm−2.

Further,the ultrasonic vibration could increase the capillary effect in the melt,promoting the penetration of the melt into the nanoparticle agglomeration.In this situation,the critical osmotic pressure pscan be expressed as[49]:

where dpis the average particle diameter,σLGis the surface tension,φis the volume fraction for particle porosity,λis the geometric factor,θis the contact angle between the particles and melt.For instance,in order to disperse the clustered SiC nanoparticles,the critical osmotic pressure pscan be determined as 313MPa in condition that the SiC nanoparticles could be completely wetted with the magnesium melt[48].Since the theoretical value is about 105MPa for the ultrasonic pressure caused by cavitation effect,which is much greater than the critical osmotic pressure needed to disperse the SiC nanoparticles.

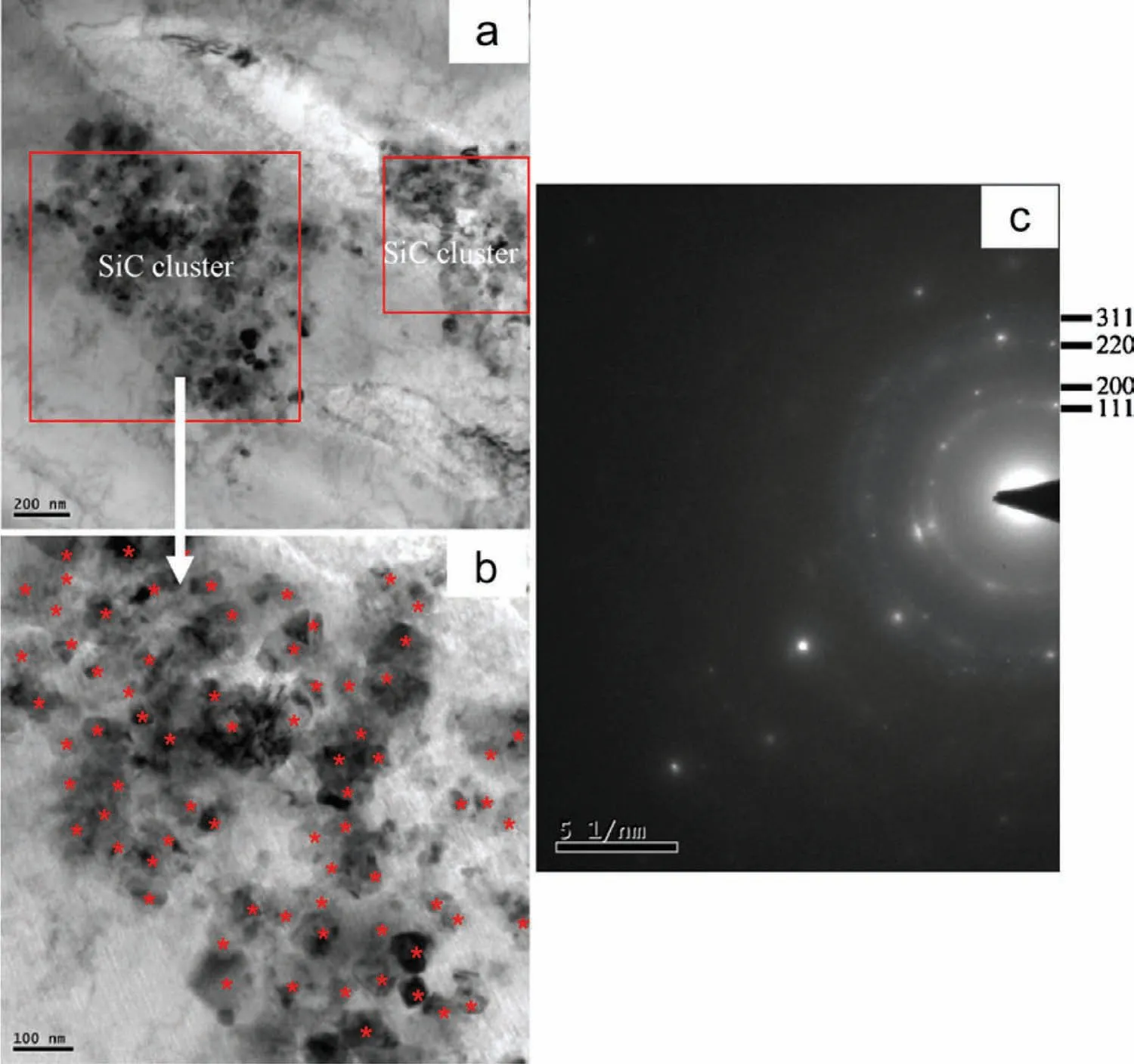

Fig.4.TEM micrographs of SiCp/AZ91 nanocomposite:(a)low magnification of SiC nanoparticles;(b)higher magnification of SiC nanoparticles;(c)electron diffraction of SiCp/AZ91 nanocomposite[34].

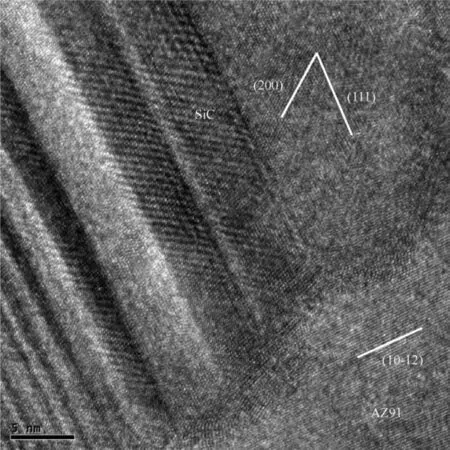

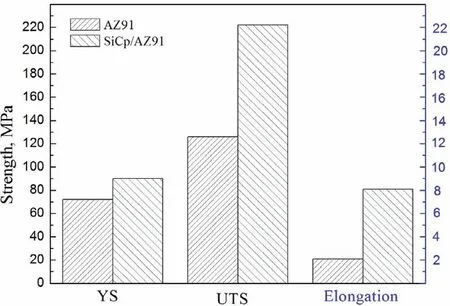

Take SiC particle reinforced AZ91 matrix composite as an example of the actual application of ultrasonic vibration,as shown in Fig.4,which gives transmission electron microscopy(TEM)image of SiCp/AZ91 nanocomposite fabricated by ultrasonic vibration[34].As shown in Fig.4(a),some SiC nanoparticles are well dispersed while some is found to be agglomerated.At higher magnification,a homogeneous distribution of the SiC nanoparticles exists outside the cluster as shown in Fig.4(b).Moreover,the agglomerated SiC nanoparticles are dispersed by the matrix alloy.The electron diffraction(ED)in Fig.4(c)demonstrates that the composition of the particle cluster is SiC nanoparticle.A high-resolution transmission electron microscopy(HRTEM)image is given in Fig.5,which shows the interface between the SiC nanoparticle and the matrix.There is no interfacial reaction observed,indicating that the SiC nanoparticles bond well with the matrix.Fig.6 shows the tensile strength of the as-cast AZ91 alloy and SiCp/AZ91 nanocomposite fabricated by simple ultrasonic vibration[34].The values of ultimate tensile strength(UTS),yield strength(YS)and elongation to fracture for the nanocomposite containing SiC nanoparticles were higher than the AZ91 alloy.This was very different from the composite reinforced with traditional micro-sized particles and fibers.Lan et al.also found that the nano-sized SiC particles were dispersed fairly well although some small clusters still existed in the AZ91D magnesium matrix nanocomposite fabricated by ultrasonic vibration[33].

Fig.5.HRTEM micrograph of interface between the SiC nanoparticle and AZ91 alloy matrix[34].

Fig.6.Tensile strength of AZ91 alloy and SiCp/AZ91 nanocomposite[34].

Fig.7.(a)Schematic of the ultrasonic processing and(b)evaporation of alloy[21].

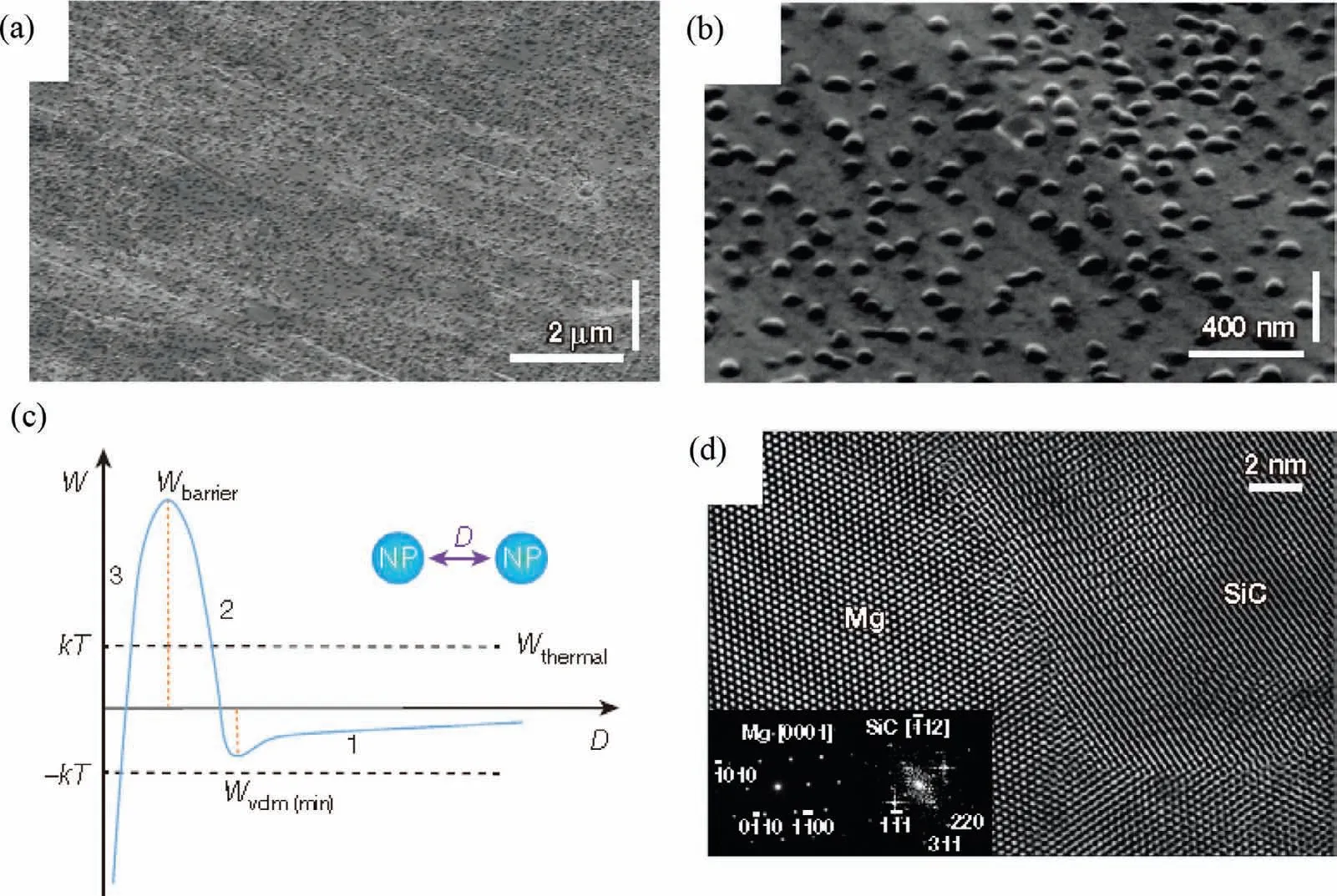

2.1.3.Mg containing a dense uniform dispersion of nanoparticles prepared by ultrasonic vibration

So far,it is very difficult to disperse high-content nanoparticles in melts by the only use of ultrasonic vibration.Therefore,the technology involving in the combination of ultrasonic processing and evaporation has been developed by Chen et al.[21]to obtain a magnesium matrix nanocomposite containing a dense uniform dispersion of nanoparticles.As shown in Fig.7,in the first step ultrasonic processing was used to prepare the Mg-6Zn matrix composite melt containing 1 vol%SiC.The second step was to evaporate away magnesium and zinc from the composite melt at 6torr in a vacuum furnace.Finally,after evaporation and slow cooling,an Mg–2Zn matrix containing about 14vol% SiC nanoparticles was successfully achieved.With regard to the microstructure of magnesium containing 14vol% SiC nanoparticles[21],there was a dense uniform dispersion of nanoparticles in the matrix as shown in Fig.8(a)and(b).Further,it confirms that SiC nanoparticles were previously well dispersed and self-stabilized in the molten magnesium before solidification as schematically shown in Fig.8(c).Besides,the bonding between some SiC nanoparticles and magnesium can be considered as semi-coherent(Fig.6(d)),which provided a convincing evidence that the interface between the particulate reinforcement and the magnesium matrix possesses a strong bonding.Accordingly,the combination of ultrasonic processing and evaporation provides a novel way to fabricate magnesium containing a dense uniform dispersion of SiC nanoparticles,which exhibits a simultaneous enhancement in strength,stiffness,plasticity and high-temperature stability,especially after subsequent high-pressure torsion(HPT)a higher yield strength 710±35MPa and higher specific modulus of 86±5GPa than almost all structural metals.

2.2.The combination of ultrasonic vibration with semisolid stirring

It is well known that stir casting involves mechanical stirring and can be applied to produce large ingots of magnesium matrix composites containing homogenous distribution of micro-sized ceramic particles[50–54].However,mechanical stirring is not adequate to disperse the nanoparticles with large surface-to-volume ratio and low wettability in magnesium melt[55].In contrast,acoustic cavitation and streaming effects resulting from ultrasonic vibration has been proven to successfully disperse nano-sized particles[33,34],but it is still difficult to produce large ingots of the composites by the only use of ultrasonic vibration[33].In this case,the combination of stir casting with ultrasonic vibration,which achieved a macroscopic and microscopic dispersion of nanoparticles and the preparation of large-size nanocomposite,has been developed to fabricate the high-quality magnesium matrix nanocomposite.Especially,SiC nanoparticles reinforced magnesium matrix composites ingots weighing up to 20kg have been successfully prepared by combination of stir casting and ultrasonic vibration.

Fig.9 gives the typical schematic of experimental setup for the combination of stir casting and ultrasonic vibration[35].The stir casting can be used to incorporate the nanoparticles while the ultrasonic vibration can be utilized to break nanoparticle clusters and clean the nanoparticle surface.Magnesium matrix composites with varying nanoparticles or matrix alloy such as SiCp/AZ91[35],SiCp/AZ31B[56],TiCp/Mg-4Zn-0.5Ca[57],TiCp/Mg–2Zn–0.8Sr–0.2Ca[58]and(SiC+TiC)p/AZ91[59]nanocomposites have been successfully fabricated by the combination of ultrasonic vibration and semisolid stirring.For instance,for the SiCp/AZ91 nanocomposite,as shown in Fig.10[35],as the semisolid stirring time was 5min,the SiC nanoparticles were homogenously dispersed in the SiCp/AZ91 nanocomposite.The increase in the stirring time led to obvious agglomeration of SiC nanoparticles as shown in Fig.10(c).TEM images at high magnification indicated that the agglomerated SiC nanoparticles were still segregated by magnesium matrix as shown in Fig.10(d).

Fig.8.(a)(b)SEM images of the Mg2Zn(14 vol% SiC)at different magnifications;(c)the principle of thermally activated dispersion and stabilization,(d)interface between a SiC nanoparticle and the magnesium matrix[21].

Fig.9.Typical schematic of experimental setup for the combination of stir casting and ultrasonic vibration.

2.3.Disintegrated melt deposition

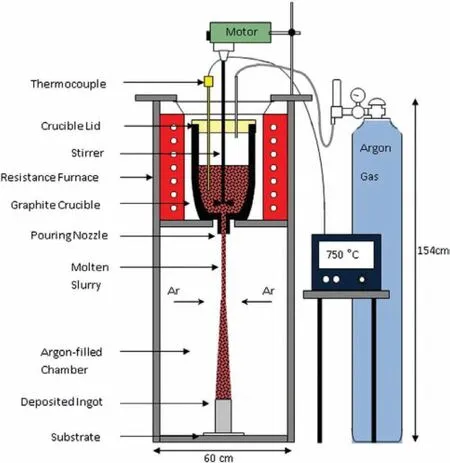

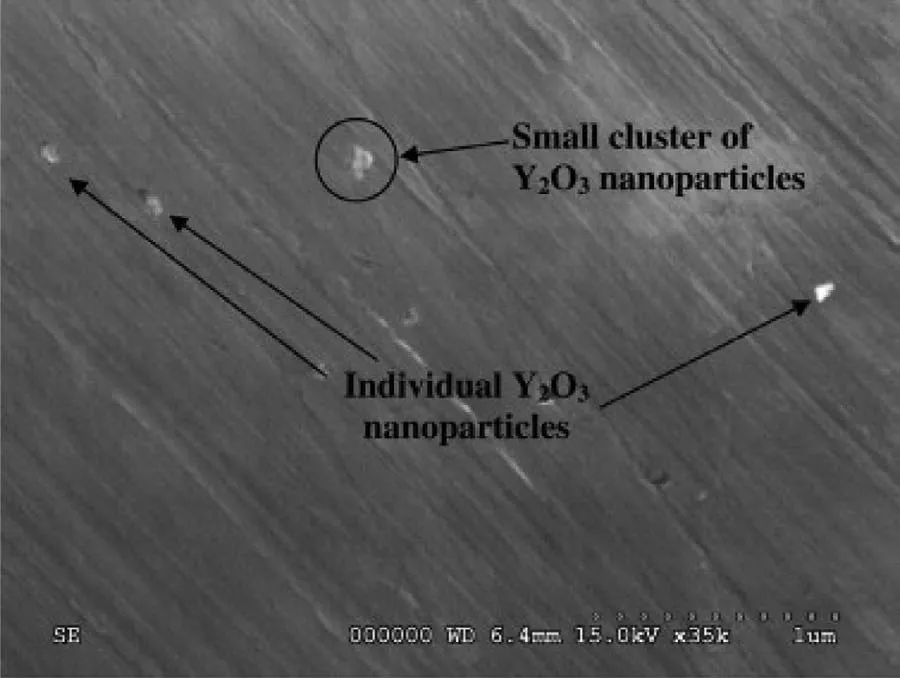

Disintegrated melt deposition(DMD)combines the advantages of spray processing and conventional casting,which utilizes higher superheat temperatures and lower impinging gas jet velocities to produce bulk composite material[6].Schematic diagram of disintegrated melt deposition setup was given in Fig.11.Bottom pouring was arranged for the crucible.Two jets of argon were used to disintegrate the composite melt.Due to the rapid solidification of the atomized melt,fine equiaxed grains,low porosity and uniform distribution of reinforcements can be obtained by the disintegrated melt deposition technology.Further,it has been reported that the melting and casting of 25kg of magnesium can be achieved by upgrading the DMD furnace,and an extruded billet with width of 140mm,thickness of 10mm and length approximately 5 to 6m can be produced.As shown in Fig.12,the representative micrographs of the Mg/Y2O3nanocomposite synthesized by the disintegrated melt deposition technology showed that the reinforcement appeared individually,and small clusters were visible in the matrix[60].The main problem which DMD should be solved in future is how to incorporate high volume fraction of reinforcements(>3% for nano-size reinforcements)due to an increase in viscosity of the melt making it difficult to stir and homogeneously distribute the reinforcements.

Fig.10.TEM images of SiCp/AZ91 nanocomposites fabricated by the combination of stir casting and ultrasonic vibration:(a)(b)stirring for 5min;(c)(d)stirring for 10min[35].

2.4.Other preparation technologies

Other commonly preparation technologies to synthesize magnesium matrix nanocomposite include in situ synthesis,friction stir processing and powder metallurgy,etc.

2.4.1.In situ synthesis method

The nanoparticles reinforcement in the in-situ magnesium matrix nanocomposites were synthesized by the reaction between the raw materials.There are many advantages for the in-situ magnesium matrix nanocomposites[36].For instance,the interfaces between the matrix and reinforcement are cleaner relative to external reinforcement,contributing to a stronger interfacial bonding.The nanoparticles are thermodynamically stable,finer and more uniformly distributed,resulting in improvement in mechanical properties both at room and high temperatures.However,only a small amount of literature focuses on magnesium matrix nanocomposite processed by in situ synthesis compared with its use in aluminum matrix composite[61–65].Fig.13 shows the microstructures of the as-cast in-situ AlN/Mg composite fabricated by bubbling nitrogen gas into a molten Mg–Al alloy[62].The black(Fig.13(a))and gray(Fig.13(b)and(c))block mass including some long-fibered structures,were uniformly distributed in the matrix,and the main composition of the block mass and fibered-shape structures are determined as AlN nanoparticles.

Fig.11.Schematic diagram of disintegrated melt deposition setup[6].

Fig.12.Representative micrographs showing the distribution of nanoparticles in a Y2O3/Mg nanocomposite synthesized by disintegrated melt deposition[60].

2.4.2.Friction stir processing

During friction stir processing(FSP)large amounts of friction heat can be generated by a hard tool which was forced into the metallic plates,raising the temperature of material in the processed zone.The processed material can be broken and mixed by the intense stir of rotating tool in FSP,thus it is able to add the particles to the plasticized matrix through the mechanical action of the tool[66,67],which is suitable for the fast fabrication of high-performance metal matrix composites[68].Due to that the substrate does not melt by the heat evolved,interfacial reactions were limited and the physical properties of the reinforcement particle had little influence on the nature of the distribution.As shown in Fig.14,an AZ91D magnesium alloy matrix composites reinforced with nano-size SiC particles has been fabricated by FSP[37].Most nanosized SiC particles dispersed singly in the AZ91D matrix.This successful applications of FSP in producing fine-grained structure and surface composite,demonstrated that FSP is energy efficient,environment friendly,and versatile,and can be developed to be a generic metalworking technique that can provide the localized modification and control of microstructures in the near-surface layers of processed magnesium[69].

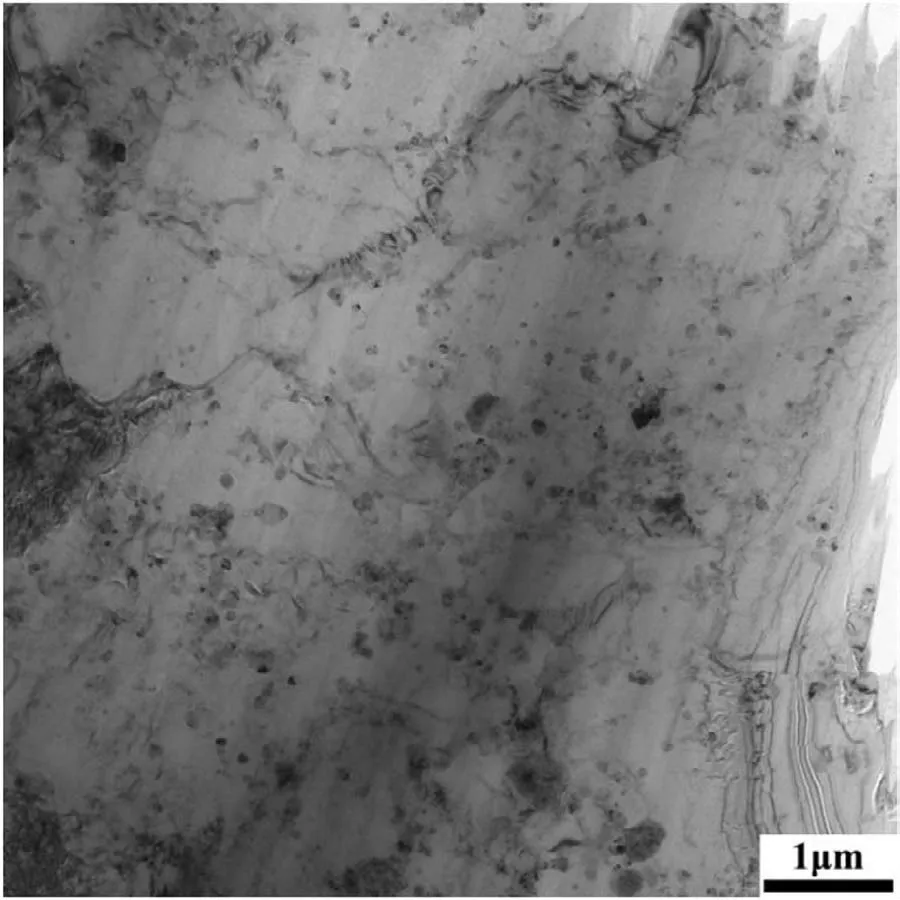

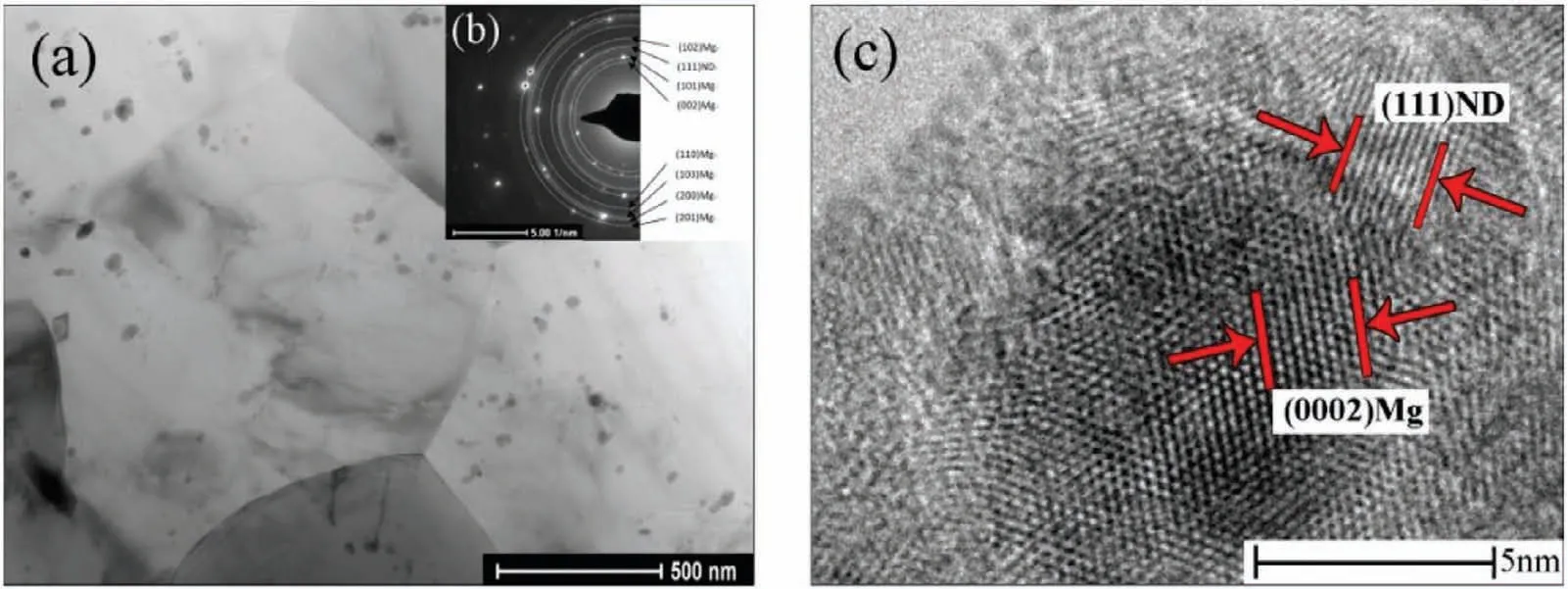

2.4.3.Powder metallurgy

Powder metallurgy(PM)technique involves mixing the metal powders and nano-reinforcements in the desired composition by simple blending or by mechanical alloying.In general,extending the blending time at high rotational speed or mechanical alloying using high energy ball milling can be used to disperse the nanoparticles.The mixed powders were then pressed to form green compacts and sintered using resistance heating or microwave heating[70].PM technique was effective in adding different types of reinforcements and higher volume fraction of reinforcements[71,72].As shown in Fig.15,a ZK60 magnesium alloys reinforced by 0.05 wt%of nano-size diamond has been successfully fabricated by PM[38].HRTEM and selected area electron diffraction(SAED)were used to analyze the distribution and interface structure of the 0.05 wt% ND/ZK60 composite.It can be seen form Fig.15(a)and(b)that the ND particles were uniformly distributed in the matrix.Fig.15(c)shows the interface structure between ND and the ZK60 matrix.No interfacial reactions can be observed which can ascribed to the chemical stability of ND particles.This clean and atomic scaled interface led to a performance improvement.In general,secondary processing such as extrusion or rolling are required to further consolidate or shape the composite prepared by PM.Further,the PM equipment is complicated,resulting in a high production cost,and thus this preparation process is not suitable for the industrial production of large-volume and complex-shaped parts.

3.Hot deformation of magnesium matrix composite reinforced by nanoparticles

It is known that the introduction of harden particle in magnesium matrix can not only affect the occurrence of dynamic recrystallization(DRX),but also influence the deformation behavior of magnesium matrix nanocomposite.More dislocations can be generated during deformation process due to the deformation mismatch between the harden particles and magnesium matrix.Meanwhile,the appearance of particles also makes it hard for the movement of dislocations and grain boundaries.For the micro size particles with a diameter larger than 1μm,the region with high-density dislocation and large orientation gradient can be formed in the vicinity of particle owing to the deformation mismatch between the particle and matrix,which is recognized as particle deformation zone(PDZ)[73,74].PDZ is about one diameter along the interface between particle and Mg matrix,which enlarges with increasing size of SiCp[11].The recrystallization nucleation can be promoted by the high storage energy in PDZ,which was called as particle stimulated nucleation(PSN)mechanism[73,74].However,for the nanoparticles smaller than 100nm,the PDF size decreases significantly,thus PDZ has a negligible effect on the promotion of recrystallization nucleation for the magnesium matrix nanocomposite.Previous works have demonstrated that fine particles had a strong pinning effect on grain boundary[75],and can promote the nucleation of DRXed grains,which made the grains in Mg matrix remarkably be refined after hot deformation for the magnesium matrix nanocomposites[76–78].It was thought that the nanoparticles could not only promote the generation of dislocations owing to deformation mismatch of the particles with matrix,but also lead to the increase of dislocation density due to their pinning effect on dislocations.Thus,the nanoparticles were considered to be beneficial to the nucleation of DRXed grains.

Fig.13.Micrographs of the in-situ-prepared AlN/Mg–Al composite[62].

Fig.14.TEM micrograph of the FSPed composite showing the distribution of SiC nanoparticles[37].

Moreover,the occurrence of recrystallization is also related to the deformation temperature and strain rate,which relates to the deformation methods.The common deformation methods available for the magnesium matrix composites reinforced by nanoparticles include hot extrusion,hot rolling,multidirectional forging,etc.

3.1.Hot extrusion

Fig.15.(a)TEM image and selected area electron diffraction(SAED)and(b)HRTEM image of the 0.05 wt% ND/ZK60 composite[38].

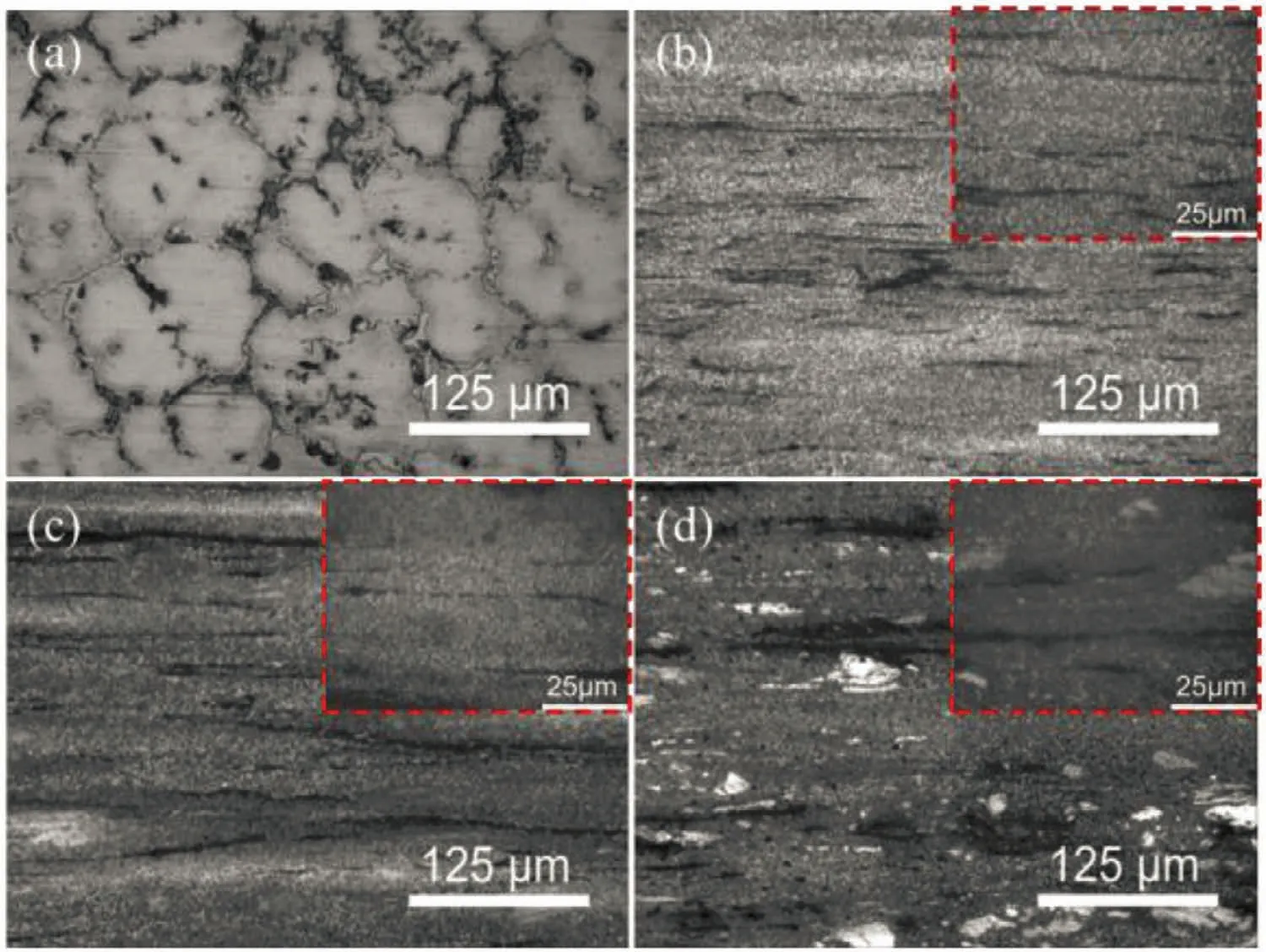

Fig.16.SEM images of as-extruded(a)(b)AZ91 alloy and(c)(d)SiCp/AZ91 nanocomposite[50].

For a common extrusion processing,a cylindrical billet of a certain length and cross section,is forced to flow through a die of a desired cross section,thus forming the billet to the new cross section.The extrusion is able to manufacture complex cross sections,which is uniform over the entire length.Similar to other forming processes,extrusion can be performed either hot or cold.The biggest advantage of extrusion carried out at elevated temperatures is that it can reduce the extrusion force and improve the ductility of the material[79].With reduced raw material wastage and high production rate,hot extrusion with low cost can be suitable for the deformation of brittle material.

Fig.17.OM micrographs of as-extruded SiCp/AZ31B nanocomposites:(a)1vol%,(b)2vol%,(c)3vol%[48].

There are some factors that affect the quality of extrusion such as extrusion ratio,billet temperature,lubrication,and extrusion speed,etc.As can be seen in Fig.16,the grain structure of the as-extruded SiCp/AZ91 nanocomposite was refined as compared to the as-cast counterpart[80].The as-extruded AZ91 alloy was composed of coarse grains with refined precipitates along the grain boundaries as shown in Fig.16(a)and(b).By contrast,the SiCp/AZ91 nanocomposite consisted of SiC nanoparticle bands and the refined-grain zones as shown in Fig.16(c).At high magnification,as shown in Fig.16(d),fine grains with SiC nanoparticles along the grain boundaries were presented in the SiC nanoparticle bands.The added SiC nanoparticles could introduce larger strain and retard the grain growth,resulting in the severer dynamic recrystallization and refiner grains[81].As shown in Fig.17,when the volume fraction of SiC nanoparticles increased from 1% to 3%,the grain size of the extruded SiC/AZ31 nanocomposites was gradually decreased while the degree of recrystallization was increased[56].Choi and Li et al.reported that the microstructure of the Mg–1%SiC nanocomposites exhibited an obvious grain refinement and the occurrence of microbands that align the SiC nanoparticles parallel to the direction of extrusion[82].The optical microstructures of the as-cast and the as-extruded(SiC+TiC)p/AZ91 nanocomposites were given in Fig.18[59].It can be seen that the average grain size for the as-cast nanocomposite was~55.79mm,which was significantly decreased to~0.82,~1.02 and~1.34mm with increasing the extrusion speed from 0.1 to 1mm/s.

3.2.Hot rolling

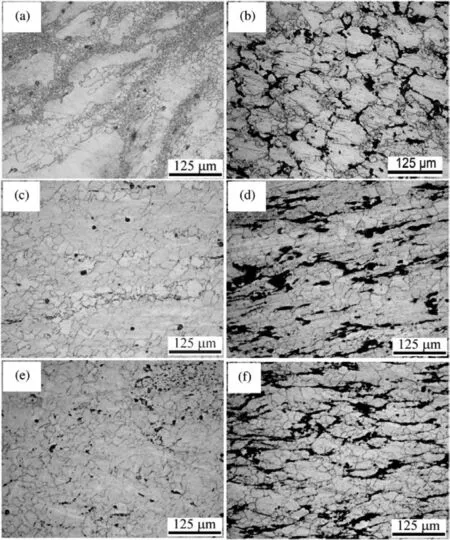

Rolling is another method often used for the hot deformation of magnesium based materials[83,84].During hot rolling,the deformation resistance is low so the amount of deformation can be increased by consuming less energy.After hot rolling,certain defects in the cast metal can be eliminated,the compactness and mechanical properties of the metal will be improved.However,the mechanical properties required for the product cannot be controlled accurately and the properties of the hot rolled product are not uniform.Only a few attempts of hot rolling have been done for magnesium matrix composites reinforced by nanoparticles[85,86].The optical microstructure of the as-rolled AZ31 alloy and SiCp/AZ31 nanocomposite sheets was given in Fig.19[85].For the AZ31 alloy,numerous fine grains were distributed in the vicinity of the initial grain boundaries as shown in Fig.19(a).Moreover,there were a number of twin lamellas in the relatively coarse grains,which served as nucleation some recrystallized grains(Fig.19(b)).The shear bands formed by the recrystallized grains within twin lamellas were at an angle of 30–45° with the rolling direction.In contrast,the microstructure of the nanocomposite with few coarse grains was more uniform and finer,which indicates that the added nanoparticles could promote the dynamic recrystallization during hot rolling.Besides,there were some discontinuous nanoparticle bands along the rolling direction and no shear band formed in the nanocomposite.

3.3.Multidirectional forging

Fig.18.OM images of(SiC+TiC)p/AZ91 nanocomposites:(a)as-cast,and extruded at the speed of(b)1mm/s,(c)0.5mm/s,(d)0.1mm/s(Inserts are high magnified OM micrographs of as-extruded(SiC+TiC)p/AZ91 nanocomposite)[59].

In addition to the application of conventional thermo mechanical process,severe plastic deformation(SPD)has been also used to achieve the exceptional grain refinement[87–90].Among the various SPD methods,multidirectional forging(MDF)possessed many advantages such as preserving the shape,especially fitting for the brittle materials and relatively large samples[91–98].The principle of MDF,i.e.multidirectional forging operation,is repeating compression process with changing the axis of the applied strain x→y→z→x→...at each step.Redundant plastic strains can be accumulated into the material as it is repeatedly deformed.Fig.20 shows the optical microstructure of AZ91 alloy and SiCp/AZ91 nanocomposites subjected to different MDF passes[92].As shown in Fig.20(a),the AZ91 alloy exhibited an inhomogeneous microstructure,which is consisted of newly formed smaller grains and original coarse grains.In comparison,the nanocomposite after 1 MDF pass was characterized by slightly increased extent of dynamic recrystallization.With increasing the number of MDF passes,the degree of recrystallization and the homogeneity of microstructure were simultaneously increased for both the AZ91 alloy and its nanocomposite.Furthermore,there was little change in the grain size after 3 and 6 passes by comparing the nanocomposite containing SiC nanoparticles to the AZ91 alloy.This suggested that the inhibition of the recrystallized grains growth caused by the added SiC nanoparticles would be impaired when the nanocomposite was subjected to MDF at high temperature.Similar microstructure evolution was found in a nano-TiCp/Mg-Zn-Ca composites after MDF at 270°C[99].

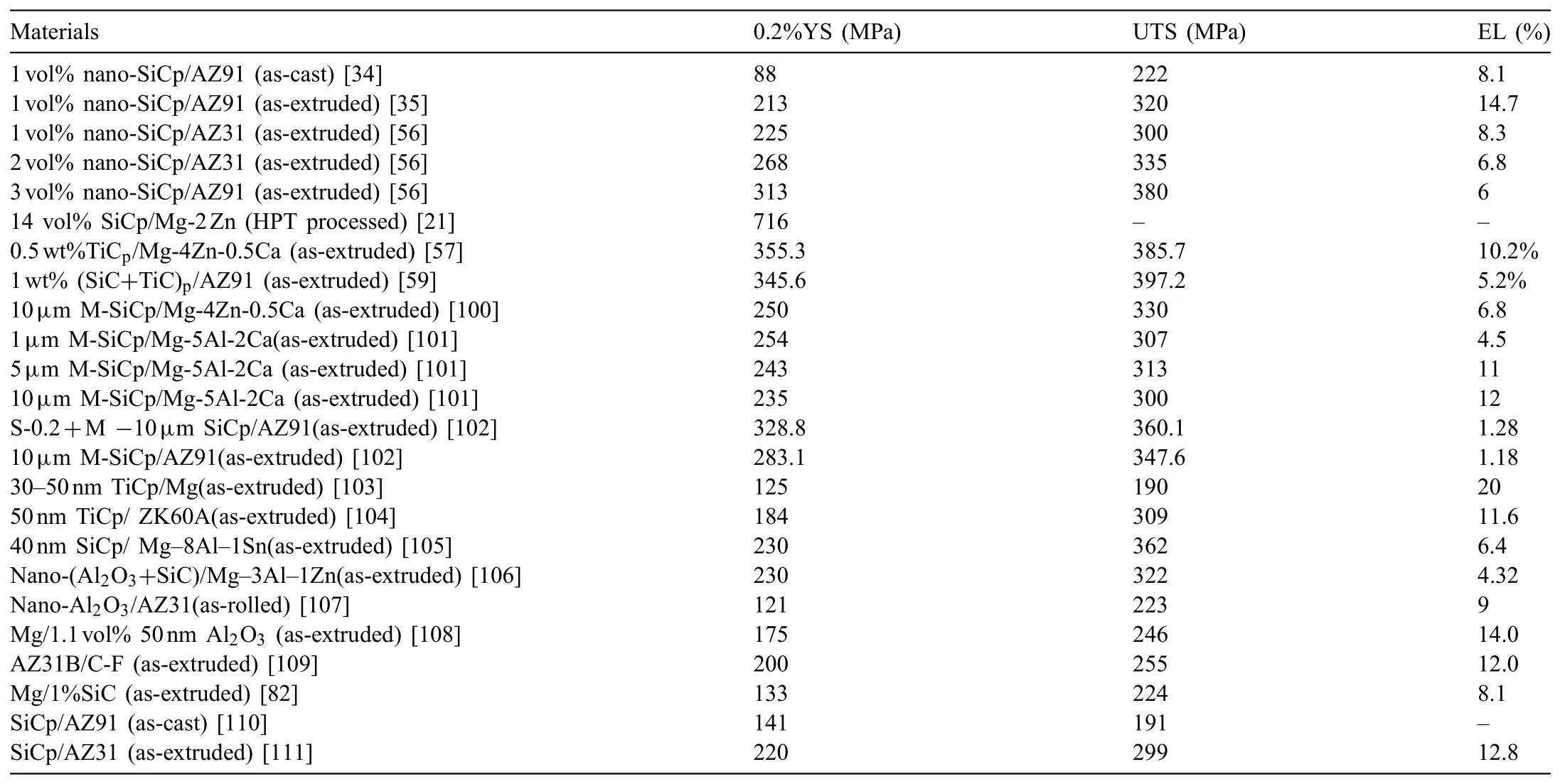

3.4.Mechanical properties of magnesium matrix composite reinforced by nanoparticles after hot deformation

The mechanical properties of magnesium matrix composite containing nanoparticles processed by different preparation or deformation methods are given in Table 1,which are compared to some typical micro-size particles reinforced magnesium matrix composites.Refs.[34],[35]and[56]are related to magnesium matrix composites containing SiC nanoparticles fabricated by the combination of ultrasonic vibration and stir casting.Refs.[57]and[59]correspond to the 0.5wt%TiCp/Mg-4Zn-0.5Ca and 1wt%(SiC+TiC)p/AZ91 magnesium matrix composites,respectively.The YS,UTS and elongation were improved for the 0.5wt%TiCp/Mg-4Zn-0.5Ca nanocomposites relative to the Mg–4Zn–0.5Ca matrix composite reinforced by micron-size SiC particles[100].Furthermore,the 1wt%(SiC+TiC)p/AZ91 nanocomposite exhibited higher YS and UTS compared with the Mg–5Al–2Ca matrix composite reinforced by micron-size SiC particles with average sizes of 1μm,5μm and 10μm[101].Regarding to the matrix alloys,for example,AZ91,pure Mg,ZK60A,AZ31,Mg–8Al–1Sn and Mg–3Al–1Zn all reinforced by micron or nano-sized particles,the YS of the both TiCp/Mg–4Zn–0.5Ca and 1wt%(SiC+TiC)p/AZ91 nanocomposite remained higher relative to other magnesium matrix composites[102–107].Besides,it can be seen that the nano-SiCp/AZ91 composites in the as-cast and as-extruded conditions exhibited reasonable elongation.As the volume fraction of SiC nanoparticles increased,the YS and UTS of nano-SiCp/AZ31 composites increased significantly while the elongation decreased gradually.With regard to the as-extruded Mg/1.1vol% 50nm Al2O3and AZ31B/C-F composites prepared by disintegrated melt deposition[108,109],the YS and UTS were lower than that of the nano-SiCp/AZ91 or nano-SiCp/AZ31 composites.Li and coworkers reported that the YS and UTS of Mg/1%SiC fabricated by single ultrasonic vibration were also improved compared with pure magnesium[82].The as-cast SiCp/AZ91 nanocomposite fabricated by ultrasonic vibration assisted stirring casting showed relatively high YS and UTS reported by Li and coworkers[110].The YS of as-extruded SiCp/AZ31 nanocomposite fabricated by single ultrasonic vibration was comparable to the as-extruded SiCp/AZ91 nanocomposite fabricated by the combination of ultrasonic vibration and stir casting[111],while the UTS and elongation were lower than the SiCp/AZ91 nanocomposite.Accordingly,the preparation technology for the magnesium matrix nanocomposites can be further optimized to achieve refined grains and homogenous nanoparticles distribution in the follow-up study.For instance,ultrasonic vibration could be added during the solidification of magnesium matrix nanocomposites and the pretreatment of the nanoparticles could be adopt for the nanoparticles.Besides,secondary deformation at slow speed and low temperatures could be applied to the magnesium matrix nanocomposites.Dynamic precipitation and ultrafine grains could occur in the magnesium matrix nanocomposites deformed at slow speed and low temperatures,which contributed to the increased mechanical properties.Furthermore,advanced detections such as neutron diffraction,in-situ SEM and TEM as well as theoretic analysis in details using materials computation have still not yet been used in the research of magnesium matrix nanocomposites.The combined strengthening by dispersed nanoparticles and grain refinement after HPT can explain the remarkable yield strength of 710±35 MPa attained for the Mg2Zn(14 vol% SiC)sample,which is the highest yield strength reported for magnesium alloys and their composites[21].

Fig.19.Optical microstructure of the as-rolled sheets after for 4 passes(the horizontal is RD):(a)(b)AZ31 alloy,(c)(d)SiCp/AZ31B nanocomposite,(e)grain size distribution of the nanocomposite[85].

3.5.Deformation mechanism of magnesium matrix composite reinforced by nanoparticles

The hot deformation behavior of material is usually investigated by the constitutive equation which represents the relationship among flow stress,strain rate and temperature.There are three constitutive equations including exponential,power and hyperbolic sinusoids,which can be used to reveal the high-temperature deformation behavior.According to the constitutive equation,the values of both the stress index n and deformation activation energy Q can be obtained,which can be used to illustrate the deformation mechanism of the material[11,112].

Fig.20.OM micrographs after MDF at 400°C:(a)1,(c)3,(e)6 passes of the AZ91 alloy;(b)1,(d)3,(f)6 passes of the SiCp/AZ91 nanocomposite[92].

Wang et al.[113]investigated the compression curves of nano-SiCp/AZ91 composite at 250–400°C,and the calculated deformation activation energy Q of~185kJ/mol for the composite was higher relative to the self-diffusion activation energy of pure magnesium(135kJ/mol)[78].The deformation mechanism of nano-SiCp/AZ91 composite was considered as dislocation climbing mechanism controlled by self-diffusion[113].Further research of Nie et al.found that the deformation ability of AZ91 alloy under high-temperature conditions can be improved by the addition of nanoparticles[114].Zhang et al.reported that the incorporation of SiC nanoparticles enhances the high temperature(>655K)workability of AZ91 by increasing the upper limit of the processing strain rate and enables low temperature processing by decreasing the lower limit of the temperature[115].

An as-extruded 1 vol% nano-Al2O3p/Mg composite has been compressed at high temperature by Prasad et al.[75],and it was found that the values of deformation activation energy Q for the nanocomposite was close to the grain boundary diffusion activation energy(92kJ/mol).Further,the variation in the strain rate affected the value of Q for the nano-Al2O3p/Mg composite.The value of Q increased to 305kJ/mol as the strain rate decreased,which was larger than the self-diffusion activation energy of pure magnesium(135kJ/mol),and thus the deformation mechanism was thought to be controlled by lattice self-diffusion[75].The high-temperature deformation behavior of a 1.5 vol% nano-Al2O3p/AZ31 composite fabricated by DMD method has been investigated by Zhong et al.[112].The grain boundary sliding which can be hindered by the existence of nanoparticles to some extent,was thought to have an important role in the as-extruded nano-Al2O3p/AZ31 composite with fine grains.

4.Strengthening mechanisms of magnesium matrix composite reinforced by nanoparticles

In general,there are different strengthening mechanisms such as grain refinement strengthening,Orowan strengthening,Taylor strengthening and load transfer mechanism for the metal matrix composites.It has been shown that Hall-Petch strengthening mechanism is the most important factor regardless of the type of the reinforcement for the magnesium matrix composites.Besides,this effect depends more on the volume fraction of the reinforcements relative to particle size.The Orowan strengthening has been reported to be not a major factor for the magnesium matrix composite reinforced by micro particles.Due to that the Orowan bowing can bypass the nanoparticles,Orowan strengthening becomes more favorable in magnesium matrix composites reinforced by highly-dispersed nano-size particles(smaller than 100nm)even for only a small volume fraction(<1%).Further,after secondary processing such as extrusion,Orowan loops are expected to exert a back stress on dislocation sources.Therefore,it is necessary to consider the Orowan strengthening for the Strengthening mechanisms of magnesium matrix composite reinforced by nanoparticles.The above strengthening mechanisms can be calculated by the following formula.

Table 1Mechanical properties of magnesium matrix composite reinforced by nanoparticles processed by different preparation or deformation methods.

(1)Grain refinement strengthening mechanism

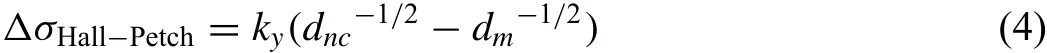

The influence of grain refinement on the mechanical properties can be described by refinement strengthening mechanism.The Hall-Petch equation was generally used to calculate the increment due to grain refinement as follows[116–119]:

whereσ0and kyare the initial strength and material constant,respectively,d is the grain size.It is well known that the enabled slip systems is few for the magnesium,so grain refinement plays a significant role in the mechanical properties of magnesium alloy and its composites.For the nano-sized particle reinforced magnesium matrix composite,the increment in the YS related to grain refinement can be described as:

where dncand dmstand for the grain size of nanocomposite matrix and the magnesium alloy,respectively.

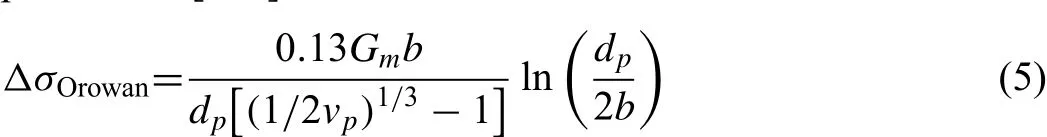

(2)Orowan strengthening mechanism

Orowan strengthening mechanism is considered to be another important mechanism for nano-sized particle reinforced metal matrix composites,which is mainly due to that the movement of dislocations could be impeded by the nanoparticle with small particles size and particles spacing.For the nano-sized particle reinforced magnesium matrix composite,the increment in the YS due to Orowan strengthening be expressed as[120]:

where dpand vpare the diameter and volume fraction of the nanoparticles,respectively,Gmand b are the shear modulus and Burgers vector of the matrix,respectively.

(3)Taylor strengthening mechanism

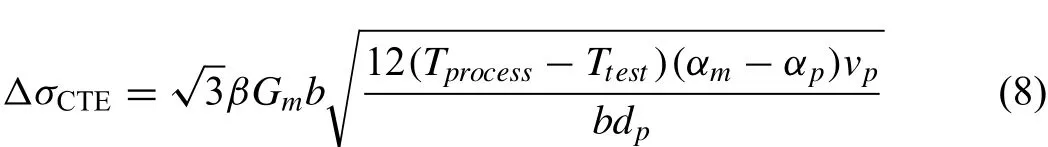

The thermal expansion coefficients and elastic modulus between the matrix and reinforcement were different,which would lead to generation of dislocation associated with work hardening or mismatch during the hot deformation.Taylor strengthening mechanism has been adopted to evaluate the effect of the dislocation on the strength of the material.For metal matrix nanocomposite,the strength variation related to the mismatch of elastic modulus and work hardening could be negligible.Thus,the increment in the YS resulting from thermal mismatch for the magnesium matrix nanocomposite can be expressed as[121]:

where M andβare Taylor factor and constant,respectively,Gmand b stand for the shear modulus and Burgers vector of the matrix,respectively.ρCTErepresents for the density of geometric dislocation and can be described by[122]:

where A is the geometric constants related to the geometric characteristics of the particles,Δαstands for the difference in the thermal expansion coefficient,ΔT stands for the temperature difference,vpand dpwere the volume fraction and diameter of the particles,respectively.Accordingly,the increment of the YS of magnesium matrix composites resulting from the thermal mismatch for the composite can be expressed as[123]:

where Tprocessand Tteststand for preparation temperature and the performance test temperature,respectively.αmandαprepresent thermal expansion coefficients of the magnesium alloy matrix and nano-sized particulate reinforcement,respectively.

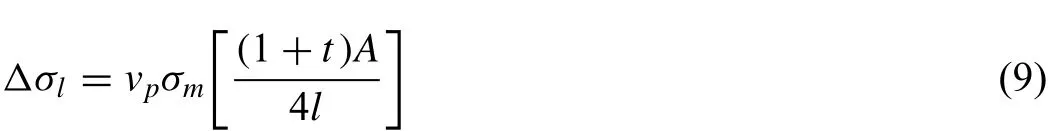

(4)Load transfer mechanism

When the interfacial bonding between the dispersed particles and the matrix was good,the load applied could be transferred from the material to the reinforcement.This load transfer mechanism can be expressed as[124,125]:

whereσmstands for the yield strength of the magnesium matrix,land t are the dimension and thickness of the nano-sized particulate reinforcement,respectively.A=l/t,which represents the aspect ratio of the particles.The increment in the YS due to load transfer can be described as[126]:

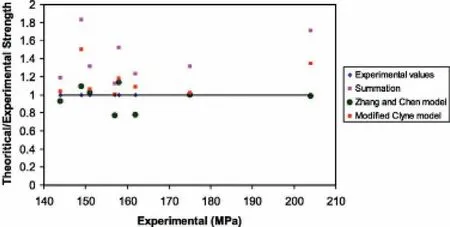

Fig.21.Diagram of theoretical/experimental strength values vs.experimental values for different unimodal nanocomposites[31].

The commonly used methods for estimating the strength of magnesium matrix nanocomposite include the simple sum of strengthening contributions,the Zhang and Chen method,and the Clyne method[31].For the sum of strengthening contributions method,each factor is considered as to be independent and the effect of different mechanisms on each other is neglected,so it is not applicable in most cases as more factors influencing the strength.With regard to the Zhang and Chen method,only load-bearing,Orowan strengthening,and thermal mismatch are considered.Thus,the precise predictions of the Zhang and Chen method is less because some important mechanisms such as Hall-Petch strengthening,modulus mismatch,and work hardening are not taken into account as these effects are obvious in some nanocomposites.The root of the sum of the squares is used in the modified Clyne method,which consider the contributions of different mechanisms into the strength.The diagram of theoretical/experimental strength of composites vs.the experimental values is given in Fig.21.It can be clear seen that the calculated values by almost all of the methods are higher relative to the experimental strength.This overestimated strength may be related to agglomeration of particles,contaminations during the process and porosities etc.which have a negative effect on the strength and not been considered.Further,the values calculated by both the Zhang and Chen method and modified Clyne method are consistent with the experimental values,and the values predicted by the modified Clyne method have the least deviation.For instance,by comparing the theoretic computation predicted by the modified Clyne method and related experiments,as the volume fraction of nanoparticles was 1vol%,the increment in the YS of the nano-SiCp/AZ91 composites could be mainly related to grain refinement mechanism and Orowan strengthening[48].In contrast,for the 14vol% SiCp/Mg–2Zn nanocomposites,because fine intermetallic precipitates were not observed and the densely dispersed nanoparticles was considered to be the main strengthening mechanism[21].Before HPT,the contribution to the strengthening from dense dispersed nanoparticles is about 360 MPa,the contribution by the mismatch of thermal expansion coefficient is 113 MPa and the rest of the strengthening contribution can be attributed to the load-bearing mechanism.After HPT,Hall–Petch mechanism is the main contribution to the strength from HPT processing.As stated above,the decrease in size and increase in volume fraction can lead to considerable increase in Orowan strengthening effect and dislocation strengthening.The load transfer mechanism contributes less due to small volume fraction of nanoparticles added.Thus,in order to further improve the performance of the magnesium matrix composites reinforced by nanoparticles,the high content of nano-size particulate reinforcement should be added in combination with subsequent secondary deformation.This can increase the Orowan strengthening effect,load-bearing mechanism and the grain refinement strengthening provided that the nanoparticles added can be dispersed evenly in the magnesium matrix.

5.Other properties of magnesium matrix composite reinforced by nanoparticles

The mechanical properties of magnesium matrix composites are determined from different strength tests,these includes tensile strength,compression test,three-point flexural strength,hardness test,impact strength etc.Literature search shows that there are limited studies regarding to the friction,wear,fatigue,fracture,corrosion,damping etc.of the magnesium matrix nanocomposites reinforced by nano-sized particles while most literatures evaluating mechanical properties(including friction,wear,fatigue,fracture,corrosion,damping etc.)focus on the magnesium matrix composites reinforced by micro-sized particles[127–142].Deepan et al.[143]investigated the strength and wear properties of Mg/SiC nanocomposite fabricated through FSP route.It was showed that the abrasive wear property of the Mg–SiC nanocomposite was verified with respect to the FSP process parameters.Selvam et al.[132]reported the dry sliding wear behavior of a magnesium matrix composite reinforced with zinc oxide nano-particles.The wear rate of the Mg/ZnO nanocomposite was found to increase with the load and sliding velocity.Jabbari et al.[135]studied the high cycle fatigue(HCF)behavior of AZ31B/1.5vol.% Al2O3nanocomposite at elevated temperatures.The results of HCF tests at 100°C and 200°C showed that enhanced ultimate tensile strength in the composite was the most important factor in modifying the HCF behavior at the higher temperature.Generally,magnesium and its alloys experience galvanic corrosion in a physiological environment due to their anodic behavior when alloyed with other metals.The addition of reinforcing nanoparticles has been reported to enhance corrosion resistance of magnesium matrices[144].The AZ91-fluorapatite(FA)nanocomposites presented increased corrosion resistance compared to the AZ91 magnesium alloy and the corrosion resistance of the AZ91-FA nanocomposites increased with an increase in FA content[145].Futher,Srivatsan et al.[146]discussed the intrinsic influence of nano-alumina particulate(Al2O3p)reinforcements on microstructure,microhardness,tensile properties,tensile fracture,cyclic stress-controlled fatigue,and final fracture behavior of a magnesium alloy.The Al2O3pnanoparticle-reinforced composite revealed improved cyclic fatigue resistance over the entire range of maximum stress at both the tested load ratios.Thus,more attention can be paid to the above mechanical properties of magnesium matrix composites reinforced by nanoparticles in order to further expand their application.

6.Potential applications of magnesium matrix composite reinforced by nanoparticles

As of now,the magnesium matrix composites reinforced by nanoparticles are not commonly available.However,owing to their lightweight,excellent dimensional stability and mechanical integrity,the development of new magnesium matrix nanocomposites are considered as possible candidates in aerospace,automotive,electronics and biomedical sectors for substituting traditional magnesium alloys and composites[147].In the automotive industry,fuel consumption will be reduced by 7% if the weight can be reduced by 10%.If the currently used automotive materials can be replaced with magnesium and its composites,there will be a reduction of 22–70% in the weight.Several AZ and AM alloys with good strength and ductility at room temperature have been applied as sheets or other automobile components in the automobile sector[148].For the developed magnesium matrix nanocomposites with good thermal and dimensional stabilities,it can be used as engine blocks in the elevated-temperature applications.The aerospace industry has the similar requirement in weight saving,so magnesium is also an available candidate which can reduce the consumption of fuel,decrease the aircraft weight and the CO2emissions[149].There has been enormous improvement in ignition temperatures of several magnesium matrix nanocomposites[150],which shows a potential advantage to be used in the aircraft industry.With regarding to consumer electronic industries,the electromagnetic shielding capacity and the ability to withstand ambient or outdoor temperatures are two key requirements for the use of an electronic equipment.Previous studies have been shown that the electromagnetic shielding capacity of magnesium is the same or even superior to that of aluminum alloys[151].Further,magnesium and its nanocomposite exhibit an excellent stiffness and the best specific damping capacities among known structural materials[152],which is viable alternative with a solid looking metallic touch.Furthermore,biomedical application is also a potential application for magnesium matrix nanocomposites[153].At present,more and more attention has been paid to bio-magnesium materials including microclips,implant materials and suture wires since magnesium was an abundant mineral in the human body.Some research suggests that excessive levels of magnesium ions introduced during the degradation or corrosion of magnesium implants could be easily excreted through urine[154–156].Thus,the development of new magnesium matrix nanocomposites with acceptable corrosion rate may be available to overcome the current limitations in magnesium alloys as biomedical materials.

7.Prospects

With the continuous advancement of nanotechnology and the urgent need for light weighting,the research and application fields of magnesium matrix composites reinforced by nanoparticles will be also expanded.In order to further improve the comprehensive performance of magnesium matrix nanocomposites and promote their research and industrialization,there are some aspects which deserve to make efforts as follows.

(1)The present research on magnesium matrix composites is mainly focused on improving the dispersion of the reinforcement and interface bonding.There is less attention on the composition optimization of matrix alloy.The current research on the low-alloyed magnesium matrix nanocomposites has shown that YS of 423.6MPa along with UTS of 436.8MPa can be obtained by adding TiC nanoparticles to Mg–1.12Ca–0.84Zn–0.23Mn(at%)alloy[157].Further,the ultrafinegrained or nanocrystalline in matrix alloy can be achieved using severe plastic deformation such as equal channel extrusion and high-pressure torsion.This is expected to develop lightweight magnesium matrix nanocomposite with high temperature super plasticity and high strength at room temperature.

(2)The preparation technology for large-size magnesium matrix composites reinforced by high-content nanoparticles is basically blank.Although the 14vol% SiCp/Mg–2Zn nanocomposite exhibited a higher specific yield strength and higher specific modulus than almost all structural metals,its weight was reported as about 1.5g[21],which cannot meet the industrial application requirement.

(3)The nanoparticles are mostly added into the magnesium using external addition method.It is an important design idea for preparing magnesium matrix nanocomposites with higher performance and more new functions through in situ method.Based on the theory of liquidsolid phase transition and in-situ synthesis technology,it is expected to synthesize magnesium matrix nanocomposites containing dispersed fine nanoparticles with controllable concentration.

(4)There are still challenges in terms of compactness,interface bonding,and abrasion resistance in the magnesium matrix nanocomposite configuration using advanced characterization methods,such as transmission electron microscopy,focused ion beam and threedimensional atom probes.The design and optimization of the existing magnesium matrix nanocomposite configuration as well as the effect of local reinforcement content and the structural parameters on the strengthening and toughening mechanism are important research directions for magnesium matrix composites.

(5)A customized microstructure of magnesium matrix nanocomposite can be produced by constructing layered scaffolds using additive manufacturing such as 3D print.Structural-functional integration is an important trend in the development of new magnesium matrix nanocomposites through coating,multilayer stacking,and gradient combination.Further,the use of nanoparticles for welding is a field worth of further investigation,the effect grain refinement caused by the nanoparticles could significantly improving the welding quality.

Conflict of Interest

The authors declare no conflicts of interest.

Acknowledgments

This work was supported by the National Natural Science Foundation of China[grant numbers 51671066,51771129,51771128],and the“Natural Science Foundation of Shanxi”[grant number 2015021067].

杂志排行

Journal of Magnesium and Alloys的其它文章

- Recent developments and applications on high-performance cast magnesium rare-earth alloys

- Surface characterization and corrosion behavior of calcium phosphate(Ca-P)base composite layer on Mg and its alloys using plasma electrolytic oxidation(PEO):A review

- Towards developing Mg alloys with simultaneously improved strength and corrosion resistance via RE alloying

- The design of Co3S4@MXene heterostructure as sulfur host to promote the electrochemical kinetics for reversible magnesium-sulfur batteries

- A new die-cast magnesium alloy for applications at higher elevated temperatures of 200–300°C

- Exploring the concept of castability in magnesium die-casting alloys