Exploring the interconnectivity of biomimetic hierarchical porous Mg scaffolds for bone tissue engineering:Effects of pore size distribution on mechanical properties,degradation behavior and cell migration ability

2021-02-24GozhiJiHuHungJilinNiuChnxinChnJinWngFiYuDliWngBinKngTiningWngGungyinYunHuiZng

Gozhi Ji ,Hu Hung ,Jilin Niu ,Chnxin Chn ,Jin Wng ,Fi Yu ,Dli Wng,Bin Kng,Tining Wng,d,∗,Gungyin Yun,∗,Hui Zng,∗

a Department of Bone &Joint Surgery,Peking University Shenzhen Hospital,Shenzhen Peking University-The Hong Kong University of Science and Technology Medical Center,Shenzhen 518036,China

b National Engineering Research Center of Light Alloy Net Forming &State Key Laboratory of Metal Matrix Composite,Shanghai Jiao Tong University,Shanghai 200240,China

c Beijing Key Laboratory of Civil Aircraft Structures and Composite Materials,Beijing Aircraft Technology Research Institute of COMAC,Beijing 102211,China

d Department of Orthopaedics,Peking University People’s Hospital,Beijing 100044,China

e National &Local Joint Engineering Research Center of Orthopaedic Biomaterials,Peking University Shenzhen Hospital,Shenzhen 518036,China

Abstract Interconnectivity is the key characteristic of bone tissue engineering scaffold modulating cell migration,blood vessels invasion and transport of nutrient and waste.However,efforts and understanding of the interconnectivity of porous Mg is limited due to the diverse architectures of pore struts and pore size distribution of Mg scaffold systems.In this work,biomimetic hierarchical porous Mg scaffolds with tailored interconnectivity as well as pore size distribution were prepared by template replication of infiltration casting.Mg scaffold with better interconnectivity showed lower mechanical strength.Enlarging interconnected pores would enhance the interconnectivity of the whole scaffold and reduce the change of ion concentration,pH value and osmolality of the degradation microenvironment due to the lower specific surface area.Nevertheless,the degradation rates of five tested Mg scaffolds were no different because of the same geometry of strut unit.Direct cell culture and evaluation of cell density at both sides of four typical Mg scaffolds indicated that cell migration through hierarchical porous Mg scaffolds could be enhanced by not only bigger interconnected pore size but also larger main pore size.In summary,design of interconnectivity in terms of pore size distribution could regulate mechanical strength,microenvironment in cell culture condition and cell migration potential,and beyond that it shows great potential for personalized therapy which could facilitate the regeneration process.

Keywords: Bone tissue engineering;Porous Mg scaffold;Interconnectivity;Pore size distribution;Cell migration.

1.Introduction

Tissue engineering provides a promising strategy for the regeneration of large-segmental bone defects caused by injury,trauma and disease,and porous scaffold acting as an artificial extracellular matrix structurally and functionally plays a key role in assisting hard tissue regeneration [1,2].Ideally,scaffold material of bone tissue engineering should be biocompatible to facilitate bone formation,bioabsorbable to allow a final complete replacement of host tissue and provide adequate mechanical properties to maintain the load transfer of bone tissues [3,4].Biomaterials,e.g.,metals(Ti alloys,stainless steel),polymers(polylactide,poly methyl-methacrylate),ceramics(hydroxyapatite,tricalcium phosphate)are being developed into three-dimensional porous structure for the potential application in tissue engineering [5].However,the ideal biological characters of scaffold material mentioned above could hardly be simultaneously realized in these biomaterials due to their own inherent drawbacks,e.g.,non-degradability of titanium and stainless steel,poor mechanical strength of polymers and brittleness of ceramics [6,7].

Mg and its alloys have been widely considered as a revolutionary biomaterial because of its good cytocompatibility and biodegradability [8,9].Numerous in vitro and in vivo studies indicated that implants of Mg and its alloys could stimulate the healing process of bone fracture [10,11].Thus,Mg and its alloys could be the promising biomaterial for bone tissue engineering scaffold [12].The first attempt to obtain an open porous structure of Mg alloy was carried out in 1999,porous AZ91 with porosity of 99.7% and pore size of 4.5 mm was achieved through replicating polyurethane form by infiltration casting [13].In 2001,ammonium bicarbonate and carbamide mixed with Mg powder was proposed to fabricate porous Mg by powder metallurgical sintering process [14].The results showed that finer pore size ranging from 200 μm to 500 μm with comparable mechanical properties to hard tissue was received,but the porosity is about 50%at most and there existed sharply drop of stress in compressive cures [15].Then,NaCl particles were used as space holder to produce porous AZ91 by infiltration casting [16],and the first in vivo trial was carried out to repair bone defect utilizing this Mg alloy scaffold[17].Up to now,various pore struts of Mg alloys scaffolds have been successfully prepared by hot press sintering Mg fibers [18,19],drilling in bulk Mg [20,21],Mg powder metallurgy [22,23],infiltration casting [24,25]and 3D printing[26–28].With the development of scaffold design and characterization,pore characteristics including the geometry of pore strut,pore size,porosity and interconnectivity functioned as test parameters have been investigated in relation with biological performance [29].Basically,the geometrical morphology of pore strut unit and pore size distribution collectively determine the porosity and interconnectivity.The effects of pore size distribution on the porosity,mechanical property and degradation behavior of Mg alloys scaffolds were mostly reported [30–32],while efforts and understanding of the interconnectivity is limited.Interconnectivity structurally represents the connections of pore space of three-dimensional porous structures,which is widely considered as a key pore characteristic modulating cell migration and integration,blood vessels into the central regions of scaffold,and exchange of nutrient and waste [33].However,due to the diverse architectures of pore struts and pore size distribution of Mg scaffold systems,the barrier for studying the biological functions of interconnectivity is preparing a series of Mg scaffolds with the same pore strut unit(whereas different pore size distribution would be designed)or pore size distribution(whereas various geometry of pore strut would be prepared).Although additive manufacturing of 3D printing could allow free design of pore struts retaining the same pore size and porosity,such research work have been rarely reported on Mg and its alloys scaffolds.Template replication method of infiltration casting provides a facile strategy to fabricate Mg scaffolds with the same pore strut but different pore size distribution.In our previous work,NaCl particles were sintered into open porous template [34],and the pore size distribution of the resulted Mg scaffolds could be controlled by the particles and the sintering necks [35].Furthermore,we optimized the preparation of the template.A significant improved sintering efficiency was achieved by substituting NaCl particles with Ti particles,and in vivo implantation of a Mg alloy scaffold indicated good regeneration of bone defect [36].With this technique,the interconnectivity could be investigated in terms of pore size distribution by tailoring the size of Ti particles and sintering necks,respectively.

To clarify the effects of pore size distribution on mechanical strength,degradation behavior and cell migration ability,in this study we fabricated five hierarchical porous Mg scaffolds with different pore size distribution and investigated them by compressive test,immersion test and direct cell culture test.Meanwhile,a quantifiable method was proposed to evaluate cell migration potential of biodegradable Mg scaffolds with different design of pore size distribution.

2.Experimental procedures

2.1.Preparation of Mg scaffolds

Hierarchical porous Mg scaffolds were fabricated by template replication method.In detail,Spherical Ti beads(purity≥99.7 wt.%,Baoji lifengyuan Titanium Industry Co.,Ltd,China)with diameter of about 400–450 μm,500–550 μm and 600–650 μm were sintered by spark plasma sintering system(SPS,FCT Systeme GmbH,Germany),respectively.SPS was carried out at 800 °C for 5 min to sinter the Ti beads into an open porous Ti template.The relative compact density of the Ti template was modulated by the sintering pressure(26 kN,35 kN,45 kN).Infiltration casting procedure was performed under a mixed protective gas containing CO2(96 vol.%)and SF6(4 vol.%)to prevent oxidation.Pure magnesium(purity≥99.98 wt.%,Henan Yuhang Metal Materials Co.,Ltd,China)ingot was placed on the Ti template in a steel mold and heated to 720 °C to melt the ingot.The molten Mg was infiltrated into the template by employing a punch pin at a speed of 1 mm/s until a pressure of 2MPa was reached.After solidification,the Ti-Mg composite ingot was driven out and machined by electrical discharge wire-cutting machine,which was followed by immersion in 40 wt.% hydrofluoric acid solution(China National Pharmaceutical Group Co.,Ltd.)to dissolve the Ti template.The hierarchical porous structure of Mg scaffold was obtained after the removal of the Ti template.Mg scaffolds prepared by spherical Ti particles with diameter of about 400–450 μm,500–550 μm and 600–650 μm at the same sintering pressure of 35kN were denoted as S-Ⅰ,S-Ⅱand S-Ⅲ,respectively.Mg scaffolds replicated from the templates with the same Ti particle size of 500–550 μm applying sintering pressure of 26kN and 45kN were labeled as S-Ⅳand S-Ⅴ,respectively.

2.2.Structure characterization

The open porous Ti template and the resulted Mg scaffold were scanned using high-resolution micro-computed tomography(μ-CT,Bruker Skyscan 1176,USA)with spatial resolution of 9 μm.3D structural analysis of the reconstructed sample was acquired using the software Mimics 19.0(materialise,Belgium).The pore size distribution,surface area,volume and porosities of Mg scaffolds were analyzed by Mimics 19.0.Archimedean method was employed to measure the volume of Mg scaffolds,and the results were used as standard to calibrate the results of volume from Mimics 19.0.Scanningelectron microscopy(SEM,Tescan VEGA3-SB,Czech Republic)equipped with energy dispersive X-ray spectrometer(EDS)was used to characterize the microstructures and surface composition.

2.3.Compression tests

The mechanical properties of the Mg scaffolds were characterized by room temperature uniaxial compressive tests using Zwick AG-100kN testing machine.The tests were conducted on the scaffolds with dimensions of 10 mm in diameter and 15 mm in height under displacement control with the crosshead speed of 1 mm/min.The elastic modulus of the Mg scaffolds was calculated according to the slope of the curves fitted to the linear elastic stages of the stress-strain curves,and the yield strength was determined using the 0.2%-offset method.

2.4.Immersion tests

Semi-static immersion tests were carried out to evaluate the degradation behavior of the Mg scaffolds with different pore size distribution.Disk-like scaffolds with dimensions of 10 mm in diameter and 2 mm in height were ultrasonically cleaned in 75% ethanol for 30 min and dried under clean bench for 2 h.Then the specimens were separately immersed in 3 mL Dulbecco’s modified Eagle’s medium Glutamax-1(DMEM,Gibco,USA)supplemented with 10% fetal bovine serum(FBS,Gibco,USA),100 units/mL penicillin(Gibco,USA)and 100 units/mL streptomycin(Gibco,USA)in 12-well plates,and put in a standard cell incubator at 37°C with 5 vol.% CO2.The corrosive medium was refreshed every 3 days.Mg2+and Ca2+concentrations of the filtered extract were measured by inductively coupled plasma optical emission spectrometer(ICP-OES;iCAP6300,Thermo,USA).The short-term degradation rates of the five Mg scaffolds were deduced from the Mg2+concentration at 3 days.The pH value and osmolality of the exacts were monitored with a pH meter(B-712,Horiba,Japan)and a freezing point osmometer(Osmomat 3000,Gonotec,Germany),respectively.The increase in pH and osmolality of the extracts were derived from the blank group without scaffold.The degradation by-products of the Mg scaffolds were removed according to the method given by ASTM G1–03 using chromic acid solution(200 g/L CrO3and 10 g/L AgNO3,Sinopharm Chemical Reagent Co.,Ltd,China).The cleaning process of degradation product was carried out at 25 °C for 1 min.The volume loss rate was calculated from the volume change after immersion tests.The degradation rate of S-Ⅱscaffold after long-term semi-static immersion tests was calculated using Eq.(1)[37]:

WhereWbefis the weight before immersion test,Waftis the weight after removal the degradation products.Ais the surface area in cm2,tis the immersion time in days,ρis the density of pure Mg(1.74 g/cm3).

2.5.Cell migration assay

1×105murine calvarial pre-osteoblasts MC3T3-E1(Cell Bank,Chinese Academy of Sciences,China)in 50 μL of the cell culture medium were dropwise seeded on the surface of the above mentioned disk-like Mg scaffold,the medium consisting of alpha-modified eagle’s medium(α-MEM,Gibco,USA)supplemented with 10% fetal bovine serum(FBS,Gibco,USA)and 1% penicillin &streptomycin.Then,the cells-loaded scaffolds were separately placed in 12-well plates with 3 mL/well of the cell culture medium,the medium was refreshed every 24 h.After incubation for 6 h,3 d and 7 d,the cells-loaded scaffolds were gently rinsed with Dulbecco phosphate buffered saline(DPBS,HyClone,USA),and then placed in 24-well plate.For cell viability assay,500 μL of the cell culture medium and 50 μL of Cell Counting Kit-8(CCK-8 solution,Beyotime Biological Technology Co.,Ltd,China)were added to the 24-well plate and incubated in a cell incubator for 2 h,then 100 μL of the extracts were measured by the optical density(OD)measurement at 450 nm with a microplate reader(imark,Bio-Rad,USA)according to the instruction of the manufacture.For cell migration assay,the cells were stained with 500 μL of the mixture of Calcein-AM and Ethidium homodimer-1 reagents(LIVE/DEAD Viability/Cytotoxicity Assay Kit,Thermo Fisher Scientific Inc,USA)for 15 min at 37 °C,the proportion of the staining reagents was 2 μL of Calcein-AM and 5 μL of Ethidium homodimer-1 in 5 mL of DPBS.After gently rinsing twice with DPBS,the cell seeding side and the reverse side of the specimens were observed under a 4x objective view by fluorescence microscopy with a accumulator module of focus stacking(Olympus IX71,Japan),the cell density on both sides was calculated by Image J.

2.6.Statistical analysis

All quantitative data were expressed as the means±standard deviations(SD)(n=3 for each group of compressive tests,n=5 for immersion tests and cell migration tests per analysis per group).The results were analyzed via one-way analysis of variance(ANOVA),and#P-value<0.05 was considered statistically significant.

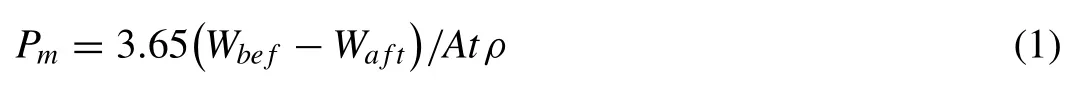

Fig.1.Micro-CT reconstructed results of typical Ti template(a,b)and Mg scaffold(c,d).

3.Results and discussion

3.1.Pore size distribution

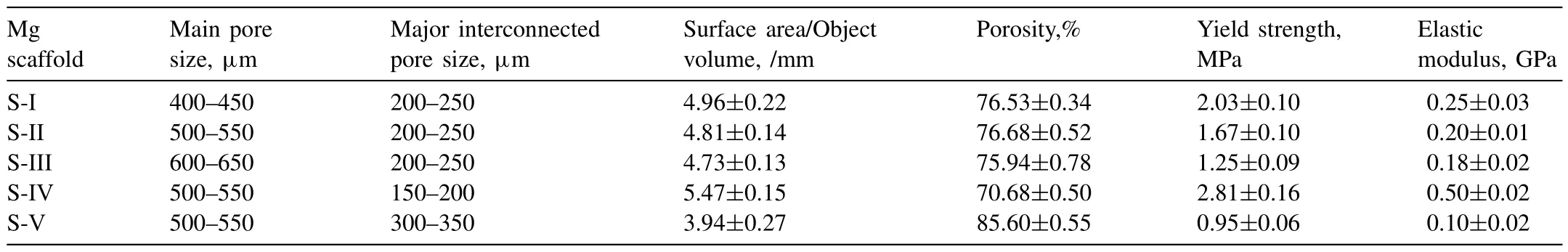

The architecture of the typical open porous Ti template and Mg scaffold was scanned and reconstructed by Micro-CT.The analysis of three-dimensional observation indicated the spatial homogeneity of the sintered Ti beads and the uniformity of the connecting necks between Ti particles(Fig.1a and b),and Mg scaffold precisely replicated the architecture of Ti template by infiltration casting(Fig.1c and d).There were two types of pores within the open porous Mg scaffold.The bigger spherical pores were replicated from Ti particles(hereafter named main pores),and the smaller pores distributed homogeneously on the wall of the spherical pores were interconnected pores of the main pores.The interconnected pore size could be adjusted through the sintering necks by modulating sintering pressure,and together with designing the Ti particle size,five Mg scaffolds(denoted as S-Ⅰ,S-Ⅱ,S-Ⅲ,S-Ⅳand S-Ⅴ,respectively)with different pore size distribution were achieved.S-Ⅰ,S-Ⅱand S-Ⅲwere fabricated using the three groups of Ti particles under a same sintering pressure of 35 kN.S-Ⅳand S-Ⅴpossessed the same main pore size as S-Ⅱ,but a lower sintering pressure of 26 kN and a higher sintering pressure of 45 kN were applied,respectively.Fig.2 shows the pore size distribution and SEM images of the five Mg scaffolds.The columnar distribution of pore size shown in Fig.2a and c confirmed the hierarchical porous structure of the five Mg scaffolds,and the liner fitting results shown in Fig.2b and d indicated two dominated pore size distribution which could be the major size distribution of interconnected pores and the main pores,respectively.The microstructure of the five Mg scaffolds was revealed in the inserted SEM images of Fig.2,the enlargement of the interconnected pore size could be easily identified in S-Ⅱ,S-Ⅳand S-Ⅴscaffold.The pore characteristics of the five Mg scaffolds were summarized in Table 1.S-Ⅰ,S-Ⅱand S-Ⅲexhibited the similar porosity while the porosity of S-Ⅱ,S-Ⅳand S-Ⅴscaffold increased with the increment of interconnected pore size.However,the specific surface area decreased with the increase of interconnected pore size.

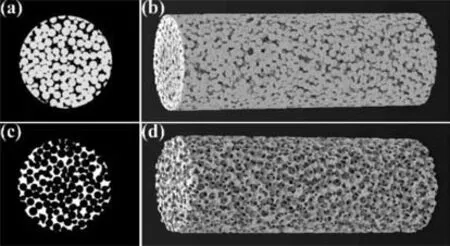

Table 1 Pore characteristics and mechanical properties of the Mg scaffolds.

Fig.2.Pore size distribution and morphologies of the resulted Mg scaffolds,(a,b)for S-Ⅰ,S-Ⅱand S-Ⅲ,(c,d)for S-Ⅱ,S-Ⅳand S-Ⅴ,the inserted SEM images are the typical microstructures of the five Mg scaffolds.

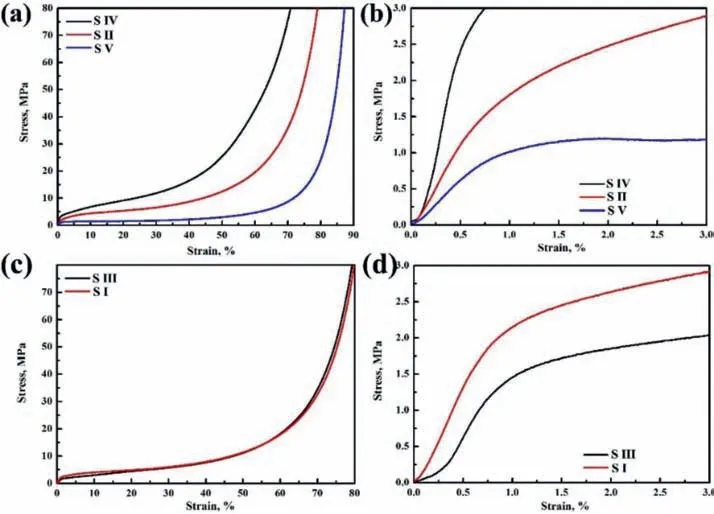

Fig.3.Typical compressive stress-strain curves of the five Mg scaffolds,(b,d)are magnified view of the strain within 3% in(a,c).

Tissue engineering involves wide scope of repair that need adjustable pore characteristic of scaffolds [2,38].The template replication methods applied by infiltration casting process give a preferable idea of regulating the porous structure [22,39].The pore morphology and pore size can feasibly replicate the geometry of the space holder particles of the template when the infiltrated liquid metal fully filled up the space between the space holder particles [13].Comparing to the low efficiency of hot press sintering NaCl particles in our previous work [34],SPS provided a precise and rapid modulation of the sintering necks between Ti particles.A porosity of 85.6% was achieved,which was the highest porosity of Mg scaffold to our best knowledge comparing to other Mg scaffolds made by space holder particles and proximate to the maximum porosity of human trabecular bone [29,40].Moreover,the highly interconnected porous structure of the Mg scaffolds was in consist with the hierarchical porous structure of cancellous bone [41].Thus,the proposed biomimetic porous Mg could be flexibly customized.Besides,the interconnectivity of open porous materials was widely considered as 100% [42].The presented Mg scaffolds were all highly open porous,however,the interconnectivity of the five Mg scaffolds could be different due to the diverse pore size distribution.S-Ⅴscaffold possessing the same main pore size as S-Ⅱand S-Ⅳmay have better interconnectivity because of the larger interconnected pores.Likewise,for S-Ⅰ,S-Ⅱand S-Ⅲdisplaying the similar major interconnected pore size and porosity,S-Ⅲscaffold with larger main pore size might present superior interconnectivity of the 3D porous structure.

3.2.Mechanical properties

Fig.3 shows the typical compressive stress-strain curves of the presented Mg scaffolds with different pore size distributions.The curves could be divided into three typical stages,the first is elastic stage where the compressive stress increases linearly with the strain,followed by a long deformation plateau during which the pore walls collapsed under slightly increasing stress,and then a densification stage where the subtended pore walls came in contact causing an abrupt rising stress.Meanwhile,the smooth changing curves without any abrupt decrease of stress revealed that the testing specimens maintained an excellent structural integrity during the deformation,which was in consist with the compressive deformation behavior of the cancellous bone [43].The compressive yield strength and elastic modulus of the five Mg scaffolds were also summarized in Table 1.The yield strength and elastic modulus of S-Ⅳ,S-Ⅱand S-Ⅴscaffolds decreased with the increase of the interconnected pore size.As for the scaffolds with similar porosity,the yield strength of S-Ⅰwas higher than that of S-Ⅱand S-Ⅲ.These results are consistent with previous reports.For example,Mukai et al.found that the compressive yield strength of porous aluminum with pore size of 1.19 mm was higher than that of porous aluminum with pore size of 2.68 mm at the same porosity of 89.5% [44].Goodall et al.investigated the compressive mechanical properties of porous aluminum with main pore size of 26,75 and 400 μm,respectively [45].The results revealed that the plastic size effect existed in the porous structures with the same porosity,i.e.the smaller pore size presented higher compressive strength.The enhancement could be attributed to the higher density of dislocations in smaller pore strut,which generated through different thermal expansion coefficients between the space holder particles and the scaffold material during the solidification of infiltration casting process[46].It could be assumed that the design of interconnectivity as well as pore size distribution could provide an extra and flexible strategy to achieve mechanical match with host tissue in addition to alloying the scaffold.

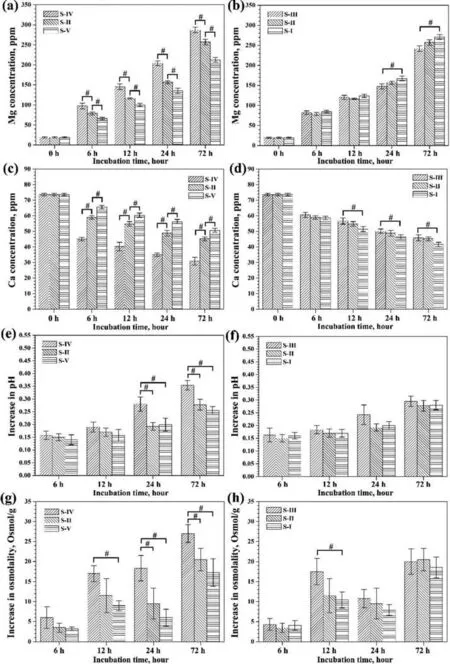

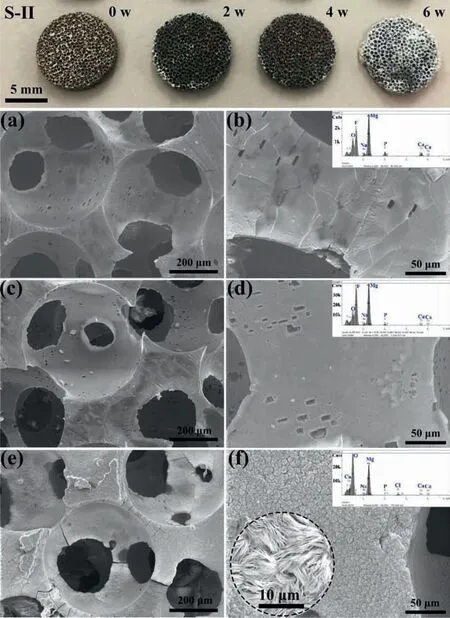

3.3.In vitro degradation behavior

Fig.4 shows the extract analysis result of the five Mg scaffolds,which indicated that the pore size distribution could affect the microenvironment of the extracts.The significantly different increase of pH,osmolality and Mg2+concentration together with the decrease of Ca2+concentration could be observed in Fig.4a,c,e and g,respectively.S-Ⅳscaffold with major interconnected pore size distributed in the range of 150–200 μm provided more surface area exposed to the corrosive medium comparing with S-Ⅱand S-Ⅴ.Thus,the release of Mg2+,deposit of Ca2+,increase in pH and osmolality of S-Ⅳwere greater than those of S-Ⅱand S-Ⅴ.However,the effect of main pore size on the change of pH,osmolality,Mg2+concentration and Ca2+concentration was evidently weakened on account of the nondistinctive porosity and similar specific surface area of S-Ⅰ,S-Ⅱand S-Ⅲ.Collectively,the effect of interconnectivity as well as pore size distribution on the change of the microenvironment in extract functioned in the manner of the specific surface area.The macrograph of the degraded S-ⅡMg scaffolds after long-term semi-static immersion tests is shown in Fig.5a.Visible degradation deposit and volume loss were observed after 6 weeks.Nevertheless,the presented Mg scaffolds provided sufficient structural integrity within 4 weeks,which could be attributed to the formation of a MgF2coating on the pore strut during the removal of Ti template in hydrofluoric acid.The MgF2layer on Mg alloys has been reported with enhanced degradation resistance due to its insolubility [47].Fig.5b-g displays the SEM images of the degraded S-Ⅱscaffolds,the inserted images are the EDS results of elemental composition on the pore strut.The micromorphology of the degraded scaffolds confirmed that few deposit particles were found on pore strut after 4 weeks,the hierarchical porous structure maintained within 6 weeks,but a deposition layer was observed on the pore strut.The EDS results depicted the increment of O and Ca along with the decrement of F on the pore strut during the tests,which further confirmed the deposit of Ca2+and the reduced protection of the fluorination.Fig.6 shows the degradation rates of the Mg scaffolds.It is interesting that the five Mg scaffolds with different pore size distribution exhibited non-differential degradation rate.Usually,higher porosity or more surface area could cause significant increase in degradation rates [20].However,Cheng et al.also reported two Mg scaffolds with the same porosity and pore geometry degraded at a same rate when the pore size was significantly different[30].Wang et al.investigated the extracts of three different open porous structures of Mg alloy with the same porosity and pore size,the results indicated that the pore strut unite could affect the degradation rate of the scaffold [48].Therefore,pore size distribution could be inert to the degradation rate of the presented hierarchical porous Mg scaffolds because of the same architecture of strut unit.Moreover,the long-term degradation rates shown in Fig.6b and c indicated a sufficient degradation resistance to maintain structural integrity of the hierarchical porous structures,which is pivotal for tissue ingrowth.

Biodegradability is essential for tissue engineering scaffold to allow the replacement of biological tissues [10].Mg has been widely recommended as a revolutionary biomedical material for its harmless degradation process [49,50].Moreover,the degradation by-product Mg2+was reported inducing local neuronal production of CGRP to improve bone fracture healing [11],which implied Mg a promising candidate for bone tissue engineering.However,the porous structure of Mg would generate more surface exposed to corrosive medium that directly accelerate the degradation rate leading to severe microenvironment change in pores [51].Considering H2gas pocket and premature structural failure might be generated by the fast degradation of porous Mg,tissue ingrowth and nutrient transport could be inhibited.Coating technology provides an effective strategy to enhance the degradation resistance of Mg substrate [52].The five Mg scaffolds displayed a reduced degradation rate and moderate microenvironment under the protection of MgF2comparing to the bare Mg scaffolds fabricated by NaCl template in our previous work [51].In addition,the degradation rate could be further modulated by alloying Mg substrate or stepwise coating on the MgF2layer.

Fig.4.Extracts analysis results of the five degraded Mg scaffolds,Mg concentration(a,b),Ca concentration(c,d),increases in pH(e,f)and osmolality(g,h).Measurements were performed in five-duplicates and the results was expressed as mean value±SD,#P <0.05.

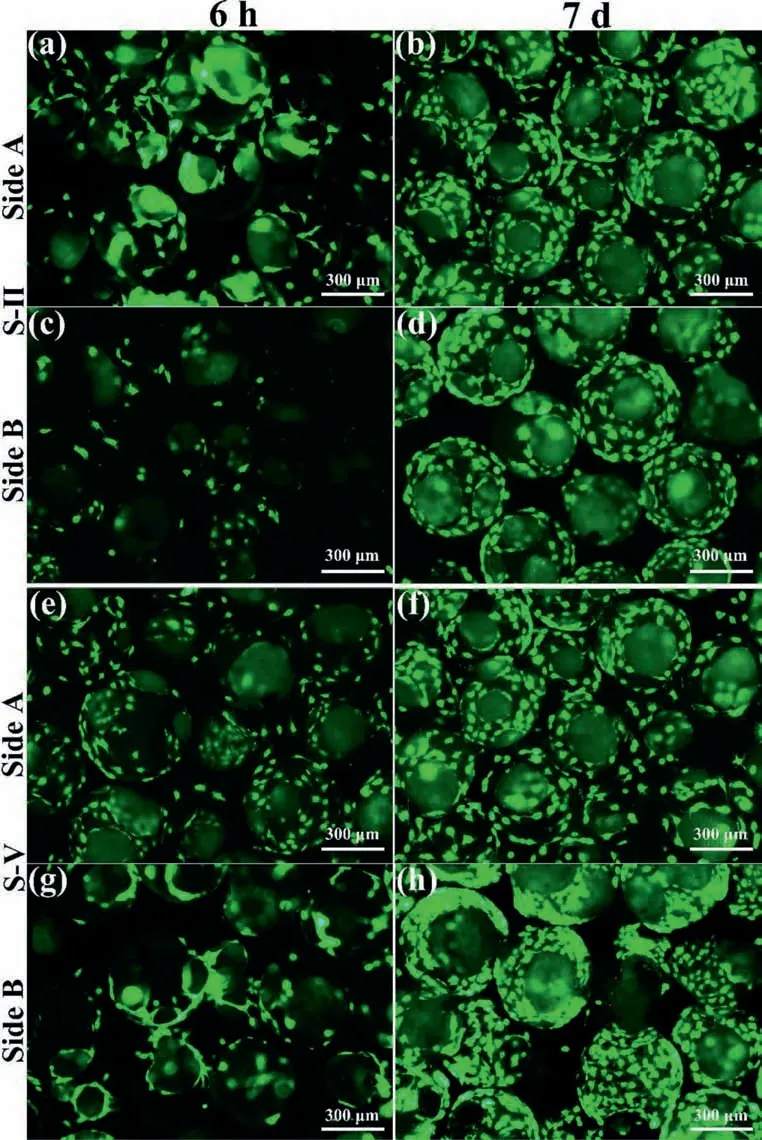

3.4.Cell migration potential

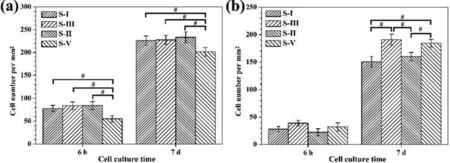

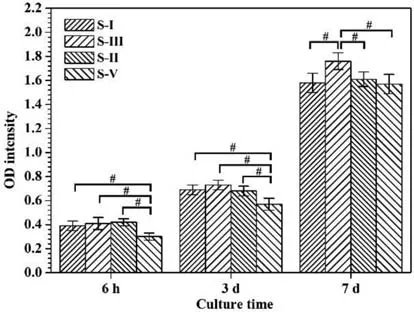

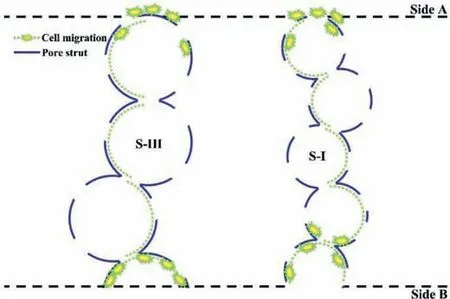

Fig.7 shows the near surface distribution of MC3T3-E1 cells on both sides of scaffold S-Ⅰand S-Ⅲ.There were less cells on side B for both scaffolds after seeding the cells on side A for 6 h comparing to the distribution of MC3T3-E1 cells on side A,which confirmed the success of single-sided cell seeding process for the migration test.Significant cell proliferation on side A of S-Ⅰand S-Ⅲwas observed,and a mass of MC3T3-E1 cells migrated to side B of S-Ⅲafter 7 days.A similar cell proliferation behavior was found on the cell seeding sides of scaffold S-Ⅱand S-Ⅴafter 7 days,as shown in Fig.8,and significant cell migration to side B of S-Ⅱand S-Ⅴwas discovered.The proliferation and migration of MC3T3-E1 cells were further confirmed by calculating the cell density on both sides of the four scaffolds,the result is shown in Fig.9.S-Ⅴscaffold with less surface area loaded fewer MC3T3-E1 cells than other three scaffolds at the cell seeding stage,which finally limited the cell density at side A.However,the cell density on side B of S-Ⅲand S-Ⅴindicated beneficial cell migration potential that allowed higher density than that of S-Ⅰand S-Ⅱ,respectively.Together with the cell viability shown in Fig.10,it could be speculated that S-Ⅲand S-Ⅴwould accelerate cell proliferation throughout the hierarchical porous structure.Generally,scaffold with higher porosity provides better interconnectivity of the porous structure that afford preferable supply of nutrient for the survival and evolution of ingrowth tissue [53].In this study,S-Ⅴwith higher porosity showed superior cell migration potential comparing to S-Ⅱ,which could be attributed to the decreased surface area and larger interconnected pore size that enhanced the cell migration to connected main pores.Meanwhile,S-Ⅲexhibited better cell migration ability than that of S-Ⅰunder the same porosity,which could be relevant to the bigger main pore size.Fig.11 shows the schematic of cell migration in the highly interconnected Mg scaffolds with the same dimension of disk-like specimens(10 mm in diameter and 2 mm in thickness).The number of stacking main pores in thickness would be about 3.2 for S-Ⅲand 4.7 for S-Ⅰ,respectively.Thus,there was more distractive directions caused by the extra main pores and affiliated interconnected pores for the migration within S-Ⅰ.Therefore,larger interconnected pore size of S-Ⅴand bigger main pore size of S-Ⅲboth demonstrated higher interconnectivity by favoring the cell migration potential.The regeneration of critical size bone defect functioned by bone tissue engineering implied implanted scaffold exceeded 3–5 mm in dimension,it could be assumed that optimization of pore size distribution would accelerate cell migration preventing bone nonunion.

Fig.5.Macrograph and micrograph of the degraded S-Ⅱscaffolds after immersion tests,(a)macrograph of the scaffolds,(b,c)SEM images at 2w,(d,e)SEM images at 4w,(f,g)SEM images at 6w,the inserted SEM image of(f)shows the magnified view of degradation layer at 6w,and EDS analysis results of strut surface are shown in the inserted chart of(b),(d)and(f),respectively.

Fig.6.Degradation performance of the presented Mg scaffolds,(a)degradation rates of the five Mg scaffolds at 3 d,(b,c)volume loss rates and degradation rates of S-Ⅱscaffolds.Measurements were performed in five-duplicates and the results are expressed as mean value±SD,#P <0.05.

Fig.7.Cell migration results of MC3T3-E1 cells on Mg scaffolds with different main pore size,(a-d)for S-Ⅲscaffold,(e-h)for S-Ⅰscaffold.

Fig.8.Cell migration results of MC3T3-E1 cells on Mg scaffolds with different interconnected pore size,(a-d)for S-Ⅱscaffold,(e-h)for S-Ⅴscaffold.

The interconnectivity of tissue engineering scaffold is a comprehensive pore characteristic regulated by the geometry of strut unit,pore size distribution.Therein the geometric design of strut unit may fundamentally vary the performance of interconnectivity [54].The presented biomimetic hierarchical porous structure,software-designed lattice-based and triply periodic minimal surface-based porous structures are widely considered possessing advantage of interconnectivity [55,56].The characterization of the interconnectivity of porous structure is mostly performed by the permeability test using flow fluid [57,58],which could represent the transportation efficiency of nutrients.Nevertheless,efforts on the effect of pore size on cell behavior indicated that pores above 300 μm could enhance cell proliferation [59],and time for MC3T3-E1 cells to bridge a pore linearly increased with the overall pore size [60].However,inspection method of mass transfer on porous scaffold,i.e.the cell migration ability in relation with the interconnectivity of tissue engineering scaffold is rarely reported.An international standard ISO 19,090:2018 proposed a method that measuring the linear longest cell migration distance,from a confluent cell layer into porous ceramic scaffold which placed on the cell layer,to quantify cell migration potential.The method was based on the principle that cell migration distance was proportional to the quality of the interconnectivity.The measurement is based on Giemsa staining and observation with a stereoscopic microscope.Although this method might be adapted to test cell migration ability of tissue engineering scaffold,it could not be applicable to Mg scaffolds while H2by-product during the degradation of Mg might inhibit the cell migration from the cell layer onto Mg strut according to the instruction of ISO 19,090:2018.Besides,as observed in this work the longest migration distance might be the same for the four tested scaffolds while the cell densities at the same migration distance could be different.Therefore,our proposed cell migration potential evaluation method could bring novel insights into characterization of cell migration test and understanding of the interconnectivity of bone tissue engineering scaffold.

Fig.9.Cell density of MC3T3-E1 cells on the Mg scaffolds,(a)Side A,(b)Side B.Measurements were performed in five-duplicates and the results are expressed as mean value±SD,#P <0.05.

Fig.10.Cell viability results of MC3T3-E1 cells on the Mg scaffolds.Measurements were performed in five-duplicates and the results are expressed as mean value±SD,#P <0.05.

Fig.11.Schematic of cell migration test on Mg scaffolds with different pore size distribution,cells were loaded on Side A,the cell density at Side A and Side B during the coculture test were measured and applied to quantify the migration potential.

4.Conclusions

The present work designed and prepared five Mg scaffolds with different pore size distribution through replicating tailored open porous Ti templates.The biomimetic hierarchical porous structure provided adjustable compressive properties and sufficient degradation resistance,which could meet the requirement of bone tissue engineering.The degradation rates of the five Mg scaffolds were independent of pore size distribution while the microenvironment of the extract could be related.We established proof of concept,for understanding the interconnectivity of hierarchical porous Mg scaffolds in terms of pore size distribution.Enlarging the interconnected pore size of Mg scaffolds enhanced the interconnectivity.Likewise,superior interconnectivity of Mg scaffolds with bigger main pore size improved the cell migration potential.This innovative biodegradable highly interconnected hierarchical porous Mg scaffold may offer great potential for the treatment of bone defect regeneration.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This study was supported by grants from Shenzhen Key Medical Subject(No.SZXK023),Shenzhen“San-Ming”Project of Medicine(No.SZSM201612092),Shenzhen Research and Development Projects(No.JCYJ20170307111755218),Guangdong Basic and Applied Basic Research Foundation(No.2019A1515011290),National Key Research and Development Program of China(No.2016YFC1102103),and China Postdoctoral Science Foundation(No.2020M672756).

杂志排行

Journal of Magnesium and Alloys的其它文章

- Mg-based materials for hydrogen storage

- Magnesium alloys as anodes for neutral aqueous magnesium-air batteries

- Biodegradable Mg alloys for orthopedic implants–A review

- A review on electromagnetic shielding magnesium alloys

- Thermodynamics and kinetics of hydriding and dehydriding reactions in Mg-based hydrogen storage materials

- Valorization of AZ91 by the hydrolysis reaction for hydrogen production(Electrochemical approach)