Variations in productivity and wood properties of Amazonian tachi-branco trees planted at different spacings for bioenergy purposes

2021-01-11MarileneOlgadosSantosSilvaMarcelaGomesdaSilvaLinaBufalinoMaraReisdeAssisDelmandeAlmeidaGonalvesPauloFernandoTrugilhoThiagodePaulaProtsio

Marilene Olga dos Santos Silva · Marcela Gomes da Silva · Lina Bufalino ·Maíra Reis de Assis · Delman de Almeida Gonçalves · Paulo Fernando Trugilho ·Thiago de Paula Protásio

Abstract Tachi-branco (Tachigali vulgaris , L.F.Gomes da Silva & H.C.Lima) is a leguminous tree species native to the Amazon rainforest that has drawn attention for its remarkably fast growth, a required trait for biomass/bioenergy plantations. In evaluations of biomass production and wood properties of T. vulgaris planted in homogeneous plantations at different spacings in the Amazonian state of Pará,Brazil, biomass of 7-year-old trees was quantified for individual trees and the entire population. Wood was also sampled to assess properties relevant to bioenergy applications.The choice for spacing dimension for planting nonclonal T. vulgaris should consider whether the priority is greater productivity per tree, achieved with greater spacings (9.0 m2and 12.0 m2), or productivity per area, achieved with closer spacings (6.0 m 2 and 7.5 m2). Genetic variability of the T.vulgaris seed stand and/or high heritability of wood traits overcame the effect of different spacing on all morphological, physical, chemical and energetic properties of T. vulgaris wood. This species has moderate basic density when cultivated at spacings larger than 6 m2and net heating value above 7.95 MJ/kg, which is suitable for bioenergy purposes.The high variation in wood properties within tree spacing is strongly indicative of great potential for genetic breeding. The fast growth and the suitable moderate wood basic density conf irm the outstanding potential of homogeneous plantations of T. vulgaris for providing wood for bioenergy.

Keywords Basic density · Heating value · Planting density · Tachigali vulgaris

Introduction

Biomass comprises organic renewable matter and derivatives obtained from living or recently living organisms that can replace conventional fossil fuels. Attractive properties for commercial applications include concentration of nonfossil carbon, wide availability, low production cost, low acidic gas emissions and no net carbon dioxide production(Jiang et al. 2014; Hupa et al. 2016; Gil et al. 2019).

Biomass can be converted into useful forms of bioenergy by thermochemical processes such as pyrolysis (Dacres et al.2019) and carbonization (Hupa et al. 2016), which are most widely used in Brazil, and liquefaction (Huang and Yuan 2015) and gasification (Gil et al. 2019). Carbonization is a slow pyrolysis that converts biomass into bio-oils, charcoal(target product) and gases by devolatilization and deoxygenation of the macromolecules (Bilgic et al. 2016). Combustion, drying and devolatilization of the biomass to form a residual char that is oxidized by O 2 , CO 2 and H2O, leaving ash, ranges from primitive open fires and traditional cooking stoves to highly controlled furnaces to generate power or heat and power combined (Hupa et al. 2016).

Unprocessed biomass can first be upgraded into energydense fuels by torrefaction (Dacres et al. 2019) and converted into pellets or briquettes for easy transport and storage (Jiang et al. 2014, 2016).

Among the many biomass resources for bioenergy production, wood is the most used. It may be obtained from bioenergy plantations, native forests or as wastes from wood harvesting and industrialization (Jiang et al. 2016; Gil et al.2019). Plantations have most recently been preferred to meet the high demand for wood (Wu et al. 2012; Qiu et al. 2018)and reduce pressure on native forests.

Both native and exotic tree species can be considered potential feedstock for bioenergy plantations, but some native species have the advantage of homogeneous growth and wider adaptability when planted in local sites with variable environmental conditions (Piotto et al. 2003). Despite Amazonia’s biodiversity, in the Pará state, 133.996 ha are cultivated with exotic eucalyptus (IBA 2017). Consequently,we need to improve our scientific knowledge of native species with potential for cutltivating in homogeneous plantation destined for bioenergy production to diversify the sources of wood to meet local demands.

The species Tachigali vulgaris L.F. Gomes da Silva and H.C. Lima (2007), popularly known as tachi or charcoal tree, is an arboreal leguminous species native to the Amazon region. T. vulgaris has been investigated for use in the recovery of degraded areas, but it also exhibits attractive technological, ecological, and silvicultural characteristics for homogeneous plantations to provide feedstock for firewood and charcoal (Carpanezzi et al. 1983; Farias et al. 2016).

Even when cultivated, without advanced technology and/or genetic improvement, this species grows rapidly and produces high amounts of biomass (Carpanezzi et al.1983; Farias et al. 2016). This rapid biomass production is attributed to the tree’s association with bacteria of the genus Rhizobium for fixing atmospheric nitrogen (N), which may promote in rapid growth and production of nutrient-rich litter that increases soil organic matter (de Souza et al. 2019).

In contrast with eucalyptus plantations, T. vulgaris showed rapid canopy cover and completely suppressed invasive grasses, generating up to 11.7 Mg/ha more litter than eucalyptus, besides being a native species that can promote the establishment of a stable forest cover in degraded sites(Farias et al. 2016). In addition, the characteristics and suitability of its wood for energy purposes are comparable to those of the traditionally used eucalyptus species in southern Brazil. Six-year-old trees of T. vulgaris from a trial plantation produced wood with a basic density of 0.645 g/cm 3 and higher heating value (HHV) of 18 MJ/kg (Tonini et al.2018).

Although T. vulgaris is already adapted to the regional environmental conditions, can help restore degraded environments, and has attractive growth characteristics, productivity gains must be achieved for its biofuel and bioenergy applications. Thus, significant research effort is needed to develop exceptionally productive tree species through genetic improvement and silviculture (Hinchee et al. 2009).Tree spacing is one factor that affects development and yield in homogeneous plantations (Silva et al. 2016) and should be tested to assure adequate supply of biomass by new species.Moreover, the wood should be suitable for the conversion processes of biomass into energy, as measured by its basic density, chemical composition, and HHV (García et al. 2012;Costa et al. 2015).

Thus, it is important to understand how different spacings of a species will affect wood properties that are relevant to energy production. Therefore, here we evaluated the variations in biomass production and wood properties of T. vulgaris trees planted at different spacings in homogeneous plantations. This study shows that, in Amazonia, it is possible to use native species instead of exotic species for fast-growing plantations.

Materials and methods

Study area and experimental design

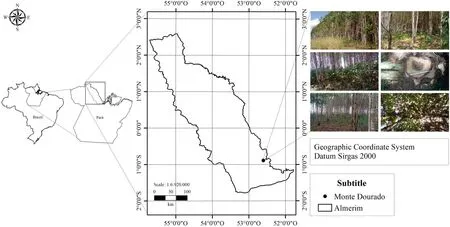

Data were collection in a trial seed plantation of approximately 6 ha in the district of Monte Dourado, Pará, Brazil and belonging to the company Jari Celulose S.A. (Fig. 1).The annual average temperature is approximately 26 °C(Demolinari et al. 2007).

The soil of the region is classified as dystrophic Yellow Latosol with medium texture. Limestone was applied at 402 kg/ha before planting. In addition, 150 kg/ha of NPK 6-30-6 and 85 kg/ha of NPK 15-0-30 were applied in the first and second year after planting, respectively.

The planting area was subdivided into three blocks according to fertility conditions (Fig. 2). Thirty-one single trunk trees and 23 forked trees were selected, excluding those with visible defects, and those that were located at the edges of the sampling areas.

Fifty-four (54) 84-year-old T. vulgaris trees (3 trees × 3 blocks × 6 spacings) were sampled. For each spacing, the mean diameter at breast height (DBH), the mean total height(Ht), and usable area occupied per plant were calculated(Table 1).

Fig. 1 Location of study area

Fig. 2 Subdivision of the planting area into blocks and tree spacing in those blocks

Table 1 Description of the treatments and trees

The circumference of all the trees was measured at 0.5,0.70, 1.30, and 2.0 m above the ground. Above 2.0 m,circumference measurements were taken every 2 m up to the height at which the “diameter with bark” was 5 cm. Secondary trunks were also measured using the same methods.Subsequently, the wood volume per tree, with and without bark, was estimated using Smalian’s formula.

Harvesting and wood sampling

The trees were felled, and six discs were cut from the trunk(and secondary trunks for forked trees), at the following locations (with the percentage values representing the distance between the base and the height up to a diameter with bark of 5 cm): base (0%), breast height, 25%, 50%, 75%,and 100%.

The heartwood to sapwood ratio (H/S) was measured in the discs removed at breast height. The disks were then sectioned into four equal wedges (quarters). Two opposite wedges were used to determine the basic density of the wood, and the remaining wedges were used for the further analyses.

Physical properties

The basic density of each wedge was determined according to the procedure described in standard NBR 11941 (ABNT 2003). The mean basic density of the tree was calculated from the arithmetic mean of all wedges obtained at each longitudinal sampling position.

where M 0% is the absolutely dry mass (g) and V s is the saturated volume (cm 3 ).

The maximum moisture content (MMC) was obtained according to the formula of Simpson and Tenwolde (1999;Eq. 2):

where MMC is the maximum moisture content (%) and ρ is the basic density (kg/m3).

Anatomical properties

Measurements of tree diameter and heartwood diameter were carried out using a 10 mm precision ruler when the moisture content of the wood was stabilized in room conditions at about 18% after 1 month passed from harvesting.The position of the sapwood-heartwood demarcation was based on color and detected visually by eye (Lin et al. 2012;de Paula et al. 2018). H/ S was calculated according to the equation of Pereira et al. (2013a, b; Eq. 3):

where Cd is the heartwood diameter (cm) and D is the diameter of the disc without bark (cm).

For the analysis of fibers, small pieces of wood were removed at each sampling position and mixed together to produce one composite sample for each tree. The plant fibers were isolated from each other by immersion in a solution of hydrogen peroxide and glacial acetic acid (1:1) for 48 h at 60 °C.

Slides were prepared for measuring the length and diameter of the fibers and lumens. For each sample, the diameter(Di), length (L) and lumen diameter (LD) of 30 fibers was measured as recommended by IAWA (1989). The thickness and the wall fraction were obtained as:

where Df is the diameter of the fiber (μm), LD is the diameter of the lumen of the fiber (μm), and WT is the wall thickness of the fiber.

Chemical properties

For the chemical analysis of the wood, a wedge from each sampling position was processed into wood chips and then milled in a Wiley mill. Volatile matter and ash content were obtained by the procedure described in standard D1762-84 (ASTM 2007), using sample fractions retained between 40- and 60-mesh sieves. The fixed carbon content was obtained by difference, by subtracting the volatile matter content and the ash content from 100%.

For the elemental chemical composition, the fractions of the samples that passed through the 60-mesh screen were used. The carbon (C), hydrogen (H), nitrogen (N),and sulfur (S) content, based on dry mass of wood, was quantified using an Elementar Vario Micro Cube Universal Analyzer (Biovera, Rio de Janeiro, RJ, Brazil). The percentage oxygen (O) content was obtained by subtraction of the percentage of other elements and ash from 100,according to Eq. 6:

HHV analysis

For the determination of HHV, the fractions of the samples that passed through the 40-mesh sieve and were retained in the 60-mesh sieve were used and analyzed with an Ika C200 digital calorimetric pump (LabControl Instrumentos Científ icos Ltda., São Paulo, SP, Brazil). The lower heating value (LHV) and net heating value (NHV) were obtained as:

where HHV is the higher heating value, H is the hydrogen content (%), LHV is lower heating value (MJ/kg), NHV is the net heating value (MJ/kg), and MC is the wood moisture content based on the dry mass (%).

NHV was calculated simulating various MCs varying from MMC to 0% at an interval of 1%.

Estimation of dry mass of wood, carbon, fuel mass,productivity, and energy density

The estimation of the wood dry mass per tree was obtained by multiplying the individual volume of each tree by the average basic density according to Eq. 9 (Meneses et al.2015; Trugilho et al. 2015). The estimation of the carbon dry mass was calculated by multiplying the wood dry mass by the elemental carbon content (Trugilho et al. 2010; Eq. 10).

where V wb is the volume without bark (m 3) and ρ is the basic density of wood (kg/m 3 ).

where M0% is the absolutely dry mass of the wood (kg/tree)and CC is the carbon content (%) divided by 100.

The estimation of the fuel mass stored in the wood considers the dry mass that will effectively burn and release energy; hence, it consists of the fuel elements C, H and S(Eq. 11), excluding the ashes that do not contribute to the energy content of the wood (Huang et al. 2009; Yin 2011;Choi et al. 2014; García et al. 2014).

where M0% is the dry mass of the wood (kg/tree); C + H + S is the sum of the elemental percentages, divided by 100; and Ash is the percentage of ash (%) divided by 100.

The energy productivity, net energy productivity, and energy density were estimated as:

where WM is the wet mass (g) obtained by the equation WM = M0%(1 + MC/100), where MC is the moisture content based on the dry mass (%) and M0% is the dry mass (g).

where ρ is the mean basic density (kg/m 3) and LHV is the lower heating value (MJ/kg).

Statistical analyses

The experiment was conducted using a randomized complete block design. The data were subjected to the Shapiro-Wilk test to conf irm normality, to the Levene and Bartlett tests to conf irm the homogeneity of variances, and to the Durbin-Watson test for the autocorrelation of residues. The results were interpreted with the aid of analysis of variance(ANOVA) and, for the variables that showed significant effect of the usable area, a simple linear regression model was adjusted.

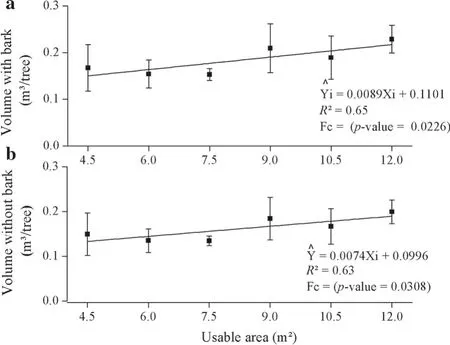

Fig. 3 Functional relationship between usable area and a tree volume with bark or b tree volume without bark per tree

Fig. 4 Relationship between tree volume per hectare and usable area

Results

Growth characteristics of the species

Tree volume with and without bark had a positive relationship with the usable area (Fig. 3). Overall, the greater usable area per tree, the larger the individual volume. Usable areas of 9.0 m2and 12.0 m2resulted in production of the largest individual volume, while usable areas of 6.0 m2and 7.5 m2produced the smallest individual volume.

For volumetric production per hectare, the closest usable area (4.5 m 2) was the most noteworthy, followed by usable areas of 6.0 and 9.0 m2. The volume of wood per hectare increased as planting density increased. The spacing decrease from 6.0 to 4.5 m2and from 12.0 to 6.0 m2remarkably increased volume per hectare in 47% and 20%,respectively (Fig. 4).

The dry mass of wood, carbon mass and fuel mass per tree increased as the usable area increased (Fig. 5), following the same tendency of the volumetric productivity per tree(Fig. 3). The amount of each stored per tree in the 9.0 and 12.0 m2usable areas was superior to those in the other conditions. In contrast, usable areas of 4.5, 6.0 and 7.5 m2led to the opposite, with the lowest yields for these characteristics.

The greatest variation in fuel mass was observed for usable areas 4.5 m2with 37.40 ± 11.67 kg/tree and 9.0 m2with 53.59 ± 15.28 kg/tree. Larger usable areas resulted in less dry mass production per hectare. The carbon mass and the fuel mass were similar across usable area, since both are directly related to dry mass (Fig. 6). The productivity of wood dry mass per hectare in the denser usable area (4.5 m2/tree) was 1.7 time higher than the productivity in the largest usable area (12.0 m2).

Fig. 5 Functional relationships between the estimated a dry mass of wood, b carbon mass and c fuel mass per tree and the usable area

Fig. 6 Relationships between the estimated dry mass of wood, carbon mass and fuel mass per hectare and the usable area

Physical and anatomical properties of T. vulgaris wood

No significant differences were observed among the usable areas for the physical and anatomical properties of T. vulgaris wood (Table 2).

It is important to highlight the distribution of the basic density values for each usable area due to the great relevance of this property for bioenergy purposes. Variation was greatest in the 12.0 m2usable area, with minimum and maximum values of 419 and 606 kg/m 3 , respectively.In the usable areas of 9.0 and 12.0 m2, the average wood density was 516 kg/m 3 , i.e., approximately 14% higher than the 454 kg/m 3 found for the wood produced in the closest usable area (4.5 m 2) (Fig. 7).

The H/S ratio was not significantly influenced by the usable area (Table 2). For T. vulgaris, the heartwood diameter increases with the tree diameter, regardless of the usable area (Fig. 8). However, no relationship was found between the tree diameter and the H/S ratio (Fig. 9). This result indicates that as the heartwood diameter increases,the total tree diameter increases by the same proportion.

The trees growing in the largest spacing (12 m2) showed the higher mean diameter of the heartwood (9.10 cm) and the highest wood density (516 kg/m 3 ). On the other hand,the trees from spacing 4.5 m2provided mean diameter of the heartwood of 7.84 cm and basic density of 454 kg/m 3 .The mean value for fiber length was 932.0 μm, 16.0 μm for fiber diameter and 9.7 μm for lumen diameter.

Chemical properties of T. vulgaris wood

No significant differences were observed between the usable areas for the chemical composition (Table 3). Average values for elemental components of T. vulgaris wood were 49.8% carbon, 6.3% hydrogen, 42.6% oxygen, 0.75% nitrogen and 0.02% sulfur. In the proximate analysis, averages of 78.54% for volatile matter content, 21% for fixed carbon content, and 0.49% for ash content were found (Table 3).The relationship between these components (volatile matter versus fixed carbon) in the T. vulgaris wood was similar across the different usable areas, presenting a mean ratio of 3.75.

Table 2 Analysis of variance for physical and anatomical characteristics of wood

Fig. 7 Basic density of Tachigali vulgaris as a function of usable area

Energy properties of the T. vulgaris wood

For all the energy properties of the wood, analysis of variance showed that the usable area effect was not significant at the 5% level (Table 4).

In this study, wood with 0% moisture content had a mean NHV of 18.33 MJ/kg, whereas at 25% moisture content,NHV fell to 14.16 MJ/kg (Fig. 10).

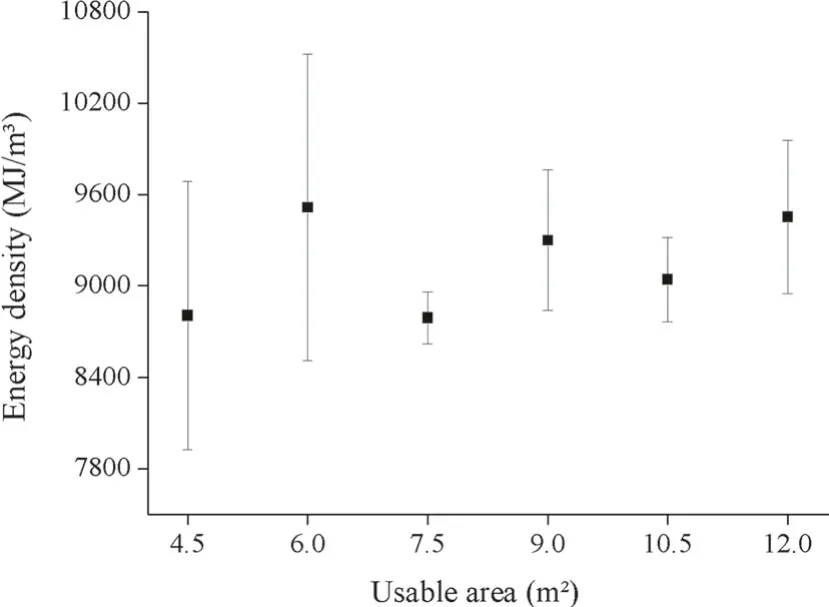

The usable areas that resulted in higher energy densities were 6.0, 9.0, and 12.0 m2, with 9516, 9300, and 9452 MJ/m 3 , respectively (Fig. 11). The energy density of these usable areas was higher by about 8.0%, 6.0%, and 7.3%, respectively, compared to the closest spacing of 4.5 m2(8806 MJ/m 3 ).

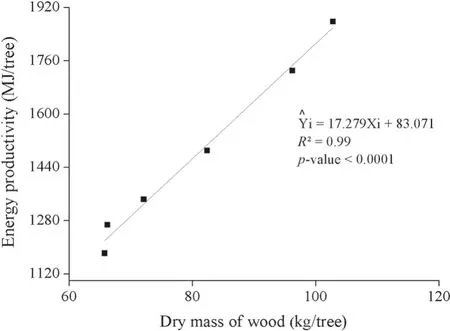

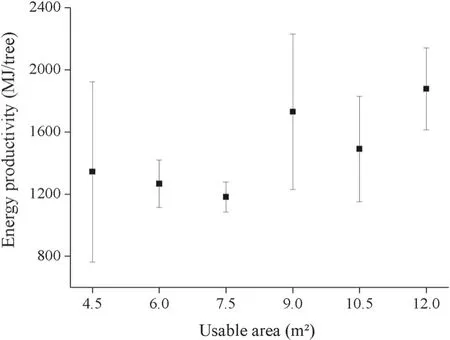

The energy productivity of the wood was statistically similar among the different usable areas. However, energy productivity tended to increase with an increase in wood dry mass (Fig. 12). It should be noted that the LHV of the wood did not differ significantly among usable areas. Thus, this variable did not influence the energy productivity per tree.

The mean energy productivity from the T. vulgaris wood in the 9.0 m2usable area was 1730 MJ/tree, 1.4 times higher than that of the 6.0 m2usable area (1267 MJ/tree) (Fig. 13).the wood increased (Fig. 14). The 9.0 and 12.0 m2usable areas showed superior energy yield in comparison to all the others(4.5, 6.0, 7.5, and 10.5 m2).

Fig. 8 Functional relationship between heartwood diameter and total tree diameter

Discussion

Growth characteristics of the species

The higher potential for volumetric growth per tree in the larger spacing is justified by the greater efficiency of the trees in the capture and use of primary resources, such as water, CO 2 , light, and nutrients, due to reduced competition(Costa et al. 2015). Oppositely, in the closer spacings, root competition can reduce photosynthetic production and cause early tree senescence and mortality (Kopp et al. 1996).Therefore, it is assumed that, in our study, competition among trees of T. vulgaris limited individual growth in the closer spacings. A similar result was observed for volume per tree in Eucalyptus clones (Berger et al. 2002; Binkley et al. 2017).

Fig. 9 Functional relationship between total tree diameter and heartwood to sapwood ratio (H/S)

Table 3 Analysis of variance for the ultimate and proximate analysis of wood

In addition, it is important to highlight the high variability of the volume data within each spacing (see high standard deviations), which is attributed to the nonclonal stand of T.vulgaris investigated in this study, which was established by planting seeds. Although spacing had a significant effect on tree growth, individual volumetric productivity in the 6.0 m2spacing (1667 trees/ha) was only 1.2 time higher than that of trees planted at a spacing of 12.0 m2(833 trees/ha). These results indicate the interference of the species genetic variability in the effect of spacing on individual growth attesting its potential for breeding programs.

As a priority, some forest plantations destined for energetic purposes must produce the largest volume of biomass per unit area in the shortest time (Hauk et al. 2014; Eloy et al. 2015; Eufrade-Junior et al. 2018; Schwerz et al. 2019).Therefore, it is necessary to evaluate not only the volume per individual tree, but also the total volume obtained per hectare. In our study, the volume of wood of T. vulgaris per hectare increased as planting density increased because there are more trees per unit area in the closer spacings.

Schwerz et al. (2019) reported better growth efficiency for stands of Acacia mearnsii cultivated in southern Brazil using the denser spacing of 2.0 × 1.0 m compared to larger spacings of 2.0 × 1.5 m, 3.0 × 1.0 m and 3.0 × 1.5 m. The authors related the results to the greater amount of radiation intercepted by tree canopy in the denser spacings, which allows higher photosynthetic rate, and consequently greater radiation use efficiency for increasing forest biomass. Similar results were observed for different species and tree ages within the genera Eucalyptus (Berger et al. 2002; Eufrade-Junior et al. 2016; Moulin et al. 2017) and Gmelina (Tenorio et al. 2016).

Because planting trees closer together may accelerate production of biomass per hectare, it is possible to harvest the forest earlier in comparison to forests with greater spacing between trees (Kopp et al. 1996; Schwerz et al. 2019). However, the possibility of decreased rotation, such as annual harvests, might be adverse to the sustainability of wood biomass production due to intense nutrient exportation (Kopp et al. 1996). The increase in tree density (e.g., from 9 m2to 4.5 m 2) in a plantation of Eycaluptus dunnii contributed to a higher nutrient depletion combined with higher biomass productivity per unit of area (Bentancor et al. 2019). In addition, longer cultivation periods oflarge-spaced trees (9 m2to 12.0 m2/tree) can be economically interesting, because costs are reduced in proportion to the forest lifetime (Hauk et al. 2014).

Therefore, the sustainability of short rotation forest of T.vulgaris using the closest spacing of 4.5 m2(3.0 × 1.5 m)must be evaluated considering the demand for wateruse, light-use efficiency, carbon balance and soil fertility(Eufrade-Junior et al. 2016).

Table 4 Analysis of variance for energy characteristics of T.vulgaris wood

Moreover, the choice of spacing depends on the purpose of the plantation, forest planning (Hauk et al. 2014) and sustainability of the soil fertility (Bentancor et al. 2019). For the production of charcoal, spacings of 9.0 m2, 10.5 m2and 12.0 m2may be better, due to the larger diameter at breast height (DBH) of the T. vulgaris trees (17.59 cm, 16.06 cm and 19.20 cm, respectively). On the other hand, spacings of 4.5 m2, 6.0 m2and 7.5 m2yielded trees with smaller DBH(14.28 cm, 14.60 cm and 14.48 cm, respectively), and, therefore, are more suitable for the production of firewood.

Fig. 10 Variation of net heating value with moisture content of the wood

Fig. 11 Energy density as a function of usable area

Fig. 12 Functional relationship between energy productivity and dry mass of wood

Fig. 13 Energy productivity as a function of usable area

Fig. 14 Relationship between net energy productivity and wood moisture content

Similar to the volume, the individual dry mass of wood increased as the spacing increased because of the reduced competition among trees for nutrients in the larger spacings,which allows higher biomass input (Neto et al. 2003; Souza et al. 2008).

The effect oflower planting density and higher fertilization levels on the greater dry matter yield, energy yield, and nutrient exports was previously reported (Eufrade-Junior et al. 2016; Resquin et al. 2019). The highest values for dry mass, carbon mass and fuel mass per tree occurred at spacings of 9.0 and 12.0 m2in this study for T. vulgaris; thus,there was a greater conversion of CO 2 into solid wood matter, which in turn would have contributed to a reduction in atmospheric CO 2 and thus of the greenhouse effect (Trugilho et al. 2015). Therefore, trees planted in the largest usable areas resulted in the greatest carbon sequestration from the atmosphere with greater allocation per unit mass. During burning, carbon is fully consumed (Mahishi and Goswami 2007), so it is expected that wood with a higher carbon content will also show higher thermal capacity as a function of greater energy release.

The fuel mass represents the quantity of carbon, hydrogen, and sulfur present in the biomass, discounting ash content. These elements, particularly carbon and hydrogen,are most closely related to the heat of combustion of wood(Telmo et al. 2010; Pereira et al. 2013a, b; Fernandes et al.2013); hence, the fuel mass represents the mass that will be effectively converted into energy.

The high variation of fuel mass within spacings may be attributed to genetic variability of the stand and indicates the necessity of genetic improvement of the species aiming to obtain a more homogeneous energetic productivity. Greater homogeneity is important for forestry planning, especially regarding accurate forecasting of the energetic stock and optimization of tree harvesting.

These results agree with the hypothesis that genetic variability and root competition, mainly in the denser spacings,reduced the volumetric productivities of wood dry mass in the T. vulgaris plantation. The plantation density and competition among trees, besides leading to a decrease in mass production, may promote alterations in wood density (Resquin et al. 2019).

The lower dry mass production per hectare, but higher dry mass production per tree with larger spacings was previously observed for 7-year-old T. vulgaris trees (Junior et al.2016).

In Brazil, a dry mass productivity of 131.04 ± 26.91 t/ha after 84 months was reported for commercial plantations of Eucalyptus grandis × Eucalyptus urophylla , cultivated with a spacing of 9.0 m2(Meneses et al. 2015). The T. vulgaris planted in the same spacing produced 88.48 ± 27.25 t/ha.

For a spacing of 4.5 m2/tree, Resquin et al. (2019) found that 76-month old trees of the E. benthamii species produced a dry mass of about 135.15 t/ha in northern and western Uruguay. In our study, 84-month old trees of T. vulgaris planted with the densest spacing in northern Brazil had an estimated dry mass productivity of 124.16 t/ha.

These results corroborate with the viability of planting T. vulgaris to support energy demands in the states of the Brazilian Amazonia, although growth of this species may be improved by genetic breeding to meet eucalyptus growth.According to Farias et al. (2016), T. vulgaris has the potential to replace eucalyptus in commercial plantations with the added benef it of being a native species that can promote the establishment of stable forest cover in degraded sites.

Physical and anatomical properties of T. vulgaris wood

Although the basic density of wood did not differ significantly among the different spacings, even small variations of this property may be relevant from a technological view.The largest spacings (9.0 and 12.0 m 2) yielded trees with a slightly higher basic wood density and, consequently, more energy stored per cubic meter, whereas wood generated with closer spacing (4.5 and 7.5 m 2) had lower basic density and thus burned faster, producing less energy per unit volume(Barros et al. 2012).

An increase of approximately 8% in the mean basic density was verified for spacings from 1.5 to 4.5 m2and 9.0 m2for Eucalyptus plantations (Rocha et al. 2016). The largest spacings might result in earlier formation of mature wood,as observed for wood from Eucalyptus (Malan and Hoon 1992). The mature wood is composed oflonger and wider fibers (Ramos et al. 2011), which is closely related to higher density (Carrillo et al. 2015).

The spacing effect on wood density is not always predictable because the growth rate of trees depends on so many factors. No effect of planting spacing (3.0 × 0.5 m to 3.0 × 1.5 m) was detected for basic density of 74-month-old Eucalyptus (Resquin et al. 2019) or for various spacings of T. vulgaris, Melia azedarach, and E. vimanalis (Leles et al.2014; Sturion et al. 1988).

In this study, the high variability of the basic density for trees within a specific spacing may be related to the high genetic variability of the trees and bifurcation that may affect radial growth, which in turn affects all wood features (Fernandes et al. 2017). The great variation in total diameter and heartwood diameter of trees established by seed plantations(e.g., 8.00 to 16.40 cm for denser spacing, 11.80 to 16.30 cm for wider spacing) possibly overcame any significant effect of spacing since the range of values overlap.

The fiber morphology of T. vulgaris wood also depends on the rate of secondary xylem formation by the vascular cambium, which is responsible for radial growth of trees.Therefore, once again, the high variation in the tree diameters of T. vulgaris possibly overcame any spacing effect.

In addition, we can infer that wood density and fiber morphology are properties that are more influenced by genetic inheritance than by the environment (Trugilho et al. 2010).Therefore, our study shows that breeding programs should select for trees of T. vulgaris with higher wood density.

Wood density is classified as moderate when varies from 500 to 750 kg/m 3 (Csanády et al. 2015). The mean values of basic density from spacings 9.0 to 12.0 m2are within this range and hence recommended for generating heat,electricity, liquid and solid fuels (Agbro and Ogie 2012;Bustamante-García et al. 2013; Pereira et al. 2019). However, some sampled trees had lower basic density than this requirement, which can be genetically improved (Csanády et al. 2015).

According to Gominho and Pereira (2005), heartwood diameter increases with the tree diameter, regardless of tree spacing. Heartwood tends to form earlier in trees planted with wider spacing (9.0-12.0 m 2) than with closer(4.5-7.5 m 2) possibly because the trunk needs to be strengthened earlier, which is corroborated by the larger volumes at wider spacings.

The fibers of T. vulgaris cultivated at all the spacings are classified as short, with mean diameter varying from 845.0 to 996.7 μm. The average wall fraction indicates that,of the total space occupied by fibers, 40% corresponds to biomass (mainly cellulose, lignin, and hemicelluloses of the cell walls), while 60% is air space.

Our results for fiber morphology conf irm the hypothesis that the trees do not differ remarkably in diametric growth because of the high variability in diameters at a specific spacing and bifurcation between 0.50 and 0.70 m in T. vulgaris trees. A thicker cell wall is indicative of more mass per wood volume; hence, more energy will be released per volume during thermal decomposition (Paula 2003).

Chemical properties of T. vulgaris wood

In 7-year-old Eucalyptus urophylla clones, carbon constituted 46.76% and hydrogen 6.14% of the total elements (Reis et al. 2012), levels that are lower than those observed in this study for T. vulgaris.

It is important to mention that, even if the differences are minimal, when the purpose is energy generation from wood,species with higher percentages of carbon and hydrogen are preferable (Pereira et al. 2013a, b). During combustion,carbon and hydrogen are oxidized by exothermic reactions(forming CO 2 and water), positively influencing the heating value of the fuel.

The average nitrogen content for T. vulgaris wood was 0.75%, which is higher than that reported by Santos et al.(2016) for clones of Eucalyptus spp. (0.15% to 0.20%). This difference can be attributed to the symbiotic association of T. vulgaris with bacteria of the genus Rhizobium, which fix atmospheric nitrogen.

Only trace amounts of sulfur were measured (on average 0.02%). Low concentrations of nitrogen and sulfur are advantageous since, when released, they form oxides that are harmful to the environment (NO x and SO x ). However, for the emission of these constituents, nitrogen concentrations > 1%and sulfur concentrations > 0.2% are necessary (Telmo et al.2010; García et al. 2012). Thus, the trace amounts of these elements does not compromise the use of T. vulgaris wood for bioenergy production.

The content of volatiles, fixed carbon and ash was similar to the 78.61% volatile materials, 21% fixed carbon, and 0.39% ash reported for T. vulgaris wood from a Brazilian Savana forest (Vale et al. 2002).

Volatile materials constitute the fraction of biomass that burns in the gaseous state, while the fixed carbon is the percentage that burns in the solid state. In this sense, a higher fixed carbon content implies a longer residence in the combustion equipment. In contrast, volatile materials rapidly volatilize and therefore decrease the residence time of the fuel within the combustion apparatus (Brand 2010).

In addition, the volatile materials facilitate flammability and the beginning of the combustion process; that is,a higher volatile content makes the fuel more reactive and easier to ignite (Fernandes et al. 2013). Thus, the combustibility of the T. vulgaris wood is expected to be the same regardless of the usable area in which it is grown. At high temperatures during combustion, ashes can melt and produce slag in the furnace (Demirbas 2004), decreasing the heating value of the biomass (García et al. 2013). Therefore,low ash is advantageous for bioenergy purposes.

Energy properties of T. vulgaris wood

The similarity of the HHV values among the different spacings is due to the similarity in the elemental compositions as discussed already. The heating value is directly related to the carbon and hydrogen content and inversely related to the oxygen content. The heating value is an indication of the chemical energy contained in the wood that is converted into thermal energy during combustion. The mean value found for the HHV was 19.7 MJ/kg, lower than 20.29 MJ/kg found by Vale et al. (2002) for samples of the same species, but from a native forest. This difference may be attributed to the older age of the sampled trees in relation to ours. Lignin content increases with age (Silva et al. 2005), which in turn,increases the HHV (Demirbas 2002).

HHV is inversely proportional to the moisture content of the wood; that is, greater moisture content in the wood reduces heat production per unit mass. The HHV takes into account the latent heat of the water vapor, which means that it is the maximum amount of energy available. For the LHV,the calories released by the condensation of the water vapor are not considered. The water generated in complete combustion evaporates and, consequently, carries a part of the energy of the system. Therefore, in the calculation of LHV,it is necessary to consider the elemental hydrogen content of the biomass.

The NHV is the amount of usable heat released, discounting the amount of heat used to evaporate the water formed by the combustion of elemental hydrogen and the moisture in the fuel. Therefore, this parameter best indicates the actual amount of energy contained in the wood. From the point of view of energy efficiency, only 77% of the available energy is used if combustion is performed at 25% moisture content,for example.

In modern cogeneration biomass combustion systems,a minimum NHV of 7.95 MJ/kg is desired (Brand et al.2011). All the results obtained in this research exceed this pre-established minimum value, conf irming the usefulness of this species for biomass production.

The energy density of the T. vulgaris wood was not significantly influenced by spacing because of the nonsignificant effects on both the heating value and the basic density of the wood. The energy density is positively correlated with the basic density (0.71) and with the LHV (0.41).

The widest spacings (6.0, 9.0, and 12.0 m2) are better than the closest spacing (4.5 m 2) when the purpose is to obtain energy from the wood because there will be more energy per cubic meter of wood, allowing for a greater amount of energy released after complete combustion. As a result, costs associated with wood transport and storage are reduced. Therefore, dry mass discussed above is a factor of fundamental importance when wood is destined for the production of energy.

The analysis of energy productivity allows for a better estimate of the energy potential of the plantation. The average energy yield of the T. vulgaris wood was 1482 MJ/tree,greater than that found by Vale et al. (2000) in 7-year-old trees of Acacia mangium (381 MJ/tree) and Eucalyptus grandis (929 MJ/tree). These results demonstrate that T.vulgaris has higher energy productivity compared to other species commonly used for energy production. However, it is important to mention that moisture content is a physical condition of wood that depends on the surrounding environment and which influences NHV. Thus, the moisture content in the wood needs to be minimized. Net energy productivity declines as the moisture content of the wood increases because NHV of the biomass decreases as moisture content increases, similar to the case for total energy yield.

Conclusions

In this study of variations in productivity and wood properties of a promising Amazonian species, T. vulgaris, cultivated in homogeneous plantations at different tree spacings, the best spacing for planting non-clonal T. vulgaris will depend on the priority. For greater productivity per tree,larger spacings (9.0 m2and 12.0 m 2) are best; for greater productivity per area, closer spacings (6.0 m2and 7.5 m2)should be chosen. Genetic variability of the T. vulgaris seed stand and/or high heritability of wood traits overcame the effect of different spacings on all morphological, chemical and energetic properties of the wood. Thus, the combustibility of the wood is expected to be the same regardless of the usable area in which it is grown. When spaced more than 6 m2apart, T. vulgaris trees have a moderate basic density and NHV above 7.95 MJ/kg, which is suitable for bioenergy purposes. The high variation in the wood properties within a specific tree spacing indicates great potential for genetic improvement. The suggested spacing for harvesting T. vulgaris plantation at 7 years is 3 × 3 m (9.0 m2), which allows good tree growth without negatively affecting the wood quality for bioenergy.

AcknowledgementsThe authors are grateful for the support provided by Agricultural Research Corporation of Amapá (EMBRAPA- Eastern Amazonia Unit), Amazonia Bank (BASA), Coordination for the Improvement of Higher Level Personnel (CAPES), the National Council for Scientific and Technological Development (CNPq), and Jari Celulose S. A. Company.

杂志排行

Journal of Forestry Research的其它文章

- A commentary review on the use of normalized difference vegetation index (NDVI) in the era of popular remote sensing

- Reconciliation of research on forest carbon sequestration and water conservation

- A theory to link relationships of stand volume, density, mean diameter and height in forestry data

- A new model for predicting the total tree height for stems cut-to-length by harvesters in Pinus radiata plantations

- Comparative performances of new and existing indices of crown asymmetry: an evaluation using tall trees of Eucalyptus pilularis(Smith)

- Tree mortality and biomass loss in drought-affected forests of East Texas, USA