Dielectric, Ferroelectric and Piezoelectric Properties of Pb(In1/2Nb1/2)O3-Pb(Ni1/3Nb2/3)O3-PbTiO3 Ternary Ceramics near Morphotropic Phase Boundary

2021-01-05GUOLinQIAOXianjiLIXiuzhiLONGXifaHEChao

GUO Lin, QIAO Xianji, LI Xiuzhi, LONGXifa, HE Chao

Dielectric, Ferroelectric and Piezoelectric Properties of Pb(In1/2Nb1/2)O3-Pb(Ni1/3Nb2/3)O3-PbTiO3Ternary Ceramics near Morphotropic Phase Boundary

GUO Lin1,2, QIAO Xianji2, LI Xiuzhi2, LONGXifa2, HE Chao2

(1. College of Chemistry and Materials Science, Fujian Normal University, Fuzhou 350117, China; 2. Key Laboratory of Optoelectric Materials Chemistry and Physics, Fujian Institute of Research on the Structure of Matter, Chinese Academy of Sciences, Fuzhou 350002, China)

Lead-based complex perovskite ferroelectric materials have been widely used as electromechanical sensors, actuators, and transducers. Among them, Pb(Ni1/3Nb2/3)O3-PbTiO3(PNN-PT) based solid solution has been drawn much attentions of scientists for its excellent dielectric and piezoelectric properties near morphotropic phase boundary (MPB) region. However, the relatively high dielectric loss andlow Curie temperature near MPB region limited its application in high temperature and high power devices. In this work, Pb(In1/2Nb1/2)O3(PIN) was introduced into PNN-PT ceramics for improving their electrical properties and Curie temperature. The ternary ferroelectric ceramicsPb(In1/2Nb1/2)O3-Pb(Ni1/3Nb2/3)O3-PbTiO3were successfully prepared by a two-step synthesis process. All samples exhibited pure perovskite phase without any secondary phase. The structure transferred from rhombohedral to tetragonal phase with increasing PT content. The MPB phase diagram of ternary system at room temperature was established based on XRD results. The values of Curie temperature were improved significantly after PIN added into PNN-PT system. Importantly, the introduction of PIN into PNN-PT system can effectively reduce dielectric loss and conductivity. The ceramics in the MPB region exhibited excellent properties. 0.30PIN-0.33PNN-0.37PT ceramic was found to have optimal properties with33=417 pC/N,C=200 ℃,′= 3206,tan=0.033,r=33.5 μC/cm2andc=14.1 kV/cm at room temperature, respectively. The Curie temperature and piezoelectric coefficient were improved while dielectric loss and conductivity were reduced after the introduction of PIN into PNN-PT. The enhancements of piezoelectric properties and high Curie temperature make this ternary system a promising material for high power and high temperature transducer applications.

ferroelectric ceramics; morphotropic phase boundary; Curie temperature; piezoelectric properties

Lead-based complex perovskite ferroelectric materials Pb(B1,B2)O3-PbTiO3(B1=Mg2+, Zn2+, Ni2+, Sc3+, In3+, Lu3+, …, B2=Nb5+, Ta5+, W6+, …) have been widely used as electromechanical sensors, actuators, and transducers[1-2]. These systems near the morphotropic phase boundary (MPB) display outstanding piezoelectric and dielectric properties[3-4]. As a typical relaxor ferroelectrics, Pb(Ni1/3Nb2/3)O3-PbTiO3(PNN-PT) have attracted great attention due to its excellent dielectric constant (> 4000) and piezoelectric coeffiecient (33450 pC/N) nearMPB region[5-6]. On this basis, PNN-based binary and ternary systems, such as Pb(Ni1/3Nb2/3)O3-PbTiO3(PNN-PT)[7],Pb(Mg1/3Nb2/3)-Pb(Ni1/3Nb2/3)O3-PbTiO3(PMN-PNN-PT)[8], Pb(Zn1/3Nb2/3)O3-Pb(Ni1/3Nb2/3)O3-PbTiO3(PZN-PNN-PT)[9], which exhibit excellent electrical properties near the MPB compositions, have been reported. Although PNN- PT binary system has outstanding electrical properties, it has some drawbacks. Fistly, the relatively low electric polarization intensity and high leakage current induced by the variable valence of Ni ions, following inferior piezoelectric coefficients[10]. Secondly, PNN-PT binary system exhibit relatively low Curie temperature near MPB region (120 ℃), which limit its application in high temperature[7-8,11]. Therefore, the addition of other component with high Curie temperature to PNN-PT system can improve electrical properties and Curie temperature, such as Pb(Lu1/2Nb1/2)O3-Pb(Ni1/3Nb2/3)O3-PbTiO3(PLN-PNN-PT), Pb(Ni1/3Nb2/3)O3-PbHfO3-PbTiO3(PNN-PH-PT) and Pb(Ni1/3Nb2/3)O3-Pb(Sc1/2Nb1/2)O3-PbTiO3(PNN-PSN-PT).These ternary systems have been confirmed to have high Curie temperature and excellent piezoelectric properties[12-14].

As a member of Pb(B1,B2)O3system, Pb(In1/2Nb1/2)O3(PIN) has Curie temperature of about 90 ℃[15]. Furthermore, the solid solution of (1–)PIN-PT near its MPB exhibits high Curie temperatureC~ 300 ℃ and excellent piezoelectric properties (33=395 pC/N)[16-18]. For above purposes, the introduction of PIN into PNN-PT system may improve its Curie temperature and piezoelectric properties, and reduced conductivity. Therefore, in present work, PIN was introduced into the PNN-PT system to form a ternary system PIN-PNN-PT. Structure, MPB diagram, electrical properties of PIN-PNN-PT were investigated.

1 Experimental

Pb(In1/2Nb1/2)O3-(1––)Pb(Ni1/3Nb2/3)O3-PbTiO3(= 0.10, 0.30, 0.50) ceramics were prepared using a two- step synthesis process and raw materials of PbO, In2O3, NiO, Nb2O5and TiO2. First, the precursors of B-site ions were prepared using the columbite or wolframite method. InNbO4(IN) was calcined according to the stoichiometric proportions at 900 ℃ for 4 h, and NiNb2O6(NN) was calcined at 1000 ℃ for 6 h. Second, IN, NN, PbO, TiO2were mixed and calcined at 800–850 ℃ for 2 h with addition of 4mol% PbO for compensating its evaporation during sintering. Third, the calcined powders were mixed with 5wt% polyvinyl alcohol as binder and then pressed into pellets. After burning out the binder at 550 ℃ for 2 h, the pellets were sintered at 1050–1150 ℃ for 2 h in a sealed Al2O3crucible to obtain the desired ceramics.

For structural analysis, the sintered samples after being pulverized into powder were examined by X-ray diffraction technique with CuKα radiation (MiniFlex II, Rigaku, Japan). A scanning electron microscope (JSM- 6700F, JEOL Tokyo, Japan) was used to investigate the morphology and microstructure of the ceramics. The dielectric properties were analyzed using a computer- controlled Alpha-A broad band dielectric/impedance spectrometer (Novocontrol, GmbH, Germany), with an AC signal of 1.0 V (peak-to-peak) applied. An aix-ACCT2000 analyzer (=4 Hz) was used to display the ferroelectric hysteresis loops at room temperature. All samples were poled at 90 ℃ for 15 min in silicone oil immersed in silicone oil using a DC electric field which was 1.5 times higher than coercive field. The piezoelectric coefficients33were measured using a quasi-static33meter (Institute of Acoustics, CAS, model ZJ-4AN, China)

2 Results and discussion

2.1 Structural analysis

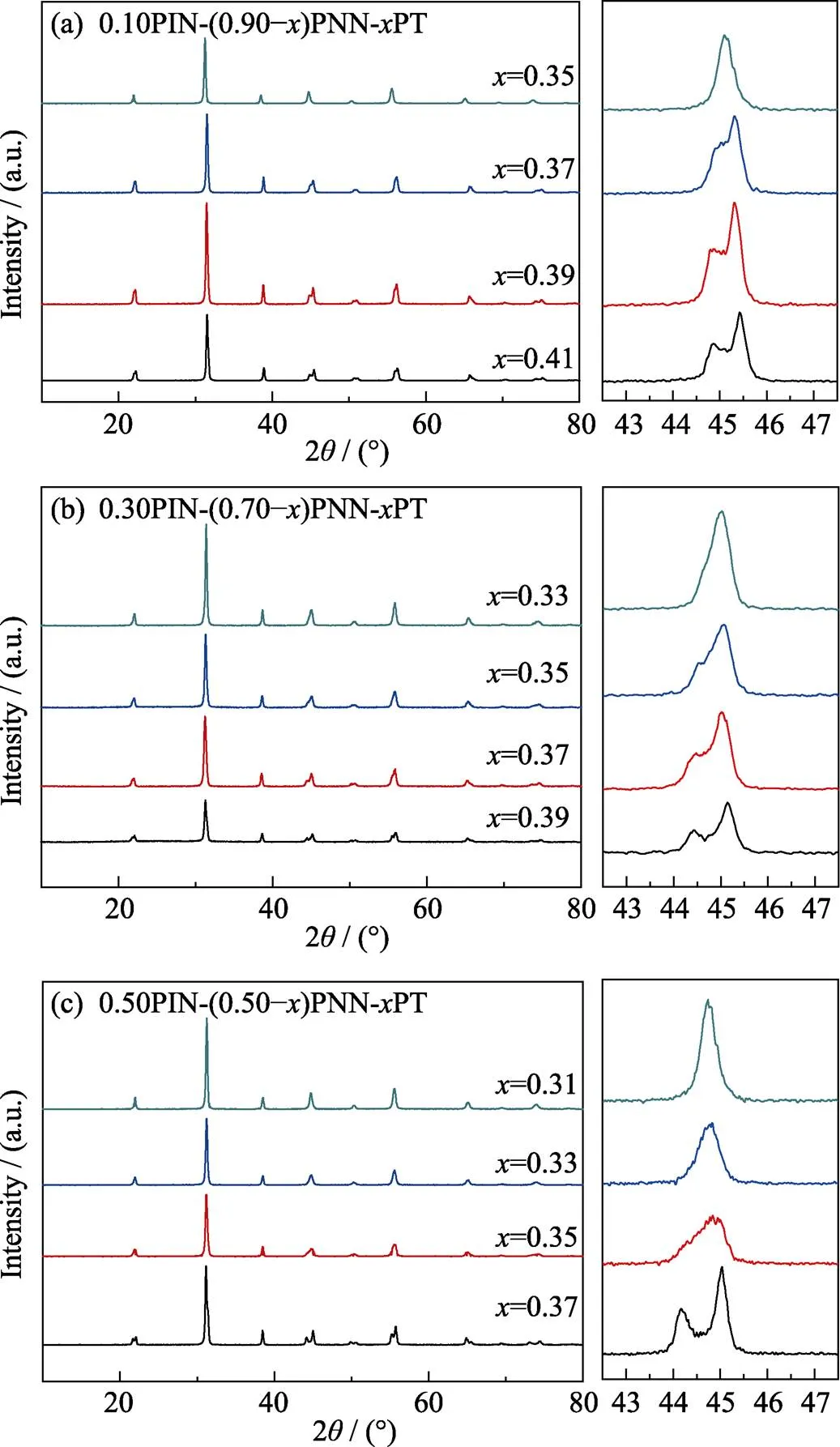

The XRD patterns of 0.10PIN-(0.90–)PNN-PT (0.35, 0.37, 0.39 and 0.41), 0.30PIN-(0.70–)PNN-PT (0.33, 0.35, 0.37 and 0.39) and 0.50PIN-(0.50–)PNN-PT (0.31, 0.33, 0.35 and 0.37) are shown in Fig. 1. All samples exhibit pure perovskite phase without any secondary phase. It can be observed that the structure of the ceramics samples is transferred from rhombohedral to tetragonal phase with increasing PT content according to the XRD patterns of (200)/(002) reflections around 2=45°, identifying one peak in rhombohedral phase and two peaks in tetragonal phase.

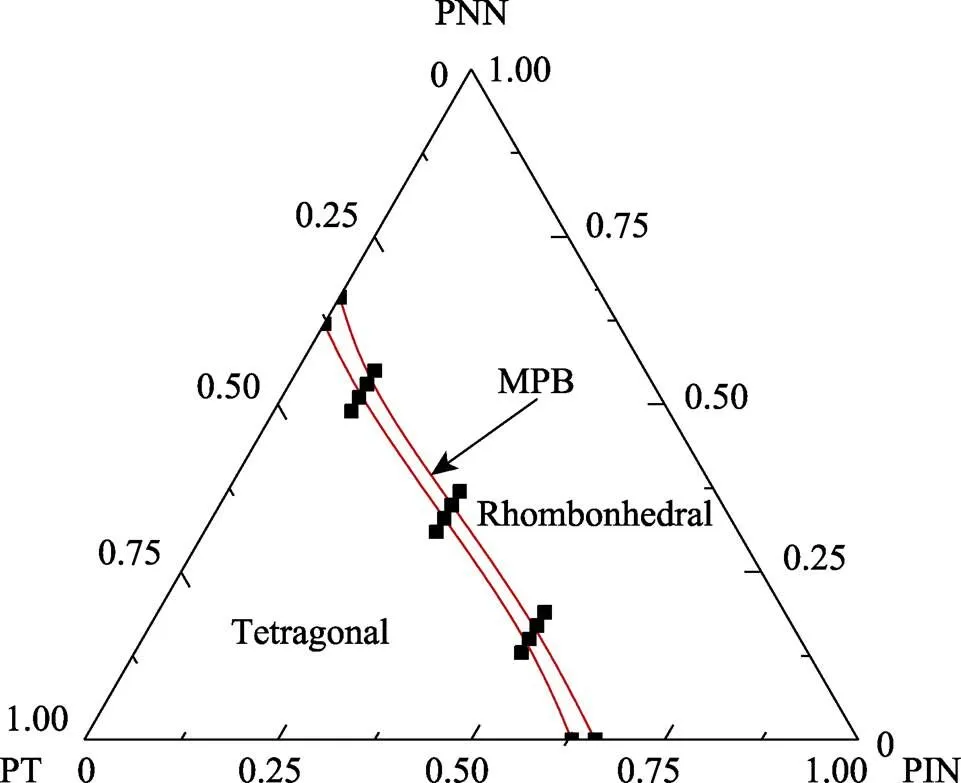

The MPB was determined to be at0.37–0.39, 0.35–0.37, 0.33–0.35 for 0.10PIN, 0.30PIN and 0.50PIN series, respectively. According to the XRD results, the MPB phase diagram of PIN-PNN-PT ternary system at room temperature was delimited as shown in Fig. 2.

Fig. 1 XRD patterns and enlarged patterns of (200)/(002) reflections of PIN-PNN-PT ceramics at room temperature

(a) 0.10PIN-(0.90–)PNN-PT; (b) 0.30PIN-(0.7–)PNN-PT; (c) 0.50PIN-(0.5–)PNN-PT

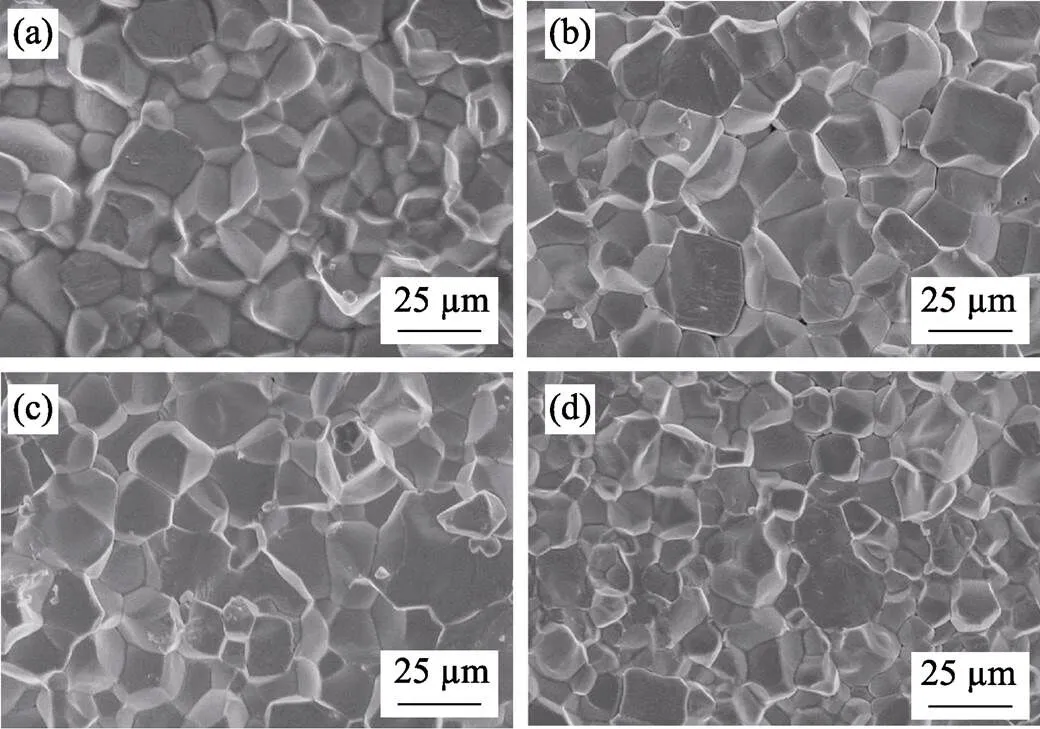

SEM micrographs of fracture surface of selected 0.10PIN-(0.90–)PNN-PT ceramics are showed in Fig. 3, indicating high density and few pore. In addition, it was found that the average grain size vary slightly for samples with different contents of PNN.

2.2 Dielectric properties

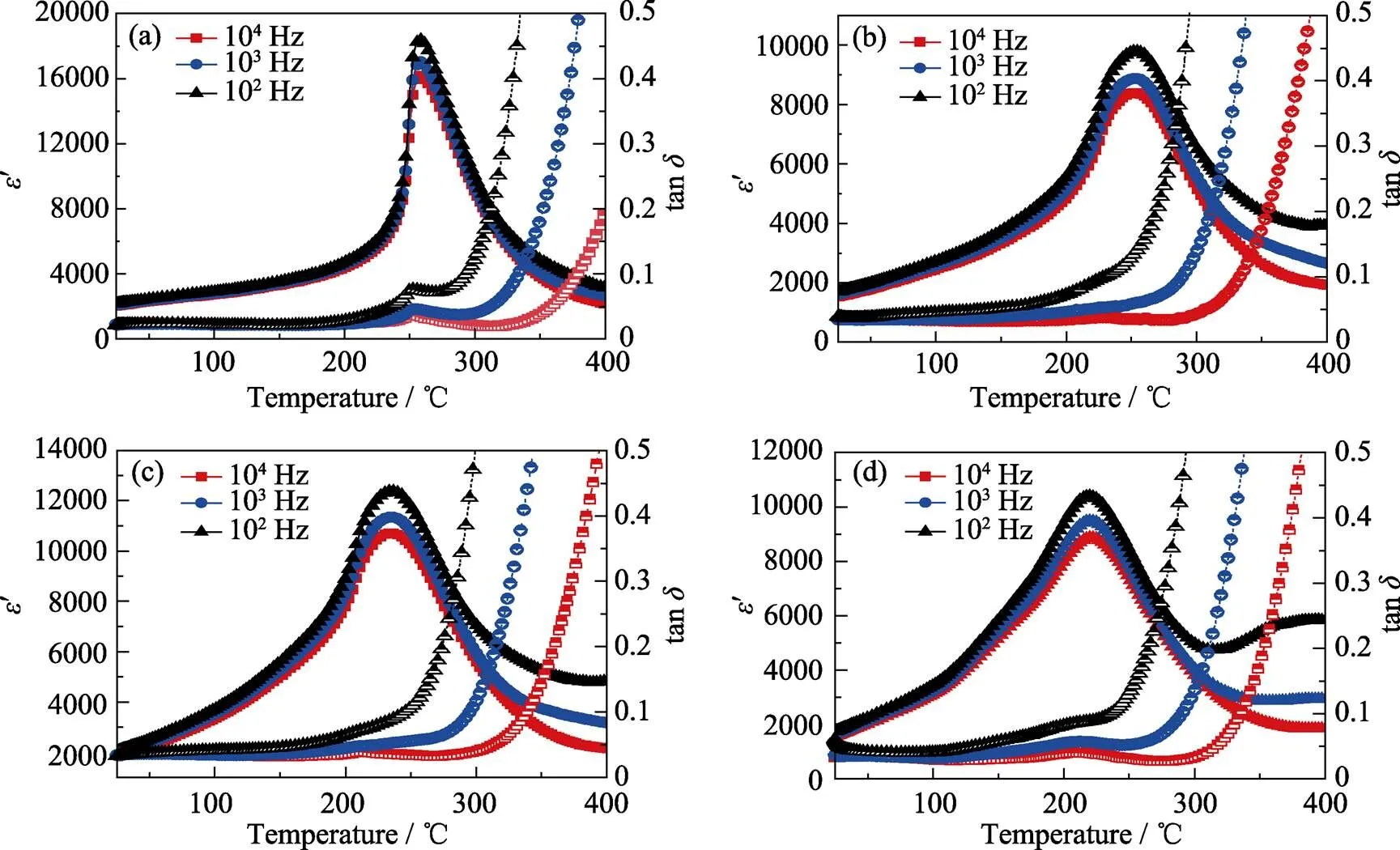

The temperature dependence of dielectric constant (΄) and dielectric loss (tan) of 0.50PIN-(0.50–)PNN-PT are shown in Fig. 4. It can be seen that the Curie temperatureCincreases with increasing PT content. The values ofCare improved significantly compared with PNN-PT binary systems[6]. In addition, the Curie temperatureCisindependentof frequency for 0.50PIN-(0.50–)PNN-PT, indicating normal ferroelectric behavior. The dielectric loss increased significantly when temperature above the Curie temperature, which was caused by leakage conductance loss.

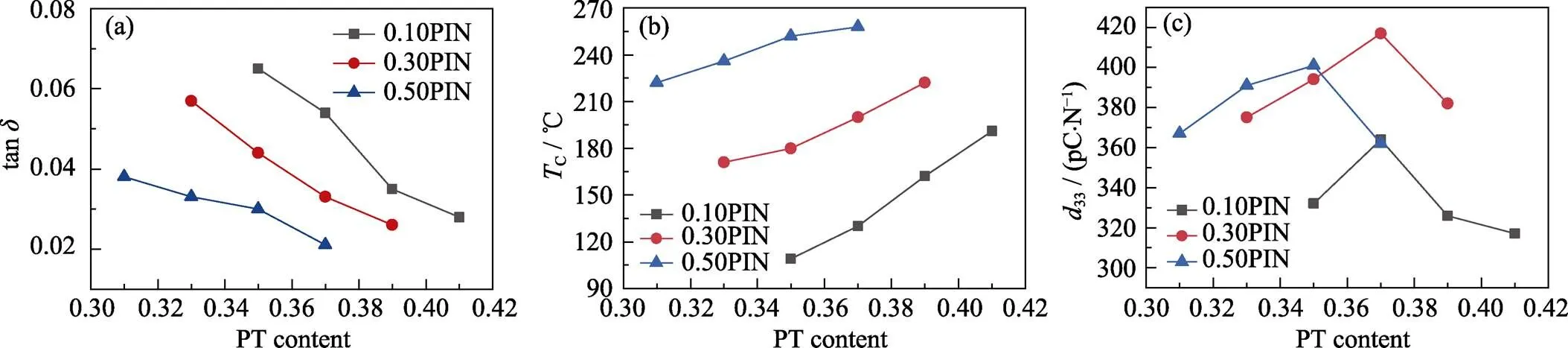

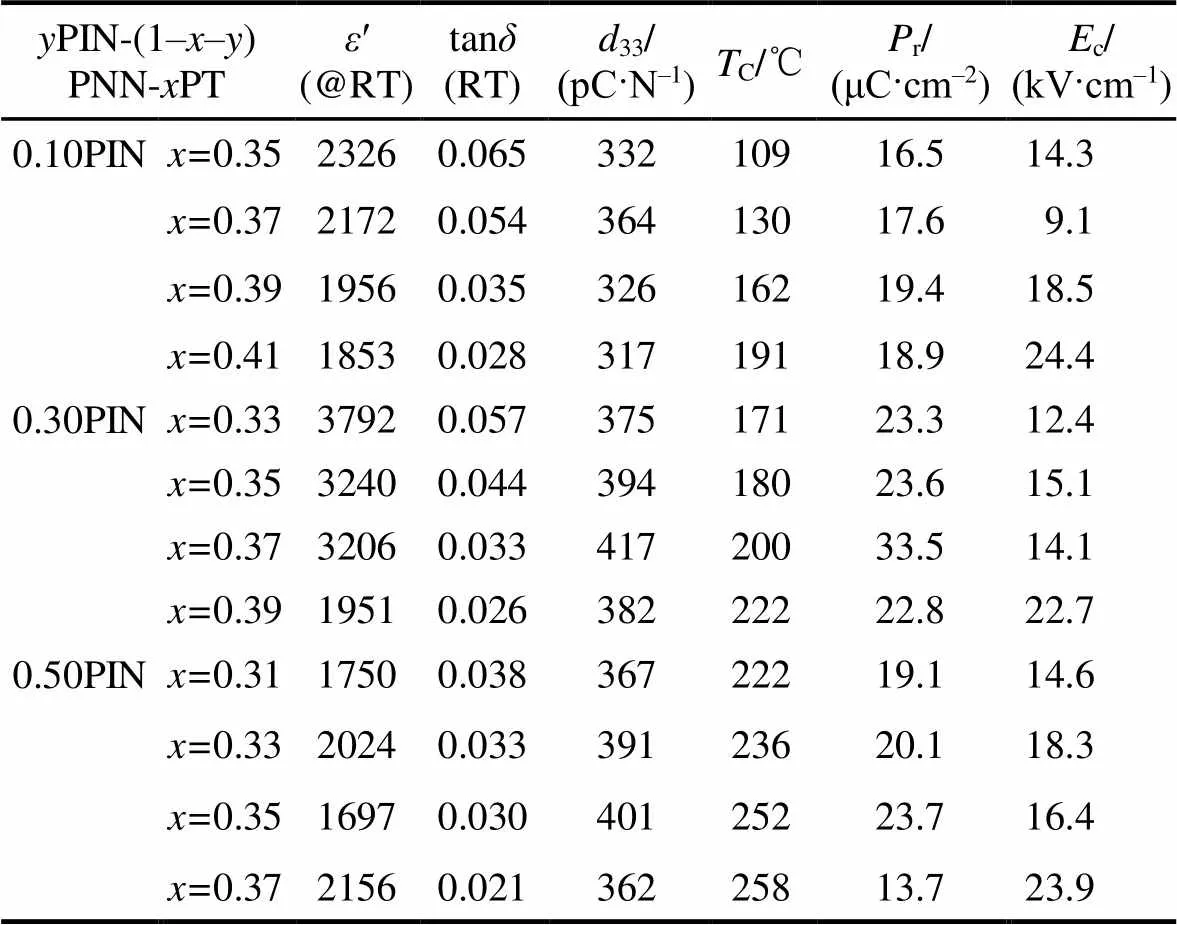

Besides, as shown in Fig. 5(a), the values of tandecrease with increasing PIN level, indicating that the introduction of PIN into PNN-PT system can effectively reduce dielectric loss and conductivity, which is a shortcoming of PNN-PT. The Curie temperatureCas a function of PT contents is displayed in Fig. 5(b). The Curie temperaturesCincrease abruptly from 109 to 191 ℃ for 0.10PIN series, from 171 to 222 ℃ for 0.30PIN series and from 221 to 228 ℃ for 0.50PIN series with increasing PT, respectively. Detailed parameters of dielectric properties measured at 1 kHz are listed in Table 1.

Fig. 2 MPB region of PIN-PNN-PT ternary system at room temperature

Fig. 3 SEM micrographs of fracture surface of 0.10PIN-xPNN-yPTceramics

(a) 0.10PIN-0.49PNN-0.41PT; (b) 0.10PIN-0.51PNN-0.39PT; (c) 0.10PIN-0.53PNN-0.37PT; (d) 0.10PIN-0.55PNN-0.35PT

Fig. 4 Temperature dependence of dielectric constant (e΄) and dielectric loss (tanδ) of 0.50PIN-(0.50-x)PNN-xPT ceramics

(a) 0.50PIN-0.13PNN-0.37PT; (b) 0.50PIN-0.15PNN-0.35PT; (c) 0.50PIN-0.17PNN-0.33PT; (d) 0.50PIN-0.19PNN-0.31PT

Fig. 5 (a) tanδ, (b) TC and (c) d33 as a function of PT contents for yPIN-(1–x–y)PNN-xPT ceramics.

2.3 Piezoelectric properties

Fig. 5(c) shows piezoelectric constant33as a function of PT content for the PIN-PNN-PT ternary ceramics. It is clearly observed that with increasing PT content, the piezoelectric constant33increases initially, reaching the maximum value at MPB region, and then decreases. The values of33vary from 317 to 364 pC/N for 0.10PIN series, from 375 to 417 pC/N for 0.30PIN series, from 362 to 401 pC/N for 0.50PIN series. The optimal electrical properties appear in the MPB composition of 0.30PIN-0.33PNN-0.37PT with the33417 pC/N. Detailed33of all samples were listed in Table 1.

2.4 Ferroelectric properties

The ferroelectric hysteresis loops of the PIN-PNN-PT ceramics were characterized as shown in Fig. 6, exhibiting well-saturated loops. The value of remnant polarization (r) and coercive field (c) of PIN-PNN-PT ceramics are displayed in Table 1. With increasing PT content, the remnant polarizationrwas found to increasefirstly, reaching the maximum at MPB composition, and then decrease, which is caused by the coexistence of rhombohedral and tetragonal phases at the MPB region. On the contrary, the coercive fieldcwas found to decrease at first, reaching the minimum at MPB region, and then increase with increasing of PT content, which was due to that free energy profile flatten at MPB region and then the reduced energy barrier causes the polarization easy to switch[19-21].

3 Conclusions

In conclusion, the PIN-PNN-PT ternary ceramics with compositions near MPB region were synthesized using a two-step method and characterized by X-ray diffraction,dielectric, ferroelectric and piezoelectric measurements. The MPB region of the ternary system were obtained. The optimized composition was found to be the composition of 0.30PIN-0.33PNN-0.37PT with the33417 pC/N,C200 ℃,′=3206, tan0.033,r33.5 μC/cm2andC14.1 kV/cm. The PIN-PNN-PT ternary ferroelectric ceramics had the advantage of PIN-PT and PNN-PT, shows larger piezoelectric performance, higherCand lower dielectric loss than those of PNN-PT ceramics, makes it a potential candidate utilize in transducer and actuator applications.

Table 1 The values of ε′, tanδ, d33, TC, Pr and EC of yPIN-(1–x–y)PNN-xPT ternary ceramics

0.10PIN, 0.30PIN and 0.50PIN indicate the=0.10, 0.30 and 0.50, respectively, inPIN-(1––)PNN-PT

Fig. 6 Ferroelectric hysteresis of (a) 0.10PIN-xPNN-yPT, (b) 0.30PIN-xPNN-yPT, and (c) 0.50PIN-xPNN-yPT ceramics

[1] HAERTLING G H. Ferroelectric ceramics: history and technology., 1999, 82(4): 797–818.

[2] RANDALL C A, BHALLA A S. Nanostructural-property relations in complex lead perovskites., 1990, 29(2): 327–333.

[3] SHEN D Q, HE C, LONG X F,. Preparation and characterization of (1–)Pb(Lu1/2Nb1/2)O3-PbTiO3binary ferroelectric ceramics with high Curie temperature., 2012, 84: 1–4.

[4] PARK S E, SHROUT T R. Ultrahigh strain and piezoelectric behavior in relaxor based ferroelectric single crystals., 1997, 82(4): 1804–1811.

[5] BORMANIS K, KALLAEV S N, OMAROV Z V,. Heat capacity and dielectric properties of the PNN-PT ferroelectric ceramics., 2012, 436: 49–53.

[6] PAN Z, CHEN J, XING X R,Both electric field and temperature independent behavior of piezoelectric property of Pb(Ni1/3Nb2/3)O3-PbTiO3., 2015, 61: 448–452.

[7] BORMANIS K, KALLAEV S N, KALVANE A,. Heat capacity and dielectric properties of the PNN-PT ferroelectric ceramics., 2012, 436: 49–53.

[8] CHEN Y, ZHANG X W, PAN J S. Study of the structure and electrical properties of PMN-PNN-PT ceramics near the morphotropic phase boundary., 2006, 16(2): 109–114.

[9] FANG B J, SUN R B, IMOTO H,. Phase transition, structural and electrical properties of Pb(Zn1/3Nb2/3)O3doped Pb(Ni1/3Nb2/3)O3- PbTiO3ceramics prepared by solid-state reaction method., 2009, 70(5):893–899.

[10] SUN C T, XUE D F. Study on the crystallization process of function inorganic crystal materials., 2014, 44: 1123–1136.

[11] YE Y, YU S H, ZHOU L M,. A polyethylene glycol-assisted route to synthesize Pb(Ni1/3Nb2/3)O3-PbTiO3in pure perovskite phase.,2009, 480(2): 510–515.

[12] QIAO X J, HE C, LONG X F,. Preparation, structure, and electric properties of the Pb(Lu1/2Nb1/2)O3-Pb(Ni1/3Nb2/3)O3-PbTiO3ternary ferroelectric system ceramics near the morphotropic phase boundary., 2017, 702: 458–464.

[13] TANG H, ZHANG M F, ZHANG S J. Investigation of dielectric and piezoelectric properties in Pb(Ni1/3Nb2/3)O3-PbHfO3-PbTiO3ternary system., 2013, 33(13/14): 2491–2497.

[14] ICHINOSE N, NATSUME S, YAMASHITA Y. Dielectric and piezoelectric properties of Pb(Sc1/2Nb1/2)O3-Pb(Ni1/3Nb2/3)O3-PbTiO3ternary ceramic materials., 1999, 19(6/7): 1139–1142.

[15] JI W, YAO K, BHATIA C S,Epitaxial ferroelectric 0.3Pb(In1/2Nb1/2)O3-0.38Pb(Mg1/3Nb2/3)O3-0.32PbTiO3thin films grown on (110)-oriented MgO substrates., 2015, 597: 193–196.

[16] YASUDA N, SHIBUYA S. Ferroelectricity in disordered Pb(In1/2Nb1/2)O3., 1989, 1(51): 10613–10617.

[17] LI T, LONG X F. High-performance ferroelectric solid solution crystals: Pb(In1/2Nb1/2)O3-Pb(Zn1/3Nb2/3)O3-PbTiO3., 2014, 97(9): 2850–2857.

[18] LI T, HE C, LONG X F. Phase diagram and properties of highC/R-TPb(In1/2Nb1/2)O3-Pb(Zn1/3Nb2/3)O3-PbTiO3ferroelectric ceramics., 2013, 96(5): 1546–1553.

[19] LI F, ZHANG S J, SHROUT T R,. Local structural heterogeneity and electromechanical responses of ferroelectrics: learning from relaxor ferroelectrics., 2018, 28(37): 1801504.

[20] DAMJANOVIC D. Contributions to the piezoelectric effect in ferroelectric single crystals and ceramics.,2005, 88(10): 2663–2676.

[21] LI F, CHEN L Q, ZHANG S J,Ultrahigh piezoelectricity in ferroelectric ceramics by design., 2018, 17(4): 349–354.

三元陶瓷Pb(In1/2Nb1/2)O3-Pb(Ni1/3Nb2/3)O3-PbTiO3准同型相界附近组分的介电、铁电和压电性能

郭霖1,2, 乔显集2, 李修芝2, 龙西法2, 何超2

(1. 福建师范大学 化学与材料学院, 福州 350117; 2. 中国科学院 福建物质结构研究所, 光电材料化学与物理重点实验室, 福州 350002)

铅基复合钙钛矿铁电材料广泛应用于机电传感器、致动器和换能器。二元铁电固溶体Pb(Ni1/3Nb2/3)O3- PbTiO3(PNN-PT)由于其在准同型相界(MPB)区域具有优异的压电、介电性能而备受关注。然而较大的介电损耗和较低的居里温度限制了其在高温高功率器件方面的应用。本研究通过引入Pb(In1/2Nb1/2)O3(PIN)作为第三组元改善PNN-PT的电学性能, 提高其居里温度; 通过两步法合成了MPB区域的三元铁电陶瓷Pb(In1/2Nb1/2)O3- Pb(Ni1/3Nb2/3)O3-PbTiO3(PIN-PNN-PT), 研究了其结构、介电、铁电和压电性能。制备的所有组分陶瓷具有纯的钙钛矿结构。随着PT含量的增加, 陶瓷结构从三方相转变为四方相。通过XRD分析得到了室温下PIN-PNN-PT体系的MPB相图。体系的居里温度由于PIN的加入得到了很大的提高, 更重要的是PIN的引入降低了PNN-PT体系的介电损耗和电导。MPB处的组分展现出了优异的电学性能, 室温下, 性能最优组分为0.30PIN-0.33PNN-0.37PT:33=417 pC/N,C=200 ℃,′= 3206, tan=0.033,r=33.5 μC/cm2,C=14.1 kV/cm。引入PNN-PT的PIN第三组元使得体系的居里温度和压电性得到提高的同时降低了的介电损耗和电导率, 因此, PIN-PNN-PT三元铁电陶瓷在高温高功率换能器等方面具备一定的应用潜力。

铁电陶瓷; 准同型相界; 居里温度; 压电性能

TQ174

A

2020-01-20;

2020-02-20

Science and Technology Project of Fujian Province (2018H0044, 2019H0052)

GUO Lin(1995–), male, Master candidate. E-mail: guolin@fjirsm.ac.cn

郭霖(1995–), 男, 硕士研究生. E-mail: guolin@fjirsm.ac.cn

HE Chao, professor. E-mail: hechao@fjirsm.ac.cn

何超, 研究员. E-mail: hechao@fjirsm.ac.cn

1000-324X(2020)12-1380-05

10.15541/jim20200042

猜你喜欢

杂志排行

无机材料学报的其它文章

- An Injectable Composite Bone Cement Based on Mesoporous Borosilicate Bioactive Glass Spheres

- A Layered Uranyl Coordination Polymer with UV Detection Sensitivity, Stability, and Reusability

- 原位聚合三维陶瓷骨架增强全固态锂电池电解质

- WO3纳米花的热处理晶格调控及WO3/CdS/α-S异质结的构筑

- 共挤出法制备双层中空纤维陶瓷复合膜

- Stable Zirconium Carbide Fibers Fabricated by Centrifugal Spinning Technique