Influence of wettability of shaly sandstone on rock electricity parameters

2020-09-23ZHAOYongqiangPANBaozhiSIZhaoweiandLINFawu

ZHAO Yongqiang, PAN Baozhi, SI Zhaowei and LIN Fawu

1. College of Geo-Exploration Science and Technology, Jilin University, Changchun 130026, China;2. Petro China Jidong Oil Field Company, Tangshan 063000, China

Abstract: It has been found that the existence of chlorite and illite will lead to the rock wettability of oil affinity. Chlorite and illite are developed in shaly sandstone of Yingcheng Formation in Longfengshan area, the saturation index n of 7 rock samples is very high, with the highest of 14.57, whereas the cementation index m is low. The X-ray diffraction of clay and whole rock analysis of 7 shaly sandstone samples are carried out, and the relationship between chlorite and illite content vs. m and n is established. It is concluded that the low m value and high n value are caused by the wettability of rock. In order to verify the influence of wettability on the parameters of rock electricity, this paper discusses the method of making artificial shaly sandstone and the control of wettability. This study provides certain reference for determining the saturation model of shaly sandstone and improving the logging interpretation accuracy of shaly sandstone reservoirs.

Keywords: wettability; rock electricity parameters; chlorite; illite; shaly sandstone

0 Introduction

The shaly sandstone in Longfengshan area has complex pore structure, strong heterogeneity, high bound water content and low porosity and permeability. In this paper, the rock electricity experiment is carried out on the shaly sandstone samples of a block in Longfengshan area. It is found that the saturation indexnvalue of some rock samples is greater than that of the normal shaly sandstone of other blocks in the study area, and the cementation indexmvalue is less than that of other blocks. In order to find out the reason, whether chlorite and illite developed in shaly sandstone in the study area are related to this has been studied.

In order to study the relationship between clay minerals as well as their contents, and the electrical parametersmandn, X-ray diffraction experiments were carried out on 7 rock samples to obtain the contents of various clay minerals in the rock. The correlation analysis between the electrical parametersm,nand the content of clay minerals showed that the contents of chlorite and illite were closely related to the electrical parametersmandn.

According to the experimental results, it is suggested that the existence of illite and chlorite may lead to the lipophilicity of the rock, which directly affects the magnitude of the rock electrical parameters of shaly sandstone. It has taken a long time to understand the wettability of rocks. Early scholars thought that all the underground oil-bearing strata are strongly water-wet, but large number of oilfield data and laboratory research later indicated that many reservoirs are not strongly water wet. There are three types of homogeneous wettability of rocks, namely, water wettability, neutral wettability and oil wettability.

In order to further determine that the largernvalue and the smallermvalue of rock samples in the study area are caused by the oil wet properties of these two clay minerals, it is necessary to increase the number of experimental samples and conduct measurement research. However, it is difficult to obtain natural core, and the actual coring process is complex, difficult and at high cost. Therefore, it is of great significance to study the influence of clay minerals on wettability by making artificial cores, of which the pore structure, porosity, permeability, clay minerals and content are in line with the actual formation.

In the late 20th century, China began to study the manufacturing of artificial core. The acid and alkaline resistance, capillary pressure curve and oil-water relative permeability curve of artificial rock samples made by Tang (1994) are basically similar to those of natural rock samples, which are ideal artificial rock sample for oil displacement comparison experiment. Liang (2008) systematically studied the influence of the main factors such as sand size ratio, binder, pressure and time on the physical parameters of artificial core. Yuetal. (2006a) designed the permeability experiment of 5 factors-5 levels for the pure sandstone artificial core by using the orthogonal experiment. The first 4 of the 5 factors refer to the different particle sizes of sand, and the last factor refers to the content of cement. 5 level refer to 5 different levels determined by each factor. The design of mixed shaly sandstone artificial core includes orthogonal test design of pure sandstone artificial core, design of dispersed shaly sandstone and design of layered clay. Xiongetal. (2018) discussed the physical characte-ristics, percolation characteristics, manufacturing methods and influencing factors of physical characte-ristics of artificial core. Based on the laboratory mea-surement data of seven natural rock samples, combined with the manufacturing of artificial shaly sandstone and the measurement of its wettability and conductivity, this paper demonstrates the relationship between the wettability and conductivity of shaly sandstone in the study block, providing a new way for logging evaluation of reservoirs different wettability.

1 Influence of clay on conductivity of shaly sandstone

The conductivity of rock refers to the ability of rock to conduct current, which is expressed by resistivityR. Through the resistivity logging method to study the conductivity of reservoir, the resistivity of rock is used to determine the oil-bearing property of the formation and calculate the oil and gas saturation quantitatively. Therefore, the study of rock resistivity and its influencing factors is the basis of calculating oil and gas saturation.

1.1 Geoelectric parameters m and n

Archie formula is an empirical formula for pure sandstone (Archie, 1942), which is still the theoretical basis for reservoir saturation logging interpretation up to now. Equations (1) and (2) are the expression of Archie's formula when the rock is full of water and oil and gas, respectively:

(1)

(2)

In the formula,R0andRtare the resistivity of the rock when it is full of water or oil, respectively,Fis the formation factor,RWis the formation water resistivity,φis the porosity,Iis the increasing rate of resistivity,SWis the water saturation,aandbare the lithology coefficient, usually taken as 1.0,mandnare the cementation index and saturation index, respectively, usually called the rock electrical parameter. For most sandstone formationsm=n=2.

According to equations (1) and (2), Equation (3) is obtained:

(3)

Equation (3) is the most basic formula for calculating water saturation in reservoir logging evaluation. Although the formula is mainly applicable to pure sandstone without clay, it is often used to determine the geoelectric parameters in the stratum with low content of shale (clay and fine silt). It can be seen from Equation (3) that bothmandnwill affect the calculation results ofSW. It is the basis to determine the parameters of rock electricity correctly, which is us-ually obtained through the measurement of rock conductivity experiment. The electrical parameters of rock are usually related to the pore structure and clay content of rock.

The wettability of rock mainly affects the distribution of pore fluids (oil and water), and the fluid in the pore plays a leading role in the conductivity of rock, so the wettability is closely related to the resistivity of rock. When there is multiphase fluid (oil, gas and water) in the pore, the wettability has more influence on the rock resistivity, which often leads to the change of the rock electrical parameters.

1.2 Analysis of influence of clay on m value

The porosity and other parameters of seven shaly sandstone samples in a block of Longfengshan area were measured after being pretreated by oil washing and salt washing. According to Equation (1), the rock electrical parametermis obtained. The content of various clay minerals was obtained by X-ray diffraction analysis. The correlation between the content of different clay minerals and the cementation indexmis analyzed. It is found that the content of chlorite and illite has obvious correlation withmvalue (Fig.1), while kaolinite and montmorillonite have no correlation. It can be seen from Fig.1 that the value ofmdecreases with the increase of the content of illite and chlorite.

Fig.1 Relationship between m value and clay content of seven shaly sandstone samples

1.3 Analysis of influence of clay on n value

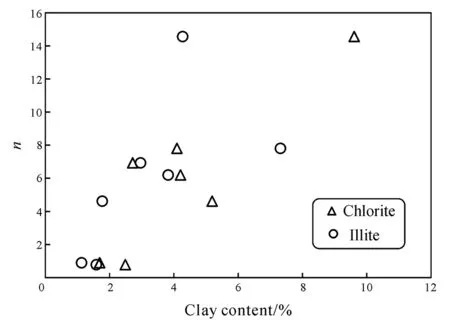

The saturation index n of rock sample is obtained by Equation (2). It is found that the content of chlorite and illite has the strongest correlation withnvalue (Fig.2). It can be seen from Fig.2 that thenvalue of the rock sample shows an upward trend with the increase of clay mineral chlorite and illite content.

Fig.2 Relationship between n value of rock sample and different clay content

1.4 Influence of rock wettability on rock electrical parameters

Wettability refers to the tendency of certain fluid to expand or adhere to the solid surface when there are multiphase fluids in the pores at the same time. Rock wettability refers to the dispersion of liquid on the rock surface under the action of molecules, depending on the interfacial tension between rock and pore fluid and the adsorption of polar substances on the surface of rock (Wangetal., 2006). In oil and gas reservoirs, wettability refers to the interaction between liquids (crude oil and water) and reservoir rocks (Jietal., 2009).

The existing research results show that some clay minerals can adsorb crude oil, which makes the rock show oil wettability. After washing oil and salt, the rock sample still retains its lipophilic nature, which leads to the deviation of the measurement results from the normal values, that is, thenvalue is higher and themvalue is lower. Trantham and Clampitt (1977) analyzed the rocks with strong oil affinity, and found that chlorite caused the wettability of rock samples to retain the original lipophilic nature even after oil washing and salt washing.

The shaly sandstone measured in this paper ge-nerally contains chlorite up to 10%, which may be an important reason for the variation ofmandnof rock electrical parameters due to the oil wetness. The correlation between illite content andm,nindicates that illite also has the wetting property similar to chlorite.

In order to further verify the above viewpoint, more rock sample measurement should be carried out. However, it is difficult to obtain natural rock samples. A way to solve the problem is to make artificial rock samples whose pore structure, porosity, permeability, clay minerals and contents are in line with the actual formation conditions.

2 Manufacturing of artificial shaly sandstone

Artificial shaly sandstone is based on the manufacturing of pure sandstone, which is mainly quartz sandstone with cement. Liang (2008) prepared artificial sandstone cores at different temperatures and pressures, and analyzed the influencing factors of porosity and permeability of artificial rocks, including quartz sand size ratio, pressure, temperature, time and cement content. Zhouetal. (2017) prepared artificial sandstone by pressing, cementing quartz sand and epoxy resin. The permeability, porosity simulation of artificial sandstone is highly matching the natural core. It is concluded that the main factors affecting permeability are the grain size of quartz sand, pres-sing pressure and content of cement.

2.1 Selection of cementing agent

Three kinds of cementing agents were used in artificial cores: epoxy resin, aluminum phosphate and silicate cementing agent. The use of resin cementing is the earliest, but the pore structure is not consi-dered. The sandstone cemented by epoxy resin has highly matched heterogeneity, permeability and poro-sity of simulated formation, and good repeatability of experiment. Tang and Lu (1986) used aluminum phosphate cemented artificial core. The aluminum phosphate gelling agent was heated and boiled, then cooled, and mixed with quartz sand and clay in proportion. It is proved that aluminum phosphate is a good cementitious agent for artificial core. Xuetal. (2011) developed new environmental friendly silicate composite cement through the environmental protection, proportioning and curing experiments of three kinds of cement (resin, phosphate and silicate). The cement is non-toxic and odorless, and the rock has the characteristics of pore connectivity and high strength after solidification.

2.2 Manufacturing of shaly sandstone

Shale is composed of fine silt and clay minerals, and the properties of fine silt and sandstone skeleton are the same, so the purpose of manufacturing shaly sandstone artificial core is mainly to add clay mine-rals.

2.2.1 Method of adding clay minerals

Clay minerals can be added by adsorption and laminating method:

Adsorption method: Firstly, the cement and quartz sand are mixed together and put into the evacuation device for evacuation. Then the clay and water are fully mixed to form a suspension. The mixture of the suspension is used to saturate the cement and quartz sand. After the surface of quartz sand is fully contacted with the clay, the redundant suspension is removed, and the operation is repeated to measure the mass of the remaining clay to obtain the clay content in full contact with quartz sand. Finally, the mixture of quartz sand, cement and clay mineral are filled into the mold, and the clay-bearing artificial core is obtained by pressure drying.

Laminating method: After heating and diluting, the cement is mixed with quartz sand to form uniform sand with cement; subsequently the clay mineral is screened and fully mixed with the prepared sand with cement; finally, the mixture is filled into the mold, pressurized and dried to obtain the clay-bearing artificial core. When adding clay, make sure that the ad-ded clay mineral adheres to the surface of the cementitious agent surrounding quartz sand (Yu,etal., 2006a).

2.2.2 Manufacturing process

For the manufacturing process of shaly sandstone, Tangetal. (1998) started the study first, but did not classify the clay, just under the control of temperature to ensure that the clay lattice does not change, so that the clay does not lose its original characteristics. Such artificial core is relatively loose, which is not suitable for low porosity and low permeability reservoirs. Then Yuetal. (2006a) systematically studied the manufacturing of shaly sandstone. According to the difference of clay properties, clay is divided into dispersed clay and layered clay. The sands are divided into different grades based on particle sizes. The composite membrane method is used to add clay minerals, and the orthogonal experiment is used to obtain artificial cores with different properties. The manufacturing process mainly includes material preparation, such as, rubber film sand material and clay film sand material preparation, compaction and cementation, heating and finalization etc. Hanetal. (2007) studied a new method of dispersing shaly cementation by orthogonal experiment. The characteristics of artificial core and natural shaly sandstone are basically similar. Fig.3 is the manufacturing effect diagram of artificial shaly sandstone. The outer layer of sand is attached by clay mineral, the cement is attached between clay mineral and sand.

Fig.3 Manufacturing effect diagram of artificial shaly sandstone (Han et al., 2007)

3 Wettability and electrical parameters of artificial shaly sandstone

The surface wettability of artificial core is related to the surface properties of solid particles and cement. Quartz sand and epoxy resin are hydrophilic after high temperature, so pure sandstone core is usually hydrophilic. The addition of clay minerals and the study of wettability are helpful to simulate physical properties of reservoirs. Zhang (2016) made artificial shaly sandstone for Xingshugang oilfield in Daqing (Fig.4). By comparing the relative permeability and saturation, it is confirmed that the wettability of artificial core and natural core is consistent.

There are many methods to measure the wettability of rocks, such as contact angle-, Amott wettability index- and USBM wettability index methods. The contact angle method is easy to operate and is intuitive, but easy to be affected by wetting lag, surface roughness and heterogeneity of samples. Amott's wettability index method can be used to measure the average wettability of core from strong hydrophilicity to strong lipophilicity, but the measurement process is complex and the sensitivity to intermediate wettability is not high. USBM method is simple and efficient, and highly sensitive to the wetting in the middle of the core, but it needs to use high-speed centrifuge, which is easy to change the micro pore structure of the core (Zhao, 2017). Considering the above characteristics, the Amott wettability index method is used to measure the wettability index of artificial coreIA(Wen, 2018):

IA=IW-IO

(4)

Fig.4 Artificial shaly sandstone samples (Zhang, 2016)

IWis the water wet index,IOis the oil wet index. By controlling the amount of wetting agent, the wetting index of artificial core at different doses is obtained (Fig.5). The wetting index changes from water wet to oil wet when the wetting control agent is about 10 g.

Fig.5 Cross plot of wetting control agent dosage and wetting index (Wen, 2018)

Yuetal. (2006b) saturated the artificial core with salt solution of different mineralization degrees, and measured the conductivity, in order to study the conductivity law of the mixed shaly sandstone. The results are shown in Table 1. It can be seen that the porosity of four rock samples is basically the same. According to Archie equations (1) and (2), Fig.6a and Fig.6b are obtained. According to Fig.6a, the conductivity of shaly sandstone is affected by the salinity of solution, and the slope of straight line in the figure ism. In Fig.6a, the clay content of No.12 and No.14 rock samples is basically the same, while theC0--CWslope of No.14 rock samples is slightly lower. The slope ofI--SWin Fig.6b representsn, and the slopes of No.12 and No.14 rock samples are obviously different, which is mainly caused by different clay types, resulting in changes in rock wettability, i.e., the increase ofnand the decrease ofmare caused by the increase of wettability.

Table 1 Basic parameters of 4 artificial rock samples (Yu et al., 2006b)

(a) C0-CW cross-plot of artificial rock samples of layered shaly sandstone; (b) I-SW cross-plot of artificial rock samples of layered shaly sandstone.Fig.6 Cross plot of C0-CW and I-SW of shaly sandstone (Yu et al., 2006b)

The measurement of the rock electricity of the artificial shaly sandstone shows that the rock samples with largernvalue and lowermvalue are mainly affected by the wettability of the rock.

4 Conclusions

(1) According to the results of rock electricity experiment and clay mineral X-ray diffraction analysis of shaly sandstone in Longfengshan area, it is found that the content of chlorite and illite has obvious linear relationship with the rock electricity parametersmandn.

(2) The development of chlorite and illite makes the shaly sandstone samples in the study area show oil affinity wettability after oil washing and salt washing, which leads to the decrease ofmand the increase ofnin the measurement of rock electricity.

(3) The wettability of shaly sandstone can be controlled by adding different types of clay mineral and adjusting clay content during the manufacturing of artificial shaly sandstone.

(4) The influence of wettability on conductivity is very obvious. The oil wet shaly sandstone is characterized by low cementation index and high saturation index.

杂志排行

Global Geology的其它文章

- Determining water well sites based on electrical structure in Taobei District of Baicheng

- Structure analysis of shale and prediction of shear wave velocity based on petrophysical model and neural network

- U-Pb-Hf isotopes of Neoarchean Shuimowan tonalites in southern margin of North China Craton: constraints on petrogenesis

- Spatial pattern analysis of forest landscape in Changbai Mountain

- Method for extracting angle-domain common image gathers in Kirchhoff beam migration

- Controlling factors of sphalerite and galena deposition in Baiyinnuo’er skarn deposit, Inner Mongolia, China