异速对辊式玉米秸秆粉碎还田装置设计与试验

2020-09-21李艳洁李洪文王庆杰卢彩云张振国李绍华

刘 鹏,何 进,李艳洁,李洪文,王庆杰,卢彩云,张振国,3,李绍华

·农业装备工程与机械化·

异速对辊式玉米秸秆粉碎还田装置设计与试验

刘 鹏1,何 进1※,李艳洁2,李洪文1,王庆杰1,卢彩云1,张振国1,3,李绍华4

(1. 中国农业大学工学院,北京 100083;2. 北京林业大学工学院,北京 100083;3. 新疆农业大学机电工程学院,乌鲁木齐 830052;4. 内蒙古长明机械有限公司,赤峰 024200)

针对玉米秸秆量大、韧性强,导致还田后秸秆粉碎不均匀影响后续整地和播种等问题,该研究提出了一种异速对辊及动态双支撑形式的玉米秸秆粉碎还田方式,并研制了相应的玉米秸秆还田装置,主要由捡拾粉碎单元、对辊滑切支撑单元、支撑板和机壳等组成。在异速动态双支撑条件下,通过对作业过程中玉米秸秆动力学分析和秸秆漏捡面积分析,对捡拾粉碎刀和对辊滑切支撑刀进行设计,建立了影响秸秆粉碎合格率的数学模型。以捡拾粉碎刀转速、L型甩刀折弯角、L型甩刀刃口长度和滑切支撑刀滑切角为因素,秸秆粉碎合格率为试验指标进行Box-Behnken试验。田间试验结果表明:当滑切支撑刀滑切角45°、捡拾粉碎刀转速1 700 r/min、L型甩刀刃口长度45 mm和L型甩刀折弯角40°时,玉米秸秆粉碎合格率为92.58%,与预测值误差<5%,满足国家标准要求。该研究提出的秸秆粉碎还田方式和研制的秸秆粉碎装置为玉米秸秆粉碎还田机设计和优化提供新的方案和技术支撑。

农业机械;速度;粉碎合格率;秸秆粉碎;异速;动态双支撑

0 引 言

玉米秸秆含有丰富的氮磷钾等营养元素,是宝贵的可再生生物质资源[1]。秸秆粉碎还田可以增加土壤有机质含量,改善土壤结构,增加作物产量[2-5],但是如果粉碎质量不合格,反而会影响后续播种质量,造成负面影响。

在中国,由于需要抢农时,为防止玉米秸秆堵塞播种机,从而降低播种质量,因此对玉米秸秆粉碎质量要求较高。为提高秸秆粉碎质量,相关学者围绕刀具结构、粉碎形式等方面开展了一系列研究。如章志强等设计的可调节式秸秆粉碎还田机,通过对粉碎刀、机壳等关键部件的设计,实现对秸秆的多次砍切、撕裂和揉搓[6];郑智旗等设计的动定刀支撑滑切式秸秆粉碎装置和和秸秆捡拾粉碎掩埋复式还田机,均通过粉碎定刀与高速旋转的粉碎动刀组合形成有支撑切割[7-8];张姬等设计的锯盘式玉米秸秆粉碎装置,通过差速锯齿圆盘来提高粉碎质量[9];张喜瑞等应用滑切原理优化了粉碎刀片的刀刃曲线,并设计了滑切防缠式香蕉秸秆还田机[10];张红霞等通过增加定刀排数,提高秸秆粉碎质量[11]。贾洪雷等通过分析现有粉碎还田刀的特点,设计了一种V-L型秸秆粉碎还田刀,并确定了刀具的关键结构参数[12]。郭俊等仿鼹鼠足趾排列设计了一种旋耕-秸秆粉碎锯齿刀片[13]。Lundin和Persson研究表明在粉碎刀刃口开有锯齿有助于提高秸秆粉碎质量[14-15]。上述粉碎装置大多采用动定刀组合,虽然有利于秸秆支撑粉碎,但当定刀与动刀间距设置不合理,尤其是在秸秆量大、韧性强的情况,导致在还田作业中秸秆粉碎不均影响后续整地和播种作用。

针对在秸秆量大、韧性强,现有秸秆粉碎装置无法满足粉碎要求的问题[16],本文设计了一种针对玉米秸秆的异速对辊式玉米秸秆粉碎还田装置,拟通过对关键部件运动学和动力学分析,得到其关键参数范围;通过Box-Behnken试验,对粉碎装置不同结构参数和运动参数组合的试验结果进行分析,从而得出异速对辊式玉米秸秆粉碎还田装置的较优的参数组合,以期为玉米秸秆粉碎还田机的研究和发展提供参考。

1 装置结构及工作原理

1.1 装置结构

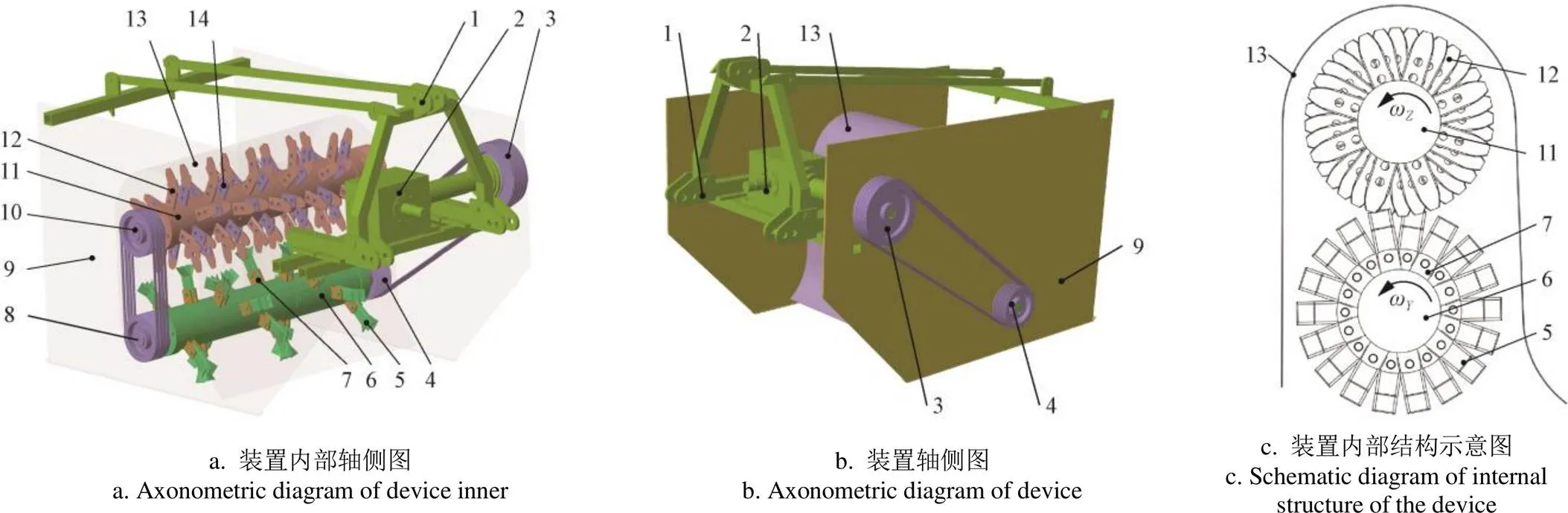

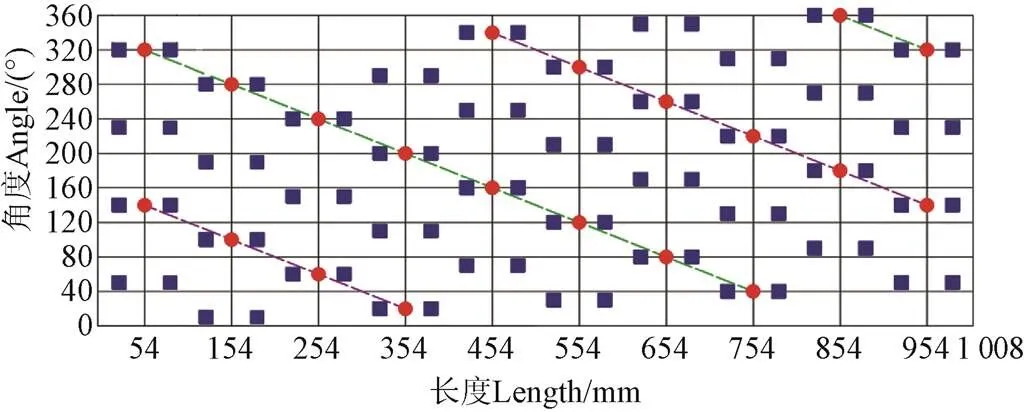

异速对辊式玉米秸秆粉碎还田装置主要由悬挂装置、传动装置、粉碎装置、支撑板和机壳组成。传动装置主要由变速箱、主带轮、捡拾粉碎刀左带轮、捡拾粉碎刀右带轮、滑切支撑刀带轮组成。粉碎装置主要包括捡拾粉碎单元和对辊滑切支撑单元,其中捡拾粉碎单元主要包括捡拾粉碎刀、捡拾粉碎刀座和捡拾粉碎刀轴;对辊滑切支撑单元主要包括滑切支撑刀、支撑刀座和滑切刀轴组成,具体结构如图1所示。

1.悬挂装置 2.变速箱 3.主带轮 4.捡拾粉碎刀左带轮 5.捡拾粉碎刀 6.捡拾粉碎刀轴 7.捡拾粉碎刀座 8.捡拾粉碎刀右带轮 9.支撑板 10.滑切支撑刀带轮 11.滑切支撑刀轴 12.滑切支撑刀 13.机壳 14.支撑刀座

1.Suspension device 2.Gearbox 3.Major belt wheel 4.Left belt wheel of chopping and collecting blade 5.Chopping and collecting blade 6.Shaft of chopping and collecting blade 7.Chopping and collecting blade holder 8.Right belt wheel of chopping and collecting blade 9.Supporting plate 10.Belt wheel of slide-cutting supporting blade 11.Blade shaft of slide-cutting supporting blade 12.Slide-cutting supporting blade 13.Shell 14.Slide-cutting supporting blade holder

注:ω和ω分别是捡拾粉碎刀和滑切支撑刀的角速度,rad·s-1。

Note: ωandωare the angular speed of the chopping and collecting blade and slide-cutting supporting blade, respectively, rad·s-1.

图1 异速对辊式玉米秸秆粉碎还田装置结构示意图

Fig.1 Structural diagram of double rollers maize stalk chopping device with different rotation speeds

1.2 工作原理及技术特点

在作业过程中,相对装置前进方向,捡拾粉碎刀和滑切支撑刀均逆时针高速转动,使得机壳内气体流速加快,从而在机壳喂入口形成负压区。在捡拾粉碎刀与和入口负压作用下,秸秆被吸入机壳内,并随捡拾粉碎刀做圆周运动。当滑切支撑刀和捡拾粉碎刀位置存在重合时,滑切支撑刀和捡拾粉碎刀同时对玉米秸秆进行砍切,并互为支撑,从而有助于对玉米秸秆切断与粉碎。滑切支撑刀转速小于捡拾粉碎刀转速,从而使得粉碎后的玉米秸秆随捡拾粉碎刀运动,并向后抛出,完成秸秆粉碎作业。因此设计的异速对辊式玉米秸秆粉碎还田装置具有以下优势:

1)异速对切,利于撕裂,增加秸秆流动性。捡拾粉碎刀和滑切支撑刀转速存在差异,但转向相同,使得捡拾粉碎刀和滑切支撑刀可对玉米秸秆施加方向相反的砍切力,有利于玉米秸秆撕裂,从而提高玉米秸秆粉碎质量和秸秆在机壳内的流动性。

2)动态双支撑,增强秸秆抗弯能力,更利于秸秆切断与粉碎。每把捡拾粉碎刀两侧均在滑切刀轴上对应安装一把滑切支撑刀,使得在粉碎玉米秸秆时,捡拾粉碎刀和滑切支撑刀互为支撑;捡拾粉碎刀和滑切支撑刀高速旋转,从捡拾粉碎刀和滑切支撑刀接触玉米秸秆表皮到切断玉米秸秆,使得捡拾粉碎刀和滑切支撑刀对玉米秸秆均处于动态双支撑状态,从而有利于玉米秸秆切断与粉碎。

3)对称双螺旋排布,有利于降低能耗。Y型粉碎刀和滑切支撑刀在粉碎刀轴上均采用正向双螺旋排布,且直刀在捡拾粉碎刀两侧对称安装,从而保证捡拾粉碎刀和滑切支撑刀在粉碎作业时一直处于动态双支撑状态,有助于降低能耗。

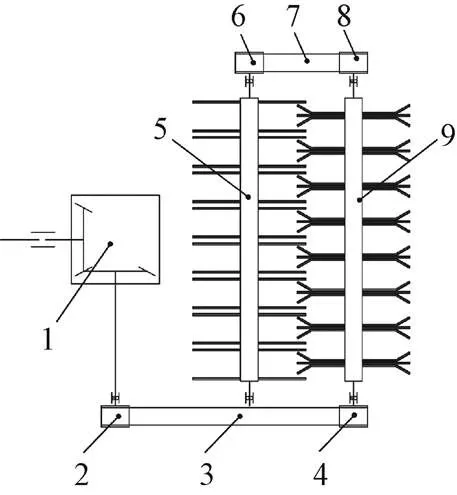

1.3 传动系统

异速对辊式玉米秸秆粉碎还田装置通过悬挂装置挂接在拖拉机后方,通过十字万向节将拖拉机动力传输到粉碎装置;随后通过变速箱、主带轮、增速皮带和捡拾粉碎刀左带轮按固定传动比将捡拾粉碎刀轴进行增速,使得捡拾粉碎刀轴达到额定转速,以满足捡拾粉碎刀捡拾和粉碎玉米秸秆的要求;之后通过滑切支撑刀带轮、降速皮带和捡拾粉碎刀右带轮按固定传动比将滑切支撑刀轴进行降速,使得滑切支撑刀和捡拾粉碎刀同向转动,以及形成对玉米秸秆动态双支撑,其动力传递示意图如图2所示。

1.变速箱 2.主带轮 3.增速皮带 4.捡拾粉碎刀左带轮 5.对辊滑切支撑单元 6.滑切支撑刀带轮 7.降速皮带 8.捡拾粉碎刀右带轮 9.捡拾粉碎单元

1.Gearbox 2.Major belt wheel 3.Belt of velocity increase 4.Left belt wheel of chopping and collecting blade 5.Double rollers chopping unit installed slide-cutting supporting blade 6.Belt wheel of slide-cutting supporting blade 7.Belt of velocity decrease 8. Right belt wheel of chopping and collecting blade 9.Chopping and collecting unit

注:PTO为拖拉机后输出轴。

Note: PTO is the rear output shaft of tractor.

图2 动力传递示意图

Fig.2 Diagram of power transfer

2 关键部件设计与参数确定

2.1 异速动态双支撑下秸秆动力学分析

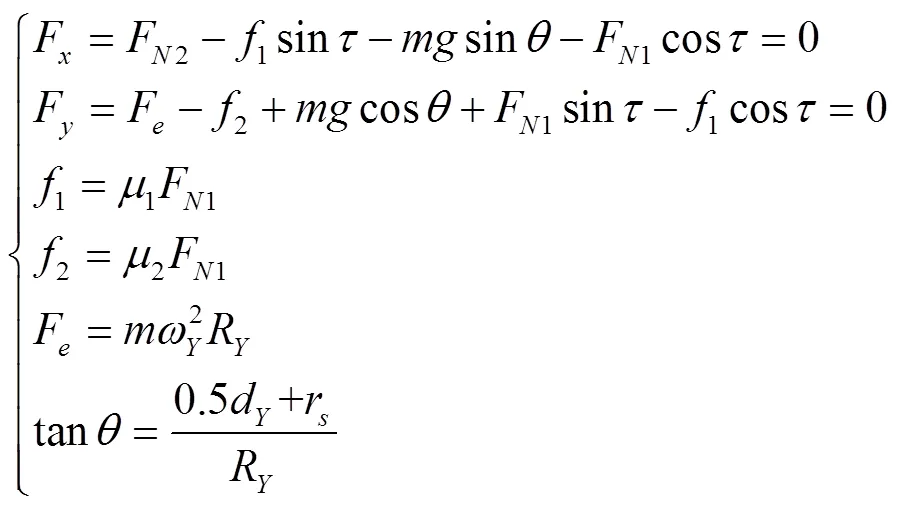

分布在地表的玉米秸秆被捡拾粉碎刀捡拾,同时玉米秸秆随捡拾粉碎刀进行转动。当捡拾粉碎刀、玉米秸秆和滑切支撑刀发生接触时,捡拾粉碎刀和滑切支撑刀同时对玉米秸秆进行砍切,而且从捡拾粉碎刀和滑切支撑刀与玉米秸秆表皮接触到玉米秸秆被切断,捡拾粉碎刀和滑切支撑刀对玉米秸秆均处于动态双支撑状态。在捡拾粉碎刀和滑切支撑刀的作用下,玉米秸秆首先受到局部塑形变形,随着捡拾粉碎刀和滑切支撑刀的转动,玉米秸秆受到弯曲和剪切变形,直至秸秆断裂。在秸秆受力过程中,由于秸秆直径相对于捡拾粉碎刀和滑切支撑刀的回转半径较小,因此在接触玉米秸秆表皮时捡拾粉碎刀和滑切支撑刀可视为处于平行位置。

秸秆受力示意图如图3所示,其中包括秸秆自身重力()、滑切支撑刀对玉米秸秆的支持力(F1)、滑切支撑刀与秸秆之间的摩擦力(1)、捡拾粉碎刀对秸秆的支持力(F2)、捡拾粉碎刀与秸秆之间的摩擦力(2)、离心力(F)。捡拾粉碎刀上的秸秆与滑切支撑刀接触后瞬间被切断,切断时间持续极短,此时秸秆依然留在捡拾粉碎刀上,并保持原有的运动状态。因此,在切断时秸秆依然保持受力平衡。以垂直于离心力F方向为轴,以离心力F方反方向为轴,以点为坐标原点,建立如图3所示的直角坐标系。

对式(1)求解可得

玉米秸秆的受力情况直接影响玉米秸秆的粉碎质量。当捡拾粉碎刀和滑切支撑刀材料确定后,则滑切支撑刀与秸秆之间的摩擦因数和捡拾粉碎刀与秸秆之间的摩擦因数为定值。因此,由式(2)可知,当滑切支撑刀滑切角在[0°,90°]区间内逐渐增大时,滑切支撑刀对玉米秸秆的支持力和捡拾粉碎刀对秸秆的支持力均随之增大;当捡拾粉碎刀的角速度逐渐增大时,滑切支撑刀对玉米秸秆的支持力和捡拾粉碎刀对秸秆的支持力均随之增大。相对于滑切支撑刀滑切角,捡拾粉碎刀角速度对捡拾粉碎刀和滑切支撑刀在玉米秸秆上的支持力影响更大。滑切支撑刀对玉米秸秆的支持力和捡拾粉碎刀对秸秆的支持力越大,越有利玉米秸秆粉碎,从而促进提升秸秆粉碎质量。

1.滑切支撑刀 2.捡拾粉碎刀 3.玉米秸秆

1.Slide-cutting supporting blade 2.Chopping and collecting blade 3.Maize stalk

注:为秸秆质量,kg;为重力加速度,9.8 m·s-2;F1为滑切支撑刀对玉米秸秆的支持力,N;1为滑切支撑刀与秸秆之间的摩擦力;F2为捡拾粉碎刀对秸秆的支持力,N;2为捡拾粉碎刀与秸秆之间的摩擦力,N;F为离心力,N;为滑切支撑刀滑切角,(°) );为在砍切玉米秸秆时捡拾粉碎刀与滑切支撑刀之间的夹角,(°) );ω和ω为角速度,rad·s-1。

Note:is mass of maize stalk, kg;is gravitational acceleration, 9.8 m·s-2;F1is the supporting force form slide-cutting supporting blade to maize stalk, N;1is the the fraction between slide-cutting supporting blade and maize stalk, N;F2is the supporting force form chopping and collecting blade to maize stalk, N;2is the fraction between chopping and collecting blade and maize stalk, N;Fis the centrifugal force, N;is the slide-cutting angle of slide-cutting supporting blade, (°) ;is the angle between chopping and collecting blade and slide-cutting supporting blade when maize stalk is chopped, (°),ωandωare angular velocity, rad·s-1.

图3 秸秆粉碎过程中受力分析

Fig.3 Stress diagram of maize stalk in chopping process

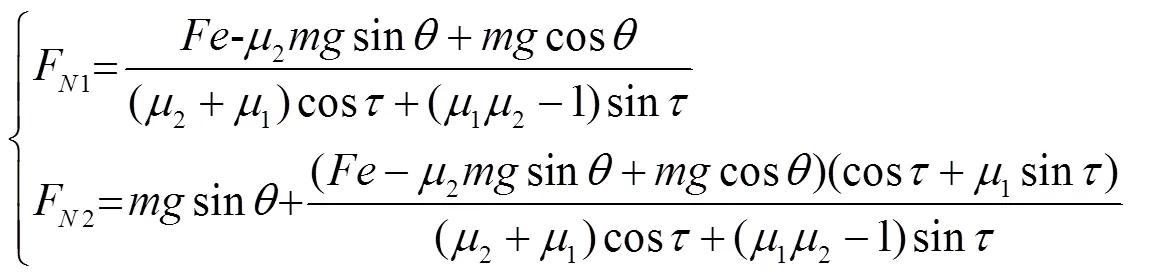

2.2 捡拾粉碎单元结构设计

捡拾粉碎单元主要包括捡拾粉碎刀、捡拾粉碎刀座和捡拾粉碎刀轴,捡拾粉碎刀座按照双螺旋排布焊接在捡拾粉碎刀轴上,捡拾粉碎刀通过销子铰接在捡拾粉碎刀座上。高速旋转的捡拾粉碎刀对地表玉米秸秆进行捡拾和粉碎,因此其结构参数直接影响着玉米秸秆的捡拾和粉碎质量。

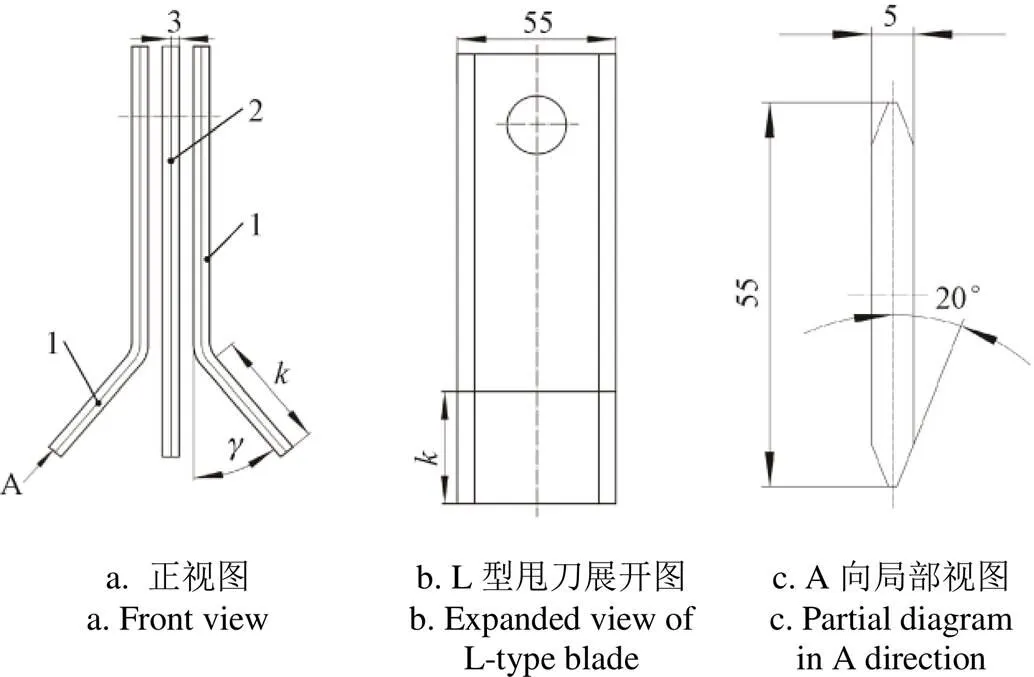

2.2.1 捡拾粉碎刀结构参数设计

捡拾粉碎刀主要由2把L型甩刀和一把直刀组成(如图4所示)。L型甩刀和直刀厚度均为5 mm,宽度均为55 mm。L型甩刀和直刀两端均开有刃口,材料均采用65 Mn,刃口进行淬火处理,以提高刀具使用寿命。研究表明[17-18],粉碎刀刃角显著影响粉碎刀切割性能,在粉碎过程中,刃角越小,粉碎刀越锋利,切割性能就越好,但是刀身越薄,在作业中越容易出现卷刃和缺口。考虑到田间环境复杂,取刃角为20°,且刃口宽度设定为3 mm。L型甩刀折弯角()和L型甩刀刃口长度()作为捡拾粉碎刀的重要结构参数,由下文运动分析和田间试验进行确定。

2.2.2 捡拾粉碎刀对秸秆漏捡面积影响分析

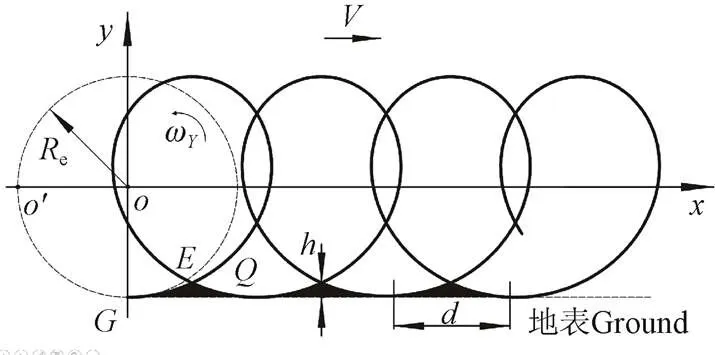

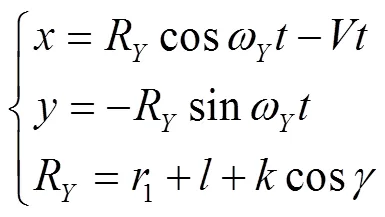

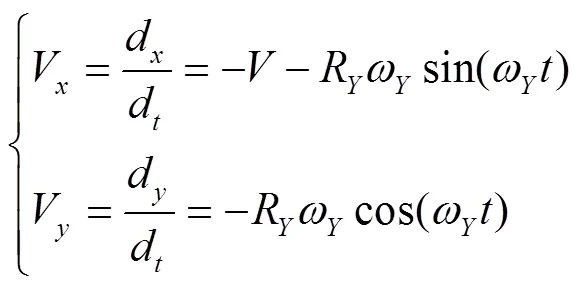

捡拾粉碎刀旋转对地表秸秆进行捡拾,低的秸秆漏捡率是保证秸秆粉碎质量的关键。作业中,捡拾粉碎刀一面旋转,一面随粉碎装置前进,所以其运动轨迹为摆线。理想状态下,捡拾粉碎刀端点的轨迹曲线与地表相切,如图5所示,以装置前进方向为轴,以竖直方向为轴,以捡拾粉碎刀轴旋转中心为坐标原点建立直角坐标系,阴影部分为秸秆漏捡区域。

1.L型甩刀 2.直刀

1.L-type blade 2.Straight blade

注:是L型甩刀刀柄长度,mm;是L型甩刀刃口长度,mm;是L型甩刀折弯角,(°)。

Note:is the blade handle length of L-type blade, mm;is the cutting edge length of L-type blade, mm;is the cutting edge bend angle of L-type blade, (°).

图4 捡拾粉碎刀结构示意图

Fig.4 Structure diagram of chopping and collecting blade

注:O’点为捡拾粉碎刀运动起始位置;RY是捡拾粉碎刀回转半径,mm;V是装置前进速度,m·s-1;h为秸秆漏捡高度,m;d为秸秆漏捡距离,m,虚线为地表位置;阴影区域GEQ为秸秆漏捡区域。

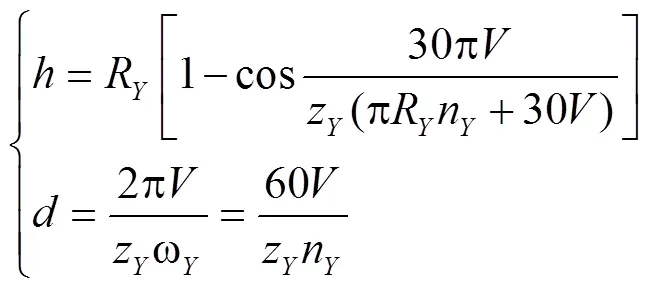

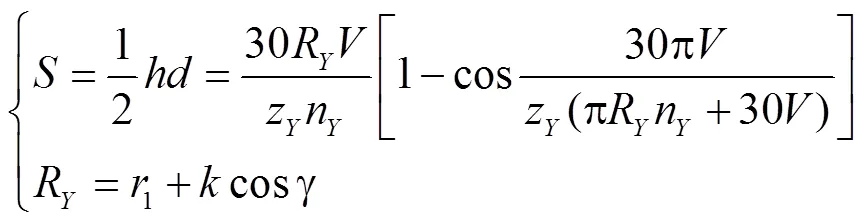

如图5所示,秸秆漏捡区域面积的大小直接影响着秸秆捡拾效率,从而影响秸秆粉碎质量。通过分析几何关系得出漏捡高度()、漏捡距离()与捡拾粉碎刀角速度、捡拾粉碎刀数量的关系。

式中z为一个圆周内的捡拾粉碎刀数量;n为捡拾粉碎刀转速,r/min。

如图5所示,秸秆漏捡区域可近似为三角形,因此,

式中为秸秆漏捡面积,mm2;1为捡拾粉碎刀座回转半径,m。

由式(4)可知,当捡拾粉碎刀座回转半径(r)、一个圆周内的捡拾粉碎刀数量(z)和装置前进速度()一定时,秸秆漏捡面积随捡拾粉碎刀转速的增大而减小;随L型甩刀刃口长度()的增大而减小;随L型甩刀折弯角()增大而增大。秸秆漏捡面积越小,越有利于提升秸秆粉碎合格率;反之则将不利于提高秸秆粉碎合格率,但捡拾粉碎刀转速对秸秆漏捡面积的影响要大于L型甩刀刃口长度和L型甩刀折弯角对秸秆漏捡面积的影响。根据实际捡拾粉碎刀结构排布和设计,L型甩刀刀刃口长度:30 mm≤≤60 mm;L型甩刀折弯角:20°≤≤60°。

2.3 对辊滑切支撑单元参数设计

对辊滑切支撑单元主要包括滑切支撑刀、支撑刀座和滑切刀轴组成。支撑刀座按照双螺旋排布焊接滑切刀轴上,滑切支撑刀通过2个螺栓固定在支撑刀座上。

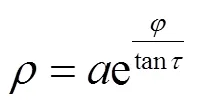

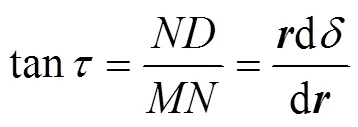

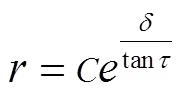

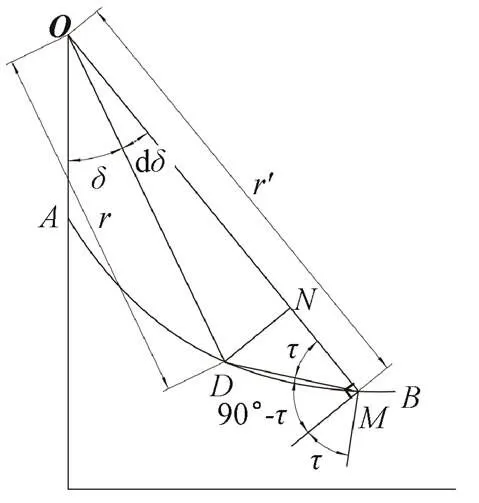

在玉米秸秆粉碎过程中,滑切支撑刀与捡拾粉碎刀形成动态双支撑,增强秸秆抗弯能力,从而更利于秸秆切断与粉碎,因此滑切支撑刀的结构参数直接影响着秸秆粉碎质量。由于直线刃刀片在切割秸秆过程中,其静态滑切角变化幅度较大,切割阻力矩变化较为迅速,功耗大[19-23]。等滑切角式粉碎刀在切割玉米秸秆方面节能效果显著[24]。根据滑切原理,滑切角应该大于摩擦角,如果滑切角越大,滑切作用越明显,但滑切角过大,则不便于加工,而且无法起到防缠效果;如果滑切角过小,滑切减阻和秸秆切断效果不明显[10]。本文选取对数螺线方程作为滑切支撑刀刃口曲线,这样可以保证滑切角大于摩擦角,便于控制滑切支撑刀刃口曲线形状,且便于加工。设滑切支撑刀刃口曲线极坐标方程为

式中为常数,为极角,(°);为极径,mm。

对式(10)变形进行积分可以得到

式中为常数。

当=0时,230 mm

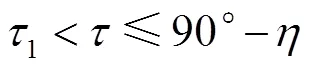

滑切支撑刀旋转前进作业时,其滑切角由静态滑切角变换为动态滑切角,为使得滑切支撑刀不发生缠草等现象,滑切支撑刀片侧刃的动态滑切角应满足[25]

式中1为秸秆滑切支撑刀片作业时,刀片任意一点的动态滑切角,(°);为玉米秸秆和滑切支撑刀的摩擦角,(°)。

注:δ是初始角度,(°);dδ是滑切支撑刀转动角度,(°);r是矢径,mm;r’ 是转动dδ后的矢径,mm;τ为滑切支撑刀的滑切角,(°);AB为滑切支撑刀刃口曲线;D为初始切割点;M为转动dθ后的切割点;N为dr在r’上的交点;O为坐标原点。

经测量玉米秸秆与钢板的摩擦角为22°~32°,本文取=30°。由式(8)知,秸秆滑切支撑刀片任意一点的静态滑切角应小于等于60°。根据滑切原理,滑切角应该大于摩擦角,因此30°<≤60°。

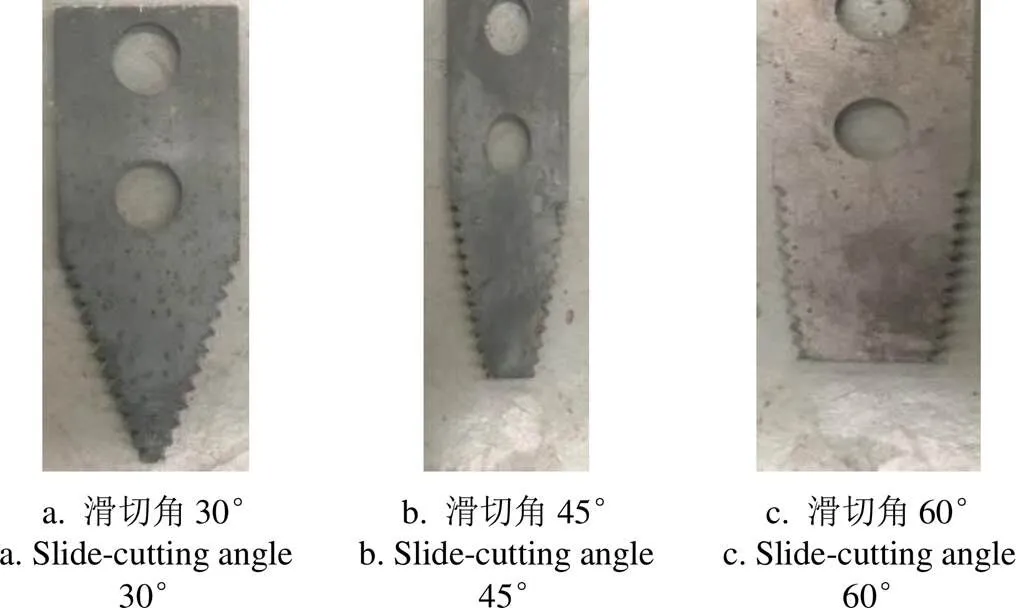

玉米秸秆是一种由维管束、纤维组织、表皮等组成的复合材料,微观结构成筛状、多孔、不均匀状态[26]。秸秆表皮具有较强的抵抗外载荷的能力,其韧性较好,不易切断[27],因此,在滑切支撑刀的刀刃上设计成锯齿形,如图7所示。

图7 带锯齿的滑切支撑刀结构示意图

2.4 捡拾粉碎单元与对辊滑切支撑单元匹配设计

捡拾粉碎单元和对辊滑切支撑单元是完成秸秆粉碎的主要部件,因此需要对粉碎装置转速以及捡拾粉碎刀和滑切支撑刀排布进行设计,以满足作业时捡拾粉碎刀和滑切支撑刀对玉米秸秆的动态双支撑。

2.4.1 粉碎装置转速确定

通过理论分析可知,随着捡拾粉碎刀和滑切支撑刀转速增大,玉米秸秆受到的支持力增大,秸秆漏捡面积而下降,从而有利于提高玉米秸秆粉碎合格率,但捡拾粉碎刀和滑切支撑刀转速增大导致还田装置功耗增大,从而增加作业成本,因此需要合理选择捡拾粉碎刀和滑切支撑刀的转速。

如图5所示,以点为捡拾粉碎刀运动起始位置,建立捡拾粉碎刀端点的轨迹运动方程。

式中和分别为捡拾粉碎刀端点位置横坐标与纵坐标。

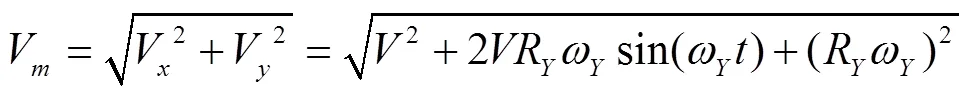

对式(9)求导可得捡拾粉碎刀端点的速度。

式中V和V分别为捡拾粉碎刀在轴方向和在轴方向的速度分量,m/s。

则捡拾粉碎刀端点的绝对速度为

式中V为捡拾粉碎刀端点绝对速度,m/s。

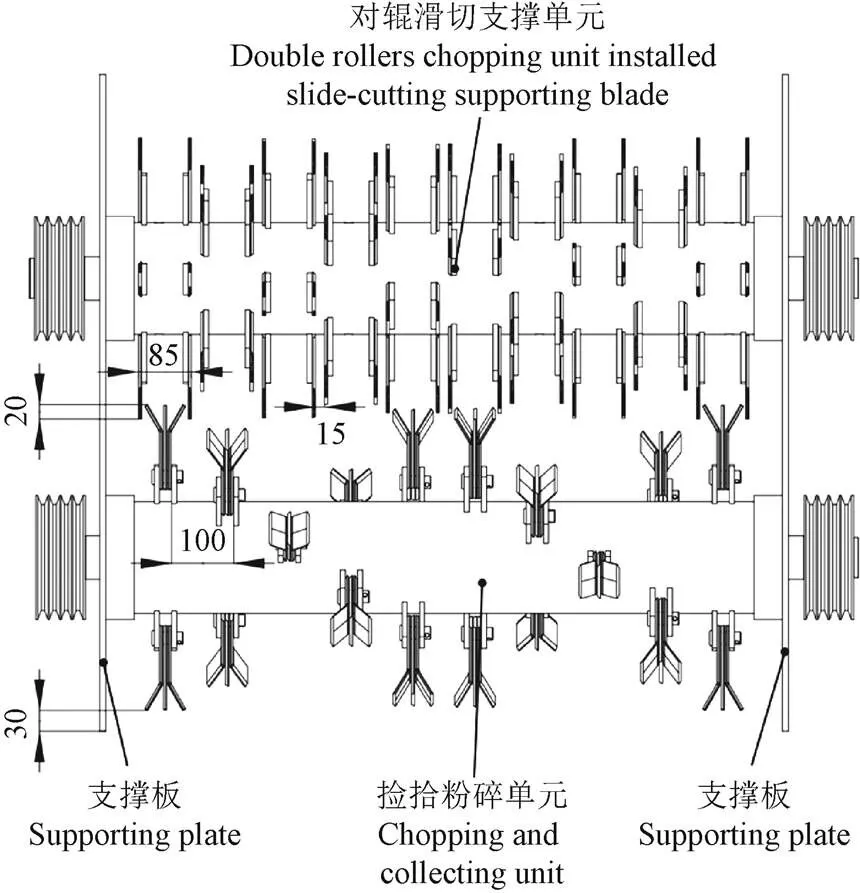

2.4.2 捡拾粉碎刀与滑切支撑刀排布

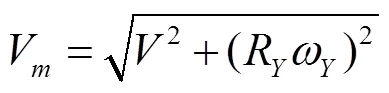

本文采用对称双螺线排布的方式排布捡拾粉碎刀和滑切支撑刀,能使粉碎刀轴受力均匀,有助于降低粉碎装置振动,提高装置作业寿命[28-29]。滑切支撑刀在滑切支撑刀轴上相对于捡拾粉碎刀两侧对称安装,从而保证捡拾粉碎刀和滑切支撑刀在粉碎作业时一直处于动态双支撑状态(如图8所示)。根据《农业机械设计手册》中粉碎刀排列密度要求[22]和异速对辊式玉米秸秆粉碎还田装置作业幅宽(1 008 mm),本文设计的捡拾粉碎刀和滑切支撑直刀数量各为10组。在径向上有2把捡拾粉碎刀和4把滑切支撑刀,因此捡拾粉碎刀数量和滑切支撑刀数量分别为20把和40把。捡拾粉碎刀和滑切支撑刀螺旋线排列展开如图8所示。

异速对辊式玉米秸秆粉碎还田装置作业幅宽为1 008 mm,轴向上捡拾粉碎刀数量为10组,因此2把捡拾粉碎刀轴向间距为100 mm。为了滑切支撑刀和捡拾粉碎刀在作业时不发生干涉,2把相邻的滑切支撑刀轴向间距分别为85 mm和15 mm,滑切支撑刀与捡拾粉碎刀在轴向最小间距为10 mm。如果滑切支撑刀与捡拾粉碎刀上下重合距离过大,则会降低滑切刀和滑切支撑刀接触玉米秸秆的线速度,从而影响玉米秸秆粉碎质量;如果滑切支撑刀与捡拾粉碎刀上下重合距离过小,则如果滑切支撑刀与捡拾粉碎刀无法对玉米秸秆形成动态支撑,从而影响粉碎质量,考虑玉米秸秆平均直径为(16.14±4.05)mm[30],滑切支撑刀与捡拾粉碎刀上下重合距离设定为为20 mm(图9)。为防止捡拾粉碎刀在高速旋转因入土而对捡拾粉碎刀轴产生冲击,设定捡拾粉碎刀离地间隙为30 mm。

注:圆点为捡拾粉碎刀安装位置,方框为滑切支撑刀安装位置。

图9 粉碎装置配合示意图

3 田间试验

3.1 试验条件

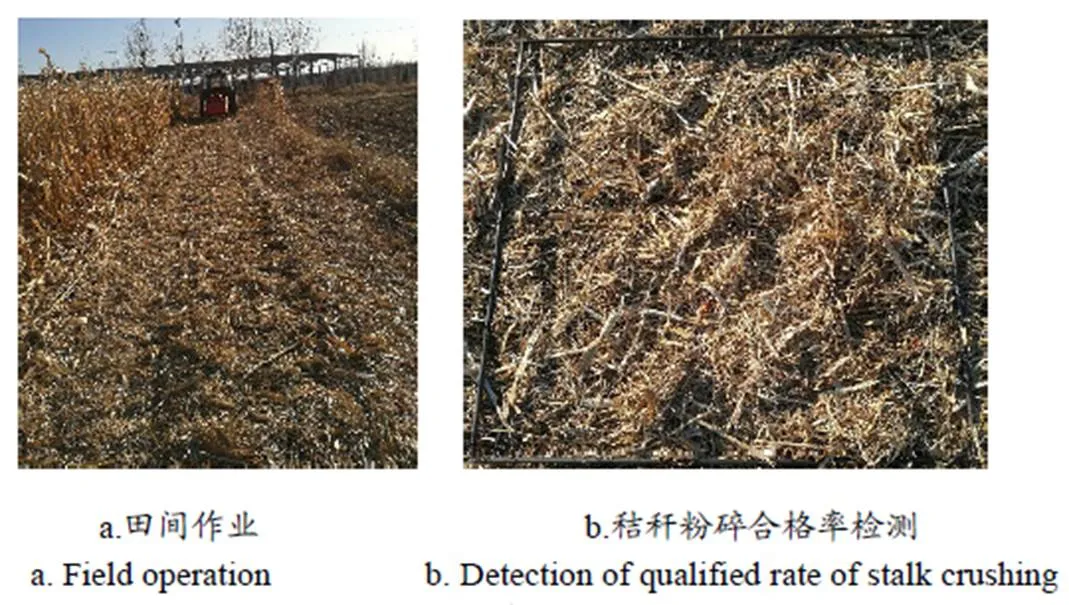

2019年11月在中国农业大学涿州科技园区保护性耕作试验田进行田间试验(如图10所示)。玉米品种为五谷631,玉米秸秆量为1.31 kg/m2,秸秆直径分布在11.2~24.8 mm之间,秸秆平均高度为2 210 mm,秸秆平均含水率为32.6%。主要仪器设备有:铁牛754拖拉机,异速对辊式秸秆粉碎装置、威衡带钩电子秤(精度:5 g)、1 m2方框等。

3.2 试验方法及结果

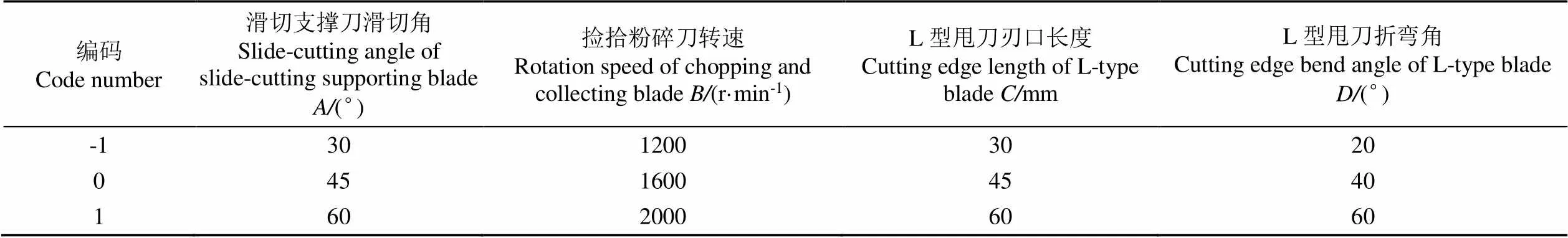

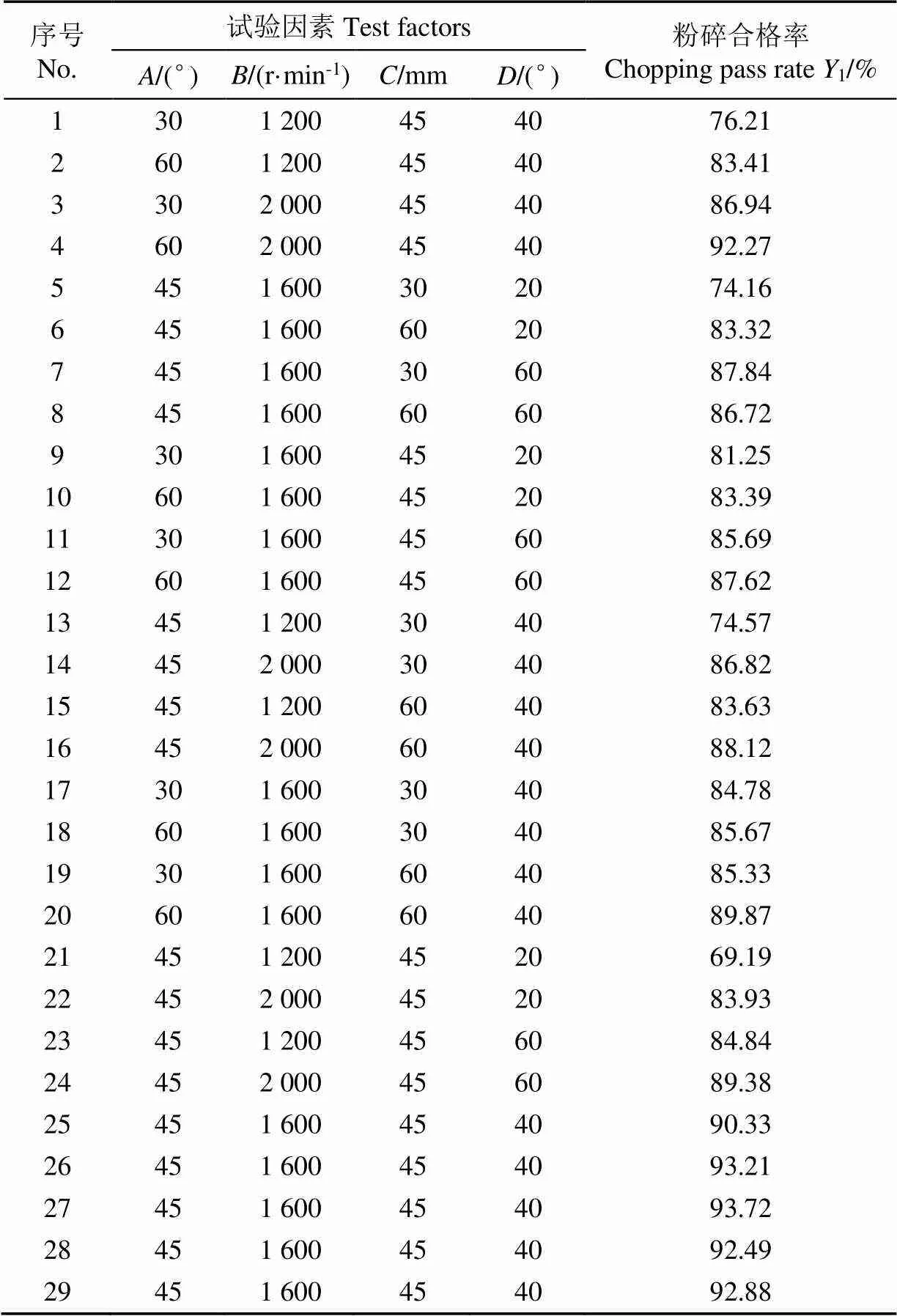

经过上文理论分析以及实际作业工况,选取L型甩刀刃口长度、L型甩刀折弯角、滑切支撑刀滑切角和捡拾粉碎刀转速为试验因素。选取以玉米秸秆粉碎合格率(1)为试验指标,采用Box-Behnken试验设计方法,进行田间试验,研究L型甩刀刃口长度、L型甩刀折弯角、滑切支撑刀滑切角和捡拾粉碎刀转速对玉米秸秆粉碎率的影响规律。其中,为保证秸秆能够充分被捡拾,L型甩刀刃口长度的试验因素水平选取为30、45和60 mm,L型甩刀折弯角的试验因素水平选取为20°、40°和60°;为保证滑切支撑刀的防缠效果和滑切作用,滑切支撑刀滑切角的试验因素水平选取为30°、45°和60°;为保证秸秆能充分粉碎,同时降低作业能耗,捡拾粉碎刀转速的试验因素水平选取为1 200、1 600和2 000 r/min。

图10 田间试验

根据GB/T24675.6—2009《保护性耕作机械秸秆粉碎还田机》进行田间试验。拖拉机前进速度保持在1 m/s,每次测试行程为20 m。在每个试验行程中,随机选取3个测试点(1 m×1 m)进行测试,收集测试点中的所有秸秆,剔除粉碎长度不合格的玉米秸秆(长度大于100 mm),并称质量、计算每个点秸秆粉碎合格率,对3个测试点的秸秆粉碎合格率求平均值。

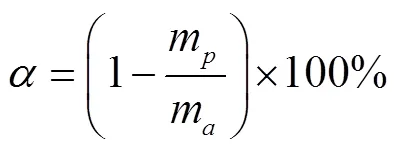

式中为秸秆粉碎合格率,%;m为测试点内长度大于100 mm玉米秸秆的质量,kg;m为测试点内玉米秸秆的总质量,kg。

通过田间试验对影响试验指标的因素进行显著性分析,根据实际需求及前文中的参考范围,对各参数组合进行优化,最终获得较优的参数组合。试验因素编码表如表1所示,试验方案及试验结果如表2所示。

表1 试验因素编码表

3.3 结果分析与回归模型建立

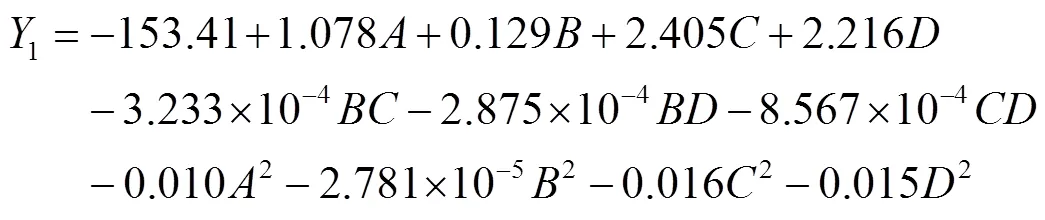

利用Design Expert 8.0.6软件对试验结果进行二次回归分析,并进行多元回归拟合,得到了以秸秆粉碎合格率1为试验指标的回归方程,并检验其显著性。

表2 试验方案与结果

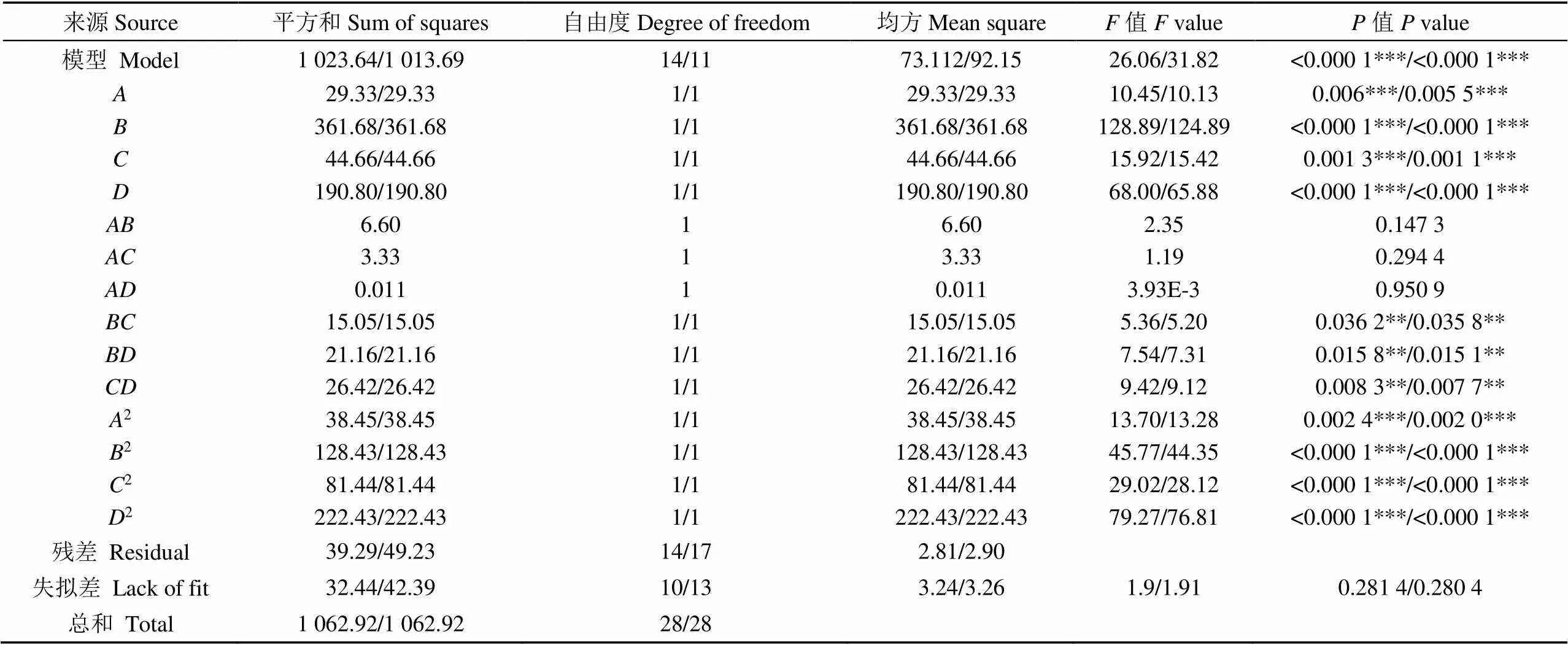

通过对试验数据的分析和拟合,秸秆粉碎合格率1方差分析如表3所示。影响试验指标秸秆粉碎合格率1的主次因素依次是捡拾粉碎刀转速、L型甩刀折弯角、L型甩刀刃口长度、滑切支撑刀滑切角。捡拾粉碎刀转速在[1 200,2 000] r/min之间,秸秆粉碎合格率呈上升趋势,但秸秆粉碎合格率在[1 200, 1 600] r/min的增长率要大于秸秆粉碎合格率[1 600, 2 000] r/min的增长率;L型甩刀折弯角在[20°,45°]时,秸秆粉碎率呈增长趋势,在[45°,60°]时,秸秆粉碎率呈下降趋势;L型甩刀刃口长度在[30°,45°]时,秸秆粉碎合格率呈上升趋势,在[45°,60°]时,秸秆粉碎率呈下降趋势;滑切支撑刀滑切角在[30°,60°]时,秸秆粉碎合格率呈上升趋势,但滑切支撑刀滑切角在[30°,50°]时的秸秆粉碎合格率增长率要大于滑切支撑刀滑切角在[50°,60°] 时的秸秆粉碎合格率增长率。滑切支撑刀滑切角、捡拾粉碎刀转速、L型甩刀刃口长度、L型甩刀折弯角、L型甩刀刃口长度与L型甩刀折弯角的交互项、滑切支撑刀滑切角的二次项2、捡拾粉碎刀转速的二次项2、L型甩刀刃口长度的二次项2、L型甩刀折弯角的二次项2对秸秆粉碎合格率1存在极其显著的影响(<0.01),捡拾粉碎刀转速和L型甩刀刃口长度的交互项、捡拾粉碎刀转速和L型甩刀折弯角的交互项对秸秆粉碎合格率1存在显著影响(0.01<<0.05),其余因素对秸秆粉碎合格率1影响不显著。将不显著的交互作用项的回归平方及其自由度并入残差项,再次进行方差分析,结果如表3所示。得到各因素对秸秆粉碎合格率1影响的回归方程。

对上述回归方程进行失拟性检验(如表3所示),=0.280 4>0.1,不显著,证明不存在其他影响指标的主要因素存在,试验指标与试验因素存在显著的二次型关系,方差分析结果准确。

表3 秸秆粉碎合格率方差分析

注:“/”后数值为剔除不显著因素秸秆粉碎合格率1方差分析结果;***表示极显著(<0.01);**表示显著(<0.05)。

Note: The number after “/” is the variance analysis results of stalk chopping pass rate after removing the insignificant factors; *** is the very significant (<0.01); ** is the significant (<0.05).

3.4 秸秆粉碎合格率双因素交互作用分析

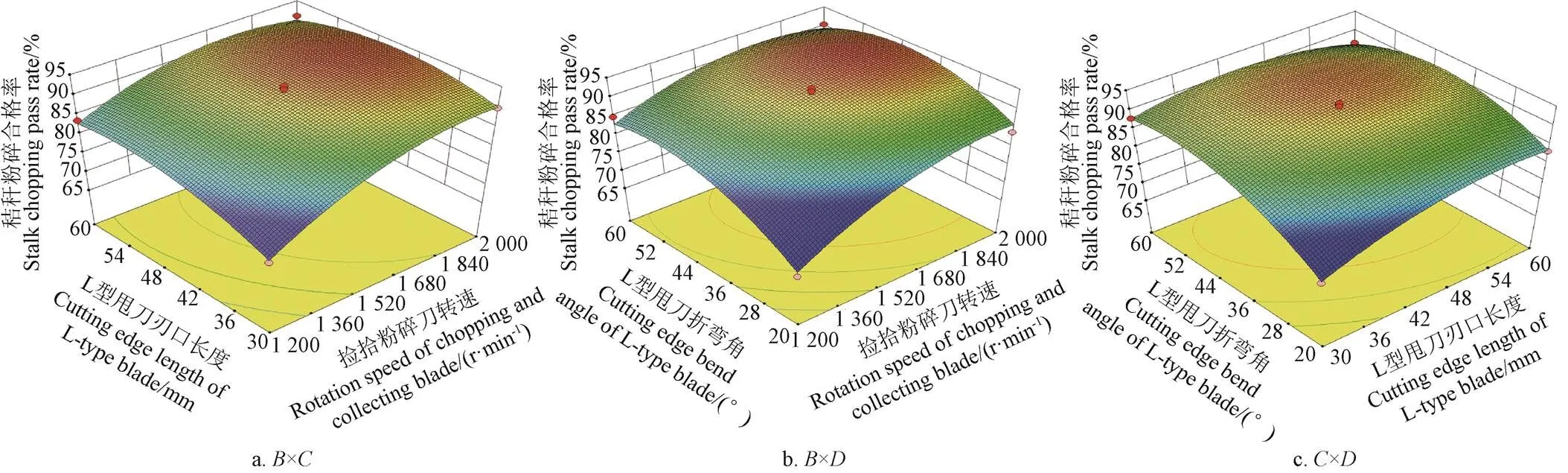

通过Design-Expert 8.0.6软件对试验数据进行处理,分析捡拾粉碎刀转速和L型甩刀刃口长度的交互作用、捡拾粉碎刀转速和L型甩刀折弯角的交互作用、L型甩刀刃口长度和L型甩刀折弯角的交互作用对秸秆粉碎合格率1影响,如图11所示。

图11 秸秆粉碎合格率双因素交互作用分析

当滑切支撑刀滑切角为45°,L型甩刀折弯角为40°时,捡拾粉碎刀转速和L型甩刀刃口长度对秸秆粉碎合格率的影响如图10a所示。当捡拾粉碎刀转速一定时,秸秆粉碎合格率与L型甩刀刃口长度呈正相关,这是因为当L型甩刀刃口长度变大时,捡拾粉碎刀端点的线速度随之增大,秸秆漏捡面积随之降低,从而有利于提高秸秆粉碎合格率,其较优的刃口长度为35~55 mm。当L型甩刀刃口长度一定时,秸秆粉碎合格率与捡拾粉碎刀转速呈正相关,这是因为随着捡拾粉碎刀转速增大,捡拾粉碎刀和滑切支撑刀施加在玉米秸秆上的能量越大,秸秆漏捡面积越小,从而越有利于提高秸秆粉碎合格率,其较优捡拾粉碎刀转速为1 300~1 900 r/min。相对于L型甩刀刃口长度,捡拾粉碎刀转速是对秸秆粉碎合格率影响最为关键的因素。

当滑切支撑刀滑切角为45°,L型甩刀折弯角为40°时,捡拾粉碎刀转速和L型甩刀折弯角对秸秆粉碎合格率的影响如图10b所示。当L型甩刀折弯角一定时,秸秆粉碎合格率与捡拾粉碎刀转速呈正相关,这是因为捡拾粉碎刀转速增大,捡拾粉碎刀刀端线速度增大,秸秆漏捡面积下降,从而提高了玉米秸秆粉碎合格率,其较优捡拾粉碎刀转速为1 400~1 900 r/min。当捡拾粉碎刀转速一定时,秸秆粉碎合格率与L型甩刀折弯角呈正相关,但秸秆粉碎合格率的增长速率逐渐降低,这是因为随着L型甩刀折弯角逐渐增大,秸秆漏捡面积增大,从而使得秸秆粉碎合格率的增长速率逐渐降低其较优的L型甩刀折弯角为25~55°。

当滑切支撑刀滑切角为45°,捡拾粉碎刀转速为1 600 r/min时,L型甩刀刃口长度和L型甩刀折弯角对秸秆粉碎合格率的影响如图10c所示。当L型甩刀刃口长度一定时,秸秆粉碎合格率与L型甩刀折弯角呈正相关,但秸秆粉碎合格率的增长速率逐渐降低,这是因为当L型甩刀刃口长度一定时,随着L型甩刀折弯角增大,捡拾粉碎刀端点线速度降低,秸秆漏捡面积增大,不利于秸秆粉碎率的增大,从而使得秸秆粉碎合格率的增长速率逐渐降低,其较优的L型甩刀折弯角为30°~50°。当L型甩刀折弯角一定时,秸秆粉碎合格率与L型甩刀刃口长度呈正相关,当L型甩刀折弯角一定时,随着L型甩刀刃口长度的增大,有利于Y型组合刀捡拾范围的增大,秸秆漏捡面积下降,捡拾粉碎刀线速度增大,从而有利于提高玉米秸秆粉碎合格率,其较优的刃口长度为40~52 mm。

通过对秸秆粉碎合格率双因素交互作用分析,利用Design-Expert 8.0.6软件中的优化模块对秸秆粉碎合格率的回归方程进行求解,根据秸秆粉碎还田机的实际工作条件、作业要求以及上文的理论分析,对优化的约束条件进行选择。

目标函数

对方程(15)进行优化求解,可以得到多种参数优化组合。考虑到实际作业情况,在多组优化参数中选取较优参数组合:滑切支撑刀滑切角为41°~57.64°、捡拾粉碎刀转速为1 657.37~1 889.97 r/min、L型甩刀刃口长度为41.7~51.71 mm、L型甩刀折弯角为36.55°~49.08°,其相应的秸秆粉碎合格率为93.74%~94.47%。

3.5 模型验证

为验证优化结果的可靠性,选取滑切支撑刀滑切角为45°、捡拾粉碎刀转速为1 700 r/min,L型甩刀刃口长度为45 mm,L型甩刀折弯角为40°,其秸秆粉碎合格率预测值为93.96%。田间试验(图12)表明,在相同参数条件下,秸秆粉碎效率为92.58%,误差小于5%,与优化结果基本一致。验证试验表明相关优化组合合理,按照优化参数条件后的秸秆粉碎还田机的秸秆粉碎效果满足作业标准。

图12 作业效果

4 结 论

1)为提高秸秆粉碎装置粉碎线速度,设计了一种异速对辊式玉米秸秆粉碎还田装置,捡拾粉碎刀和滑切支撑刀同向转动,实现了对玉米秸秆的动态双支撑粉碎;设计了一种带锯齿等滑切角的滑切支撑刀,并对捡拾粉碎刀进行了参数优化。

2)通过对玉米秸秆粉碎过程受力分析和捡拾粉碎刀结构参数对秸秆漏捡面积影响分析得出:当捡拾粉碎刀轴半径、捡拾粉碎刀数量和装置前进速度一定时,L型甩刀刃口长度、L型甩刀折弯角、捡拾粉碎刀转速和滑切支撑刀滑切角对秸秆粉碎合格率有影响,并确定了捡拾粉碎刀和滑切支撑刀的转速范围。

3)根据实际作业条件和要求对装置结构参数范围进行选取,以秸秆粉碎合格率为试验指标,通过对秸秆粉碎合格率双因素交互作用分析和对目标函数进行优化求解,最终确定了较优结构参数,在地表秸秆量为4 300 kg/hm2、秸秆含水率为32.6%的条件下,滑切支撑刀滑切角为45°、捡拾粉碎刀转速为1 700 r/min,L型甩刀刃口长度为45 mm,L型甩刀折弯角为40°时,作业后秸秆粉碎合格率为92.58%,与预测值误差小于5%,指标满足相关标准规定。

[1] 韩鲁佳,闫巧娟,刘向阳,等. 中国农作物秸秆资源及其利用现状[J]. 农业工程学报,2002,18(3):87-91. Han Lujia, Yan Qiaojuan, Liu Xiangyang et al. Straw resources and their utilization in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(3): 87-91. (in Chinese with English abstract)

[2] Liu P, He J, Li H, et al. Effect of straw retention on crop yield, soil properties, water use efficiency and greenhouse gas emission in China: A meta-analysis[J]. International Journal of Plant Production, 2019, 13(4): 347-367.

[3] Zhao H, Sun B, Jiang L, et al. How can straw incorporation management impact on soil carbon storage? A meta-analysis[J]. Mitigation and Adaptation Strategies for Global Change. 2015, 20(8): 1545-1568.

[4] Yeboah S, Lamptey S, Zhang R, et al. Conservation tillage practices optimizes root distribution and straw yield of spring wheat and field pea in dry areas[J]. Journal of Agricultural Science. 2017, 9(6): 37-48.

[5] 王秋菊,刘峰,迟凤琴,等. 秸秆还田及氮肥调控对不同肥力白浆土氮素及水稻产量影响[J]. 农业工程学报,2019,35(14):105-111. Wang Qiuju, Liu Feng, Chi Fengqin et al. Effect of straw returning and nitrogen fertilizer regulation on nitrogen and rice yield in albic soil with different fertilities[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(14): 105-111. (in Chinese with English abstract)

[6] 章志强,何进,李洪文,等. 可调节式秸秆粉碎抛撒还田机设计与试验[J]. 农业机械学报,2017,48(9):81-92. Zhang Zhiqiang, He Jin, Li Hongwen, et al. Design and experiment on straw chopper cum spreader with adjustable spreading device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 76-87. (in Chinese with English abstract)

[7] 郑智旗,何进,李洪文,等. 动定刀支撑滑切式秸秆粉碎装置设计与试验[J]. 农业机械学报,2016,47(S1):108-116. Zheng Zhiqi, He Jin, Li Hongwen, et al. Design and experiment of straw-chopping device with chopping and fixed knife supported slide-cutting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(S1): 108-116. (in Chinese with English abstract)

[8] 郑智旗,何进,王庆杰,等. 秸秆捡拾粉碎掩埋复式还田机设计与试验[J]. 农业机械学报,2017,48(7):87-96. Zheng Zhiqi, He Jin, Wang Qingjie, et al. Design and experiment on straw collecting-chopping and ditch-burying integrated machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 87-96. (in Chinese with English abstract)

[9] 张姬,于泳涛,杨启勇,等. 高留茬玉米秸秆复式割台粉碎还田装置设计与试验[J]. 农业机械学报,2018,49(S1):42-49. Zhang Ji, Yu Yongtao, Yang Qiyong, et al. Design and experiment of smashed straw unit for high stubble maize double header[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(S1): 42-49. (in Chinese with English abstract)

[10] 张喜瑞,王自强,李粤,等. 滑切防缠式香蕉秸秆还田机设计与试验[J]. 农业工程学报,2018,34(3):26-34. Zhang Xirui, Wang Ziqiang, Li Yue, et al. Design and experiment of sliding-cutting and anti-twining returning device for banana straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(3): 26-34. (in Chinese with English abstract)

[11] 张红霞,刘师多,师清翔,等. 玉米秸秆粉碎刀具和刀速对粉碎功耗和质量的影响[J]. 河南科技大学学报:自然科学版,2003,24(2):1-4. Zhang Hongxia, Liu Shiduo, Shi Qingxiang, et al. Influence of macerator’s blades disposal and rotatory speed on power consumption and smashing quality of cornstalk[J]. Journal of Henan University of Science and Technology (Natural Science), 2003, 24(2): 1-4. (in Chinese with English abstract)

[12] 贾洪雷,姜鑫铭,郭明卓,等. V-L型秸秆粉碎还田刀片设计与试验[J]. 农业工程学报,2015,31(1):28-33. Jia Honglei, Jiang Xinming, Guo Mingzhuo, et al. Design and experiment of V-L shaped smashed straw blade[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(1): 28-33. (in Chinese with English abstract)

[13] 郭俊,张庆怡,Muhammad Sohail Memon,等. 仿鼹鼠足趾排列的旋耕-秸秆粉碎锯齿刀片设计与试验[J]. 农业工程学报,2017,33(6):43-50. Guo Jun, Zhang Qingyi, Muhammad Sohail Memon, et al. Design and experiment of bionic mole's toe arrangement serrated blade for soil-rototilling and straw-shattering[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(6): 43-50. (in Chinese with English abstract)

[14] Lundin G. Chop length capability and wearing qualities for two types of straw chopper knives at combine harvesting[J]. Tarim Makinalari Bilimi Dergisi, 2008, 4(1): 99-103.

[15] Persson S. Mechanics of cutting plant material[J]. St. Joseph, MI: ASAE, 1987, 7: 266-283.

[16] Zhang Zhiqiang, David M H A, Li Hongwen, et al. Global overview of research and development of crop residue management machinery[J]. Applied Engineering in Agriculture, 2017, 33(3): 329-344.

[17] 王庆杰,刘正道,何进,等. 砍切式玉米秸秆还田机的设计与试验[J]. 农业工程学报,2018,34(2):10-17. Wang Qingjie, Liu Zhengdao, He Jin, et al. Design and experiment of chopping type maize straw returning machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(2): 10-17. (in Chinese with English abstract)

[18] 陈昕. 四倍体刺槐饲料收获机往复切割器切割性能研究[D].北京:北京林业大学,2011. Chen Xin. The Research of Reciprocating Knife Cutting Performance Used for Tetraploid Robinia Pseudoacacia Harcester[D]. Beijing: Beijing Forestry University, 2011. (in Chinese with English abstract)

[19] 陈黎卿,王莉,张家启,等. 适用于全喂入联合收割机的1JHSX-34型秸秆粉碎机设计[J]. 农业工程学报,2011,27(9):28-32. Chen Liqing, Wang Li, Zhang Jiaqi, et al. Design of 1JHSX-34 straw crusher for whole-feeding combine harvesters[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(9): 28-32. (in Chinese with English abstract)

[20] 孙妮娜,王晓燕,李洪文,等. 差速锯切式水稻秸秆粉碎还田机设计与试验[J]. 农业工程学报,2019,35(22):267-276. Sun Nina, Wang Xiaoyan, Li Hongwen, et al. Design and experiment of differential sawing rice straw chopper[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(22): 267-276. (in Chinese with English abstract)

[21] 吴子岳,高焕文,张晋国. 玉米秸秆切断速度和切断功耗的试验研究. 农业机械学报,2001,32(2):38-41. Wu Ziyue, Gao Huanwen, Zhang Jinguo. Study on cutting velocity and power requirement in a maize stalk chopping process[J]. Transactions of the Chinese Society for Agricultural Machinery, 2001, 32(2): 38-41. (in Chinese with English abstract)

[22] 中国农业机械化科学研究院. 农业机械设计手册[M]. 北京:中国农业科学技术出版社,2007.

[23] 郭茜,张西良,徐云峰,等. 藤茎类秸秆专用切割刀片的设计与试验[J]. 农业工程学报,2014,30(24):47-53. Guo Qian, Zhang Xiliang, Xu Yunfeng, et al. Design and experiment of cutting blade for cane straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(24): 47-53. (in Chinese with English abstract)

[24] Yagelski MY, Rodimtsev SA. Types and classification of blades of straw chopper spreaders in combine harvesters[J]. Vestnik of Voronezh State Agrarian University, 2017, 1: 114-122.

[25] 贾洪雷,赵佳乐,姜鑫铭,等. 行间免耕播种机防堵装置设计与试验[J]. 农业工程学报,2013,29(18):16-25. Jia Honglei, Zhao Jiale, Jiang Xinming, et al. Design and experiment of anti-blocking mechanism for inter-row no-tillage seeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(18): 16-25. (in Chinese with English abstract)

[26] 何勋,王德福. 基于纤维形态特征分析的玉米秸秆皮拉伸特性[J]. 农业工程学报,2015,31(10):92-98. He Xun, Wang Defu. Tensile property of corn stalk rind based on analysis of fiber morphology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(10): 92-98. (in Chinese with English abstract)

[27] 陈争光,王德福,李利桥,等. 玉米秸秆皮拉伸和剪切特性试验[J]. 农业工程学报,2012,28(21):59-65. Chen Zhengguang, Wang Defu, Li Liqiao, et al. Experiment on tensile and shearing characteristics of rind of corn stalk[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(21): 59-65. (in Chinese with English abstract)

[28] 吕金庆,王英博,兑瀚,等. 驱动式马铃薯中耕机关键部件设计与碎土效果试验[J]. 农业机械学报,2017,48(10):49-58. Lv Jinqing, Wang Yingbo, Dui Han, et al. Design of key components of driving type potato cultivator and its soil-broken effect experiment[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(10): 49-58. (in Chinese with English abstract)

[29] 张慧明,陈学庚,颜利民,等. 随动式秸秆还田与残膜回收联合作业机设计与试验[J]. 农业工程学报,2019,35(19):11-19. Zhang Huiming, Chen Xuegeng, Yan Limin, et al. Design and test of master-slave straw returning and residual film recycling combine machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(19): 11-19. (in Chinese with English abstract)

[30] 张李娴. 玉米秸秆力学特性的离散元建模方法研究[D]. 杨凌:西北农林科技大学,2017. Zhang Lixian. Research on the Discrete Element Modeling Method of Corn Stalk’s Mechanical Characteristics[D]. Yangling: Northwest A&F University, 2017. (in Chinese with English abstract)

Design and experiment of double rollers maize stalk chopping device with different rotation speeds

Liu Peng1, He Jin1※, Li Yanjie2, Li Hongwen1, Wang Qingjie1, Lu Caiyun1, Zhang Zhenguo1,3, Li Shaohua4

(1.,,100083,; 2.,,100083,; 3.,,830052,; 4..,.,024200,)

A large amount of maize stalks are produced each year, due to the maize is serving as one of the main grain crop in China. Maize straw retention to the field after chopped is widely used in most disposal approaches. However, the currently used single shaft maize stalk chopping and retention machine can not meet the quality requirements of stalk chopping, such as too long maize stalk after chopping, and the low chopping pass rate of maize stalk, particularly when the amount of maize stalk was large, while the scarf skin of maize stalk was toughness. The shortcoming of maize stalk chopping directly determines the next seeding production, seed germination, and final crop yield. This paper aims to propose a novel chopping method, and thereby to design a double rollers type stalk chopping and retention device with different rotation speed and dynamic double support. The device mainly included the shell, supporting plate, suspension device, gearbox, transmission, chopping and collecting blade, shaft of chopping, collecting blade, blade shaft of slide-cutting supporting blade, and slide-cutting supporting blade. In operation, the chopping and collecting blade with anticlockwise rotation, firstly collected and chopped maize stalk in the field; then the maize stalk was chopped in dynamic support of side-cutting supporting blade with same rotation direction of chopping and collecting blade. A mechanical analysis of maize stalk was conducted under the effect of chopping and collecting blade, as well the slide-cutting supporting blade. The results showed that the rotation speed of chopping and collecting blade, and the slide-cutting angle of slide-cutting supporting blade were the main factors to affect the stalk chopping process. Furthermore, a motion analysis of chopping and collecting blade was carried out, including two L-type blades and a straight blade. The results revealed that the bend angle and length along the cutting-edge of L-type blade, and the rotation speed of chopping and collecting blade, were the main factors to affect the unpicking rate of maize stalk, and chopping pass rate, when the number of chopping and collecting blade and operation speed of device were fixed. In the slide-cutting supporting blade, the cutting-edge curvilinear equation was in the form of the logarithmic spiral equation. Moreover, the range of slide-cutting angle was 30º-60º, due to the slide-cutting angle can be more than frictional angle between maize stalk and slide-cutting supporting blade, according to slide-cutting principle. Importantly, the cutting edge of slide-cutting supporting blade with sawtooth was designed to increase the fraction of maize stalk and slide-cutting supporting blade. Prior to accurately coordinating between chopping and collecting blade, and side-cutting supporting blade, the rotating speed range of chopping and collecting blade was determined as 1 150 -2 500 r/min, to ensure the high stalk chopping pass rate. The rotation speed of slide-cutting supporting blade was one half that of chopping and collecting blade, to guarantee the speed of backward spread of chopped maize stalk. Simultaneously, the chopping and collecting blade, and side-cutting supporting blade, both were double helix arrangement to reduce machinery vibration, while increase machinery life. One device was installed 20 chopping and collecting blades, and 40 slide-cutting supporting blades. A quadratic rotation orthogonal combination test was used in the field research, to obtain the optimal structure parameters, where the chopping pass rate of maize stalk was set as test index. Some test factors were selected, including the cutting-edge bend angle of L-type blade (20º ≤≤60º), and cutting-edge length of L-type blade (30 mm ≤≤60 mm), rotation speed of chopping and collecting blade (1200 r/min≤n≤2 000 r/min), and slide-cutting angle of slide-cutting supporting blade (30°≤≤60°). The Design-Expert 8.0.6 software was applied to analyze the double factors interaction on stalk chopping pass rate, thereby to obtain the regression model between test factors and index. The primary and secondary factors that affect the maize stalk chopping pass rate were the rotation speed of chopping and collecting blade, the length of cutting-edge bend angle, the cutting-edge length of L-type blade, and the slide-cutting angle. In multiple objective optimization, the optimum ranges can be achieved, including the cutting-edge bend angle of L-type blade (41º≤≤57.64º), the cutting-edge length of L-type blade (41.7 mm≤≤51.71 mm), the rotation speed of chopping and collecting blade (1 657.37 r/min≤n≤1 889.97 r/min), and slide-cutting angle of slide-cutting supporting blade (36.55º≤≤49.08º). In the field test, the rotation speed of chopping and collecting blade, the length of cutting-edge bend angle, and cutting-edge length of L-type blade, and slide-cutting angle were set as 1700 r/min, 40º, 45mm, and 45º, respectively. The field test results demonstrated that the maize stalk chopping pass rate was 92.58% under the optimal working parameters, while the error with the predictive value (93.96%) was less than 5%, indicating the reliable optimization of parameters. The finding can offer a sound reference to improve the chopping quality of maize stalk in the chopping and retention machine.

agricultural machine; speed; stalk chopping pass rate; stalk chopping; different rotation speed; dynamic support

刘鹏,何进,李艳洁,等. 异速对辊式玉米秸秆粉碎还田装置设计与试验[J]. 农业工程学报,2020,36(14):69-79.doi:10.11975/j.issn.1002-6819.2020.14.009 http://www.tcsae.org

Liu Peng, He Jin, Li Yanjie, et al. Design and experiment of double rollers maize stalk chopping device with different rotation speeds[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(14): 69-79. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.14.009 http://www.tcsae.org

2020-01-08

2020-03-07

国家自然基金项目(31971803)

刘鹏,博士生,主要从事现代农业装备与计算机测控技术研究。Email:liupeng_ctrc@cau.edu.cn

何进,教授,博士生导师,主要从事现代农业装备与计算机测控技术研究。Email:hejin@cau.edu.cn

10.11975/j.issn.1002-6819.2020.14.009

S244.29

A

1002-6819(2020)-14-0069-11