O2O在线回收企业再售策略研究

2020-05-21李增禄聂佳佳

李增禄,郭 强,聂佳佳,冯 琳

O2O在线回收企业再售策略研究

李增禄,郭 强,聂佳佳,冯 琳

(西南交通大学 经济管理学院,四川 成都 610031)

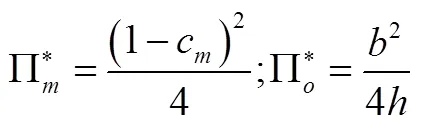

研究了O2O在线回收企业再售策略选择问题。研究发现:当制造商单位产品生产成本和处理商单位产品回收价格较低时,在线回收企业采取全部再售策略;当处理商单位产品回收价格居中时,在线回收企业采取部分再售策略;当处理商单位产品回收价格较高时,采取无再售策略。相对无再售行为的传统第三方回收而言,再售策略下O2O在线回收企业利润较优,故在线回收企业有动力进行再售,并且再售策略下消费者剩余优于传统第三方回收,而制造商利润降低。此外,全部再售策略下在线回收企业废旧品回收量优于传统第三方回收,有助于提升产品利用率,保护环境。

O2O在线回收;再售;回收量;回收成本

0 引言

据再生资源信息网报道,我国每年电子产品报废量达两亿多台,并呈逐年上升趋势。同时我国又是全球最大的家用电器生产和消费国,废旧家用电器所带来的环境压力也日趋严重。虽然国家启动了一系列废旧品回收法律法规,鼓励企业回收废旧产品,但回收量依然较低[1-3]。近些年随着互联网的发展,O2O在线回收逐渐兴起,众多企业相继涉足该领域。比如,作为国内首家电子产品在线回收企业,爱回收将回收业务与互联网相结合,由此形成了O2O回收模式的基础。随后,以二手手机与废旧手机回收为主营业务的易机网和淘绿环保等企业纷纷效仿,成为互联网产业的新秀。此类回收企业不仅扮演传统回收者的角色,同时还扮演零售商角色,将回收品以二手产品形式进行再售,在线回收企业该采取何种再售策略(全部再售、部分再售、无再售),其再售策略会对供应链成员造成何种影响是个值得思考的问题。

虽然回收被认为是应对废旧产品问题的一种有效方式,但受回收基础设施、回收价格和消费者环保意识等因素的影响回收率依然较低。面对该现实问题,学术界的研究从未停息。Savaskan等[4]较早的对制造商回收渠道问题进行研究,并提出了零售商回收、制造商回收和第三方回收模型。在此基础上,有些学者从回收成本结构[5]、回收品质量[6]、回收责任或成本分担[7-8]以及制造商产能约束[9]等角度对该问题进行了深入研究。Atasu等[5]研究认为最优回收渠道是由成本结构决定的;聂佳佳和邓东方[6]指出再制造产品在零售商回收模式下质量较高;Shi等[7]和郑本荣等[8]引入回收责任和回收成本分担机制,从各博弈方的角度分析了企业的最优回收模式;在制造商产能约束下,舒秘等[9]发现回收率在制造商回收时达到最高。刘慧慧等[10]和周岩等[11]分别从政府补贴以及模糊需求角度对双渠道回收问题进行了研究;而董乾东等[12]分别建立生产商及零售商混合回收、生产商及第三方混合回收和零售商及第三方混合回收三种模型,认为生产商及零售商混合回收是最优的。Ferguson和Toktay[13]在制造商回收再制造的基础上引入独立再制造商研究了竞争情形下的回收和再制造问题。在此基础上,孟丽君等[14]研究了集成制造商和独立再制造商的双寡头竞争问题。

以上文献讨论了废旧品回收渠道问题,但对于回收品处理方式主要集中于制造商或独立再制造商对回收品进行再制造,然后进行重新销售的情况。在再制造产品销售方面,早期的研究多假设再制造产品与新产品无差异[4,15,16]。然而,随着学者对产品认知程度的加深以及出于现实情况的考虑,近几年的研究将新产品与再制造产品进行差异化假设[6,14,17],消费者对新产品的价格、质量等估值均要高于再制造产品。回收产品或再制造产品的销售主体主要有三个:(1)制造商销售[13,18]。制造商对回收产品再制造并进行销售,如Ferguson和Toktay[13],Robotis等[18];(2)再制造商销售[19-22]。独立的再制造商对回收品再制造并进行销售,如Esenduran等[20]分析了独立再制造商与原始设备制造商竞争条件下对再制造水平、消费者剩余和OEM利润的影响;熊中楷等[22]认为旧产品回收再制造与专利许可有关;(3)零售商再售[23-26]。零售商对回收或退货产品加工再售,Wang等[25]分析了旧产品质量、消费者对再售品购买意愿以及渠道结构等因素对接收退货零售商的再售策略的影响。在耐用品市场,赵培[26]基于旧产品不同的回收成本,研究零售商开通二手市场对自身以及制造商利润的影响。针对本文研究所涉及的O2O在线回收企业,其在市场中扮演回收和再售的双重角色,成为再制造企业与消费者之间联系的“纽带”,加速了供应链成员之间的信息传递。一方面,O2O在线回收企业可直接从消费者处获得旧产品,为再制造企业整合了消费者资源,降低再制造企业的回收运营成本;另一方面,为消费者提供了丰富全面的再售品服务信息,同时较为透明的回收价格也增强了消费者的回收动机。可以看出,O2O在线回收企业的回收与再售模式在供应链结构以及决策主体方面均有别于传统模式,这也成为本研究的创新之处。

综上所述,虽然学者对于制造商回收渠道选择以及再制造问题进行了充分研究,但鲜有学者考虑互联网环境下O2O在线回收企业对回收产品以二手产品形式进行再售的情形,此时的在线回收企业充当零售商角色与制造商进行市场竞争,其再售行为会对制造商和自身带来何种变化呢?再售行为又会对其回收量以及消费者剩余产生何种影响?以上问题都将成为本文研究的重点。此外,文章还分析制造商最优产量以及在线回收企业最优再售量和最优回收率的问题,希望所得结论能够为逆向物流参与者决策提供理论依据。

1 问题描述

图1 传统回收模型

Figure 1 Traditional recycling model

图2 O2O在线回收模型

Figure 2 O2O online recycling model

1.1 符号约束

符号与变量表示如下:

1.2 模型假设

(2)博弈主体都为完全信息拥有者,制造商与O2O在线回收企业同时进行决策,制造商决策新产品产量,而O2O在线回收企业决策回收率以及回收品的再售量。

(3)O2O在线回收企业回收成本是其回收量的二次函数,表示随着其回收量的增加边际回收成本递增,该回收成本形式在以往研究中已被广泛使用,如Atasu 等[5],Ferguson和Toktay[13]以及Esenduran等[20]。

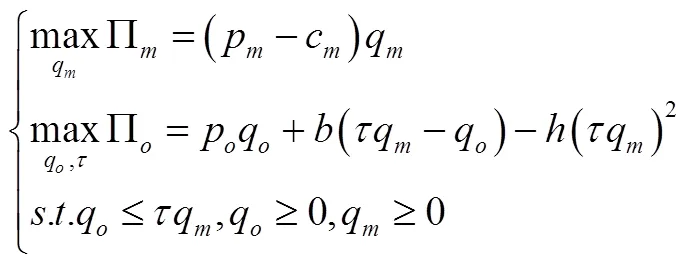

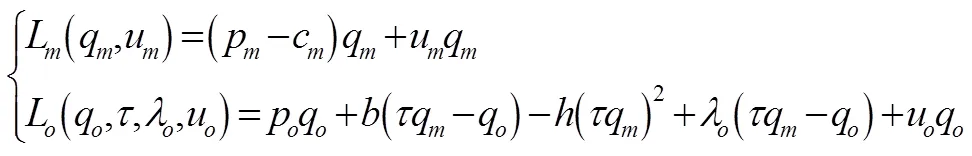

2 传统回收模型

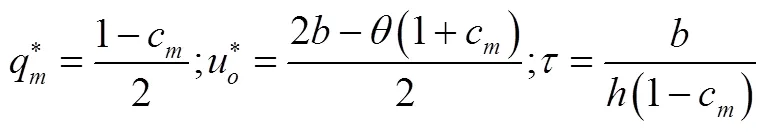

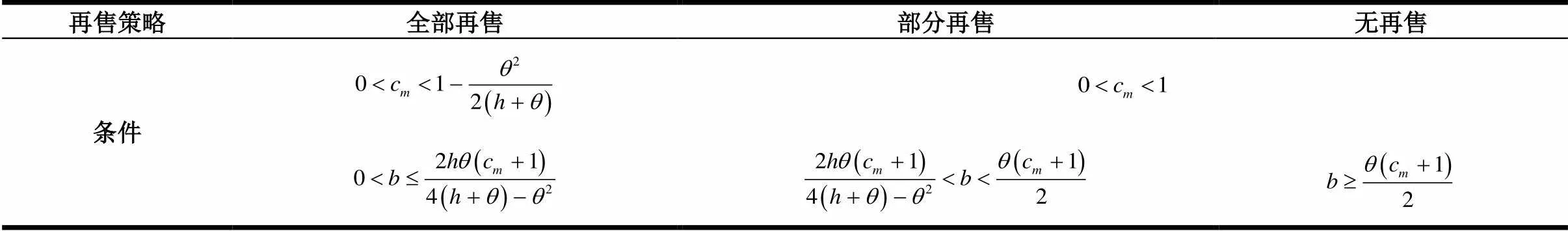

根据式(1)可求解制造商最优产量以及第三方回收企业最优回收率,如命题1所示。

(3)

3 O2O在线回收模型

此时制造商与O2O在线回收企业需求函数分别为:

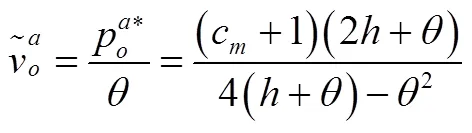

3.1 O2O在线回收企业全部再售

3.2 O2O在线回收企业部分再售

3.3 O2O在线回收企业无再售

命题2:根据3.1-3.3部分计算可得O2O在线回收企业再售策略如表1所示。

表1 O2O在线回收企业再售策略

表2 再售策略下制造商最优产量及利润

4 对比分析

命题4:相对传统第三方回收模型而言,全部再售或部分再售策略下O2O在线回收企业利润变大,O2O在线回收企业有较强的动力进行再售。

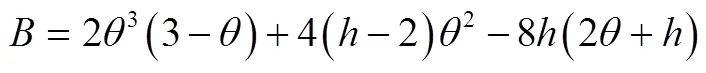

证明:由传统第三方回收模型与O2O在线回收模型中回收企业最优利润可得:当O2O在线回收企业全部再售时:

式(16)恒大于0。当O2O在线回收企业无再售时,在其策略约束空间内最优利润与传统回收模型无差异。

命题5:相对传统回收模型而言,当O2O在线回收企业选择全部再售策略或部分再售策略时制造商利润变小;当O2O在线回收企业选择无再售策略时制造商利润不变。

证明:由传统第三方回收模型与O2O在线回收模型中回收企业最优利润可得:当O2O在线回收企业全部再售时:

在传统回收模型中制造商垄断消费者市场,拥有较高的产量和零售价格。在O2O在线回收模型中,在线回收企业将回收品以“二手产品”形式再售给消费者,此时在线回收企业和制造商在消费者市场中进行竞争,打破了制造商的垄断。具体来说,当在线回收企业采取全部再售策略时,市场竞争较为激烈,制造商利润最低;当在线回收企业采取部分再售策略时,随着再售量的下降,制造商利润有所提升;当在线回收企业采取无再售策略时,制造商重新垄断市场获得垄断利润。在O2O在线回收模型中,从制造商的角度来看,制造商希望具有再制造能力的处理商给在线回收企业一个高的回收价格,从而缓解市场竞争。若制造商进行产品专利保护,对处理商收取专利许可费,想必会弥补其利润损失,但本文研究重点在于在线回收企业的再售策略,故不对该问题进行深入分析。

命题6:相对传统回收模型而言,全部再售策略下O2O在线回收企业废旧产品回收量较大,而部分再售和无再售策略下回收量无差异。

该结论比较分析了传统第三方回收模型和O2O在线回收模型中回收企业回收量问题。从命题6中发现,全部再售策略下在线回收企业回收量优于传统第三方回收;而部分再售和无再售策略下在线回收和传统回收模型中回收量相同。若从环境保护、提升产品利用率的角度来看,制造商应该通过技术创新降低生产成本,而处理商应该给在线回收企业提供一个较低的单位产品回收价格,只有这样才能促使在线回收企业采取全部再售策略。虽然全部再售策略有助于保护环境,提升产品利用率,但是由命题5可知,全部再售策略下市场竞争激烈对制造商不利,若此时政府能够为制造商提供一定补贴,将更有利于在线回收企业全部再售策略的实施。

5 算例分析

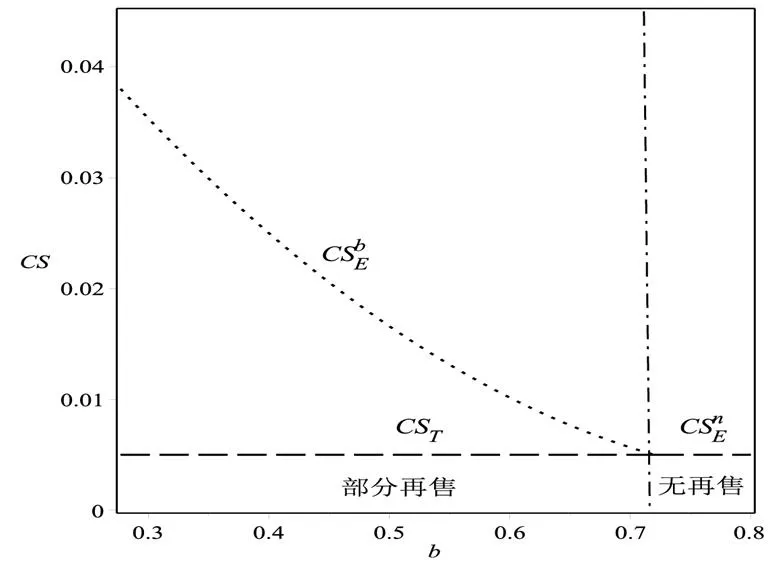

以上内容分析了O2O在线回收企业再售动力以及不同再售策略下制造商利润和回收量的变化情况,该部分将考察不同再售策略下消费者剩余相对传统第三方回收的变化情况。

5.1 传统第三方回收模型中消费者剩余

传统回收模型中消费者剩余是关于制造商单位产品回收成本的减函数,原因在于较高的生产成本势必引起制造商制定高的零售价格,从而降低了消费者购买产品时所获得的净效用,故消费者剩余降低。

5.2 O2O在线回收模型中消费者剩余

5.2.1 当O2O在线回收企业采取全部再售策略时

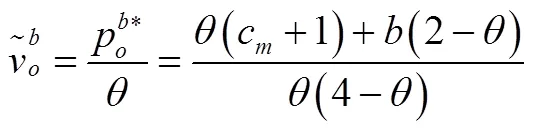

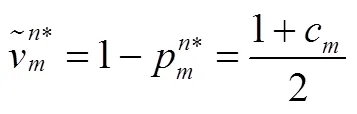

根据3.1部分最优解可得消费者是否购买O2O在线回收企业再售产品的效用无差异点为:

在全部再售策略成立的约束范围内,消费者剩余随制造商单位产品生产成本的增大而减小,原因在于生产成本的增大,引起制造商零售价格提升,此时在线回收企业为追求高的边际利润也提升再售价格,所以无论消费者购买制造商产品还是再售品所获得净效用都降低,故消费者剩余减小。在线回收企业全部再售策略下,消费者剩余不受处理商单位产品回收价格影响。

5.2.2 当O2O在线回收企业采取部分再售策略时

根据3.2部分最优解可得消费者是否购买O2O在线回收企业再售产品的效用无差异点为:

在线回收企业部分再售策略下,消费者剩余与制造商单位生产成本以及处理商单位产品回收价格都呈现负相关性。较高的单位产品生产成本和回收价格会造成制造商零售价格以及在线回收企业再售价格增高,降低了消费者剩余。

5.2.3 当O2O在线回收企业采取无再售策略时

虽然从数值上看O2O在线回收企业采取无再售策略下消费者剩余与传统回收模型无差异,但是其成立条件并不相同。接下来将通过算例来分析不同模型下消费者剩余的变化情况。假设参数为:绘制图3和图4。

图4 当时消费者剩余分析

6 总结与展望

[1] 付小勇, 朱庆华, 赵铁林. 基于逆向供应链间回收价格竞争的回收渠道选择策略[J]. 中国管理科学, 2014, 22(10):72-79.

Fu X Y, Zhu Q H, Zhao T L. Selection of the Recovery Channel Based on Recovery Price Competition between the Reverse Supply Chains[J]. Chinese Journal of Management Science, 2014, 22(10):72-79.

[2] 范体军, 楼高翔, 王晨岚, 等. 基于绿色再制造的废旧产品回收外包决策分析[J]. 管理科学学报, 2011, 14(8):8-16.

Fan T J, Lou G X, Wang C L, et al. Analysis of outsourcing decision-making on used products collection for green remanufacturing[J]. Journal of Management Sciences in China, 2011, 14(8):8-16.

[3] 吕君, 谢家平. 基于空间相关性的 WEEE 逆向物流回收预测研究[J]. 管理工程学报, 2015, 29(4): 152-161.

Lyu J, The Prediction of Returns in WEEE Reverse Logistics Based on the Spatial Correlation[J]. Journal of Industrial Engineering and Engineering Management, 2015, 29(4): 152-161.

[4] Savaskan R C, Bhattacharya S, Van Wassenhove L N. Closed-loop supply chain models with product remanufacturing [J]. Management science, 2004, 50(2): 239-252.

[5] Atasu A, Toktay L B, Wassenhove L N V. How Collection Cost Structure Drives a Manufacturer's Reverse Channel Choice [J]. Production & Operations Management, 2013, 22(5):1089–1102.

[6] 聂佳佳,邓东方. 再制造产品质量对闭环供应链回收渠道选择的影响[J]. 工业工程与管理, 2014,19(1):1-7.

Nie J J, Deng D F. Effect of Remanufacturing Product Quality on Recovery Channel in Closed-loop Supply Chain[J]. Industrial Engineering and Management, 2014,19(1):1-7.

[7] Shi Y, Nie J, Qu T, et al. Choosing reverse channels under collection responsibility sharing in a closed-loop supply chain with re- manufacturing[J]. Journal of Intelligent Manufacturing, 2015, 26(2): 387-402.

[8] 郑本荣, 杨超, 刘丛. 成本分摊对制造商回收闭环供应链的影响[J]. 系统工程理论与实践, 2017, 37(9):2344-2354.

Zheng B R, Yang C, Liu C. The effect of cost sharing on manufacturer collecting closed loop supply chain[J]. Systems Engineering—Theory & Practice, 2017, 37(9):2344-2354.

[9] 舒秘,聂佳佳. 产能约束对再制造闭环供应链回收渠道选择的影响[J]. 运筹与管理, 2015,24(4):52-57.

Shu M, Nie J J. Effect of Capacity Constraint on Choice of Collecting Channels in Closed-loop Supply Chain[J]. Operations Research and Management Science, 2015,24(4):52-57.

[10] 刘慧慧, 黄涛, 雷明. 废旧电器电子产品双渠道回收模型及政府补贴作用研究[J]. 中国管理科学, 2013, 21(2):123-131.

Liu H H, Huang T, Lei M. Dual-channel Recycling Model of Waste Electrical and Electronic Equipment and Research on Effects of Government Subsidy[J]. Chinese Journal of Management Science, 2013, 21(2):123-131.

[11] 周岩, 胡劲松, 孙浩, 等. 具有模糊需求的双渠道闭环供应链网络均衡[J]. 中国管理科学, 2012,20(S2):481-490.

Zhou Y, Hu J S, Sun H, et al. Closed-Loop Supply Chain Hetwork Dual Channel Equilibrium Model with Fuzzy Demand[J]. Chinese Journal of Management Science, 2012,20(S2):481-490.

[12] 董乾东, 李敏, 姜素红. 基于产品质量差异的闭环供应链混合回收模式[J]. 系统工程, 2017,35(2):116-121.

Dong Q D, Li M, Jiang S H. Hybrid Recovery Mode of Closed-loop Supply Chain Based on Production Quality Differentiation[J]. Systems Engineering, 2017,35(2):116-121.

[13] Ferguson M E, Toktay L B. The Effect of Competition on Recovery Strategies[J]. Production & Operations Management, 2006, 15(3):351-368.

[14] 孟丽君, 黄祖庆, 张宝友, 等. 基于OEM与IR竞争的产品差异定价研究[J]. 中国管理科学, 2017,25(11):111-121.

Meng L J, Huang Z Q, Zhang B Y, et al. Optimal Pricing for New and Remanufactured Products Based on the Competition Between OEM and IR[J]. Chinese Journal of Management Science, 2017,25(11):111-121.

[15] Vaidyanathan Jayaraman. Production planning for closed-loop supply chains with product recovery and reuse: an analytical approach[J]. International Journal of Production Research, 2006, 44(5):981-998.

[16] Gaurav Agarwal, Sikhar Barari, M.K. Tiwari. A PSO-based optimum consumer incentive policy for WEEE incorporating reliability of components[J]. International Journal of Production Research, 2012, 50(16):4372-4380.

[17] 张汉江, 余华英, 李聪颖. 闭环供应链上的回收激励契约设计与政府补贴再制造政策的优化[J]. 中国管理科学, 2016, 24(8):71-78.

Zhang H J, Yu H Y, Li C Y. Incentive Contract Design and Optimization of Government Subsidies Policy in the Closed-loop Supply Chain[J]. Chinese Journal of Management Science, 2016, 24(8): 71-78.

[18] Robotis A, Bhattacharya S, Van Wassenhove L N. The effect of remanufacturing on procurement decisions for resellers in secondary markets[J]. European Journal of Operational Research, 2005, 163(3): 688-705.

[19] Majumder P, Groenevelt H. Competition in remanufacturing[J]. Production and Operations Management, 2001, 10(2): 125-141.

[20] Esenduran G, Kemahlıoğlu‐Ziya E, Swaminathan J M. Impact of Take‐Back Regulation on the Remanufacturing Industry[J]. Production and Operations Management, 2017, 26(5): 924-944.

[21] Mitra S, Webster S. Competition in remanufacturing and the effects of government subsidies[J]. International Journal of Production Economics, 2008, 111(2): 287-298.

[22] 熊中楷,申成然,彭志强.专利保护下再制造闭环供应链协调机制研究[J].管理科学学报, 2011, 14(6): 76-85.

Xiong Z K, Shen C R, Peng Z Q. Closed-loop supply chain coordination research with remanufacturing under patent protection[J]. Journal of Management Sciences in China, 2011, 14(6): 76-85.

[23] Thierry M, Salomon M, Van Nunen J, et al. Strategie issues in product recovery anagement[J]. California management review, 1995, 37(2): 114-135.

[24] Guide V D R, Wassenhove L N. Managing product returns for remanufacturing[J]. Production and operations management, 2001, 10(2): 142-155.

[25] Wang L, Cai G G, Tsay A A, et al. Design of the Reverse Channel for Remanufacturing: Must Profit‐Maximization Harm the Environment?[J]. Production and Operations Management, 2017, 26(8): 1585-1603.

[26] 赵培, 熊中楷, 熊榆. 零售商开通二手市场对供应链成员收益的影响[J]. 系统工程理论与实践, 2015, 35(4):882-891.

Zhao P, Xiong Z K, Xiong Y. The effect of the secondary market operated by the retailer on the profits of supply chain partners[J]. Systems Engineering—Theory & Practice, 2015, 35(4):882-891.

The resale strategies of the online recycler

LI Zenglu, GUO Qiang , NIE Jiajia , FENG Lin

(School of Economics and Management, Southwest Jiaotong University, Chengdu 610031, China)

Remanufacturing is beneficial to both the environment and the enterprise, but the recovery rate is rather low still. This interesting phenomenon can be explained by many reasons, such as insufficient recycle stations, low recovery prices, poor environmental awareness, and so on. With the rapid development of the internet, some companies, like Aihuishou (www.aihuishou.com), Taolvhuanbao (www.taolv365.com), Lijiang (www.58yiji.com) and so on can collect the waste products from the consumers through the online channel. Compared with traditional recycling, online recycling in O2O (Online and Offline) has many advantages due to its, more transparency recovery price, less investing in building recycle stations, and the effects of scale economies in recycling. Moreover, the recycled products can be sold by the online recycling companies to an independent processor or consumers as second-hand goods travel through their recycling platform. The new model is different from the traditional wisdom that analyzes the problems of recycling channels or cooperation between supply chain members. Because of the benefit, we decided to explore the resale strategies of an online recycling company.

This paper investigates a supply chain consisted of a manufacturer, an online recycler, and an independent processor. The manufacturer produces raw materials, while the online recycler takes back reusable items from the market and then sells them to the processor or the consumers as a second-hand good. Thus the online recycler has three resale strategies, i.e., selling all the recycled products, selling partial ones, or no resale. For simplicity, we propose the following assumptions: 1) The manufacturer does not have the processing qualification with waste products, so there is no recycled product flow to the manufacturer; 2) Considering the better quality, durability and quality assurance services of new products, consumers have a higher valuation of the products from the manufacturer than the resale ones from the online recycler; and 3) All the players have complete information. To be consistent with the literature about remanufacturing, we take the recovery model without resale as a benchmark. The profit functions of the manufacturer, the online recycler, and the independent processor under different scenarios are developed, respectively. Then the equilibrium outcomes of the decision models are derived by the nonlinear programming theory and the static game method.

It is found form the results that: (1) The O2O online recycler always has an incentive to resell the recycled products because it would bring more profits. (2) The O2O online recycler’s resale strategies depend on the unit production cost of the manufacturer and the unit recovery price of the processer. Specifically, i) if both of the unit production cost and the unit recovery price are low, the online recycler sells all the recycled products to consumers; ii) when the unit recovery price is moderate, the online recycler sells part of the recycled ones to consumers; iii) when the unit recovery price of the processer is high, the online recycler sells all the recycled products to the independent processor.

The online recycler’s resale strategies are harmful to the manufacturer. Luckily, the consumers would benefit from the online recycler’s resale strategies, which induce the product market to be more competitive. An increase in the unit cost of the product causes an increase in the profit of the online recycler but a decrease in the profit of the manufacturer. Besides, in the case where an online recycler resells all the recycled products, the online recycler improves a larger amount of recycled products than the traditional third party recycling mode because it helps to protect the environment and save the resource. We hope that our findings are helpful for the online recycling company.

Certainly, our works are limited and can be extended from many aspects. For example, 1) considering the manufacturer with the waste product processing qualification, the resale strategies and the output of manufacturer may be changed in such closed-loop supply chain; 2) if the government subsidizes the online recycler, the results may be different; and 3) Considering the asymmetric information between the online recycler and the consumer on the quality of resale products, there will also be some new conclusions.

O2O online recycling company; Resale; Recycling amount; Collecting cost

2017-09-25

2018-05-02

F270.5

A

1004-6062(2020)03-0191-008

10.13587/j.cnki.jieem.2020.03.020

2017-09-25

2018-05-02

国家自然科学基金资助项目(71440016、71672153);四川省科技计划项目(2015GZ0083-1)

李增禄(1991—),男,河南宝丰人;西南交通大学经济管理学院博士研究生;研究方向:物流与供应链管理,合作广告优化分析。

Funded Project:Supported by the National Natural Science Foundation of China (71440016, 71672153) , and the Sichuan Science and Technology Program (2015GZ0083-1)

中文编辑:杜 健;英文编辑:Charlie C. Chen