Analysis on Safety Problems in Power Engineering Management

2019-12-26OuHuibin

Ou Huibin

(Hunan Chendian International Development Co.LTD,Yizhang Branch Company,Chenzhou,Hunan 424200)

Abstract:In the process of power engineering management,the adoption of effective safety management measures will not only help to guarantee the construction quality and progress of the whole project,but also help to ensure the safety of life and property of relevant construction personnel,which has great significance to maintain social stability.This paper will expound the common safety problems in the current power engineering management,and put forward some effective control measures combined with examples,and provide reference for the relevant workers.

Key words:power engineering;safety problems;field management

In the process of the development of China's socialist modernization,the power resources have made a great contribution,but at the same time,it has also got a rapid development.However,in the process of power engineering construction,it is affected by various factors,such as non-standard construction,loopholes in management,etc.,which leads to the continuous occurrence of all kinds of safety accidents and causes relatively bad social impact.Therefore,we must pay attention to the field safety management of power engineering,take effective management measures to control all kinds of safety risks in the embryonic stage,and ensure the smooth construction of power engineering.

I.Analysis of Safety Problems in Power Engineering Management

(i)The Relevant Management System is Not Perfect

At present,in the process of power engineering construction,on the one hand,the relevant managers themselves have a weak sense of safety prevention.In the process of site management,there are omissions in detail management,and they cannot take effective management measures to prevent the safety risks existing in the construction site,leading to frequent safety accidents.On the other hand,the safety-related management system is not perfect,resulting in many work in the implementation stage,there is no specific implementation norms,and there is no corresponding management mechanism for all kinds of safety risk settings.These two reasons lead to a lot of resistance and obstacles in the safety management of power engineering,which cannot eliminated safety hazards completely.

(ii)Enterprise Risk Awareness is Weak

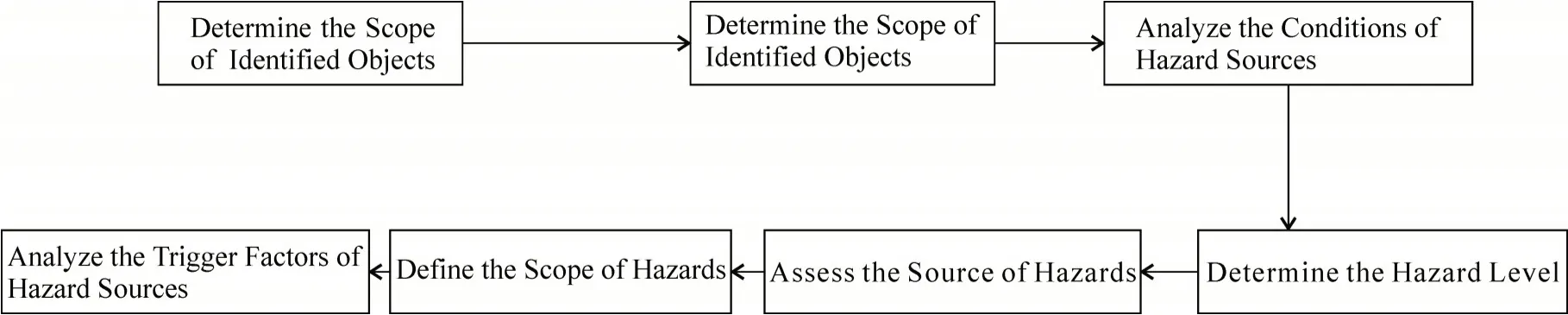

Figure 1 Electrical Engineering Safety Hazard Identification Program

Lack of attention is also one of the main reasons that lead to all kinds of power engineering risk accidents.Many construction enterprises mainly focus on the quality and progress of construction,and pay insufficient attention to the safety risk management of the project and lack of risk awareness.As a result,effective risk prevention measures are not taken or the scope of risk prevention measures cannot cover the whole power engineering project.

(iii)Safety Management Equipment is Insufficient

Lots of corresponding safety management equipment of power engineering construction site has the problem of insufficient input,and the construction personnel can’t be protected effectively.Even some construction enterprises are not equipped with the corresponding safety protection tools in the construction process in order to meet the requirements of the project construction progress,which has buried a huge safety hidden trouble to the power project construction.

In addition,the lack of on-site management level leads to the chaotic organization of the construction site of the power project.Lots of equipment is not placed in the designated position according to the requirements,which not only affects the smooth construction of the whole project,but also affects the personal safety of the relevant construction personnel.

(iv)Power Engineering Construction Personnel Quality is Not High

In the electric power engineering construction,many construction personnel themselves have low level of education,the professional technical level is seriously insufficient,and not yet able to operate some professional electric power construction equipment.In addition,the project management personnel of electric power engineering are lack of communication with the construction personnel,unable to effectively convey the management intention and technical points,and fail to effectively convey the safety hidden dangers found to the construction personnel,resulting in many safety hidden dangers in the construction site.

In addition,in order to speed up the construction progress,many construction personnel did not carry out construction in strict accordance with the requirements of the construction design in the actual operation process,they only execute based on experience construction,which also laid a great safety hazard to the project.

II.Safety Management Strategy in Force Engineering Management Process

In the process of safety management of power engineering,it is necessary to correctly identify the safety risks on site,then take effective control means to control and manage the identified safety risks,and finally complete the risk notification,assessment and evaluation.

(i)Safety Hazard Identification Procedures

Generally,according to the safety hazard sources during the construction of power engineering,the hazard sources are determined according to the steps shown in figure 1.

(1)Determine the identified objects.For power engineering,all the construction related risk factors are the objects of safety hazard identification.

(2)Identify the hazard sources.This process is mainly to identify the hazard sources in the construction site of electric power engineering,and to analyze the types of safety accidents and potential hazards that may result from them.Combined with the characteristics of the construction site of electric power engineering,hazard identification should be carried out from the aspects of construction methods,mechanical equipment and tools,use of chemicals,material handling,integrity of protective facilities,temporary equipment and operating environment.

(3)Determine the trigger conditions,factors and scope of influence of hazard sources.Based on the identified safety risk sources,the occurrence conditions,influencing factors and the possible influence range are evaluated,which can provide theoretical basis for the formulation of safety management measures,reduce possible errors in subjective judgment and minimize the occurrence of safety accidents.

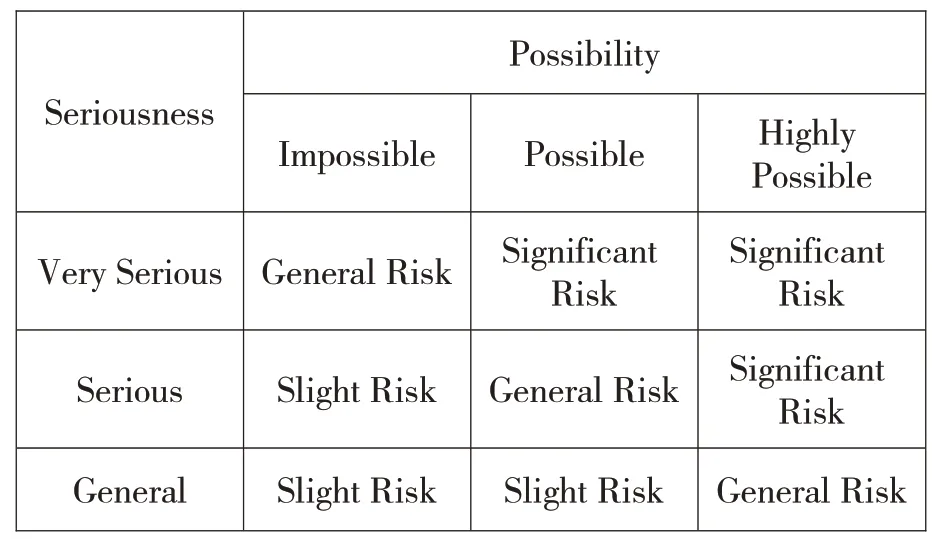

(4)The level of security risk.Through the above steps,the various safety risks existing in power engineering are classified according to the accident risk level (as shown in table 1),so as to help relevant managers to focus on the safety management of the site.

Table 1 Classification of Safety Risk Level in Power Engineering Site

(ii)Power Engineering Safety Management and Control Mode

(1)Feed forward control.Before power engineering construction,identify,analyze and judge the possible hazard sources of the project,set corresponding technical and management measures for different levels of safety risk sources,and take preventive measures to eliminate hazard sources in advance to avoid the occurrence of safety accidents.

(2)In-process control.During the construction of power engineering,the main hazard activities should be monitored in real time,relevant safety information should be timely grasped,and the deviation should be rectified with effective control measures in time,so as to avoid the occurrence of safety accidents.

(3)Emergency control.Emergency control is a relatively passive management mode.It is to reduce the loss caused by the safety accident according to the pre-set emergency control plan after the accident occurs.It is commonly used to deal with the safety risks caused by some force majeure factors,such as rainstorm,mountain flood,earthquake,etc.

(iii)Risk Notification

Risk notification is to take various forms,such as meetings,posters,official websites and other ways to publicize the risks found in the construction site of power engineering,so as to ensure that all the personnel involved in the construction are aware of the types of safety hazards and the control measures needed to be taken,so as to improve the risk management awareness of safety officers and avoid the occurrence of safety accidents.

III.An Example Analysis of Safety Management Measures in Power Engineering

An 110kV substation project is designed with a total scale of 2×40 MVA and a total land area of 12,301 square meters.This project is mainly to complete the construction tasks of comprehensive production building,110kV and 35kV structure support foundation,main transformer foundation and other projects of the substation,so as to provide stable and reliable power supply for the covered area.From the perspective of construction technology,the construction content and construction difficulty of the project are relatively low.According to the investigation results of the construction site,the amount of earthwork in the early stage is relatively large due to the complex landform in this area.Moreover,the situation of cross operation in the construction site is serious.In order to ensure the safety of construction,the project adopts the following management measures.

(i)The Perfection of Organization

In order to ensure the smooth implementation of safety management of the whole project,the construction enterprise established a safety management team headed by the general manager,and set up professional technical personnel and safety supervision personnel to identify the safety risks existing in the site and prepare relevant preventive measures.At the same time,a part-time safety administrator is also set up for each work team to be responsible for the on-site safety supervision and inspection of each work team,and build up a comprehensive safety supervision network for the whole substation project.

(ii)Security Identification

Combined with the actual situation of the project and the characteristics of the surrounding environment,the project adopts the safety identification method of upper evaluation and lower debate.Firstly,according to the actual situation of the electric power engineering site,professional technical personnel will identify the safety of the construction site,so as to improve the safety risk awareness and method level of the site.Then,according to the actual situation,include the key safety risk points in the standardized operating instructions,and formulate corresponding management and control measures.Finally,the professional team carried out implementation and control of each behavior on the operation site to complete the identification and control of safety risks in the operation process.

(iii)Safety Management Measures

(1)Safety measures.According to the actual situation of the project,the location of temporary facilities,firefighting facilities,mechanical equipment and materials is clearly divided,and the general layout of construction is drawn to guide the classification and storage of all kinds of equipment and materials.At the same time,from the point of view of safety,the warehouse of dangerous goods is mainly managed,especially inflammable and explosive materials.In order to avoid their mutual ignition and detonation,effective protection and warning measures are taken.

(2)Safety equipment using Specification.For all electrical equipment and tools used in this project,it is required to conduct useful earthing and test the resistance of the ground connector to ensure that it meets the requirements of the standard specification before use.At the same time,all transformers,current transformers,capacitors,lightning protection equipment and so on in the construction process are required to achieve two-way grounding,no one from a grounding network at the same time into two grounding points.

(3)Fire control management system.In the process of construction,the distribution room,temporary shed,mobile room and so on are equipped with a corresponding number of firefighting equipment,and no one is allowed to misappropriate or damage the construction site firefighting equipment.At the same time,specially-assigned personnel should be assigned to check and replace firefighting equipment regularly to ensure its effectiveness.

(iv)Safety Management and Control

In order to further strengthen the safety management level of the site,the project also strengthened the collection and sorting of all kinds of construction information,through the timely analysis and processing of these information,with the help of the information management mode,the safety status of this project can be grasped in real time.For example,check the equipment use,maintenance and repair record information of the project to ensure the safe operation of the equipment.

IV.Conclusion

In conclusion,this paper analyzes the common safety problems in the management of electric power engineering by combining with the examples of electric power engineering,and effectively avoids the safety hidden dangers in the electric power engineering by identifying the safety risks and managing them in different levels.At the same time,information management means are also used to timely grasp the safety status of the site,which improves the timeliness and effectiveness of safety management,making the power engineering safety management level on a new level.