Discussion on the Role of Construction Engineering Safety Standardization in Safety Production

2019-12-26ZhangYongyong

Zhang Yongyong

(China Resources Construction Co.,LTD,Beijing 100000)

Abstract:The scale of construction project has become larger and larger,but in the process of construction there are also many safety problems.Construction engineering safety standardization plays an increasingly important role in the process of actual safety production.This paper will analyze the construction of safety standardization based on actual cases.

Key words:construction engineering;safety standardization;standardized construction;safety production;strategy discussion

With the rapid growth of the economy,people's living standards are constantly improving,the majority of the construction industry has also achieved a good development.However,with the number of construction projects increasing,many people begin to pay attention to the safety problems in the construction of projects.In order to realize the sustainable development of Chinese construction industry,we can adopt the management mode of safety standardization to manage construction projects better.This paper mainly discusses the role of safety standardization construction in safety production.

I.The Concept of Construction Safety Quality Standardization

In general,the construction safety quality standardization has many meanings,mainly including the following points:Firstly,all the contents of construction safety and quality standardization can often explain the content of construction site safety protection better.Construction personnel must ensure their own safety.Secondly,in the actual construction process,on the one hand,we should pay attention to the management mode of production,on the other hand,we should also pay attention to the safety and quality of the building,and effectively discuss whether the whole construction process seems reasonable.Therefore,in the actual construction,we can work out a reasonable construction process,and then choose professional construction personnel and construction team to build.When necessary,scientific management may be adopted.Be sure to involve all personnel in the construction process,only in this way can mistakes be avoided in the actual construction process.

II.The Content of Construction Project Safety Standardization Construction

(i)Managing the Construction Personnel According to the"Standard"

Firstly,all technical personnel should be assessed on their posts,and formulate the practical technical personnel mount post system according to actual development to ensure that all technical personnel are certified.Secondly,to better translate the responsibilities of all employees into actual work,and develop the relevant workflow in the actual process of work.Implement the safety responsibility into every post[1].Thirdly,let each department should be clear about their own responsibility,and fully implement the actual work.In the actual construction operation process,it is also necessary to effectively follow the relevant safety standards to perform better.Fourthly,carry out the supervision work strictly in accordance with the standard norms of the supervision and management personnel,and ensure that all personnel can carry out the supervision work in accordance with the regulations in the process of the operation,so as to eliminate the potential safety hazards.

(ii)Creating a Safe Working Environment

Relevant departments at all levels need to interact directly with other departments in the actual process of work,and then create more forms of activities,so as to better carry out work safety standardization.When necessary,people who have made outstanding contributions in their work can also be publicized and recognized through the news media and the Internet,and try to repost something positive.If the company does not complete the task within the specified time,the media can expose some bad behavior.

(iii)Ensuring Safety Input by Effectively Strengthening the Organization

In the actual construction process,we should first establish a leading organization responsible for construction safety,and effectively implement and study some daily work in the construction,and then better define everyone's responsibilities.Each project department of a construction project should have a number of dedicated personnel in place and effectively enforce some safety standards related to the construction site,only in this way can we create favorable conditions for the work of safety standards.

III.Current Situation of Standardization of Building Safety Quality

At present,most enterprises still have many problems in the process of standardization of construction quality,mainly include the following contents.

(i)The General Safety Education and Management Regulations are not In Place,Safety Technology Disclosure Work Cannot be Well Implemented

At present,in the process of safety management,Chinese construction enterprises have integrated more content of building safety production.Therefore,safety production has always played an important role in construction production.In the process of practical management,we must first develop the concept of "people-oriented" and take the core idea of scientific development as a guide.In addition,in the actual construction process,we also need to better improve the safety of all standardized construction measures,and conduct construction safety management strictly.In the actual operation process,it is also possible to comprehensively summarize the personal safety,operation behavior and site protection of the construction personnel,so as to better improve the whole construction environment,reduce the dangerous factors existing in the site,and make the safety production of the construction project better.Figure 1 shows some professionals learning safety education and management practices.People should organize more such learning and communicate with each other,so that the whole safety education and management procedures can be better implemented.

Figure 1 Security Specification Learning Scenario

(ii)Awareness of Major Hazards is Poor

According to the relevant data,the safety accidents that are easy to happen in the construction site at present mainly include falling objects,machines injury,object strike and other accidents.And the tools such as scaffold,earthwork and tower crane are more likely to induce safety accidents.It is precisely because the majority of construction units and construction personnel have insufficient awareness of prevention that such accidents can be induced[2].Although some people will come to the site for regular safety inspection,the risk of construction accidents cannot be really reduced.Therefore,it is necessary to strengthen the risk awareness of relevant personnel in time.

(iii)Construction Enterprise Management Model is Not Standardized

In general,no one has a comprehensive control of material management.The plan for the procurement phase is not very clear and the whole procurement process is not completed according to the actual requirements.In the process of construction,there are still some people disregard the interests of the collective profiteering and often buy some inferior materials,even did not consider the quality problem afterwards.In addition,there is no pre-job training for relevant personnel,who do not know the relevant rules very well,which will eventually lead more serious quality problems.If we do not pay attention to the repair and maintenance of machinery,it will affect the quality of the project.

IV.Countermeasures to Promote Construction Quality and Safety Standardization

(i)Optimizing Oversight and Management Measures

In the process of actual work,the existing working mode can be analyzed first,then the improvement method can be put forward,if necessary,it can be better managed by increasing the intensity and frequency of spot checks.Change the inspection method,which used to be just a formality,to ensure that all the inspection and technical disclosure work will play its due effect.

Through the effective improvement of the information system to monitor the progress of the project anytime,so that more information can be feedback.People also need to effectively understand the operational risks,potential safety accidents and other safety conditions in the actual process of work,and propose relevant solutions in a timely manner when problems are found.In the daily meeting,the summary opinions can also be put forward in time,and set up records later to avoid other problems occurs in the follow-up work.

(ii)Controlling Safety Problems by Strengthening Hazard Sources

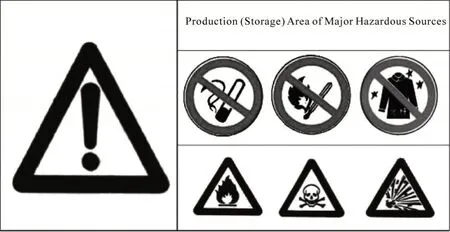

The majority of construction units need to conduct a comprehensive investigation of the hazard sources existing in the project.Before the actual construction,the hazard sources of this project can be analyzed first,and then timely summarize and sorted out the hazard sources and report to the department head.After receiving the report,relevant departments also need to make response in the first time.They can set warning signs near the source of danger.In addition,they can also make comprehensive monitoring with the help of modern means.Only when the environment is truly safe can the construction be carried out effectively[3].If there is no effective monitoring of the source of danger,it is necessary to deal with the relevant person in charge in the first place.When necessary,the person in charge can be punished accordingly.Only by effectively regulating the behavior of the construction personnel can the construction process become safer.Figure 2 shows warning signs near common hazard sources.Workers can place such a sign near the source of hazard.

Figure 2 Construction Hazard Sign

(iii)Formulating Corresponding Measures of Reward and Punishment

In view of the phenomenon that the management of the majority of construction enterprises is not standardized,the safety management departments at all levels should first establish the corresponding reward mechanism and punishment mechanism.Management departments at all levels need to inspect construction enterprises from time to time,and actively inform some personnel who have performed well in the construction of work safety standardization.If there are individuals who are not performing well in the production process,it is necessary to do rectification work within a certain period of time,and the personnel whose rectification is not in place need to be punished.Finally,a set of safety standards should be established.

V.Conclusion

To sum up,this paper first summarizes the concept of standardization of construction safety quality,and then analyzes the current situation of standardization of construction safety quality,so as to find the problems existing in its development process.The construction of safety standardization of construction engineering needs to adopt the methods of"optimizing oversight and management measures","controlling safety problems by strengthening hazard sources" and "formulating corresponding measures of reward and punishment"to solve related problems according to the actual situation.