Effect of tongue clearance on hydraulic performance of double support vortex pump

2019-10-31XingyngLiWnqingChenShengdunZho

Xing-yng Li ,Wn-qing Chen ,Sheng-dun Zho

a Pump Equipment Engineering Research Center of Shaanxi Province,Xi'an Aeronautical University,Xi'an,710077,China

b School of Mechanical Engineering,Xi'an Jiaotong University,Xi'an,710049,China

Keywords:Vortex pump Tongue clearance Non-uniform flow passage Numerical simulation

A B S T R A C T In order to study influence of tongue clearance on the hydraulic performance of double support vortex pump,three dimensional flow model with symmetric variable size tongue clearance was established by changing section parameter of tongue clearance,and applied to numerically simulate the steady inner flow in a vortex pump based on fixed working conditions and impeller through ANSYS FLUENT.The numerical results show the influence of tongue channel with two sections(non-uniform and uniform sections)on flow field characteristics in vortex pump.Firstly,the variation of tongue channel section changes the vortex structure distribution in circumferential flow channel.Specifically the spiral forward vortex structure in the circumferential direction shifts to large radius side with increasing tongue width.Secondly,the circumferential velocity gradient and axial pressure gradient both diminish with the increase of the tongue section,and the inlet/outlet pressure difference and velocity distribution also reduce with increasing tongue channel section.Finally,for vortex pump with non-uniform section of tongue channel,the head diminishes and the efficiency remains constant approximately with the increase of the tongue width,while the head and the efficiency both diminish for uniform section of tongue channel.

1. Introduction

Due to many advantages of simple structure,low power consumption,small size and high dependability,dual-support vortex pumps have been widely used in various occasions such as civil aviation,ships,military armored vehicles,and chemical industries[1],in order to replace other types of pump which face many restrictions in the context of use[2—4].Since the development of the vortex pump theory,due to the constraints of low efficiency in the use of traditional vortex pumps, it has become an important research on how to improve the coupling mechanism between vortex pump rotors and flow channels,in order to improve the output characteristics of vortex pumps under the same rotor conditions,and reduce the internal flow loss for improving working efficiency.In the open literatures,scholars at home and abroad reveal the coupling mechanism of impeller and fluid inside vortex pump, and analyze the energy transfer law between rotating impeller and fluid,based on the study of the flow theoretical model of vortex pump[3,4].At the same time,a large number of scholars[4—7]analyze the flow field structure of different vortex pumps in detail by the numerical simulation method,and obtain the influence rules of design parameters of vortex pump on its performance.Furthermore,the general effects of the structure parameter,such as number of blades and the size of flow channel,on the output performance of vortex pump are analyzed[8—10]by means of the experimental method,which provides an important reference for optimal design of vortex pump. In addition, many domestic research institutions such as Jiangsu university and Lanzhou university of technology have carried out a lot of works on impeller and runner structures [11—16], and Northwest A&F university[17—19]makes remarkable achievement in many aspects such as Modeling oscillation modal interaction in a hydroelectric generating system and Hamiltonian modeling of multi-hydro-turbine governing systems with sharing common penstock.The theoretical analysis and verification conclusions in their published literature provide important references for the design of vortex pumps.

For the research on flow field mechanism and structure optimization of vortex pump,published literatures show that a lot of works are mainly focused on analyzing mechanism about the influence of impeller structure on internal flow,while few researches have been made on flow field and output performance for the mature application of structure expansion for vortex pump product.Based on the previous research methods and the double support vortex pump with typical closed rectangular symmetric flow passage,this paper studies the effect of two kinds of continuously variable section of tongue flow passage,namely the uniform and non-uniform sections,on the hydraulic performance of the vortex pump.In this paper,a three-dimensional flow field calculation model is designed through Pro-E software,and the steady flow is simulated by ANSYS-FLUENT based on non-structured tetrahedral grid.Based on the structure of the impeller and the inlet/outlet,as well as the design parameters,this paper gives the characteristics of the output performance of the vortex pump about the tongue channel with the uniform and non-uniform cross-sections,and shows the influence of the flow passage section characteristic parameters on the inner flow field in the vortex pump.And then by comparing with the experimental results of the typical dualsupport vortex pump design model,this paper analyzes the influence mechanism of two kinds of sectional size parameters on the head and efficiency of vortex pump,which provides important reference for the optimal design of vortex pump.

2. Double support vortex pump model

The vortex pump studied in this paper is a typical closed double support structure,whose structure is shown in Fig.1(a).The vortex pump is composed of a pump body,a pump cover and an impeller.The inlet and outlet of the vortex pump are located at the top of the pump cover.The Fig.1(b)is the internal flow domain of the vortex pump,in which D2is impeller diameter.

The hydraulic structure about the cross-section of the flow passage of the vortex pump is shown in Fig.2(a),and the parameters in Fig.2(a)are given in Table 1 and Table 2.Fig.2(b)is the axial crosssection diagram of the vortex pump,which shows the location of the inlet/outlet,the distribution pattern of the blades and the location of the tongue.The rotations of the blades,which are distributed averagely along the radial direction,make the fluid move forward along the circumferential direction, when the fluid passes the spinning wheel of the impeller after entering the passage of the vortex pump.Meanwhile,the rotating kinetic energy is transformed into the fluid pressure energy,and finally the fluid discharges from the outlet of the vortex pump.The research in this paper is mainly the effect of the tongue clearance on the performance of the vortex pump,including the characteristic parameter of the tongue channel with variable and uniform cross-sections which are shown in Fig.2(c)and(d),respectively.Table 3 shows the working condition about the cross-sectional size of the tongue channel.In Fig.2(c),through keeping the height of the tongue channel G fixed and changing the width E1~E3,it is studied that the performance and inner flow field of the vortex pump are affected by the tongue clearance with the channel section increasing under the condition of the variable cross-sectional area A of the tongue channel.In Fig.2(d),through keeping the cross-sectional area of the tongue channel fixed and changing the width E1~E3 as well as the height G1~G3,it is studied that the performance and inner flow field of the vortex pump are affected by the tongue clearance under the condition of the fixed cross-sectional area A of the tongue channel.

3. Numerical method

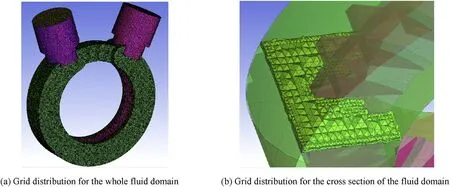

3.1. Computational mesh

Due to the complex structure of the dual support vortex pump fluid domain,the non-structured tetrahedral grid is obtained by ICEM software.The grid distributions of the whole fluid domain and its flow channel section are shown in Fig.3.Local mesh refinement is carried out for the region near blade,interface and channel shape with large gradient.Meanwhile,the domain nearby the wall at the tongue gives a small volume division to prevent the excessive size of the mesh in the variable-section region from affecting the overall grid quality and calculation accuracy.In order to improve the accuracy of the numerical simulation,the grid independence of the model is analyzed by calculating the percentage of the head of the vortex pump based on five different grids.The result is shown in Fig.4.It is indicated clearly that,with the number of grid gradually increasing,the difference in the percentage of the head gradually decreases.Considering the deviation of the calculation results and computation efficiency,the number of computational grid is set as 5.58×106,and the maximum deviation of the head is approximately 2.87%.

3.2. Governing equations and boundary conditions

Fig.1.Dual support vortex pump with closed impeller.

Fig.2.Parameters for the cross-section of the flow channel and the variation character of parameter for the cross-section of the tongue channel of the typical double support vortex pump.

Table 1 Design parameters of vortex pump.

Table 2 Structure parameters of vortex pump.

Based on the three-dimensional steady Reynolds-average N-S equations and RNG k-epsilon turbulence model,the flow in the double support vortex pump with rectangular channel was simulated with the segregated implicit method and the SIMPLEC algorithm of the pressure-velocity coupling. The Pressure term is computed by the two-order central difference scheme,and the velocity term,turbulent kinetic energy term and turbulence viscosity coefficient are computed by the two-order upwind scheme.For the numerical iterative computation,the convergence precision is 10-5[12,13].

About the numerical simulation for flow in the vortex pump based on the ANSYS-FLUENT,the boundary conditions are as follows:(1)The inlet is the boundary mass flow rate,and the flow rate was 0.6 m3/h according to the design parameters in Tables 1 and 2.(2)The water was used and its density is 998kg/m3.(3)The outlet is the condition natural outflow,and the flow rate is 1.(4)The boundary condition is no slip at the wall of the passage and the tongue region,and the standard wall function was used with the relative velocity ω being 0 rad/s.(5)The secondary boundary condition based on pressure was used for three-dimensional simulation,and the undeveloped turbulent flow was corrected by the wall function method.(6)The flow between the impeller and volute was disposed by the dynamic-static double coordinate systems.The region of impeller channel was based on the rotating coordinate system,and the angular velocity of rotation at the design condition ω is set to 345.4 rad/s according to the design speed.The angular velocity of rotation at impeller wallω is 0 rad/s.

3.3. Key performance parameters

The head of the vortex pump[12],with the unit being M,is calculated through the following expression:

In the Eq.(1),Po,Pi,νo2and νi2are pump exit static pressure,import static pressure,export speed,and import speed,respectively.The height difference between imports and exports can be considered as zero. And for working medium water, ρ=998kg/m3,g=9.98m/s2.

The expression about the efficiency of the vortex pump η[12]is

In the Eq.(2),Q and M are the mass flow and the torque with theunit being m3/h and Nm,respectively,ω is the rotation angular velocity,and the expression is ω=(n×2π)/60.

Table 3 Working conditions for numerical simulation on vortex pump.

Fig.3.Gird distribution for double support vortex pump.

4. Numerical results of the flow field in vortex pump with tongue channel of non-uniform cross section

4.1. Streamline structure in the channel of vortex pump

Based on the working conditions for carrying out the numerical simulation of the flow field in vortex pump with variable cross-section tongue channel,which are shown in Table 3,the velocity streamline characteristics in the vortex pump are analyzed by increasing the cross-section width of the tongue channel(E)under the condition of constant height of the tongue channel(G).Fig.5 shows the velocity streamline of the working conditions case 12 and case 19,which are corresponding to the small and large cross-section of the tongue channel respectively.

Fig.5(a)and(b)are the velocity streamlines starting at the inlet with different sectional area of tongue channel respectively.The fluid enters the circumferential passage of the vortex pump from the inlet along the radial direction,a spiral forward vortex along flow direction is formed and its size and strength increase gradually.The reason is that with the impeller rotating,the fluid at the root of the blade enters the clearance for the periodicity of blade which rotates with the impeller,and the fluid flows along radial direction with rotating centrifugal force,so that the spiral forward vortex is formed along the direction of rotation of the blade.The rotational kinetic energy of the impeller is converted into the pressure energy in the process of the fluid squeezed out periodically from the groove to the channel,and the pressure energy is increased with the influence of impeller when the fluid flows along the circumferential direction.Fig.5(a)shows that the streamline in the inlet region is affected by cross-section of the tongue channel,and the effect of the tongue clearance to backflow is small which results from the leaking fluid in the outlet region flowing into the inlet region.Therefore,the rotational kinetic energy of the impeller is converted to the fluid,so that the head increases.While for the large tongue channel,because the fluid is leaked to the inlet region from the tongue channel,the high pressure backflow has a strong import on the flow in the inlet region and impeller,as shown in Fig.5(b).It makes the fluid not effectively flowing into the impeller to achieve energy conversion,which affects the energy output efficiency of the vortex pump.Fig.6(c)and(d)are the velocity streamline distributions along the horizontal center section(Y=0)for tongue channel of different sectional area respectively.It can be seen that a high speed flow zone cannot be formed at the root of the blade for the tongue channel with larger area.A rotating vortex moving forward helically is not formed.The energy output action is weakened from the impeller to the fluid.And a strong fluid leakage occurs in the tongue clearance,a longitudinal vortex cannot be formed in the blade clearance for the backflow so as not to achieve efficient energy transfer process.While for the tongue channel with small area,there is obvious vortex structure characteristic between the blades and the fluid.It makes the rated capacity cavity to fully reflect the energy transfer of the fluid driven by the rotating blade,so that the fluid enters the flow passage and continuously outputs the pressure energy along the flow direction,thus improving the output head of the vortex pump.In Fig.5,the distribution law of velocity streamlines in different sections shows that:the distribution of tongue clearance has a great influence on the flow field structure inside the vortex pump.By setting a reasonable tongue clearance,the energy transfer between the impeller and the fluid can be effectively improved.

Fig.5.Velocity streamlines of vortex pump affected by tongue channel with variable cross-section.

4.2. Pressure and velocity field of the vortex pump

Fig.6 shows the pressure distribution at the axial cross-section of the vortex pump with tongue channel of two different crosssectional areas which correspond to case 12 and case 19.It can be seen that as the pressure gradually increases along the circumferential direction from the inlet to the outlet,the increase amplitude and law of increase about the pressure are similar basically at the inlet and outlet.Due to the influence of the cross-sectional width of tongue channel,a large area of low pressure is formed at the root of blades which are nearby the inlet,because the fluid leaks to the inlet along the sides of the tongue which is caused by the high pressure at the outlet,and it is so difficult for the fluid at the inlet to enter the impeller as to not form the effective energy exchange,and reduce the energy transfer efficiency. Meanwhile, the tongue channel with large cross-sectional area has disadvantages of not improving the inlet/outlet pressure differential and the head of the cortex pump.For the tongue channel with small cross-sectional area,the inlet/outlet pressure differential is larger,and there is an obvious pressure differential on both sides of the tongue region and increasing pressure gradient along the circumferential direction.These show that the small tongue clearance is beneficial to the energy transfer,and the pressure and efficiency increase normally.

Fig.6.Pressure distribution of cross-section of vortex pump with non-uniform cross-section tongue channel(z=-2mm).

Fig.7(a)and(b)are the velocity vector distributions of the variable cross-sectional tongue channel vortex pump,and two cross-sectional locations y=0 and x=0 are shown in Fig.5.By comparing the left figures in Fig.7(a)and(b),a symmetrical longitudinal vortex structure is formed on the central section of the blade clearance,the fluid enters the blade clearance from the outside of the impeller along the root of the blade,and flows toward the outside along the radial direction,then through both sides of the passage,finally goes back to the clearance at the root of the blade again.Therefore,a periodic spiral vortex is formed.For the tongue channel with small cross-sectional area,the cross-sectional velocity gradient is larger,and larger energy transfer is obtained when the fluid flows along the impeller.While for the tongue channel with large cross-sectional area,the radial velocity gradient is smaller,and the energy of the fluid cannot be increased because of the rotation of the impeller.By comparing the right figures in Fig.7(a)and(b),there is high speed leaked fluid at the cross-section of tongue channel with large area,which is bad to improvement of output pressure and energy output.It can be seen from velocity distribution at the axial section which shown in Fig.8(c)and(d),radial sectional velocity gradient is small for the tongue channel with large cross-section area,it is difficult to form a transverse vortex structure in the blade clearance,this is consistent with the distribution laws of the pressure field and velocity streamline,which is not conducive to the improvement of the output head of the vortex pump.

5. Numerical results of the flow field in vortex pump with tongue channel of uniform cross-section

5.1. Streamline structure in the channel of vortex pump

Based on the working conditions for carrying out the numerical simulation of the flow field in vortex pump with uniform crosssection tongue channel,which are shown in Table 3,the velocity streamline characteristic in the vortex pump are analyzed by adjusting the cross-section width(E)and height(G)of the tongue channel under the condition of constant cross-sectional area of the tongue channel.

Fig.8(a)and(b)show the velocity streamline of the working conditions case12 and case19,which are corresponding to the narrow and wide cross-section of the tongue channel respectively.By comparing Fig.8(a)with Fig.8(b),it can be seen that the streamline distribution standing for higher flow speed is formed on the outside channel of the impeller for the condition of the tongue channel with narrow cross-section,the fluid could not enter the impeller channel from both sides of impeller so as not to form flow vortex,but there is a large amount of fluid entering the both sides of the impeller for the tongue channel with wide cross-section,so that there is a longitudinal vortex structure distribution in impeller channel.Vortex structure for the condition of the wide crosssection has a relatively small impact on the inflow,while the outside channel of impeller for the condition of narrow crosssection has strong impact on the inflow,which weakens the energy exchange process between fluid and impeller.Therefore,it is effective to avoid the situation that the leak flow is formed at the outside diameter clearance of impeller because of the high pressure at the outlet by increasing the width of tongue channel,and then the influence of the outlet on the flow at the inlet region is reduced,so that the energy increasing process of the vortex pump along the circumferential direction is more efficient and continuous,finally the output efficiency and the head are improved.

5.2. Pressure and velocity field of the vortex pump

Fig.9(a)and(b)shows the radial cross-section pressure distributions of the vortex pump corresponding to the narrow and wide cross-sectional tongue channels respectively.The tongue width contributes to the improvement of the circumferential pressure gradient.The reduction of the tongue width leads to the outside clearance of the impeller increasing and the radial outside flow having strong leak,so as to affect the flow at the inlet and the improvement of the head and efficiency.

Fig.10(a)and(b)are the velocity vector characteristics of vortex pumps with two kinds of uniform cross-section tongue channel.The high speed leak occurs in the outside channel of the impeller for the condition of the narrow cross-section,and it is difficult for the fluid in inlet to enter the impeller for energy exchange.While for the condition of the wide cross-section,the longitudinal vortex structure is formed on both sides of the impeller and moves ahead along the circumferential direction in tongue region.This reduces the influence of the high pressure at the outlet on the flowfield in the inlet,and improves the head and efficiency of the vortex pump.According to the circular cross-sectional velocity distribution shown in Fig.10(c)and(d),the velocity gradients on the radial cross-section are similar for the narrow and wide cross-sections.However,the velocity gradient on the circular cross-section of the tongue region is larger,and the transverse vortex structure which moves along the flow direction is formed between the blades.This improves the energy transfer and the head of the vortex pump.

Fig.7.Velocity distribution of cross-section of vortex pump with non-uniform cross-section tongue channel(y=0 mm、x=0 mm).

Fig.8.Velocity streamlines of vortex pump with uniform cross-sectional tongue channel.

Fig.9.Pressure distribution of cross-section of vortex pump with uniform cross-section tongue channel(z=-2mm).

Fig.10.Velocity distribution of cross-section of vortex pump with uniform cross-section tongue channel(y=0 mm、x=0 mm).

6. Effect of the cross-section of the tongue on the performance of vortex pump

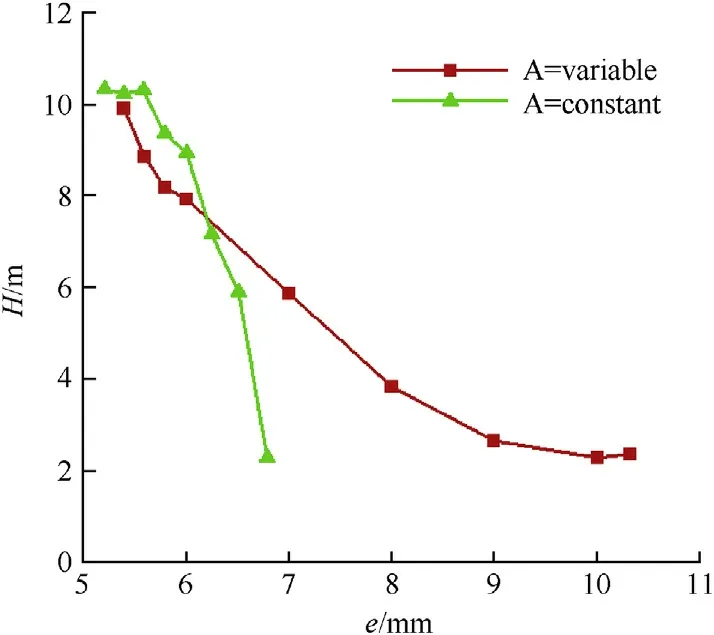

Fig.11 shows the effect of cross-sectional width(E)on the head of vortex pump with the tongue channel of the two kinds of crosssection.It can be seen from the Fig.11,as the width increases,the head of vortex pump reduces.And the laws of the influence of the cross-section on the output head are coincident basically.Fig.12 shows the effect of cross-sectional width on the output efficiency of vortex pump with the tongue channel of the two kinds of crosssection.It can be seen from the Fig.12,with the increase of the cross-sectional width of the tongue,the efficiency remains basically unchanged for the condition of variable cross-section,while reduces for the condition of uniform cross-section.

7. Conclusion

In this paper,the effects of tongue channel with different crosssection on the internal flowfield and performance of vortex pump were studied under the conditions of the fixed flow channel and impeller,and the conclusions were given as follows.

(1)The effects of the cross-section characteristic of the tongue channel on the performance of the vortex pump were studied.The variation of cross-section of the tongue channel could affect the vortex structure distribution of the radial inlet flow of the vortex pump in the flow channel,so that the energy exchange efficiency between the impeller and the fluid and the pressure distribution of the vortex pump are changed.

(2)With the increase of the width of the tongue,the inlet flow of the vortex pump will be more difficult to enter the channel of the impeller.And the spiral forward vortex structure of the vortex pump will shift along large radius.Furthermore,the output efficiency and the head of the vortex pump are both reduced.

(3)Increasing the cross-section of the tongue channel will reduce the velocity gradient along the circumferential direction and axial pressure gradient.And the radial vortex structure shifts towards the side of the large radius.This is not conductive to the improvement of the head and the efficiency.

(4)When the width of the tongue channel increases,the head of the vortex pump reduces and the efficiency is not changed basically for the condition of the variable cross-section,while the both reduce for the condition of the uniform crosssection.

Fig.11.Effect of the width of tongue passage on the head

Fig.12.Effect of the width of tongue passage on the efficiency.

According to the results of numerical simulation,this paper only studies the influence of single features including width and height of the rectangular tongue channel of vortex pump.The output performance and internal flow field of vortex pump are obtained,but the influence of many coupling factors in the vortex pump design cannot be taken into account.The subsequent researches include the coupling analysis of design and structure and iterative simulation of structure multi-parameters. At the same time,through the numerical simulation for the double support vortex pump,the fast model of its specific structure can be established and the flow field characteristics can be analyzed.In the study of numerical simulation for the double support vortex pump,the reliability and accuracy of the numerical simulation can be constantly improved by modifying its computing method and boundary conditions based on the existing test data.Then the basic experimental research of the similar model for the flow field structure of the vortex pump and the design of the visualization research method of the flow field are carried out.Finally the law about the influence of the internal flow field on the output performance of the vortex pump is verified by the tests,which provides important data support for fully mastering the optimization design method of the vortex pump.

Acknowledgment

We would like to thank the National Natural Science Foundation of China(No.51575420);the Local Service Special Project of the Education Department of Shaanxi Province,China(No.14 JF011);the Special Fund Project of Major Science and Technology Innovation of Shaanxi Province,China(No.2017ZKC01-24,No.2018TP-17);Xi'an Science and Technology project,China(No.201805032YD10CG16(5))for the support.

杂志排行

Defence Technology的其它文章

- Defence Technology

- Electrodynamic response study on railgun launcher based on electromechanical coupling model

- Electroless nickel fabrication on surface modified magnesium substrates

- The catalytic activity of transition metal oxide nanoparticles on thermal decomposition of ammonium perchlorate

- Nuclear radiation shielding effectiveness and corrosion behavior of some steel alloys for nuclear reactor systems

- Surface modification of ammonium nitrate by coating with surfactant materials to reduce hygroscopicity