Novel aspects for thermal stability studies and shelf life assessment of modified double-base propellants

2019-07-16SherifElsuneyAshrfElghfourMostfRdwnAhmedFhdHosmMostfRmySdekAmrMotzSchoolofChemiclEngineeringMilitryTechniclCollegeKoryElKoCiroEgypt

Sherif Elsuney , Ashrf.M. A. Elghfour , Mostf Rdwn , Ahmed Fhd ,Hosm Mostf , Rmy Sdek , Amr Motz School of Chemicl Engineering, Militry Technicl College, Kory El-Ko, Ciro, Egypt

b British University in Egypt, Elshrouk city, Cairo, Egypt

Keywords:Double-base propellant Thermal stability Artificial aging Shelf-life assessment

A B S T R A C T Modified DB propellants, based on energetic nitramine (RDX) were manufactured by solventless extrusion process. Thermal stability and shelf life assessment of modified DB propellant were investigated. Shelf life assessment was evaluated using Van't Hoff's formula and artificial aging at 70°C up to 120 days. Quantification of total heat released and heat flow with aging time was conducted using differential scanning calorimetry (DSC) and thermal activity monitoring (TAMIII) respectively. Modified DB formulation based on 20 wt % RDX demonstrated enhanced thermal stability in terms of controlled heat flow, and slow decomposition reactions at elevated temperature. This formulation demonstrated extended service life up to 56 years compared with reference formulation. These novel finding was ascribed to the high thermal stability of RDX and its compatibility with DB constituents.This manuscript shaded the light on novel and effective approach for thermal stability via monitoring thermal activity with aging.

1. Introduction

Modified double-base (DB) propellants have found wide applications in modern military and space rocketry, due their superior performance in terms of enhanced thrust compared to conventional DB[1,2].Modified DB propellants are evolved by integrating energetic fillers such as HMX or RDX[3-6]. Energetic heterocyclic nitramine (RDX) could be an ideal energetic filler for DB propellants. RDX can offer potential characteristics including [7]:

· High thermal stability with decomposition temperature 213°C

· High enthalpy of formation +318 kJ/kg

· High heat of combustion 5.647 kJ/kg

· High volume of gaseous products 903 L/kg

All these features can inherit RDX a vital role for the development of DB propellants. Therefore RDX can significantly enhance the combustion characteristics in terms of specific impulse(thrust per unit weight of effective propellant),as well as burning rate.RDX can act as a blowing agent generating large amount of inert gasses pushing the luminous flame from the burning surface.Therefore it can offer superior platonization characteristics.

RDX has a slightly negative oxygen balance as well as high heat of combustion. This means large amount of gaseous products at high combustion temperature. These features can offer enhanced combustion and ballistic characteristics mainly high specific impulse. Specific impulse is the thrust conveyed to a vehicle per effective weight of propellants; it is expressed in second (S).Modified DB propellants based on RDX can offer wide range of specific impulse that can be varied from 220 to 270 S [8-11]. This can extend the application of DB propellants in booster, sustainer,and dual thrust rocket motors [11-13]. Our recent research conducted on ballistic performance of modified DB propellants demonstrated enhanced combustion characteristics; as RDX offered enhanced thrust and action time. Fig. 1 represents the impact of RDX content on pressure-time curve of DB propellants using small-scale ballistic evaluation test motor.

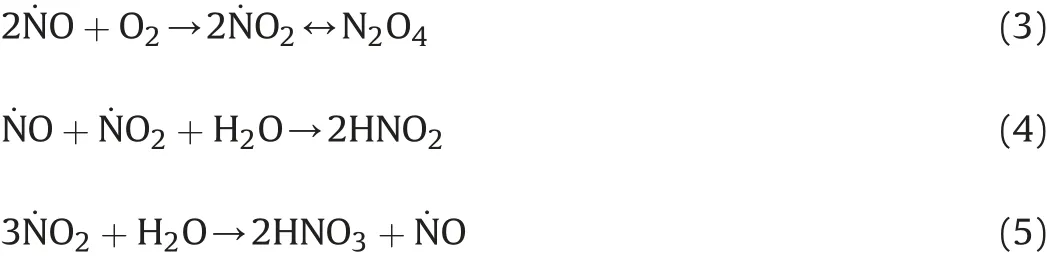

RDX offered an increase in specific impulse, characteristic exhaust velocity,action time,and total impulse(Table 1)[11,14-16].

There was an increase in the total impulse with RDX content.

The great impact of RDX on combustion characteristics was attributed to its positive heat of formation (+417 kJ/kg). RDX is an efficient explosive material with explosion heat of 5.647 kJ/g and gaseous product of 903 L/kg [14]. RDX has a slightly negative oxygen balance which means low molecular weight decomposition products [14,17]. Although, much research has been directed to investigate the combustion characteristics of modified DB propellants [7,18-20]; less attention has been directed to explore the impact of different energetic additives on thermal stability and shelf life assessment [21]. Thermal and chemical stability is one of the major drawbacks of DB propellants. The main energetic constituents of DB propellants i.e. nitrocellulose (NC) and nitroglycerine (NG) are molecules that aren't chemically stable. Whereas,decomposition of DB propellants is slow at ambient conditions; it becomes autocatalytic in harsh environmental conditions [9]. The main mechanisms through which chemical decomposition could take place include:

1.1. Chain reactions

Chain reactions begin with the homolytic breaking of the weak O-NO2bond,forming nitrogen dioxide and corresponding alkoxyl free radical [22-24]. The generated reactive free radicals instantly undergo successive reactions with nearby nitrate ester molecules(Equation (1)) [24].

1.2. Saponification (hydrolysis)

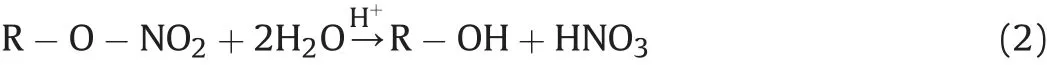

Another decomposition mechanism is hydrolysis of nitrate esters[23].This reaction is catalyzed by moisture and acidic residues(Equation (2)).

Another main decomposition reaction is the enhanced hydrolysis.This reaction with low activation energy of 71 kJ/mol could be the dominant reaction at low temperatures [25].

1.3. Auto-catalytic reactions

Decomposition products of reaction (2) can undergo further decomposition in the presence of moisture and oxygen as follow

Whereas the primary hemolytic reaction (2) can't be suppressed, the consecutive reactions (3-6) can be slowed down by binding or elimination of acidic residues from the system. Stabilization of DB propellants can be achieved by integrating stabilizing agents [25,26]. Stabilizers are capable of binding with nitrogen oxides to neutralize the decomposition products[27].Stabilized DB propellants can offer a safe shelf life of at least 20 years[28];similar shelf life should be secured for modified systems [29]. Completeinformation about the influence of high energy ingredients on thermal behavior and shelf life assessment of DB propellant is vital[30-33].So far,the real impact of energetic nitramines on thermal behavior and shelf life assessment of modified DB propellant is not fully investigated [34].

Table 1Combustion characteristics of modified DB propellants based on RDX.

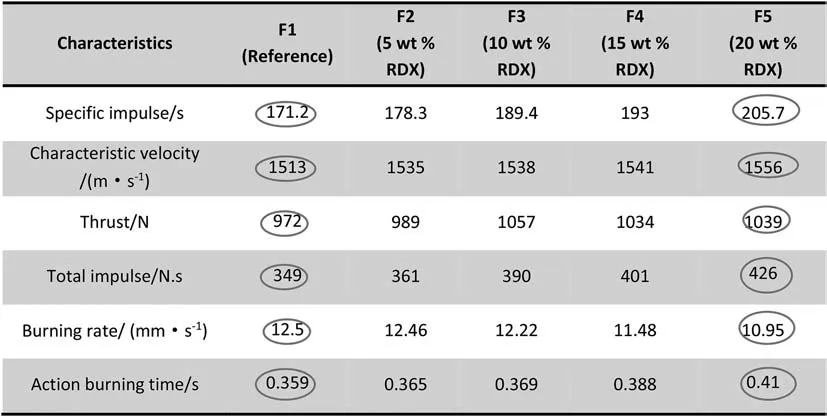

It is widely accepted that thermal analysis (i.e. DSC) refers to a group of techniques in which a physical property of a substance is measured as a function of temperature whilst the substance is being subjected to a controlled heating in a controlled atmosphere.Calorimetry refers to measuring techniques that are used for direct determination of rate of heat production, heat flow, and heat capacity as function of temperature and time (Fig. 2).

All chemical and physical processes result in either heat production or heat consumption. Micro calorimetry is a versatile technique that can monitor the thermal activity in terms of heat,heat flow,and heat capacity.Thermal activity monitoring(TAM III)works by channeling the heat produced or consumed by a reaction in the sample through heat flow sensors comprised of thermoelectric modules. When a temperature gradient is imposed across the thermoelectric module, a voltage is created. This voltage is proportional to the heat flow through the thermoelectric module and hence proportional to the rate of heat production or consumption by the sample.One side of the thermoelectric module is in contact with the sample and the other is kept isothermal by a heat sink. TAMIII can find wide application in monitoring the thermal stability of DB propellants with aging time.

This paper is devoted to investigate the effect of energetic nitramine (RDX) on thermal stability of DB propellants, as well as shelf life assessment. Shelf life assessment of modified DB propellants was conducted using artificial aging by isothermal heating at 70°C for up to 120 days and employing Van't Hoff's equation.Quantification of total heat released with aging time was conducted using DSC.Furthermore quantification of heat flow with aging time was performed using TAMIII. Modified DB formulation based on RDX demonstrated enhanced thermal stability with lower decomposition rate relative to reference formulation. Furthermore it demonstrated extended service life up to 56 years. This is the first time ever to employ TAMIII in shelf life investigation.

2. Manufacture of modified DB propellants

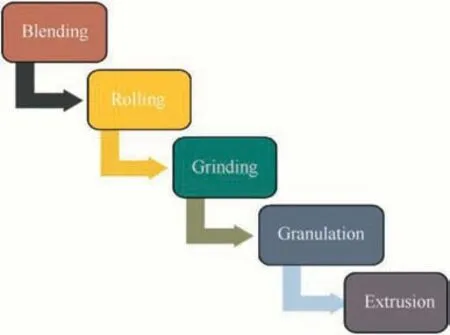

It is widely accepted that screw extrusion technique can secure good mixing of different ingredients to the molecular level, high density,and dimensional stability of DB propellants.This technique includes many stages including: blending, followed by rolling,grinding, granulation, and finally extrusion to obtain DB grains of required shape and dimensions (Fig. 3) [35].

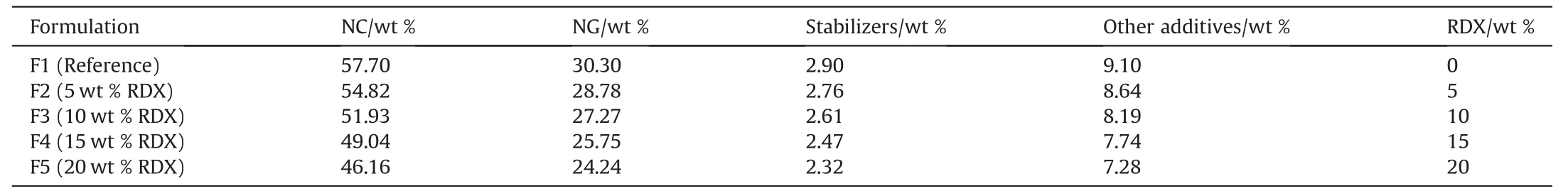

Different modified DB propellants based on RDX up to 20 wt %were developed by solventless extrusion technique. The chemical composition of developed modified DB formulations is represented in Table 2.

Fig. 2. Schematic for common techniques of thermal analysis and calorimetry.

Fig. 3. Schematic for solventless extrusion process for manufacture of modified DB propellants.

3. Thermal stability of modified DB propellants

The impact of nitramine additive on thermal stability was investigated to secure safe storing, handling transportation, and processing [5,27-29]. Onset decomposition and self-ignition temperatures as well as total heat released upon combustion are the main parameters which need to be precisely evaluated. These parameters were assessed for modified DB propellant using DSC.The thermal activity during isothermal heating was monitored using TAM III.

3.1. Thermal behavior using DSC

DSC measurements offer quantitative information about physical and chemical changes (i.e. onset temperature, phase change,exothermic/endothermic decompositions) as a function of temperature or time (according to STANAG 4515). The measurements were performed using DSC-Q 2000 (Thermo-scientific, USA).1 mg of modified DB propellant was heated up to 350°C at 10°C/min,under nitrogen gas flow at 5 ml/min.

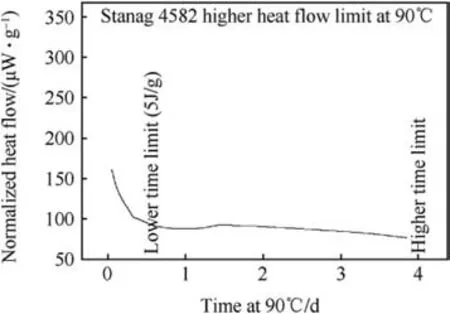

3.2. Thermal activity monitoring using TAM lll

TAMIII represents an ultra-sensitive heat flow measurement.This technique is complementary to thermal analysis instruments such as DSC. The NATO standardization STANAG 4582 was employed to standardize a procedure for the assessment of DB propellant thermal stability based on heat flow micro calorimetry method. Heat flow measurements were carried out via isothermal mode at 90°C. The weight of investigated sample was 4 g. The tested propellant sample was stored at isothermal heating 90°C for 3.43 days.It is widely accepted that these conditions are equivalent to an isothermal storage at 25°C for at least 10 years.According to STANAG 4582, the tested sample can offer 10 years service life, if the maximum heat flow is ≤of 5 J/g (350 μW/g at 90°C for 3.43 days).

4. Shelf life assessment of DB propellants

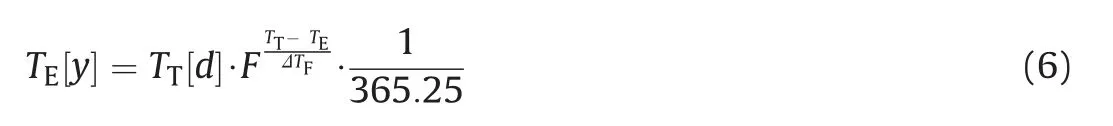

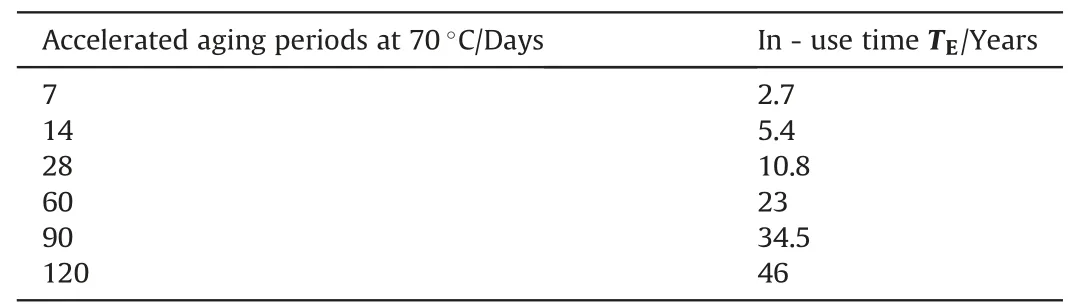

Artificial aging was conducted to reduce the time scale by storing the propellant at high storing temperature. This approach can offer prediction of service life in short time interval [36,37].Artificial aging was performed by isothermal heating at 70°C under ambient atmospheric conditions. The developed modified DB formulations were stored under isothermal heating for 7,14,28,60,90 and 120 days [38]. Van't Hoff's formula (Equation (6)) allowed the estimation of in-service periods at given in-storage temperatures,from the equivalent time-temperature loads during the artificial ageing. Van't Hoff's formula has been proved to be appropriate to ascertain the time-temperature profile [39].

Table 2Chemical structure of developed modified DB propellants.

WhereTE, TT, F and ΔTFare time in years at the in-service temperature(TEin°C),test time in days at the test temperature(TTin°C),reaction rate change factor per 10°C of temperature change (F usually between 2 and 4),and temperature interval for actual value F respectively. Factor F was determined using Arrhenius Equation(7) [39].

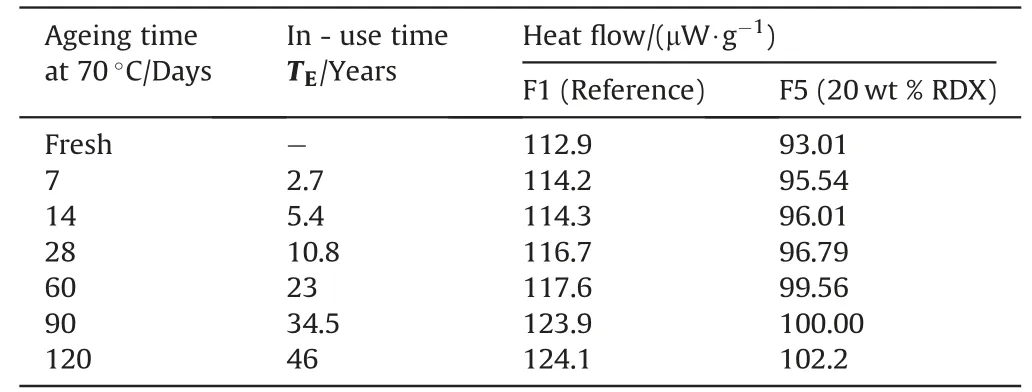

Where Eais the activation energy (kJ/mol), and R is the ideal gas constant; F factor was deduced by compiling and comparing reaction rates obtained at different temperatures [36]. The range for F factor is often between 2 and 4 [39]. Table 3 demonstrates the artificial ageing conditions simulating an in-use time up to 46 years at 25°C for developed modified DB propellants.

5. Thermal behavior of modified DB propellants

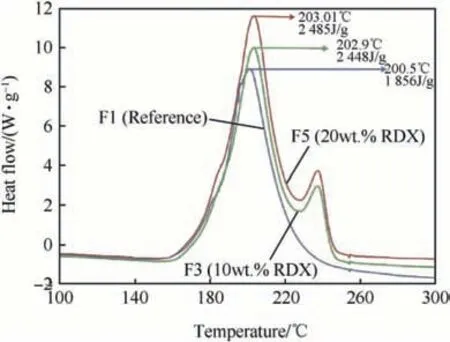

Differential scanning calorimetry (DSC) can monitor any physical or chemical change which involves the evolution/absorption of heat. The total heat released maximum decomposition temperature, and onset decomposition temperature all these parameters can be evaluated using DSC; these parameters were evaluated for modified DB formulations compared to reference formulation.Even though, modified DB propellant demonstrated thermal behavior similar to reference formulation in terms of maximum decomposition temperature;they were found to be more energetic with an increase in total heat released with RDX content (Fig. 4).

It is apparent that the onset decomposition temperature and maximum decomposition temperature are similar for all formulations. Modified DB formulation based on RDX demonstrated an extended decomposition peak with further heat output at 240°C.The extended secondary decomposition peak was correlated to exothermic decomposition of RDX. RDX is an energetic filler with high decomposition temperature and high thermal stability [7].Modified DB with 10 wt % and 20 wt % RDX demonstrated an increase in total heat release by 21%and 34%respectively.The impact of artificial aging on thermal behavior of reference formulation was investigated using DSC (Fig. 5).

Table 3Ageing times calculated on the basis of thermal equivalent load at TE=25°C using the generalized Van't Hoff's rule with factor F=3.

Fig. 4. DSC thermograms of fresh F0 (Reference), F2 (10% RDX), F4 (20% RDX)formulations.

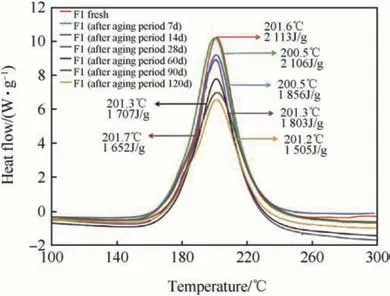

One of the main outcomes of this study is that reference formulation demonstrated a dramatic decrease in total heat release with aging time; this behavior was ascribed to the thermal decomposition reaction with aging.These decomposition reactions include chain reactions (Equation (1)), saponification (Equation(2)), and autocatalytic (Equations (3)-(5)). The breakdown of explosophorous groups to free radicals could decrease the resulted heat output during combustion.

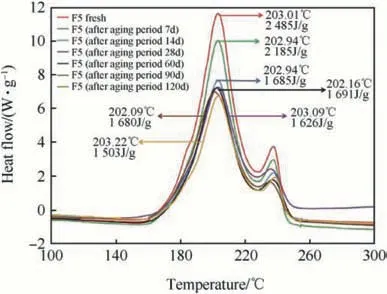

All developed modified DB formulations exhibited similar thermal behavior with aging time to reference formulation. This behavior includes a decrease in total heat released with aging(Fig. 6). Modified DB propellants may degrade by thermal decomposition of NC and NG, which might start with the hemolytic breakdown of the O-NO2bond of the aliphatic nitrate esters[25].This degradation can withstand the decrease in heat released with aging time.DSC thermograms confirmed the finding that there is in total heat release with aging time.This behavior was ascribed to the decrease in the required activation energy to start the chemical conversion.

Fig. 5. Thermal behavior of F0 (Reference) DB formulation with aging time.

Modified DB propellant based on RDX demonstrated thermal behavior with aging time similar to reference formulation. The secondary decomposition peak at 240°C can be ascribed to the thermal stability of RDX; higher energy is required for the activation of RDX.

Fig. 6. Thermal behavior of modified DB propellant F4 (20% RDX) with aging time.

6. Thermal stability of modified DB propellants

Thermal stability was assessed using micro calorimeter; this was accomplished by monitoring the heat flow as a function of time while the sample being heated at 90°C for 3.43 days.These testing conditions mimic the real storage conditions for 10 years[STANAG 4582]. In this study TAM III micro calorimeter was employed to assess the thermal stability of developed modified DB propellants by monitoring of the heat flow versus time (days) and its value at the end of experiment.The heat flow thermogram of DB propellant using TAM III at isothermal heating temperature of 90°C is represented in Fig. 7.

The heat flow measurements were conducted for the freshly manufactured DB propellants.The change in thermal stability with aging time was further investigated for modified DB propellants to reference formulation.The tracing of the heat flow for modified DB propellant based on 20 wt % RDX to reference formulation with aging was performed in an attempt to determine the maximum shelf life developed propellant (Table 4). The critical point for thermal stability is 350 μW/g at 90°C according to standard STANAG 4582.

The analysis of the obtained results proved that the formulation samples examined by TAM III satisfy the criteria of limit of stability presented by STANAG 4582,and that modified DB propellant based on RDX demonstrated higher thermal stability than reference formulation.Modified DB formulation is stable for 46 years and can be stored for further 10 years.It is apparent that TAMIII an invasive technique that can offer fast recognition about thermal stability and shelf life of DB propellant.

Fig. 7. STANAG plot of NEDB propellant base on 20% RDX (7 Days aged).

Table 4TAM III Thermal behavior of Reference and MDB (20% RDX) with aging time.

7. Conclusion

Modified DB propellant based on RDX 20 wt % offered not only enhanced ballistic performance but also good thermal stability using DSC and advanced thermal activity monitoring (TAMII)micro-calorimeter. Artificial aging was found to be an effective approach to facilitate the planning service life and to simulate the natural ageing of developed MDB propellants. Artificial aging was conducted using and Van't Hoff's formula. Quantification of total heat release with aging time was conducted using DSC. Furthermore,novel approach to quantify thermal activity with aging time was conducted using TAMIII. MDB propellant formulations based on RDX demonstrated enhanced thermal stability and extended service life compared with reference formulation. It exhibited service life up to 56 years. This novel finding confirms that RDX is effective energetic filler that could enhance both the combustion characteristics and thermal stability.

杂志排行

Defence Technology的其它文章

- Body armour - New materials, new systems Ian G. Crouch*

- Special materials in pyrotechnics VII: Pyrotechnics used in thermal batteries☆

- Real-time calculation of fragment velocity for cylindrical warheads

- Heavy metal free primers: Polymorphism of gadolinium and titanium in the context of GSR glass phase Felice Nunziata

- Mitigation of EDFA transient effects in variable duty cycle pulsed signals

- Ballistic impact properties of woven bamboo- woven E-glassunsaturated polyester hybrid composites