楔形减阻旋耕刀设计与试验

2019-05-24郝建军于海杰赵建国李建昌马志凯蔡金金

郝建军,于海杰,赵建国,李建昌,马志凯,蔡金金

楔形减阻旋耕刀设计与试验

郝建军,于海杰,赵建国,李建昌,马志凯,蔡金金

(河北农业大学机电工程学院,保定 071001)

为解决旋耕整地作业阻力大、能耗高等问题,该文基于旋耕刀理论受力模型设计了一种楔形减阻旋耕刀。采用Inventor和HyperMesh软件分别创建国标旋耕刀及楔形减阻旋耕刀的三维模型和切削土壤模型,分析了楔形减阻旋耕刀的应力强度,对比了国标旋耕刀与楔形减阻旋耕刀的切削阻力。通过田间试验对比了国标旋耕刀与楔形减阻旋耕刀的扭矩、功耗与碎土率。结果表明:楔形减阻旋耕刀所受最大应力为29.49 MPa,远小于材料的屈服强度430 MPa,在保证刀身强度的前提下,与国标旋耕刀相比,楔形减阻旋耕刀质量减轻8.3%;平均切削阻力较国标旋耕刀下降10.65%。在相同工况条件下,楔形减阻旋耕刀的平均扭矩为648.916 N·m,较国标旋耕刀下降11.35%;楔形减阻旋耕刀的平均功耗为67.3 kW,较国标旋耕刀下降9.29%,碎土率提高4%,耐磨性能与国标旋耕刀持平,能够达到在降低作业功耗的同时,提高耕作质量并保证刀具使用寿命。

农业机械;土壤;模型;楔形减阻旋耕刀;田间试验

0 引 言

旋耕可一次完成耕地、碎土、整地等作业,达到犁耙几次耕地的效果,且旋耕后的地表平整、松软,一次性使土壤达到待播状态,是目前平原地区采用的主要耕作方式[1-3]。旋耕阻力及能源消耗主要来源于旋耕刀[4]。为减小旋耕阻力,生产中通常采用理论减阻、振动减阻和仿生减阻等方法。理论减阻主要是通过改变旋耕刀的工作参数、折弯角和刃口角等结构,来降低切削阻力[5-7],如陈雪等采用ADAMS软件对旋耕刀工作参数进行了优化,极大地降低了旋耕刀阻力[8]。盖超等采用COSMOSwork软件分析了不同旋耕刀折弯角的切削功耗,结果表明折弯角在125°~130°时功耗最小[9]。康松林等采用LS-DYNA软件分析了双面刃口与单面刃口对切削阻力的影响,结果表明双面刃口阻力小于单面刃口阻力[10];振动减阻通过凸轮机构的摆动使旋耕刀在切削土壤的同时,通过振动使土壤疏松,从而达到降低耕作阻力的目的[11-13]。如蒋建东等在旋耕刀轴部位加装凸轮机构,利用刀具振动来降低切削阻力,结果表明合适的震动频率及幅值能够实现土壤耕作减阻[14];仿生减阻主要是参考蚯蚓、鼹鼠等动物表皮、爪趾等特点,对旋耕刀的材料和结构进行优化设计,从而达到减少耕作阻力的目的[15-17]。如郭俊等根据鼹鼠指爪结构优化旋耕刀,结果表明在秸秆覆盖50%以上时,优化的旋耕刀耕作阻力低于国标旋耕刀[18]。上述减阻技术虽在一定程度上都能降低旋耕耕作阻力,但振动减阻需要加装相应装置,在增加了制造成本的同时也增加了机具故障率;仿生减阻多为被动模仿生物的生物学特性,结构复杂,不易加 工[19-21]。而理论减阻通过优化改进刀具自身结构参数实现减阻,不增加机械结构且易成型加工。为此,本文针对典型的IT245型国标旋耕刀旋耕阻力大的不足,设计一种楔形减阻旋耕刀,旨在通过改变旋耕刀表面形状结构以降低切削阻力。

1 旋耕刀结构与受力分析

1.1 国标旋耕刀结构、工作过程及受力分析

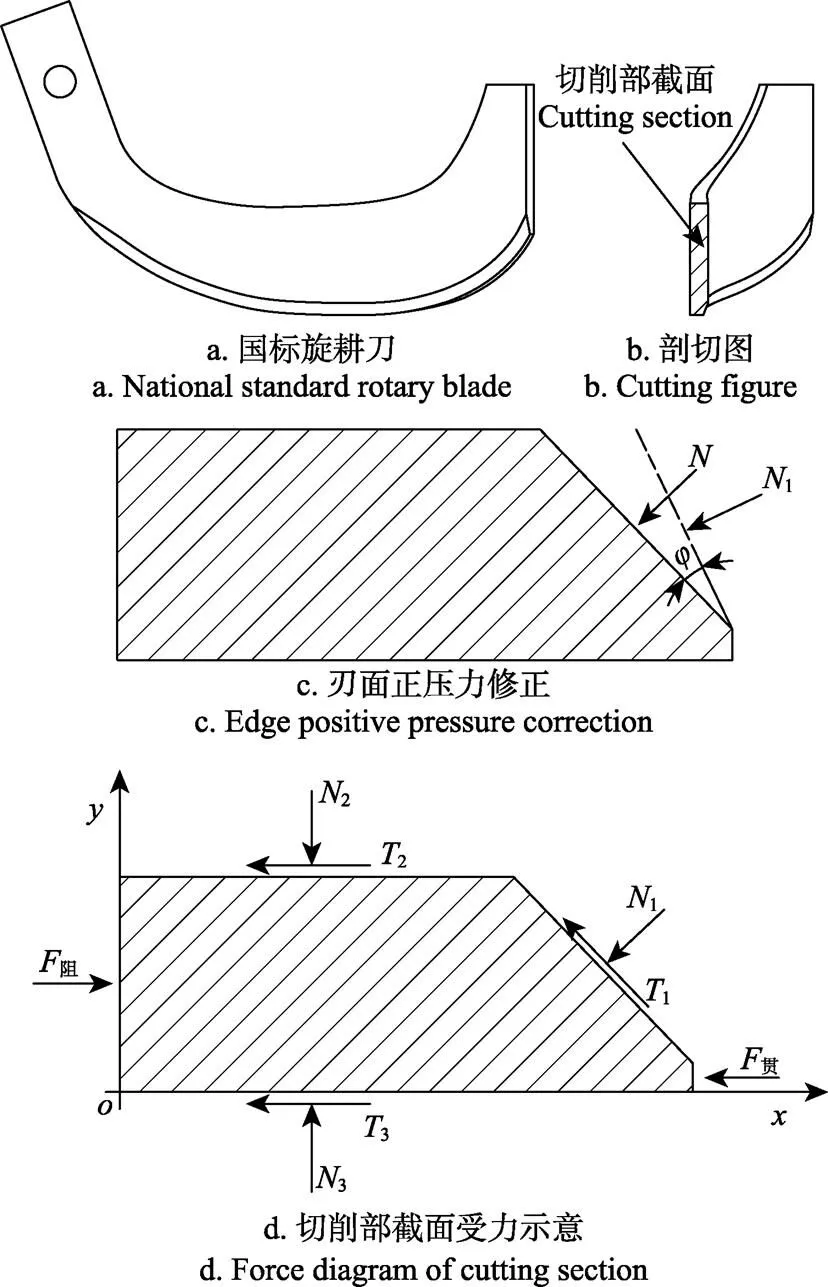

根据其弯转向不同,旋耕刀可分为左旋刀与右旋刀2类。典型的IT245型右旋国标旋耕刀结构及其参数如图1。旋耕作业时,旋耕刀侧切刃与正切刃先后切入土壤,通过对土壤进行周期性挤压、切削、破碎、抛甩,完成旋耕作业[22-23]。

如图2,以国标旋耕刀切削部任一截面为研究对象,进行受力分析。假设旋耕为纯切削(主要以刃口贯入与切开阻力为主,以Kostritsyn建立的切削计算模型,未考虑土壤粘附力,只考虑了土壤变形破坏后对刀具所起反力的作用平衡)[24],土壤为均质土壤[25],并认为不发生其他形式的土壤破坏[26],刀具匀速切入土壤。当考虑摩擦时,依据文献[10],土壤相对旋耕刀的滑动摩擦系数为0.2,土壤与刃口发生滑动摩擦,产生摩擦角,且相当于把刃口角增加,如图2c所示,刀刃面上修正后的正压力1为:

式中1为修正后刃面上的正压力,N;为修正前刃面上正压力,N;为土壤和滑切刃之间的动摩擦角,(°)。

1. 刀柄 2. 刀头 3. 主切削刃 4. 副切削刃 5. 国标旋耕刀(右旋)6. 土壤 7. 刀座 8.刀轴

1. Blade handle 2. Blade head 3. Main cutting edge 4.Auxiliary cutting edge 5. National standard rotary blade (right-rotary) 6. Soil 7. Blade holder 8. Blade shaft

注:刀柄宽=30 mm;刀轴孔直径=13 mm;刀轴孔边距=15 mm;旋转半径=245 mm;切削刃宽度=12 mm;切削刃厚度=4 mm;正切面高度=50 mm;耕作宽幅=50 mm;折弯角=120°;折弯半径=30 mm;为旋耕刀旋转速度,r·min–1;为拖拉机前进速度,km·h–1。为坐标原点。

Note: Blade handle width=30 mm; Rotary blade hole diameter=13 mm; Rotary blade hole space=15 mm; Radius of gyration=245 mm; Cutting edge width=12 mm; Cutting edge thickness=4 mm; Blade height=50 mm; Tillage width=50 mm; Bending angle=120°; Bend radius=30 mm;is rotation speed of rotary blade, r·min–1;is tractor forward speed, km·h–1.is origin of coordinates.

图1 右旋国标旋耕刀结构参数与工作示意图

Fig.1 Structural parameters and working sketch of right-handed national standard rotary blade

依上所述,对国标旋耕刀进行受力分析。图2为国标旋耕刀切削部任一截面受力分析图。设沿轴向右、轴向上为正方向,旋耕刀沿、方向的受力如下:

式中为力的个数;X为国标旋耕刀切削部截面投影在方向的第个力,N;Y为国标旋耕刀切削部截面投影在方向的第个力,N。

注:x为横坐标,y为纵坐标,T1为刃面剪力(即摩擦力),N;N2为刀身正面的正压力,N;T2为刀身正面的剪力,N;N3为刀身背面的正压力,N;T3为刀身背面的剪力,N;F贯为旋耕刀切入土壤的贯入阻力,N;F阻为旋耕刀切入土壤所受到的阻力和(即切削阻力),N;j为动摩擦角,(°)。N、N1为修正前后刃面正压力,N

需要说明的是,刃面剪力1在方向上的投影未作用在国标旋耕刀上,所以公式(3)未对其进行考虑,当考虑摩擦力时,1、2、3均为土壤相对于旋耕刀表面的滑动摩擦力,其滑动摩擦力公式为:

式中T为刀面及刃面上的第个剪力,N;为滑动摩擦系数;tan;N为刀面及刃面上的第个正压力,N。将式(4)代入式(3),求得3为:

将式(5)代入式(2),求得阻为:

由公式(6)可知,切削阻力阻与刀面及刃面上的正压力N、滑动摩擦因数和刃口角有关,N值越大切削阻力越大,表明土壤越不易切削;在其他条件不变的情况下,滑动摩擦因数越大,切削阻力越大。旋耕刀刃口角过小时,土壤与滑切刃之间摩擦剧烈,土壤与刃口面直接摩擦,使得刃口面发生变形失效,如果刃口角度过大,旋耕刀的切削阻力也会随之增加[27]。研究表明,在进行土壤切削时,旋耕刀最小阻力刃口角在20°~45°之间[28],为便于冲压加工,国标旋耕刀对刃口进行45°倒角形成刃口角[29]。

1.2 楔形减阻旋耕刀设计及受力分析

1.2.1 楔形减阻旋耕刀设计

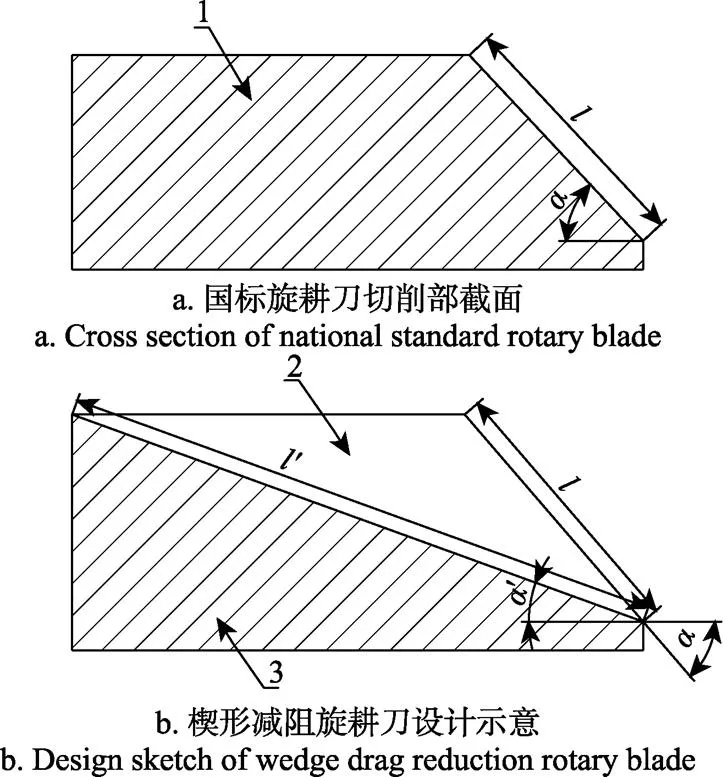

由上文可知,旋耕刀的切削阻力主要与刀面及刃面上的正压力、滑动摩擦因数和刃口角有关,由于滑动摩擦因数固定(滑动摩擦因数与接触材料和相对运动速度有关,耕作同一地块时,土壤参数基本一致,刀具相对运动速度一定),楔形减阻旋耕刀设计主要通过增大刃面宽度及减小刃口角来降低切削阻力。楔形减阻旋耕刀依据楔子原理将国标旋耕刀刀身变成一个较锋利的刃口,即楔形刃口,如图3所示。

1. 国标旋耕刀切削部截面 2. 优化部分 3. 楔形减阻旋耕刀切削部截面

1. Cross section of cutting part of national standardrotary blade 2. Optimized part 3. Cross section of cutting part of wedge drag reduction rotary blade

注:为国标旋耕刀刃面宽度,mm;为楔形减阻旋耕刀刃面宽度,mm;为国标旋耕刀刃口角,(°);为楔形减阻旋耕刀刃口角,(°)。

Note:is edge width of rotary blade, mm;is edge width of wedge drag reduction rotary blade, mm;is edge angle of rotary blade, (°);¢is edge angle of wedge drag reduction rotary blade, (°).

图3 楔形减阻旋耕刀设计原理

Fig.3 Design principle of wedge drag reduction rotary blade

如图3所示,1为国标旋耕刀切削部截面,去除优化部分2,得到楔形减阻旋耕刀的切削部截面3。楔形减阻旋耕刀的刃面宽度大于国标旋耕刀的刃面宽度,刃口角小于国标旋耕刀的刃口角,刀柄宽度、刀孔直径、刀孔距、旋转半径、刃口厚度、正切面宽度、耕作宽幅、折弯角均与国标旋耕刀相同。

如图4所示,为楔形减阻旋耕刀(以右旋为例)结构参数示意图。

耕作深度是评价旋耕质量的指标之一,旋耕刀的旋转半径及弯折角影响耕作深度。楔形减阻旋耕刀与国标旋耕刀的旋转半径与弯折角相同,因此,评价耕作质量时耕作深度不予考虑。楔形减阻旋耕刀刃口角变小,与国标旋耕刀相比更容易切入并切碎土壤,因此,本文仅以碎土率评价耕作质量。

注:刃面宽度l'=31~50.09 mm。

1.2.2 楔形减阻旋耕刀受力分析

为明确楔形减阻旋耕刀是否满足减阻要求,对楔形减阻旋耕刀进行受力分析,图5所示为楔形减阻旋耕刀切削部任一截面的受力情况。

注:o为坐标原点;x为横坐标;y为纵坐标;N1¢为修正后刀刃面上的正压力,N;T1¢为刃面剪力(即摩擦力),N;N3¢为刀身背面的正压力,N;T3'为刀身背面的剪力,N;F阻¢为楔形减阻旋耕刀切入土壤所受到的阻力和(即切削阻力),N。

与1.2.1节国标旋耕刀给定情况相同,其沿、方向的受力为:

将式(4)代入式(8),求得3¢为:

再将式(9)代入式(7),求得阻¢为:

由图2d、图5可知,旋耕刀刃口厚度不发生变化,即贯大小相同,比较阻与阻¢,由式(4)可知,当动摩擦因数一定时,T与N正相关,由《机械土壤动力学》可知,当刀具单位载荷一定(即刀具均匀受力)时,其所受正压力与承载面积成正比。楔形减阻旋耕刀刀身表面所受压力小于国标旋耕刀,即阻¢<阻,因此楔形减阻旋耕刀能够达到降低切削阻力的目的,且更易于切削土壤。

2 旋耕刀切削运动仿真

采用HyperMesh软件分别对国标旋耕刀与楔形减阻旋耕刀的切削土壤过程进行仿真,分析其切削过程、应力大小及切削阻力,以验证楔形减阻旋耕刀设计的合理性。

2.1 有限元模型建立

2.1.1 刀具有限元模型

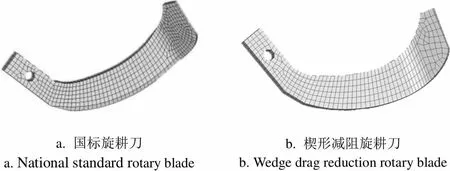

在Inventor软件中按照GB/T5669—2008《旋耕机械刀与刀座》中旋耕刀几何参数进行三维实体建模,同时对楔形减阻旋耕刀建模,如图6所示,利用HyperMesh(能够测量刀具质量,楔形减阻旋耕刀质量减轻50 g,较国标旋耕刀下降8.3%)完成刀具有限元模型的网格划分,采用5 mm网格对2种旋耕刀进行划分,国标旋耕刀的网格数量为931个,楔形减阻旋耕刀的网格数量为670个,参照LS-DYNA-971用户手册,刀具单元定义为刚性材料MATL20,2种刀具模型材料均为65 Mn,密度为7.8×10-6kg/mm3,弹性模量为2.1×108kPa,泊松比为0.3。

a. 国标旋耕刀a. National standard rotary bladeb. 楔形减阻旋耕刀b. Wedge drag reduction rotary blade

2.1.2 土壤-刀具模型

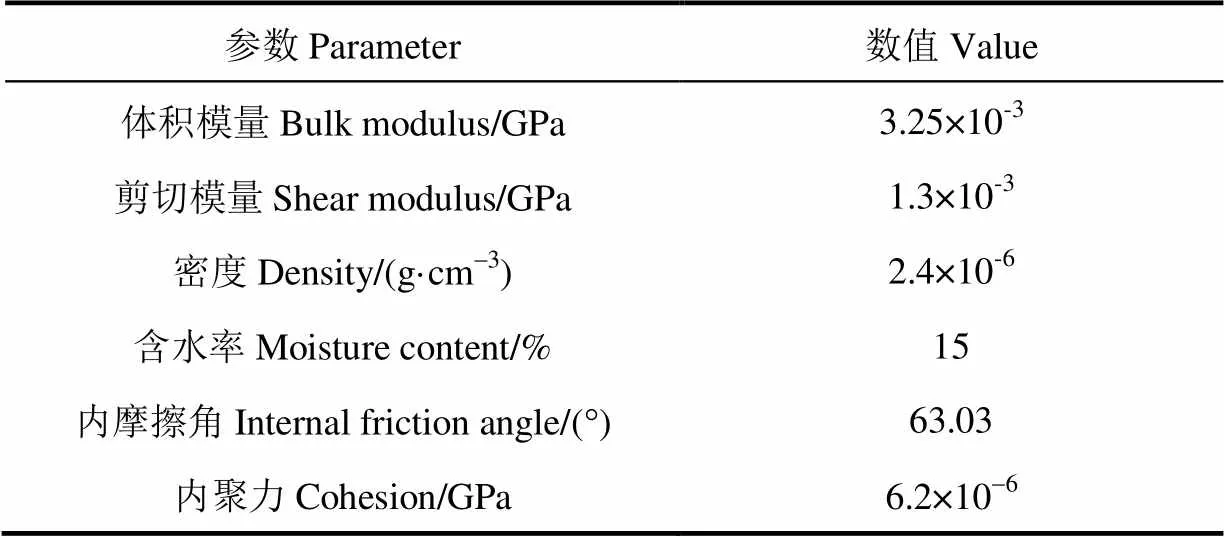

由于HyperMesh软件中没有自带土壤模型,在仿真过程中先选择HyperMesh自带的材料模型MATL1,然后根据关键字手册把土壤模型改为MAT193(MAT_drucke_ prager)塑性土壤模型,并结合华北地区土壤特性[30]输入材料参数。土壤模型的主要参数取值如表2所示(依据后文田间试验土壤实际状况,秸秆均已粉碎还田,仿真试验未考虑秸秆状况)。

表2 土壤参数

图7所示为土壤-旋耕刀初始模型,土壤模型尺寸为520 mm×200 mm×240 mm,为了缩短计算时间,采用分割法划分网格,将土壤网格划分为切削部分(尺寸为4 mm)和未切削部分(尺寸为8 mm)。

2.2 边界条件

对刀具与土壤进行相应的条件约束,第一步是对土壤模型的四周与底面进行全约束,保证在旋耕刀切削土壤过程中土壤能够保持恒定不动。第二步定义旋耕刀运动,使旋耕刀能够围绕旋转中心做旋转运动且有向前行进的速度。第三步对旋耕刀与土壤接触添加定义,选用面面接触AUTOMATIC_SUFACE_TO_SUFACE中的Eroding侵蚀接触,这种定义能够真实反映旋耕刀与土壤进行接触情况,设定滑动摩擦因数为0.2。

2.3 刀具切削过程及应力分析

刀具切削土壤时,随着载荷的增大,土壤先发生弹性变形,然后发生塑性变形,随后进入屈服状态并出现硬化现象。随着刀具的切入,应力继续增大,土壤发生失效,进而破裂[31]。

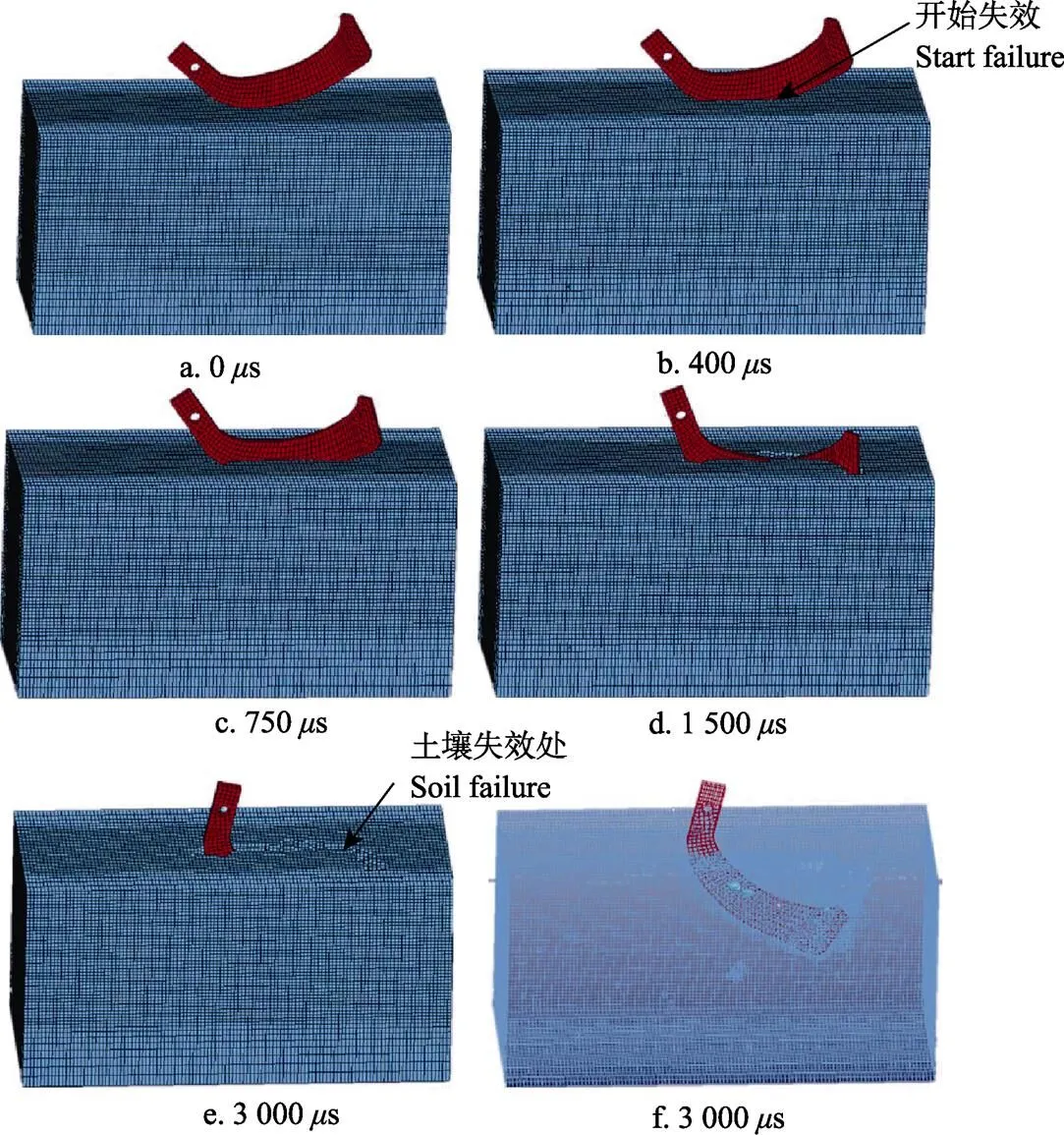

图8为国标旋耕刀在LS-DYNA中模拟仿真切削土壤过程。切削参数依据《GB/T 5668-2008 旋耕机》[32]选取:旋耕刀转速300 r/min(5 r/s),前进速度4.10 km/h(1.1 m/s),耕深150 mm。

由图8可知,0s时,旋耕刀与土壤进行接触;400s时,旋耕刀先沿侧切刃由近及远切入土壤,土壤受到剪切力的作用,开始发生变形;750~3 000s时,正切刃切入土壤,在旋耕刀的剪切与挤压共同作用下,土壤沿着旋耕刀正面发生破坏变形。

由图9a可知,国标旋耕刀工作时所受的最大应力为35.68 MPa,其远小于刀具材料的屈服强度430 MPa,验证了国标旋耕刀设计合理性;由图9b可知,楔形减阻旋耕刀工作时所受最大应力(29.49 MPa)小于国标旋耕刀最大应力(35.68 MPa),满足强度设计要求。另外,在满足强度设计的要求下,与国标旋耕刀相比,楔形减阻旋耕刀质量较小。

图8 旋耕刀切削土壤过程

图9 2种旋耕刀应力图

2.4 切削阻力分析

依照上文,已对2种旋耕刀的材料参数进行定义与边界约束,其工作参数为前进速度1.1 m/s,旋转速度5 r/s,耕作深度150 mm,定义旋耕刀为正旋,以切削阻力为指标,在HyperMesh软件中对2种旋耕刀的切削阻力进行分析,导出K文件,将K文件导入LS-DYNA中进行计算,对比2种旋耕刀切削阻力。

图10为国标旋耕刀与楔形减阻旋耕刀切削阻力仿真结果对比。由图10可知,旋耕刀由0s开始,切削阻力先上升,达到最大切削阻力之后再下降,直至旋耕刀切出土壤。模拟仿真的切削阻力趋势与参考文献[10,33]相似,证明了其研究可行性。国内学者葛云[34]、陈雪等[8]对国标旋耕刀切削阻力做了研究,得出国标旋耕刀的最大切削阻力大概为450~500 N,本文中,国标旋耕刀最大切削阻力为530 N,平均切削阻力为375.5 N,楔形减阻旋耕刀最大切削阻力为510 N,平均切削阻力为335.5 N,楔形减阻旋耕刀平均切削阻力比国标旋耕刀平均切削阻力降低了10.65%。

图10 旋耕刀切削阻力仿真结果对比

3 田间试验

为了进一步验证楔形减阻旋耕刀的减阻降耗效果与耕作质量,与国标旋耕刀进行了田间对比试验,以旋转扭矩[35]、功率消耗及碎土率为指标,评价楔形减阻旋耕刀的减阻降耗效果与耕作质量。

3.1 试验方法

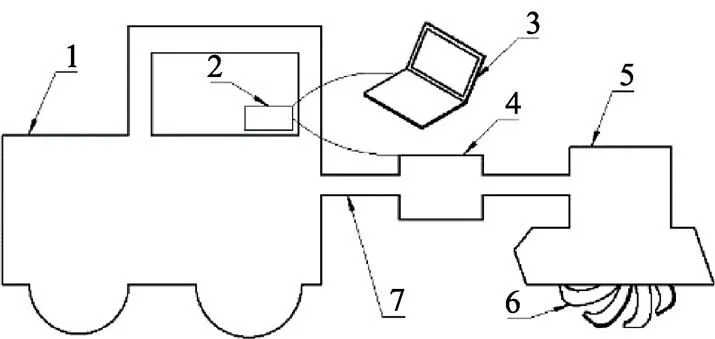

3.1.1 设备安装及扭矩传感器标定

如图11所示,将试验旋耕刀安装在旋耕机刀轴上,扭矩传感器在拖拉机后输出轴上与旋耕机相连。扭矩-转速-功率显示仪与扭矩传感器相连,并连接至电脑,将扭矩、功率信号通过数据线传递给电脑,用M400数据分析软件进行实时记录。

1. 拖拉机2. 扭矩-转速-功率显示仪3. 电脑4. 扭矩传感器5. 旋耕机6. 旋耕刀7. 输出轴

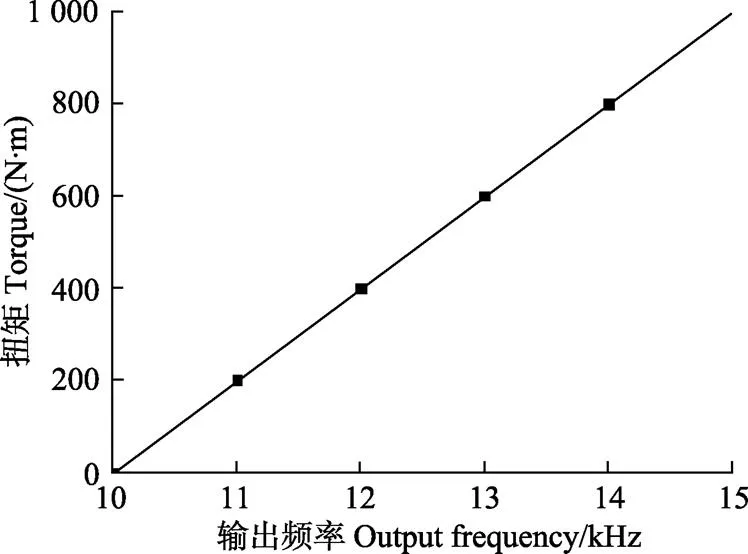

扭矩传感器标定结果如图12所示。根据标定结果,静止时,扭矩传感器的频率在10 000~10 040 Hz之间波动,扭矩传感器存在的误差为0.4%(即静止时,传感器频率波动值与初始频率的比值),误差在可接受范围之内,满足试验要求。

图12 扭矩传感器标定结果

3.1.2 试验设置

试验于2018年9月26号在河北省定州市内化村进行。

试验地为壤土,地势平坦,虽有部分秸秆,但均已粉碎还田,对土壤旋耕功耗不造成影响,0~150 mm土层内平均硬度为6.5 kg/cm2,平均含水率为15%。

将楔形减阻旋耕刀和国标旋耕刀分2次各自安装在河北双天机械制造有限公司生产的1GKN- 220A1旋耕机上,依次进行田间试验。

选取地势平坦的100 m×30 m地块,去除地头地尾各10 m,在中间80 m的旋耕机稳定运行段进行5次重复试验,测试旋转扭矩和功率消耗,取平均值。依据上文作业参数为:拖拉机前进速度取4.10 km/h,后输出转速540 r/min,刀辊转速为300 r/min,耕作深度为150 mm。试验装备及实物图如图13所示。

3.2 试验结果与分析

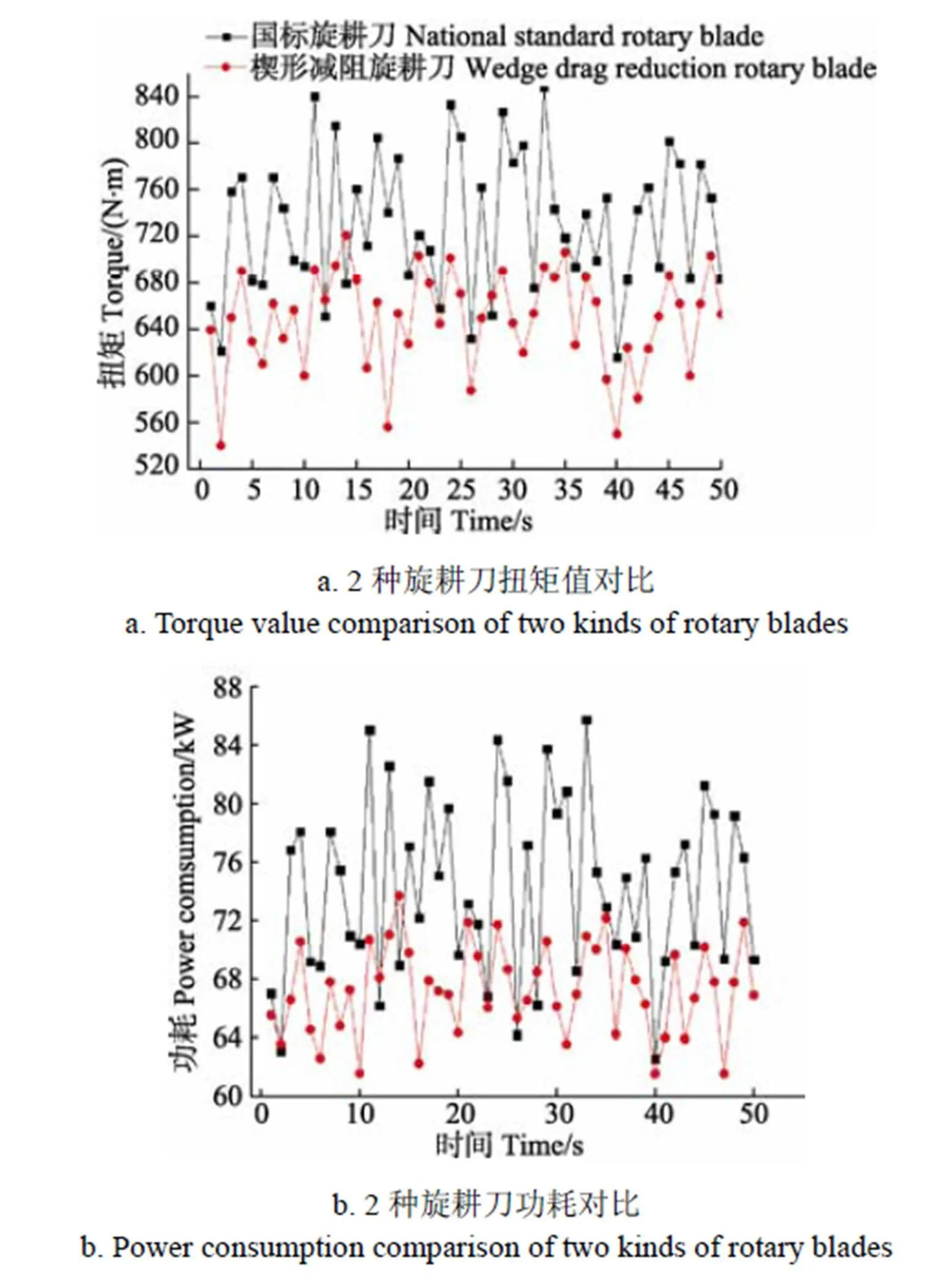

每次试验取稳定段测试数据,每次记录50 s数据,2种旋耕刀的扭矩和功耗测试结果如图14所示,质地复杂,旋耕扭矩波动比较大,2种旋耕刀扭矩趋势大致相似,符合试验要求。

由图14a可知,国标旋耕刀的平均扭矩值为732.038 N×m,楔形减阻旋耕刀的平均扭矩值为648.916 N×m,楔形减阻旋耕刀较国标旋耕刀平均扭矩下降11.35%。由前文可知,拖拉机后输出转速固定,结合扭矩计算公式[35],扭矩值能够对功耗进行表达且与功耗呈正线性相关,楔形减阻旋耕刀在作业过程中平均扭矩优于国标旋耕刀,进一步验证了楔形减阻旋耕刀节能降耗的可行性。

由图14b可知,楔形减阻旋耕刀功耗整体优于国标旋耕刀,国标旋耕刀平均功耗为74.2 kW,楔形减阻旋耕刀平均功耗为67.3 kW,楔形减阻旋耕刀较国标旋耕刀平均功耗降低了9.29%。

切削阻力与旋转扭矩都能够表示旋耕功耗,由仿真试验与田间试验可知,楔形减阻旋耕刀的切削阻力与旋转扭矩(均与功耗呈正线性相关)均较国标旋耕刀有所下降,功耗的下降虽然存在一定误差,但都在可接受范围之内。

图13 试验装备及实物图

如图15所示,对试验土壤采样并计算碎土率以评价旋耕刀耕作质量。在已旋耕的500 mm×500 mm耕层进行土壤采样5次,分别测试采样土壤质量总及土壤中直径大于40 mm的土块质量>40 mm,根据公式(13)计算碎土率R。

计算结果表明,国标旋耕刀与楔形减阻旋耕刀的平均碎土率分别为75%和79%。楔形减阻旋耕刀碎土率较国标旋耕刀提高了4%,耕作质量优于国标旋耕刀。

2018年9月30日,在河北保定庞口试验田对国标旋耕刀与楔形减阻旋耕刀的耐用性进行了田间对比试验。试验结果表明:经过连续不间断33 hm2耕作后,楔形减阻旋耕刀未发生崩刃和断裂现象,且其磨损程度与国标旋耕刀相当:国标旋耕刀的平均磨损量为98.5 g,楔形减阻旋耕刀的平均磨损量为97.3 g,磨损量相差1.3%。按规定旋耕刀磨损量超过100 g即无法继续使用。上述结果表明,在保证与国标旋耕刀耐用性基本持平的情况下,楔形减阻旋耕刀能提高耕作质量,降低作业功耗。

图14 2种旋耕刀的扭矩和功耗测试结果

图15 碎土率测算

4 结 论

1)基于楔子理论与刀具受力模型设计一种楔形减阻旋耕刀,分析国标旋耕刀与楔形减阻旋耕刀受力,可知切削阻力主要与动摩擦因数、刃口角与刃口角表面正压力相关;且国标旋耕刀切削阻力大于楔形减阻旋耕刀。

2)以旋耕刀与楔形减阻旋耕刀为研究对象,运用Inventor软件建立刀具三维模型,基于HyperMesh-LS- DYNA软件对刀具进行了切削过程及切削阻力分析。结果表明:模拟动态仿真能够客观的反映旋耕刀切削土壤过程;国标旋耕刀最大应力为35.68 MPa,楔形减阻旋耕刀的最大应力为29.49 MPa,其应力远远小于刀具材料的屈服强度430 MPa,在质量减轻8.3%的情况下,保证了刀身强度。国标旋耕刀的最大切削阻力为530 N,楔形减阻旋耕刀最大切削阻力为510 N,楔形减阻旋耕刀平均切削阻力比国标旋耕刀平均切削阻力低10.65%,验证了楔形减阻旋耕刀设计可行性。

3)田间试验结果表明:在标准工况条件下,楔形减阻旋耕刀的平均扭矩较国标旋耕刀下降11.35%,平均功耗较国标旋耕刀下降9.29%,平均碎土率较国标刀提高4%,楔形减阻旋耕刀与国标旋耕刀磨损量相差1.3%,耐用性基本保持一致。进一步验证了楔形减阻旋耕刀设计的合理性。

[1] 车刚,张伟,万霖,等. 基于灭茬圆盘驱动旋耕刀多功能耕整机设计与试验[J]. 农业工程学报,2012,28(20): 34-40. Che Gang, Zhang Wei, Wan Lin, et al. Design and experiment of multifunctional tillage machine with driven bent blade by stubble ploughing disk[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2012, 28(20): 34-40. (in Chinese with English abstract)

[2] Temesgen M, Hoogmoed W B, Rockstrom J, et al. Conservation tillage implements and systems for smallholder farms insemi-arid Ethiopia[J]. Soil and Tillage Research, 2009, 104(1): 185-191.

[3] 熊平原,杨洲,孙志全,等. 基于离散元法的旋耕刀三向工作阻力仿真分析与试验[J]. 农业工程学报,2018,34(18):113-121. Xiong Pingyuan, Yang Zhou, Sun Zhiquan, et al. Simulation analysis and experiment for three-axis working resistances of rotary blade based on discrete element method[J]. Transactions of tne Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 113-121. (in Chinese with English abstract)

[4] 方会敏,姬长英,张庆怡,等. 基于离散元法的旋耕刀受力分析[J]. 农业工程学报,2016,32(21):54-59. Fang Huimin, Ji Changying, Zhang Qingyi, et al. Force analysis of rotary blade based on distinct element method[J]. Transactions of tne Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(21): 54-59. (in Chinese with English abstract)

[5] 张居敏,周勇,夏俊芳,等. 旋耕埋草机螺旋横刀的数学建模与参数分析[J]. 农业工程学报,2013,29(1):18-25. Zhang Jumin, Zhou Yong, Xia Junfang, et al. Mathematical modeling and analysis of helical blade for stul rotary tiller[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(1): 18-25. (in Chinese with English abstract)

[6] 贾洪雷,汲文峰,韩伟峰,等. 旋耕-碎茬通用刀片结构参数优化试验[J]. 农业机械学报,2009,40(7):45-50. Jia Honglei, Ji Wenfeng, Han Weifeng, et al. Optimization experiment of structure parameters rototilling and stubble breaking universal blade[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(7): 45-50. (in Chinese with English abstract)

[7] 汤楚宙,谢方平,向卫兵,等. 自推进耕耘机械研究现状与分析[J]. 农业机械学报,2001,32(5):112-114. Tang Chuzhou, Xie Fangping, Xiang Weibing, et al. Current situation of study on self-propelled cultivation machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2001, 32(5): 112-114. (in Chinese with English abstract)

[8] 陈雪,张周,黄化刚,等. 基于ADAMS旋耕刀工作参数优化及ANSYS仿真分析[J]. 现代农业科技,2018(2):167-170. Chen Xue, Zhang Zhou, Huang Huagang, et al. Optimization of rotary blade working parameters based on ADAMS and ANSYS simulation analysis[J]. Modern Agricultural Sciences and Technology, 2018(2): 167-170. (in Chinese with English abstract)

[9] 盖超,董玉平. 基于COSMOS的还田机械旋耕刀弯折角优化[J]. 农机化研究,2011,33(3):30-33. Gai Chao, Dong Yuping. Optimization of bending angle of rotary machine rotary tilling blade based on COSMOS[J]. Journl of Agricultural Mechanization Research, 2011, 33(3): 30-33. (in Chinese with English abstract)

[10] 康松林. 微耕机刀具的有限元分析及优化[D]. 重庆:重庆理工大学,2015. Kang Songlin. Finite Element Analysis and Optimization of the Tool of Rotary Tillers[D]. Chongqing: Chongqing University of Technology, 2015. (in Chinese with English abstract)

[11] Butson M J, Mac I D. Vibratory cutting soil tank studies of draught and power requirements[J]. Journal of Terramechanics, 2004, 40 (1): 186-190.

[12] 殷涌光,程悦荪,李俊明. 振动式二维切削土壤减小阻力机理[J]. 农业机械学报,1992,23(2):11-16. Yin Yongguang, Cheng Yuesun, Li Junming. The reasons of resistance reduction for vibaatory cutting soil in two directions[J]. Transactions of the Chinese Society for Agricultural Machinery, 1992, 23(2): 11-16. (in Chinese with English abstract)

[13] 高洁,赵颖娣,Willem Hoogmoed,等. 基于ALE有限元仿真的土壤切削振动减阻[J]. 农业工程学报,2012,28(增刊1):33-38. Gao Jie, Zhao Yingdi, Willem Hoogmoed, et al. Numerical simulation on resistance reduction of soil vibratory tillage using ALE equation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(Supp.1): 33-38. (in Chinese with English abstract)

[14] 蒋建东,高洁,赵颖娣,等. 土壤旋切振动减阻的有限元分析[J]. 农业机械学报,2012,43(1):58-62. Jiang Jiandong, Gao Jie, Zhao Yingdi, et al. Finite element simulation and analysis on soil rotary tillage with external vibration excitation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(1): 58-62. (in Chinese with English abstract)

[15] 陈秉聪,任露泉,李安琪,等. 蚯蚓体表液收取方法的初步研究[J]. 农业工程学报,1990,6(2):7-12. Chen Bingcong, Ren Lunquan, Li Anqi, et al. Initial study on the method of collecting the body surface fluid of erathworms[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1990, 6(2): 7-12. (in Chinese with English abstract)

[16] 李晓鹏. 马铃薯耦合仿生挖掘及其减阻研究[D]. 成都:西华大学,2018. Li Xiaopeng. Research on Potato Coupled-Bionic Digging and its Drag Reduction[D]. Chengdu:Xihua University. 2018. (in Chinese with English abstract)

[17] 汲文峰,贾洪雷,佟金. 旋耕-碎茬仿生刀片田间作业性能的试验研究[J]. 农业工程学报,2012,28(12):24-30. Ji Wenfeng, Jia Honglei, Tong Jin. Experiment on working performance of bionic blade for soil-rototilling and stubble-breaking[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(12): 24-30. (in Chinese with English abstract)

[18] 郭俊,张庆怡,Muhammad Sohail Memon,等. 仿鼹鼠足趾排列的旋耕-秸秆粉碎锯齿刀片设计与试验[J]. 农业工程学报,2017,33(6):43-50. Guo Jun, Zhang Qingyi, Muhammad Sohail Memon, et al. Design and experiment of bionic mole’s toe arrangement serrated blade for soil-rototilling and straw-shattering[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(6): 43-50. (in Chinese with English abstract)

[19] 薛维良. 仿生减阻双圆盘开沟器设计与研究[D]. 长春:吉林大学,2017. Xue Weiliang. Design and Research on Bionic Double Disc Opner with Drag Reducing[D]. Changchun: Jilin University, 2017. (in Chinese with English abstract)

[20] 杨晓东,任露泉. 形体减阻类型、减阻机理与仿生[J]. 农业机械学报,2003,18(1):130-133. Yang Xiaodong, Ren Luquan. Typers and mechanisms of shape drag reduction[J]. Transactions of the Chinese Society for Agricultural Machinery, 2003,18(1): 130-133. (in Chinese with English abstract)

[21] 张清珠. 仿生几何结构表面土壤镇压辊[D]. 长春:吉林大学,2014.Zhang Qingzhu. Soil Press Roller with Bionically Geometrically Structured Surfaces[D]. Changchun: Jilin University, 2014. (in Chinese with English abstract)

[22] 丁为民,徐志刚,汪小函. 斜置旋耕刀滑切角及其方程[J]. 农业工程学报,2002,18(3):49-53. Ding Weimin, Xu Zhigang, Wang Xiaohan. Grass sliding cutting angles and their equations of oblique rotary blades[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(3): 49-53. (in Chinese with English abstract)

[23] 刘永清,桑正中. 潜土逆转旋耕刀数学模型及参数优化[J]. 农业工程学报,2000,16(4):88-91. Liu Yongqing, Sang Zhengzhong. Mathematical model of submerged reverse-rotary tiller and parameters optimization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2000, 16(4): 88-91. (in Chinese with English abstract)

[24] 曾德超. 机械土壤动力学[M]. 北京:北京科学技术出版社. 1995.

[25] 赵家丰,汪伟,孙中兴,等. 均质土壤承压下陷模型改进及验证[J]. 农业工程学报,2016,32(21):60-66. Zhao Jiafeng, Wang Wei, Sun Zhongxing, et al. Improvement and verification of pressure-sinkage model in homogeneous soil[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(21): 60-66. (in Chinese with English abstract)

[26] 熊平原,杨洲,孙志全,等. 旋耕刀三向工作阻力试验及作业参数优化[J]. 农业工程学报,2017,33(19):51-58. Xiong Pingyuan, Yang Zhou, Sun Zhiquan, et al. Experiment on three-axis working resistances of rotary blade and working parameters optimization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(19): 51-58. (in Chinese with English abstract)

[27] Gill , Vanden Berg. Soil dynamics in tillage and traction[J]. Journal of Terramechanics, 1968, 5(4): 65-66.

[28] 郑侃,何进,李洪文,等. 基于离散元深松土壤模型的折线破土刃深松铲研究[J]. 农业机械学报,2016,47(9):62-72. Zheng Kan, He Jin, Li Hongwen, et al. Research on polyline soil-breaking blade subsoiler based on subsoiling soil model using discrete element method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(9): 62-72. (in Chinese with English abstract)

[29] 朱留宪. 基于SPH算法的微耕机旋耕刀有限元仿真与优化[D]. 重庆:西南大学,2012. Zhu Liuxian. Finite Elements Simulation and Optimization of Rotary Blade of Mini-Tiller Based on SPH Algrithm[D]. Chongqing: Southwest University, 2012. (in Chinese with English abstract)

[30] 卢彩云,何进,李洪文,等. 基于SPH算法的平面刀土壤切削过程模拟[J]. 农业机械学报,2014,45(8):134-139. Lu Caiyun, He Jin, Li Hongwen, et al. Simulation of soil cutting process by plane blade based on SPH method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 134-139. (in Chinese with English abstract)

[31] 顾耀权,贾洪雷,郭慧,等. 滑刀式开沟器设计与试验[J]. 农业机械学报,2013,44(2):38-42. Gu Yaoquan, Jia Honglei, Guo Hui, et al. Design and experiment of sliding knife furrow openner[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(2): 38-42. (in Chinese with English abstract)

[32] 中国机械工业联合会. 旋耕机:GB/T 5668-2008 [S]. 北京:中国标准出版社. 2009.

[33] 刘谦文,杨有刚. 基于ANSYS/LS-DYNA的旋耕刀强度和功耗研究[J]. 中国农机化学报,2017,38(6):16-19. Liu Qianwen, Yang Yougang. Research on strength and power consumption of rotary blade based on ANSYS/LS- DYNA[J]. Journal of Chinese Agricultural Mechanization , 2017, 38(6): 16-19. (in Chinese with English abstract)

[34] 葛云,吴雪飞,王磊,等. 基于ANSYS微型旋耕机旋耕弯刀的应力仿真[J]. 石河子大学学报:自然科学版,2007,25(5):627-629. Ge Yun, Wu Xuefei, Wang Lei, et al. The strss simulation for the rotary blade of self propelled rotary cultivator based on ANSYS[J]. Journal of Shihezi University: Natural Science, 2007, 25(5): 627-629. (in Chinese with English abstract)

[35] 方会敏. 基于离散元法的秸秆—土壤—旋耕刀相互作用机理研究[D]. 南京:南京农业大学,2016. Fang Huimin. Research on the Straw-Soil-Rotary Blade Interaction Using Discrete Element[D]. Nanjing: Nanjing Agricultural University, 2016. (in Chinese with English abstract)

Design and test of wedge drag reduction rotary blade

Hao Jianjun, Yu Haijie, Zhao Jianguo, Li Jianchang, Ma Zhikai, Cai Jinjin

(071001)

In order to solve the problems of high resistance and high power consumption of rotary tillage and land preparation, the rotary blade is studied based on theoretical analysis, simulation and field experimentin this paper. First, a wedge drag reduction rotary blade is designed based on the theoretical force model of cutting tools in mechanical soil dynamics. Second , the three-dimensional model of the national rotary blade and the wedge drag reduction rotary blade is established by using the Inventor software and the simulation experiment is carried on. The cutting soil model of 2 kinds of rotary blades is established by using HyperMesh software, and the material parameters, boundary constraints and working parameters are defined. On this basis, the soil cutting process, stress and cutting resistance are analyzed. It is proved that the wedge drag reduction rotary blade design is reasonable. In order to verify whether the wedge drag reduction rotary blade meets the strength requirement, the stress of the rotary blades is analyzed, and the cutting resistance of the national rotary blade and the wedge drag reduction rotary blade are compared. Third, field comparative experiments are carried out on national rotary blade and wedge drag reducing rotating blade with the evaluation indexes of torque, power consumption and soil breakage. The results show that the cutting resistance of the wedge drag reduction rotary blade is smaller than that of the national rotary blade; the maximum stress of the national rotary blade is 35.68 MPa and the maximum stress of the wedge drag reduction rotary blade is 29.49 MPa, which is less than that of the national rotary blade and far less than the yield strength of the material 430 MPa. On the premise of ensuring the strength of the blade body, the weight of the wedge drag reduction rotary blade is reduced by about 50 g, which is about 8.3% lower than that of the national rotary blade. The maximum cutting resistance of the national rotary blade is 530 N, the average cutting resistance is 375.5 N, and the maximum cutting resistance of the wedge drag reduction rotary blade is 510 N, the average cutting resistance is 335.5 N, the average cutting resistance of the wedge drag reduction rotary blade is 10.65% lower than that of the national rotary blade, which proves the feasibility of the wedge drag reduction rotary blade designed; The average torque of the wedge drag reduction rotary blade is 11.35% lower than that of the national rotary blade. In the working process of rotary blades, the average power consumption of the national rotary blade is 74.2 kW, the average power consumption of the wedge drag reduction rotary blade is 67.3 kW, and the average power consumption of the wedge drag reduction rotary blade is 9.29% lower than that of the national rotary blade. The average breaking rate of soil of the national rotary blade is 75%, and the average breaking rate of wedge drag reduction rotary blade is 79%, which is 4% higher than that of the national rotary blade; After continuous 33 hm2tillage, rotary blades did not break, and the average wear of the national rotary blade is 98.5 g, the average wear of the wedge shaped drag reduction rotary blade is 97.3 g, the wear difference is 1.3%, and the wear degree is the same. The wedge drag reduction rotary blade can effectively solve the problems of high resistance and high power consumption of rotary blade, which is helpful to accelerate the development of arable land machinery, improve the mechanization level of cultivated land, and reduce the production cost of crops.

agricultural machinery; soil; models; wedge drag reduction rotary blade; field experiment

2019-01-09

2019-03-20

国家重点研发计划(2017YFD0300907)

郝建军,博士,教授,博士生导师,从事农机装备设计与制造。Email:hjjpaper@163.com

10.11975/j.issn.1002-6819.2019.08.007

S222.12+9

A

1002-6819(2019)-08-0055-10

郝建军,于海杰,赵建国,李建昌,马志凯,蔡金金.楔形减阻旋耕刀设计与试验[J]. 农业工程学报,2019,35(8):55-64. doi:10.11975/j.issn.1002-6819.2019.08.007 http://www.tcsae.org

Hao Jianjun, Yu Haijie, Zhao Jianguo, Li Jianchang, Ma Zhikai, Cai Jinjin. Design and test of wedge drag reduction rotary blade[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(8): 55-64. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.08.007 http://www.tcsae.org