Effects of Bacterial Manure from Cassava Alcohol Fermentation Mash on Yield and Starch Content of Cassava

2019-03-20,,,

, , ,

Mingyang Biochemistry Group Co., Ltd., Guangxi Farm Reclamation Bureau/State Key Laboratory of Non-grain Biomass Enzymolysis, Nanning 530226, China

Abstract In order to provide a scientific basis for the utilization of cassava alcohol fermentation mash and the high-yield and high-efficiency cultivation of cassava, compound microbial inoculum was inoculated into the cassava alcohol fermentation mash to prepare bacterial manure, which was then applied to two cassava varieties, Nanzhi 199 and SC 205 to explore the optimum application amount, application method and application concentration. The results showed that when the inoculation amount of the compound microbial inoculum was 2‰ of the mass of the mash, the requirements of industrial production of liquid bacterial manure and agricultural application can be met, saving costs. After the emergence of cassava seedlings, if they were drenched with the bacterial manure of cassava alcohol fermentation mash through roots once according to the amount of 67.5 t/ha and irrigated with the bacterial manure once every 15 d under drought conditions, both the yield and quality of cassava can be improved significantly. The yield and starch content of Nanzhi 199 reached 26 196.23 kg/ha and 30.32%, 36.57% and 4.75 percentage points higher than those of CK. The yield and starch content of SC 205 reached 41 126.06 kg/ha and 23.74%, 99.25% and 3.19 percentage points higher than those of CK. Under the application modes of foliar spray, root irrigation and foliar spray+root irrigation, the fertilization effect was more obvious. When undiluted bacterial manure of cassava alcohol fermentation mash was applied according to the amount of 52.5 t/(ha·time), the fertilization effect of the application mode of foliar spray+root irrigation was the best. The bacterial manure from cassava alcohol fermentation mash can be directly applied without dilution, and the fertilizer efficiency will be reduced significantly after dilution.

Key words Bacterial manure from cassava alcohol fermentation mash, Agricultural application, Cassava, Yield, Starch content

1 Introduction

Guangxi is rich in cassava resources, and its planting area and total output account for about 70% of the national totals. However, at present, China’s cassava planting generally has problems of high production cost, low yield, low benefit and poor farmers’ enthusiasm for planting, which lead to the majority of processing cassava raw materials in China relying on imports. Therefore, it is imperative to achieve high-yield and high-efficiency cultivation of cassava. In the processing of cassava, China mainly produces starch and alcohol from cassava, between which, the production of alcohol accounts for more than 80% of the country’s total[1]. At present, most enterprises have low utilization rate for a large amount of waste mash produced in the production process of alcohol. Waste mash is often subjected to anaerobic fermentation, aerobic treatment and then directly discharged after reaching the standard, resulting in great waste. Therefore, the harmless treatment and resource utilization of mash has become an urgent problem to be solved. Using microorganisms to change the physical and chemical properties of mash to prepare organic liquid bacterial manure can realize the harmless and resource utilization of mash, increasing the added value of mash[2-3]. The most direct and cost-effective way to utilize mash resources is direct irrigation or dilute irrigation in agricultural production. The use of harmlessly treated mash in agricultural production, the direct application of mash produced in the processing of cassava in cassava cultivation, and the establishment of a sustainable circular economy model will generate enormous economic, environmental and social benefits.

Alcohol fermentation mash contains a large amount of unused cellulose, residual sugar, yeast metabolite protein, and elements such as calcium, nitrogen, phosphorus, potassium, iron and zinc[2]. Organic matter in mash can improve the physical, chemical and biological properties of the soil, regulate plant growth, and enhance plant resistance[4]. Under light anaerobic or dark aerobic conditions, PSB photosynthetic bacteria can degrade and differentiate organic matter. After being subjected to microbial action, the mash will become neutral or weakly acidic, and its COD will be reduced. The waste mash treated by the technology is a highly active, high-quality liquid bacterial manure[5-6]. In agriculture, mash is used as foliar fertilizer, soilless nutrient solution and soaking solution. The application of mash can reduce soil salt damage[7], increase the total amount and activity of soil microorganisms, improve soil fertility[8], and significantly increase crop yield and quality[9-10], instead of causing excessive soil heavy metals. Currently, there is no research or report on the application technology and application effect of alcohol fermentation mash on cassava. To this end, according to the nutritional characteristics of mash, a field planting test was conducted in 2012-2015 to study the effects of cassava alcohol fermentation mash on the growth of cassava and explore the optimum application amount, application mode and application concentration of the mash, thereby providing a scientific basis for high-yield and efficient planting of cassava and resource utilization of cassava alcohol fermentation mash.

2 Materials and methods

2.1Testmaterials

2.1.1Cassava varieties. Nanzhi 199 and SC 205 are the main varieties of Mingyang Biochemistry Group Co., Ltd., Guangxi Farm Reclamation Bureau. Nanzhi 199 is a sweet early-maturing variety, with low fresh tuber yield (about 21 t/ha) and high crude starch content (about 27%). SC 205 is bitter medium-maturing variety with high fresh tuber yield (about 27 t/ha) and low crude starch content (about 22%).

2.1.2Alcohol fermentation mash. Cassava alcohol fermentation mash refers to the waste liquid retaining after the cassava starch raw material is saccharified and fermented to produce alcohol. It was produced by the Mingyang Biochemistry Group Co., Ltd., Guangxi Farm Reclamation Bureau, with pH of 3.0-5.5, total nitrogen of 70.96 mg/L, total phosphorus of 23.88 mg/L, total potassium of 83.33 mg/L, chemical oxygen demand (COD) of 21 200 mg/L, biological oxygen demand (BOD) of 10 400 mg/L, NH3-N of 84 mg/L and solid suspension of 11 000 mg/L.

2.1.3Bacterial manure from cassava alcohol fermentation mash. The compound microbial agent[Bacillusamyloliquefaciens∶Bacillusmucilaginosus:Bacillussubtilis∶Bacillusmegaterium=1∶1∶1∶1 (m∶m∶m∶m)]was inoculated to the cassava alcohol fermentation mash according to 1‰, 2‰, 3‰, 4‰ and 5‰ of the mass of the mash, respectively. The living bacteria count in the bacterial manure from cassava alcohol fermentation mash under different inoculation amounts was determined. After the fermentation ended, the bacterial manure (pH 5.5-7.5) from cassava alcohol fermentation mash contained 70%-80% of organic matter, 0.4%-0.6% of total nitrogen, 0.03%-0.05% of P2O5, 0.6%-1.3% of K2O, and a small amount of trace elements such as Ca, Fe, Zn, Cu and Mn.

2.1.4Overview of the test site. The test was carried out in the cassava breeding nursery of the Mingyang Biochemistry Group Co., Ltd., Guangxi Farm Reclamation Bureau in Nanning, Guangxi. The test site is flat and sunny, and the test soil was yellow-brown clay loam, of which the texture was easy to be knotted, pH was 5.02, organic matter was 2.3%, alkali-hydrolyzable nitrogen (N) was 51.4 mg/kg, available phosphorus (P2O5) was 8.8 mg/kg, available potassium (K2O) was 44.2 mg/kg, and fertility was medium.

2.2Testdesign

2.2.1Application amounts of the bacterial manure from cassava alcohol fermentation mash. Total six treatments were designed for each cassava variety: the application amounts of the bacterial manure from cassava alcohol fermentation mash were 37.5, 52.5, 67.5, 82.5 and 97.5 t/ha, and conventional application of industrial clean water was used as the control (CK). Three repetitions were arranged for each treatment. Randomized block design was adopted. The area of each plot was 41 m2(2.0 m×20.5 m). The plant and row spacing was 0.8 m×1.0 m. There were 40 cassava plants in each plot. After the emergence of cassava seedlings, root irrigation was carried out once every 15 d under drought conditions (the interval was adjusted in rainy days) until harvest. Other cultivation and management measures were consistent.

2.2.2Application modes of the bacterial manure from cassava alcohol fermentation mash. Total four treatments were designed for each cassava variety: foliar spray (sprayed on the front and back of the leaves on a sunny afternoon without wind), root irrigation (irrigated to the roots of each cassava plant at a radius of 30 cm), foliar spray+root irrigation, and blank control (CK). When the cassava plants were 1.5, 2.0, 2.5 and 3.0 m high, fertilization is applied once, respectively. The single-time application amount of the undiluted bacterial manure was 52.5 t/ha. Other cultivation and management measures were consistent.

2.2.3Application concentrations of the bacterial manure from cassava alcohol fermentation mash. Total four treatments were designed for each cassava variety: undiluted bacterial manure from cassava alcohol fermentation mash (CK, application amount of 67.5 t/ha), bacterial manure from cassava alcohol fermentation mash diluted two times, bacterial manure from cassava alcohol fermentation mash diluted four times and bacterial manure from cassava alcohol fermentation mash diluted six times. Fertilization was carried out along with root irrigation once during the sowing young seedling, robust seedling, tuberization and maturity stages, respectively. Other cultivation and management measures were consistent.

2.3GrowthindexandqualitydeterminationDuring the harvest period (December), 40 plants were selected randomly from each plot for measurement of single-tuber circumference (one medium-sized tuber was selected from each plant, and the circumference in the middle of the tuber was measured) and tuber number per plant. The yield of fresh tubers in each plot was measured. Total 3-5 medium-sized tubers were selected randomly from each plot, and their starch content was determined by the DNS method on the day of harvest or the next day.

2.4DatastatisticsandanalysisStatistics and drawing were carried out using Microsoft Excel 2007. Analysis of variance was performed using SPSS17.0. Significance test of differences was performed using Duncan’s new multiple range method.

3 Results and analysis

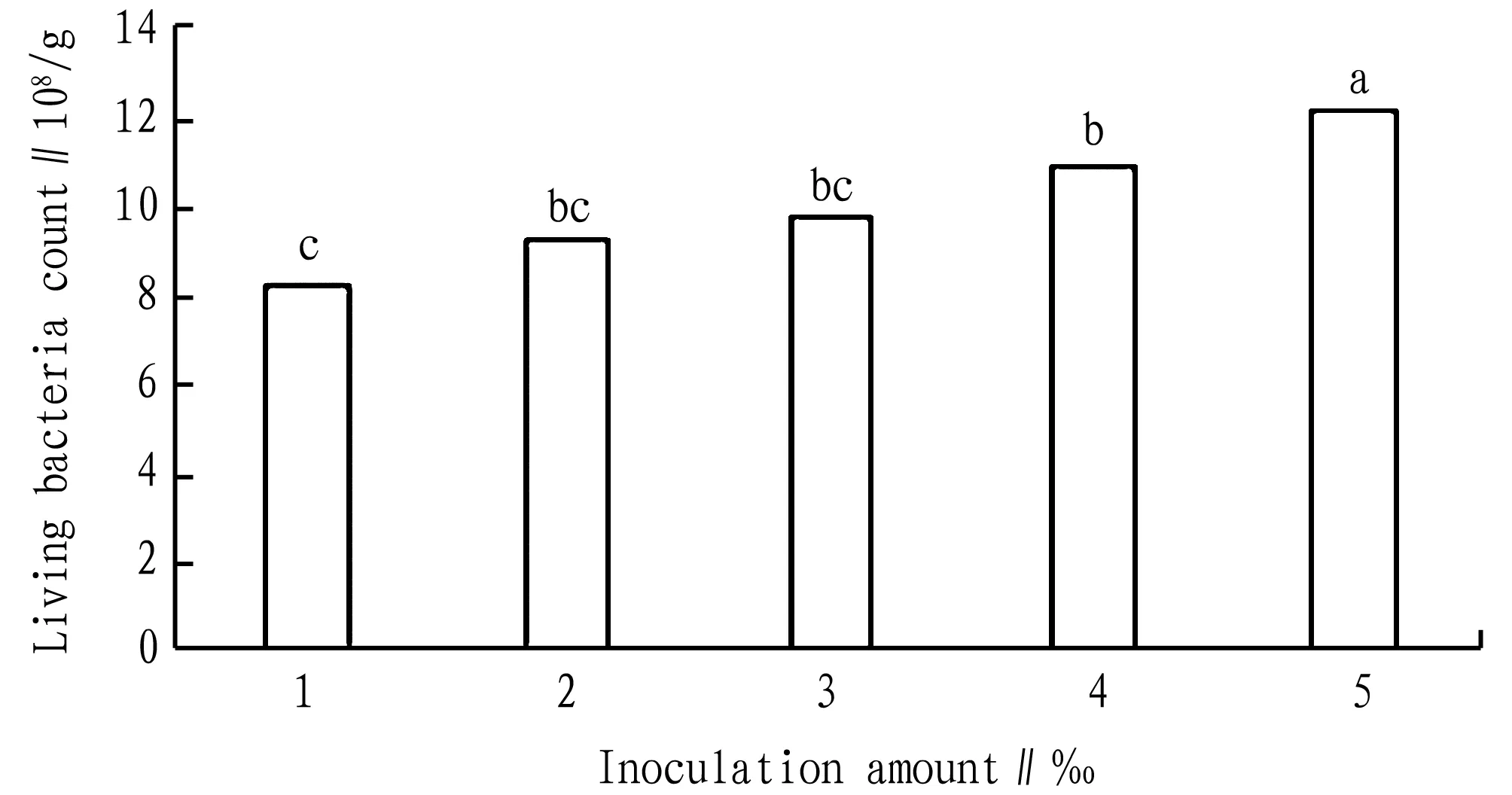

3.1CountofbacteriainthemanurefromcassavaalcoholfermentationmashinoculatedwithdifferentamountofthecompoundmicrobialinoculumAs shown in Fig.1, the living bacteria count in the bacterial manure from cassava alcohol fermentation mash increased with the increase of inoculation amount of the compound microbial agent. The living bacteria count under the inoculation amount of 5‰ was significantly greater than those under the other inoculation amounts. There was significant difference in the living bacteria count between the inoculation amounts of 4‰ and 1‰; while no significant differences were found between the inoculation amounts of 2‰, 3‰ and 4‰.Considering production costs, as the living bacteria count under the inoculation amount of 2‰ could already meet the industrial production of bacterial manure from cassava alcohol fermentation mash and the requirements of agricultural application, so the inoculation amount of 2‰ was the optimum.

Note: Different lowercase letters on the top of columns indicate significant differences at the 0.05 level. The same below.

Fig.1Livingbacteriacountofbacterialmanurefromcassavaalcoholfermentationmashinoculatedwithdifferentamountofcompoundmicrobialagent

3.2Performanceofagronomictraits,yieldandstarchcontentofcassavaappliedwithdifferentamountofthebacterialmanurefromcassavaalcoholfermentationmashAs shown in Table 1, when the application amount of the bacterial manure from cassava alcohol fermentation mash ranged from 37.5 to 67.5 t/ha, the plant height, stem diameter, single-tuber circumference, tuber number per plant, yield, starch content of cassava all increased with the increase of the application amount of bacteria manure from cassava alcohol fermentation mash. When the application amount of the bacterial manure exceeded 67.5 t/ha, the phenomenon of spindly growth was observed, and the stem diameter, single-stem circumference, tuber number per plant, yield and starch content of cassava all decreased with the increase in the application amount of the bacterial manure. When the application amount of the bacterial manure reached 97.5 t/ha, most indexes in the treatment groups were lower than those in the CK, indicating that cassava has a certain limit on the tolerance of bacterial manure. Therefore, in the cultivation of cassava, the application amount of the bacterial manure from cassava alcohol fermentation mash must be controlled within an appropriate range. When the application amount of the bacterial manure was 67.5 t/ha, the stem diameter, single-tuber circumference, tuber number per plant, yield and starch content of cassava all reached the maximum. The yield and starch content of Nanzhi 199 were 26 196.23 kg/ha and 30.32%, 36.57% and 4.75 percentage points higher than those of CK; and the yield and starch content of SC 205 were 41 126.06 kg/ha and 23.74%, 99.25% and 3.19 percentage points higher than those of CK. It suggested that appropriate application of bacteria manure from cassava alcohol fermentation mash was conducive to the improvement of the growth, yield and starch content of cassava, and the application amount of 67.5 t/ha was the optimum.

Table1Agronomictraits,yieldandstarchcontentofcassavaappliedwithdifferentamountofbacterialmanurefromcassavaalcoholfermentationmash

CassavavarietyFertilizationamount∥t/haPlantheight∥cmStemdiameter∥cmSingle-tubercircumference∥cmFresh tubernumber per plantFresh tuberyield∥kg/haStarchcontent∥%Nanzhi 19937.5326.34 d3.24 g11.03 g11 e20 276.08 h28.43 c52.5334.22 c3.64 c13.63 e13 c24 617.18 e29.74 b67.5351.05 b3.83 a15.25 c16 a26 196.23 d30.32 a82.5360.82 a3.44 e14.26 d14 b23 367.13 f26.86 d97.5265.41 g3.03 i9.80 i10 f16 964.32 j24.25 fCK262.11 g3.14 h12.15 f12 d19 181.34 i25.57 eSC 20537.5276.11 f3.37 f14.34 d9 g 22 576.14 g21.42 i52.5285.93 e3.52 d16.76 b11 e35 276.14 b 22.95 h67.5326.04 d3.71 b17.88 a12 d41 126.06 a23.74 g82.5332.92 c3.22 g15.30 c10 f34 371.16 c21.08 i97.5261.63 g2.92 j10.54 h 7 i19 876.41 i20.16 kCK259.33 h3.13 h13.94 e8 h20 640.56 h20.55 j

Note: Different lowercase letters in the same column indicate significant differences at the 0.05 level. The same below.

3.3Single-tubercircumference,freshtuberyieldandstarchcontentofcassavaunderdifferentapplicationmodeofthebacterialmanurefromcassavaalcoholfermentationmashThe single-tuber circumference, fresh tuber yield and starch content of cassava under different application mode of the bacterial manure from cassava alcohol fermentation mash were shown in Fig.2.

3.3.1Single-tuber circumference. The single-tuber circumference of cassava under the application mode of foliar spray+root irrigation was the greatest, 17.86 cm for SC 205, 68.17% larger than that of CK, followed by those under the application modes of root irrigation and foliar spray, and the single-tuber circumference of cassava in the CK was the smallest. The single-tuber circumferences of SC 205 applied with the bacterial manure were significantly greater than those of Nanzhi 199, and no significant difference was found between the two control groups. It indicated that single-tuber circumference was related to the variety, and application of bacterial manure help to promote the expansion of cassava tubers.

3.3.2Fresh tuber yield. The application of the bacterial manure could significantly increase the yield of cassava. The yield of cassava under the application mode of foliar spay+root irrigation was the highest, 39 525.00 kg/ha for SC 205 (100.37% higher than that of the CK) and 33 265.00 kg/ha for Nanzhi 199 (100.11% higher than that of the CK). The yield of cassava under the application modes of root irrigation, foliar spray ranked second and third, respectively. The yield of cassava in the control groups was the lowest. It indicated that the application of the bacterial manure was conducive to the improvement of cassava yield, and the application mode of foliar spray+root irrigation was the best.

Fig.2Single-tubercircumference,freshtuberyieldandstarchcontentofcassavaunderdifferentapplicationmodeofbacterialmanurefromcassavaalcoholfermentationmash

3.3.3Fresh tuber starch content. The application of the bacterial manure could significantly increase the starch content of fresh cassava tubers. The starch content of cassava under the application mode of foliar spray+root irrigation was the highest, 27.77% for Nanzhi 199 (55.31% higher than that of the CK) and 24.86% for SC 205 (64.09% higher than that of the CK). The application of the bacterial manure help to improve the quality of cassava, and the application mode of foliar spray+root irrigation was the best.

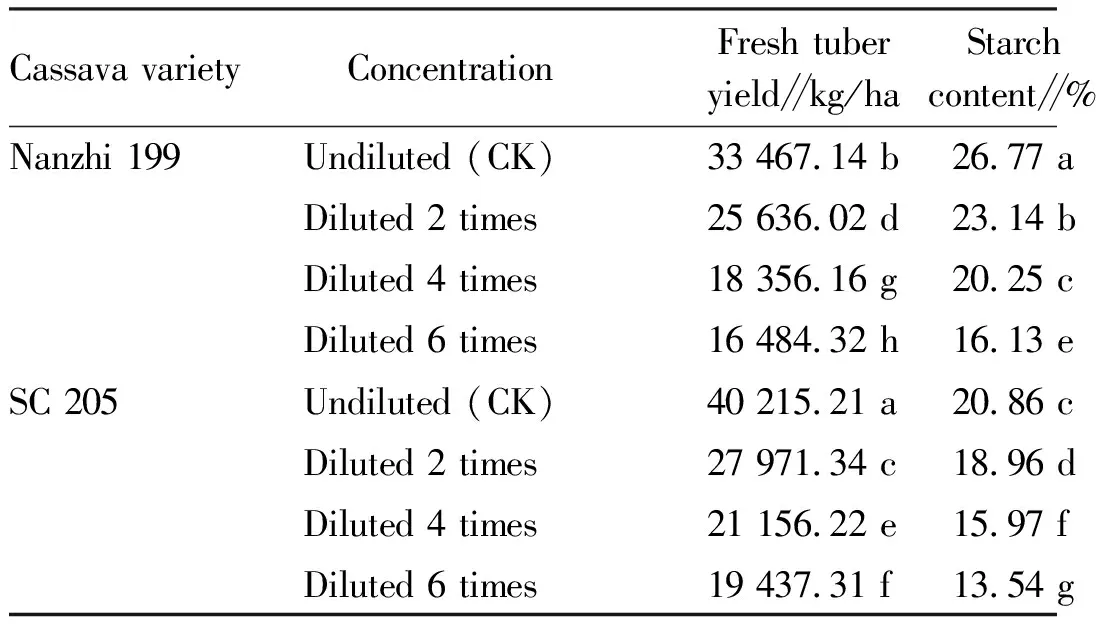

3.4YieldandstarchcontentofcassavaappliedwithdifferentconcentrationofbacterialmanurefromcassavaalcoholfermentationmashAs shown in Table 2, the yield and starch content applied with undiluted bacterial manure from cassava alcohol fermentation mash were both higher than those of cassava applied with diluted bacterial manure. With the increase of dilution times, the yield and starch content of cassava declined significantly. The application effect of the undiluted bacterial manure was the best. When applied with undiluted bacterial manure, the yield and starch content of SC 205 were 40 215.21 kg/ha and 20.86%, re-

Table2Yieldandstarchcontentofcassavaappliedwithdifferentconcentrationofbacterialmanurefromcassavaalcoholfermentationmash

Cassava varietyConcentrationFresh tuberyield∥kg/haStarchcontent∥%Nanzhi 199Undiluted (CK)33 467.14 b26.77 aDiluted 2 times25 636.02 d23.14 bDiluted 4 times18 356.16 g20.25 cDiluted 6 times16 484.32 h16.13 eSC 205Undiluted (CK)40 215.21 a20.86 cDiluted 2 times27 971.34 c18.96 dDiluted 4 times21 156.22 e15.97 fDiluted 6 times19 437.31 f13.54 g

spectively, and those of Nanzhi 199 were 33 467.14 kg/ha and 26.77%, respectively. The application effect of the diluted bacterial manure reduced significantly.

4 Conclusions and discussions

The cassava alcohol fermentation mash is a waste liquid discharged from the bottom of the crude distillation tower after the cassava starch raw material is saccharified and fermented to produce alcohol, and the pH is usually 3-5. It is rich in organic matter, N, P, K and various trace elements required by the growth of plants, with low heavy metals content[11]. The mash can be prepared into organic liquid bacterial manure after mixed with a certain proportion of compound microbial agent. It decomposes organic matter using microorganisms. At the same time of changing the physical and chemical properties, the fertilizer efficiency is improved, thus achieving the effects of decomposing, deodorizing, killing germs and eggs, reducing the contention of suspended solids and reducing the chemical oxygen demand. The use of organic liquid bacterial manure as a fertilizer and soil amendment can promote the absorption of nutrients by crops, regulate crop growth, enhance crop resistance[12], and reduce pests and diseases, thereby improving crop yield and quality. The microorganisms can convent cellulose, residual sugar, and protein into humic organic matter, playing the role of nitrogen fixation, phosphorus solubilization, and potassium dissolving[13], increasing the living bacteria count of the soil, improving the biological, physical and chemical properties of the soil, thereby increasing the fertility of the soil. Therefore, the harmless treatment and direct agricultural application of cassava alcohol fermentation mash is the most direct and lowest-cost resource utilization pathway.

Wang Fenfen[2]found that it was feasible to produce polymyxa bacillus manure through the fermentation of cassava alcohol fermentation wastewater, and the application the bacterial manure significantly increased the fresh weight, dry weight and quality of tomato and green vegetables and reduced the content of nitrate in the green vegetables. Among them, the fresh weight was increased by more than 60%. There was no significant difference between the 10 times dilution of cassava alcohol fermentation wastewater and the blank treatment (clean water). Wei Minzhengetal.[6]used cassava alcohol anaerobic fermentation mash as part of irrigation water and fertilizer source instead of chemical fertilizer for banana production. The yield of banana applied with the fermentation mash was increased by 19.80% compared with conventional fertilization. The Vc content and soluble sugar content of banana fruit were increased by 28.19% and 5.22%, respectively. The contents of alkaline-hydrolyzable nitrogen, available phosphorus and available potassium of the soil were increased by 12.76%, 267.40% and 53.51%, respectively. Hu Kailinetal.[14-16]irrigated the cassava alcohol anaerobic fermentation mash with COD of 1 200-2 000 mg/L to banana that was then mulched with plastic film according to the amount of 900 m3/ha. The results showed that the contents of organic matter and available potassium of the soil and the stem height, stem circumference, green leaf number, chlorophyll content and yield of banana were all increased significantly. The results of this study found that when the cassava alcohol fermentation mash could be used as organic liquid bacterial manure after harmless treatment with compound microbial agent, and the optimum inoculation amount of the compound microbial agent was 2‰ of the mass of the mash. The root irrigation of the undiluted bacterial manure after the emergence of cassava seedlings could significantly promote the growth, increase the yield, and improve the quality of cassava. When the application amount of the mash was 67.5 t/ha, the yield and starch content of Nanzhi 199 were 26 196.23 kg/ha and 30.32%, 36.57% and 4.75 percentage points higher than those of the CK, and the yield and starch content of SC 205 were 41 126.06 kg/ha and 23.74%, 99.25% and 3.19 percentage points higher than those of the CK. At the same time, the stem diameter, single-tuber circumference, and tuber number per plant of cassava reached the maximum. Under different application modes, the bacterial manure from cassava alcohol fermentation mash all significantly increased the yield and improved the quality of cassava. Under the application amount of 52.5 t/ha, the application mode of foliar spray+root irrigation was the best, which significantly increased the stem diameter, single-tuber circumference, tuber number per plant, yield and starch content of cassava. It suggests that the bacterial manure from cassava alcohol fermentation mash can provide nutrients for plants. The direct application of the bacterial manure to agricultural production is characterized with low costs, high efficiency, environmental pollution reduction and soil improvement. The bacterial manure from cassava alcohol fermentation mash can be promoted and applied in agricultural production. Simultaneously, the development of this manure can provide a scientific reference for the sustainable development of the cassava industry.

Mash has a positive effect on soil structure and nutrient regulation. When applied within the appropriate range, it will not cause groundwater contamination. However, there is a risk of contamination to the soil and water environment when applied excessively[5]. Therefore, corresponding treatment should be carried out before mash is applied to degrade organic pollutants, thereby improving the safety of mash application. At the same time, it is necessary to master the appropriate dosage to avoid adverse consequences, thus reducing the use of chemical fertilizers and production costs and providing scientific guidance for the resource treatment of mash. Subject to conditions, this study only explored the effects of the bacterial manure from cassava alcohol fermentation mash on the growth, yield and starch content of cassava. The combined effects of the bacterial manure on disease resistance and stress resistance of cassava, as well as its effects on nutrients and heavy metals of soil and environment of groundwater remain to be further studied.

杂志排行

Asian Agricultural Research的其它文章

- Economic Value Evaluation of Fine Individual Plants ofRibesrubrum Linn.Based on AHP

- Mechanized Grafting Technology for Apple Seedlings

- High Efficiency Hypocrellin Production by a Novel Mutant Isolated fromShiraiabambusicola

- Investigation and Analysis on Agricultural Biological Resources of Wuchuan Gelao and Miao Autonomous County,Guizhou Province

- The Mode of Promoting Industrial Targeted Poverty Alleviation through Land Circulation in Western Mountainous Region of China

——A Case Study of Luquan Yi and Miao Autonomous County in Yunnan Province - Reconstruction Mode of Rural Dilapidated Houses in Alpine and Gorge Area of Southwest China

——A Case Study of Scientific Identification and Precision Reconstruction of Rural Dilapidated Houses in Luquan County, Yunnan Province