High Efficiency Hypocrellin Production by a Novel Mutant Isolated fromShiraiabambusicola

2019-03-20,,*

, ,*

1. Shandong Provincial Engineering and Technology Research Center for Wild Plant Resources Development and Application of Yellow River Delta, Binzhou University, Binzhou 256600, China; 2. Shandong Key Laboratory of Eco-environmental Science for the Yellow River Delta, Binzhou University, Binzhou 256600, China; 3. School of Biological and Environmental Engineering, Binzhou University, Binzhou 256600, China

Abstract The fungusShiraiabambusicolaGZ19M1 is biotechnologically important due to its ability to biosynthesis the pigment hypocrellins. Results showed that ethyl methane sulfonate (EMS) was effective mutagenic agent for strain and potentially produced large numbers of random mutations broadly and uniformly over the whole genome to generate unique strains. Wild-type cultures ofS.bambusicolaGZ19 were subjected to EMS (80 mM) induction targeted at approximately 20% spores’ survival. When surviving spores were selected in sufficient numbers and cultured on PDA medium for 7 d at 26℃, five novel mutagenizedS.bambusicolastrains were obtained. A mutant GZ19M1 that exhibited an activity of more than two times over the wild strain was obtained. Also, batch experiments were carried out to achieve the suitable conditions for hypocrellin. Glucose and rice extract were the most favorable carbon and nitrogen sources for hypocrellin production by submerged culture ofS.bambusicolaGZ19M1, and initial glucose and rice extract concentrations were at 35 and 250 g/L, respectively. The optimal surfactant were found to be 0.008V/VTween 80, it was added into cultivation medium at 24 h. Hypocrellin concentration reached 498.89 mg/L under optimal nutritional conditions, an increment of about 8.70 times of hypocrellins production was observed compared with that of in non-optimized medium by the wild strain.

Key words Hypocrellin,Shiraiabambusicola, Mutagenesis, Tween 80, Rice extract

1 Introduction

Hypocrellin is a naturally occurring hydrophobic perylenequinoid pigment isolated from the stromata ofHypocrellabambusae(Berk.et Br.) Sacc. andShiraiabambusicolaHenn. Hypocrellin has been used as orally taken folk medicine for several centuries in China to treat gastric diseases and rheumatoid arthritis[1]. In the recent two decades, hypocrellin has attracted considerable attention because of its excellent light-induced anticancer and antiviral activities, especially for the treatment of microvascular diseases and diabetes[2-4]. The production of hypocrellin fromS.bambusicolais not high, therefore, the search forS.bambusicolawith enhanced HA production and study on its fermentation condition is important in order to obtain these outcomes on a large scale.

There are many papers concerning the isolation and screening ofS.bambusicolawith high HA production, but only few of them involved mutagenesis techniques. Mutagenesis with chemical or physical agents followed by titer test of a large number of isolates has been used successfully to improve the productivity of several fungal metabolites and enzymes. Savergaveetal.[5]screened high erythritol producing Candida magnolia by ultraviolet (UV) and chemical mutagenesis. Naveenaetal.[6]improved the production of thrombinase by Streptomyces venezuelae mutated by ethyl methane sulfonate (EMS). Production of hypocrellin by mutants has not been given much attention. Therefore in this study we focused on enhancing the hypocrellin production through strain improvement onS.bambusicola. Our experimental results show that the colonies characters ofS.bambusicolastrains had significant differences with hypocrellin A content, substrate mycelium color ofS.bambusicolahas the most distinct correlation with the yield of hypocrellin A, this results are also helpful when screening large numbers of strains[7]. In addition to the strain improvement, some of the other important facts have also to be considered. The production of hypocrellin could be significantly enhanced by a wide variety of materials, including surfactants, ultrasound and light[8-10]; however, a great many of materials which add in medium were not studied.

In this study, we described five novelS.bambusicolastrains that were obtained by EMS of wild-type (WT)S.bambusicolaGZ19 cultures. EMS is a standard technique[6]for inducing mutations in fungi. TheS.bambusicolaWT strain was not recovered from the plates after this treatment. The EMS-mutagenized strains were able to grow fast on medium with the black substrate mycelium than the WT strain. To improve the hypocrellin production, it was showed by the mentioned strain using mutagenesis inS.bambusicolaGZ19. The mutant strainS.bambusicolaGZ19M1 with hypocrellin yield significantly improved was screened. Effect of different culture medium on yield of hypocrellin was studied by the single factor test using the mutant strain GZ19M1.

2 Materials and methods

2.1MicroorganismandmediaShiraiabambusicolaGZ19 from the China Center for Type Culture Collection (Wuhan, China) was used as the parent strain. Both the wild and mutants strain were grown at 26℃ on potato dextrose agar (PDA) slants for preservation, or cultivated for 7 d in 250-mL flasks containing 100 mL potato dextrose medium at 26℃ and 150 rpm. The PDA medium contained (g/L) potato extracts 200, glucose 20, and agar 20. Preparation spores of the medium (g/L): potato extracts 100, glucose 5, NaAc 4, agar 15, pH 7.2-7.4. Spore suspensions, prepared by adding saline solution onto the slope, were mixed with glycerol up to 10% concentration and maintained at -4℃[7].

2.2MutagenesisprocedureThe mutants were determined according to previous complex mutagenesis method[11]with slight modification. UV mutagenesis: the induction of mutagenesis was carried out by UV irradiation at 30 cm under a UV lamp (25 W).S.bambusicolaGZ19 survival to the UV-radiation at different irradiation times was determined using both spore suspensions (106-107spores/mL) and spores spread on PDA plate at 30 cm under a UV lamp (25 W), respectively. Then, the PDA plate with spores was incubated at 26℃ for 7 d. EMS mutagenesis: Spores were treated with EMS solution in the concentration 80 mM at 26℃ for 0-30 min and washed four times with sterilized water. The concentration of the spore suspension was determined using a hemocytometer and about 500 spores were spread onto a PDA plate. Then, the PDA plate with spores was incubated at 26℃ for 7 d.

2.3CultivationActively growing mycelia were obtained from a newly prepared agar-plate culture after it was incubated for 108 h at 26℃. For the seed growth stage, mycelium from a plate culture was inoculated into 50 mL of seed medium and grown at 26℃ with 150 rpm on a shaker incubator (Ts-2102, Tensuc, China) for 48 h. Then, 10 % (V/V) seed cultures were were then transferred into a 250-mL flask that contained 100 mL of media, which consisted of the following components (g/L): K2HPO41.0, MgSO4·7H2O 0.5, KCl 0.5 and various carbon, nitrogen sources and surfactants according to the experimental design. The media were autoclaved at 121℃ for 30 min, unless otherwise specified; the cultivation was carried out at 26℃ on a rotary shaker incubator at 150 rpm for 108 h. In all experiments, multiple flasks were run at the same time, and three flasks were sacrificed at each sampling point.

The effect of nitrogen source on the fungus culture was studied by using 3 g/L of yeast extract, peptone, urea, (NH4)2SO4, NaNO3, casein, NH4NO3, soybean extract, rice extract, corn extract, potato extract as well as buckwheat extract. The other culture medium components were glucose 35 g/L, K2HPO41 g/L, MgSO4·7H2O 0.5 g/L, 0.008V/VTween 80 and KCl 0.5 g/L. Effects of carbon sources on liquid cultures ofS.bambusicolawere studied by using 30 g/L of glucose, lactose, maltose, sucrose, mannitol, xylose as well as fructose. The other culture medium components were rice extract 250 g/L, K2HPO41 g/L, MgSO4·7H2O 0.5g/L, 0.008V/VTween 80 and KCl 0.5 g/L. Effects of surfactants on liquid cultures ofS.bambusicolawere studied by using 0.006V/Vof sodium dodecyl sulfonate (SDS), Tween 40, Tween 80 and Triton X-100. The other culture medium components (g/L) were glucose 35, rice extract 250, K2HPO41, MgSO47H2O 0.5 and KCl 0.5.

For the survey on initial glucose, rice extract and Tween 80 concentrations, glucose was used with levels of 20, 25, 30, 35, 40, 45 and 50 g/L, rice extract was used with levels of 150, 200, 250, 300, 350 and 400 g/L, Tween 80 was used with levels of 0.01, 0.008, 0.006, 0.004, and 0.002V/V.

2.4MeasurementofhypocrellinHA was isolated fromShiraiabambusicolaand recrystallized three times from acetone according to Yangetal.[12]. The strains incubated into PD media in duplicate at 26℃, mycelia were collected by centrifugation at 5 000 g for 20 min, and washed with distilled water three times, then dried. The determination of hypocrellin content was similar to the method described by Yangetal.[12]. The dried mycelia (100 mg) were treated in 6M HCl at 60℃ (1 h), and the precipitate was collected by centrifugation and extracted by ethanol (5 mL) for 24 h (twice). After removal of mycelia by centrifugation, the content of hypocrellin in supernatant was measured by a spectrophotometer at 465 nm. The samples which showed higher hypocrellin production compared with the wild were considered as positive mutants and the rest were considered as negative. Further, the mutant with highest hypocrellin production was isolated and used for further experiments.

3 Results and discussions

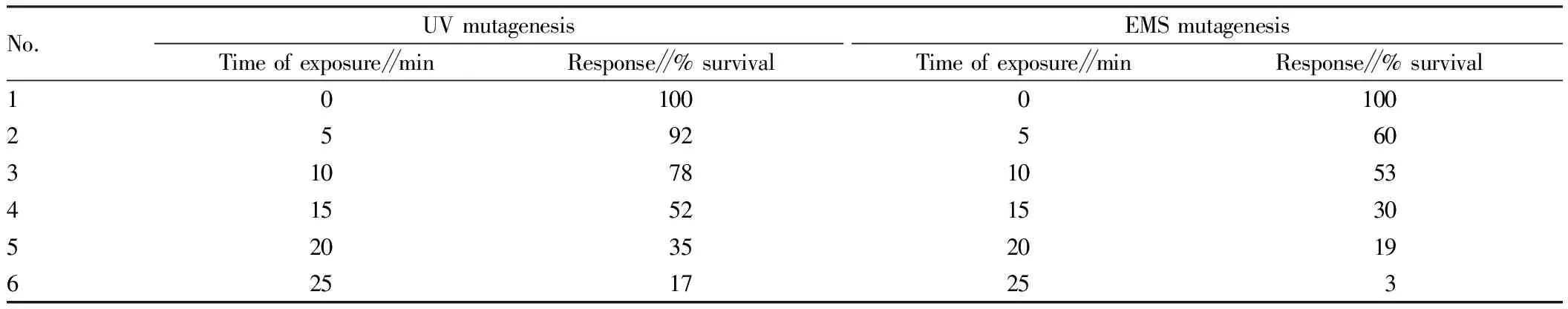

3.1MutagensisanalysisThe dose response analysis for both UV mutagenesis and chemical mutagenesis ofS.bambusicolawas done and the survival values (%) are shown in Table 1. The dosage was expressed in terms of time of exposure to the UV irradiation and varied in the range 0-30 min, to analyze the survival capacity and mutation effect. The fungus did not respond well to UV mutagenesis when compared to the chemical mutation by EMS. Since the DNA of the isolate contains more GC basepairs than AT base pairs as it belongs to the group of imperfect fungi, mutation by EMS causes GC transversions[13]. Similar trend was found by Gharibzahedietal.[14], in the case ofDietzianatronolimnaea, where the survival capacity obtained by EMS mutation was higher than UV. At the same time, while comparing with those results the survival capacity of the mutant was severely affected as the dosage of EMS was increased. The transversion mutation in DNA caused by EMS was responsible for the DNA damage. Since the self DNA repair mechanism fails in certain instances the mutation caused by EMS became permanent. Moreover prolonged incubation causes uncontrolled DNA damage which leads to cell death and hence a suitable incubation limit for good mutagenesis to occur can be determined by selection process.

Table1DoseresponseforUVandEMSmutagenesis

No.UV mutagenesisTime of exposure∥min Response∥% survivalEMS mutagenesisTime of exposure∥minResponse∥% survival101000100259256031078105341552153052035201962517253

3.2StrainsfromEMSThe plates obtained after 80 mM EMS-induced for 5 min spores followed by 7d incubation on PDA medium showed the brown substrate mycelium, but 11 colonies appeared the black substrate mycelium. Samples of these colonies were incubated on PDA media, two mutagenized strains, 19-1 and 16-1, demonstrated growth faster. Both the black substrate mycelium and the growth capabilities are important for the optimum performance of a high efficiency strain[7]. Initially, a typical 5-min induction time was used, but the resulting plates showed considerable background growth so it was decided to use a longer induction time. The results are listed in Table 1, the average percentage survival after 20 min was 19%. With the longer induction time, very little background growth was seen after growth on PDA plates so the surviving colonies were easier to isolate. Of the 42 surviving colonies, the five that grew best on PDA with the black substrate mycelium, 19M1, 19M2, 19M5, 16M4 and 16M12, were then incubated on plates for analysis using microscope.

3.3SelectionofmutantsPreliminary screening of hypocrellin-producing strains was performed based on the black substrate mycelium and the growth capabilities according to Duetal.[7]. After preliminary screening, five target strains were obtained. Secondary screening was then developed by incubating the above-mentioned selected strains into PDA media in duplicate, respectively. PDA medium was used to the start of hypocrellin, and the mycelia of PDA medium cultured for 5 d was collected, and then extracted by ethanol. After removal of mycelia by centrifugation, the content of hypocrellin in supernatant was measured.

Since the wild-type strains synthesis only low quantities of hypocrellin, the strain improvement by common mutagens such as ultraviolet (UV) and EMS is convenient and can yield a several-fold enhancement in the process, as proved in several cases[13-14]. The mutant GZ19M1 obtained from EMS, which exhibited about 2-fold increase in hypocrellin production. None of the strains mutated by UV showed more hypocrellin production than this mutant. Many researchers also find EMS mutagens more effective than UV irradiation[15]. Recently, Yangetal.[12]used a UVS.bambusicolamutant to produce hypocrellin, the yield of overall hypocrellin was about 196.9 mg/L. Compared with this results, our optimization result is higher than their contents, probably because we used mutant strains ofS.bambusicola, strain improvement by random mutagenesis using EMS was found to be effective than UV irradiation.

After each subculture, the mutants were tested for its ability to stably produce hypocrellin. The mutants GZ19M1 maintained the same production yield after being subcultured 6 times, indicating that the mutation is stably heritable. The mutant GZ19M1 exhibited the highest hypocrellin production of 138.75 mg/L after 5 d, which is 2.43 times of that of the wild strain. Thus, the mutant GZ19M1 was selected as a preferable hypocrellin-producer for further studies.

3.4HypocrellinproductionbythemutantstrainsGZ19M1infermentor

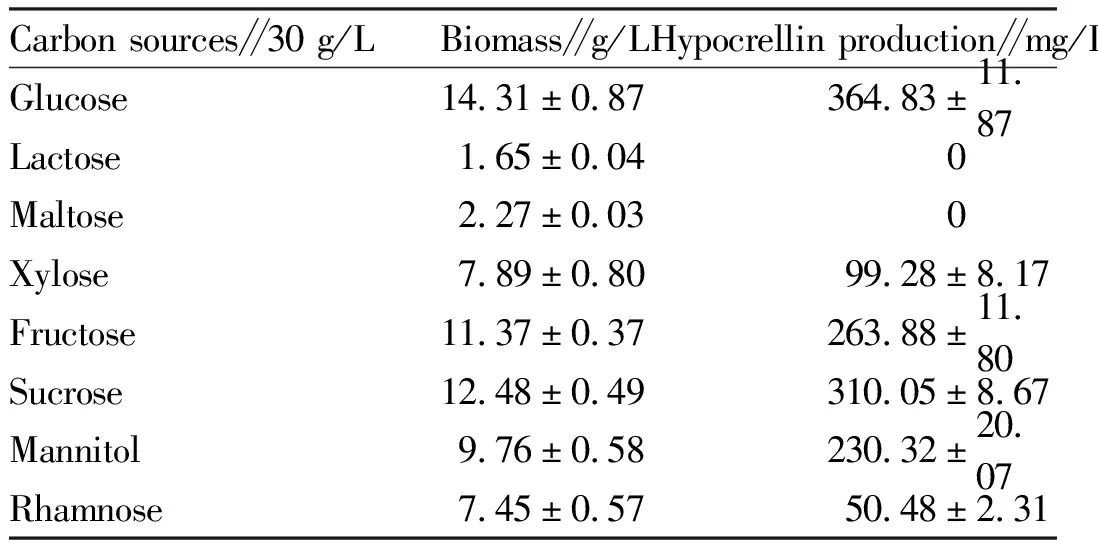

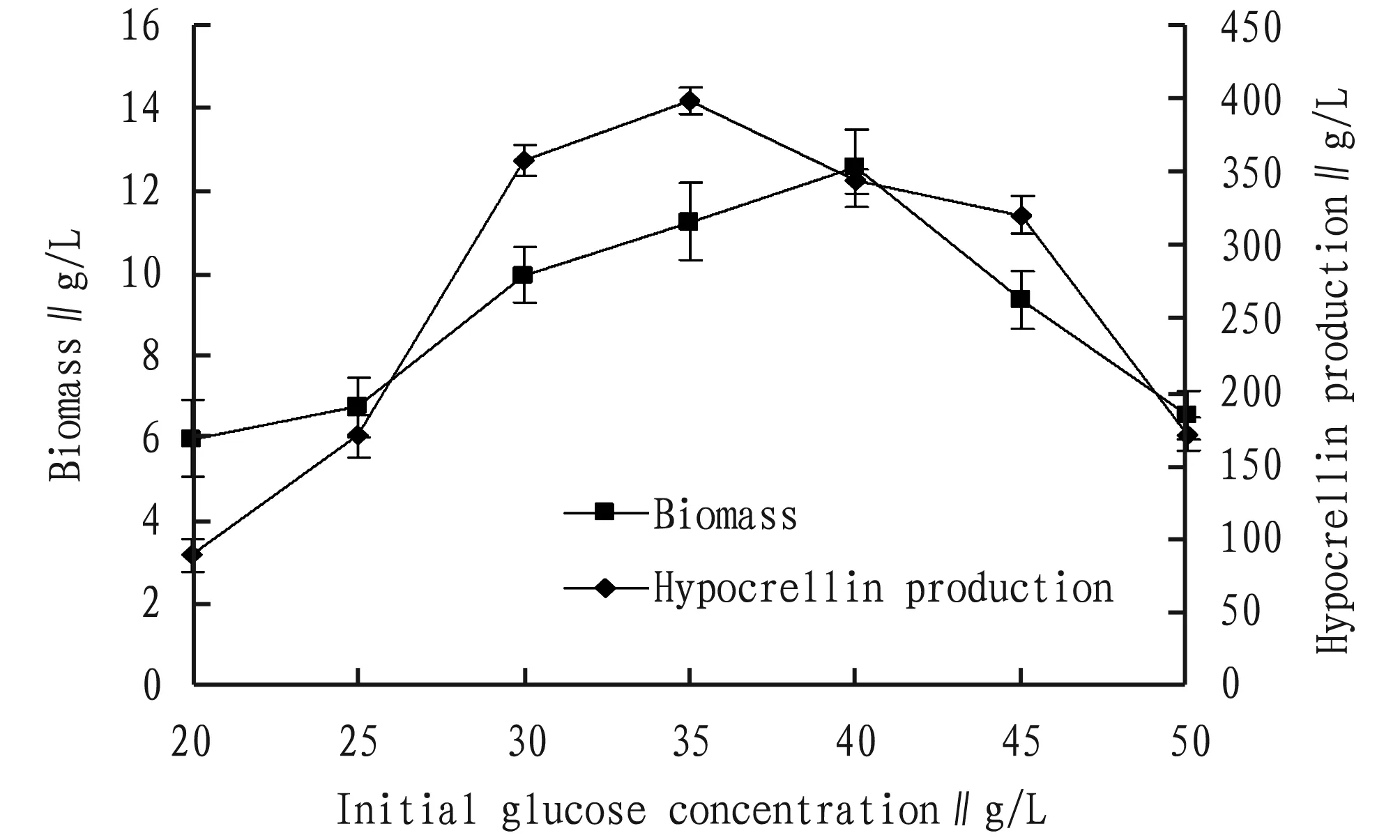

3.4.1Effect of carbon sources. Culture medium is important to the yield of any fermentation products, and carbon sources generally play a significant role because these nutrients are directly linked with cell proliferation and metabolite biosynthesis[16]. Carbohydrates are a key component of the cell cytoskeleton and an important nutritional requirement for the higher fungi growth[17]. To identify a suitable carbon source for hypocrellin production by submerged cultivation ofS.bambusicola, different carbohydrates,i.e. glucose, lactose, maltose, sucrose, mannitol, xylose, fructose and so on were tested. As shown in Table 2, among the carbon sources, glucose (364.83 mg/L) proved to be the best carbon source for both cell growth as well as hypocrellin production by the strain. Sucrose also gave a similar pattern result followed by fructose, mannose, mannitol, xylose and rhamnose respectively. No hypocrellin was produced when the medium was supplemented with lactose and maltose as a sole carbon source. Carbohydrates such as glycerol, maltose, lactose and some others are known to have interference with the production of secondary metabolites. In the present study, the strain was found to produce high levels of hypocrellin production in the medium supplemented with glucose as sole carbon source, this result was similar with reported inStreptomycessp.[18]. As reported by Yangetal.[12], sucrose yielded the best mycelial growth, glucose was the best carbon source to hypocrellin production. Based on the above results, glucose was selected as carbon sources for further studies. The effects of initial glucose concentrations on mycelial growth and hypocrellin production were shown in Fig.1. Mycelial growth increased with an increase of initial glucose concentrations between 20 and 50 g/L. When the initial glucose concentration was more than 40 g/L, the mycelial growth decreased. For hypocrellin formation, its highest production was obtained at 35 g/L initial glucose, which reached 399.23 mg/L. The results indicated that a high initial glucose concentration (50 g/L) was unfavorable to hypocrellin biosynthesis.

Table2EffectsofcarbonsourcesonthebiomassandhypocrellinproductionofShiraiabambusicolaGZ19M1

Carbon sources∥30 g/LBiomass∥g/LHypocrellin production∥mg/LGlucose14.31±0.87364.83±11.87Lactose1.65±0.040Maltose2.27±0.030Xylose7.89±0.8099.28±8.17Fructose11.37±0.37263.88±11.80Sucrose12.48±0.49310.05±8.67Mannitol9.76±0.58230.32±20.07Rhamnose7.45±0.5750.48±2.31

Fig.1Effectofinitialglucoseconcentrationsonthebiomassandhypocrellinproduction

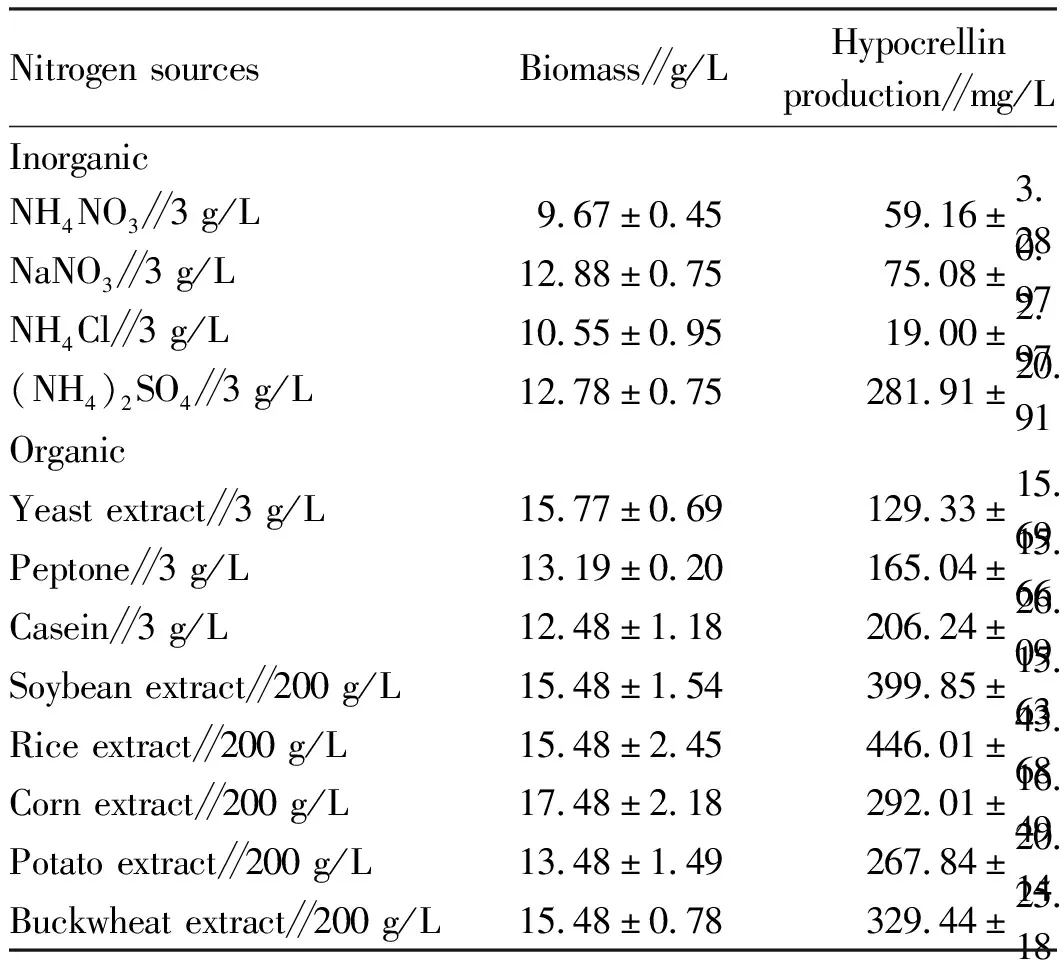

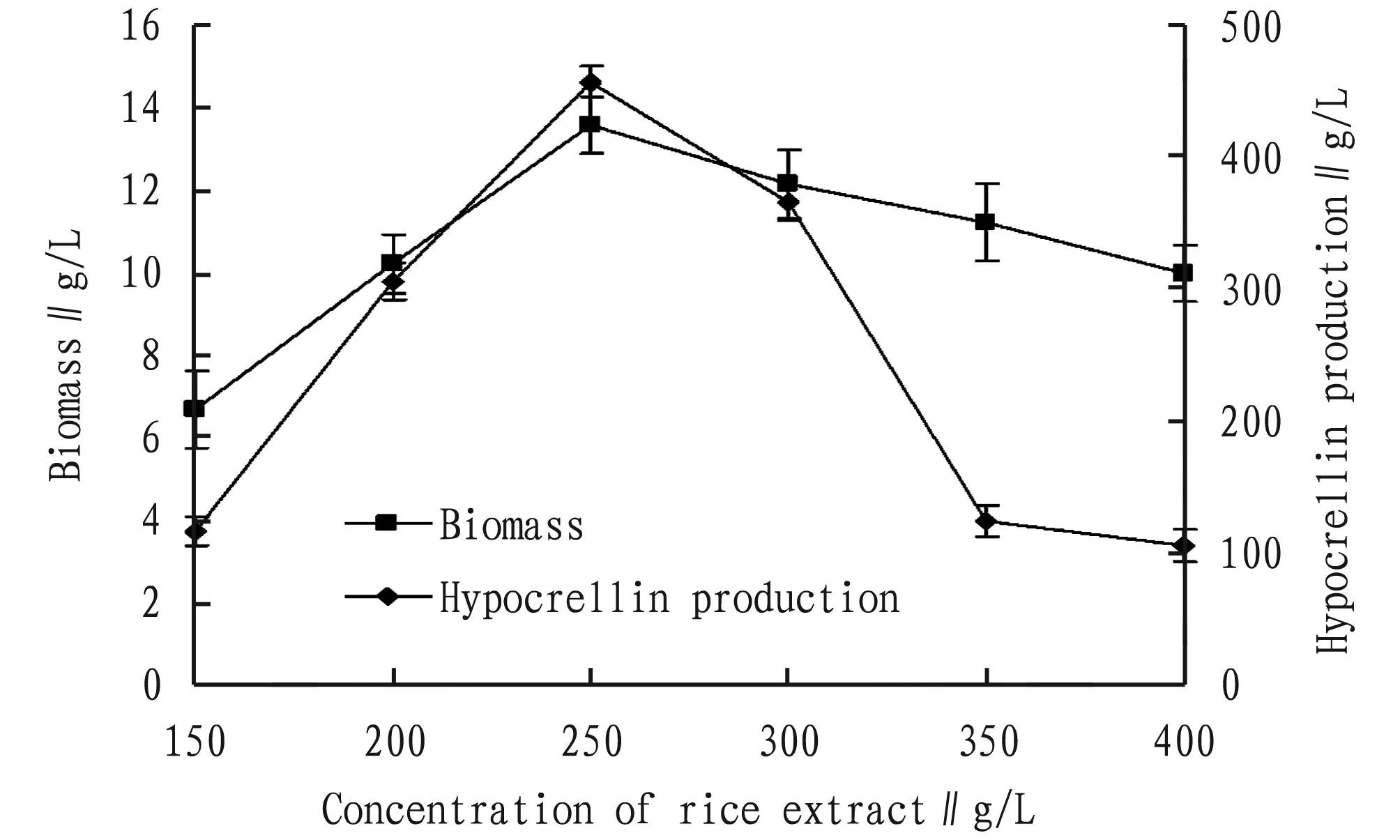

3.4.2Effect of nitrogen sources. Another factor reported to be essential for efficient hypocrellin production is the nature of the nitrogen sources for fungal cultivation[19]. We examined the ability of six inorganic nitrogen and eight organic nitrogen sources to stimulate hypocrellin production byS.bambusicolaGZ19M1. Table 3 shows the results for the cultures. In the cultures ofS.bambusicolaGZ19M1, all inorganic nitrogen sources examined, with the notable exception of NH4Cl, increased hypocrellin production (Table 3). Unconsumed NH4Cl in the medium may have affected hypocrellin production, as chloride ion is a potent inhibitor of the growth in some fungus[20]. Biomass production whenS.bambusicolaGZ19M1 was cultured under different conditions was also similar, with the exception of NH4Cl. Among the organic nitrogen sources yeast extract, peptone, casein, soybean extract, rice extract, corn extract, potato extract and buckwheat extract were used to identify, the results are also shown in Table 3. All organic nitrogen sources examined strongly aroused hypocrellin production inS.bambusicolawhen added to the basal medium. Rice extract (446.01 mg/L) was the best nitrogen source for hypocrellin production; corn extract was the best nitrogen source for the cell growth. From the above data, it was apparent that rice extract was most beneficial to hypocrellin production by submerged cultivation ofS.bambusicola. The effects of initial rice extract concentrations on mycelial growth and hypocrellin production are shown in Fig.2. Mycelial growth increased with an increase of initial rice extract concentrations between 150 and 400 g/L, whereas maximal hypocrellin production (456.14 mg/L) was obtained at 250 g/L initial rice extract. The hypocrellin production decreased when initial rice extract concentration was 300 g/L. The results indicated that a high initial rice extract concentration inhibited hypocrellin formation by submerged cultivation ofS.bambusicola. It was reported that complex nitrogen sources could increase the production of hypocrellin byShiraiasp.[7]. These sources could sustain high hypocrellin production and this property is supposed to be linked to the slow release of nitrogenous components during the course of the fermentation. More generally, several studies have shown that nitrogen assimilation is crucial for the regulation of antibiotic production but the mechanisms involved is not clearly understood[7,8]. The components of rice extract which can promote the hypocrellin production is still deserves further study.

Table3EffectsofnitrogensourcesonthebiomassandhypocrellinproductionofShiraiabambusicolaGZ19M1

Nitrogen sourcesBiomass∥g/LHypocrellinproduction∥mg/LInorganicNH4NO3∥3 g/L9.67±0.4559.16±3.28NaNO3∥3 g/L12.88±0.7575.08±0.97NH4Cl∥3 g/L10.55±0.9519.00±2.97(NH4)2SO4∥3 g/L12.78±0.75281.91±20.91Organic Yeast extract∥3 g/L15.77±0.69129.33±15.69Peptone∥3 g/L13.19±0.20165.04±15.66Casein∥3 g/L12.48±1.18206.24±26.09Soybean extract∥200 g/L15.48±1.54399.85±15.63Rice extract∥200 g/L15.48±2.45446.01±43.68Corn extract∥200 g/L17.48±2.18292.01±16.49Potato extract∥200 g/L13.48±1.49267.84±20.14Buckwheat extract∥200 g/L15.48±0.78329.44±25.18

Fig.2Effectsofriceextractconcentrationonthebiomassandhypocrellinproduction

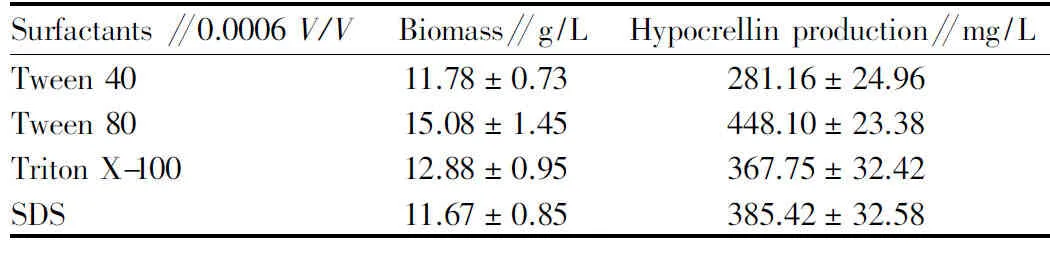

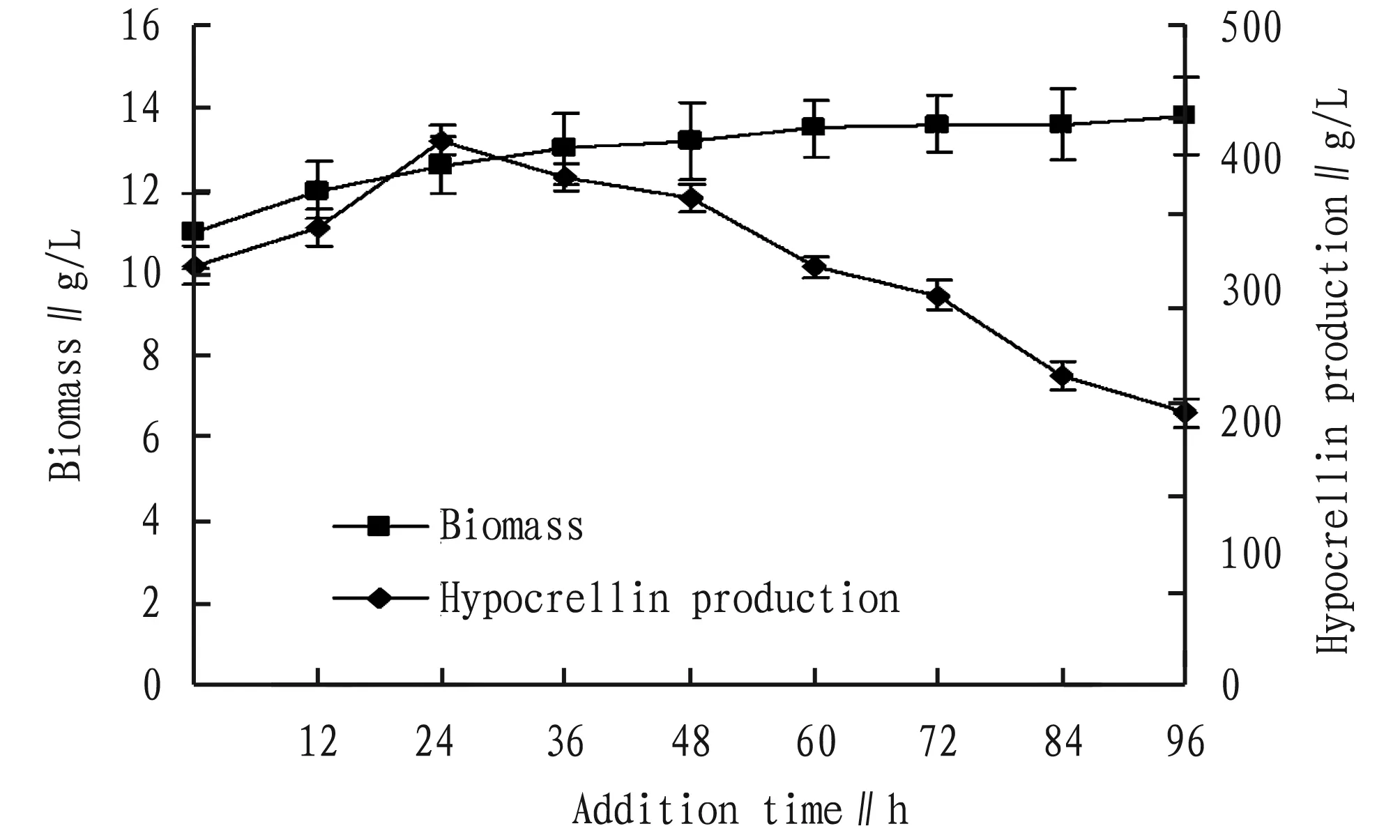

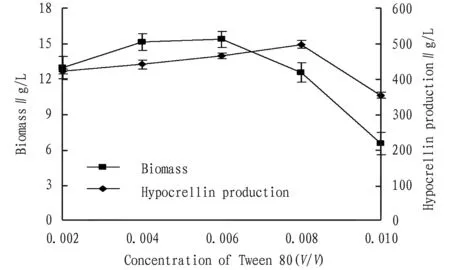

3.4.3Effect of surfactants. The use of surfactants in enzyme production has been well-documented. Surfactants increase the permeability of the membrane’s lipid bilayer, which facilitates the secretion of intracellular enzymes[20]. Experimental results showed that surfactants could induce the production of hypocrellin byS.bambusicolaGZ19M1 which increased hypocrellin by adding tested surfactants in varying degrees, such as Tween 40, Tween 80, Triton X-100 and SDS. It is also shown that Tween 80 was the best surfactants. Table 4 indicates that the addition of SDS and Tween 40 in the range 0.006V/Vto a submerged culture ofS.bambusicolaGZ19M1 increased the biomass yield. The influence of Tween 80 time of supplement on the yield of hypocrellin is shown in Fig.3. To investigate the effect of addition time of Tween 80 on hypocrellin production, Tween 80 (0.006V/V) were added into medium at different times of the flask cultivations, and optimal feeding time of Tween 80 were obtained at 24 h of cultivation. It is interesting that the results obtained when Tween 80 was added: 468.97 mg/L were obtained after 106 h of cultivation. Besides the distinct effect of addition time of Tween 80, the concentrations of Tween 80 also affect hypocrellin production. Therefore, the concentrations of Tween 80 in medium were employed in the range of 0-0.01V/Vat 24 h. Fig.4 indicates that Tween 80 was essential for hypocrellin production and enhanced hypocrellin production significantly. The highest hypocrellin production (498.89 mg/L) was detected in the medium supplemented with 0.008V/VTween 80, whereas further increment of Tween 80 concentration in medium resulted in an obvious decrease of hypocrellin production. As reported by Dekkeretal.[19], Tween 80 requirements by microorganisms were usually satisfied by low concentrations but toxic to fungal metabolism at higher concentrations. Surfactants have been widely used to increase the yield of fermentation product. From experimental results reported in the literature, we can find that Tween 80 was always the best choice of surfactants. For example, Tween 80 of Tween series surfactants exhibited the maximum stimulatory effect on laccase production by submerged culturedCoriolusversicolor. It is evident from our experimental that Tween 80 induced the production of hypocrellin.

Table4EffectsofsurfactantsonthebiomassandhypocrellinproductionofShiraiabambusicolaGZ19M1

Surfactants ∥0.0006 V/VBiomass∥g/LHypocrellin production∥mg/LTween 4011.78±0.73281.16±24.96Tween 8015.08±1.45448.10±23.38Triton X-10012.88±0.95367.75±32.42SDS11.67±0.85385.42±32.58

Fig.3EffectsofadditiontimeofTween80onthebiomassandhypocrellinproduction

Fig.4EffectsofTween80concentrationsonthebiomassandhypocrellinproduction

4 Conclusions

In this work, strain improvement by random mutagenesis using EMS was found to be effective than UV irradiation. EMS potentially produces large numbers of random mutations broadly and uniformly over the whole genome to generate unique. When surviving cells were selected in sufficient numbers and cultured on medium at 28℃, five novel mutagenizedS.bambusicolastrains were obtained. The mutant GZ19M1 strain was obtained with about 2.43 times hypocrellin production compared with that of the wild strain. A process of submerged cultivation ofS.bambusicolaGZ19M1 for hypocrellin production was demonstrated. The effects of major nutrients,i.e. carbon sources, nitrogen sources and surfactants, on hypocrellin production were studied in order to obtain a suitable fermentation medium. According to the experiment design and analysis, an optimal carbon source (35 g/L glucose), nitrogen source (250 g/L rice extract) and surfactant (0.008V/VTween 80) were identified and a maximal hypocrellin production. Further enhanced hypocrellin production was achieved by surfactants, especially with 0.008V/VTween 80. The addition time of Tween 80 was at 24 h of cultivation, resulting in the maximum hypocrellin production of 498.89 mg/L. Our future task is to carry out the experiments for the deeper insight into the specific role of rice extract and Tween 80 at the molecular level.

杂志排行

Asian Agricultural Research的其它文章

- Economic Value Evaluation of Fine Individual Plants ofRibesrubrum Linn.Based on AHP

- Mechanized Grafting Technology for Apple Seedlings

- Investigation and Analysis on Agricultural Biological Resources of Wuchuan Gelao and Miao Autonomous County,Guizhou Province

- The Mode of Promoting Industrial Targeted Poverty Alleviation through Land Circulation in Western Mountainous Region of China

——A Case Study of Luquan Yi and Miao Autonomous County in Yunnan Province - Reconstruction Mode of Rural Dilapidated Houses in Alpine and Gorge Area of Southwest China

——A Case Study of Scientific Identification and Precision Reconstruction of Rural Dilapidated Houses in Luquan County, Yunnan Province - Research on Satisfaction ofexsitu Relocated Households