Study of the relationship between the local geometric structure and the stability of La0.6Sr0.4MnO3-δand La0.6Sr0.4FeO3-δ electrodes

2019-02-27ChengZhiGuanJingZhouHongLiangBaoChengPengXiaoLinGuoPingXiaoJianQiangWangZhiYuanZhu

Cheng-Zhi Guan·Jing Zhou·Hong-Liang Bao·Cheng Peng·Xiao Lin·Guo-Ping Xiao·Jian-Qiang Wang·Zhi-Yuan Zhu

Abstract Sr-substituted ABO3perovskite oxides such as La0.6Sr0.4MnO3-δ(LSM)and La0.6Sr0.4FeO3-δ(LSF)are widely used as oxygen electrode materials in solid oxide cells.The substituted Sr is not adequately stable under the operating conditions,because of the surface segregation of Sr.Herein,we focused on investigating the relationship between the local geometric structure due to Sr substitution and stability of LSM and LSF.We characterized the local geometric structure of Sr atoms via X-ray absorption spectroscopy.A greater Debye-Waller factor and a longer bond length of both the second and third Sr-O shells were observed in LSF,which demonstrates that LSF has a higher local structural disorder and that Sr in LSF requires less energy to segregate.After 20 h of heat treatment in the presence of a Fe-Cr alloy interconnect,the Sr/La molar ratio on LSF was observed to be much larger than that on LSM.This result unequivocally suggests that Sr in LSF is not as stable as in LSM,and the reaction between Sr and Cr accelerates the Sr surface segregation in LSF.

Keywords Solid oxide cell·Perovskite·Strontium surface segregation·X-ray absorption spectroscopy·Chromium poisoning

1 Introduction

ABO3perovskite oxides are widely used as oxygen electrode materials in both solid oxide fuel cells and solid oxide electrolysis cells,owing to their excellent electrical conductivity,electrochemical catalytic performance,as well as low cost[1-3].Typically,rare earth and alkaline earth elements are used at the A-site and reducible transition metals such as Mn,Fe,Co,Ni are used at the B-site[4].ABO3oxides with Sr2+substitution in the A-site,includingLa1-xSrxMnO3-δ(LSM),La1-xSrxCo1-yFey-O3-δ(LSCF),La1-xSrxFeO3-δ(LSF),La1-xSrxCoO3-δ,Sm1-xSrxCoO3-δ,and Ba1-xSrxCo1-yFeyO3-δ,possess much better O2-transport ability and lower polarization resistance for oxygen reduction reaction(ORR)and oxygen evolution reaction(OER)[5-11].However,such Sr-doped electrodes suffer from Sr surface segregation(SSS),which seriously decreases the ORR and OER activities[12-15].Therefore,it is urgent to investigate the relationship between Sr substitution and the stability of the ABO3oxides for developing chemically stable Sr-substituted electrodes with high catalytic activities.

To date,numerous reports have been published on the elemental surface segregation phenomena,including some reviews on the materials,mechanisms,and methods.Understanding the correlation between the surface structure and stability of the electrodes has been emphasized[16,17],which is critical for the rational design of more ef ficientperovskites and perovskite-related electrode materials for intermediate-temperature solid oxide fuel cells[18].In case of the La1-xCaxFe0.8Ni0.2O3-δsystem,the content of the A-site Ca atoms determines whether the material is monophasic or not[19].Low-energy ion scattering spectroscopy has been used to study the outer atomic surfaces of a series of perovskite materials.The results indicate that the segregated A-site cations dominate the outer surfaces while the B cations are enriched below the surface[20].Total re flection X-ray fluorescence,X-ray photoelectron spectroscopy,and static secondary ion mass spectrometry have also been used to study the Sr enrichment on the surface[21-23].According to previous reports,many conditions in fluence Sr segregation.In particular,the Sr concentration on the surface increases with elevating temperature and decreasing partial pressure of oxygen[21,22],and increased SrO is formed on the surface in humidi fied air[24].Furthermore,polarization is another important factor that signi ficantly in fluences the formation of insulating SrO on the cathode surface or its removal from the surface.Anodic polarization induces the formation of SrO while cathodic polarization removes SrO[23].Moreover,SSS phenomenon is also associated with Cr contamination of the surface of cathodes under the operating conditions,and the segregated SrO also enhances the deposition of Cr species in the presence of a Fe-Cr alloy metallic interconnect.Additionally,Mn2+and SrO in LSM and LSCF are considered as the nucleation centers of Cr deposition as well[25-28].Recently,SSS has also been intensively explored via the first principles studies.Further,surface charge minimization and strain relaxation have been considered as the two possible thermodynamic driving forces during SSS[14].In particular,tensile strain and size mismatch between the cations at the A-site are demonstrated to be the fundamental factors leading to surface enrichment in selected elements(Ca,Sr,Ba)doped LnMnO3(Ln=La,Sm)at elevated temperatures[29].Based on these findings,the suppression of SSS in LSCF is achieved by the in filtration of Sm-doped CeO2,BaO,La0.8Sr0.2MnO3-δ,La0.1Sr0.9Co0.5Mn0.5O3-δ,PrSrCoMnO6-δ,and Pr0.75Sr0.25MnO3-δ[30-34].

In view of the crystal structure,Sr stability in perovskite oxides with Sr substitution is closely related to the fine structures around the Sr atoms.However,little effort has been focused on establishing the relationship between the local geometric structure of the perovskite electrodes and Sr segregation.In this work,we utilized X-ray absorption spectroscopy(XAS),an excellent method to probe the local atomistic and electronic structure[35-37],to establish correlation between the Sr stability and local geometric structures around the Sr atoms in LSM and LSF.Scanning electron microscopy (SEM),energy-dispersive X-ray spectroscopy(EDS),and X-ray diffraction(XRD)were also employed to identify the segregated compounds formed on the surfaces of LSM and LSF.Further,the effect of Cr deposition on Sr segregation was also been taken into consideration in the research.

2 Experimental section

2.1 Synthesis of LSM and LSF materials

Powders of LSM and LSF were prepared by the conventional solgel method.For the synthesis of LSM,stoichiometric amounts of La(NO3)3·6H2O (Strem Chemicals),Sr(NO3)2(Alfa Aesar),and Mn(NO3)2(Alfa Aesar)were mixed and dissolved in distilled water to obtain a precursor solution.After that,citric acid(Alfa Aesar)was added as the complexing agent into the precursor solution.Then,ethylenediaminetetraacetic acid(EDTA,J&K Chemical)was dissolved in ammonium hydroxide on a hot plate at 80°C.The molar ratio of citric acid/EDTA/total metal ions was fixed at 1.2:1.5:1.The pH of the solution was adjusted to 7 using ammonium hydroxide and nitric acid solutions.The two prepared solutions were mixed and slowly evaporated at 80°C under stirring over 5 h to obtain a gel.Then,the gel was decomposed at 150°C in an oven for 24 h.Finally,the powder was ground in a mortar and calcined at 1000°C for 4 h in air.The synthesis of LSF was carried out following the same procedure using Fe(NO3)3·9H2O(Strem Chemicals)instead of Mn(NO3)2.

2.2 XRD and XAS characterization

XRD patterns were collected in 0.02°steps over the 2θ range of 20°-90°to verify the phase purity of raw powders using a Bruker D8 ADVANCE X-ray diffractometer with Cu Kαradiation.The K-edge X-ray absorption spectra of Sr,Mn,and Fe atoms in LSM and LSF were obtained using the BL14W1 beam line at the Shanghai Synchrotron Radiation Facility(SSRF),operated at 3.5 GeV with the injection current of 200 mA.A Si(111)double-crystal monochromator was used for energy selection.All the spectra were collected in the transmission mode.The powder to be characterized was pressed into a self-supporting disk and then sealed with Kapton membrane before subjecting to XAS measurements.XAS data analyses were carried out using the software package of Ifef fit[38].The relative structural parameters such as coordination numbers(N),bond distance(R),the Debye-Waller factor(σ2),and inner potential shift(ΔE0)were calculated from the XAS data.

Fig.1(Color online)XRD patterns of LSM and LSF phases

2.3 Preparation of LSM and LSF electrodes on GDC substrates

Gadolinium-doped ceria(GDC,Fuelcell materials)was pressed into disks and sintered at 1600°C for 4 h in air to form the electrolyte pellets.The disks were approximately 20 mm in diameter.LSM and LSF slurries were obtained by mixing the powders and special inks and then screenprinted to obtain the GDC electrolyte,followed by sintering at 1100°C for 2 h.The effective area of the electrode was fixed at 0.5 cm2.

2.4 Heat treatment of the electrodes and posttreatment analysis

All the electrodes were sintered at 900°C for 20 h in a furnace;a commercial Fe-Cr alloy bulk was placed on top of each electrode as the source of Cr species.The alloy(RA446,23-27 wt%Cr,1.5 wt%Mn,1 wt%Si,0.2 wt%C,0.12 wt%N,and remaining Fe)was machined into cuboids (12 mm×12 mm×4 mm), with channels(1.2 mm×1.2 mm)cut on one side.The rib of the Fe-Cr cuboid was in touch with the electrode,while the channel region of the alloy was not.Finally,SEM and EDS were performed to characterize the morphologies of the electrodes using a LEO1530VP FE-SEM(ZEISS,Germany)equipped with an Oxford energy-dispersive X-ray spectrometer.Since the surfaces of the samples were not flat enough,we selected three points in each region for EDS analysis and used the mean value of the elemental content to calculate the Sr/La ratio.Further,XRD was used to characterize the composition of the as-prepared and heattreated porous electrodes.

3 Results and discussion

3.1 XRD characterization

The structure of the LSM and LSF powders was characterized by XRD(Fig.1).XRD data indicates that both samples are of a single phase with the hexagonal perovskite structure belonging to the R-3c space group.The diffraction angles shift to smaller values as the B-site element changes from Mn to Fe,owing to the different ionic radii of these two metals.The re fined lattice parameters are shown in Table 1.A smaller volume and smaller lattice parameters are observed for LSM as compared to those of LSF.The average crystalline sizes of LSM and LSF calculated from the full width at half maximum of the(110)peak using the Scherrer equation are 21.5 and 35.0 nm,respectively.

3.2 X-ray absorption measurements

Since the XRD data reveals the long-range structural order,it cannot provide information on the local environment of a speci fic element.Therefore,to identify the local structure around the Sr atoms,we collected the K-edge X-ray absorption spectra of Sr,Mn,and Fe atoms for LSM and LSF(Fig.2).X-ray absorption near edge structure(XANES)and Fourier transform extended X-ray absorption fine structure(FT-EXAFS)are presented to suggest the oxidation state and the local structural details,respectively.

To quantitatively discuss the differences between the local structure around the Sr,Mn,and Fe atoms,curve fitting was performed.For fitting,the following equations[39]were used:

Table 1 Re fined lattice parameters of LSM and LSF

Fig.2(Color online)XANES(a)and FT-EXAFS(b)of Sr in LSM and LSF;FT-EXAFS of Mn and Fe in LSM and LSF(c);slab model of SrBO3(d)

where χ is the oscillation in k space,N is the coordination number,f(k,π)is the back-scattering amplitude,σ2is the Debye-Waller(DW)factor,R is the interatomic distance,λ is the mean free path,and φ is the phase shift of the photoelectrons.f(k,π),λ and φ can be calculated using the FEFF software.

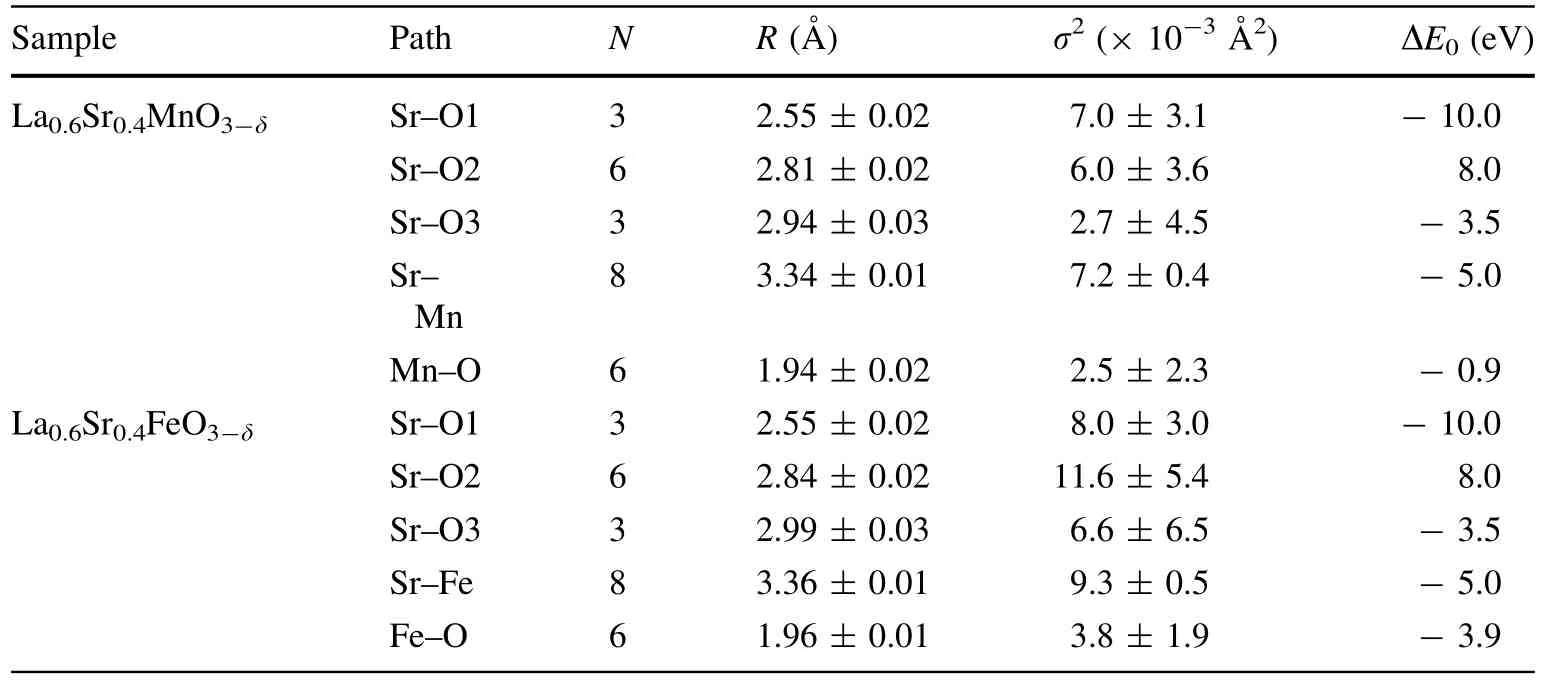

From Sr K-edge XANES spectra in Fig.2a,we find that Sr atoms in LSM and LSF have overlapped pre-edges and absorption edges.Further,no binding energy shifts can be observed.These results indicate that the Sr atoms in both LSM and LSF have the same oxidation state and other similar features.In Fig.2b,the peaks emerging at 2.85 A˚ for LSM and 2.88 A˚for LSF can be assigned to the contributions of Sr-O bond in each sample.The structural parameters obtained by fitting the K-edge EXAFS data are listed in Table 2.The average Sr-O bond length in LSM is shorter than that in LSF,indicating that the Coulomb interaction of Sr and O in LSM is stronger than that in LSF.The DW factors of Sr-O and Sr-Mn in LSM are smaller than those of the corresponding bonds in LSF,which demonstrates that LSM has lower local structural disorder.Figure 2c shows the Mn and Fe K-edge EXAFS spectra and the fitted curves.The average Mn-O bond length is 1.94 ± 0.02 A˚,while the interatomic distance between Feand O is 1.96 ± 0.01 A˚,implying slight lattice expansion.The DW factor for Mn-O is smaller than that for Fe-O.All these results suggest that LSM is more stable than LSF.

Table 2 Structural parameters obtained from the analysis of the EXAFS spectra at the Sr/Mn/Fe K-edge for LSM and LSF

Fig.3 SEM morphology of the LSM electrode surfaces:pristine LSM(a)and sintered LSM(b)

Fig.4 SEM images of the LSF electrode surfaces:fresh sample(a)and sintered sample(b-d)(b is the boundary,c is the channel region,and d is the rib region)

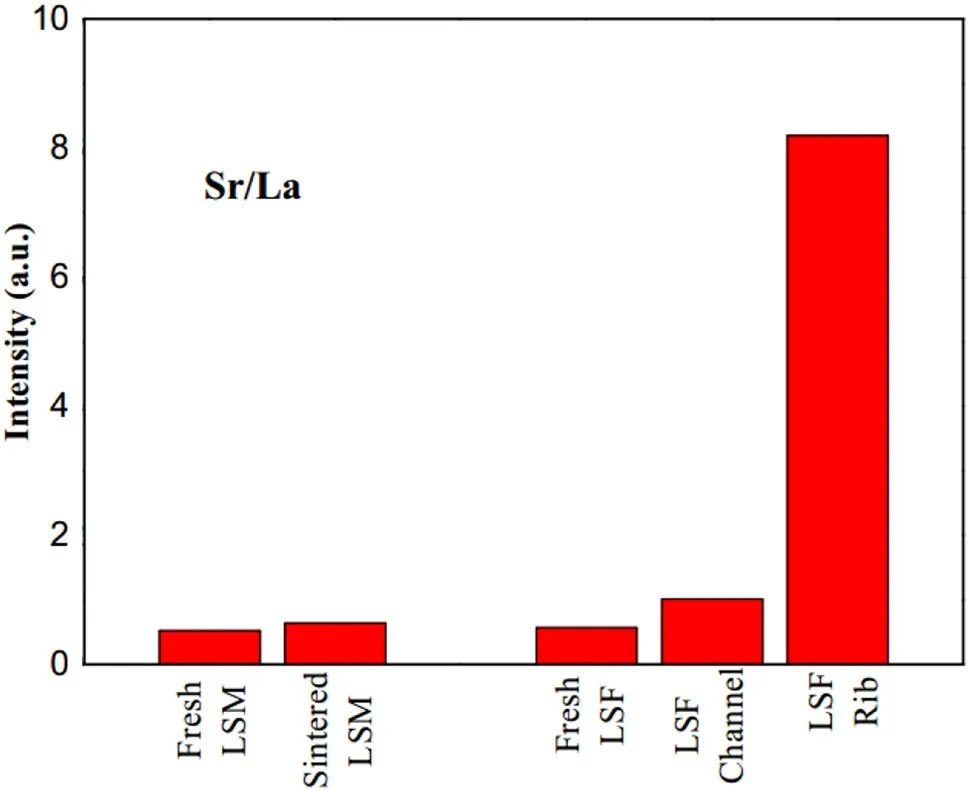

Fig.5 Molar ratio of Sr/La on the surfaces of LSM and LSF

A simpli fied slab model with R-3c structure for ABO3(B=Mn/Fe,A=Sr)is built as shown in Fig.2d for further discussion of the local structural changes geometrically.The hexahedron model consists of one Sr atom,three O atoms from different Sr-O shells,and one B atom.Compared with the perfect cubic perovskite structure,the SrBO3model is distorted.The distance between Sr and different O atoms varies,while the bond length of B-O bond is the same,in accordance with the EXAFS results.As discussed above,the Fe-O bond is longer than the Mn-O bond.Therefore,when the Mn atom is replaced with Fe,the hexahedron structure will be expanded,resulting in an increase in the average Sr-O bond length.Meanwhile,the substitution of the transition metal elements may lead to more severe structural distortion of the octahedron,which also contributes to the Sr-O bond length.To sum up,the difference between the Sr-O bond lengths in different shells is due to the combined effects of structural expansion and structural distortion.Therefore,we obtain varied bond lengths of second and third Sr-O bonds,while no obvious change is found for the length of the first Sr-O bond.

3.3 Morphology and analysis of the components

We then employed SEM to study the morphology of the surface of pristine LSM and sintered LSM(LSM was sintered in the presence of Fe-Cr alloy interconnect for 20 h)(Fig.3).Upon comparing the surface of pristine and sintered LSM,it is observed that limited agglomerated particles are present on both the planar surfaces and the particle size increases slightly during 20 h of sintering treatment.None of the boundaries of the rib region and channel region are observed on the surface of either of the LSM samples.

However,the surface of LSF after heat treatment is distinguishable from that of the pristine LSF.As shown in Fig.4a,several isolated grown grains are mixed in the LSF coating,owing to the sintering of particles during the stage of elevated temperature.The microstructures of sintered LSF coating are shown in Fig.4b,c,d.The morphologies of the LSF electrode under the rib and channel regions of the interconnect are apparently different(Fig.4b).The rib region of the electrode surface(Fig.4d)is covered by a dense film consisting of larger particles owing to the severe deposition of Cr species from the Fe-Cr interconnect.Even in the channel region shown in Fig.4c,much more agglomerated grains are found in comparison with that found in the fresh LSF electrode.

From Fig.5,the SEM-EDS results further reveal that the molar ratio of Sr/La on the LSM surface increases from 0.52 to 0.64 after sintering in the presence Fe-Cr for 20 h.In contrast,the molar ratio of Sr/La on the LSF surface increases much more from 0.57 to 1.01 for the channel region and 8.19 for the rib region.This result indicates that Fe accelerates SSS,especially in the presence of Cr species.

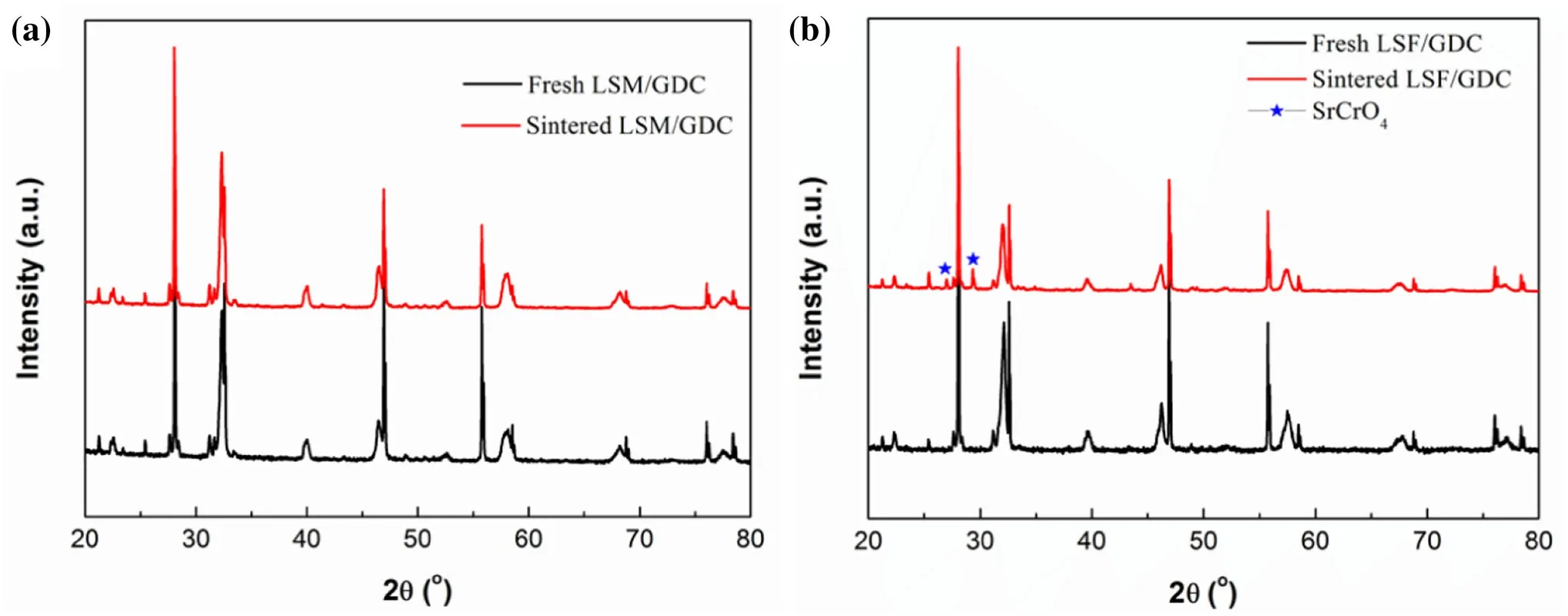

Fig.6(Color online)XRD patterns of fresh and sintered samples:a LSM and b LSF

The compounds formed on the LSM and LSF electrodes surfaces were characterized by XRD.As shown in Fig.6,the XRD pattern of sintered LSM sample is similar to that of the pristine one,indicating that no impurity phase appears on the surface of the LSM electrode or that the content of the impurity is below the limit of detection.However,the characteristic peak of SrCrO4is observed in the XRD pattern of sintered LSF sample,indicating that Sr segregation occurs on the surface of LSF and further leads to a dense film observed in Fig.4d.Since the formation of the Sr-Cr-O oxide particles is associated with the amount of segregated Sr atoms on the surface of the electrodes,SrCrO4can be regarded as an indicator of the surface enrichment with Sr.

4 Conclusion

In this study,synchrotron-based X-ray spectroscopy was used to investigate the local structure of Sr atoms in LSM and LSF.The bond length of Sr-O in LSF is longer by 0.03 A˚than that in LSM,and the Coulomb interaction between Sr and O in LSF is weaker than that in LSM,indicating that the Sr-O bond in LSF can be broken easily.After 20-h heat treatment in the presence of a Fe-Cr metallic interconnect,SrCrO4composite was found on the surface of LSF,while no Cr species were evidenced on the surface of LSM.Moreover,contact with Cr species results in much more segregation of Sr on the surface of the LSF electrode.

杂志排行

Nuclear Science and Techniques的其它文章

- Simulation study of the dose and energy responses of FNTD personal neutron dosimetry

- Using monochromatic light to measure attenuation length of liquid scintillator solvent LAB

- Solution of the finite slab criticality problem using an alternative phase function with the second kind of Chebyshev polynomials

- Determination of water equivalent ratio for some dosimetric materials in proton therapy using MNCPX simulation tool

- Application of Monte Carlo method to calculate the effective delayed neutron fraction in molten salt reactor

- Analysis of beryllium poisoning effect on liquid metal reactor with U-Be alloy fuel