Development of Ternary Phosphate-based Inorganic Dry Pre-lubricant Reagent and Its Applicatuion in Improving Forming Properties of Galvannealed Autosheets

2019-02-26ZHAOXiaofeiMIAOYufangLIMinYUDongyun

ZHAO Xiao-fei, MIAO Yu-fang, LI Min, YU Dong-yun

Development of Ternary Phosphate-based Inorganic Dry Pre-lubricant Reagent and Its Applicatuion in Improving Forming Properties of Galvannealed Autosheets

,,,

(User Technology Institute, Shougang Research Institute of Technology, Beijing 100043, China)

The work aims to synthesize an inorganic pre-lubricant reagent for improving the formability of the galvannealed steel sheets, so as to reduce the friction coefficient on the surface of galvannealed steel sheets and decrease the defects during stamping. Phosphoric acid and metallic nitrate were used as the main materials to prepare the inorganic pre-lubricant reagent and then a uniform and continuous inorganic pre-lubricant film was obtained on the galvannealed steel sheet. The basic morphology and thickness of such film formed on the material was characterized by SEM and GDS. The surface friction coefficient and stamping properties of materials coated with inorganic pre-lubricant film were analyzed by plate friction test and deep drawing test. Meanwhile, the welding/cementing and coating properties of galvannealed steel sheet coated with inorganic pre-lubricant film were analyzed according to certification features of steel sheet. A uniform and continuous inorganic film could be formed on the surface of the galvannealed steel sheet by roller coating method and the thickness of such inorganic film was 50~60 nm. The surface frictional coefficient of such pre-lubricant film coated galvannealed steel sheet was 13% lower than that of the plain galvannealed steel sheet, and such decrease of surface frictional coefficient became more obvious with the increasing surface temperature of the sheet. Moreover, such pre-lubricant film coated galvannealed steel sheet also showed well spot weldability (including welding window and welding service life) that met the certification requirements of the steel sheet with the same thickness and had good compatibility with typical automotive structural adhesives. At last, automotive OEM showed that such inorganic dry pre-lubricant film on the galvannealed steel sheet could be completely removed under the present degreasing process and the thickness and grain size of obtained phosphating film was the same as that of ordinary galvannealed sheet. The currently developed inorganic pre-lubricant reagent can form a film on the galvannealed sheet and can effectively reduce the material friction coefficient and provide guarantee for reduction of stamping defects without affecting other properties of materials.

galvannealed steel sheet; inorganic dry pre-lubricant film; surface frictional coefficient; spot weldability; automotive structural adhesives; phosphating treatment

As we all know, various zinc coated steel sheets, especially the galvannealed steel sheets have become a very important component of automotive body panels due to its good corrosion resistance and reasonable production cost[1-5]. On the other hand, however, the presence of softphase on the surface of the galvannealed steel might cause the increase of the friction coefficient and press troubles such as fracture[3]. A typical DP590 D+Z pressing part fracture example can be seen in Fig.1.

Fig.1 Typical press cracking of galvannealed steel sheet

At this point, a strong demand arises to reduce the surface friction coefficient and improve the press property of the galvannealed steel sheets by using an easy-handling, reasonable post-treatment method on the material surface. To meet this requirement, various kinds of organic/inorganic dry pre-lubricant film coatings for galvannealed sheet with good frictional properties have been developed[5-16]. However, except for a improving frictional property, such post-treatment or film on the galvannealed sheet surface should show a good compatibility with the existing adhesive, weldability and painting technology in the whole white body manufacturing process.

In this article, a novel ternary phosphate-based inorganic reagent was prepared and then a dry pre-lubricant film could be easily obtained on the surface of the galvannealed steel sheet surface. The characterization results indicated that, compared with the galvannealed steel sheet only coated with traditional anti-corrosion oil, the samples coated both dry pre-lubricant film and equal anti-corrosion oil showed an obvious reduction of friction coefficient on the surface. Furthermore, the galvannealed steel sheet coated such dry pre-lubricant film also meet all the technological requirement of the automotive body panel material, including adhesive bonding, welding and painting technology. The galvannealed sheet with the novel dry pre-lubricant film also showed an outstanding anticorrosion property.

1 Experimental Section

1.1 Synthesis of the ternary phosphate-based inorganic reagent

The ternary phosphate-based inorganic reagent was synthesized under room temperature. A 0.12 mol/L H3PO4solution was firstly prepared, and then 0.035 mol/L ZnO powder was slowly dissolved in the above H3PO4solution under magnetic stirring condition. Then 0.021 mol/L Ni(NO3)2·6H2O, 0.022 mol/L Mn(H2PO4)2, 0.010 mol/L Na2SiF6and 0.004 mol/L (NH2OH)2·H2SO4were dissolved in the above solution separately. The pH of the final solution was 2.30.

1.2 Synthesis of inorganic dry pre-lubricant film coated galvannealed steel sheet

0.8 mm CR3 galvannealed steel sheets were selected in this work. The dry pre-lubricant film coated on the galvannealed steel surface was obtained though roller coating method with the above inorganic reagent under room temperature. First of all, the above solution was diluted to 75% of the original concentration; before the roll coating procedure, the galvannealed steel sheets were totally cleaned using alkaline degreasing solution to obtain a clear surface; a home-made roller coating machine was used to obtain a uniform, continuous liquid film on the galvannealed steel sheet surface; and then the such sample was dried in the oven under 50 ℃ for 3 minutes.

The microstructure of the as-prepared samples was characterized by SEM and GDOES. The compatibility evaluation of the dry pre-lubricant film with the existing automotive manufacturing process included adhesive bonding, welding, and phosphatizing processes. Before all the above evaluation and the frictional properties test, all the samples with/without dry pre-lubricant film were coated with equal amount (1500 mg/m2) anti- corrosion film.

The frictional properties were examined by the sheet forming friction testing machine according to the YB/T 4286—2012 black metallurgy industry standard of the People's Republic of China: test method for friction coefficient of metal material thin plate and thin band; the final frictional coefficient µ was evaluated in terms of the applied forcedand the drawing forcen:=d/2n. The deep-drawing property of different samples was measured on Zwick BUP 400 Sheet Metal Ductility Testing Machine, the drawing depthwas 15 mm and the drawing speedand blank holder forcewere set as 2.0 mm/s and 10 kN, respectively.

The compatibility of the galvannealed sheet with dry pre-lubricant film was investigated using 5 different kinds of typical structural adhesives. The adhesive joints were prepared according SAE J1523 Metal-to-Metal overlap shear strength Test for automotive-type adhesives. The illustration of the adhesive joints was shown in Fig.2: the size of the steel sheet was 100 mm×25 mm, and the thermal curing condition of all 5 selected structural adhesives was 180 ℃ for 30 min. The shear strength of adhesive joint samples were tested using a Zwick Z100 Tensile Testing Machine, all specimens were tested at a pull rate of 13 mm/min under 23±2 ℃.

For the welding, the weldable current range and continuous spot weldability evaluation of the galvannealed sheet with/without dry pre-lubricant film were carried with the following conditions: the electrode force is 2.2 kN, and the holding time is 100 ms, and the face diameter of the electrode is 6 mm. The degreasability and phosphability coupon tests of the galvannealed sheet with dry pre-lubricant film were done in an automotive OEM. The phosphate crystals formed after the phosphating treatment was observed by SEM.

Fig.2 Schematic diagram for test of adhesive property

2 Results and discussion

2.1 Characterization of dry pre-lubricant film coated on the galvannealed steel sheet

The surface morphology of the dry pre-lubricant film coated galvannealed steel sheets (Fig.3c and d) were very similar to the plain galvannealed steel samples (Fig.3a and b), and a typical EDS result was shown in Fig.4: in the crater on the sample surface (spectrum 2, 3, 4 and 7), the relative content of P element is 1.6%~2.2%, while above the higher place on the sample surface (spectrum 1, 5, 6 and 8), the relative content of P element is 0.6%~0.8%. Furthermore, the depth distribution of typical elements of dry pre-lubricant film (P, Si and Mn) was shown in Fig.5. The thickness of such dry pre-lubricant film was 50~60 nm. All results indicated that an uniform, complete dry pre-lubricant film was formed on the galvannealed steel sheet surface.

Fig.3 SEM images for surface of inorganic pre-lubricant coated galvannealed sheet

Fig.4 EDS results of the inorganic pre-lubricant coated galvannealed sheet

Fig.5 GD-OES results of the inorganic pre-lubricant coated galvannealed sheet

2.2 Frictional Property and Press Formability of dry pre-lubricant film coated galvannealed steel sheet

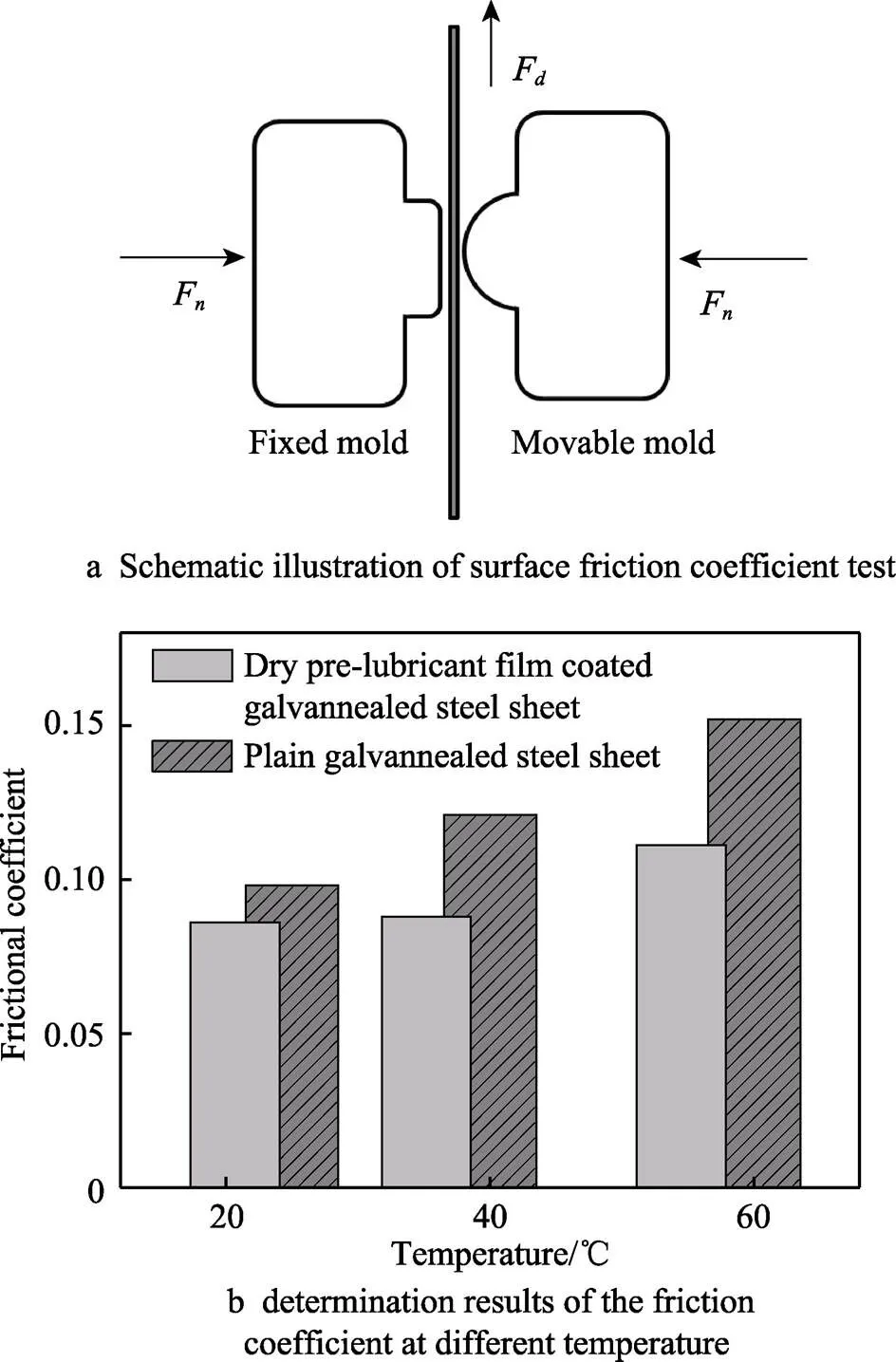

The surface friction property and press formability of such pre-lubricant film coated galvannealed steel sheet were discussed respectively. As can be seen in Fig.6, the surface friction coefficient of pre-lubricant film coated galvannealed steel sheet under 25 ℃ was 0.086, and it was 12% lower than the surface friction coefficient of the plain galvannealed steel sheet, and such results indicated that, under the similar anti-corrosion oil film thickness condition, the pre-lubricant film could offer effective protection during the forming process. Moreover, considering the surface temperature of the autosheet might increase during the forming process, the surface friction coefficients under high temperature of such two samples were measured. As can be seen in Figure 6, the surface friction of pre-lubricant film coated galvannealed steel sheet under 40 ℃ is 0.088, decreasing 27% than that of the plain galvannealed steel sheet sample; such effective decrease of surface friction was much obvious when the temperature rise to 60 ℃.

Fig.6 Schematic illustration of surface friction coefficient test and determination results of the friction coefficient at different temperature

Deep drawing is a forming process in which a sheet metal blank is drawn into a regular or irregular box or a cylindrical part with a forming die, and Figure 7a showed an illustration for the typical cylinder parts drawing. Generally, factors influencing the deep drawing process of cylinder sheet mainly included the properties of sheet metals, fillet radii of concave and convex dies, and the friction between the blank and die. Therefore, the frictional behavior of sheet metals before and after pre-lubrication was investigated using the method of deep drawing experiment of cylinder sheets and experiment results were shown in Fig.7b. During the deep drawing process, a blank primarily sustained both the deformation and friction resistance. With other conditions unchanged, the frictional behavior before and after pre-lubrication treatment was consequently evaluated via the measurement of forming force during the drawing process. Obviously, it is seen that under the same condition, the forming force of all pre-lubricated samples is relatively lower than that of ordinary steels, with a reduction of about 5%. Thus, such pre-lubricant treatment improved the surface properties of sheet metal and reduces the frictional resistance during forming process.

Fig.7 Schematic illustration of deep drawing test and deep drawing results of different materials

2.3 Spot weldability of dry pre-lubricant film coated galvannealed steel sheet

Under the setting welding parameters, it can be seen from the Figure 8a that the welding current window size of plain galvanized steel sheet is 3.4 kA, ranging from 8 kA to 11.4 kA. The welding current window size of dry pre-lubricant steel sheet is 3.2 kA, ranging from 8.4 kA to 11.6 kA. The minimum and maximum current of the dry pre-lubrication steel sheet are both larger than that of plain galvanized steel sheet and the window size is slightly smaller than that of plain galvanized steel sheet. It can be seen that the coating makes the welding window slightly move up and the window size changes little.

For the electric cap in the life test, the welding current is the maximum current minus 200 A, and a total of 1000 points are measured. The diameter of the welding spot is measured at every 40 points. The results are shown in Fig.8b. As the test is carried out, the welding spot diameter of dry pre-lubrication steel sheet and plain galvanized steel sheet both decreased. When welding to 1000thpoints, the surface of the electrode cap is severely damaged. The welding spot diameter of dry pre-lubrication steel sheet is 4.5 mm and welding spot diameter of plain galvanized steel sheet is 4.9 mm. They are both much greater than the minimum diameter, which means the service life of the electrode cap more than 1000 spots. These results indicated that such dry pre-lubricant film coating had no significant effect on the life of electrode cap.

Fig.8 Welding window and life test results

2.4 Compatibility with adhesives of dry pre-lubricant film coated galvannealed steel sheet

Table 1 and Fig.9 showed the compatibility of dry pre-lubricant film coated galvannealed steel sheet with five different typical automotive structural adhesives and one typical adhesive sealant. As can be seen in Table 1, the shear strength of the dry pre-lubricant film coated galvannealed steel sheet was equal or somewhat better than those of the plain galvannealed steel sheet. In addition, the fraction modes of all dry pre-lubricant film coated galvannealed steel samples were all cohesion failure (CF).

Tab.1 Shear strength measurement results of single lap joints of different materials

表1 不同材料单搭接胶接结构剪切强度结果

Fig.9 Results of failure mode for lap joints

Fig.10 Phosphating experiment results

2.5 Phosphatability of dry pre-lubricant film coated galvannealed steel sheet

As we all know, phosphating process is a crucial procedure in the whole pretreatment process for the autosheets material. According to the previous research, autosheets material surface with a high cleanliness is the key precondition for the formation of a continuous, homogeneous phosphating film. Therefore, for the practice application of the dry pre-lubricant film coated galvannealed steel sheets, a complete clean for such material a formation of high-quality phosphating film under the present degreasing and phosphating process condition and in most automotive OEMs is the most critical factor. In our present work, practical degreasing and phosphating processes in an OEM were performed for both pre-lubricant film coated galvannealed steel sheet and the plain galvannealed steel sheets. Fig.10 shows SEM images of phosphate crystals on galvannealed steel sheet with/without dry pre-lubricant film. As we can see, the phosphate crystals on the dry pre-lubricant film coated galvannealed steel sheet were equivalent to those of the plain galvannealed steel sheet, and no missing or unevenly distributed crystals can be observed. The sectional SEM view indicated that, compared with phosphate film on the plain galvannealed steel sheets (Fig.10a, film thickness 1.23 µm) a uniform, continuous phosphate film also were formed on the dry pre-lubricant film coated galvannealed steel sheet after the alkaline degreasing treatment process (Fig.10c, film thickness 1.79 µm). Such results confirmed that the dry pre-lubricant film on the galvannealed steel sheet surface was almost completely dissolved into the alkaline degreasing solution by the present alkaline degreasing treatment, and a complete clean surface could be obtained for the phosphating process. All these results indicated that the dry pre-lubricant film coated galvannealed steel sheet had a good compatibility with the pretreatment process of OEMs.

3 Conclusions

A uniform, continuous pre-lubricant film could be formed on the galvannealed steel sheet surface under the room temperature through the roller coating process. Combined with the anti-corrosion oil film of similar weight, such pre-lubricant film could efficiently reduce the surface friction coefficient of the galvannealed steel sheet and decrease the wearing of the zinc coating of the galvannealed steel sheet. Such pre-lubricant film coated galvannealed steel sheets showed good bonding and welding properties. Furthermore, the pre-lubricant film had a good compatibility with the present degreasing process and it could be totally dissolved in the alkaline degreasing solution. Moreover, the phosphate film formed on the pre-lubricant film coated galvannealed steel sheet had a good crystallinity and particle size distribution.

[1] ZHANG Q F, HUANG J Z, ZHAO P, et al. Development of continuous coating and plating strip steel[J]. Journal of iron and steel research, international, 2001, 8(2): 34-41.

[2] FEI J Y, LIANG G Z, XIN W L, et al. Surface modification with zinc and Zn-Ni alloy compositionally modulated multilayer coatings[J]. Journal of iron and steel research, international, 2006, 13(4): 61-67.

[3] SONG J Z, YANG Z Y. Corrosion resistance of sintered NdFeB permanent magnet with Ni-P/TiO2composite film[J]. Journal of iron and steel research, international, 2009, 16(3): 89-94.

[4] BAO Z Q, BAO Z Y. Research of application of alloying-pot-galvanized sheet for making rolling stock[J]. Materials for mechanical engineering, 1996, 19(6): 22-28.

[5] ZHU J F. Review on production technology of hot dip galvanizing sheet for autobile abroad[J]. Metallurgical information review, 2007(4): 33-39.

[6] IRIE H, YAMAMOTO T, SHIMIZU M. Characteristics of prephosphated galvannealed steel sheets[J]. Kobe research and development, 2000, 50(2): 10-14.

[7] SUGIMOTO Y, SAKURAI M, KATO C. Lubricant treated anti-corrosion steel sheets for automotive use-galvannealed steel sheets with excellent press formability[J]. JFE technical report, 2004(4): 50-57.

[8] CUI L, ZHAO Y L, REN M, et al. Research progress of self lubricating galvanized steel sheet[J]. Research on iron & steel, 2010, 38(6): 268-272.

[9] YU Y, ZHAO H Y, SONG Q F et al. Influence of surface and lubrication on forming ability of cold-rolled thin plate for home made cars[J]. Metal forming technology, 2000, 18(1): 41 -43.

[10] GONG H Y, LI S P, ZHANG Z L. Influence of process parameters on hit-dip galvanized steel sheet forming properties[J]. Forging technology, 2003(6): 33-36.

[11] JIANG H M, CHEN X P, WU H, et al. The effect of mechanical properties of prephosphated electrogalvanised sheet on stamping process of side-frame outer panel[J]. Plastic working technology, 2003(6): 34-36.

[12] YUAN X, LIU X, YANG C S, et al. State of art and progress of self-lubricated galvanized sheets[J]. Corrosion & protection, 2011, 32(12): 976-979.

[13] LI S M, AN C Q, HAO J J. Research progress of self-lubricating coating on galvanized sheet[J]. Plating and finishing, 2015, 37(5): 12-18.

[14] SEIJI N, TOMOKATSU K, CHIAKI K. Inorganic dry film lubricant coated galvannealed steel sheet with excellent press formability and adhesive compatibility[J]. Kawasaki steel technical report, 2003, 48: 23-27.

[15] LIU X, YU W G, ZHANG W G, et al. Influence of surface roughness of galvanized steel sheet on self-lubricated coating[J]. Journal of iron and steel research, international, 2014, 21(3): 342-347.

[16] SAKURAI M, JUN-ICHI I, YAMASAKI Y, et al. Development of “PZA-N” galvannealed steel sheet with high formability[J]. Bulletin of the Japan institute of metals, 2001, 40(2): 190-192.

三元磷酸盐体系无机预润滑试剂的研发及其在改善热镀锌汽车板成形方面的应用

赵晓非,苗雨芳,黎敏,于东云

(首钢集团有限公司技术研究院 用户技术研究所,北京 100043)

旨在合成一种用于改善热镀锌汽车板材料成形性能的无机预润滑试剂,以期降低热镀锌板表面摩擦系数,进而减少冲压过程中开裂等缺陷的发生。以磷酸、金属硝酸盐等为主要试剂合成机预润滑试剂,在热镀锌汽车板材料表面得到均匀、连续的无机预润滑薄膜。采用扫面电子显微镜、辉光光谱仪等手段对材料表面所形成的无机预润滑薄膜的基本形貌、厚度等进行表征。采用平板摩擦、深冲实验对材料涂覆预润滑膜后的表面摩擦系数及冲压性能进行分析。同时,根据汽车板材料认证特点,对无机预润滑处理后的热镀锌汽车板材料的焊接/胶接、涂装性能进行分析。采用辊涂法在热镀锌汽车板材料表面可形成厚度为50~60 nm连续、均匀的薄膜。较之普通热镀锌材料,上述表面涂覆无机预润滑薄膜后的热镀锌材料表面摩擦系数可有效下降13%。,且伴随板面温度升高,无机预润滑热镀锌材料表面摩擦系数的下降愈发明显;同时,无机预润滑处理热镀锌材料的焊接性能(包括焊接窗口、焊接寿命)符合同等厚度汽车板材料的认证需求。涂覆无机预润滑薄膜热镀锌板表面与汽车结构胶具有良好的兼容性;此外,汽车主机厂挂片实验结果证实,现有的脱脂工艺可将材料表面无机预润滑膜彻底脱除,所得磷化膜厚度、晶粒大小与普通热镀锌板无异。当前所研发的无机预润滑试剂在热镀锌板表面形成薄膜,在不影响材料其他各项性能的前提下,可有效降低材料摩擦系数,为减少冲压缺陷的发生提供保证。

热镀锌汽车板;无机预润滑薄膜,表面摩擦系数;点焊性能;汽车结构胶;磷化处理

2018-06-25;

2018-11-12

10.16490/j.cnki.issn.1001-3660.2019.02.036

2018-06-25;

2018-11-12

ZHAO Xiao-fei (1982—), Female, Doctor, Research focus: marine antifouling coating. E-mail: mybrightlife@126.com

赵晓非(1982—),女,博士,主要研究方向为船用防污涂料。邮箱:mybrightlife@126.com

TH117.2

A

1001-3660(2019)02-0253-07