Laterally pre-compressed SiC tiles against long rod impact

2018-10-18BoyangLuoWeiliangGohZhongChenJianmingYuan

Bo-yang Luo,Wei-liang Goh,Zhong Chen,Jian-ming Yuan

aTemasek Laboratories,Nanyang Technological University,50 Nanyang Drive,637553,Singapore

bSchool of Materials Science and Engineering,Nanyang Technological University,639798,Singapore

Keywords:Pre-compressed SiC tile DOP test WHA long rod

ABSTRACT A combined experimental and computational study was carried out to investigate ballistic performance of laterally preload compressed SiC tile against long rod impact.A 100×100 by 20 mm thick SiC tile was pushed into a 5 mm thick steel frame at high temperature of 430oC so that after cool down to room temperature,the lateral preload compressive stress was developed in the SiC tiles.Depth of penetration tests of the SiC tiles with and without pre-stress were performed,where tungsten alloy long rods at a nominal velocity of 1240 m/s were launched to hit the SiC tiles backed by the steel blocks.Compared with the SiC tiles without any pre-stress,the pre-compressed SiC tiles were found to reduce significantly the residual penetration in the backing block.Simulations were carried out using the LS-dyna hydrocode,taking account of preload stress.The simulations showed that the lateral preload compression strengthened the intact SiC tiles and dwell occurred in the early penetration stage,eroding the striking long rod efficiently.

1.Introduction

Ceramics exhibit excellent ballistic protection capability.For instance,it was demonstrated that SiC ceramics could defeat high density long rods launched at velocities up to 1600m/s,with little or no penetration[1,2].To establish the potential of the protection capability of such ceramics,various configurations of ceramic armour had been previously investigated,especially making the use of pre-stress technique.Hauver et al.[3]used thick titanium alloy confinement in the armour modules,where hot isostatic press processing formed residual compressive stresses in the ceramic tile during cool down of the assembly from the pressing temperature.Lundberg et al.[2]applied thick cover layers and backing supports to create pre-stress to the ceramics using a heat shrink technique.These research efforts demonstrated that ballistic performance of ceramics against long rod penetration could be maximized through the proper component design to generate pre-compression in ceramics.However,the investigated designs using thick and heavy components presented a limitation to actual lightweight ceramic armour applications.

This paper sought lightweight design concept to improve ceramic performance through introduction of preload stress.Heat shrink technique was applied to produce lateral preload compression inside square SiC tiles by using 5mm thick steel frames.The effect of lateral pre-compression on ballistic performance of SiC tiles against tungsten long rod impact was investigated.The interaction of the long rods with the pre-stressed ceramic tile was studied by means of depth penetration experiments and hydrocode simulations.

2.Experiment and results

Fig.1 shows fabrication of the laterally pre-compressed SiC tile.The 3 M SiC tiles with dimensions of 100mm×100mm by 20 mm thickness were used.Several frames made of AISI 4340 steel were machined with the length range of the internal width 99.50-99.90 mm.The steel frame and SiC tile were placed in a temperature chamber and hit up to 430oC,where the SiC tile was pushed into the steel frame and then cooled down to room temperature.When cooling to room temperature,the residual stresses in both the SiC tile and steel frame were developed due to the difference in coefficient of thermal expansion(CTE)of SiC ceramic(CTE=4.0×10-6K-1)and steel(CTE=1.2×10-5K-1).For the steel frames with short width length like 99.50 mm,fracturing of the SiC occurred because of too high localized residual stress generated inside the SiC tiles,after they were cooled down from 430oC to room temperature.As the length of the steel frames' internal width increased from 99.50 to 99.90 mm,fracturing of the SiC tiles occurred lesser,meanwhile the residual stress inside the SiC tiles became lower.Controlling of fracture of SiC tiles during fabrication relied upon some estimation work and trial-and-error,as it was dependent upon many factors(e.g.SiC fracture toughness and frame precision machining)and not just the interference or shrink fit between the SiC tile and frame.Fabrication demonstrated that the SiC tile(Fig.1)with relatively high laterally pre-compression was successfully prepared for the tiles with the length of the internal width was around 99.70mm.

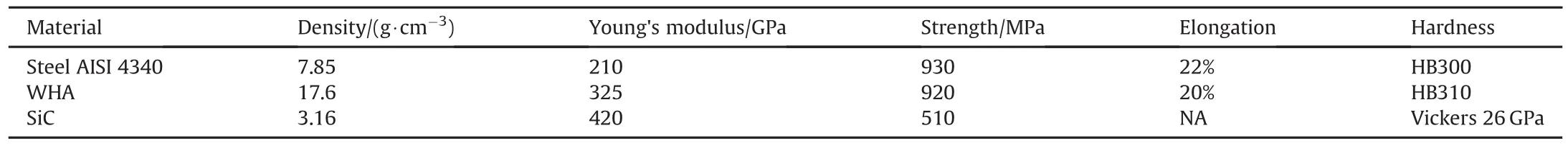

Fig.2 shows the samples used in depth of penetration(DOP)experiments to access ballistic performance of pre-stressed SiC tiles.The laterally pre-compressed SiC tile(Fig.1)was mounted adhesively into the cavity in the backing cylinder made of steel AISI 4340,diameter 180 mm by length 100mm.The layer of adhesive was controlled to be 0.25 mm.The projectiles used in DOP tests were 115mm long conical-nosed rods made of tungsten alloy,8.3 mm in diameter.In DOP tests,the long rodsimpacted the targets with a nominal velocity of 1240m/s.DOP tests of the SiC tile targets with and without pre-stress were conducted for comparison.The mechanical properties of the materials used in tests were listed in Table 1.

Fig.3 shows the tested samples.The long rod penetrated through the SiC tiles and generated a hole with a residual penetration into the backing blocks.The laterally pre-compressed SiC tile showed a little penetration on the surface of the backing block,DOP=3.0 mm(Fig.3(a)),whilst the non-prestressed SiC tile demonstrated a deep penetration hole,which was measured to be DOP=23 mm(Fig.3(b)).

In DOP tests(Fig.2),a ceramic tile of thickness tcand densityρc,is inserted and glued in a cavity within a thick metallic block of densityρ0.The residual penetration of the projectile(DOP),Pr,into the backing block determines the differential efficiency factor(DEF)of the ceramic tile[4],

where P0is the reference penetration depth of the projectile into the backing block without using a ceramic tile.For the long rods used in DOP tests,P0=50 mm at v=1240m/s.Hence,DEFpre-compression=5.75 was obtained for the laterally pre-compressed SiC tile,which displayed an increase of 74%compared to DEFnon-prestress=3.30 for the non-pre-stressed SiC tile.Hence,the laterally pre-compression significantly enhanced ballistic performance of the tested SiC tiles.

3.Hydrocode simulation and results

Simulations of the interaction between the pre-stressed ceramic tiles and long rods were investigated using the LS-DYNA hydrocode[5].The simulations focussed on understanding the effects of laterally pre-compression on ballistic performance of the SiC tiles against impact of the tungsten heavy long rods.Fig.4(a)shows the quarter geometry simulation model of the experimental setup(Figs.1 and 2),as symmetry was used to reduce the computational effort.A gap of 0.25mm between the steel frame and backing block(Fig.4(e))was applied to represent the gap filled up with adhesive in the SiC target(Fig.1).The sizes of the solid elements and SPH particles in the simulation model were 0.5-1.0 mm.

The tungsten alloy rod was modelled using the SPH solver,whilst the steel confinement and backing were modelled using Lagrange solver.For the SiC tile,it was modelled using solid to SPH solvers.A polynomial equation of state,in combination with the JH-1 strength and damage models,was used for the SiC[6].The tungsten alloy and steel were modelled with a polynomial equation of state,JC strength and damage models[7].The material model constants were validated against available test data[8,9].The same nominal impact velocity 1240 m/s was applied in simulation.

In order to account for thermal residual stresses,thermal mechanical simulation was run,which applied a temperature change(ΔT)from an assumed stress-free temperature(430oC)toroom temperature.Time-dependent viscous effects,such as creep,were not considered,because SiC and steel did not creep below this temperature.Thermal-mechanical analysis was imposed by using key words[5],*LOAD_THERMAL_LOAD_CURVE,and the overall thermal strain developed in the component of SiC and steel frame(Fig.4(b)),εthermal=ΔT·(CTEsteel-CTEsic)=0.0032.Dynamic relaxation method[5]was applied to determine the pre-load stresses in the SiC tile and steel frame before long rod impact.

Table 1 Mechanical properties of materials used IN tests.

Tensile stress was developed in the steel frame whilst compressive stress was created in the SiC tile.Fig.5 displays the hydrostatic pressure developed in the SiC tile and the steel frame,obtained from simulation.The average pressure in the centre of the SiC tile was around 65 MPa.As the strength of the SiC tile is dependent upon hydrostatic pressure[3],the pre-stress of pressure 65 MPa will enhance the strength of the intact SiC tile,improving its ballistic performance.

Fig.6 compares the results of simulation of the conducted experiments as shown in Figs.2 and 3,where the SiC tile with and without pre-stress were used in DOP tests.For the laterally precompressed SiC tile,the simulation shows little penetration,DOP=5mm,on the surface of the steel backing block,which is consistent with the test observation(Fig.3(a)).For the SiC without any pre-stress,the simulation resulted in DOP=22 mm,which was consistent with the experiment result(Fig.3(b)).The established simulation model predicted the experimental results with good accuracy.

Fig.7 presents the penetration processes between the SiC tiles with and without pre-stress.Damaged SiC was represented by SPH particles converted from the solid elements in Fig.7.It can be seen that as the penetration of the projectiles into the SiC tiles increases,the damage zone(yellow highlighted points)in front of the projectiles increases.The pre-stress in the SiC tile delays the forming of the(yellow highlighted)damage zone in front of the projectile,which eventually reduces the residual penetration in the backing blocks.In addition,simulation showed that dwell occurred for precompressed SiC tile,shown through little penetration into the SiC tile surface,for initial t=50μs.

4.Discussion and summary

Simplified stress analysis of the ceramic tile and frame sample is schematically shown in Fig.8.The thermal residual stresses in the frame and ceramic tile along the cross-section must be in equilibrium,

Considering hydrostatic pressure,P=- (σ1+ σ2+ σ3)/3,σ2=σ3= σsic, σ3=0,and Eq.(2),the hydrostatic pressure in the laterally pre-compressed SiC tiles can be estimated to be

In this study,Tst=10 mm,Tsic=100mm,and yield stress of steel σst=930 MPa,Psic=62 MPa,which is consistent with the simulation results as shown in Fig.5.The higher the pre-stress of hydrostatic pressure in SiC tiles,the better the ballistic performance.From Eq.(3),the pre-stress of hydrostatic pressure in the SiC tiles can be increased by increasing of Tst(the thickness of the steel frame),σst(the yield stress of the frame steel),or decreasing of Tsic(the width of the SiC tile).

In this paper,DOP experiments and hydrocode simulations were conducted to study the enhancement of the ballistic performance of the SiC tiles against impact of long rod projectiles,through the use of lateral pre-compression.The 100mm by 100mm SiC tile was pushed into the 5 mm thick steel frame at temperature 430oC,which developed pre-load compressive stress in the SiC tile when cool down to room temperature.The study showed that compared to the SiC tile without any pre-stress,the laterally pre-compressed SiC tile significantly improved its ballistic performance with the increase of differential efficiency factor by 74%measured from DOP testing.The simulations showed that the lateral pre-compression improved ballistic performance of the SiC tiles.As a result,dwell occurred in the early stage of penetration,eroding the striking long rod projectile efficiently.It also showed the lateral pre-compression delayed the development of damage in the SiC tiles,allowing the ceramics to maintain its excellent ballistic protection capability for a longer duration.This study demonstrated the feasibility of lightweight design concept of introducing lateral pre-compression by the use of the thin steel frames to improve ballistic performance of the SiC tiles.

This report is only a starting point for some more in-depth investigation and does not claim to be comprehensive because of the limited experiments conducted.One potential research is to apply smaller sized SiC tiles or confinement frames made of higher strength steel,which can develop higher pre-stress in SiC tiles to achieve better ballistic performance.

杂志排行

Defence Technology的其它文章

- GUIDE FOR AUTHORS

- A novel strategy of smart manipulation by micro-scale oscillatory networks of the reactionary zones for enhanced extreme thrust control of the next-generation solid propulsion systems

- Method of ballistic control and projectile rotation in a novel railgun

- Conceptual design of 2 MJ capacitive energy storage

- LTT switch unit for capacitive energy storages

- Safety analysis on truing process of solid propellant