LTT switch unit for capacitive energy storages

2018-10-18NechevFridmnKhpuginMrtynenkoSererov

N.E.Nechev,B.E.Fridmn,*,A.A.Khpugin,V.A.Mrtynenko,R.A.Sererov

aD.V.Efremov Scientific Research Institute of Electrophysical Apparatus,Saint Petersburg,196641,Russia

bElectrovipryamitel,Saransk,430001,Russia

Keywords:Energy storage Power semiconductor switches Photothyristors Pulse power systems

ABSTRACT When the capacitor cell is discharged in the short-circuit mode,the current pulse amplitude and duration are maximal.Therefore,this mode is the most severe for discharge switches of capacitive energy storage.The characteristics of the transient process of the discharge capacitive energy storage and the current loads acting in the facility discharge circuit have been defined for this mode.The test bench for definition of the LTT(Light Triggered Thyristors)loading capacity is described.The limiting characteristics have been experimentally obtained for LTT,at which there emerges the thermo-generation peak.The process of OFF-ON switching of LTTs has been investigated,the necessity is shown to use the speedup R-C circuits to ensure fast and stable transition of LTT into the conducting state.The design of the switch unit for the capacitive energy storage comprising LTTs and crowbar diodes is described,and the transient processes of current switching in crowbar diodes are considered.The tests carried out during switching of pu1se current up to 100kA at a voltage of 6 kV have confirmed the workability of the switch unit.

1.Introduction

For capacitive energy storages with the discharge process lasting fractions of milliseconds or several milliseconds the most suitable are semiconductor switches built on Light Triggered Thyristors(LTT)[1,2].To ensure reliable operation of the switches at heavy currents and high voltages it is necessary to provide the switching processes taking into account the LTTs features.

The purpose of the present study is to analyze the operation features and permissible modes of LTTas a discharge currents witch of the capacitive energy storage,as well as to discuss the design of the semiconductor switch composed of LTTs and crowbar diodes for pulse currents up to 100kA.

2.Transient process of capacitor bank discharge

At a discharge of the capacitive energy storage in the shortcircuit mode the pulse current amplitude and pulse duration are maximal.Therefore,the capacitive energy storages and their discharge current switches are developed taking into account potential short-circuit under load and are tested in this regime.

The capacitive energy storages comprise a set of capacitor banks,which are synchronously or according to the pre-set time program are discharged into load.At a short-circuit under load the discharge processes in capacitor cells do not impact each other.Therefore,the operation conditions of the discharge current switch in this mode severe for the switch can be considered separately for each capacitor bank.In this case,the equivalent discharge circuit of one capacitor cell with a pulse forming network,with the LTT used as a discharge current switch,will correspond to the circuit shown in Fig.1.

The transient process at shorting of the circuits(Fig.1)can be divided into three stages:

I.Discharge of the capacitor C and charge of the inductive storage(inductor)L;

II.Switching of current into the crowbar diode D;

III.Discharge of the inductive storage L.

Present-day capacitor cells should have low energy losses in the discharge circuits making it possible to neglect ohmic losses at the first and second stages of the discharge process for estimates of current and voltage in the circuit(Fig.1).

The transients at the stages can be described as follows:

Stage I at 0≤ t≤ t1≈

Stage II at t1≤ t≤ t2≈t1+

The crowbar diode D starts to conduct the current.The transients in the circuit consisting of the capacitor C and diode D are described by the differential equation

As a rule,the time duration of Stage II is very short,t2-t1≈< <t1.Therefore,the current in the inductor L does not practically change at Stage II I3=Im=I1+I2≈const.The solutions of differential Equation(1):

By the end of Stage II at t2≈t1+the values of current and voltage are as follows:I1(t2)=0,I2(t2)≈Im,

Stage III.The decaying pulse current flows in the circuit D-L.The current decay is determined by energy dissipation in the inductor conductors[3].

Fig.2 shows the current and voltage curves at a shorting discharge of the capacitive energy storage.The Roman numerals indicate the stages of transient processes.

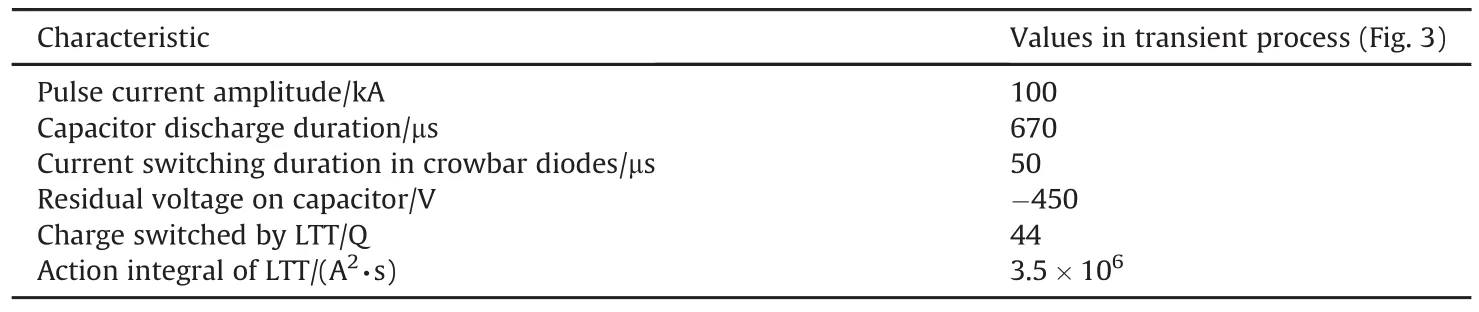

These characteristic features of the transient process of the capacitor cell discharge with the pulse forming network(PFN)are seen on the oscillograms of the discharge process(Fig.3).As seen from these oscillograms,after completion of the first stage of the transient process a negative voltage remains on the capacitor,the value of which can be pre-calculated by formula(2).Table 1 presents the characteristics of the discharge process calculated by the oscillograms given in Fig.3.

3.Load capacity of LTTs

At heavy pulse currents the volt-ampere characteristics(VAC)of the semiconductor structure are as follows:

where VT(TO)-the threshold voltage and rT-the on-state slope resistance of a semiconducting device.The parameters VT(TO)and rTcan be found in Manufacturer's catalogs or defined by the direct VAC of LTT in the on-state.

As a first approximation,the energy W released in LTT depends on the chargeidt and the action integral of current pulse

where tp-the current pulse duration.

The load capacity of LTT was experimentally defined on the testcurrent was switched by the Triggered Vacuum Switches(VS1,VS2),а triggering pulse for LTT was applied 10 μs earlier than the triggering moment of VS1and VS2,thus providing no high-voltage on the LTT electrodes(VS3)and making it possible to use low-voltage instruments to measure the voltage drop on an open LTT.

Table 1Characteristics of the discharge process.

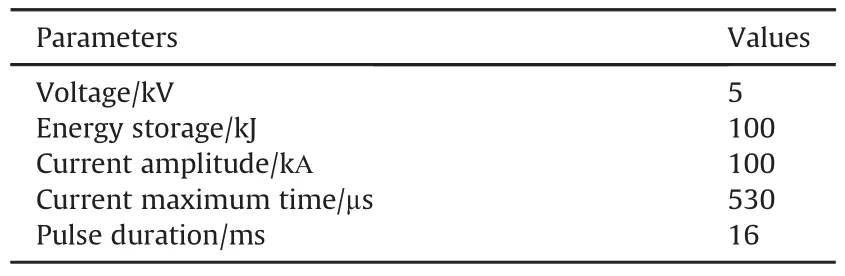

Table 2 Parameters of test bench(Fig.4).The LTT was triggered by a light pulse with a power of about 250 mW.This light pulse is generated by the driver in the circuit in Fig.4.

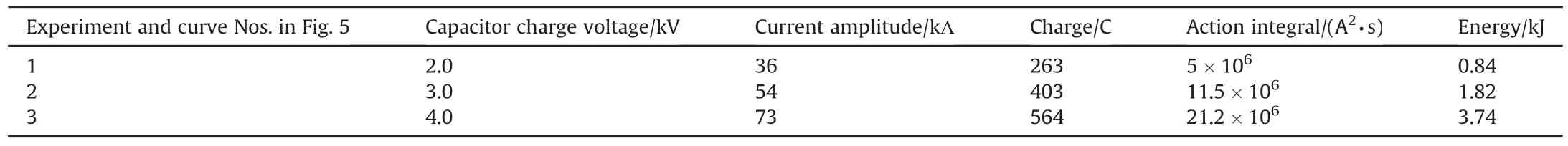

The limiting current loads of LTT were defined during the experiments.At a high anode current the maximum appears on the voltage drop curve(Fig.5(b),curve 3)as a result of thermogeneration processes in the semiconductor.Table 3 presents the bench(Fig.4,Table 2).The LTT(VS3)under test was connected to the output terminals of two cells with the pulse forming network(PFN)consisting of the crowbar diodes D and inductor L.Triggered Vacuum Switches(VS1,VS2)were used as discharge switches in the cells.

The tested LTT(VS3)cannot switch the discharge of the capacitors in the circuit(Fig.4),as the capacitor charge voltage exceeds the permissible anode voltage of LTT.Therefore,the discharge time moment,when the thermo-generation peak ttp=2.14ms emerges,and the integral characteristics for this moment.

At a relatively high value of the anode current the semiconducting structure is overheated and LTT is damaged.It is illustrated by the oscillogram of current I and direct voltage U on LTT during the experiment,when the thermo-generation peak was attained resulting in damage of the tested LTT.

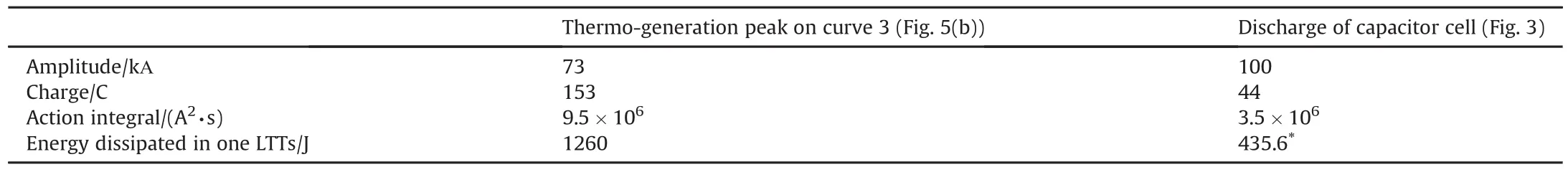

Table 3 LTT testing results.

Table 4 Comparative characteristics of current pulses.

Comparison between the LTT modes in the capacitor cell,and the mode,when the thermo-generation peak emerges(curve 3 in Fig.6(a)and(b))shows that LTT is not overheated during operation in the capacitor cell(Table 4).

4.LTT switch-on

When LTT is switched on,the current rise rate is limited by the circuit inductance(L1+L2in Fig.1).In the capacitor cell at a low current rise the transition of LTT to the open state becomes unstable;voltage division between connected-in-series LTTs is non-uniform,and they can be damaged(Fig.8(а)).The reason is that at a high outer inductance the anode current is not sufficient for fast and effective switch-on of the amplifiers of the triggering signal inside LTT.To ensure stable and fast switch-on of LTT the speed-up R-C circuits connected in parallel to each LTT were used(R1and С1in Fig.7),which provided with current the drivers for triggering of current inside LTT.R1=12Ω,C1=0.36μF.

5.LTT switch-off

At switch-off the overvoltage pulse caused by the LTT reverse recovery appears on the LTT.In this case,the negative anode voltage might exceed the allowable limits,and the semiconductor structure might be damaged.In the capacitor cell with the PFN(Fig.1)the overvoltage pulse acts also on the crowbar diodes,and overvoltage might appear acting on LTTs and crowbar diodes at current break in load.Therefore,the semiconductor switch is provided with snubber circuits connected in parallel to each diode.These snubber circuits,in addition to suppressing the overvoltages,equalize voltages between the connected-in-series diodes.Figs.9 and 10 show the typical oscillograms for current switch-off in LTTs and current transition in the crowbar diodes.

6.Switch unit

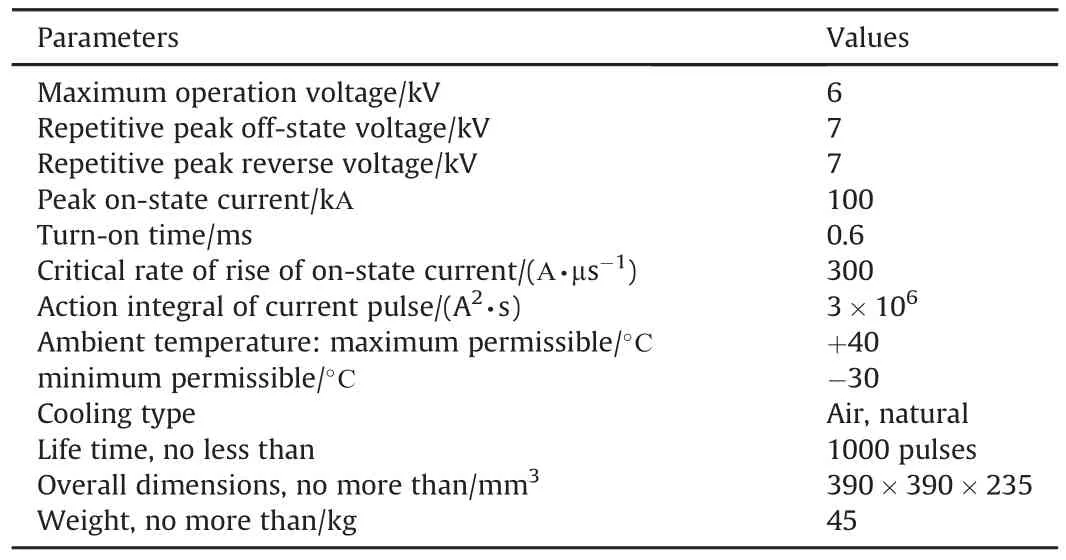

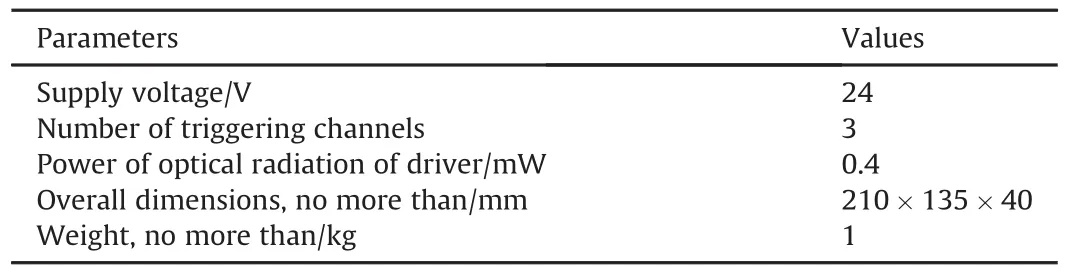

The semiconductor switch БК3ТФИ2Д-100000-7,0-Е has been developed for the capacitor bank.This switch is manufactured by JSC “Electrovipryamitel”(Saransk,Russia).The electrical circuit of this switch is shown in Fig.11.The main parameters of this switch unit are presented in Table 5.

The switch unit consists of three connected-in-series LTTs ТФИ193-2500-42 and two crowbar diodes Д193-2500-50S.All semiconductor elements are made as one assembly,which makes the БК3ТФИ2Д-100000-7,0-Е switch rather compact.The diodes and LTTs are connected to the inductor and capacitor through three buses in the circuit points X1,X2,X3(Fig.11).The boards(А1,А2,А3)are connected in parallel to each LTT.These boards have speed-up RC circuits and circuits for monitoring of the anode voltage on LTTs.The LTTs are triggered by light pulses,which are transmitted through fiber-optic cables from three drivers located in the control panel of the facility.

Table 5 Parameters of БК3ТФИ2Д-100000-7,0-Е

The switch unit comprises diagnostics means including LEDs U1,U2,U3located on the boards A1,A2,A3.These LEDs are connected in series with the resistors R2ensuring equalization of voltage between LTTs.Light signals are transmitted throughthe fiber-optic cables to the control panel,where they are converted to an electric signal arriving at the PLC inlet,which performs the functions of diagnostics and control of the facility.At the stage,when the capacitors of the energy capacitive storage are charged,LEDs should light up on the capacitors at a specified voltage.In this case,PLC receives information on that the LTT is not shorted and withstands the applied anode voltage.Absence of one of the light signals generated by LEDs is a symptom of LTT malfunction.In this case,PLC triggers the discharge of the capacitor into a ballast resistor,and a fault message is sent to the operator.

Table 6 Parameters of the driver panel.

The photograph of the unit with the panel,where three drivers of LTT are arranged,is shown in Fig.12.Table 6 presents the main parameters of the control driver.

7.Testing of switch unit

The developed semiconductor switch БК3ТФИ2Д-100000-17,0-Е based on LTTs and crowbar diodes has withstood the following tests:

· tests by a direct high voltage of 6kV,with the off-state leakage current not exceeding 50μA.

·life time tests in the shorting mode(about 1000 switches-on)at a direct current amplitude of about 100 kA and a charge voltage of the capacitor cell of 6 kV(Fig.13(а));

·tests in no-load condition at a charge voltage of the capacitor cell of 6 kV(Fig.14);

·tests at capacitor cell discharge into an active load of 12 mOhm(Fig.13(b));

·tests in the frequency operation mode for an active load of 12 mOhm(Fig.13(b)).

8.Conclusions

Eight different design versions of the semiconductor switch unit have been studied during its development.The experimental investigations of these versions and the analysis of their operation conditions have made it possible to design the semiconductor switch on the basis of LTTand pulse diodes ensuring the stable and reliable operation of the capacitive energy storage.

The capacitor cell with the switch unit БК3ТФИ2Д-100000-7,0-Е has withstood multiple tests under laboratory and rigorous operation conditions.

杂志排行

Defence Technology的其它文章

- Overview of Al-based nanoenergetic ingredients for solid rocket propulsion

- Implications of fine water mist environment on the post-detonation processes of a PE4 explosive charge in a semi-confined blast chamber

- Systematic research on the performance of self-designed microwave plasma reactor for CVD high quality diamond

- cis-1,3,4,6-Tetranitrooctahydroimidazo-[4,5-d]imidazole(BCHMX)as a part of explosive mixtures

- Joining and machining of(ZrB2-SiC)and(Cf-SiC)based composites

- Structural evolution,optoelectrical and corrosion properties of electrodeposited WO3integration on Zn-TiO2electrolyte for defence super application