Study on the analysis method on ballistic performance of deterred propellant with large web size in large caliber artillery

2018-10-18YuweiWangWenfangZhuJiaweiDiXiaohongHu

Yu-wei Wang,Wen-fang Zhu,Jia-wei Di,Xiao-hong Hu

Northwest Institute of Mechanical and Electrical Engineering,Xianyang,Shaanxi,China

Keywords:Deterrent propellant Interior ballistic Closed-bomb Burning rate law

ABSTRACT As for the characteristics of combustibility of deterrent propellant with large web size which is used in large-caliber gun and interior ballistic performance,the combustion characteristics of deterrent propellant are obtained by using closed-bomb experiments.The combustion law of deterrent propellant and the classic interior ballistic model of composite charge are given.By simulation and analysis the results of the artillery firing test,the burning rate variation law and the interior ballistics simulation parameters of propellant A are determined,and the burning rate relationship between propellant A and propellant B obtained from closed-bomb,then the ballistic performance of propellant B is predicted.The results show that the predicted results are in good agreement with the experimental results.The study shows that the burning rate law of deterrent propellant with large web size can be obtained by closed-bomb experiment.Using the method provided in this paper can accurately predict the interior ballistic performance and provide an important basis for improving the accuracy of interior ballistic calculation.

1.Introduction

The change of pressure in bore is affected by two factors,one is the combustion gas from propellant which,whilst burning,makes the pressure continuously increasing,and the second is the motion of the projectile which increases the space behind the projectile and makes the pressure continuously decreasing.Under the combined effect of these two factors,the pressure-time curve in the chamber rises firstly and then decreases.The maximum pressure and the muzzle velocity of the projectile are important parameters of the interior ballistic process.The target of the interior ballistic design of gun is to achieve higher muzzle velocity under the smaller maximum chamber pressure.The burning law of the propellant directly affects the formation rate of burning gases,which affects the change of the chamber pressure and finally realize different muzzle velocity.Therefore,the technology of controlling the burning law of propellant has been an important part of interior ballistics design.In order to improve the performance of gun continuously,it cannot meet the requirements only by controlling the geometry shape of propellant in the maximum pressure limit,so more investigators use the technology of deterrent propellant which has a better progressive combustibility to achieve higher muzzle velocity in the maximum pressure limit.

The technology of deterred propellant is by in filtrating the slow burning material into a certain thickness on the surface of propellant,which can reduce the formation rate of burning gases during initial combustion of propellant.When the deterrent layers gradually finish the combustion to finish,the generation rate of burning gases is gradually increased by progressive burning,which can increase the chamber pressure to offset the decrease of chamber pressure because of the projectile motion.By using this principle,the chamber pressure drop down not too fast after the maximum chamber pressure and we can get the higher muzzle velocity of projectile.Therefore,it is generally believed that the muzzle velocity of projectile can be improved by using the technology of deterred propellant.The analysis of Li Jie[1]shows that the use of technology of deterred propellant in 35mm antiaircraft gun is better than increasing the number of perforated propellant holes.Under the same maximum chamber pressure,the muzzle velocity can be increased 2%by using technology of deterred propellant with the same charge structure.At present,the technology of deterred propellant has been widely applied to small caliber gun,and applied to large caliber gun charge in some countries with advanced technology[2].The prominent feature of technology of deterred propellant is the control of combustion law,which has a better progressive combustibility.

The application of deterred propellant for large caliber gun is studied in this paper,especially for the combustion law,combustion model and interior ballistic performance of deterred propellant.An interior ballistic simulation software has programed for deterred propellant in large caliber gun by establishing combustion model of deterred propellant,classic interior ballistic model of hybrid propellants and the method of combustion rate processing for different propellants.Through the comparative analysis of the test results,the software and the model can accurately simulate the ballistic performance of large caliber gun by using deterred propellant.

2.Experimental data processing of closed-bomb for propellant

In order to improve the muzzle velocity of the projectile at the limited maximum chamber pressure,the propellant with largeweb size is usually used in large caliber artillery.In this paper,the study of the combustion law and the interior ballistic performance analysis has been done for the charge with 19 perforated plum blossom deterred propellant,and the web size of this propellant is changing from 1.8 mm to 2.0 mm.The deterrent material was applied within the perforations and also on the surface of the propellant.The depth of deterrent layer was 20%of the web size.First of all,a closed-bomb experiment was carried out for two kinds of propellants to obtain the combustion law of the propellant under static combustion conditions.The parameters of propellant for the two kinds of propellants are shown in Table 1.

The process of the experiment is to ignite the propellants which are put into a closed bomb at a loading density of 0.35kg/m3,and record the change process of pressure and time(P-T)curve during burning.The relative combustion amount of propellant can be obtained at different times from the P-Tcurve,and then the change rate of burning distance can be obtained from the relative combustion amount and the geometric parameters of propellant.The burning rate of propellant u can be got by using the change rate of burning distance.

The relationship between burning rate and pressure is obtained by using the method of numerical fitting.At present,the exponential burning rate law is usually used to characterize the burning rate of propellant,the expression is as follows

In the formula,u1is the coefficient of burning rate,n is the exponent of burning rate,p is chamber pressure(Pa).Table 2 is the experiment results of the burning rate which was been fitted in 10%-70%of maximum pressure.

According to the burning rate of two kinds of propellants in Table 2,the contrast curve of burning rate for two kinds of propellants under the same chamber pressure is calculated and shownin Fig.1,and the relative coefficient of burning rate for two kinds of propellants k1is given.

Table 2 Experiment results of burning rate for two kinds of propellant.

uA,uBare the burning rate of the propellant A and B at different pressures as formula(3),and show in Fig.1.Fig.2 shows the curve of k1which obtains form curve A dividing by curve B in Fig.1.

Table 1 Geometric parameters of two kinds of propellants.

It can be seen by contrasting Figs.1 and 2 that the exponent of propellant A is larger than propellant B.So the burning rate of propellant A is slower than propellant B when the pressure is less than 350MPa.But when the pressure is greater than 350MPa,the burning rate of propellant A is greater than propellant B,and the relative coefficient changes only slightly.Over the pressure range 0-600 MPa,the burn rate of propellant A is generally lower than that of propellant B.The average relative change of the burning rate for two kinds of propellants is obtained by means of the value of the relative coefficient of the burning rate at different pressures(the calculation method is shown in formula 4).So the average relative change of the burning rate for two kinds of propellant can be calculated,which is=1.285.

By comparing with the formation rate of burning gases for the two kinds of propellants,the dynamic vivacity curve of two kinds of propellantΓ-Ψ are obtained

Ψis the mass of proellant divided bythe mass of burned propellant.Figs.3 and 4 show the Γ-Ψ curve of propellant A and B in closed bomb respectively.Each Fig.gives the curves of two tests for same propellat(No 1 and No 2).From the contrast of Figs.3 and 4,the dynamic vivacity of propellant A is obviously less than B in the early stage of combustion(Ψ<0.2),and the dynamic vivacity of propellant A is also less than B in the later stage of combustion.

By analysis from above,we can see that the burning rate of propellant A is obviously smaller than that of propellant B.The main reasons are:(1)the density of propellant A is larger;(2)the effect of deterrent on propellant A is more obviously because of having different their production process for propellant A and B.

3.Burning rate process method of deterred propellant

The combustion model of deterred propellant should be established in order to describe the combustion characteristics of deterred propellant when calculating the process of interior ballistic.It is generally believed that the layer thickness of the deterred propellant is between 0.1 mm and 0.3 mm[3].The Zsis used to represent the relative thickness of the layer which be deterred.The deterred propellant combustion model is as follows

u1(Z)is the burning rate coefficient of the deterred propellant,Z is the relative burned thickness of the propellant.On the assumption that the change of u1(Z)is linear in the whole deterred area.The expression is as follows

ζis the ratio of the burning rate of the deterred layer to the undeterred partial.

4.The calculation model of interior ballistic

In order to study the performance characteristics of interior ballistic in large caliber gun with deterred propellant,the classic model of interior ballistic was established for the mixed charge with a deterred propellant[4].The model considers the mixed charge structure which has different propellants in the charge.That is to say that the propellant charge is composed of a deterred propellant and undeterred propellants.Meanwhile,the interior ballistic performances are compared with different kinds of deterred propellants.The deterred propellant combustion model established in this paper also includes the parameters of the thickness of the deterred layer and the ratio of the burningspeed of the deterred layer.The classical interior ballistic equations are as follows

Table 3 Comparision of test results with calculation results for the maximum chamber pressure and the muzzle velocity when using the deterred propellant A.

φ is secondary work coefficient,

In the formula,the subscript 1 represents deterred propellant,the subscript 2 represents the undeterred propellant,ψiis the relative quality of the propellant i;Ziis the relative burned thickness of the propellant i;Zkiis the relative burned thickness when all fractured propellant burning out; χi′λi′μi′χsi′λsiareshape coefficient of propellant i;u1i、niare the burning rate coefficient and burning rate exponent of propellant i.

The interior ballistic equations include the ordinary differential equations and algebraic equations.We solve differential equations numerically by using the Runge-Kutta method,and obtain parameters such as chamber pressure and muzzle velocity of the projectile during the process of internal ballistics.

5.Comparison with calculation and test results for interior ballistic

The comparative study for interior ballistic performance has been done with experiment and calculation for deterred propellant in a large caliber gun.We can get the effect of different kinds of deterred propellants on the interior ballistic performance.

In this paper,the burning rate expression obtained from the closed bomb is directly applied to the solution of the gun's interior ballistic equations,and the maximum chamber pressure and muzzle velocity of projectile are compared with the firing test.By adjusting the burning rate coefficient of propellant and secondary work coefficient,the maximum chamber pressure and muzzle velocity of projectile are achieved from interior ballistics calculation,which is in good agreement with the result of firing test.

Table 3 gives the maximum chamber pressure and muzzle velocity of projectile obtained from the firing test in a large caliber artillery using propellant A,and the results calculated by this method.

Fig.5 shows the contrast between the P-Tcurve of the firing test of the propellant A and the calculated curve.It can be seen that the calculated results agree well with the experimental results from the graph.It shows that the interior ballistics calculation method can be used to analyze the variation laws of various parameters in the process of interior ballistics,and provide an important method for analyzing the burning rate variation of deterred propellants.

Using the interior ballistic simulation parameters for propellant A,together with its relative burn rate relationship with propellant B,then the interior ballistic performance for propellant B can be predicted.The relative relationship of the burning rate between the propellant A and the propellant B was used to carry out the interior ballistic calculation.The results of the prediction and the test are shown in Table 4.

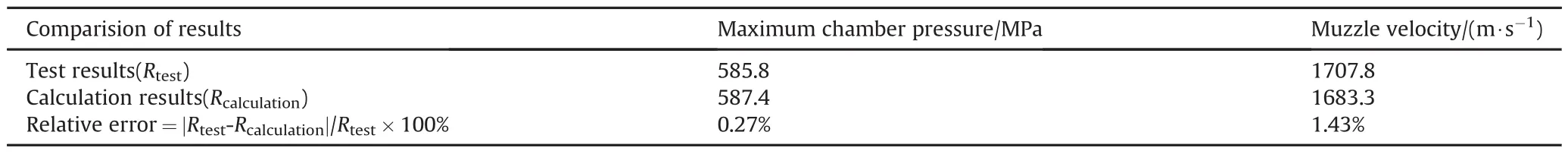

Fig.6 shows the contrast of the P-Tcurve between firing test and the calculation for the propellant B.It can be seen that the calculated results are in good agreement with the experimental results.Without changing the simulation parameters of interior ballistics,it can be seen that the relative error between predicted value and experimental value of chamber pressure is 0.27%and the relative error of muzzle velocity is 1.43%by using the parameters of propellant B and the burning rate processing method provided in this paper.It is enough for using in engineering analysis.The above results show that the interior ballistic performance of the gun can be predicted by using the burning rate processing method and the interior ballistic model of the deterred propellant.

Fig.7 compares the P-T curves for propellant A and propellant B for the experimental results.From the figure,we can see that the chamber pressure curve is quite different because of thedifference of burning rate for the two kinds of propellants.The low burning rate for propellant A is not beneficial to increasing the muzzle velocity,and the higher initial burning rate for the propellant B can make the projectile accelerate faster at the initial process of interior ballistics,which is useful to improve muzzle velocity.If we can effectively control the thickness of the deterred layer and burning rate of the deterred layer of the propellant B,and adjust the burning rate of the undeterred layer of the propellant,we can further reduce the chamber pressure and increase the muzzle velocity.

Table 4 Comparision of test results with calculation results for the maximum chamber pressure and the muzzle velocity for propellant B.

6.Conclusions

In order to get the combustion characteristics and interior ballistic characteristics of deterred propellant with large web size used in large caliber gun,serial analysis methods have been done.Firstly,we can get the combustion characteristics of deterred propellant by closed bomb experiment,and then two models have been built,one is combustion model of the deterred propellant and another is the classical interior ballistic model of mixed charge with two kinds of propellant.By using this method,we can get the variation rule of burning rate and simulation parameters of interior ballistic for propellant A by experiments results of closed bomb and test results of gun firing.At the same time,the burning rate relationship between propellants A and B is obtained by closed bomb experiments.On the basis of this,it can be predicted out the interior ballistic performance of propellant B by the classical interior ballistic model.The predicted results are in good agreement with the gun firing tests.The prediction accuracy of the chamber pressure and muzzle velocity of projectile is greater than 98%.So we can reach the following conclusions from the study:

(1)The burning rate of propellant measured from closed bomb can directly apply to gun interior ballistic calculation and ballistic performance prediction by using the burning rate processing method of propellant in this paper;

(2)The combustion model of deterred propellant and the classical interior ballistic model provided in this paper can be used to analyze the ballistic characteristics and design of interior ballistic;

(3)In order to achieve the target of decreasing chamber pressure and increasing the muzzle velocity,it is necessary to optimize the burning rate of deterred layer and the total burning rate of propellant for large caliber gun with deterred propellant in the future.

The research results can be used to analyze the interior ballistic performance and design the charge for large caliber artillery with deterred propellant.The results are also an important method for studying the performance of deterred propellant in this paper.

杂志排行

Defence Technology的其它文章

- Overview of Al-based nanoenergetic ingredients for solid rocket propulsion

- Implications of fine water mist environment on the post-detonation processes of a PE4 explosive charge in a semi-confined blast chamber

- Systematic research on the performance of self-designed microwave plasma reactor for CVD high quality diamond

- cis-1,3,4,6-Tetranitrooctahydroimidazo-[4,5-d]imidazole(BCHMX)as a part of explosive mixtures

- Joining and machining of(ZrB2-SiC)and(Cf-SiC)based composites

- Structural evolution,optoelectrical and corrosion properties of electrodeposited WO3integration on Zn-TiO2electrolyte for defence super application