Studies of a combined way of flame stability in ramjet combustor

2018-10-18JiaxinTao

Jia-xin Tao

Pump Equipment Research Center of Xi'an Aeronautical University,Xi'an,710077,China

Keywords:Cavity Strut Bleeding Ramjet combustor Numerical simulation

ABSTRACT numerical simulation was conducted to study the influence of bleeding.The Euler-Lagrange method was used to investigate the two-phase turbulent combustion flow.Standard k-ε turbulent model was adopted in the continuous phase simulation and particle-trajectory model was adopted in the dispersed phase simulation.The results demonstrates:air bleeding can improve the flow field after the strut and the stability of trapped vortex in the cavity;change of bleeding temperature has little effect on the total pressure recovery coefficient and significant effect on combustion efficiency;When fuel-air ratio changes,the combustor performs better in a lean oil state.

1.Introduction

Flame stabilization is achieved by creating a continuous ignition source by mixing high temperature products and the combustion gas with fresh gas-oil mixture in the recirculation zone[1].Flame stabilization technology is generally divided into three categories:Swirl type,blunt body type and cavity type[2].At present,the flame stabilization technology of cavity used in supersonic flow has been success-fully applied in laboratory and real flight test[3],[4].Bruno[5]of Lund university has proposed an improved cavity structure and applied in a subsonic combustor to achieve higher combustion efficiency and lower pressure drop. The ignition performance of a ramjet engine based on cavity flame holder was experimentally investigated by Li[6]of National University of Defense Technology.The strut flame holder belongs to a blunt body type,and it is an effective hybrid enhancement method.Hsu and his colleges[7]applied cavity-strut flame holder in supersonic combustion.The experimental results show that cavity-strut structure can effectively improve the ignition ability and pro-mote the stability of the flame.Chen[8][9],of the Chinese Academy of sciences studied the coupling of fuel injection with the geometry of cavity-strut flame holder.Wang[10]discovered it is good for improving the combustor performance when hot air is imported to heat oil in ramjet combustor through numerical method.

This paper combines the fuel injection strut flame holder and cavity flame holder in ramjet combustor in order to improve combustion efficiency using high temperature air bleeding technology using numerical simulation.

2.Combination flame stabilization method

In general,there are three requirements for flame holder:wide range of work,low fluid resistance,and high efficiency combustion.In the ramjet combustor,the inlet velocity is high and the total temperature and the total pressure are low,which brings great difficulties to flame stability.

In this paper,the flame stability range is widened by the combination of the strut flame holder and the cavity flame holder with the help of the high temperature air bleeding.From the Longwell flame stabilization model,it can be known that the flame stabilization technique is usually realized by a certain way to form a recirculation zone.The local flow velocity in recirculation zone is below the turbulent flame propagation velocity,so that the necessary conditions for flame stabilization is satisfied;Once there is an ignition source with enough power,the combustible mixture can be ignited.As shown in Fig.1,high temperature recirculation zone formed in the flow through the strut after the main-stream,premixed entraining air and main-stream flow into the recirculation zone and trigger piloted flame after mixing.Then combustion products with high temperature flow through the recirculation zone and return up-stream,creating a stable and continuous ignition source.The recirculation zone plays a role in heat storage in this process.It contributes to transporting the active matter and necessary energy to mixed gas which is combustible in the form of mass transfer and heat transfer so that the flame spread rapidly in the combustor.However,it is difficult to achieve a wide range of flame stability by relying only on one flame stabilization method when the total temperature and total pressure of mainstream are low and the flow velocity is large.In the combined flame stabilization mode,the streamwise trapped vortex can be produced behind the longitudinal strut and the longitudinal trapped vortex can be produced in the inner region of cavity flame holder,which makes the energy in the recirculation zone propagate to the whole combustor.At the same time,the premixed air with high temperature can make the fuel atomization effect better,and the fresh mixed gas near the strut has an appropriate equivalence ratio,so that even if the flow condition is poor,the stable piloted flame can also be produced.

3.Numerical calculation method

3.1.Computational model

The combustor model used in this paper is shown in Fig.2(a).The combustor is rectangular cross section,and the left and right sides are symmetrical.After the air enters in the isolator of the combustor,the pressure is firstly increased through the expansion segment by a step.The width of the combustor is 100 mm.

High temperature air enters from the bottom of the strut and then mixes with oil which is ejected from the centrifugal nozzle in order to promote its evaporation from the side of the strut,which is shown in Fig.2(b).The ba-ckswept design of the strut can improve the flow,reduce the axial resistance[11][12],and the enhance the longitud-inal flame effect.The cavity is located downstream of the strut,and the back wall of the open cavity is titled.

3.2.Mesh information

In this paper,ICEM is used to mesh the combustion chamber geometry.Hexahedral grid(Hexa)is a better structured grid.Using hexahedral mesh can greatly reduce the number of grid and save the cost of calculation when the shape of the calculation area is more regular.In ICEM,hexahedral grids are generated based on model partition topology block.In this paper,the whole computing area is divided into 32 blocks,and about 6 million hexahedral grids and 320 thousand quadrilateral grids are generated,as shown in Fig.3.

3.3.Physical parameters and boundary conditions

Using the commercial software CFX,the Euler-Lagrange method is applied to the numerical simulation of turbulent two-phase flow combustion.The continuous phase is simulated by the standard kepsilon turbulence model.The original CO2and H2O in the air is not considered in this caculation.The dispersed phase is simulated by the particle trajectory model.The chemical formula of fuel is C12H23,and the initial temperature is 300K.The reaction takes a single step overall reaction and the combustion uses the eddydissipation model(EDM).The reaction equation is as follows:

Gases used in the calculation are considered as calorically perfect gas.The dynamic viscosity is defined by Sutherland formula,and the thermal conductivity is given a fixed value of 0.01W·(m·K)-1.The relationship between specific heat,enthalpy,entropy and temperature is defined by NASA format.The inlet of the combustoruses the mass flow and the total temperature boundary condition,the outlet uses the static pressure boundary condition,and the wall uses the adiabatic non-slip condition.The inlet velocity and the static temperature of the air bleeding are fixed,the flow rate and the particle diameter of the fuel are specified.

4.Calculation results and analysis

4.1.Effects of air bleeding

For studying the effects of premixed air bleeding in a cavity strut structure,this paper firstly compares the combustion gas flow field using air bleeding or not under the condition of a total flow temperature of 700 K,the flow Mach number of 0.4 the flow rate of oil of 0.06kg/s and the gross ratio of oil and gas of 0.04.The central section and the near wall section are named as Y1 and Y2 sections respectively.11 sections named as X0-X10 are selected by equidistant along the flow direction.

Fig.4 is the distribution of carbon dioxide mass fraction at X4-X10 sections for the absence of air bleeding(Fig.4(a))and the presence of air bleeding(Fig.4(b)).It can be seen that in the absence of air bleeding,the combustion occurs in the region directly behind the bluff body,and the combustion of the cross flow direction is not ideal.Until the exit of the nozzle,there is still a large area with almost no CO2distribution.After air bleeding,combustion in a short distance to realize the diffusion of cross flow,inlet CO2distribution is uniform,the air bleeding plays a certain role in transverse cross flame.

Fig.5 is a comparison of streamlines at the cavity.The obvious trapped vortex in the cavity of the Y1 section is produced after air bleeding.According to the trapped vortex combustion theory,the trapped vortex combustion can be regarded as a combination of radial propagation process and axial propagation process.In the beginning,the flame appears in the rich mixture region of the cavity.Then a radial mixing with the main stream takes place through the trapped vortex.Ultimately the flame spreads along the axial direction with the mainstream.In the absence of air bleeding,because of the larger Ma,the recirculation zone after the strut is not large enough to form trapped vortex in the cavity.The unburnt gas and the burned gas have not fully mixed which leads to a low combustion efficiency.In the Y2 section,there is a small trapped vortex when the air bleeding is absent,and the trapped vortex disappears when the air bleeding is present.

4.2.Selection of air bleeding conditions

Because the influence of air bleeding condition on combustion performance is not clear,it is necessary to determine a better air bleeding parameter.In order to make the air entraining and kerosene premixed more fully,the fixed gas velocity and oil injection speed are the same,and the air bleeding temperature is changed,and compared with the state of no air bleeding.In Fig.6 and Fig.7 there is total pressure recovery coefficient and combustion efficiency comparison on the X0~X10 section under different air bleeding conditions.Total pressure recovery coefficient is calculated by:

Because the reaction used here is a single step overall reaction,the calculation formula of combustion efficiency can be simplified as follows:

In this formula:mCO2,actualis the mass flow rate of the actual outlet,mCO2,theoryis the mass flow corresponding to the mass flow rate of the outlet in complete combustion.

It can be seen from Fig.6 that the air bleeding has almost no influence on the total pressure before the strut.When the air bleeding is applied,due to the shear effects on the mainstream,the total pressure recovery coefficient along the axial direction is slightly lower than the no air bleeding state.In the nozzle exit total pressure recovery coefficient is reduced by about 0.02.Change of bleeding temperature has little effect on the total pressure recovery coefficient.Total pressure recovery coefficient is a bit higher when the static temperature of air bleeding is 750 K,but the flow resistance loss is negligible compared to the total.Therefore,it can be concluded that the air bleeding temperature has little effect on the total pressure recovery coefficient.

It can be seen from Fig.7 that the combustion efficiency is lower when the air bleeding is absent.In the exit the combustion efficiency is only 60%.When the air bleeding is applied,the combustion efficiency is in-creased obviously,in the sections after x/L=0.4,due to the high temperature gas accelerates the fuel evaporation,strengthen the mainstream and the fuel mixture,the gas combusts more completely.When the temperature of bleed air is 350K,the combustion efficiency is about 84%at the outlet,but the combustion efficiency begins to decrease when the air temperature continues to increase.This is be-cause fuel evaporation has been more fully when the temperature is 350K while maintaining air bleeding velocity under the condition of constant.If the temperature continues to in-crease,the resistance caused by the bleed air to the mainstream is reduced.Under this condition,the choke ratio of the bluff body flame holder is not big enough to create a large recirculation zone and in the end the combustion efficiency reduces.

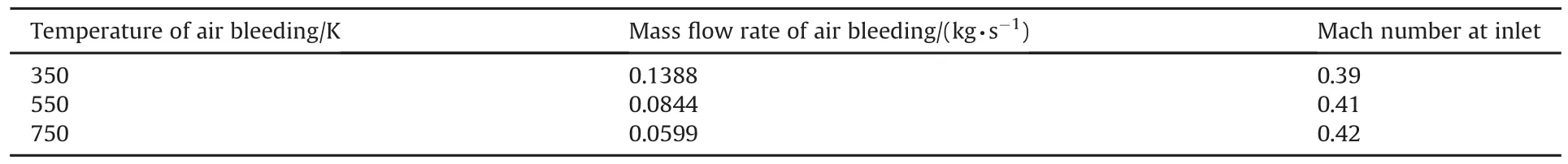

Table 1 shows the influence of air bleeding temperature on the mass flow rate of bleed air and Mach number at the combustor inlet In the case of a constant bleed air velocity and a constant mass flow rate at the combustor inlet.As mentioned above,increase of bleeding temperature makes the hindering effect of bleeding on the mainstream decreased and the velocity in the mainstream under the same mass flow rate conditions increased,the flame stability is more difficult,this is the main reason leading to the combustion efficiency decrease.

Table 1 Air bleeding parameter.

4.3.Influence of gross fuel-air ratio

Fig.8 and Fig.9 are the curves of total pressure recovery coefficient and combustion efficiency along the axial direction under different fuel-air ratio.Total pressure recovery coefficient near the flame holder is lower and the total pressure recovery coefficient is higher than anywhere else,which indicates that through air bleeding the flame holder can make greater resistance and lower mixing loss in a lean oil state.The combustor combustion efficiency at the outlet reaches 0.98 when the gross fuel-air ratio is 0.03,which is much higher than when the gross fuel-air ratio is 0.04(a more rich oil state).It verifies that air bleeding in a lean oil state can make oil and oxygen distribution more uniform,leading to a more complete combustion.

5.Conclusions

Through the analysis of this paper,the conclusions can be summarized as follows:

(1)Cavity-strut flame holder for ramjet combustor with air bleeding technology can achieve better combustion performance.

(2)The air bleeding methods used in this paper,change of air bleeding temperature has little effect on total pressure recovery coefficient,but has significant effect on combustion efficiency;

(3)Between rich oil and lean oil states(the fuel-air ratio is 0.03 and 0.04),the results of air bleeding with appropriate parameters have large differences.In the lean state the combustor has a higher total pressure recovery coefficient and combustion efficiency.

杂志排行

Defence Technology的其它文章

- Overview of Al-based nanoenergetic ingredients for solid rocket propulsion

- Implications of fine water mist environment on the post-detonation processes of a PE4 explosive charge in a semi-confined blast chamber

- Systematic research on the performance of self-designed microwave plasma reactor for CVD high quality diamond

- cis-1,3,4,6-Tetranitrooctahydroimidazo-[4,5-d]imidazole(BCHMX)as a part of explosive mixtures

- Joining and machining of(ZrB2-SiC)and(Cf-SiC)based composites

- Structural evolution,optoelectrical and corrosion properties of electrodeposited WO3integration on Zn-TiO2electrolyte for defence super application