Limestone mechanical deformation behavior and failure mechanisms:a review

2018-06-27WeiLiXianjinAnHepingLi

Wei Li•Xianjin An•Heping Li

1 Introduction

Limestone is a common carbonate sedimentary rock,widely distributed at Earth’s surface and in the upper crust.Carbonate strata are rich in oil and natural gas resources,and one of the riskiest bedrocks for construction of highways,railways,tunnels,and other infrastructure.Carbonate melts are considered important active metasomatic agents and efficient transport agents;their thermodynamic properties at high temperature and pressure have been the focus of various geochemical analyses(Zhang and Liu 2015).With the national energy development strategy gradually shifting to deep oil and gas exploration and development(You 1998),and the pace of western development quickening,carbonate strata are garnering more interest as geological prospects,and limestone mechanical properties research has become especially important(Chen et al.2009a).Understanding the evolution of the strength of porous carbonate rocks under mechanical,thermal,and chemical loads has broad implications for reservoir and earthquake engineering(Lisabeth and Zhu 2015).Historically,limestone was broadly considered prime bedrock for roadbeds,bridge and tunnel construction,slope protection engineering,water conservancy,and hydropower engineering.Peak strength and mechanical deformation characteristics of limestone directly relate to these projects’stability,and is therefore helpful to forecast risk.Furthermore,research on behavior of limestone under natural and experimental conditions is helpful in explaining rheological characteristics of upper crustal rocks,chemical and physical effects of fluid in geologic processes,the meaning of tectonophysics,structural adjustment of the upper crust,and dynamic processes of fault zone formation and evolution with fluid;it is also helpful in explaining seismogenic mechanisms and seismic wave propagation.Thirdly,limestone can be used as a kind of storage and overburden rock to effectively isolate CO2gas(Xie et al.2011;Córdoba et al.2017),helping to reduce the greenhouse effect,improve air quality,and improve the ecological environment.Limestones have also been considered a candidate rock to site deep geological repositories for the storage of heat-emitting nuclear fuel waste(Selvadurai and Najari 2017).In such a situation,the main mineral,calcite,reacts with CO2(supercritical state)(Liteanu and Spiers 2009;Le Guen et al.2007;Grgic 2011;Vialle et al.2014)by pressure solution,stress corrosion,and subcritical crack growth,leading to changes in the mechanical deformation properties.Decades of experiments and theoretical research on limestone have elucidated the characteristics of mechanical deformation curves(Baud et al.2000;Guo et al.2001;Zhang et al.2009;Tang et al.2011;Brantut et al.2014;Baud et al.2016;Han et al.2016;Tufail et al.2017);elastic parameters such as elastic modulus,Poisson ratio,and other elastic parameters(Alshayea 2004;Iscan et al.2006;Chen et al.2009b;Borgomano et al.2017);elastic wave broadcasting and wave velocity variation(Schubnel et al.2005;Chao et al.2009;Grgic 2011;Eslami et al.2012;Ercikdi et al.2016);permeability variation(Zhang et al.1994a,b;Iscan et al.2006;Xiao et al.2006;Ghabezloo et al.2009;Selvadurai and Głowacki 2017);evolution of interior cracks in rocks(Barber and Wenk 1973;Sammis and Ashby 1986;Ashby and Sammis 1990;Wong 1990;Dautriat et al.2011;Brantut et al.2013,2014;Brantut 2015;Regnet et al.2015;Zhang et al.2017);brittle–ductile transition(Heard 1960;Renner and Rummel 1996;Vajdova et al.2010;Wong and Baud 2012);rheological behavior(Kennedy and Logan 1998;Liu and Weber 2002;Liu et al.2005);ways of failure(Schubnel et al.2005;Feng and Ding 2007;Chen et al.2009a;Nicolas et al.2017);and strength criterion equations(You 2002;Zan and Wang 2002;Xiong et al.2007;Hu and Li 2010).

According to research objectives,purposes,and conditions,mechanical properties research on limestone is divided into two categories:engineering mechanics and mechanics of high temperature and high pressure.For the former,the main purpose is to ensure stability of rock engineering on Earth’s surface;for the latter,the focus is on deformation processes and mechanisms of an interior solid Earth medium over large-scale time and space.The two have in common basic mechanics principles and research methods.Sample preparation and loading are done according to the standard method suggested by the International Society of Rock Mechanics,but there are some differences.While the security of engineering(maximum tolerance force problem)focuses on engineering rock mechanics,in the study of limestone as a solid Earth medium,both stability and instability must be considered,and the rock instability process after failure is as important as the mode of instability(slow or fast,gradual or episodic),mechanical deformation mechanism,and failure equations under the conditions of high temperature,high pressure,strong constraints,wide time domain and large scale,and physical and chemical effects.In contrast,in the field of engineering mechanics of rock,researchers pay more attention to deformation behavior before failure,and failure mode of tensile splitting(uniaxial compression)and shear plane formation(triaxial compression),so as to ascertain peak rock strength(maximum tolerance)and residual strength.These studies are rarely concerned with rock deformation behavior after destruction of the rock or plastic flow.Through long-term experimental research and significant engineering experience,engineering rock mechanics in high temperature and high pressure systems has greatly improved;at the same time,high temperature and pressure,the wide time domain,and large deformation,contribute to what we know about the instability of rock deformation and failure,which could provide reference and clues for further engineering rock mechanics research(Wang 1995).

With deepening knowledge and advancing technology come requirements for a deeper understanding of the interior Earth.Depending solely on observable structural features and test data under surficial temperature and pressure conditions,it is impossible to reliably infer evolution of the deep Earth.The plate tectonic theory, fluctuations in the boundary between the core and mantle,the crustal growth model,and frequent volcanoes and earthquakes all reflect Earth science’s need for a more comprehensive and complete understanding of the interior Earth.Rock mechanics is a foundation by which to understand the crust-mantle structure.But experimental engineering mechanicsdata fail to comprehensively explain deformation character and failure ways of deep limestone,causing many researchers to turn their focus to simulating complex original rock environments(high temperature and pressure together with fluid ingress).It is necessary to simulate the conditions of the interior Earth and mechanical–physical–chemical coupling processes among materials(rock,mineral, fluid)to understand mechanical deformation behavior and failure mechanisms of the Earth medium.

2 Mechanical deformation behavior of rock

Rock mechanical deformation can be divided into two types:elastic and plastic,according to whether or not the deformation is reversible(residual deformation).However,the boundary between elastic and plastic deformation is not absolute.Rock may undergo elasticity and plasticity at different deformation stages—the brittle–ductile transition,for example.Characteristics of limestone mechanical deformation are intimately related to mineral composition,internal structure,grain size,and porosity;external conditions such as temperature,confining pressure,loading mechanism, fluid,and loading rate also play an important role.This paper will discuss the effects of the main external conditions(temperature,confining pressure, fluid)on compressive mechanical properties and modes of failure for limestone.The range of temperature and confining pressure of Earth is shown in Table 1.

2.1 Confining pressure effect

Generally,research on the mechanical properties of limestone is based on the theory of solid mechanical deformation and on experimental technology.All tests assume that limestone is an isotropic,homogeneous,and continuous solid medium.The equation σ1>σ2= σ3is applied for the conventional triaxial compression test.The convention is adopted that compressive stress and compressive strain are positive(i.e.,specimen shortens and porosity decreases).Griggs(1936)was the first to experimentally study the effects of confining pressure on mechanical deformation of limestone.Later,many researchers’work was confined to rock mechanics engineering under room temperature and confining pressure of less than 100 MPa.Since the 1970s,research has focused on the mechanical deformation behavior of limestone at high temperature and high pressure.In the early 21st century,study became more comprehensive.

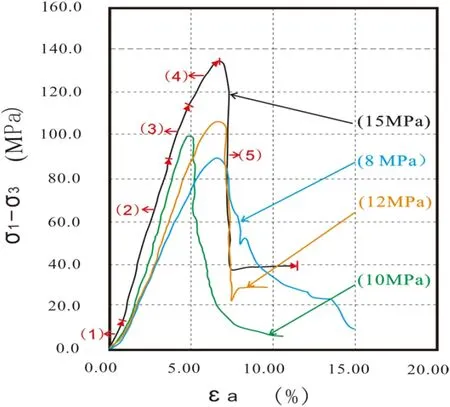

Fig.1 Limestone deviator stress versus axial strain at different confining pressures(after Guo et al.2001).Color-coded bracketed numbers represent experimental confining pressure.Red bracketed numbers denote stress and strain stages

Limestone deformation characteristics at room temperature and low confining pressure are shown in Fig.1.The stress and strain deformation curve of rock contains five typical stages(Zhao and Cao 2013):(1)Compaction:preexisting cracks in rock gradually compress and close;deformation is nonlinear,the curve has an upwards concave form on a gentle slope,and the length of fragment is related to how many fissures there are in the rock.(2)Linear elastic deformation:after the rock is compacted,it is changed from a discontinuous medium to a similar continuous medium,and stress accumulates along a straight line up to the yield point.(3)Crack-generation and stable propagation:microcracks initiate at points of concentrated stress(e.g.pre-existing crack tips,pore boundaries,grain boundaries,twin crystal interfaces,and so on),and extend parallel or at an angle to the maximum principal stress direction,and a curve of upwards convex form slowly rises to a threshold point.(4)Unstable cracks grow until failure:microcracks coalesce,nucleate,and unsteadily grow,and rocks enter internal damage stage,with an upwards convex curve rapidly rising to a peak stress point.(5)Post-failure:when rock is damaged,the stress value does not immediately drop to zero,and the rock still has residual strength.

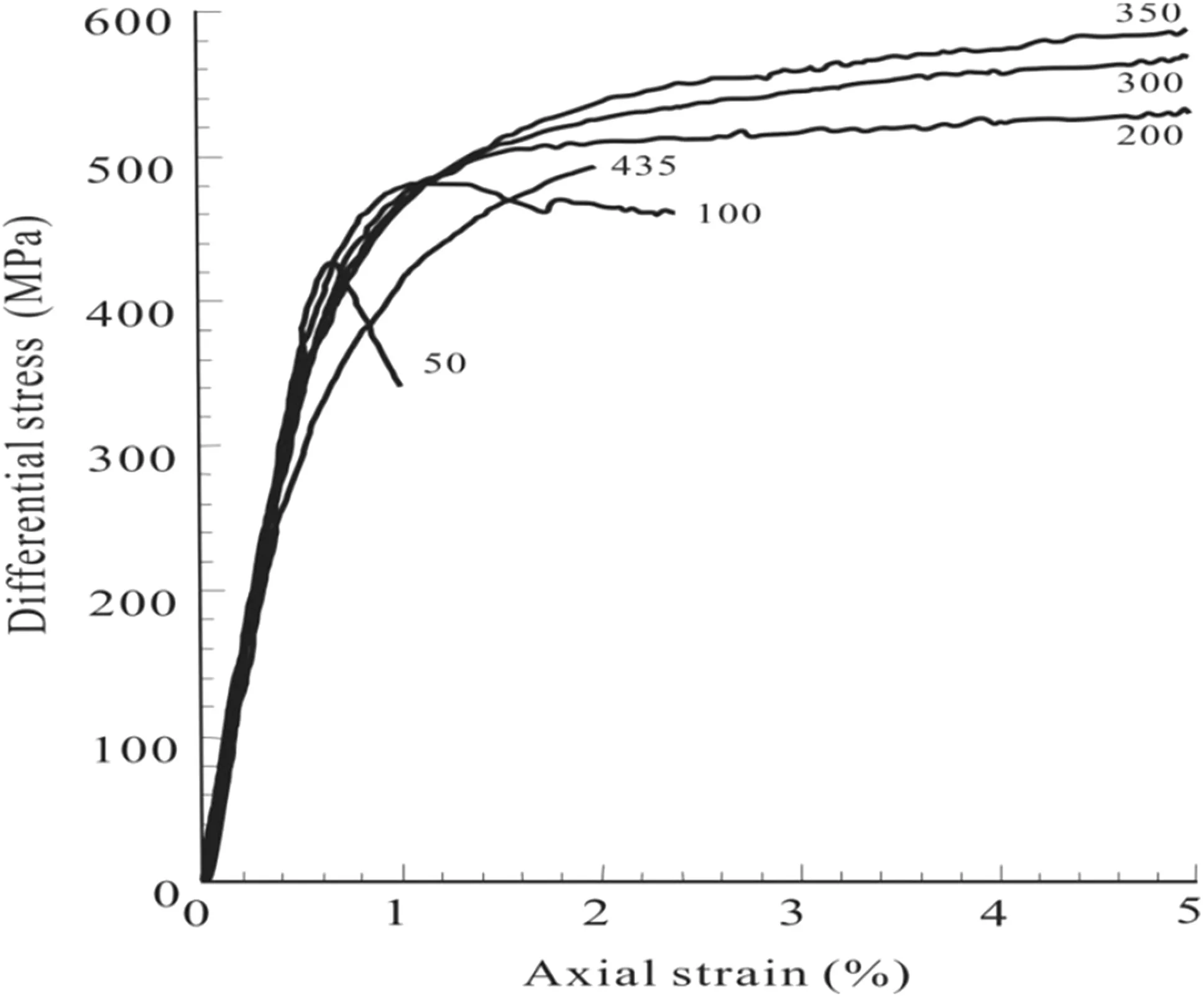

If rocks are uniaxially loaded,the stress–strain diagram of Stage 5 is altered;stress rapidly drops and brittle failuretypically occurs(Huang et al.2016;Nie and Chen 2016).With sufficient confining pressure,Stage 5 in Fig.1 changes and brittle–ductile transition and plastic deformation are observed(Głowacki and Selvadurai 2016).Fig.2 shows brittle–ductile transition deformation characteristics of large-porosity limestone.At transformational confining pressure of 100 MPa,deviatoric stress peak values remain the same,but axial strain gradually increases;at confining pressure>100 MPa,there is no obvious peak stress point,and deviatoric stress increases along with strain—the upwards convex form curve slowly rising until the rock is damaged,just like the curves at 200,300,and 350 MPa.

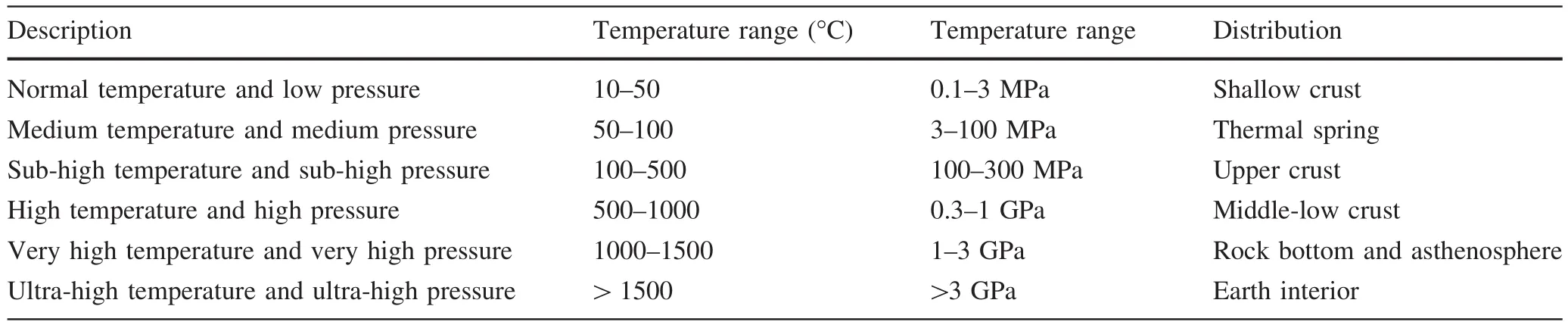

Table 1 The range of temperature and pressure of earth

Fig.2 Limestone differential stress versus axial strain(modified after Baud et al.2000).Numbers at ends of curves represent the experimental confining pressure

Limestone can undergo brittle–ductile transition even at room temperature when the confining pressure is high enough(Robertson 1955;Heard 1960;Byerlee 1968;Rutter 1972a;Evans et al.1990;Guo et al.2001),possibly because calcite easily forms mechanical twins or causes dislocation glide along the crystal plane at relatively low shear stress(Turner et al.1954;Griggs et al.1960).Researchers previously thought the brittle–ductile transition was mainly influenced by external factors,and tried to elucidate the critical condition.Heard(1960)found that when rock is damaged,axial strain reaches 3–5%,which can be considered the brittle–ductile transition.Singh et al.(1990) proposed critical conditions of σ1/σ3≈3~3.5,σucs/σ3≈ 0.5~1.25 where σ1,σ3,σucsare maximum principal stress,minimum principal stress,and uniaxial compression strength(UCS),respectively.Renner and Rummel(1996)found critical conditions exist with a hardening coefficient of zero or σ3/σmax≈ 0.2-0.3 where σmaxmaximum deviatoric stress.However,Baud et al.(2000)found this mechanism not only relates to external factors(temperature,confining pressure,pore pressure,strain rate, fluid),but also to a rock’s intrinsic characteristics(mineral composition,porosity,grain size).Recently,Wong and Baud(2012)found the deformation mechanism is intimately related to porosity.

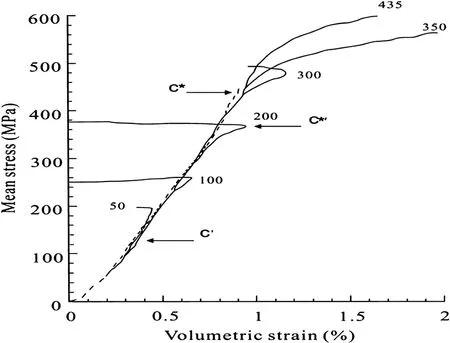

In the process of plastic deformation,rock undergoes smaller scale fracture and hyperplasia,and relative movement,rotation,or extrusion of mass or particles,known as‘false elastic’or ‘quasi elastic.’Dilatancy is commonly observed as a precursor for brittle failure in both compact and porous rocks(Brace 1978;Paterson and Wong 2005).In the early 21st century,researchers(Baud et al.2000;Vajdova 2004;Baud et al.2009;Vajdova et al.2010,2012;Zhu et al.2010;Wong and Baud 2012)found higher porosity limestone(≥3%)exhibits inelastic compression deformation(Fig.3),challenging conventional thought.When confining pressure is between 100 and 300 MPa,the deformation curve is clearly divided in three stages.In the first stage,triaxial compressive deformation basically coincides with the hydrostat up to a critical stress state(indicated by C*for the curve at confining pressure of 300 MPa).In the second stage,at stress levels beyond C*,there is an accelerated decrease of volume in comparison to the hydrostat;this phenomenon of ‘shear-enhanced compaction’persists until the volumetric strain switches from compaction to the third stage—dilation.This transition from compressive to dilatant cataclastic flow occurs at the critical stress state,C*’(confining pressure of 200 MPa).The volume dilates,and negative volumetric strain increases rapidly.When confining pressure is greater than 300 MPa,the rock undergoes strain hardening.The Stroh model(Stroh 1957)for microcrack nucleation due to dislocation pile-up could be used to analyze the transition from shear-enhanced compaction to dilatant cataclastic flow.

Fig.3 Limestone volumetric strain versus mean stress(modified after Baud et al.2000).Pconf(in MPa)is indicated on each curve.For reference,the hydrostat is shown as a heavy dashed line.The critical stress states for dilatancy C’,onset of shear-enhanced compaction C*,and transition from shear-enhanced compaction to dilatancy C*’are indicated by arrows for experiments performed at Pconfof 50,300,and 200 MPa

2.2 The temperature effect

Because the temperature gradient is roughly 30°C/km in the shallow depths of Earth(Turner and Verhoogen 1960),temperature may reach several thousand degrees.To simulate the environment of limestone in the upper crust and the processes of diagenesis and mineralization in the interior Earth,temperature is a vital factor.Barber and Wenk(1973)and Wenk et al.(1973)microscopically observed that mineral composition of limestone varies with increasing temperature,the aragonite phase appears,cracks and crystal dislocations appear with unequal distribution,many crossed,and tangled dislocations appear.Qin et al.(2009)and Liu(2011)microscopically found limestone presents different colors at temperature(T)ranging from 20 to 800°C,and internal mineral composition and microstructure change with temperature.When temperature is 500–800 °C,internal main minerals(calcite)decompose(Chen et al.2008).Chen et al.(2009b)observed rock dilates byT=300°C;intragranular cracks appear at 500°C.Nasseri et al.(2013)found considerably reduced triaxial compressive strength at 150 compared to 100°C.Zhang et al.(2016)showed that with the increase of temperature in the tested range of 25–900 °C,uniaxial peak compressive strength and elastic modulus both decrease.Changes in the external characteristic of limestone are mainly induced by internal structure variation.When temperature increases,dominant minerals(calcite)gradually undergo phase transition and melting,with increased intra-and inter-granular cracks,induced intracrystal plasticity deformation,and even dynamic recovery and recrystallization,destroying the previous internal structure and quickening rock fracture.At high temperature,crystal sliding is more likely.Liu and Liu(2000)pointed out whenT<400°C,e-plane twins are the primary slip system,and at 400–700 °C,twins of e-and r-planes coexist,while at a higher temperature,f-plane sliding plays an increasingly important role.Generally,calcite twinning appears at low temperature,but with grain size and strain rate decrease and temperature increase,its importance weakens(Schmid 1982).Calcite can deform mechanical twinning or r-,f-dislocation glide even at room temperature(De Bresser and Spiers 1993,1997).

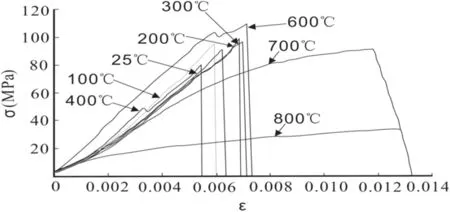

Temperature effect on limestone uniaxial compression deformation is shown in Fig.4.From the figure we know rock undergoes several deformation stages at 25–600 °C.Peak strength and elastic modulus show a downward trend from normal temperature to 200°C,but little change from 200 to 600 °C.Above 600 °C,peak strength decreases sharply,and axial peak strain and residual strain quickly increase—clear plastic deformation.

Fig.4 Limestone uniaxial compression stress versus axial strain at different temperatures(modified after Zhang et al.2009).The temperature(in°C)is indicated on each curve

The temperature of 600°C seems to be critical for the brittle–ductile transition for uniaxial compression of limestone.Lin and Zhang(2009)found limestone uniaxial peak strength gently increases with rising temperature in the range of 25–500 °C.In the range of 500–800 °C,peak strength declines with increasing temperature,and internal structure changes significantly.Zhang etal.(2009)observed maximum uniaxial compression strength of limestone at 600°C,possibly because atT<600°C,structural stress due to volume dilation is always smaller than uniaxial compression strength,tension stress is not enough to force new cracks to initiate,and the rock maintains its integrity.Additionally,thermal dilation forces preexisting fissures to squeeze and close,enhancing peak strength.WhenT>600 °C,cohesion among mineral grains weakens and internal cracks initiate and unstably grow;crystal plastic deformation increases.

2.3 Synthetic effect of temperature and confining pressure

Temperature and confining pressure’s comprehensive effect on limestone deformation properties is a focus for researchers.When temperature and confining pressure are raised,limestone may skip elastic deformation and instead enter directly into the ductile flow stage.Because its ductile strength is high,and brittle-plastic transformation and plastic rheological characteristics outstanding,calcite was one of the most sensitive stress minerals in the tectonic stress field(Rybacki et al.2011,2013).In a steady rheological stage,temperature is one of the most important parameters.With temperature rising,the rheological mechanism may transform from dislocation creep to diffusion creep,and even to superplastic flow.From laboratory experiments(T≥500°C,Pconf≥200 MPa),three major regimes of plastic flow have been delineated by differential stress for calcite rocks or synthetic calcite aggregates.(1)At high flow stress,an exponential law is the best fit,while deformation is accommodated primarily by e-twinning and intracrystalline slip(Turner et al.1954;Heard 1963;Heard and Raleigh 1972;Rutter 1974;Schmid et al.1977,1980;Walker et al.1990).(2)At intermediate flow stress,a power law describes flow with stress exponent n≥4,associated with dislocation creep processes and dynamic recrystallisation by subgrain rotation;grain bulging dominates (Heard and Raleigh 1972;Rutter 1974,1995;Schmid et al.1977,1980;Walker et al.1990;De Bresser and Spiers 1993).(3)At highest temperature and low stress regime,diffusion creep and grain boundary sliding dominate(Schmid 1976;Schmid et al.1977,1980;Walker et al.1990).Good crystal limestone may appear superplastic(Schmid et al.1977;Rutter et al.1994;Casey et al.1998).The mechanism originally was found in metal(Jenkins 1928;Underwood 1962;Backofen et al.1964).Ashby and Verrall(1973)and Wang and Jin(2001)researched crystal plastic deformation,including Weertman creep,Harper–Dorn Creep,Nabarro–Herring creep,Coble creep,and superplastic and dynamic recrystallization.Verberne et al.(2015)showed that dislocation and/or diffusion creep likely plays a role in experiments performed at T ≥ 400°C for dense calcite polycrystals.Some scholars have investigated the crystallographic preferred orientation of Solnhofen limestone (Rutter et al.1994;Rybacki et al.2003;Barnhoorn et al.2005;Llana-Fúnez and Rutter 2005,2008,2014).De Bresser(2002)at confining pressure of 100–600 MPa,and temperature 600–800 °C,experimentally discovered single calcite crystals’ flow stress increasing with Pconfat a rate of 1.6% per100 MPa.Renner and Evans(2002)at 400–1050 °C and Renner et al.(2002)at 600–800 °C discussed the power-law creep equation,and how strength decreased with increasing grain size following a Hall–Petch relation.Freund et al.(2001,2004)and Wang et al.(1996)pointed out trace amounts of dissolved Mn(10–670 ppm)decrease the strength of calcite during both dislocation and diffusion creep.Xu et al.(2009)at 700–800 °C and Pconf=300 MPa experimentally studied the influence of dissolved magnesium on the transition from diffusion creep to dislocation of calcite aggregates.Covey-Crump et al.(2016)showed the dependence of plastic flow properties on the 3rd invariant of the deviatoric stress tensor(J3),at 300 MPa confining pressure and 500–650 °C on Solnhofen limestone.

2.4 The fluid factor

The wide distribution of fluids(mainly aqueous solution)through the lithosphere leads to complex dynamic interactions between fracture,deformation,dissolution or precipitation,and fluid flow(Gratier et al.2013).Limestones are subject to deformation and fluid flow processes occurring in the upper crust(Brantut et al.2014).Wanless(1979)observed dolomitization of limestone layers in the field due to the pressure solution effect;dolomite usually grows along stylolite.Liu et al.(2005)pointed out that the fluid effect on rock is the same as temperature in the process of deformation.Peng and Chen(2002)emphasized that structural stress and fluid are two basic factors that play an important role in many geological processes;pressure solution,stress corrosion,crack closure,and others are all important types of tectonic fluid action.Liu et al.(2001)highlighted how fluid effects hydrolysis weakening of limestone;enhances the activities of lattice defects,dislocation climbing and sliding deformation mechanisms;and elucidates the process of crystal plasticity.Zhang et al.(2010)concluded the dominant deformation mechanism for wet samples is intergranular pressure solution due to pore fluid.

2.4.1 Effect of water

Water in the crust ushers calcite rocks through the brittle–ductile transition;hydrolysis weakening isdominant(Kennedy and Logan 1998).The effect of water on limestone has been the subject of extensive experimental and theoretical research.Heard (1960)studied Solnhofen limestone subjected to pore- fluid(water and CO2)at temperatures up to 150°C.Handin et al.(1963)described the pore-water pressure variation effect on the strength and ductility of Marianna Limestone.Rutter(1972b)summarized the ways that water affects strength and ductility of calcite rocks:(1)physicochemical action at grain boundaries,and(2)the mechanical effects of the pressure it exerts,according to the law of effective stress.Yi(2010)concluded water effects mechanics and physical chemistry of limestone.The uniaxial compression strength and elastic modulus of limestone decrease with increasing degree of saturation(Griggs 1936;Chen and Zhou 1991;Xu et al.2008).Huang et al.(2006)pointed out the mechanical effect of water interacting with rock has a clear time dependence,and chemical corrosion significantly decreases compressive strength and the elastic modulus.Nicolas et al.(2016)indicated water delays the onset of dilatancy in the brittle regime,but no measurable influence on peak strength.Water effects rock in three ways:physical(lubrication,softening,argillation,reinforcement of bound water),chemical(ion exchange,dissolution,hydration,hydrolysis,oxidation–reduction,etc.),and mechanical(pore hydrostatic pressure,pore hydrodynamic pressure effect)(Wu 1999).Ercikdi et al.(2016)found calcium carbonate ionic bonds reduce UCS by weakening the interfaces between grains.

When the rock surface is first immersed in water,water enters along the fissures,then flows along channels composed of pores and cracks,so that internal minerals are lubricated,weathered,dissolved,and mudded,reducing friction among grain interfaces,enlarging gaps among the particles,and weakening cohesion within mineral grains.The variation of internal structure leads to declined strength and mechanical deformation.Pore water supplies tensile stress,which can reduce confining pressure.Additionally,water produces a splitting effect on crack tips,speeding the growth of new cracks,and quickening rock failure.When stress and water coexist for a long time,limestone readily exhibits intergranular pressure solution mechanics,and leads to discrete sutures and subcritical cracks(Clarke et al.1986;Røyne et al.2011;Liteanu et al.2013;Mallet et al.2015).

2.4.2 Other fluid effects

Other fluid within the lithosphere also affects rock deformation(Zhou and He 1999).Researchers have studied NaCl,NaHCO3,and CaCl2solutions’effects on limestone mechanical deformation properties(Ding and Feng 2004;Feng and Ding 2007;Feng et al.2009;Khadra et al.2017).Boozer et al.(1963)subjected Indiana Limestone to porefluid pressures ofn-hexadecane,water,and oleic acid.Hutchinson et al.(1993)simulated the acid rain corrosion effect on limestone with H2SO4,and HCl.Yao et al.(2009a)discussed how Na2SO4and CaCl2solutions and distilled water affect the cohesion,porosity,elastic modulus,and Poisson’s ratio of limestone and found the brittle–ductile transition was accelerated by chemical corrosion.Chen et al.(2010)pointed out that with increased solution pH,elastic modulus and peak strength are slightly reduced;at the same pH,the degree of weakening was progressively less with Na2SO4solution,distilled water,and CaCl2solution.Xie et al.(2011),by injection of NH4NO3solution during a long-term creep experiment,found lateral strain of limestone to be a function of time,and observed connected wormholes on the rock surface.Different ions,pH,and fluid concentration effect limestone mechanical deformation behavior to varying degrees,intimately related to the internal mineral composition.Because the cation of calcite is Ca2+,the solution is weakly alkaline after calcite hydrolysis(CaCO3+H2O→Ca2++HCO3-+-OH-).If the solution pH is lower,and the H+concentration higher,neutralization ismore intense.Mineral dissolution accelerates,intra-and inter-granular pores and cracks increase,and peak strength declines.Due to the common-ion effect,Ca2+does not promote calcite dissolution,so CaCl2has less impact on limestone than other solutions.

As a consequence,chemical reaction increases porosity and deteriorates the mechanical properties of the rock.The chemical process is generally coupled with hydromechanical behavior of rock materials;for instance,a change in permeability due to chemical dissolution modifies the diffusion process of mineral species.Ding and Feng(2005)emphasized rock mesoscopic structure changes with chemical corrosion,an essential factor to change rock mechanical properties,with variable damage on the basis of porosity,which could quantitatively reflect the mesoscopic degree of damage to rock.

3 Rock failure mechanisms and strength criterion

Through engineering mechanics and experimental results,the understanding of limestone deformation and failure has reached consensus.Limestone failure is not instantaneous,but rather a process through which concentrated energy is released—numerous cracks grow,propagate,coalesce,and nucleate(Olsson and Peng 1976)until a macro fracture plane forms or ductile flow initiates.This is a process of local stress distribution.

Broadly,rock failure is divided into brittle fault and ductile flow.The essential difference between brittle and ductile behavior is a macroscopic one:whether or not the rock is capable of undergoing substantial permanent strain without the occurrence of macroscopic fracture(Paterson and Wong 2005).Due to limestone’s physical and chemical characteristics,stress conditions,and the chemical environment,there are complex and diverse destructive forms.Yao et al.(2009b)pointed out that stress-selected corrosion of a chemical solution increases the heterogeneity of limestone,and the existence of hydraulic pressure changes limestone’s internal fissure surface or the inter-granular stress state;these two aspects increase the diversity of fracture forms.For brittle limestone deformation,internal heterogeneity has an important effect on macroscopic fracture formation(Wang et al.2006).For the same rock,under uniaxial compression at low confining pressure,a single shear fault plane may form;at high confining pressure,ductile failure along multiple shear planes is likely(Zhou et al.2001).

3.1 Brittle fault mechanism

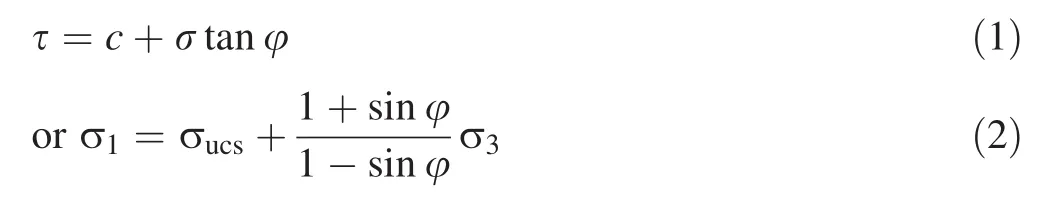

The macroscopic characteristics of a brittle fault include a flush and orderly fault plane,cleavage or quasi-cleavage,no fibrous area alongside the fracture,and obvious diastrophism and displacement between the two fracture planes.Because tensile strength is low,when rock is uniaxially compressed,tension failure along the axial direction obscures the shear failure characteristics(You 1998).When limestone is uniaxially compressed,rock splits into several pieces(Chen et al.2003;Yang et al.2005;Lin and Zhang 2009;Yang and Zhou 2010).Generally,rock samples display shear failure along a single plane when subjected to conventional triaxial compression(Xiong et al.2007).In the field of rock brittle fault,the Mohr–Coulomb strength criteria are usually used:

where the coefficients τ,c,φ are shear stress of the failure plane,internal cohesion,and internal friction angle,respectively.The other parameters are the same as mentioned above.

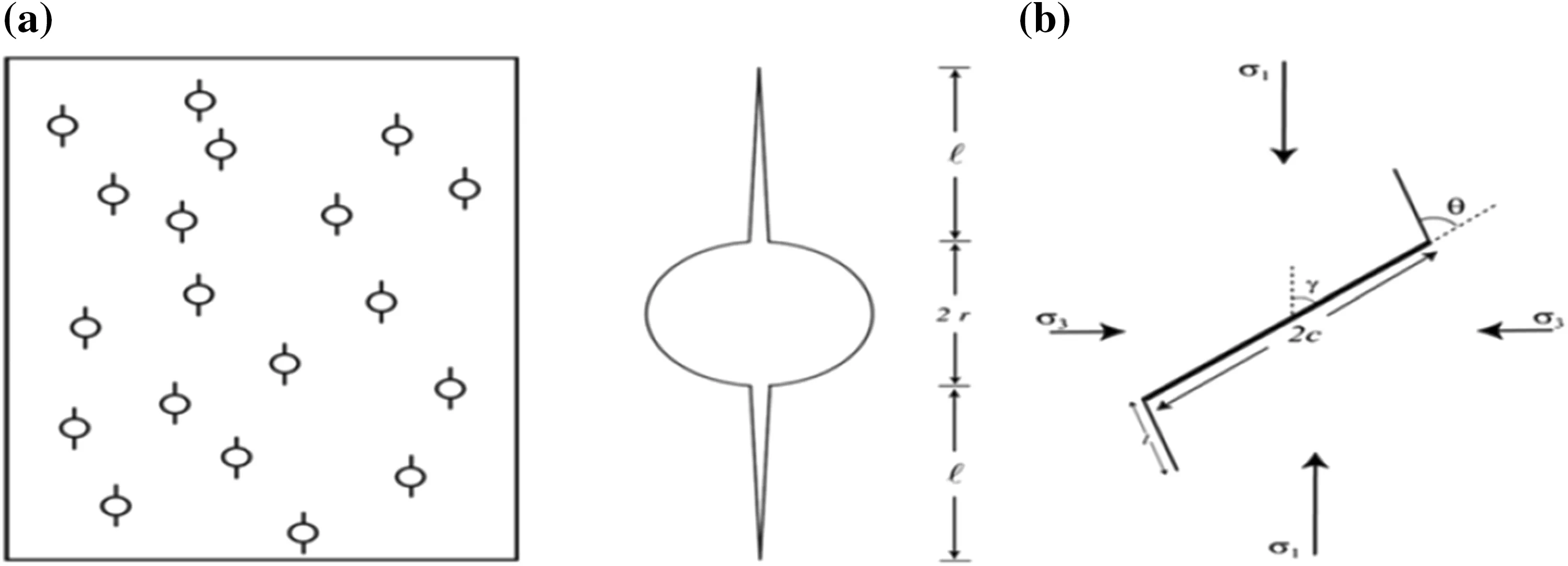

Microscopically,rock is made of porous,cracked particles bound together according to mechanical law.Rock failure occurs due to the coalescence of cracks caused by the accumulation of damage governed by increased applied stress or by progressive time-dependent growth of microcracks(Olsson 1974).Myer et al.(1992)found variations in deformation character and failure mechanism of limestone at different confining pressure,mainly due to varied propagation of internal cracks.The existence and evolution of micro- fissures within carbonate rock has a dominant effect on mechanical properties(Luo 2008).Therefore,researchers discuss rock failure in the context of microcracks,which provide a theoretical basis for rock dilatancy before macro fault formation.The microstructure of rock can be idealized as an inclusion model with micro-cracks and equant pores embedded in a continuous elastic media.Two crack evolution modes according to different stress states are shown in Fig.5.

The pore-emanated cracking model(Sammis and Ashby 1986)provides a relatively simple micromechanical interpretation for UCS dependence on porosity and pore size:when rock is uniaxially compressed,and as applied stress increases,the stress intensity factor of a small crack on the circular surface eventually attains the critical valueKIC,at which point wing cracks propagate to a distancelparallel to the stress direction.As the wing cracks propagate further—up to the size of the whole grain—they interact with one another to induce additional tensile stress.If space is confined,coalescence of cracks ultimately leads to instability and rock failure.

On the other hand,the sliding wing crack model(Horii and Nemat-Nasser1986;Ashby and Sammis1990;Kemeny and Cook 1991)explains that when rocks are triaxially compressed,tensile stress is concentrated at the tips of preexisting cracks.Applied stress induces shear traction on the crack plane(length of 2c),and if shear traction exceeds frictional resistance along the closed crack,slip occurs,inducing concentration of tensile stress at the two tips that may initiate and propagate wing cracks parallel or at an angle to maximum principal stress.As wing cracks propagate,they interact and ultimately coalesce,resulting in instability and leading to rock macroscopic fracture.

Crack evolution under uniaxial compression is different from conventional triaxial compression(Horii and Nemat-Nasser 1986).For the former,new cracks grow parallel to axial stress,extend to several times the length of the preexisting crack,coalescence,and eventually lead to rock damage.Generally the primary nucleation cracks are the largest ones in the rock.For the latter,the bigger cracks grow preferentially,propagating to a certain length and then stopping;the small cracks start to evolve the same way,ultimately leading to a macro shear fault plane form.

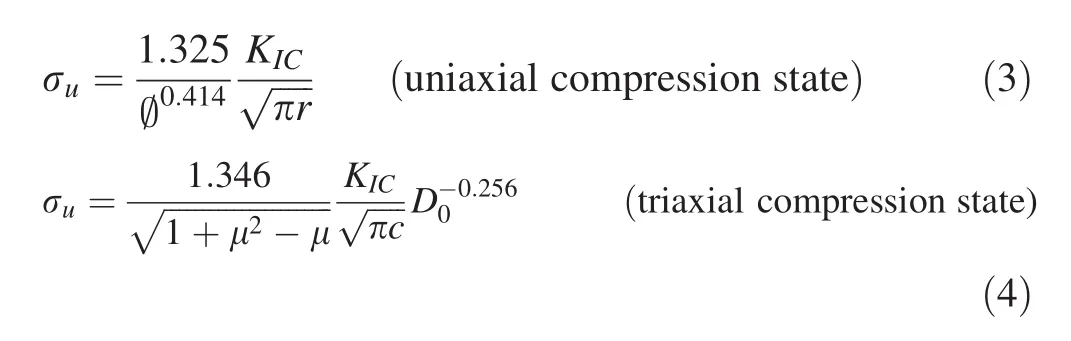

In conclusion,damage to rock is directly related to porosity from a microscopic view(Wong et al.2012),so strength equations are established as follows:

Fig.5 a Pore-emanated cracking model(Sammis and Ashby 1986).A two-dimensional elastic medium permeated by circular holes of uniform radius r.Cracks emanate from circular pores when subjected to remotely applied axial stress.The stress-induced cracks propagated to length l.Propagation and coalescence of pore-emanated cracks leads to instability and macroscopic failure.b Sliding wing crack model(Ashby and Sammis 1990).Directions of maximum and minimum principal stress are indicated.The sliding and wing cracks are at angles of γ and θ,respectively,with respect to the σ1direction.The half-length pre-crack is c

where σU,Ø≤40%,KIC=0.2MPa m0.5,μ=0.3~0.7,D0=0.1~0.4,r,c are failure strength,porosity,critical crack extension factor,friction coefficient,initial strain localization area,native radius of pore,and half-length of original crack,respectively.

3.2 Ductile damage mechanism

At higher confining pressure or temperature,plastic deformation increases and brittle fault is gradually replaced by plastic flow.The single fracture plane is replaced by dispersed shear fracture planes or even ductile shear bands.This is both the elastic to plastic deformation transition and the brittle to ductile failure transition.It is also a local to homogenous transition.

Macroscopically,ductile damage generally does not exhibit a shear fracture plane,and the rock specimen dilates in the middle.If there is a fracture plane with a cone form,there is a clear,slow tearing,usually with a fibrous texture around the damage zone.Rock characteristics such as porosity,grain size,and composition,and external characteristics,such as temperature,confining pressure,and fluid influence the mechanism of ductile failure,which can include cataclastic flow at low temperature,inelastic compaction deformation with cataclastic flow(expansion or compression),a discontinuous compression shear band,and stable rheology.Generally the Tresca or von Mises strength criterion has been used as the earlier ductile failure strength criterion;it is unaffected by confining pressure(Mogi 1967).In the context of our deepening understanding,the valid range needs to be re-discussed.

Because of complex media in the interior Earth and environment,ductility,brittleness,and brittle creep are further divided into brittleness,half-brittleness,half-ductility,network flow ductility,and uniform flow ductility.Rock crystal plastic flow is not limited to dislocation motion and vacancy,particle diffusion,etc.In the brittle and half-brittle regimes of the shallow-middle crust,rock rheology may be influenced by fracture,crazing,and friction,and become cataclastic or pseudoplastic flow.During research of the brittle–ductile transition,researchers have noticed a corresponding relationship among mechanical behavior,the macroscopic mechanicsm,and microscopic structure;the ductility domain comprises two kinds of macroscopic structure(network flow and uniform flow).

3.2.1 Cataclastic failure at low temperature

Rutter(1972a)observed limestone mainly undergoes pressure solution plastic flow at low temperature.Liu and Weber(2002)microscopically observed field limestone damage due to cataclastic flow at low temperature.Vajdova et al.(2010)summarized microscopic characteristics of limestone cataclastic flow:grains slip along boundaries,mechanical twins are common,grain size and crack density do not differ significantly between damage and deformation domains,crack distribution is homogeneous,and grain size uniform.

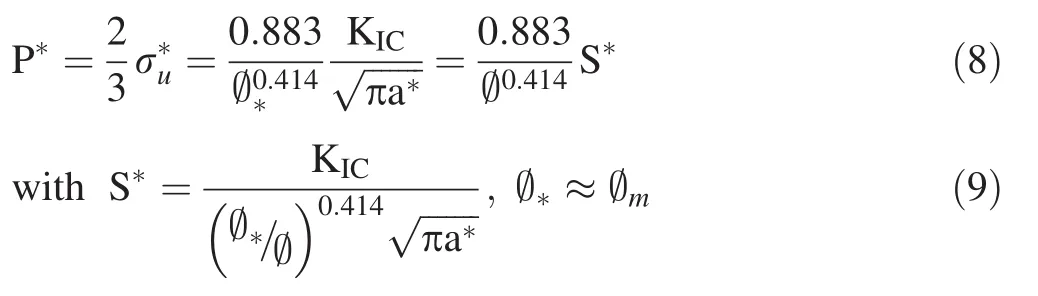

3.2.2 Inelastic compression deformation and failure

Inelastic compression deformation(shear-enhanced compaction deformation)may eventually cause cataclastic flow or compression shear bands in limestone with porosity greater than 3%.There are some essential differences between this type of deformation and the general plastic cataclastic flow failure(e.g.low temperature cataclastic flow).In microscopic terms,larger pores seem to collapse first.Additionally,cataclasis and microcracks(rather than crystal plasticity)seem to be the dominant deformation mechanisms in the proximity of a collapsed pore.Relatively intense cracks develop in a concentric halo surrounding the pore,and comminuted fragments may fall into voids.

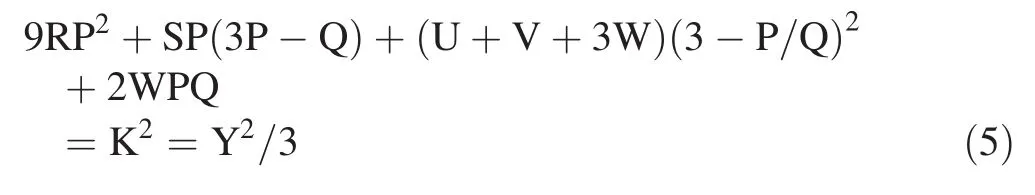

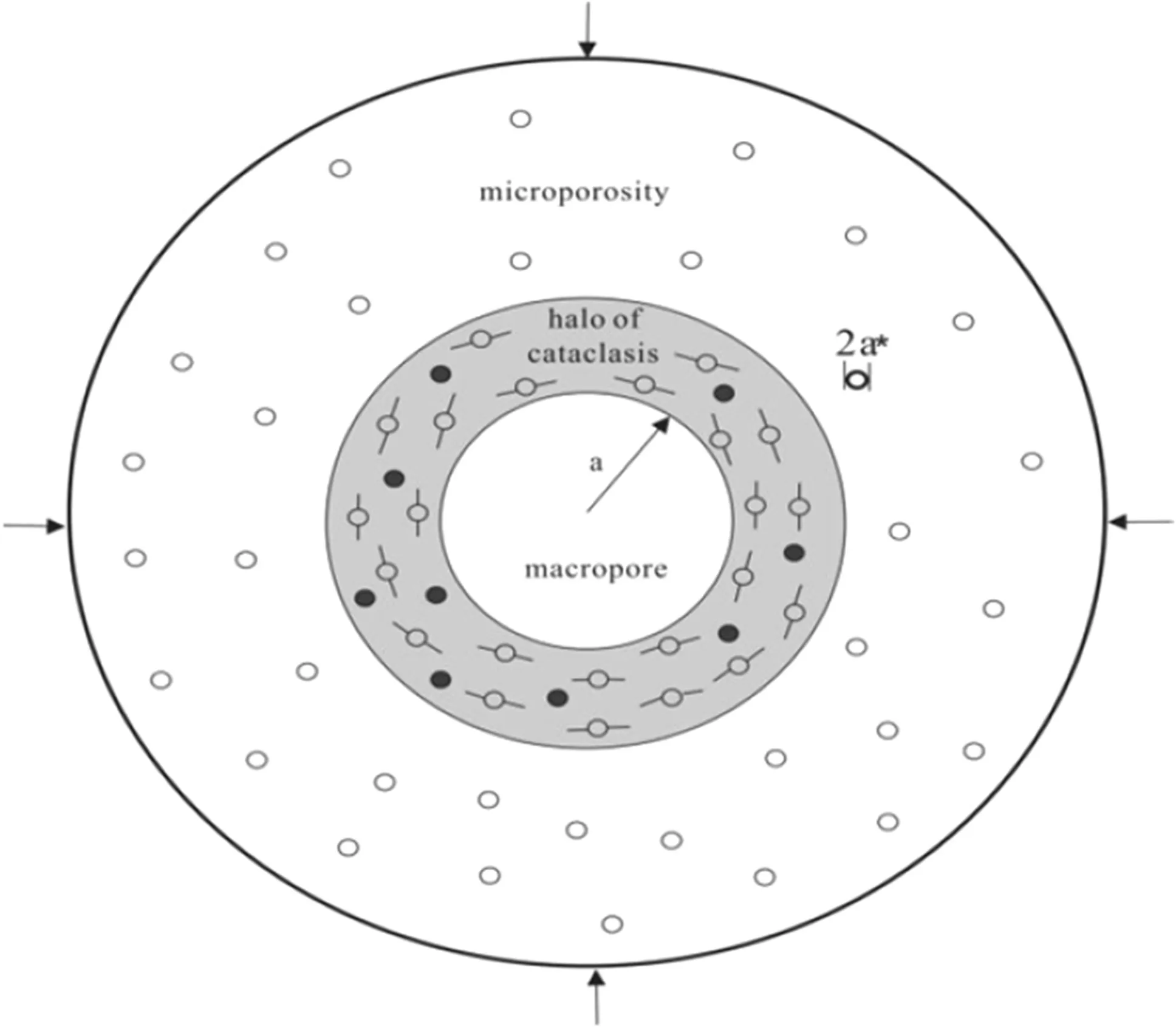

Research has shown that grain and pore size directly influence the failure mechanism of limestone.Baud et al.(2000)put forward the spherical pore damage model(Curran and Carroll 1979):for limestone with 3%porosity,the stress of the pore-collapsed starting point P*(triaxial hydrostatic compression),and C*(conventional triaxial compression)satisfy the equation:

withK=563 MPa and Y=975 MPa are the plastic yield stresses for pure shear and uniaxial tension(or compression)strength,respectively,and the coefficients U,S,V,W,and R depend on the rock elastic modulus and porosity.

The valid conditions are isotropic,homogeneous,and continuous matrix skeleton of which various sizes of spherical pores have been destroyed.When rocks were damaged,both crystal plastic deformation and crack growth occurred.

However,Vajdova(2004)found that in two limestones with high porosity(15.6%and 10.4%),the spherical pore collapse model cannot consistently satisfy the yield cap for both hydrostatic and conventional triaxial compression loading with the same set of yield parameters.Vajdova tried to use the brittle fault criterion to address the inconsistency,but did not succeed.

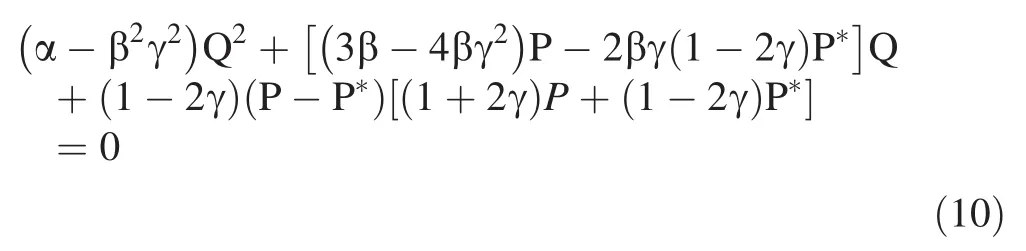

Later,Baud et al.(2009)put forward an equation that satisfies both the critical stress of starting point P*and C*for large porosity(>30%)limestone:

wheren≈2-2.5 n increases with porosity increase,B/A≈0.48-0.97 P and Q are the same as mentioned above,and R the radius of the large pores.

Equation(6)was put forward according to the Hertzian fracture criterion for sandstone(Zhang et al.1990);the preconditions of Eq.(7)are a lack of crystal plastic deformation within limestone,and that stress-induced cracks and crushed grains are the dominant micro-deformation mechanisms.

Due to the complication of inelastic compression deformation involved in internal pore collapse and granular plastic deformation(or crack evolution),to attain laboratory data more consistent with the model,the model must be modified to account for coupling of crystal plasticity and cataclastic mechanisms such as fracture and frictional sliding.From the perspective of macro character,establishing a strength criterion equation is difficult;different equations only satisfy a specific scope of porosity,which is confined to broadly practical application and promotion,so researchers have begun to explore wider adaptability of the strength criterion equation.

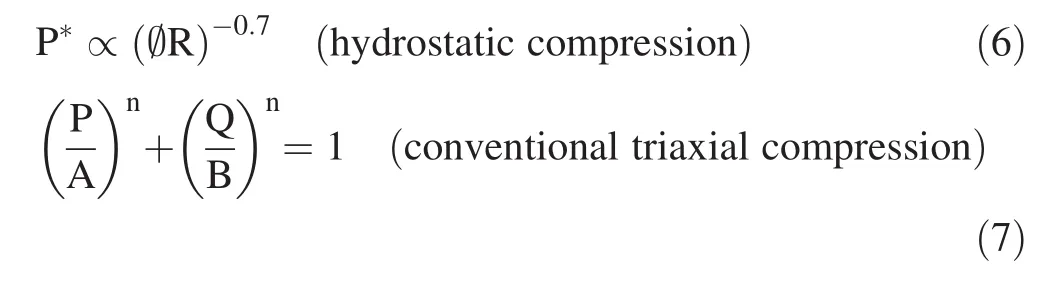

Fig.6 Pore cataclastic failure model(Zhu et al.2010).A macropore of radius a surrounded by an effective medium made up of many micropores of radius a*.Principal stress direction is indicated by arrows.Stress-induced pore-emanated cracks in the vicinity of the macropore led to its collapse;grey shading represents the collapsed area

The dual porosity concept(Fig.6)has been accepted widely in carbonate sedimentology(Choquette and Pray 1970;Pittman 1971;Anselmetti et al.1998;Baechle et al.2008;Zhu et al.2010;Vajdova et al.2012;Wong and Baud 2012).The model treats limestone as a dual porosity medium,with total porosity divided into macroporosity and microporosity.The representative volume element is made up of large pores which are surrounded by an effective medium with microporosity.Ji et al.(2012)proposed that limestone is made of three domains:the solid,the void(made up of macropores),and an intermediate domain made of voxels containing solid material embedded with micropores.The dual porosity model failure is:local stress concentration in the peripheral continuous effective matrix skeleton induces countless cracks and produces cataclastic activities,forming a circular damaged area,because small cracks grow and extend,destabilizing the rock and leading to failure.Practice has proven that the dual model improves upon previous proposed models of inelastic compaction deformation,and fits well with experimental data.When limestone is subjected to uniaxial compression,the stress of starting point P*satisfies the strength equation(Wong and Baud 2012):

where Ø*,Øm,a*are the porosity of skeleton effective continuous matrix,rock micro-porosity,and radius of the effective continuous micro-pore matrix skeleton,respectively,and the other parameters are the same as above.For the lowest porosity(3%),S*=130 MPa,Ø≥23%,and S*=20 MPa.

Conventional triaxial compression of starting point C*stress satisfies the equation:

where α =100(7-13ν+7ν2/9(7-5ν)2,β=100( 1+ν)/9( 7-5ν), and γ=2sinφ/3+sinφ,Poisson’s ratio ν =0.2,and the other parameters are the same as above.

3.2.3 Crystal plastic failure

Dislocation creep can be expressed as follows(Rutter 1974;Schmid 1976,Schmid et al.1977;Evans and Kohlstedt 1995;Song et al.2014):

with f1(σ)=Bexp( cσ) orf1(σ)=Dσn,and where exponential law is suitable for a regime of low temperature and large flow differential stress(σ>100MPa);the power creep law is suitable for(σ<100MPa);the coefficients ε˙,σ,Q,n,T are strain rate,differential stress,diffusion surface free energy,and temperature in K,respectively;A,B,D,and c are all constant;stress exponent n=2~8;and the gas constant R=8.314.

The mechanisms are predominantly dislocation of non-Newtonian flow and diffusion of Newtonian flow(or approximate Newtonian flow).Generally,the dislocation mechanism controls non-Newtonian flow(stress index n≥l),while the diffusion mechanism controls Newtonian flow or approximate Newtonian flow(n≅1).

Dislocation creep microscopic characteristics include:particles obviously flattened or elongated,a large number of celled or tangled dislocations in false hexagon form,no particle rotation,and particle boundaries serrated.

The grain-size sensitive creep law at low stress(Schmid et al.1977)is:

where d is grain size,b=2~3;and other parameters are as above.The viscous line model controlled by diffusion creep satisfies n=1 and b=2(Nabarro–Herring creep)or b=3(Coble creep)(De Bresser et al.2002;Ji and Xia 2002).Grain-sensitive creep includes diffusion creep and superplastic flow(n=1~3).

Microscopic characteristics of diffusion creep include:particles not stretched,but rotated;positions of adjacent particles and crystals exchanged;girdle structure;and appearance of an edge.

Grain boundary sliding is the most prominent feature of superplastic flow for smaller grain sizes(Schmid 1976;Schmid et al.1977;Rutter et al.1994),and it intimately relates to dislocation creep and diffusion creep.It is the competitive result between grain boundary sliding and dislocation climbing.Because superplastic flow evidence is hard to detect in the field,we generally believe that rheological mechanisms mainly include dislocation creep and diffusion creep.However,in the process of rheological deformation,structure performance may be inconsistent with macroscopic activity.Xiao et al.(1993)microscopically observed two groups of conjugate dark shear belt exhibiting prominent crystal plastic deformation,conjugate shear network transition to uniform flow at 1000°C,and sub-grains and dynamic recrystallization grains widely distributed within the rock.

4 Future research directions

Limestone is a common rock distributed in the upper crust and surface.Under surficial temperature and confining pressure,extensive research exists on elastic parameters,mechanical deformation,and failure features.However,as emissions of carbon dioxide(CO2)gas increase and radioactive nuclear fuel and waste accumulation have intensified environmental problems,more attention has turned to limestone.CO2capture and storage(CCS)is considered a potential mitigation option for climate change(Garcia-Rios et al.2015).Sub-surface limestone may permanently seal these pollutants,improving the environment by slowing down the greenhouse effect.The shallow upper crust has high temperature,geostress,and fluid in filtration,compared with surface conditions,so mechanical properties and failure mechanisms are very different there.It is difficult to accurately infer deep limestone deformation and mechanical properties based on experimental data attained at surficial conditions.Researchers should strengthen macro and micro research of rock in mechanical–physical–chemical coupling under high temperature–high pressure,fluid injection conditions to elucidate rock deformation characteristics and failure mechanisms.

Depending solely on experimental curves,such as the stress–strain curve,creep curve,failure model,etc.does not achieve accurate extrapolation and application.Using only a phenomenological description of natural rock fabric and structure,it is difficult to grasp quantitative mechanical data.Only if study of the mechanical behavior of rock and physical mechanisms is combined with macro and micro characteristics and experimental data,can a full understanding be achieved of the constitutive relationship of rock deformation and fracture mechanism,and the complex associated natural processes.We therefore make the following recommendations for future research.

4.1 Fluid-rock interaction research

We have summarized how fluid(water solution)plays an important role in limestone mechanical deformation and failure mechanism.The plastic and crystal plastic deformation of limestone at low temperature,mainly caused by hydrolysis weakening,pressure solution,mechanical twinning,and rheological behavior are transferred through progressive deformation.Predecessors have researched the fluid effect on mechanical deformation characteristics,but,even though the kinds of fluid were complex and varied,and the simple chemical dissolution effect and stress corrosion discussed,work has been limited to low confining pressure and room temperature or uniaxial compression.

The main component of fluid in the lithosphere is NaCl aqueous solution;distributed in rock fissures,its concentration changes with depth(Zhang and Hu 1998).The solubility of calcite increases with salinity in solutions in equilibrium with the atmosphere,but the effect of salinity on calcite dissolution and precipitation kinetics remains unclear.Dilute NaCl aqueous solution can promote the dissolution of calcite,speed pressure solution creep,improve the stress corrosion effect,promote sub-critical crack growth,and chemically weaken the mechanical properties of rocks(e.g.peak strength,elastic parameters).Dissolution is a process by which rocks or minerals dissolve into aqueous fluid.This process leads to changes in chemical composition,porosity,and permeability.Generally,porosity and permeability increase due to dissolution of the solid mineral components.Pressure solution is a petrologic process whereby grains dissolve at inter-granular contacts under pressure.The process leads to a loss of porosity and may increase rock strength through intergranular compaction.Stress corrosion is a cracking process induced by the combined influence of tensile stress and a corrosive environment.Cracks induced by stress corrosion may be inter-granular,trans-granular,or mixed in nature.

Since,in the original environment,rock materials are simultaneously subjected to mechanical load and high temperature and chemical attacks by NaCl solution,research on limestone mechanical deformation and failure mechanisms is necessary.Especially under the condition of fluid injection,it is important to conduct high temperature–mechanical fluid flow coupled mechanics experiments.

In future work,researchers should further investigate deformation properties,elastic parameters,failure mechanisms,and flow law of limestone;determine rock and fluid physical–chemical–mechanical quantitative relationships and mathematical models;and discuss the mutual influence and conditionality between fluid and diffusion material migration in rheological deformation.

4.2 Mutual transition between natural conditions and laboratory research

The purpose of research on limestone mechanical deformation characteristics and failure modes is to apply test results and theory in geological,geophysical,and engineering mechanics fields.However,there are different analysis results between rock deformation characteristics in the field and laboratory simulation under the same conditions.Therefore,a major challenge is how to extrapolate laboratory data and results to the field.For example,with constant strain rate loading for compression tests,the minimum value for an experimental machine is 10-8/s,but in the shallow Earth the minimum value is about 10-14/s.Rheological law based on strain rate parameters encounters difficulties when applied to the geological environment.Paterson(1990)put forward the possibility of‘temperature compensation time.’Under the same deformation mechanism,temperature is elevated and time prolonged for equivalent rock creep.In this way,shallow crust rock deformation at 700°C and strain rate of 10-8/s is simulated by conditions of 100°C and strain rate of 10-14/s.

The transition relationship is reasonable theoretically,but strain rate and temperature are both important parameters for the transition of rheological mechanisms.When temperature and strain rate are changed,how do we ensure the rheological mechanism has not been changed?As we know,rock easily undergoes cataclastic failure at low temperature,which is very different from crystal plastic deformation at high temperature.Besides,at high temperatures,crystal dynamic recovery and recrystallization will occur.Moreover,high strain is characterized by dislocation creep;low strain rate by diffusion creep or superplastic flow.In addition,strain rate increase will affect mechanical deformation behavior,peak strength,and elastic parameter values of limestone,and may lead to augmenting or delaying rheological behavior.

Laboratory creep experimental results of rocks and minerals under relatively wide conditions include a wide variety of deformation mechanisms;related to power flow law is the ‘average flow law’(Gleason and Tullis 1995).

Finally,there is a span of time and space difference between experimental research and field rock deformation.Natural rocks exposed in the surface need a big span of time and undergo a series of weathering processes.Natural rock deformation and failure characteristics cannot be reliably simulated in the laboratory.Tondi et al.(2006)found widespread localized deformation bands in granular limestone mountains in Italy.Rath et al.(2011)found an extensive deformation zone in large-porosity limestone.However,to date,laboratory results reported in the literature find few deformation bands.

Despite these practical problems,it is possible to use rheological results at high temperature and pressure to explain geological phenomena.The key to application of these results is to more closely approximate real geological conditions in the laboratory to garner evidence of the deformation characteristics of the lithosphere.With the deformation mechanism, flow law,and micro fabric at experimental temperature and pressure equal to the lithosphere,the experimental condition,deformation mechanism,and micro fabric should been seen as an organic whole.Based on the micro fabric,we can extrapolate the deformation mechanism and understand lithospheric rheological properties.In this way there is little deviation.So in the future,our view will only be changed from the perspective of rock deformation in the laboratory,and attempts will be made to establish a relationship with the field observations to gain complementary insights and a deeper understanding of deformation mechanics,simulate the natural rock deformation process,and elucidate the natural laws.

4.3 The uniform strength criterion for shearenhanced compaction deformation

The Mohr–Coulomb strength criterion can well solve problems of limestone failure in a brittle regime.In halfbrittle or half-ductility regimes there are various failure mechanisms and strength criterion equations,due to complex external conditions and variations in the rock itself,and it is difficult to set up a unified strength theory equation.In particular,for limestone with higher porosity(>3%)at room temperature and high confining pressure,researchers have discovered a new inelastic compression deformation.The plastic pore damage model and bimodal pore model were proposed,and the Hertz theory(for sandstone)and Drucker–Prage strength criterion conjured in a failed attempt to qualitatively and quantitatively analyze the mechanism.While research suggests the dual porosity model is well-adapted to limestone of 3–30%porosity,and the equation matches well with test data,neither is suitable for higher porosity(due to discontinuous deformation characteristics of the compression shear zone).

What are the adaptive conditions of the dual porosity model?Is there a better model and strength criterion to satisfy initial stress conditions for shear-enhanced compaction deformation regardless of porosity?A more appropriate micromechanical model should take into account the geometric complexity of the rock microstructure(pore shape,grain size distribution,etc.).It would therefore require a very accurate description of the rock microstructure using techniques such as mercury porosimetry,and further quantitative microstructural analyses such as computed tomography(CT).Collapsed pores and crushed particles are a prominent formation feature of higher porosity limestone,and its failure characteristic is similar to the discontinuous compression band of sandstone.But can the sandstone Different Element Model simulate the limestone failure process?Future study can help answer this question.

4.4 Test equipment

Rock mechanical test machines have gradually evolved from the immeasurable radial strain of the original Paterson type(Paterson 1970,1990)or improved Paterson type(Paterson and Olgaard 2000;Paterson and Wong 2005;Shao et al.2011;Li et al.2013),to the Heard type(Peach et al.2001;Chester et al.2004),Griggs or improved Griggs equipment(Griggs 1967;Tullis and Tullis 2013;Tingle et al.1993),and two big rock mechanics test systems—MTS(Lau and Chandler 2004;Zhu et al.2007;Liu et al.2009)and RMT(Ge and Zhou 1994).MTS and RMT are now frequently used in the laboratory for rock mechanics engineering.Their function is relatively complete,measurable accuracy is higher,and pore pressure and confining pressure are easily controlled and recorded.But the tests are confined to high temperature,and errors exist in measuring large deformation and radial strain when fluid is injected.Though there are other self-regulating or improved machines to study fluid effects on rock in the process of mechanical loading,experimental temperature and confining pressure are too low.

Fluid composition and concentration are detected and identified after the test under room temperature and atmospheric pressure.There are two defects in this method:first,in the process of quenching and unloading,secondary sediment may be generated by water flowing to the free surface of solid samples.Second,at high temperature and pressure,physical and chemical properties of water(e.g.pH)change significantly,and the concentration and state of fluid components may also change.Therefore,after quenching and stress release the product assessment results do not represent the experimental situation,resulting in experimental error that can be avoided by in situ measurement technology.A linear variable differential transducer inductive displacement sensor,resistance strain gauge,or annular strain band pasted on the sample surface is used to measure radial strain.It is challenging to insert the technology in the complex environment of high temperature,high pressure,and fluid;besides,the strain of large porosity rock is too high to measure accurately in the late failure stage,especially following fracture and breach.All these factors limit mechanical study of rock development,inspiring scientists and engineers to develop new technologies and invent new high-performance mechanical testing machines.

4.5 Superplastic flow mechanism research

Rheological phenomena of limestone is a focal problem on Earth’s surface and upper crust.In the past,superplastic flow was not fully understood,despite being an important phenomenon of rock deformation.Laboratory tests show that superplastic flow is confined to crystallization of particles and small grains(< 10 μm)in limestone.But Luo and Jin(2003)pointed out that superplastic deformation and the geological environment of natural rock differ from experimental conditions,so particle size can reach tens of microns,and sometimes up to hundreds of microns.

Hence,in future research on rock superplastic flow,(a)diffusion creep and superplastic flow must be further differentiated as grain boundary sliding is considered characteristic of both,making it is easy to confuse the two and(b)researchers should thoroughly and systematically explore the effect of superplastic deformation on continental dynamics and deep Earth material dynamics.

AcknowledgementsThe paper is supported by Strategic Priority Research Program(B)of the Chinese Academy of Sciences under Grant XDB18010401,and 135 Program of the Institute of Geochemistry,Chinese Academy of Sciences.

Alshayea N(2004)Effects of testing methods and conditions on the elastic properties of limestone rock.Eng Geol 74:139–156

Anselmetti FS,Luthi S,Eberli GP(1998)Quantitative characterization of carbonate pore systems by digital image analysis.AAPG Bull 82:1818–1836

Ashby MF,Sammis CG(1990)The damage mechanics of brittle solids in compression.Pure appl Geophys 133:489–521

Ashby MF,Verrall RA(1973)Diffusion-accommodated flow and superplasticity.Acta Metall 21:149–163

Backofen WA,Turner IR,Avery DH(1964)Superplasticity in an Al-Zn alloy.Trans ASM 57:980–990

Baechle GT,Colpaert A,Eberli GP,Weger RJ(2008)Effects of microporosity on sonic velocity in carbonate rocks.Lead Edge 27:1012–1018

Barber DJ,Wenk HR(1973)The microstructure of experimentally deformed limestones.J Mater Sci 8:500–508

Barnhoorn A,Bystricky M,Burlini L,Kunze K(2005)Post deformational annealing of calcite rocks.Tectonophysics 403:167–191

Baud P,Schubnel A,Wong TF(2000)Dilatancy,compaction,and failure mode in Solnhofen limestone.J Geophy Res 105:19289–19303

Baud P,Vinciguerra S,David C,Cavallo A,Walker E,ReuschléT(2009)Compaction and failure in high porosity carbonates:mechanical data and microstructural observations.Pure appl Geophys 166:869–898

Baud P,Rolland A,Heap M,Xu T,NicoléM,Ferrand T,ReuschléT,Toussaint R,Conil N (2016)Impact of stylolites on the mechanical strength of limestone.Tectonophysics 690:4–20

Boozer GD,Hiller KH,Serdengecti S(1963)Effects of pore fluids on the deformation behavior of rocks subjected to triaxial compression.Rock Mech 5:579–624

Borgomano JVM,Pimienta L,Fortin J,Guéguen Y(2017)Dispersion and attenuation measurements of the elastic moduli of a dualporosity limestone.J Geophy Res 122:2690–2711

Brace WF(1978)Volume changes during fracture and frictional sliding:a review.Pure appl Geophys 116:603–614

Brantut N(2015)Time-dependent recovery of microcrack damage and seismic wave speeds in deformed limestone.J Geophys Res 120:8088–8109

Brantut N,Heap MJ,Meredith PG,Baud P(2013)Time-dependent cracking and brittle creep in crustal rocks:a review.J Struct Geol 52:17–43

Brantut N,Heap MJ,Baud P,Meredith PG(2014)Mechanisms of time-dependent deformation in porous limestone.J Geophys Res 119:5444–5463

Byerlee JD(1968)Brittle–ductile transition in rocks.J Geophys Res 73:4741–4750

Casey M,Kunze K,Olgaard DL(1998)Texture of Solnhofen limestone deformed to high strains in torsion.J Struct Geol 20:255–267

Chao JQ,Luo YJ,Hou JJ,Zhen F(2009)The experimental study of limestone vertical wave velocity at high temperature.J Henan Univ Sci Technol Nat Sci 28:778–782(in Chinese with English Abstract)

Chen GL,Zhou RD(1991)Water effect on mechanical stress of rock macroscopic deformation and destruction of experimental research.J Geophys 34:335–342(in Chinese with English Abstract)

Chen SL,Feng XT,Li SJ(2003)Rock uniaxial compressive strength and the fracture characteristics of the chemical corrosion effect.Chin J Rock Mechan Eng 22:547–551(in Chinese with English Abstract)

Chen LJ,Zhao HB,Liu XL,Huang XG(2008)Sandstone and limestone thermal expansion force experimental study.J China Univ Min 37:670–674(in Chinese with English Abstract)

Chen LJ,He J,Chao JQ,Qin BD(2009a)Swelling and breaking characteristics of limestone under high temperatures.Min Sci Technol 1(9):503–507

Chen Y,Meng QS,Wang N(2009b)Carbonate rock strength characteristics experimental study.J Geotech Found 23:80–82(in Chinese with English Abstract)

Chen BR,Feng XT,Yao HY,Xu SC(2010)Limestone mechanical characteristics and neural network simulation study under water chemistry solution.Rock and Soil Mech 31:1173–1180(in Chinese with English Abstract)

Chester JS,Lenz SC,Chester FM,Lang RA(2004)Mechanisms of compaction of quartz sand at diagenetic conditions.Earth Planet Sci Lett 220:435–451

Choquette PW,Pray LC(1970)Geologic nomenclature and classification of porosity in sedimentary carbonates.AAPG Bull 54:207–244

Clarke DR,Lawn BR,Roach DH(1986)In fracture mechanics of ceramics.Springer,New York,pp 341–350

Córdoba P,Cherqaoui L,Garcia S,Maroto-Valer MM(2017)Effect of limestone and buffer solution in the aqueous speciation and pH of brines for CO2sequestration.Energy Proc 114:4865–4871

Covey-Crump SJ,Xiao WF,Mecklenburgh J,Rutter EH,May SE(2016)Exploring the influence of loading geometry on the plastic flow properties of geological materials:results from combined torsion+axial compression tests on calcite rocks.J Struct Geol 88:20–31

Curran JH,Carroll MM(1979)Shear stress enhancement of void compaction.J Geophys Res 84:1105–1112

Dautriat J,Bornert M,Gland N,Dimanov A,Raphanel J(2011)Localized deformation induced by heterogeneities in porous carbonate analysed by multi-scale digital image correlation.Tectonophysics 503:100–116

De Bresser JHP(2002)On the mechanism of dislocation creep of calcite at high temperature:inferences from experimentally measured pressure sensitivity and strain rate sensitivity of flow stress.J Geophys Res.https://doi.org/10.1029/2002JB001812

De Bresser JHP,Spiers CJ(1993)Slip systems in calcite single crystals deformed at 300–800 °C.J Geophys Res 98:6397–6409

De Bresser JHP,Spiers CJ(1997)Strength characteristics of the r,f,and c slip systems in calcite.Tectonophysics 272:1–23

De Bresser JHP,Evans B,Renner J(2002)On estimating the strength of calcite rocks under natural conditions.Geol Soci,London,Special Pub 200:309–329

Ding WX,Feng XT(2004)Testing study on mechanical effect for limestone under chemical erosion.Chin J Rock Mechan Eng 23:3571–3576(in Chinese with English Abstract)

Ding WX,Feng XT(2005)Limestone chemical damage effect of mesoscopic structure and quantitative research methods to explore chemical injury. Chin J Rock Mechan Eng 24:1283–1288(in Chinese with English Abstract)

Ercikdi B,Karaman K,Cihangir F,Yilmaz T,Aliyazicioglu S,Kesimal A(2016)Core size effect on the dry and saturated ultrasonic pulse velocity of limestone samples.Ultrasonics 72:143–149

Eslami J,Hoxha D,Grgic D(2012)Estimation of the damage of a porous limestone using continuous wave velocity measurements during uniaxial creep tests.Mech Mater 49:51–65

Evans B,Kohlstedt DL(1995)Rheology of rocks.Rock physics and phase relations:a handbook of physical constants.AGU,Washington,D.C.,pp 148–165

Evans B,Fredrich JT,Wong TF(1990)The Brittle–Ductile transition in rocks.Recent experimental and theoretical progress.AGU,Washington,D.C.,pp 1–20

Feng XT,Ding WX(2007)Experimental study of limestone microfracturing under a coupled stress, fluid flow and changing chemical environment.Int J Rock Mech Min Sci 44:437–448

Feng XT,Ding WX,Zhang DX(2009)Multi-crack interaction in limestone subject to stress and flow of chemical solutions.Int J Rock Mech Min Sci 46:159–171

Freund D,Rybacki E,Dresen G(2001)Effect of impurities on grain growth in synthetic calcite aggregates.Phys Chem Miner 28:737–745

Freund D,Wang ZC,Rybacki E,Dresen G(2004)High-temperature creep of synthetic calcite aggregates:influence of Mn-content.Earth Planet Sci Lett 226:433–448

Garcia-Rios M,Luquot L,Soler JM,Cama J(2015)Influence of the flow rate on dissolution and precipitation features during percolation of CO2-rich sulfate solutions through fractured limestone samples.Chem Geol 414:95–108

Ge XR,Zhou BH(1994)The new progress of indoor rock mechanics test device-RMT-64 rock mechanics test system.Rock and Soil Mech 15:50–56(in Chinese with English Abstract)

Ghabezloo S,Sulem J,Guedon S,Martineau F(2009)Effective stress law for the permeability of a limestone.Int J Rock Mech Min Sci 46:297–306

Gleason GC,Tullis J(1995)A flow law for dislocation creep of quartz aggregates determined with the molten salt cell.Tectonophysics 247:1–23

Głowacki A,Selvadurai APS(2016)Stress-induced permeability changes in Indiana limestone.Eng Geol 215:122–130

Gratier JP,Dysthe DK,Renard F(2013)The role of pressure solution creep in the ductility of the Earth’s upper crust.Adv Geophys 54:47–179

Grgic D(2011)Influence of CO2on the long-term chemomechanical behavior of an oolitic limestone.J Geophys Res 116:1–22

Griggs DT(1936)Deformation of rocks under high confining pressures:I.Experiments at room temperature.J Geol 44:541–577

Griggs DT(1967)Hydrolytic weakening of quartz and other silicates.Geophys J Royal Astron Soc 14:19–31

Griggs DT,Turner FJ,Heard HC(1960)Deformation of rocks at 500 to 800 °C.Geol Soc Am Mem 79:39–104

Guo ZH,Zhu ZD,Hua JN,Zhang AJ,Fang Z(2001)Limestone strength characteristics of experimental analysis and mathematical simulation.J Undergr Sp 21:280–286(in Chinese with English Abstract)

Han B,Xie S,Shao J(2016)Experimental investigation on mechanical behavior and permeability evolution of a porous limestone under compression.Rock Mech Rock Eng 49:3425–3435

Handin J,Hager RV Jr,Friedman M,Feather JN(1963)Experimental deformation of sedimentary rocks under confining pressure:pore pressure tests.AAPG Bull 47:717–755

Heard HC(1960)Transition from brittle fracture to ductile flow in Solenhofen limestone as a function of temperature,confining pressure,and interstitial fluid pressure.Geol Soc Am Mem 79:193–226

Heard HC(1963)Effects of large changes in strain rate in the experimental deformation of Yule marble.J Geol 71:162–195

Heard HC,Raleigh CB(1972)Steady-state flow in marble at 500°to 800°°C.Geolo Soc Am Bull 83:935–956

Horii H,Nemat-Nasser S(1986)Brittle failure in compression:splitting,faulting and brittle-ductile transition.Philos Trans R Soc London,Ser A 319:337–374

Hu JQ,Li WB(2010)Criterion of rock strength theory discussion.J Inf Sci Technol 43:29–29(in Chinese with English Abstract)

Huang W,Zhou WB,Chen P(2006)Water-rock chemical mechanics on the effect of study.J West Explor Eng 18:122–125(in Chinese with English Abstract)

Huang ZP,Zhang Y,Sun YK,Liu CY,Wu WD(2016)Mechanical and acoustic characteristics of high temperature limestone with water cooling treatment.J Cent South Univ Sci Technol 47:4181–4189(in Chinese with English Abstract)

Hutchinson AJ,Johnson JB,Thompson GE,Wood GC,Sage PW,Cooke MJ(1993)Stone degradation due to wet deposition of pollutants.Corros Sci 34:1881–1898

Iscan A,Kok M,Bagci A(2006)Estimation of permeability and rock mechanical properties of limestone reservoir rocks under stress conditions by strain gauge.J Pet Sci Eng 53:13–24

Jenkins CHM(1928)Strength of Cd-Zn and Sn-Pb alloy solder.J Inst Metals 40:21–39

Ji SC,Xia B (2002)Rheology of polyphase earth materials polytechnic.Polytechnic International Press,Montreal,p 259

Ji YT,Baud P,Vajdova V,Wong TF(2012)Characterization of pore geometry of Indiana limestone in relation to mechanical compaction.Oil Gas Sci Technol 67:753–775

Kemeny JM,Cook NGW(1991)Micromechanics of deformation in rocks.Toughening Mech Quasi-Brittle Mater 195:155–188

Kennedy LA,Logan JM(1998)Microstructures of cataclasites in a limestone-on-shale thrust fault:implications for low-temperature recrystallization of calcite.Tectonophysics 295:167–186

Khadra WM,Stuyfzand PJ,van B BM(2017)Hydrochemical effects of saltwater intrusion in a limestone and dolomitic limestone aquifer in Lebanon.Appl Geochem 79:36–51

Lau JSO,Chandler NA(2004)Innovative laboratory testing.Int J Rock Mech and Min Sci 41:1427–1445

Le Guen Y,Renard F,Hellmann R,Brosse E,Collombet M,Tisserand D,Gratier JP(2007)Enhanced deformation of limestone and sandstone in the presence of high Pco2fluids.J Geophys Res 112:1–25

Li JF,Song MS,Shao TB,Xia Y,Wang Q,Zhou W(2013)Correction for the axial deformation data recorded by patersontype gas medium high-pressure high-temperature machine.Geotecton et Metallog 37:127–137(in Chinese with English Abstract)

Lin X,Zhang ZY(2009)A preliminary study on the basic mechanical properties at high temperature environment of limestone.J Metal Mine,29–31(in Chinese with English Abstract)

Lisabeth HP,Zhu W(2015)Effect of temperature and pore fluid on the strength of porous limestone.J Geophys Res 120:6191–6208

Liteanu E,Spiers CJ(2009)Influence of pore fluid salt content on compaction creep of calcite aggregates in the presence of supercritical CO2.Chem Geol 265:134–147

Liteanu E,Spiers CJ,De Bresser JHP(2013)The influence of water and supercritical CO2on the failure behavior of chalk.Tectonophysics 599:157–169

Liu YQ(2011)Limestone structural analysis under high temperature and two-way constraints.China Sci Technol Overv,243(in Chinese with English Abstract)

Liu JL,Liu ZH(2000)The upper crustal rock mass deformation and calcite rocks of low temperature flow.World Geol 19:209–216(in Chinese with English Abstract)

Liu JL,Weber K(2002)Low-temperature plasticity of naturally deformed calcite rocks.Acta Geol Sinica 76:292–299

Liu JL,Ma LJ,Cui YC,Guan HM(2001)Role of fluid for limestone of brittle-ductile transition on the earth’s crust environment.Geol Fron 8:171–176

Liu JS,Polak A,Elsworth D,Grader A(2005)Dissolution-induced preferential flow in a limestone fracture.J Contam Hydrol 78:53–70

Liu RH,Feng WG,Long L,Liu WG,Shan YM(2009)Dense carbonate rock mechanics and acoustics experiment study.J Daqing Pet Geol Dev 27:131–135(in Chinese with English Abstract)

Llana-Fúnez S,Rutter EH(2005)Distribution of non-plane strain in experimental compression of short cylinders of Solnhofen limestone.J Struct Geol 27:1205–1216

Llana-Fúnez S,Rutter EH(2008)Strain localization in direct shear experiments on Solnhofen limestone at high temperature-effects of transpression.J Struct Geol 30:1372–1382

Llana-Fúnez S,Rutter EH(2014)Effect of strain geometry on the petrophysical properties of plastically deformed aggregates:experiments on Solnhofen limestone.Geol Soc Lond Spec Pub 394:167–187

Luo Q (2008)Carbonate rock stress-strain relationship and microstructure analysis. Chin J Rock Mechan Eng 27:2656–2660(in Chinese with English Abstract)

Luo ZY,Jin ZM(2003)Superplastic deformation of roks and its dynamic implication.Geol Sci Technol Inf 22:17–23

Mallet C,Fortin J,Guéguen Y,Bouyer F(2015)Role of the pore fluid in crack propagation in glass.Mech Time-Depend Mater 19:117–133

Mogi K(1967)Effect of the intermediate principal stress on rock failure.J Geophys Res 72:5117–5131

Myer LR,Kemeny JM,Zheng Z(1992)Extensile cracking in porous rock under differential compressive stress.Appl Mech Rev 45:263–280

Nasseri MHB,Goodfellow SD,Wanne T,Young RP(2013)Thermohydro-mechanical properties of Cobourg limestone.Int J Rock Mech Min Sci 61:212–222

Nicolas A,Fortin J,Regnet JB,Dimanov A,Guéguen Y(2016)Brittle and semi-brittle behaviours of a carbonate rock:influence of water and temperature.Geophys J Int 206:438–456

Nicolas A,Fortin J,Regnet JB,Verberne BA,Plümper O,Dimanov A,Spiers CJ,Guéguen Y(2017)Brittle and semibrittle creep of Tavel limestone deformed at room temperature.J Geophys Res 122:4436–4459

Nie G,Chen JZ(2016)Experimental study of AE serials of limestone under uniaxial compression.Value Eng 119:119–123(in Chinese with English Abstract)

Olsson WA(1974)Microfracturing and faulting in a limestone.Tectonophysics 24:277–285

Olsson WA,Peng SS(1976)Microcrack nucleation in marble.Int J Rock Mech Min Sci Geomech Abstr 13:53–59

Paterson MS(1970)A high-pressure,high-temperature apparatus for rock deformation.Int J Rock Mech Min Sci 7:517–526

Paterson MS(1990)Rock deformation experimentation.In:the Brittle-Ductile transition in rocks. AGU, Washington,pp 187–194

Paterson MS,Olgaard DL(2000)Rock deformation tests to large shear strains in torsion.J Struct Geol 22:1341–1358

Paterson MS,Wong TF(2005)Experimental rock deformation-the brittle field,vol 2.Springer,Berlin,pp 147–163

Peach CJ,Spiers CJ,Trimby PW(2001)Effect of confining pressure on dilatation,recrystallization,and flow of rock salt at 150°C.J Geophys Res 106:13315–13328

Peng B,Chen GH(2002)Several important effect of tectonics- fluid in the process of geology.Geol Rev 48:495–504(in Chinese with English Abstract)

Pittman ED(1971)Microporosity in carbonate rocks:geological notes.AAPG Bull 55:1873–1881

Qin BD,Chao JQ,Chen LJ,Dun ZL(2009)The fabric analysis of limestone under high temperature and two-way constraints.J Min Saf Eng 26:244–248(in Chinese with English Abstract)

Rath A,Exner U,Tschegg C,Grasemann B,Laner R,Draganits E(2011)Diagenetic control of deformation mechanisms in deformation bands in a carbonate grainstone.AAPG Bull 95:1369–1381

Regnet JB,David C,Fortin J,Robion P,Makhlou fiY,Collin P-Y(2015)Influence of microporosity distribution on the mechanical behavior of oolithic carbonate rocks.Geomech Energy Environ 3:11–23

Renner J,Evans B(2002)Do calcite rocks obey the power-law creep equation?Geol Soc Lond Spec Pub 200:293–307

Renner J,Rummel F (1996)The effect of experimental and microstructural parameters on the transition from brittle failure to cataclastic flow of carbonate rocks. Tectonophysics 258:151–169

Renner J,Evans B,Siddiqi G(2002)Dislocation creep of calcite.J Geophy Res 107:1–16

Robertson EC(1955)Experimental study of the strength of rocks.Geolo Soc Am Bull 66:1275–1314

Røyne A,Bisschop J,Dysthe DK(2011)Experimental investigation of surface energy and subcritical crack growth in calcite.J Geophys Res.https://doi.org/10.1029/2010JB008033

Rutter EH(1972a)The effects of strain-rate changes on the strength and ductility of Solenhofen limestone at low temperatures and confining pressures.Int J Rock Mech Min Sci 9:183–189

Rutter EH (1972b)The influence of interstitial water on the rheological behaviour of calcite rocks.Tectonophysics 14:13–33

Rutter EH(1974)The influence of temperature,strain rate and interstitial water in the experimental deformation of calcite rocks.Tectonophysics 22:311–334

Rutter EH(1995)Experimental study of the influence of stress,temperature,and strain on the dynamic recrystallization of Carrara marble.J Geophy Res 100:24651–24663

Rutter EH,Casey M,Burlini L(1994)Preferred crystallographic orientation development during the plastic and superplastic flow of calcite rocks.J Struct Geol 16:1431–1446

Rybacki E,Paterson MS,Wirth R,Dresen G(2003)Rheology of calcite-quartz aggregates deformed to large strain in torsion.J Geophys Res.https://doi.org/10.1029/2002JB001833

Rybacki E,Janssen C,Wirth R,Chen K,Wenk HR,Stromeyer D,Dresen G(2011)Low-temperature deformation in calcite veins of SAFOD core samples(San Andreas Fault)-Microstructural analysis and implications for fault rheology.Tectonophysics 509:107–119

Rybacki E,Evans B,Janssen C,Wirth R,Dresen G(2013)Influence of stress,temperature,and strain on calcite twins constrained by deformation experiments.Tectonophysics 601:20–36

Sammis CG,Ashby MF(1986)The failure of brittle porous solids under compressive stress states.Acta Metall 34:511–526

Schmid SM (1976)Rheological evidence for changes in the deformation mechanism of Solenhofen limestone towards low stresses.Tectonophysics 31:21–28

Schmid SM(1982)Laboratory experiments on rheology and deformation mechanisms in calcite rocks and their application to studies in the field.Geologisches Institut der Eidg.Technische Hochschule und der Universität Zürich

Schmid SM,Boland JN,Paterson MS(1977)Superplastic flow in fine grained limestone.Tectonophysics 43:257–291

Schmid SM,Paterson MS,Boland JN(1980)High temperature flow and dynamic recrystallization in Carrara marble.Tectonophysics 65:245–280

Schubnel A,Fortin J,Burlini L,Guéguen Y(2005)Damage and recovery of calcite rocks deformed in the cataclastic regime.Geol Soc Lond Spec Pub 245:203–221

Selvadurai APS,Głowacki A(2017)Stress-induced permeability alterations in an argillaceous limestone.Rock Mech Rock Eng 50:1079–1096

Selvadurai APS,Najari M(2017)The thermo-hydro-mechanical behavior of the argillaceous Cobourg limestone.J Geophys Res 122:4157–4171

Shao TB,Ji SC,Li JF,Wang Q,Song MS(2011)Paterson gas medium high-pressure high-temperature testing system and its applications in rheology of rocks.Geotecto et Metallog 35:457–476(in Chinese with English Abstract)