中碳铬钨渗氮轴承钢旋转弯曲疲劳性能研究

2018-05-14程世超魏慧君孙世清王松王瑞阳崔博帅尉念伦

程世超 魏慧君 孙世清 王松 王瑞阳 崔博帅 尉念伦

摘 要:针对轴承钢失效形式主要为疲劳破坏的问题,对中碳铬钨渗氮轴承钢进行旋转弯曲疲劳(RBF)试验及分析。分析轴承钢经调质处理(880 ℃+540 ℃)后的组织,再经RBF试验后疲劳断口和渗氮处理的作用,还分析了非金属夹杂物对轴承钢RBF的影响,构建了非金属夹杂物深度和尺寸对中碳铬钨渗氮轴承钢RBF极限强度影响的模型。实验结果表明:试验钢调质处理后,组织为回火索氏体,主要析出M6C型和M23C6型碳化物,力学性能优良,RBF极限强度达到729 MPa;疲劳源分为表面缺陷和内部非金属夹杂物,表面缺陷主要包括非金属夹杂物脱落形成的凹坑以及机加工留下的刀痕,非金属夹杂物主要为镁铝酸盐;轴承钢在NH3渗氮气氛中560 ℃恒温保持25 h,渗氮层厚度达360 μm以上,渗氮工艺合适。研究结果对中碳铬钨渗氮轴承钢的发展及其疲劳性能的提高有一定的参考价值。

关键词:黑色金属及其合金;渗氮轴承钢;旋转弯曲疲劳;表面缺陷;非金属夹杂物

中图分类号:TG156.8+2 文献标志码:A

文章编号:1008-1542(2018)04-0365-07doi:10.7535/hbkd.2018yx04011

Abstract:Aiming at the problem that the failure mode of bearing steels is mainly fatigue failure, RBF (rotating bending fatigue) test of medium carbon Cr and W nitriding bearing steel and analysis are conducted for the medium carbon Cr and W nitriding bearing steel. The microstructure of the bearing steel after hardening and tempering (880 °C+540 °C), the fatigue fracture after the RBF test and the effect of nitriding are analyzed. The ultimate strength influencing model of non-metallic inclusions and size on medium carbon Cr and W nitriding bearing steel RBF is established. The results of experiments show that the microstructure of the test steel after hardening and tempering is tempered sorbite, the main precipitations are M6C and M23C6 carbides, the mechanical properties are excellent and its fatigue limit is 729 MPa. Fatigue source are divided into surface defect cracking and the internal non-metallic inclusions cracking. Surface defects include the pits after the falling of non-metallic inclusions and the machining marks. Non-metallic inclusions are mainly magnesium aluminates. The bearing steel is kept at a constant temperature of 560 °C for 25 hours in NH3 nitrogen atmosphere, and the nitriding layer thickness is more than 360 μm, showing the nitriding process is suitable. The research has some reference value for the development of the medium carbon Cr and W nitriding bearing steel and the improvement of fatigue performance.

Keywords:black metal and its alloys seepage; nitrided bearing steel; rotating bending fatigue; surface defects; non-metallic inclusions

軸承钢被誉为钢中之王,质量要求高,是衡量国家工业化水平的标志之一[1-3]。疲劳断裂前形变小、不易察觉,是轴承的主要失效形式[4]。轴承钢拥有高强度、高硬度、优良的韧性、耐磨性和一定的耐热性,渗氮后性能进一步提高,在航空航天等重要传动方面有广泛的应用[5-6]。渗氮处理氮化层包含多种氮化物,表面形成压力层,硬度可达 900(HV)以上,氮化层具有优异的耐磨性、耐蚀性、抗咬合、抗擦伤能力及疲劳强度[7-9]。中碳轴承钢的特点是具有较好的强韧性能,屈强比高,在经过渗氮处理后,轴承表面具有一定的抗咬合、抗擦伤能力,且热处理过程变形小,使轴承精度更高[10]。中低碳钢的疲劳裂纹始于驻留滑移带、晶界或其他缺陷部位[11]。非金属夹杂物[12-13]和材料表面的加工缺陷对材料疲劳裂纹也具有非常重要的影响。MURAKAMI和ENDO等利用夹杂物等效投影面积模型给出了夹杂物尺寸对RBF(rotating bending fatigue)极限强度的影响,得出疲劳极限公式[14-18]。本文重点研究夹杂物深度对中碳铬钨渗氮轴承钢RBF强度的影响,并构建夹杂物深度与尺寸对中碳铬钨渗氮轴承钢RBF性能影响的模型。

1 实验材料及方法

实验材料为真空感应冶炼的中碳铬钨轴承钢,化学成分如表1所示。

将Φ60 mm的棒料按GB/T4337—2008 《金属旋转弯曲疲劳试验方法》加工成Φ14.5 mm的圆棒状RBF试样毛坯,试样工作区直径:(5.97±0.03)mm。

调质处理工艺:880 ℃×50 min+油淬(OQ)+540 ℃×125 min+空冷(AC)。

RBF Test:PQ1-6型RBF Test机,四点加载,应力比R=-1,终止实验周次N=107。

金相腐蚀剂为4%硝酸酒精溶液,蔡司显微镜拍摄宏观断口形貌,日立S-4300冷场发射SEM观察纳米级微光组织和断口,TEM分析析出相和板条形貌。

渗氮工艺:离子渗氮炉,NH3为渗氮剂,560 ℃恒温保持25 h,研究渗氮层结构及厚度。

2 实验结果和分析

2.1 试验钢的组织和性能

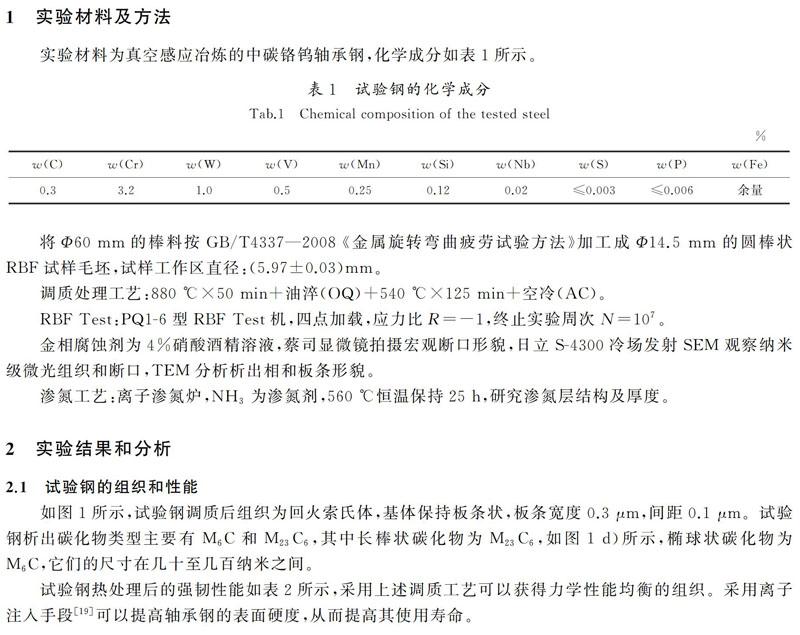

如图1所示,试验钢调质后组织为回火索氏体,基体保持板条状,板条宽度0.3 μm,间距0.1 μm。试验钢析出碳化物类型主要有M6C和M23C6,其中长棒状碳化物为M23C6,如图1 d)所示,椭球状碳化物为M6C,它们的尺寸在几十至几百纳米之间。

试验钢热处理后的强韧性能如表2所示,采用上述调质工艺可以获得力学性能均衡的组织。采用离子注入手段[19]可以提高轴承钢的表面硬度,从而提高其使用寿命。

中碳铬钨渗氮轴承钢氮化层分为化合物层和氮化层,如图2所示。化合物层主要由 Fe3N和Fe4N构成,厚度最薄达9.2 μm,最厚达16 μm。渗层硬度达1 060 HV,有效渗层平均达371.5 μm,渗氮性能优异。此外,渗氮后进行冷处理[20]可进一步提高材料的强硬性。

2.2 试验钢的S-N疲劳曲线

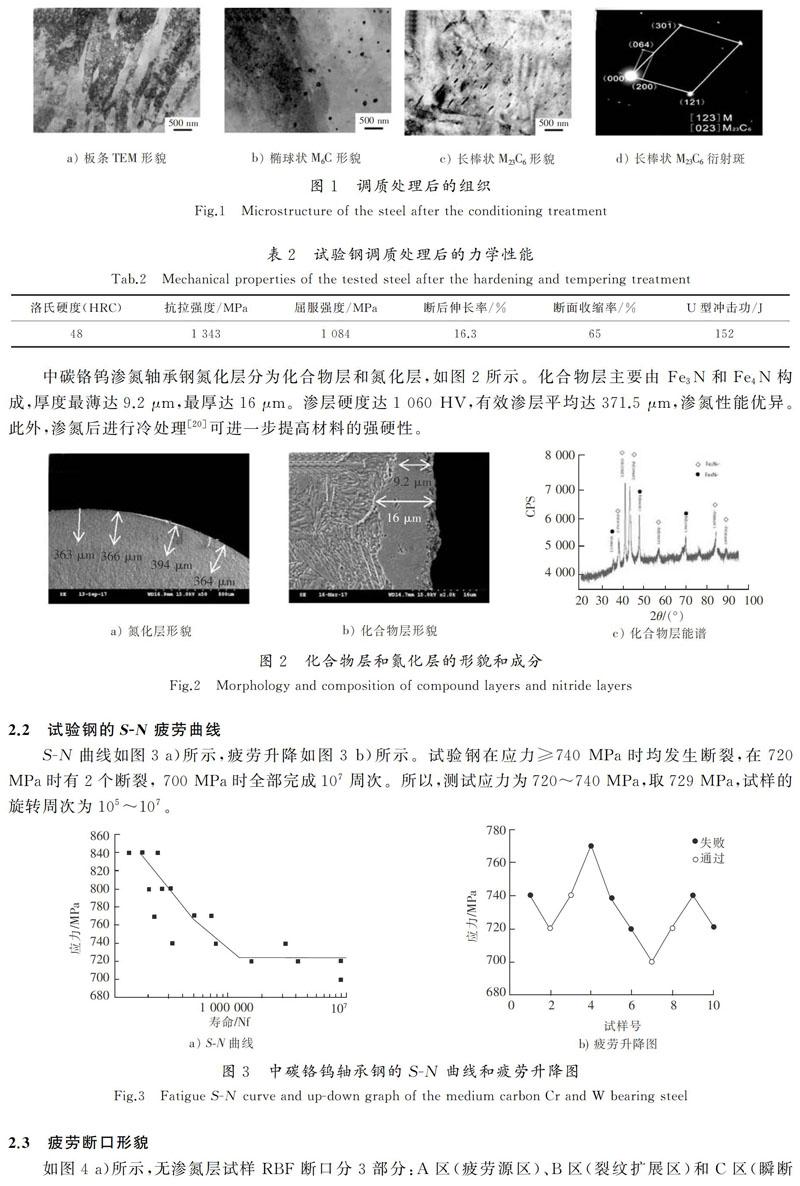

S-N曲线如图3 a)所示,疲劳升降如图3 b)所示。试验钢在应力≥740 MPa时均发生断裂,在720 MPa时有2个断裂, 700 MPa时全部完成107周次。所以,测试应力为720~740 MPa,取729 MPa,试样的旋转周次为105~107。

2.3 疲劳断口形貌

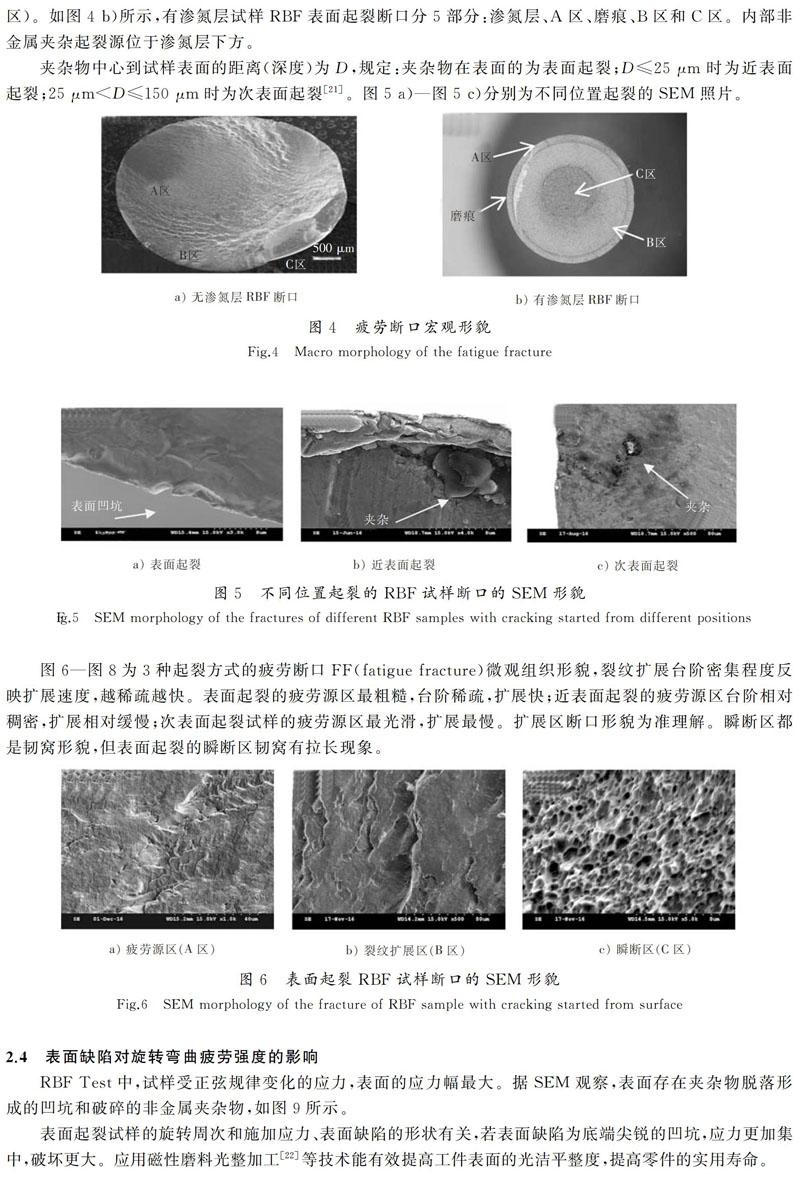

如图4 a)所示,无渗氮层试样RBF断口分3部分:A区(疲劳源区)、B区(裂纹扩展区)和C区(瞬断区)。如图4 b)所示,有渗氮层试样RBF表面起裂断口分5部分:渗氮层、A区、磨痕、B区和C区。内部非金属夹杂起裂源位于渗氮层下方。

夹杂物中心到试样表面的距离(深度)为D,规定:夹杂物在表面的为表面起裂;D≤25 μm时为近表面起裂;25 μm 图6—图8为3种起裂方式的疲劳断口FF(fatigue fracture)微观组织形貌,裂纹扩展台阶密集程度反映扩展速度,越稀疏越快。表面起裂的疲劳源区最粗糙,台阶稀疏,扩展快;近表面起裂的疲劳源区台阶相对稠密,扩展相对缓慢;次表面起裂试样的疲劳源区最光滑,扩展最慢。扩展区断口形貌为准理解。瞬断区都是韧窝形貌,但表面起裂的瞬断区韧窝有拉长现象。 2.4 表面缺陷对旋转弯曲疲劳强度的影响 RBF Test中,试样受正弦规律变化的应力,表面的应力幅最大。据SEM观察,表面存在夾杂物脱落形成的凹坑和破碎的非金属夹杂物,如图9所示。 表面起裂试样的旋转周次和施加应力、表面缺陷的形状有关,若表面缺陷为底端尖锐的凹坑,应力更加集中,破坏更大。应用磁性磨料光整加工[22]等技术能有效提高工件表面的光洁平整度,提高零件的实用寿命。 3 结 语 1)中碳铬钨渗氮轴承钢调质处理(880 ℃+540 ℃)后基体为回火索氏体,并析出长棒状M23C6型碳化物和椭球状M6C型碳化物。 2)中碳铬钨渗氮轴承钢在NH3渗氮气氛中560 ℃恒温保持25 h,氮化层厚度达360 μm以上,渗层硬度达1 060(HV)。渗氮层分为化合物层和扩散层,化合物层主要由 Fe3N和Fe4N构成,渗氮性能优异。 3)中碳铬钨渗氮轴承钢的旋转弯曲疲劳破坏裂纹源有表面缺陷和内部夹杂物(镁铝酸盐)。表面缺陷分为表层夹杂物(Al2O3,MgO,CaOH和SiO2)脱落形成的凹坑和机加工遗留的凹痕。 4)中碳铬钨渗氮轴承钢的旋转弯曲疲劳强度预测模型为σw′(R)=1.71D0.08(H+120)/(πd/2)1/6。5)减小钢中的非金属夹杂物,能有效提高钢的旋转弯曲疲劳强度,但无限的追求钢的洁净度会导致生产成本大幅度提高。控制夹杂物在一定深度下(>20 μm),可有效降低夹杂物导致的疲劳破坏。 6)有关中碳铬钨渗氮轴承钢渗氮后的组织和力学性能研究不足,下一步工作的重点是对此进行深入的探索,并与无渗氮处理进行对比分析。 参考文献/References: [1] 陈光军,毕立歌,薛迪,等.精密切削淬硬轴承钢GCr15的表面粗糙度预测与加工参数优化[J].河北科技大学学报,2012,33(2):119-121. CHEN Guangjun, BI Lige, XUE Di, et al. Surface roughness prediction and parameters optimization of precision turning hardened bearing steel GCr15[J].Journal of Hebei University of Science and Technology,2012,33(2):119-121. [2] JIAN Guan, WANG Liqin, ZHANG Zhiqiang, et al. Fatigue crack nucleation and propagation at clustered metallic carbides in M50 bearing steel[J]. Tribology International,2017,119:2017.10.016.

[3] WANG Fangfang, ZHOU Chungen, ZHENG Lijing, et al. Corrosion resistance of carbon ion-implanted M50NiL aerospace bearing steel[J]. Progress in Natural Science: Materials International, 2017,27(5):615-621.

[4] 徐鹤琴. 滚动轴承内部载荷序列分析与寿命计算[D]. 杭州:浙江大学,2017.

XU Heqin.Internal Load Sequence and Life Analysis of Rolling Bearing[D].Hangzhou:Zhejiang University,2017.

[5] 宗男夫,张慧,张兴中.国内外高品质轴承钢洁净化与均质化控制技术的进展[J].轴承,2017(1):48-53.

ZONG Nanfu, ZHANG Hui,ZHANG Xingzhong.Advances in control technologies for cleanliness and homogeneity of high-quality bearing steel at home and abroad[J].Bearing,2017(1):48-53.

[6] 张志慧. 高氮轴承钢组织演变与疲劳行为的研究[D]. 石家庄:河北科技大学,2017.

ZHANG Zhihui. The Study on Microstructure Evolution and Fatigue Behavior of High Nitrogen Bearing Steel[D].Shijiazhuang:Hebei University of Science and Technology, 2017.

[7] ADACHI S, UEDA N. Formation of expanded austenite on a cold-sprayed AISI 316L coating by low-temperature plasma nitriding[J]. Journal of Thermal Spray Technology, 2015, 24(8):1399-1407.

[8] ADACHI S, UEDA N. Surface hardness improvement of plasma-sprayed AISI 316L stainless steel coating by low-temperature plasma carburizing[J]. Advanced Powder Technology, 2013, 24(5):818-823.

[9] ISSARTEL C, BUSCAIL H, CAUDRON E, et al. The nitridation, a way to improve high temperature oxidation behaviour of AISI 304[J]. Materials Science Forum, 2008,595/596/597/598:987-994.

[10]楊晓蔚. 对轴承钢的一般认识和深入认识[J]. 轴承, 2012(9):54-58.

[11]何春双,罗志强,郭军,等.Cr4Mo4V高温轴承钢滚动接触表面特征与疲劳损伤机制[J].金属热处理,2018,43(2):1-7.

HE Chunshuang, LUO Zhiqiang,GUO Jun,et al.Rolling contact fatigue and surface characteristics of high temperature bearing steel Cr4Mo4V[J].Heat Treatment of Metals,2018,43(2):1-7.

[12]XU Haifeng, YU Feng, WANG Chang, et al.Comparison of microstructure and property of high chromium bearing steel with and without nitrogen addition[J].Journal of Iron and Steel Research,International, 2017,24(2):206-213.

[13]张志慧,杨卯生,孙世清,等.高氮不锈轴承钢碳化物演变规律及球化机制[J].材料热处理学报,2017,38(9):104-113.

ZHANG Zhihui, YANG Maosheng, SUN Shiqing, et al. Carbides evolution and spheroidization mechanism of high nitrogen stainless bearing steel[J]. Transactions of Materials and Heat Treatment, 2017, 38(9):104-113.

[14]NAKAGAWA A, SAKAI T, HARLOW G, et al. A probabilistic model on crack initiation modes of metallic materials in very high cycle fatigue[C]//21st European Conference on Fracture.Catania:[s.n.], 2016: 1199-1206.

[15]MURAKAMI Y, KODAMA S, KONUMA S. Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels. Ⅰ: Basic fatigue mechanism and evaluation of correlation between the fatigue fracture stress and the size and location of non-metallic inclusions[J]. International Journal of Fatigue,1989, 11(5): 291-298.

[16]MURAKAMI Y, USUKI H. Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels. Ⅱ: Fatigue limit evaluation based on statistics for extreme values of inclusion size[J]. International Journal of Fatigue, 1989, 11(5): 299-307.

[17]RADHAKRISHNAN V M, MUTOH Y. On fatigue crack growth in stage I[J]. Egf1, 2013, 10(1):1-11.

[18]MURAKAMI Y, ENDO M. Effects of hardness and crack geometry on ΔK_ of small cracks[J]. Journal of the Society of Materials Science, Japan, 1986, 35: 911-917.

[19]李文忠,劉振宇,张少波.离子注入对Cr4Mo4V轴承钢摩擦学性能的影响[J].河北科技大学学报,2010,31(2):97-99.

LI Wenzhong, LIU Zhenyu, ZHANG Shaobo. Effect of ion-implantation on tribological properties of Cr4Mo4V[J]. Journal of Hebei University of Science and Technology, 2010, 31(2): 97-99.

[20]孙世清,梁文瑞,张楠.9Cr5MoV钢的磁性分析与深冷处理[J].河北科技大学学报,2013,34(1):75-78.

SUN Shiqing, LIANG Wenrui, ZHANG Nan. Magnetic analysis and deep cryogenic treatment of 9Cr5MoV steel[J]. Journal of Hebei University of Science and Technology, 2013,34(1):75-78.

[21]侯杰,董建新,姚志浩.夹杂物对超高强度钢应力应变场的影响[J].工程科学学报,2017,39(7):1027-1035.

HOU Jie, DONG Jianxin, YAO Zhihao.Influence of inclusion on stress and strain fields in ultra-high strength steel[[J].Chinese Journal of Engineering,2017,39(7):1027-1035.

[22]马付建,陶德松,宫臣,等. 难加工合金材料复杂曲面磁性磨料光整加工技术[J].河北科技大学学报,2016,37(5):449-456.

MA Fujian, TAO Desong, GONG Chen, et al. Technology of magnetic abrasive finishing in machining of difficult-to-machine alloy complex surface[J]. Journal of Hebei University of Science and Technology, 2016,37(5): 449-456.