Spray freeze drying of small nucleic acids as inhaled powder for pulmonary delivery

2018-03-28WnlingLingAlnYChnMichelYChowFionLoYingshnQiuPhilipKwokJennyLm

Wnling Ling,AlnY.L.Chn,MichelY.T.Chow,Fion F.K.Lo,Yingshn Qiu,Philip C.L.Kwok,b,Jenny K.W.Lm,*

aDepartment of Pharmacology and Pharmacy,Li Ka Shing Faculty of Medicine,The University of Hong Kong,21 Sassoon Road,Pokfulam,Hong Kong,China

bAdvanced Drug Delivery Group,Faculty of Pharmacy,The University of Sydney,Building A15,Sydney,NSW

2006,Australia

1. Introduction

Small nucleic acid molecules such as small interfering RNA(siRNA)have a huge therapeutic potential to treat respiratory diseases including asthma,influenza,respiratory syncytial virus(RSV)infection and tuberculosis.[1–4]siRNA works by inhibiting specific gene expression through RNA interference(RNAi),which is a Nobel Prize-winning discovery[5].One of the barriers to the clinical application of siRNA therapeutics is delivery.Pulmonary delivery of siRNA could increase drug concentration at the site of action and minimize systemic exposure.It can also avoid serum interaction and nuclease degradation that occurs in the bloodstream.One interesting observation of pulmonary siRNA delivery is that naked siRNA(without the use of delivery vector)could mediate gene-silencing effect in animal models and clinical trials[6–10].It has been suggested that the presence of pulmonary surfactants in the airway could act as‘natural carrier’that facilitate the cellular uptake of siRNA.While the cellular uptake mechanism of naked siRNA remains to be elucidated,it is highly desirable to develop an inhaled formulation of siRNA that can maximize pulmonary delivery efficiency.

Dry powder formulation has several advantages over liquid aerosol formulation when it comes to macromolecules such as nucleic acids.Dry powder formulation offers better stability.It minimizes the exposure to high shear stress(during nebulisation)and avoids the compatibility issues with propellants(in metered dose inhaler(MDI)).Several particle engineering methods have been considered to be suitable for preparing inhaled powder formulation of nucleic acids,namely spray drying,spray freeze drying and supercritical fluid technology[11].It is the interest of this paper to explore the potential of spray freeze drying for preparing inhaled powder formulation of siRNA.

Spray freeze drying is a multi-step process that involves the spray freezing step and freeze drying step.The potential of spray freeze drying is being explored in the food industry and the pharmaceutical industry[12,13].During the spray freezing step,the drug dissolved or suspended in liquid is atomized into fine droplets which are frozen instantaneously by a cryogenic fluid,usually liquid nitrogen.Subsequently,the frozen particles are subjected to freeze drying,in which the solvents are sublimed at low temperature and pressure,leading to the formation of dried porous particles.The porous particles produced by spray freeze drying have made this technology an attractive method for preparing inhaled powder.Porous particles with large physical size and low density exhibit small aerodynamic size,which can promote high flowability.The small contact surface area to volume ratio leads to low cohesion force between particles,thereby facilitates dispersibility in air.In addition,porous particles have high specific surface area,thereby enhancing dissolution rate in the lungs.Spray freeze drying also holds several advantages over spray drying and supercritical fluid drying,which are also investigated in the preparation of inhaled powder formulation of small nucleic acid[14–16].In spray drying,materials are inevitably exposed to elevated temperature,which may lead to significant loss of biological activity.In addition,the recovery yield is relatively low.In supercritical fluid drying,the size and morphology of powders cannot be easily controlled,rendering the optimisation process extremely difficult.Spray freeze drying can avoid these problems associated with these two drying technologies[11].

Previously,our group has demonstrated the use of spray freeze drying technology to produce dry powder of DNA complexes that are suitable for inhalation[17].To the best of our knowledge,using spray freeze drying technology to produce siRNA,either with delivery vector or in its ‘naked’form,has not been reported.This study aimed to investigate the use of spray freeze drying to prepare inhaled dry powder formulation of siRNA,with mannitol employed as a bulking agent.Initially,herring sperm DNA(<50 base pairs),which has a size comparable to that of siRNA(21 base pairs),was used as model nucleic acids to examine how the solute concentrations and nucleic acids concentrations affect the physicochemical properties and aerosol performance of the spray freeze dried powder.Subsequently,the siRNA powder was prepared with the optimized formulation.The integrity of siRNA,the particle size distribution,morphology and the aerosol performance of the siRNA formulation were evaluated.

2. Materials and methods

2.1. Materials

Mannitol(Pearlitol 160C)was obtained from Roquette(Lestrem,France).siRNA targeting interleukin 10(IL-10)(antisense strand:5’-CAUUAAGGAGUCGGUUAGCUU-3’)was purchased from Integrated DNA Technologies Pte.Ltd.(Singapore)as custommade RNA duplexes.Herring sperm DNA,other reagents and solvents were purchased from Sigma(Poole,UK)and were of analytical grade or better.DNA was puri fied by ethanol precipitation before use.

2.2. Spray freeze drying of nucleic acid formulations

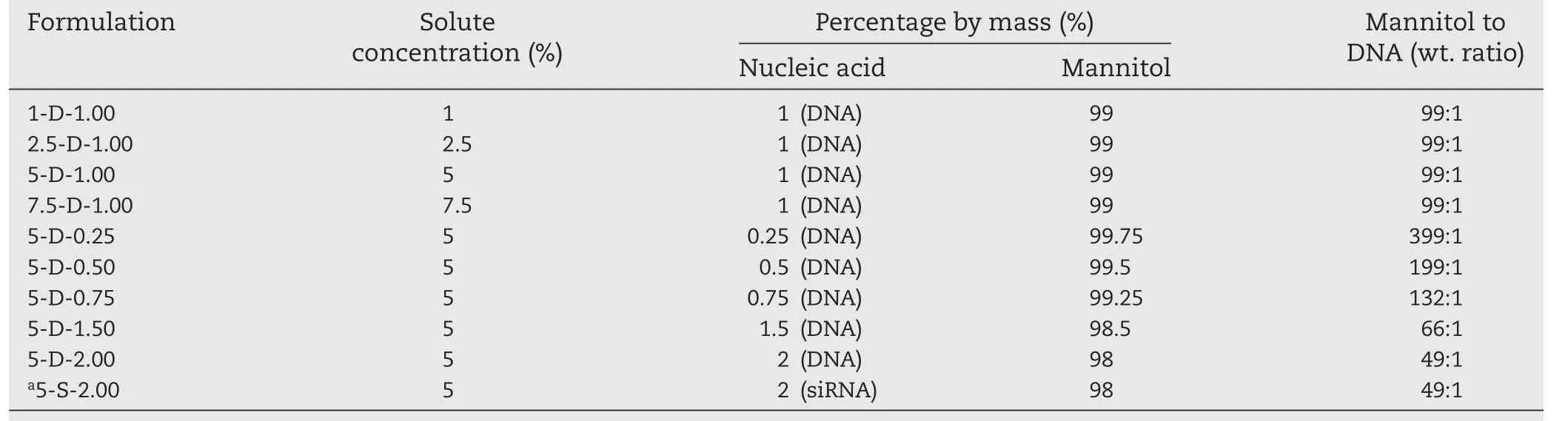

Table 1 shows the different formulations of mannitol/DNA or mannitol/siRNA solutions that were prepared in ultrapure water at solute concentrations ranging from 1%to 7.5%w/v.The spray freeze drying process is illustrated in Fig.1.The solutions(5 ml)were transferred into a syringe and fed to an ultrasonic atomiser nozzle(130K50ST,Sonaer®,Farmingdale,NY,USA)operating at 130 kHz powered by digital ultrasonic generator for atomisers(Sonaer®,NY,USA)at a controlled rate of 2 ml/min via a syringe pump.The atomised liquid droplets were collected in liquid nitrogen to allow instant freezing.The frozen particles were lyophilised.The samples were kept under vacuum(chamber pressure below 0.133 mBar)at −25 °C for 40 h,followed by secondary drying at 20°C for 8 h.The dried powders were collected and stored in dessicator with silica gel at ambient temperature until further analysis.The production yield was calculated by dividing the total mass of powder collected by the initial mass input.

2.3. Particle size distribution

The particle size distribution of the spray freeze dried powder was measured by laser diffractometer operated with the MicroLiquid Module(LS 13 320;Beckman Coulter,Pasadena,USA).Approximately 5 mg of powders were suspended in 7.5 ml of chloroform.The suspended particles were de-aggregated by ultra-sonication for approximately 10 s.Immediately after deaggregation,the suspension was added to the sample compartment dropwise until the optimal obscuration(8%–12%)was achieved.The stirrer was switched on to minimize re-aggregation.The refractive index of mannitol was set at 1.544,and the attenuation coefficient(imaginary refractive index)was set at 0.1.The median(D50),the tenth(D10)and the ninetieth(D90)percentile of the volumetric diameter were reported.The width of the size distribution was expressed in terms of the span:(D90–D10)/D50.The particle size of each formulation was measured in triplicates.

Table 1–Different spray freeze dried formulation containing mannitol and nucleic acids(DNA or siRNA).

2.4. Morphology study

The morphology of the spray freeze dried powder was observed by field emission scanning electron microscopy(Hitachi S-3400N,Tokyo,Japan)at 10 kV.The powders were sprinkled onto carbon stick tape that was mounted on SEM stubs.Excess powders were removed by blowing with clean compressed air.The powders were sputter coated with a sputter coater(Baltec SCD 005 Sputter Coater,Bal-Tec GmbH,Schalksmühle,Germany)with approximately 11 nm gold-palladium alloy in two cycles(60 s each)to avoid overheating.

2.5. Aerosol performance

The aerosol performance of the spray freeze dried powder was evaluated by a Next Generation Impactor(NGI;Copley,Nottingham,United Kingdom)in accordance to the British Pharmacopoeia 2017[18].For each dispersion,approximately 4.0±0.5 mg of powders were loaded in a size 3 hydroxypropyl methylcellulose capsules(Capsugel,West Ryde,NSW,Australia),which were placed in a Breezhaler® (Novartis Pharmaceuticals,Hong Kong).The dispersion rate and duration were 100 l/min and 2.4 s,respectively.Prior to each dispersion,a thin layer of silicon grease(Dry Film Silicone Lubricant,LPS Laboratories,GA,USA)was coated onto the impactor stages to minimize particle bounce.After dispersion,the powders deposited on the inhaler and NGI stages were collected by rinsing with 4 ml of ultrapure water.For each powder formulation,powder dispersions were performed in triplicates.The emitted fraction(EF)was de fined as the mass of powders(as calculated with the assayed mannitol)that exited the inhaler with respect to the recovered dose.The fine particle fraction(FPF)was de fined as the mass of powders with aerodynamic diameter<5.0µm with respect to the recovered dose.

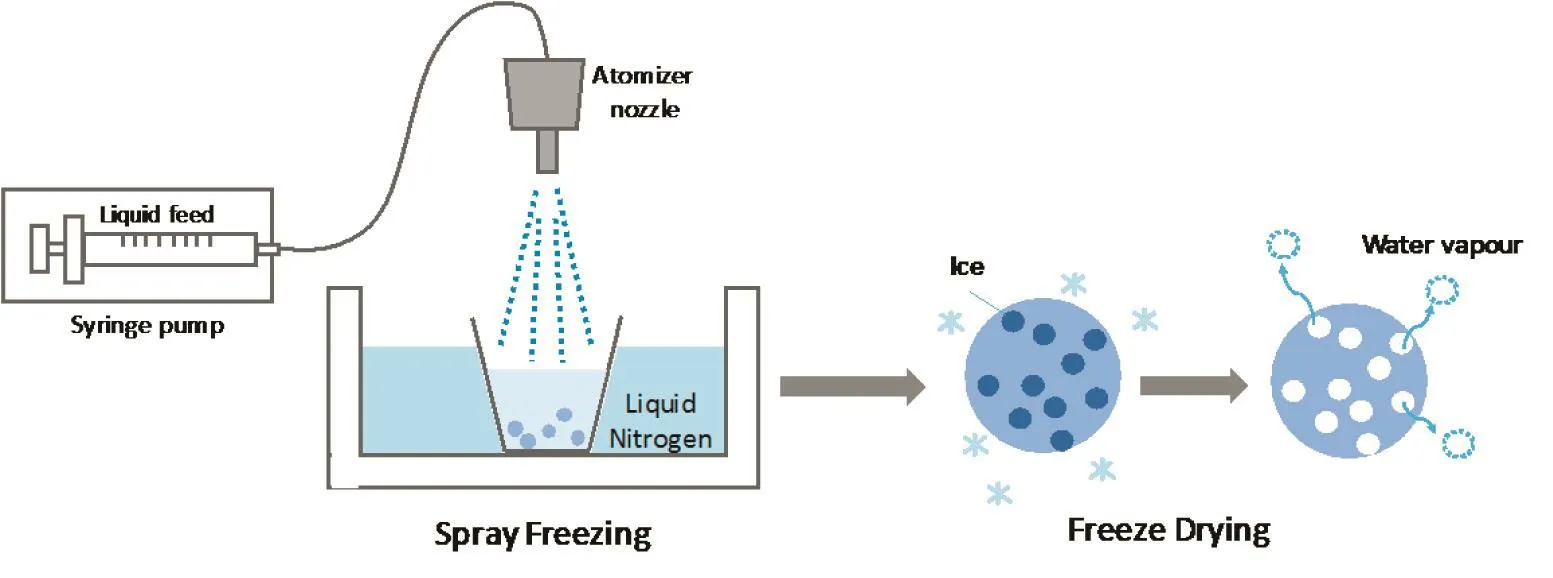

Fig.1–Schematic diagram of spray freeze drying process.The feed liquid containing mannitol and nucleic acids is atomised through the atomizer nozzle into fine droplets.The feeding rate is controlled by the syringe pump.A conducting collector containing liquid nitrogen was immersed in an insulating container which is half- filled with liquid nitrogen.The droplets are instantaneously frozen when they are in contact with the liquid nitrogen in the collector.The frozen particles are then subjected to freeze drying in which ice crystals are sublimed to vapour at low temperature and pressure,leading to the formation of dried porous particles.

2.6. High performance liquid chromatography(HPLC)

Quantification of mannitol in the dispersed samples in NGI was performed using HPLC(Agilent 1260 Infinity;AgilentTechnologies,Santa Clara,USA)with a refractive index detector(G1362A;Agilent Technologies).The injection volume was 50µl and the samples were passed through an ion-exchange ligand-exchange column(Agilent Hi-Plex Ca,7.7 mm×300 mm,8µm;Agilent Technologies)maintained at 75°C with ultrapure water running at 0.6 ml/min as the mobile phase.The actual mass of powder deposited in various stages of the NGI was calculated based on the formulation compositions.For siRNA-containing samples,the integrity of siRNA was studied by HPLC using column for ion-pair reversed-phase separation(AdvanceBio Oligonucleotide,2.1 mm×50 mm,2.7µm;Agilent Technologies)[19].The siRNA powder was dissolved in water.Unformulated siRNA and the sense strand of the siRNA were included as controls.Mobile phase A consisted of 100 mM triethylamine acetate(TEAA)at pH 7;mobile phase B consisted of 20% acetonitrile in mobile phase A.The column temperature was maintained at 30°C.The injection volume was 5µl with a flow rate of 0.3 ml/min.Gradient was 35%to 50%mobile phase B over 10 min.A photodiode array detector was used for signal detection at 260 nm.

2.7. Gel retardation assay

To examine the integrity of siRNA following spray freeze drying,the powders were reconstituted inTris-borate-EDTA(TBE)buffer and resolved by gel retardation assay.Unformulated siRNA and the sense strand of the siRNA were included as controls.Samples containing 1µg of nucleic acid in a final volume of 10µl were loaded into a 15%(w/v)native polyacrylamide gel.Gel electrophoresis was run at 60 V for 3 h inTBE buffer(Mini-PROTEAN Tetra Cell,Bio-Rad Laboratories,California,USA).Nucleic acids in the gel were stained with GelRed™Nucleic Acid Gel Stain(Biotium,Hayward,CA,USA)in TBE buffer for 30 min.Subsequently,the gel was visualized and captured under UV illumination(G:Box XR5;Syngene,Cambridge,United Kingdom).

2.8. Statistical analysis

Statistical analyses were performed by GraphPad Prism statistics software(Version 6.0b).The data were analysed by oneway ANOVA followed by Tukey’s post-hoc test.Differences were considered as statistically significant atP<0.05.

3. Results and discussion

3.1. Physical properties of DNA powder formulations

To allow efficient lung deposition,an inhaled dry powder formulation must exhibit good dispersibility.The optimal particle size for lung deposition is reported to be between 1–5 µm aerodynamic diameter,which is affected by the geometric diameter as well as the density of the particles[20].Particles with a geometric diameter of 1–5 µm usually have poor flowability and dispersibility due to the strong cohesion force.On the other hand,porous particles with large geometric size tend to have small aerodynamic size because of the low density.These types of particles are desirable for inhalation due to the good flowability and dispersibility[21].Spray freeze drying is one of the particle engineering technologies to produce porous powder.By altering the solute concentration of the feed solution for spray freeze drying,the porosity of the particles could be controlled.

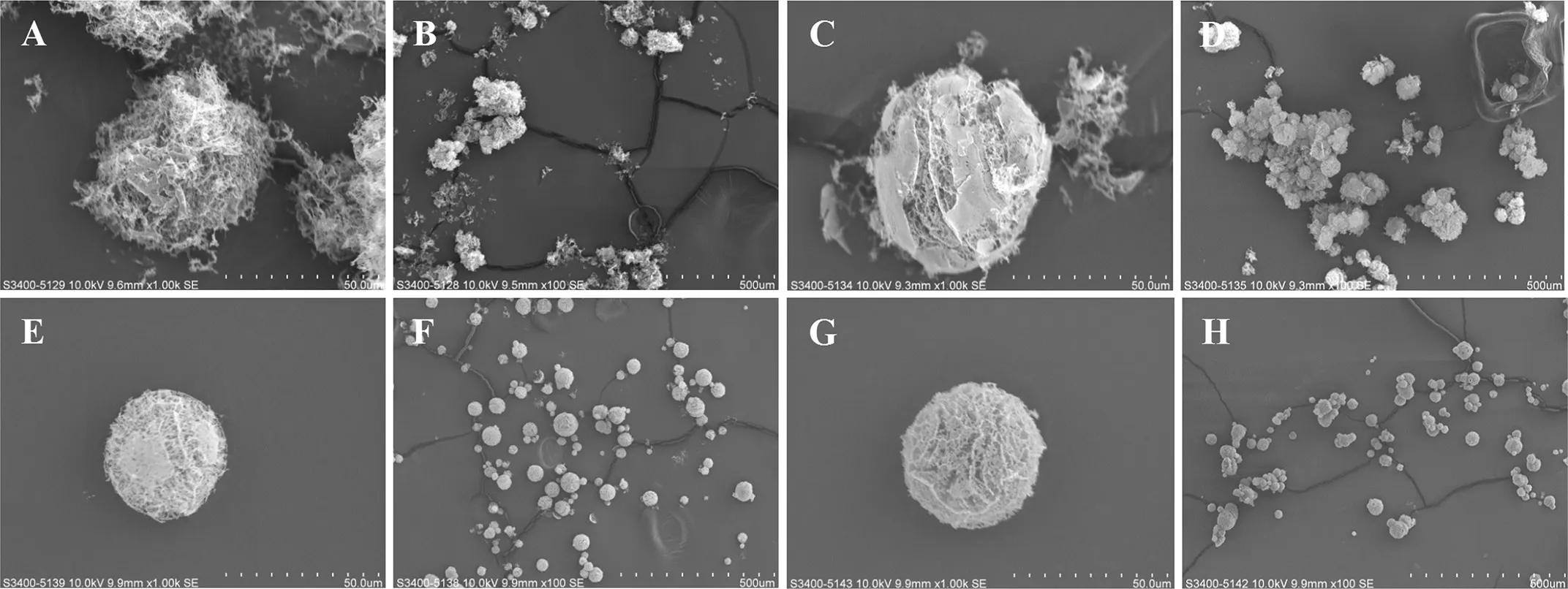

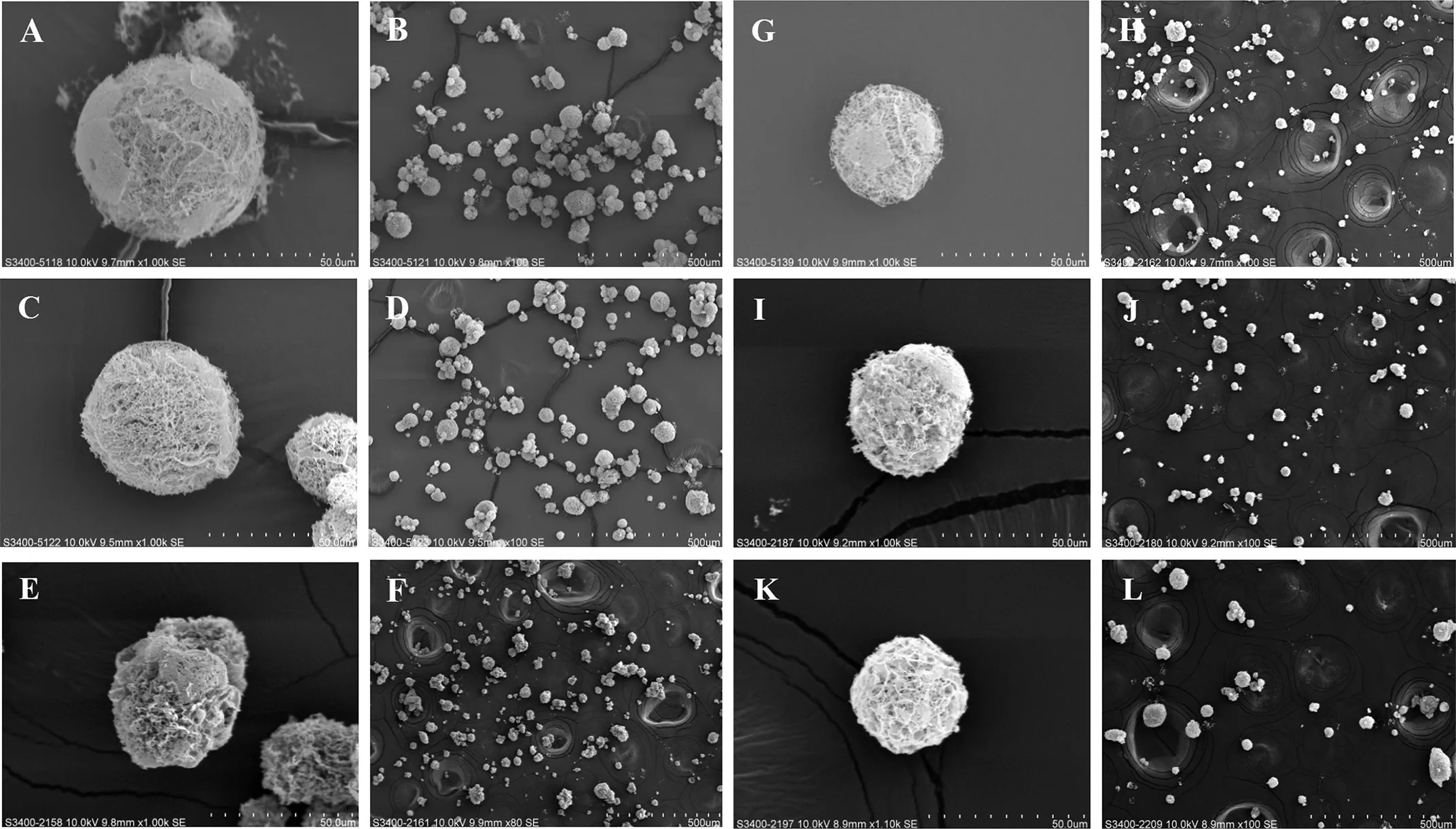

Production yield is an important factor to consider in preparing powder formulation of nucleic acids which are more expensive than the small drug molecules.Table 2 shows the production yield of the spray freeze dried formulations,and all formulations had a satisfactory yield,with at least 83%w/w yield obtained.Most of the formulations had a yield above 90%w/w.The effect of solute concentration on powder properties was first examined.A series of DNA formulations was prepared at various solute concentration from 1%to 7.5%w/v,whilethe DNA concentration was kept at 1%w/w.As shown in Table 2,the volumetric diameter of the particles was measured by laser diffraction.The median diameter of the particles ranged from 8.7µm to 12.6µm.Formulation formed with 1%w/v solute concentration was generally smaller than the rest of the formulations in the same series.The median diameter of 5-D-1.00(5%w/v solute concentration)was significantly larger than that of 1-D-100(1%w/v solute concentration)(P<0.05).Fig.2 shows the morphology of the particles examined by SEM.Overall,the particles of different formulations were spherical in shape.As expected,spray freeze drying of liquid with lower solute concentration(1%and 2.5%)produced particles of higher porosity,according to the SEM images,which is a qualitative evaluation.As shown in Fig.2A-D,these particles appeared to be more fragile,as fragments were easily noticed in the images.In addition,the low magnification images,Fig.2B and 2D,showed that the powders of these formulations were highly aggregating.On the other hand,the particles produced with higher solute concentration(5%and 7.5%),as demonstrated in Fig.2E-H,appeared as individual,discrete particles.The particle size data from laser diffraction showed that the higher the solute concentration,the lower the span value,indicating that the particle size distribution was more uniform as solute concentration increased.It was obvious that the D10value of formulation with low solute concentration was much smaller,possibly due to the presence of the small fragmented particles and debris.Judging from the SEM images,the spray freeze dried powders have to be prepared with at least 5%w/v solute concentration to be considered as ‘robust’enough as inhaled formulations.

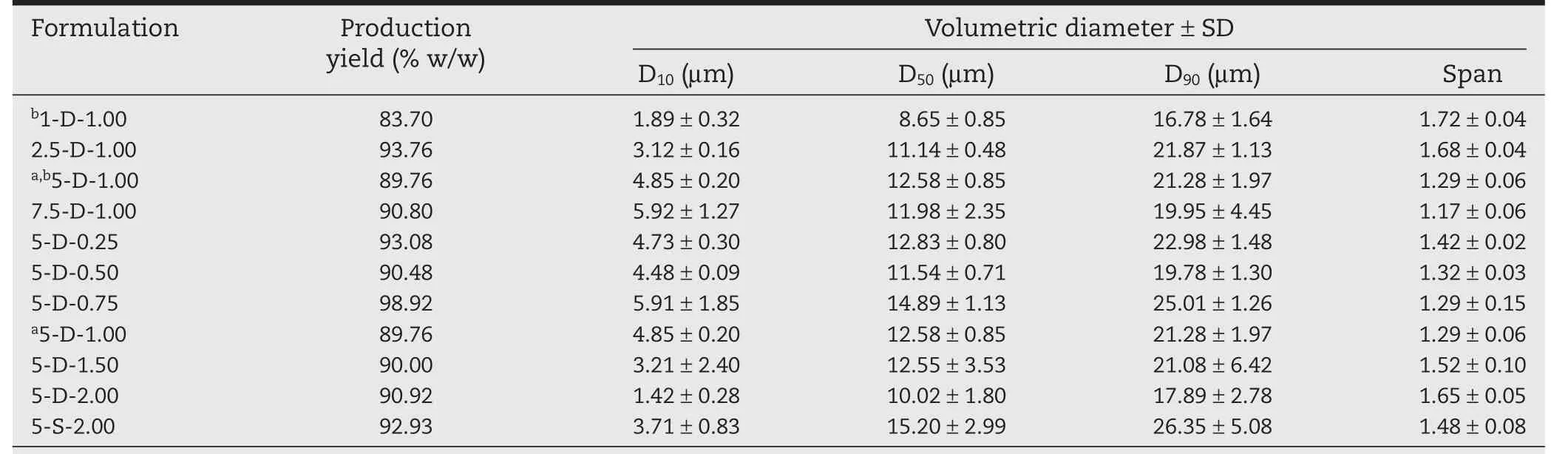

Table 2–The production yield and particle size distribution(measured by laser diffraction)of spray freeze dried formulation.The volumetric diameter was presented as mean±SD(n=3).

Fig.2–Representative scanning electron microscopy(SEM)images of various spray freeze dried powder formulations with 1%w/w DNA concentration and varying solute concentrations:(A,B)1%w/v solute(1-D-1.00);(C,D)2.5%w/v solute(2.5-D-1.00),(E,F)5%w/v solute(5-D-1.00);(G,H)7.5%w/v solute(7.5-D-1.00).Images A,C,E and G were taken at 1000×magnification(scale bar=50 μm);images B,D,F and H were taken at 100 × magnification(scale bar=500 μm).

To examine the effect of DNA concentration in the formulation,another series of spray freeze dried powders was prepared,with the solute concentration kept at 5%w/v while the DNA concentration varied from 0.25%to 2%w/w.As shown in Table 2,the median diameter of the particles ranged from 10.0µm to 14.9µm,with no clear trend observed as the DNA concentration varied.Fig.3 shows the SEM images which reveal that all the particles of this series appeared to be porous and spherical.However,there was no obvious difference in porosity between these formulations when observed by the SEM.It is noted that SEM is not a quantitative method to measure particle porosity.Techniques such as gas adsorption and Brunauer,Emmett and Teller(BET)analysis as well as mercury intrusion porosimetry could be employed to examine the porosity of powders in the future.

3.2. Aerosol performance of DNA powder formulations

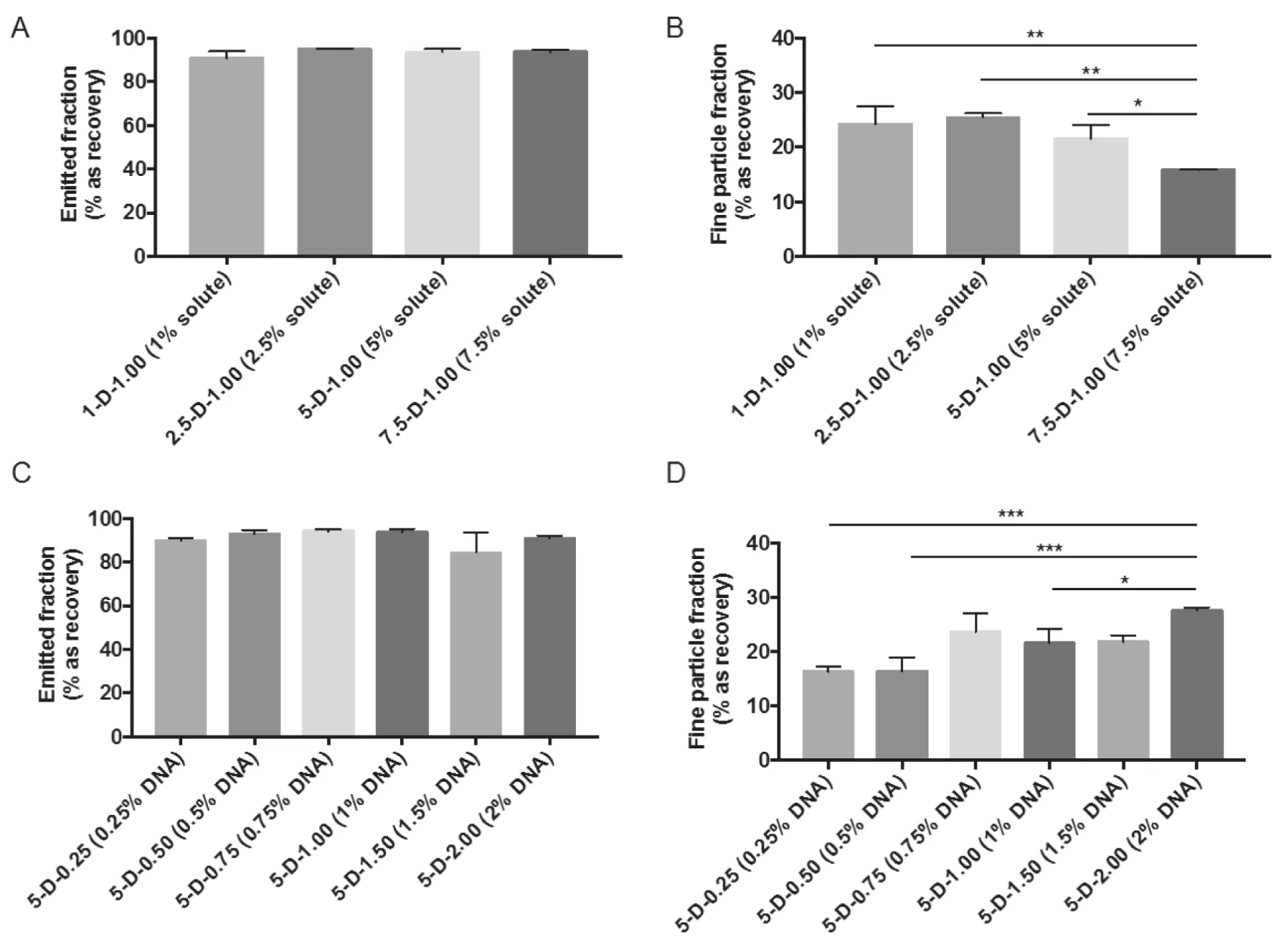

Next generation impactor(NGI)was employed to evaluate the aerosol performance of the spray freeze dried powder formulations.In particular,two parameters were closely examined and compared between different formulations.The first one is the emitted fraction(EF),which is shown in Fig.4A and 4C.EF indicates the fraction of powder that was successfully dispersed under the experiment condition(i.e.,NGI operated at 100 l/min,equivalent to 4 kPa pressure drop)and exited the inhaler(Breezhaler®,which is a low-resistance inhaler).All the DNA formulations prepared in this study achieved a satisfactory EF of over 90%,with no statistical significant difference between all the formulations.The good dispersibility was attributed to the porous structure and relatively large volumetric size,which is the characteristic feature of powders formed by spray freeze drying.

Once the powder successfully exited the inhaler upon inhalation,it becomes available to the patients.However,only particles that exhibited aerodynamic diameter between 1–5 µm can reach the deep lung.Particles above that size range are likely to be impacted at the back of the throat or in the upper respiratory tract.The second important parameter is the fine particle fraction(FPF),which is shown in Fig.4B and 4D.FPF indicates the fraction of powder with aerodynamic diameter<5µm and could be deposited in the lower respiratory tract.When the solute concentration increased,the FPF decreased gradually.As shown in Fig.4B,the formulation prepared with 7.5%w/v solute concentration exhibited a significantly lower FPF(around 15%)than the rest of the formulations within the same series,while there was no significant difference in FPF between the others(FPF between 20%–25%).Since aerodynamic diameter is influenced by particle density,as the solute concentration increased,particles with lower porosity and higher density were formed,thereby increasing aerodynamic diameter and decreasing FPF.

Fig.3–Representative scanning electron microscopy(SEM)images of various spray freeze dried powder formulations with 5%w/v solute concentration and varying DNA concentrations:(A,B)0.25%w/w DNA(5-D-0.25);(C,D)0.5%w/w DNA(5-D-0.50),(E,F)0.75%w/w DNA(5-D-0.75;(G,H)1%w/w DNA(5-D-1.00),(I,J)1.5%w/w DNA(5-D-1.50);(K,L)2%w/w DNA(5-D-2.00).Images A,C,E,G,I and K were taken at 1000 × magnification(scale bar=50 μm);images B,D,F,H,J and L were taken at 100 × magnification(scale bar=500 μm).

Considering the morphology and aerosol performance of the formulations,powders prepared with 5%w/v solute concentration appeared to be the optimal formulation within the series as they demonstrated porous but ‘robust’structure,and a modest FPF value.As shown in Fig.4D,when the solute concentration of the formulations was maintained at 5%w/v and the DNA concentration increased,there was a gradual increase in FPF.The 2%w/w DNA formulation(the highest concentration of DNA used in this study)performed significantly better than the 0.25%,0.5%and 1%w/w counterparts.The FPF of the 2%w/w DNA formulation was close to 30%,which was the highest value amongst all the DNA formulations prepared in this study.One key advantage of using a higher drug concentration in inhaled formulation is that the amount of excipient and hence the powder mass are reduced,avoiding repeated administration to achieve the same therapeutic dose.The inter-stage distributions that are shown in Fig.S1 in the supplementary information suggested that the majority of the powder was deposited on Stage 1 which has a cutoff diameter of 6.12µm.This indicates that the particles were still too large for efficient lung deposition.Further increase in DNA concentration could be explored to improve FPF.Alternatively,size reduction could be achieved by decreasing liquid feed flow rate during atomisation or varying the frequency of the ultrasonic nozzle[12,22].For the interest of this paper,the best performing formulation identified with herring sperm DNA in the current study was employed in the subsequent siRNA formulation study.

3.3. Spray freeze dried formulation of siRNA

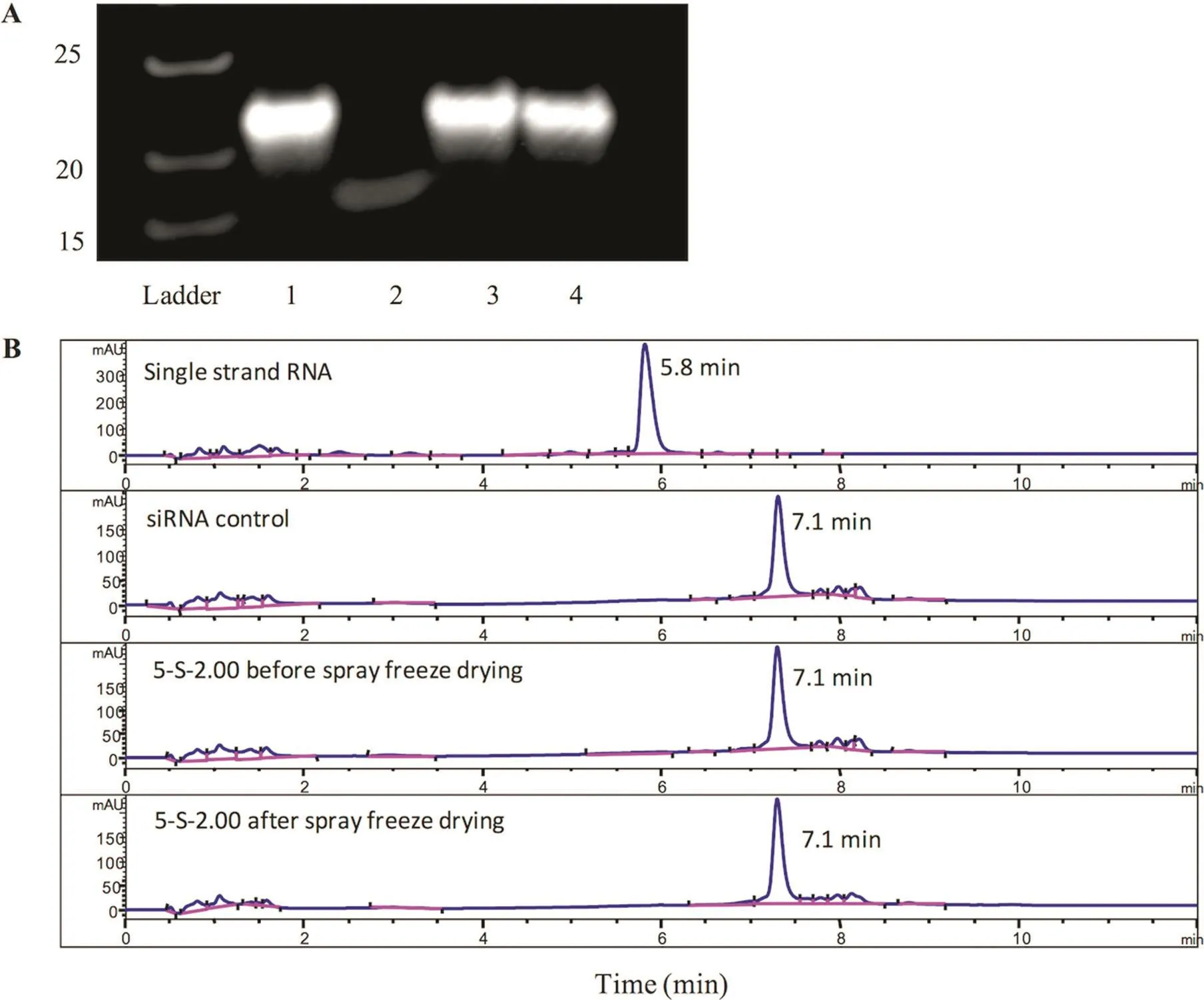

Among the DNA formulations studied,the one prepared with 5%w/v solute concentration and 2%w/w DNA exhibited the best aerosol performance.This formulation was therefore adopted to prepare siRNA powder.The production yield was over 90%,which was similar to DNA formulations.One of the challenges in preparing dry powder of naked siRNA is to maintain the structural integrity of the unprotected nucleic acids.During spray freeze drying,the materials are inevitably exposed to high shear stress(during atomisation)and thermal stresses(during freezing).These stresses could lead to strand separation and fragmentation of the unprotected siRNA[11],impairing its biological activity.To evaluate the integrity of the siRNA after spray freeze drying,gel retardation assay and liquid chromatography assay were performed.In both assays,a single strand RNA(the sense strand of siRNA)was included as control.The gel image,as shown in Fig.5A,revealed that the siRNA in the powder formulation remained intact,with no observable degradation upon drying.The results from the liquid chromatography assay,which is shown in Fig.5B,were consistent with the gel retardation assay.The spectrum of siRNA obtained from the reconstituted powder was almost identical to that obtained from the feed solution of the same formulation prior to spray freeze drying.

Fig.4–In vitro aerosolisation performance of spray freeze dried powder formulations of DNA evaluated by next generation impactor(NGI).(A)The emitted fraction of powders prepared at different solute concentration;(B)The fine particle fraction of powders prepared at different solute concentration;(C)The emitted fraction of powders prepared at different DNA concentration;and(D)The fine particle fraction of powders prepared with different DNA concentration.Data was presented as mean ± SD(n=3).Significant differences were determined using one-way ANOVA analysis followed by Tukey’s post-hoc test.*,**and***represents P<0.05,P<0.01 and P<0.001 respectively.

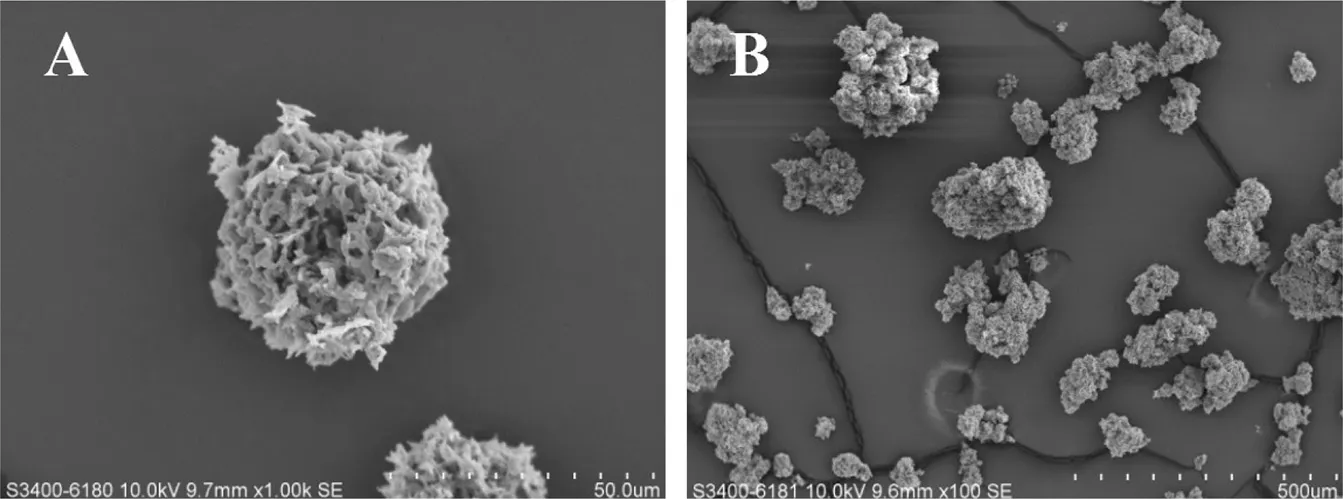

Table 2 shows the particle size of the siRNA formulation measured by laser diffraction.The median diameter of siRNA powder was around 15.2µm,which was considerably larger than any of the DNA formulations.The morphology of the siRNA formulation was also different from the DNA formulations.Fig.6 shows the SEM images of the siRNA formulation.The siRNA powder appeared to be more porous and less spherical in shape.High level of particle aggregation could be observed in image that was taken at lower magnification.

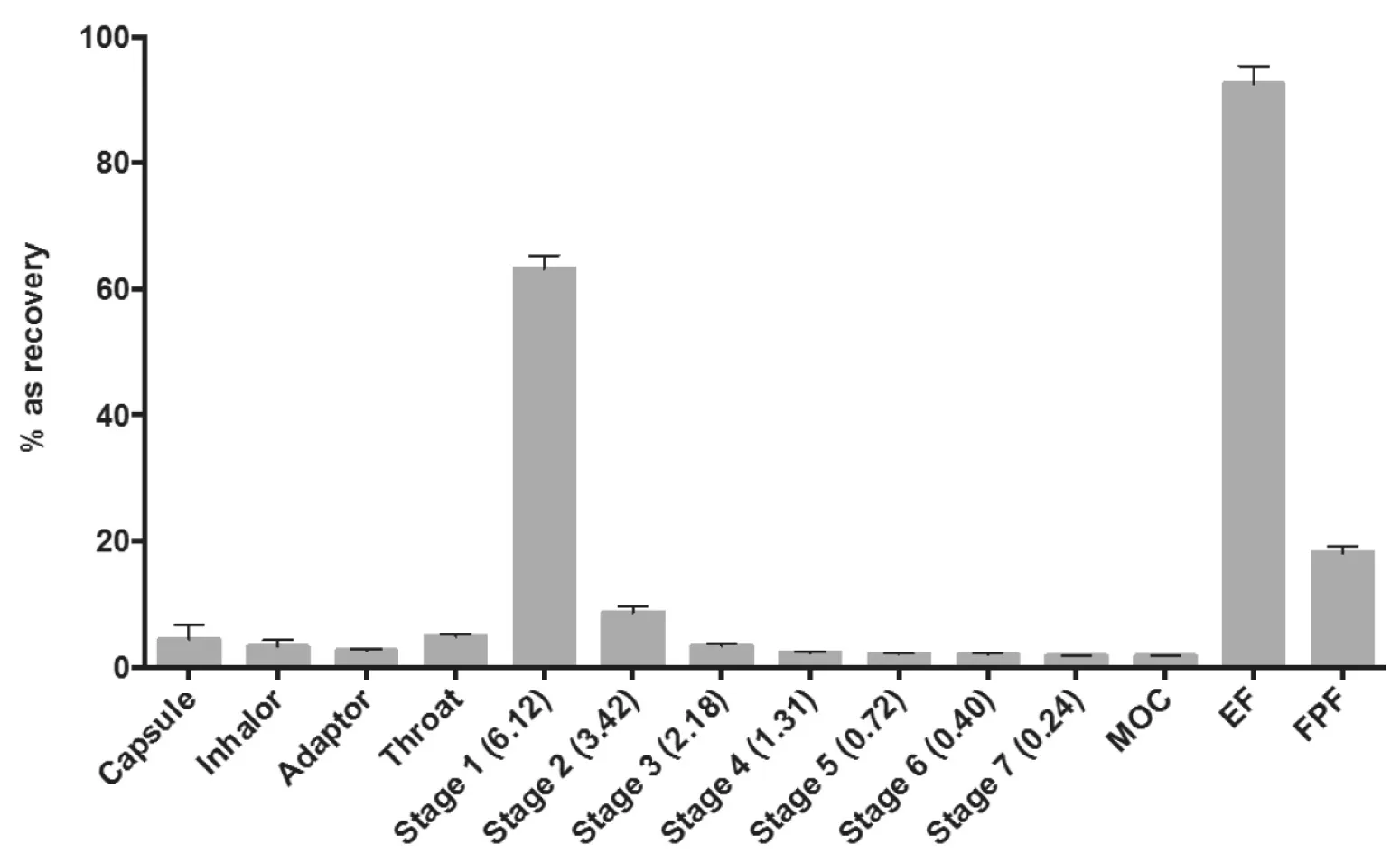

The aerosol performance of siRNA powder was evaluated by NGI,which is shown in Fig.7.Similar to the DNA formulations,the siRNA formulation had a satisfactory EF of over 90%.The FPF was around 18%which was disappointing.The interstage distribution pro file showed that the majority of the siRNA powders(~60%)was deposited in Stage 1.The relatively low FPF of siRNA powder formulation(~18%)compared to its DNA counterpart(~28%)could be explained by the larger particle size,probably due to the stronger cohesion force and thus high level of aggregation,rendering the particles failed to deposit in the lower stages.

The siRNA formulation behaved somewhat differently to its DNA counterpart.Overall,the siRNA powder formulation exhibited a larger particle size,appeared to be more porous and less robust.The aerosol performance of the siRNA formulation was also less satisfactory.Despite that both siRNA and herring sperm DNA are double stranded nucleic acid molecules with comparable size,the siRNA has a specific sequence and well-defined molecular weight while the herring sperm contained a heterogeneous mixture of oligonucleotides of variable size.This subtle difference may partly contribute to their difference in the surface and structural characteristics and hence their aerodynamic properties.While further investigation is required,herring sperm DNA may not be an ideal nucleic acid model for siRNA for the initial formulation optimisation.Nevertheless,this proof-of-concept study is the first to report the use of spray freeze drying technology to produce dry powder formulation of naked siRNA with modest aerosol properties.Importantly,the physical integrity of siRNA was successfully preserved in the absence of delivery vectors.Since the aerosol performance of a powder formulation is also affected by the design of inhaler,a careful selected inhaler device could improve the delivery efficiency.Further formulation optimisation using a design of experiment(DoE)approach will be carried out and the biological activities of the powders will be evaluated in the future using suitablein vivomodels.

Fig.5–The integrity of siRNA after spray freeze drying.(A)Gel retardation assay of siRNA samples.Each well contained 1 μg of nucleic acids.Numbers to the left of the ladder refer to the size of nucleic acids(DNA in base pairs).The samples are:(1)siRNA control;(2)sense strand of siRNA;(3)5-S-2.00 before spray freeze drying;and(4)5-S-2.00 after spray freeze drying.(B)HPLC spectra of siRNA samples.Retention time of siRNA duplex and its sense strand was 7.1 min and 5.8 min,respectively.Unformulated siRNA and its sense strand were included as controls at equal amount to the powder samples.

Fig.6–Scanning electron microscopy(SEM)images of siRNA spray freeze dried powder formulation prepared at 5%w/v solute concentration 2%w/w siRNA(5-S-2.00).The images were taken at(A)1000 × magnification(scale bar=50 μm);and(B)100 × magnification(scale bar=500 μm).

Fig.7–In vitro aerosolisation performance of spray freeze dried powder formulations of siRNA evaluated by next generation impactor(NGI).The formulation was prepared at 5%w/v solute concentration and 2%w/w siRNA concentration.The emitted fraction(EF)and fine particle fraction(FPF)was expressed by mass relative to the recovered dose.Data was presented as mean ± SD(n=3).S1-7 denotes impactor stages 1–7,with the corresponding lower cut-off diameter(in μm)given in the parenthesis.MOC is the micro-orifice collector in the NGI.

4. Conclusion

In this study,the use of spray freeze drying to prepare inhaled dry powder of small nucleic acids was explored.By manipulating formulation parameters such as solute concentration and nucleic acid concentration,the physical properties including the porosity,particle size and aerodynamic performance could be controlled.The presence study has successfully demonstrated that spray freeze drying can be used to produce naked siRNA formulation with intact integrity.The siRNA powder exhibited an excellent dispersibility with a modest fine particle fraction.Further exploration of this technology to optimise inhaled dry powder formulation of siRNA is warranted.

Declaration of interest

The authors declare that there are no conflicts of interest.The authors alone are responsible for the content and writing of this article.

This study was funded by the Health and Medical Research Fund,Hong Kong(15140962)and Research Grant Council,Hong Kong(17110414).The authors would like to thank the Electron Microscope Unit,The University of Hong Kong for the assistance in the SEM study.

Appendix:Supplementary material

Supplementary data to this article can be found online at doi:10.1016/j.ajps.2017.10.002.

[1]Qiu Y,Lam JK,Leung SW,et al.Delivery of RNAi therapeutics to the airways-from bench to bedside.Molecules 2016;21:1249.

[2]Man DK,Chow MY,Casettari L,et al.Potential and development of inhaled RNAi therapeutics for the treatment of pulmonary tuberculosis.Adv Drug Deliv Rev 2016;102:21–32.

[3]DeVincenzo JP.The promise,pitfalls and progress of RNA-interference-based antiviral therapy for respiratory viruses.Antivir Ther 2012;17:213–25.

[4]Koli U,Krishnan RA,Pofali P,et al.SiRNA-based therapies for pulmonary diseases.J Biomed Nanotechnol 2014;10:1953–97.

[5]Fire A,Xu S,Montgomery MK,et al.Potent and specific genetic interference by double-stranded RNA in Caenorhabditis elegans.Nature 1998;391:806–11.

[6]Goh FY,Cook KL,Upton N,et al.Receptor-interacting protein 2 gene silencing attenuates allergic airway inflammation.J Immunol 2013;191:2691–9.

[7]Rosas-Taraco AG,Higgins DM,Sanchez-Campillo J,et al.Intrapulmonary delivery of XCL1-targeting small interfering RNA in mice chronically infected with Mycobacterium tuberculosis.Am J Respir Cell Mol Biol 2009;41:136–45.

[8]Zamora MR,Budev M,Rolfe M,et al.RNA interference therapy in lung transplant patients infected with respiratory syncytial virus.Am J Respir Crit Care Med 2011;183:531–8.

[9]DeVincenzo J,Lambkin-Williams R,Wilkinson T,et al.A randomized,double-blind,placebo-controlled study of an RNAi-based therapy directed against respiratory syncytial virus.Proc Natl Acad Sci USA 2010;107:8800–5.

[10]Ge Q,Filip L,Bai A,et al.Inhibition of influenza virus production in virus-infected mice by RNA interference.Proc Natl Acad Sci USA 2004;101:8676–81.

[11]Chow MY,Lam JK.Dry powder formulation of plasmid DNA and siRNA for inhalation.Curr Pharm Des 2015;21:3854–66.

[12]Ishwarya SP,Anandharamakrishnan C,Stapley AGF.Sprayfreeze-drying:a novel process for the drying of foods and bioproducts.Trends Food Sci Technol 2015;41:161–81.

[13]Wanning S,Suverkrup R,Lamprecht A.Pharmaceutical spray freeze drying.Int J Pharmaceut 2015;488:136–53.

[14]Liang W,Chow MYT,Lau PN,et al.Inhalable powder formulations of siRNA and pH responsive peptides with antiviral activity against H1N1 influenza virus.Mol Pharm 2015;12:910–21.

[15]Chow MYT,Qiu Y,Lo FFK,et al.Inhaled powder formulation of naked siRNA using spray drying technology with L-leucine as dispersion enhancer.Int J Pharm 2017;530(1–2):40–52.In press.

[16]Okuda T,Kito D,Oiwa A,et al.Gene silencing in a mouse lung metastasis model by an inhalable dry small interfering RNA powder prepared using the supercritical carbon dioxide technique.Biol Pharm Bull 2013;36:1183–91.

[17]Liang W,Kwok PCL,Chow MYT,et al.Formulation of pH responsive peptides as inhalable dry powders for pulmonary delivery of nucleic acids.Eur J Pharm Biopharm 2014;86:64–73.

[18]British Pharmacopoeia commission.Appendix XII:C.Consistency of formulated preparations.In:British pharmacopoeia 2017:appendices,vol.V.London:TSO;2017.

[19]McCarthy SM,Gilar M,Gebler J.Reversed-phase ion-pair liquid chromatography analysis and purification of small interfering RNA.Anal Biochem 2009;390:181–8.

[20]Pilcer G,Amighi K.Formulation strategy and use of excipients in pulmonary drug delivery.Int J Pharm 2010;392:1–19.

[21]Chow AH,Tong HH,Chattopadhyay P,et al.Particle engineering for pulmonary drug delivery.Pharm Res 2007;24:411–37.

[22]Costantino HR,Firouzabadian L,Hogeland K,et al.Protein spray-freeze drying.Effect of atomization conditions on particle size and stability.Pharm Res 2000;17:1374–83.

杂志排行

Asian Journal of Pharmacentical Sciences的其它文章

- Combretastatin A4/poly(L-glutamic acid)-graft-PEG conjugates self-assembled to nanoparticles

- Development of lamellar gel phase emulsion containing baru oil(Dipteryx alata Vog.)as a prospective delivery system for cutaneous application

- Preparation and toxicity evaluation of a novel nattokinase-tauroursodeoxycholate complex

- Quantification and spatial distribution of salicylic acid in film tablets using FT-Raman mapping with multivariate curve resolution

- Tablets of paliperidone using compression-coated technology for controlled ascending release

- Role of clove oil in solvent exchange-induced doxycycline hyclate-loaded Eudragit RS in situ forming gel