船用蓄电池组健康管理系统设计

2018-03-10德伯尔孔庆福

德伯尔,孔庆福,祝 剑

船用蓄电池组健康管理系统设计

德伯尔,孔庆福,祝 剑

(海军工程大学,中国武汉 430033 )

蓄电池是一种重要的船用能量源,比如当潜艇处于水下时。因此,保持蓄电池组良好的技术状态非常重要。蓄电池性能劣化的机理非常复杂,船员往往难以掌握。为实现对船用蓄电池组的科学使用和管理、保证其工作可靠性,本文设计了一套船用蓄电池组健康管理系统。系统由一个状态监测子系统和性能预测子系统组成。为实现蓄电池组性能预测功能,构建了基于支持向量机的智能预测模型,通过历史监测数据自动寻找电池组的性能劣化规律。测试结果表明了系统性能预测功能的有效性。

蓄电池 健康管理 监测数据 支持向量机 性能预测

0 引言

在舰船上,通常将单个蓄电池组合成蓄电池组的方式来给各类船用设备供电。当潜艇处于水下工况时,蓄电池组作为唯一的能量源,是潜艇上最重要的设备之一。蓄电池组技术状态的好坏对于潜艇各类任务的顺利完成具有极为重要的影响。如果船员能够实时掌握蓄电池组的实际技术状态,并以此为依据实现对蓄电池组的科学使用和合理维护,则可有效保证蓄电池组的工作可靠性和安全性。然而,船用蓄电池组无论是内部电化学反应、还是外部的工作环境都非常复杂,使得基于人工的船用蓄电池组健康管理工作往往变得非常困难[1-3]。有鉴于此,本文开发了一套船用蓄电池组健康管理系统(HMS)。系统主要由一个在线监测子系统和一个性能预测子系统组成。其中,在线监测子系统负责在线监测数据收集、信息显示和超限报警等任务;性能预测子系统采用了基于最小平方根-支持向量机(LS-SVM)的预测模型。

1 船用蓄电池组健康管理系统设计

1.1 船用蓄电池性能劣化机理

作为舰船用蓄电池,通常要求有较大的功率输出,铅酸蓄电池因具有相对较大的功率输出而在舰船上得到了广泛的应用。铅酸蓄电池通过一个可逆的电化学反应来实现电能的存储和提供。在充电过程中,蓄电池的阳极被氧化而产生电子,阴极消耗电子;蓄电池放电过程则相反。蓄电池在每次的充放电过程中,其内部都会产生一定的不可逆化学反应,从而对蓄电池的性能造成不可避免的损害。如果在使用中还存在过充或过放等不正确操作,蓄电池性能的下降将会更显著。即使使用中没有不正确操作,由于部件老化等原因,蓄电池的容量也会随着充放电次数的增加而下降。上述因素都会造成蓄电池的性能劣化,从而导致蓄电池组总体性能的退化[4-5]。

1.2 船用蓄电池组的健康管理策略

尽管大多数情况下蓄电池组性能退化往往是一个连续的发展过程,但由于外部使用环境和内部电化学反应的复杂性,蓄电池组性能退化范围通常有较大的差别。当蓄电池性能劣化时,可观察或测量到如下的现象:电池电压下降、充电时间变长、电池内部电阻变大、电池温度变高。也就是说,上述信息可用来评估蓄电池性能劣化的趋势和程度,只是鉴于船用蓄电池组工作参数与实际技术状态之间存在的复杂映射关系,找到一个能正确评估蓄电池实际技术状态和预报性能发展趋势的有效方法具有较大的难度。实践证明,单纯依靠人工进行船用蓄电池健康管理具有较大的难度。人工智能技术是解决此类复杂问题的有力工具,例如,基于最小平方根-支持向量机(LS-SVM)的学习算法已被证明能自动地从机械设备历史工作数据中学习、并具有对数据进行有效分类的能力[3, 6]。

基于前述讨论,本文设计的船用蓄电池组健康管理系统的健康管理策略和信息处理流程如图1所示。系统实时监测的蓄电池工作数据有4类:单体蓄电池电压、蓄电池组电压、蓄电池组电阻、蓄电池组温度[5, 7]。系统采集到蓄电池(组)工作数据后,首先执行超限报警判别;随后,相关工作数据被送至一个基于最小平方根-支持向量机(LS-SVM)算法的预测模型用来进行蓄电池组性能发展预测。

1.3 船用蓄电池组健康管理系统组成

船用蓄电池组健康管理系统的基本组成如图2所示,主要由一个在线监测子系统和一个故障预测子系统组成。

1.3.1 在线监测子系统

潜艇上通常配置有许多的蓄电池组,各蓄电池组分别布置在不同的位置;基于这一实际情况,在设计中采用了一个分布式监测子系统来对所有蓄电池组的工作参数进行采集。

图1 健康管理系统的信息处理流程

实时监测,在各蓄电池组内部分别配置了相应的传感器。通过一套无线通信模块,所有监测数据都被送到监测计算机处。在监测计算机中,各数据首先分别与其设定的报警值进行比较,如果超出报警值,系统将给出相应的报警信号;随后,数据以一定的存储间隔和数据结构形式被存储在监测计算机硬盘之中,并以数据和图表的形式在显示器中显示出来。

1.3.2 性能预测子系统

在系统中采用了一个内含基于最小平方根-支持向量机(LS-SVM)算法预测模型的管理上位机来执行蓄电池性能发展预报功能。在系统进行性能预报之前,先要对预测模型进行有效的充分训练。在进行蓄电池性能预测时,在线监测的工作数据和存储在计算机硬盘中的最近历史工作数据首先被送往上位机中的性能预测模型,预测模型基于对历史工作数据的学习和辨识,能够自动给出蓄电池(组)电压、电阻和温度参数的变化趋势,并提供给船员蓄电池(组)可能的下次故障发生时间点,以协助船员进行正确的使用管理和设备维护。

图2 健康管理系统的基本组成

2 基于LS-SVM的预测算法

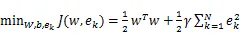

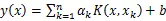

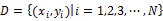

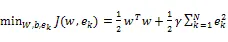

最小平方根-支持向量机(LS-SVM)算法是一种有监督的自学习算法,在其使用前须进行有效和充分的训练。假设训练集为:

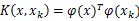

以及

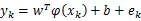

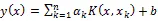

为解决非线性分类问题,核空间非线性匹配函数的目标从原始空间挑选出合适特征量、与训练数据进行匹配以形成一个高维特征向量空间。为得到优化函数,可定义如下的Lagrangian函数:

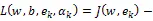

已证明,Karush-Kuhn-Tucker (KKT)条件对于非线性优化问题的寻优解法是充分和必要条件[8,9]。基于Karush-Kuhn-Tucker (KKT)条件[8,9]可得到如下的方程:

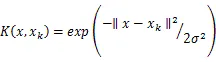

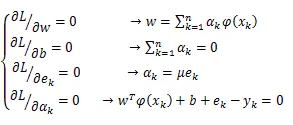

有不少函数可以被当作核函数,其中,径向基(Radial Basis Function - RBF)函数是支持向量机(SVM)算法中最为广泛采用的。径向基核可以用下式描述:

3 性能预报测试结果

性能预报功能是船用蓄电池健康管理系统的核心功能。为验证其有效性,采用了一个测试来检验其预测结果的有效性。在系统测试中,选取一套已在潜艇上服役了一段时间的蓄电池组作为测试对象,并通过如下步骤完成测试过程:

1) 收集该蓄电池组包括电压、温度和电阻在内的历史监测数据。

2) 对所收集的历史数据进行预处理,包括无效数据清除和数据标准化等工作,最后形成训练数据集。

3) 基于训练数据集,采用LM-SVM 算法对预测模型进行有效训练。

4) 向预测模型提供不同于训练数据集的其它输入数据,获得预测结果。

5) 在潜艇蓄电池组工作一段时间后获得相关电池组的实际工作数据。

6) 将预测模型输出预测数据与实际数据进行比较。

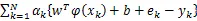

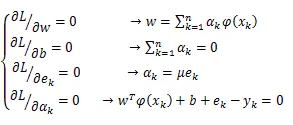

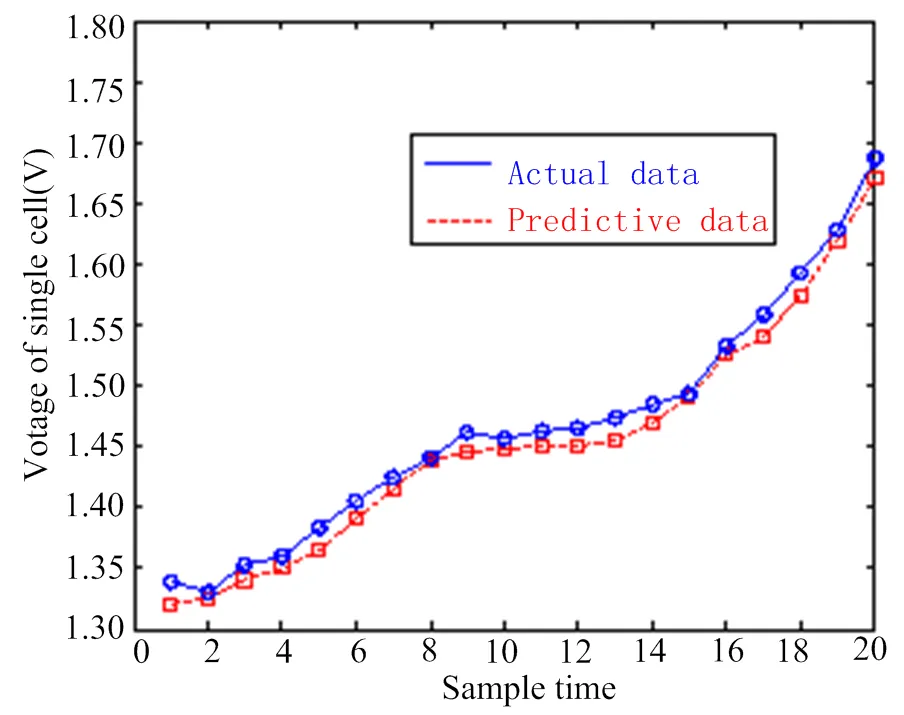

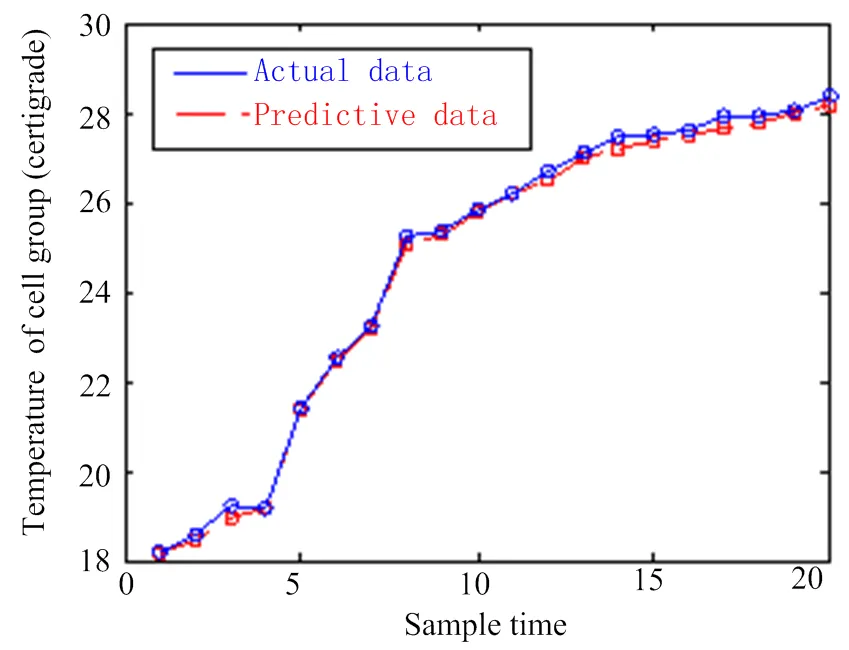

图3和图4分别展示了预测数据与实际数据的部分比较结果。其中,图3展示了蓄电池组电压的比较结果,图4展示了蓄电池组温度的比较结果。从图示比较结果可知,基于LM-SVM 算法的预测模型具有令人满意的预测能力。

图3 蓄电池组电压预测值与实际值比较结果

图4 蓄电池组温度预测值与实际值比较结果

4 结论

在实际使用过程中,船用蓄电池的性能会逐渐劣化,从而给蓄电池的工作可靠性和安全使用带来消极影响。由于蓄电池性能劣化机理的复杂性,单纯凭人工来预测蓄电池的性能发展趋势比较困难。本文介绍了所开发的一套船用蓄电池健康管理系统,通过实时采集和无线传送重要的蓄电池(组)工作参数到监测计算机,实现工作参数的实时监测、显示和报警功能。为实现精准的蓄电池性能预报功能,构建了一个基于支持向量机的智能预报模型,使得系统能够从蓄电池组的历史工作数据中进行有效自学习,并能最终给出科学的性能趋势预报。本系统的应用可以有效协助船员进行船用蓄电池科学维修决策。

0 Introduction

Storage batteries are usually combined as batteries to supply power to all kinds of devices equipped in a battleship. Batteriesare one of the most important devices in the submarine because it is usually the unique power resource while the submarine is under the water. Performance of the batteries plays an important role on the effectiveness of the submarine to finish its task. In consideration of working reliability and safety, it will be very helpful for the crew to master the actual health conditions of batteries so that decisions of scientific usages and rational maintenances can be made to the batteries. However, because of the complexity of both the external environment and the internal electro-chemistry reactions of the batteries, manual health management of the batteries has been proved to be a difficult work[1-3].

In order to solve the problem mentioned above, a Health Management System (HMS) for marine batteries is presented in the paper. The HMS consists mainly of two parts: an on-line monitoring subsystem and a performance prediction subsystem. The monitoring subsystem is designed to finish the task of on-line data collection, information display and alarm judgement. As to the key task of performance prediction, a prediction model based on Least Square-Support Vector Machine (LS-SVM) is built in the prediction subsystem.

1 Design on HMS for marine batteries

1.1 Performance deterioration of storage battery

It is usually required for the marine storage battery to supply relative larger output power, so lead-acid type rechargeable battery is widely used in the submarine. The battery stores or supplies electrical energy through a reversible electro-chemical reaction. During charging course of the battery, the positive active material of the battery is oxidized, producing electrons, and the negative material is reduced, consuming electrons. During discharging course of the battery, the process is reversed. However, during each charging or discharging course, there are usually undesirable and irreversible chemical reactions called cell reverse occurred inside the battery cell, which cause a permanent damage to the cell. If the battery is operated with mistreatment, such as over charged or over discharged, the situation will become worse. Even if the battery is used repeatedly without mistreatment, it loses capacity as the number of charging and discharging cycles increase because of aging effect of the components. All the factors mentioned above cause performance deterioration in the battery, which also results in a general degradation of the batteries[4-5].

1.2Health management strategy of batteries

Although the performance descending course of the battery is a continual developing course in most cases, but the descending tendency usually varies in a large range because of the complexity of the external usage environment and the internal electro-chemistry reactions of the storage battery. However, following phenomena can be observed and measured while the performance of the battery descends: voltage of the cell descends; charging time becomes longer; internal resistance will be enlarged; temperature of the battery becomes higher. That is to say, the information mentioned above can be used to judge the descending tendency of the battery performance. The problem is just how to find a way to give accurate performance judgement and prediction since the relationship between working parameters and performance conditions in a batteries is so complex. Manual health management for marine batteries has been proved to be a difficult work, but artificial intelligence is a powerful tool to solve this problem. For example, the LS-SVM algorithm has already been tested to have great ability to learn key knowledge from historical data[3, 6].

Based on the discussion mentioned above, health management strategy and information processing course of HMS for marine batteries are designed, as shown in figure 1. Four types of working parameters are measured on-line: voltage of the single battery, voltage of the batteries, electrical resistance of whole batteries, temperature of the batteries[5, 7]. Once the data are acquired, an alarm judgement is firstly completed. Furthermore, relative historical data are sent to a prediction model based on LS-SVM algorithm to give accurate prediction.

1.3 Construction of the HMS for marine batteries

Figure 2 shows the fundamental construction of the HMS for marine batteries. There are two primary parts: an on-line monitoring subsystem and a fault prediction subsystem.

1.3.1 On-line monitoring subsystem

There are many batteries equipped in a submarine, each batteries is placed in a suitable space. According to this factor, a distributed monitoring subsystem is designed to collect the working parameters of all batteries.

Fig. 1 Information processing course of the HMS

Sensors are equipped within the batteries so that the essential working parameters can be measured. By means of a set of wireless communication unit, all measured parameters are transferred to the monitoring computer. In the monitoring computer, the parameters are firstly compared with their alarming-setting values, if exceed the setting value, an alarm will be presented by the computer. Then, the data are saved with a certain sampling time and structure in the hard disk of the computer and then displayed by mean of data and diagram in the monitor.

1.3.2 Performance prediction subsystem

A managing computer is engaged in the HMS to perform the function of performance prediction. A model based on LS-SVM algorithm is built in the managing computer. The performance prediction model should be well trained before it is engaged to give performance prediction. While making prediction, the on-line monitored working parameters and recent historical data saved in the hard disk of the monitoring computer are firstly sent to the performance prediction model in the managing computer, and then developing tendencies of both voltage, resistance and temperature can be made automatically by the model based on the historical data. Estimated time points when faults maybe occur will be presented to the crew to help them to take correct maintenance operations.

Fig. 2 Fundamental Construction of the System

2 Prediction algorithm of LS-SVM

The LS-SVM is a supervised learning algorithm and should be well trained before it works. Suppose that the training dataset is:

Subject to:

In order to solve the optimal function, the Lagrangian function may be defined as:

Following equations can be obtained based on the Karush-Kuhn-Tucker (KKT) condition[8,9], which is a necessary and sufficient condition for the optimal solution of the object function in the problem of non-linear optimization.

Many functions can be adopted as the kernel function, the radial basis function (RBF) is one of the most popular kernel function for SVM. The RBF kernel can be described as the following formula:

3 Testing results of performance prediction

Performance prediction is the key function of the HMS for marine batteries. In order to test its validity, an experiment is completed to check the accuracy of the prediction results. A set of marine batteries is chosen as testing object, who has served in a submarine for a certain period. The test is completed with following steps:

1) Collecting the historical monitored voltage, temperature and resistance data of the batteries.

2) Pre-treating the collected data to build the training data set, including invalid data eliminating, data standardization and so on.

3) Training the prediction model with LM-SVM algorithm using the training data set.

4) Presenting input data different from the training data set to the prediction model and acquire the prediction results.

5) Acquiring actual working data from the submarine after a period of time.

6) Making a comparison between the prediction results and the actual work data.

Figure 3 and 4 show partial comparison results between the prediction results and the actual work data. Figure 3 shows the comparison result of cell voltage; and figure 4 shows the comparison result of cell temperature. It can be seen from the comparison results that the model based on LM-SVM algorithm has an excellent prediction performance.

Fig. 3Comparison result of cell voltage

4 Conclusion

Performance of storage battery usually deteriorates during usage, which brings negative effect on the using reliability and safety. It is difficult to master the performance developing tendency manually because of the complex deterioration mechanism. A health management system for marine batteries is introduced in the paper. Important parameters are collected and sent wirelessly to a computer to complete on-line monitoring function including parameters display and alarm judgement. In order to realize performance prediction, an intelligent forecasting model based on support vector machine is built, with which the system can learn knowledge from the historical data and make accurate prediction. With help of the system, maintenance decisions for marine batteries can be made scientifically.

Fig. 4 Comparison result of batteries temperature

//Reference:

[1] Wagner R. Failure modes of valve-regulated lead-acid batteries different applications. Power Sources, 2009, 53: 153-162.

[2] Lin Z C. The design of intelligent monitoring unit of aviation battery charge and discharge system. Chengdu: University of Electronic Science and Technology of China, 2010.

[3] Ji Y X, Du H J, Sun H. A survey of state of charge estimation methods. Electrical Measurement& Instrumentation, 2014, 51: 18-22.

[4] Li J H, Yan G G, Zhu Y. Design of VRLA battery-state monitoring system based on DSP2812. Electrical Measurement&Instrumentation, 2012, 49: 85-88.

[5] Zhao Y B, He X N, Ding J S. Study on the storage battery real and dynamic intelligent monitor and control system. Electric Engineering, 2005, 12: 21-23.

[6] Doerffel D, Sharkh S A. A critical review of using the Peukert equation for determining the remaining capacity of lead-acid and lithiumion batteries. Journal of Power Sources, 2006, 155: 395-400.

[7] Ye D. Design of precise charge and discharge coulometer apply for storage battery. Electric Engineering, 2004, (4): 16-19.

[8] Nie Z Q. Research and Implementation of battery monitoring and diagnosis expert system. Beijing: Tsinghua University, 1998.Date of receipt:2017-11-20About the author:Aymen Derbel(1990-), Male, postgraduate, Professional direction: Marine Engineering.

Design on A Health Management System for Marine Batteries

Aymen Derbel, Qingfu Kong, Jian Zhu

(Naval University of Engineering, Wuhan 430033, Hubei, China)

TM912.1

A

1003-4862(2018)02-0001-07

2017-11-20

德伯尔(1990-),男,外国留学生。研究方向:轮机工程。Email: aymenamine10@yahoo.com