Reduction rules-based search algorithm for opportunistic replacement strategy of multiple life-limited parts

2018-02-02XuyunFUShishengZHONG

Xuyun FU,Shisheng ZHONG

Department of Mechanical Engineering,Harbin Institute of Technology at Weihai,Weihai 264209,China

1.Introduction

Much equipment must be continuously maintained under certain maintenance policies to ensure the safety and reliability.This especially applies to aircraft engines,nuclear power plants and other complex equipment whose failure may result in disastrous consequences.Every year,equipment operators invest many human resources and materials in equipment maintenance.For example,Air China spends over 300 million USD($)on aircraft engine maintenance every year.Therefore,equipment maintenance has attracted the attention of both the industrial circle and the academic circle.

Many equipment maintenance problems can be abstractly deemed as optimization problems,and one of the important problems is Opportunistic Maintenance(OM).1–4Preventive Maintenance(PM)and Corrective Maintenance(CM)are two widely used maintenance policies.PM is regularly performed on equipment to lessen its likelihood of failing.CM is performed after failure occurrence.OM means the combination of PM and CM.Every equipment halt for failure occurrence or other reasons is deemed as an ‘opportunity’,and even if there is no PM activity planned to be carried out at this time,some PM activities may be shifted to this earlier moment.OM can effectively reduce the number of maintenance occasions,thus reducing the cost for disassembling and assembling equipment.5Many results from the study of OM have been achieved in multiple aspects such as modelling,algorithms and engineering applications.6–11

As a variant of the OM problem,the opportunistic replacement of multiple Life-Limited Parts(LLPs)is a problem widely existing in industry.LLPs are components with mandatory replacement limits,which are also called ‘life limits’.The life limits are often specified in the maintenance manual by equipment manufacturers,and equipment operators must abide by the life limits.When the operation time reaches its life limit,an LLP must be replaced no matter what its true technical status is;if not,the equipment will not be allowed to operate according to relevant regulations.In order to ensure that the LLP life does not exceed its life limit,equipment operators must accurately record all the LLP data.To a piece of equipment with multiple LLPs,if LLPs are replaced in advance,life wastage of LLPs will be caused;if all LLPs are not replaced until their life limits are reached,the number of maintenance occasions will be significantly increased.12How to balance the number of maintenance occasions and the wastage of LLPs is the goal of the opportunistic replacement of multiple LLPs.

George et al.were thefirst to come up with the opportunistic replacement of multiple LLPs.13,14They studied the opportunistic replacement of two LLPs atfirst.When an LLP needs to be replaced,it is checked whether the residual life of the other LLP is lower than a certain threshold.If yes,the other LLP also needs to be replaced;if not,the other LLP will not be replaced.The solution to this threshold is given.The strategy for the opportunistic replacement of two LLPs also applies to the opportunistic replacement of multiple LLPs.The same threshold is used for all LLPs.This replacement strategy cannot guarantee to identify the optimal solution for the opportunistic replacement of multiple LLPs. Epstein and Wilamowsky further proposed the solution to the optimal replacement strategy involving the least calculation for the opportunistic replacement of two LLPs.15Dickman et al.studied the opportunistic replacement of multiple LLPs through the nonlinear 0–1 integer programming model and the linear mixed integer programming model,16pointed out that the solving difficulty under the finite time horizon is higher than that under the infinite time horizon,and studied the integer programming model of the opportunistic replacement of two LLPs under the finite time horizon.17Andre´asson expanded the model,studied the opportunistic replacement of multiple LLPs under thefinite time horizon,builded the dynamic programming model and the linear integer programming model,studied the convex hull of the feasible solution under the linear integer programming model,and pointed out that the convex hull is generally full-dimensional.18Almgren et al.further theoretically proved that the opportunistic replacement of multiple LLPs is an NP-hard problem and proposed an acquisition method of a new class of facets.19For cost monotones with time,another constraint is added:the equipment is maintained only when the replacement of at least one LLP is necessary.This constraint can reduce the time consumed to obtain the optimal solution.When maintenance occasions arefixed,the problem is solved through a greedy algorithm.

The study in this article is based on problems encountered in aircraft engine maintenance.LLP cost is an important part of aircraft engine maintenance cost.Both maintenance occasions in the whole life cycle and LLPs replaced in each maintenance affect the total LLP cost in the whole life cycle of aircraft engines.How tofind the optimal replacement strategy is a difficulty in aircraft engine maintenance.Obviously,this is a problem about the opportunistic replacement of multiple LLPs.According to the literature review,no quick and effective method has been applied to such engineering applications so far.

This article starts from the problem solution space,analyzes the conditions of the feasible solution and optimal solution,suggests the reduction rules for the problem solution space,and proposes a quick search algorithm for the opportunistic replacement strategy of multiple LLPs.This search algorithm can identify one or several optimal solutions.

The remaining part of this article is organized as follows:first,the opportunistic replacement of multiple LLPs is formally described,the solution space is analyzed,and the solution space reduction rules and the search algorithm process are proposed;then,a numerical experiment of the algorithm is carried out using randomly generated problems;finally,a practical application case is given.

2.Problem description

Consideration is given to the opportunistic replacement problem with the equipment total lifeTtandn(n≥2)LLPs.The disassembling and assembling cost involved in the replacement of LLPs iscb,which is independent of the number of replaced LLPs.Each LLP is denoted asAi(i=1,2,...,n),its life limit is denoted asti,lim,and its cost is denoted asci.The equipment operation time is denoted asT,and the operation time ofAiis denoted asti.With the increase inT,tiincreases accordingly.Whenti=ti,lim,Aimust be replaced,and the incurred cost iscb+ci.After the replacement ofAi,tireturns to zero and begins to accumulate again.To reduce the number of maintenance occasions in the whole life cycle,certain LLPs may be replaced in advance when others are replaced,i.e.,there exists an ‘opportunity’,so that the disassembling and assembling cost is reduced but some lives of LLPs are wasted.The number of maintenance occasions inTtis denoted asm,and each maintenance occasion is denoted asTj(j=1,2,...,m).m,Tjand the LLPs replaced in each maintenance all influence the total LLP costCin the whole life cycle.The aim of this article is to determine the optimal opportunistic replacement strategy of LLPs,i.e.,determinem,T1,T2,...,Tmand the LLPs replaced in each maintenance,so thatCis the lowest.

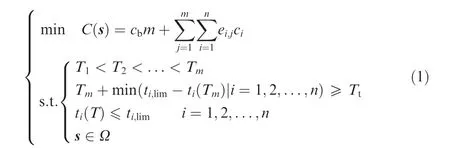

The opportunistic replacement of multiple LLPs can be expressed as

where s=[m,T1,T2,...,Tj,...,Tm,e1,1,e1,2,...,ei,j,...,en,m]is the decision variable vector;ei,jmeans whetherAiis replaced in thejth maintenance(1 for replacement and 0 for nonreplacement);the calculation ofti(T)is shown in Eq.(2);Ω={s=[m,T1,T2,...,Tj,...,Tm,e1,1,e1,2,...,ei,j,...,en,m]|m∈ N∩[0,Tt],Tj∈ N∩[0,Tt),ei,j∈{0,1}}is the solution space,and N is the natural number set.

whereT0=0,ti(T0)is the initial operation time ofAi.

3.Search algorithm

3.1.Analysis of solution space

The opportunistic replacement of LLPs is a combinatorial optimization problem.It is not difficult to obtain the solution space scale of this problem according to the definition domain of decision variables,as shown in Eq.(3).

As can be seen,the solution space scale of this problem is large,and the main influencing factors are the numbernof LLPs and the total lifeTtof equipment.Even if the total life of equipment and the number of LLPs are not large,it is still impossible to obtain the optimal solutions through the complete traversal of solution space.

Equipment maintenance follows a natural time sequence,and thus the solution space can be naturally denoted as a tree,as shown in Fig.1.The root nodeN0means the initial state(T=0),the child nodes ofN0mean thefirst maintenance,the child nodes ofN11,N21,etc.mean the second maintenance,and so on.Each node of the tree except the root node means the corresponding maintenance.The decision variables contained in each node corresponding to thejth maintenance areTjandei,j(i=1,2,...,n).mcorresponds to the length of the path fromN0to the leaf node.The path fromN0to any leaf node corresponds to a solution to the problem.

Therefore,the search algorithm may be used to solve the problem.To improve the search efficiency,the solution space can be reduced in the following aspects:(A)to only traverse feasible solutions;(B)to only traverse the values of the decision variables which may lead to optimal solutions in the traversal of the child nodes of nodes;(C)the timely termination of the search of the nonoptimal solutions.As a result,the reduction rules for the solution space are studied next in four aspects:solution feasibility,determination of the replacement of LLPs,determination of the maintenance occasion and solution optimality.

3.2.Reduction rule for feasibility

It is not difficult to obtain the following reduction rule for feasibility based on the constraints in Eq.(1).

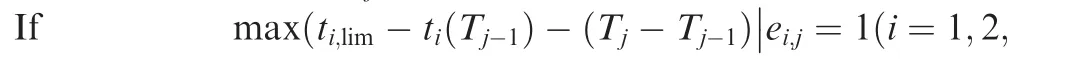

Reduction rule for feasibility:Consider the opportunistic replacement problem of multiple LLPs and its solution space tree.Nj-1is any node of the solution space tree.IfNj-1has a child nodeNj,thenTj-1<Tj≤Tj-1+min(ti,lim-ti(Tj-1)|i=1,2,...,n).Further,ifti,lim-ti(Tj-1)-(Tj-Tj-1)=0,thenei,j=1.

The reduction rule for feasibility covers the range of values of the decision variableTjand the sufficient condition ofei,j=1.

The following two lemmas can also be easily proven based on the constraints in Eq.(1).

Fig.1 Solution space tree.

Lemma 1.Consider two LLPsAiandA′iof the same type.If there existsTaso thatti(Ta)≥t′i(Ta),wheretiis the operation time ofAiandt′iis the operation time ofA′i,then all the feasible replacement strategies forAiapply toA′iwhenT>Ta.

Lemma 2 is about two feasible solutions:at some operation time of the equipment,if the operation time of all LLPs corresponding to one feasible solution is longer than that corresponding to the other feasible solution,then the replacement strategies corresponding to this feasible solution after this operation time also apply to the other feasible solution.

3.3.Reduction rules for replacement of LLPs

The proof of Reduction rule 1 for replacement of LLPs is given in Appendix A.

According to Reduction rule 1 for replacement of LLPs,when equipment is sent for maintenance,determining replaced LLPs in ascending order of each LLP’s residual life can guarantee to reach the optimal solution,and the traversal of all the possible combinations of LLPs is unnecessary.

The proof of Reduction rule 2 for replacement of LLPs is given in Appendix B.

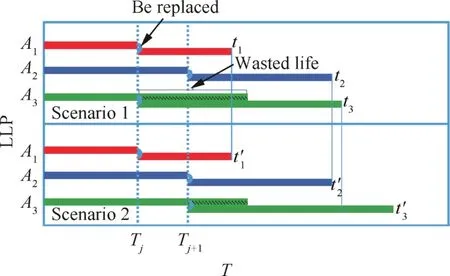

Fig.3 presents Reduction rule 2 for replacement of LLPs.As shown in Fig.3,in Scenario 1,A3is replaced atTj;in Scenario2,A3isreplacedatTj+1;whenT=Tj+1+1,ti(T)≥t′i(T)(i=1,2,3);Scenario 2 is not worse than Scenario 1.

According to Reduction rule 2 for replacement of LLPs,when equipment is sent for maintenance,the LLPs which have reached their life limits must be replaced;in addition,if another LLP needs to be replaced,its residual life should be shorter than the life limits of the LLPs already replaced this time.It is unnecessary to replace the LLPs whose residual lives are longer than the life limits of the replaced LLPs.

3.4.Reduction rule for maintenance occasion

Reduction rule for maintenance occasion:Consider the opportunistic replacement problem of multiple LLPs and its solution space tree.Njis any node of the solution space tree.Ifti,lim-ti(Tj-1)- (Tj-Tj-1)> 0(i=1,2,...,n),then there must exist a feasible solution not includingNjthat is not inferior to the feasible solutions includingNj.

Reduction rule for maintenance occasion is similar to Proposition 3 of Almgren et al.19Its proof can also refer to Proposition 3’s proof.

Fig.2 Reduction rule 1 for replacement of LLPs.

Fig.3 Reduction rule 2 for replacement of LLPs.

Fig.4 Reduction rule for maintenance occasion.

Fig.4 presents reduction rule for maintenance occasion.As shown in Fig.4,in Scenario 1,A1,A2andA3are replaced atTj;in Scenario 2,A1,A2andA3are replaced atTj′;whenT=Tj′+1,ti(T)≥t′i(T)(i=1,2,3);Scenario 2 is not worse than Scenario 1.

According to reduction rule for maintenance occasion,the optimal solution can be determinately traversed if and only if there exists an LLP reaching its life limit when equipment is sent for maintenance.In other words,for the child nodeNjofNj-1,lettingTj=Tj-1+min(ti,lim-ti(Tj-1)|i=1,2,...,n)can guarantee to traverse the optimal solution,and the traversal of (Tj-1,Tj-1+min(ti,lim-ti(Tj-1)|i=1,2,...,n)]is unnecessary.

3.5.Reduction rules for optimality

SupposeNais a node of the solution space tree,but not a leaf node.The estimated lower-bound valueCe(Na)of the objective function of all the solutions containingNacan be calculated with

Reduction rule 1 for optimality:Consider the opportunistic replacement problem of multiple LLPs and its solution space tree.The best value of the objective function of all the traversed solutions is denoted asCmin.Nais a node of the solution space tree,but not a leaf node.IfCe(Na)>Cmin,then the solution containingNacannot be the optimal solution.

Reduction rule 1 for optimality is evident.

According to Reduction rule 1 for optimality,once it is found that the estimated lower-bound value of the objective function of all the solutions containing the current node exceeds the best value of the objective function of all the traversed solutions in the search process,the search of the path containing the current node will be terminated.

The proof of Reduction rule 2 for optimality is given in Appendix C.

According to Reduction rule 2 for optimality,in the search process of child nodes of a node,if the replaced LLPs of each child node are determined in ascending order of the residual lives,and it is found that the estimated lower-bound value of the objective function of all the solutions containing the current child node exceeds the best value of the objective function of all the traversed solutions,the search of the child nodes of the node will be terminated.

3.6.Search algorithm process

The reduction rule for feasibility,the two reduction rules for the replacement of LLPs and the reduction rule for maintenance occasion can be deemed as the generation rules of nodes on the solution space tree,and the two reduction rules for optimality can be deemed as the search termination rules.Based on the above reduction rules,a search algorithm for the opportunistic replacement strategy of multiple LLPs is proposed.

Step 1.Initialize the optimal valueCmin,the optimal leaf node setSmin,the live node listSLand the root nodeN0.Cminis initially set as a large number,Smin=Ø,SL=Ø,T0=0.

Step 2.Judge whethermin(ti,lim-ti(T0)i=1,2,...,n|

)≥Tt.If true,Cmin=0,Smin=Ø,and terminate the search;otherwise,addN0toSL.

Step 3.TraverseSLin the reserve sequence of the adding of nodes.IfSL=Ø,terminate the search;otherwise,extract the last node ofSLand designate it as the current nodeNc.

Step 4.A setSRis formed for the residual lives of the LLPs ofNc.The total number of elements inSRisK;obviously,K≤n.TraverseSRin ascending order of residual lives.Initializek=1,and denote thekth residual life astk,R.

Step 5.Denote the minimum life limit of all the LLPs whose residual lives are shorter than or equal totk,RinNcastc,lim.Judge whethertk,R≥tc,lim.If true,return to Step 3;otherwise,generate thekth child nodeNc,kofNc.The maintenance occasion ofNc,kisTc+1=Tc+min(ti,lim-ti(Tc)|i=1,2,...,n),and the replaced LLPs are those whose residual lives are shorter than or equal totk,R.

Step 6.Judge whetherTc+1+min(ti,lim-ti(Tc+1)|i=1,2,...,n.)≥Tt.If true,updateCminandSmin,and return to Step 3;otherwise,proceed to the next step.

Step 7.Judge whetherCe(Nc,k)>Cmin.If true,return to Step 3;otherwise,proceed to the next step.

Step 8.AddNc,ktoSL,k=k+1.Ifk≤K,return to Step 5;otherwise,return to Step 3.

4.Numerical experiment

The following numerical experiment is carried out in order to verify the algorithm.

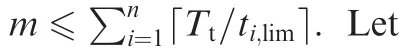

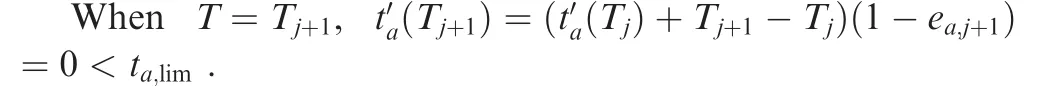

The algorithm is used to solve randomly generated problems for the opportunistic replacement of multiple LLPs.The algorithm is achieved by Java.Ttis 25000,30000,35000,40000,45000,50000,55000 and 60000 respectively,andnis 5,6,7,8,9,10,11 and 12 respectively.20 problems are randomly generated for each group of(Tt,n),wherecb~U(100000,300000),ti,lim~U(15000,30000),ci~U(30000,300000),andti(0)~U(0,ti,lim).The numerical experiment is conducted on an ordinary computer(CPU:Intel Core(TM)i7,memory:4 GB).The timetconsumed for solving each problem,the total numbercnof searched nodes,the total numberccof terminated nodes and the total numberclof searched leaf nodes are respectively recorded.The results are shown in Table 1.tavg,cn,avg,cc,avgandcl,avgin Table 1 mean the average values oft,cn,ccandclrespectively.

As can be seen from Table 1,tavg,cn,avg,cc,avgandcl,avggradually increase with the increase ofTtandn.

The sumcf,avgofcc,avgandcl,avgmeans the number of searched feasible solutions(including those terminated in advance or those not terminated),reflecting the effectiveness of the node generation rules.Fig.5 shows the comparison betweenthenaturallogarithmvalueofcf,avgandthenaturallogarithmvalueoftheestimatedupperlimitcuofthesolutionspace scale in the search algorithm whenTt=40000 andTt=60000.ComparingEq.(5)with Eq.(3),wecanseethatcuismuchsmaller than the solution space scale of the problem.As can be seen from Fig.5,cf,avgis much lower thancu.We takeTt=60000 andn=12 as an example.The solution space scale of the problem is about e1159191andcuis about e119,butcf,avgis only about 127.9.Therefore,the node generation rules in the search algorithm are effective.pavg=cc,avg/(cc,avg+cl,avg)means the proportion of the number of terminated feasible solutions inthe number ofsearched feasible solutions,reflecting theeffectivenessoftheterminationrules.AscanbeseenfromFig.6,pavggradually increases with the gradual increase ofTtandn.WhenTt≥40000 orn≥7,pavgis above 0.75.WhenTt=60000 andn=12,pavgis 0.99995.Therefore,the termination rules in the search algorithm are effective.

As can be seen from Table 1,whenTt≤55000 andn≤11,tavg≤37918 ms.WhenTt=60000andn=12,tavg=1046724 ms,i.e.about 17.4 min.WhenTtandncontinue to increase,tavgwill be several hours or longer based on the trend oftavg.This means that it is inadvisable to directly use the algorithm in the engineering applications with highTtandnif there is no strong computing power.

5.Case

Air China is one of the largest commercial airlines in China.We developed a system named‘Civil Aircraft Engine HealthManagement and Maintenance Decision Support System’for Air China in order to manage aircraft engine operation and maintenance data and to supply maintenance decision support.The main functions of the system include basic data management,operation and maintenance data management,condition monitoring,removal deadline prediction,maintenance plan optimization,maintenance workscope decision,cost and budget management,and maintenance effect evaluation.The system has been applied to Air China since 2010.20

Table 1 Numerical experiment results.

The aircraft engine is a typical repairable system with multiple LLPs,and the LLP replacement cost is a major part of the maintenance cost.CFM56-5B is taken as an example.CFM56-5B contains 20 LLPs,and the replacement of the whole set of LLPs costs about 2.6 million USD.When determining the maintenance workscope of an aircraft engine before a shop visit,engineers often have to consider which LLPs should be replaced.Normally engineers will set a maintenance objective according to their experience.The maintenance objective is total expectedflight cycles or hours after maintenance,and often is set to be the mean time between overhaul.If its current life plus the maintenance objective is less than or equal to its life limit,an LLP is considered to meet the maintenance objective.When it meets the maintenance objective,an LLP does not to be replaced.When it does not meet the maintenance objective,an LLP must be replaced.Because the system has recorded detailed data of all LLPs,to-be-replaced LLPs are easily determined.

The LLP replacement strategy determined by the above method may lead to the high total LLP cost in the whole life cycle,and it is difficult for engineers to consider LLP replacement strategy comprehensively from the perspective of the whole life cycle.Therefore,we apply the proposed algorithm to determining LLP replacement strategy in Air China.A CFM56-5B engine is taken as an example.Table 2 is the LLP list of the engine.

According to the historic maintenance data,the mean time between overhaul is about 12000 FCs andcbis about 160000 USD.We supposeTt=60000FCs.

Firstly,we use the traditional method to determine LLP replacement strategy in the whole life cycle.Each maintenance occasion is when there exists an LLP reaching its life limit.The maintenance objective is 12000 FCs.The results are shown in Table 3.The number of maintenance occasions is 4,and the total LLP cost is 9740820 USD.

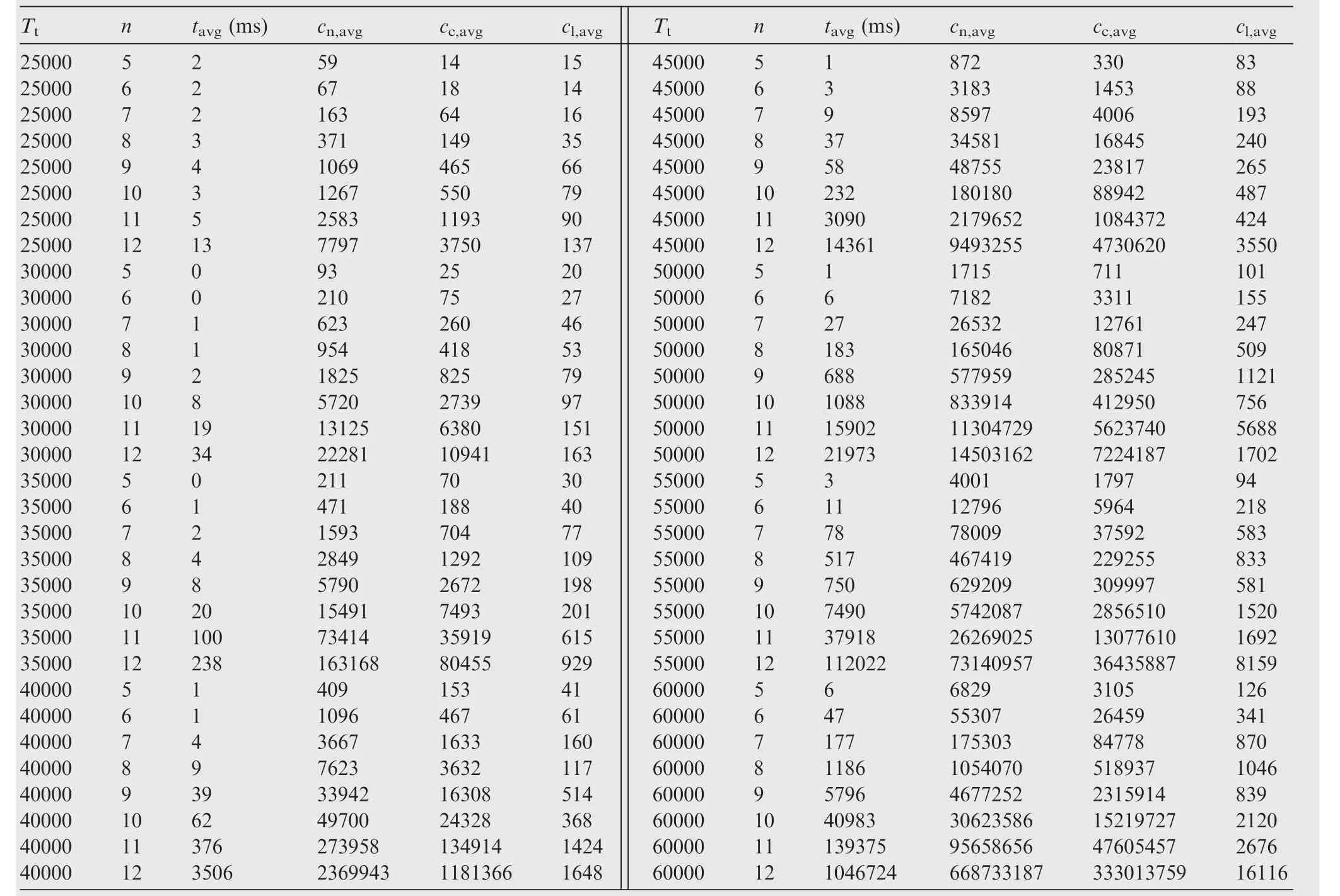

Then,the algorithm proposed in this article is used to search the optimal opportunistic replacement strategy of LLPs in the whole life cycle.Two optimal solutions are obtained by this algorithm,and the optimal value is 7912360 USD,which is 1828460 USD less than the strategy determined by the traditional method.The number of maintenance occasions of these two optimal solutions is 5,and each maintenance occasion and the replaced LLP number in each maintenance are shown in Table 4.

Fig.5 Natural logarithm value for number of searched feasible solutions(cf,avg)and estimated upper limit of solution space scale in search algorithm(cu).

Fig.6 Proportion of number of terminated feasible solutions in number of searched feasible solutions.

The time consumed by this algorithm is 9995 ms.In the numerical experiment,whenTt=60000 andn=12,the time consumed by this algorithm is about 17.4 min,104.7 times as much as the time consumed in this case.The main reason for this phenomenon is that many LLPs in this case have the same life limit.Although the LLPs with the same life limit have different initial operation time,once several of them are replaced at the same time,the replaced LLPs will have the same operation time.The LLPs with the same operation time and life limit can be deemed as an LLP group.As can be seen from Step 5 of this algorithm,the LLPs in such a group should be replaced at the same time or should remain nonreplaced at the same time.The existence of such LLP groups will significantly reduce the solution spacescalewhich needsto besearched in this algorithm.This characteristic can be found in various aircraft engines widely used nowadays.Therefore,this algorithm is applicable to the engineering applications concerning opportunistic replacement of multiple LLPs in aircraft engines.

Table 2 LLP list for some CFM56-5B engine.

Table 3 Results of traditional method.

6.Conclusions

A quick search algorithm for the opportunistic replacement strategy of multiple LLPs is proposed based on six reduction rules.According to these reduction rules,the search algorithm can identify one or several optimal solutions.

The numerical experiment shows that these six reduction rules are effective,and the time consumed by the algorithm is less than 38 s if the total life of equipment is shorter than 55000 and the number of LLPs is less than 11.When the total life of equipment is longer than 60000 and the number of LLP is more than 12,the consumed time will be more than 17.4 min.

For the opportunistic replacement of multiple LLPs in aircraft engines,we confirm that the algorithm consumes a short time,and it is applicable to the engineering applications concerning opportunistic replacement of multiple LLPs in aircraft engines.

The maintenance occasions in the model is affected only by LLPs.In engineering applications,maintenance occasions are also affected by equipment performance degradation,component failure and other factors.Therefore,the next step is tostudy the optimization of equipment maintenance occasions based on multiple factors during the whole life cycle.

Table 4 Optimal solutions.

Acknowledgements

This study is co-supported by the Key National Natural Science Foundation of China(No.U1533202),the Civil Aviation Administration of China(No.MHRD20150104)and the Fundamental Research Funds for the Central Universities(No.HIT.NSRIF.201704).

Appendix A.Proof for Reduction rule 1 for replacement of LLPs

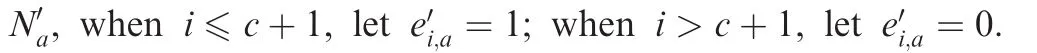

WhenT>Tj+1,sincet′a(Tj+1)=0,t′a(Tj+1)≤ta(Tj+1).According to Lemma 1,t′a(T)<ta,lim.

To sum up,s′is a feasible solution.According to Eq.(1),C(s′)≤C(s).It is thus proven.

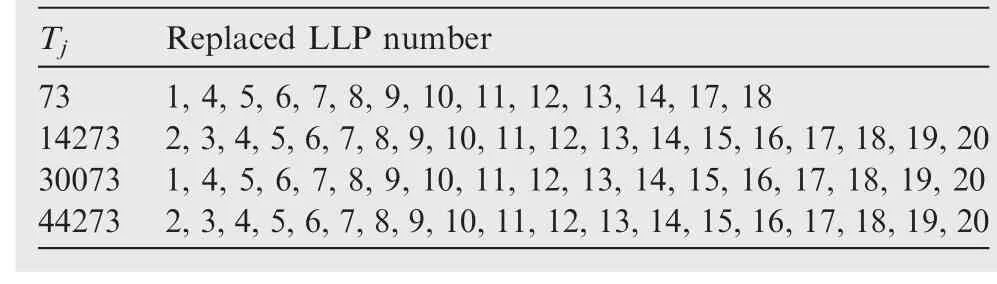

Appendix B.Proof for Reduction rule 2 for replacement of LLPs

WhenT=Tj,ta,lim-t′a(Tj)=ta,lim-ta(Tj-1)- (Tj-Tj-1)can be obtained through Eq. (2). Substituteta,lim-ta(Tj-1)- (Tj-Tj-1)≥tb,liminto it,ta,lim-t′a(Tj)≥tb,lim> 0.Thus,t′a(Tj)<ta,lim.

To sum up,s′is a feasible solution.According to Eq.(1),C(s′)≤C(s).It is thus proven.

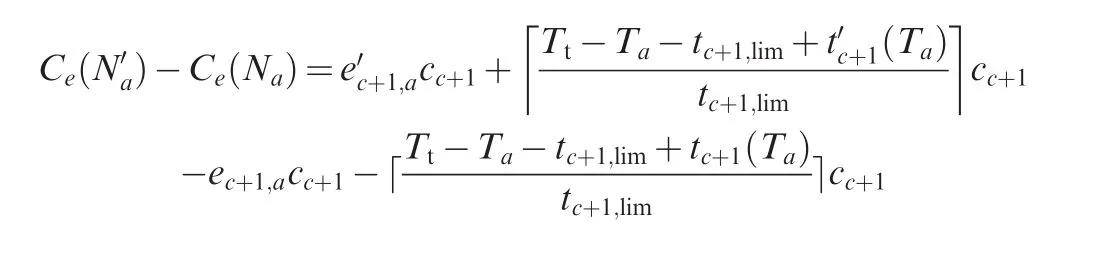

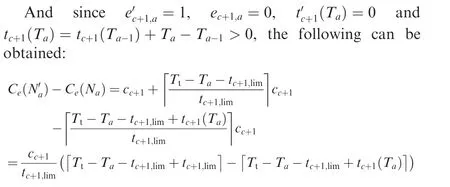

Appendix C.Proof for Reduction rule 2 for optimality

ForNaandN′a,whenj≤a-1,ei,j=e′i,jandti(Tj)=t′

Sincetc+1,lim>tc+1(Ta),Ce(N′a)-Ce(Na)≥ 0.It is thus proven.

1.Dekker R.Applications of maintenance optimization models:A review and analysis.Reliab Eng Syst Saf1996;51(3):229–40.

2.Nowakowski T,Werbin´ka S.On problems of multicomponent system maintenance modelling.Int J Autom Comput2009;6(4):364–78.

3.Dekker R,Wildeman RE,Van der Duyn Schouten FA.A review of multi-component maintenance models with economic dependence.Math Methods Oper Res1997;45(3):411–35.

4.Cho DI,Parlar M.A survey of maintenance models for multi-unit systems.Eur J Oper Res1991;51:1–23.

5.Ab-Samat H,Kamaruddin S.Opportunistic Maintenance(OM)as a new advancement in maintenance approaches:A review.J Qual Maint Eng2014;20(2):98–121.

6.Kececioglu D,Sun F-B.A general discrete-time dynamic programming model for the opportunistic replacement policy and its application to ball-bearing systems.Reliab Eng Syst Saf1995;47(3):175–85.

7.Zhang XH,Zeng JC.A general modeling method for opportunistic maintenance modeling of multi-unit systems.Reliab Eng Syst Saf2015;140:176–90.

8.Epstein S,Wilamowsky Y.A replacement schedule for multicomponent life-limited parts.Nav Res Logist Q1982;29(4):685–92.

9.Fard N,Zheng XT.An approximate method for non-repairable systems based on oppurtunistic replacement policy.Reliab Eng Syst Saf1991;33(2):277–88.

10.Hu JQ,Zhang LB.Risk based opportunistic maintenance model forcomplex mechanicalsystems.ExpSystAppl2014;41(6):3105–15.

11.Bedford T,Dewan I,Meilijson I,Zitrou A.The signal model:A model for competing risks of opportunistic maintenance.Eur J Oper Res2011;214(3):665–73.

12.Ghobbar AA,Cator E,Mayordomo AF.A decision support tool for strategic engine maintenance planning and life limited parts.Stjepandic´J,Rock G,Bil C,editors.Concurrent engineering approaches for sustainable product development in a multidisciplinary environment.London:Springer;2013.p.449–61.

13.George LL,Lo YH.An opportunistic look-ahead replacement policy.J Soc Logist Eng1980;14(4):51–5.

14.Day JA,George LL.Opportunistic replacement of fusion power system parts.Reliability and maintainability symposium;1982 Jan 22–24;Los Angeles,USA;1982.

15.Epstein S,Wilamowsky Y.Opportunistic replacement in a deterministic environment.Comput Oper Res1985;12(3):311–22.

16.Dickman B,Epstein S,Wilamowsky Y.A mixed integer linear programming formulation for multi-component deterministic opportunisticreplacement.JOperResSocIndia1991;28(3):165–75.

17.Dickman B,Wilamowsky Y,Epstein S.Modeling deterministic opportunistic replacement as an integer programming problem.Am J Math Manage Sci1990;10(3–4):323–39.

18.Andre´asson N.Optimization of opportunistic replacement activities in deterministic and stochastic multi-component systems[dissertation].Sweden:Chalmers University of Technology and Go¨teborg University;2004.p.29–93.

19.Almgren T,Andre´asson N,Patriksson M,Stro¨mberg AB,Wojciechowski A,O¨nnheim M.The opportunistic replacement problem:theoretical analyses and numerical tests.Math Methods Oper Res2012;76(3):289–319.

20.Fu XY,Zhong SS,Zhu JM.Civil aeroengine health management and maintenance decision support system:development and application.2013 Aug 12–14;Aviation technology,integration,and operations conference.Los Angeles,USA.Reston:AIAA;2013.p.12–4.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Multi-mode diagnosis of a gas turbine engine using an adaptive neuro-fuzzy system

- PHM with Aerospace Applications

- A critique of reliability prediction techniques for avionics applications

- Satellite lithium-ion battery remaining useful life estimation with an iterative updated RVM fused with the KF algorithm

- A Bayesian approach for integrating multilevel priors and data for aerospace system reliability assessment

- High-speed unsteadyflows past two-body configurations