三种干燥方式对粪污厌氧残余物化学性质的影响

2018-01-08杨厚花张克强李佳佳王丽娜沈仕洲赖睿特

杨厚花 ,张克强 ,闫 雷 ,李佳佳 ,王丽娜 ,沈仕洲 ,赖睿特 ,王 风 *

三种干燥方式对粪污厌氧残余物化学性质的影响

杨厚花1,2,张克强2,3,闫 雷1*,李佳佳2,王丽娜4,沈仕洲2,3,赖睿特2,王 风2,3*

(1.东北农业大学资源与环境学院,哈尔滨 150030;2.农业部环境保护科研监测所,天津 300191;3.农业部大理农业环境科学观测实验站,云南 大理 671004;4.天津农学院园艺园林学院,天津 300384)

为揭示干燥方式对粪污厌氧残余物化学性质的影响,开展了真空冷冻干燥、风干干燥和热风干燥对粪污pH值、氨氮、总氮、含盐量、总有机碳和溶解性有机碳的影响,对客观认识粪污理化性质和粪污厌氧残余物干燥方式的优选提供依据。研究结果显示真空冷冻干燥处理方式各化学指标相比于风干干燥和热风干燥方式数值较大,表明真空冷冻干燥处理过程能够维持粪污厌氧残余物化学形态和较高的含量。在此基础上,比较发现真空预冻3 h和预冻6 h对各化学指标的影响差异不显著。建议真空冷冻干燥并且预冻3 h作为粪污厌氧残余物相对较适宜的干燥方式,不仅能够较少地破坏粪污化学性质,同时具有操作简便、节省时间等优点。

粪污厌氧残余物;真空冷冻干燥;风干干燥;热风干燥;化学性质

粪污厌氧残余物是沼气发酵后剩余的半固体物质,含有丰富的有机质、腐植酸、氨基酸、氮、磷、钾和微量元素,还田施用能够提高土壤肥力、改善土壤结构,增强土壤持续生产能力[1]。干燥是粪污厌氧残余物最主要的初级处理方式,粪污厌氧残余物干燥有利于原料的保存、深度处理和进一步的科学研究。而不同干燥方式对粪污厌氧残余物的理化性质影响巨大,选择适宜的干燥方式对于优化资源化处理方案和科学技术研究具有一定的意义。

传统的干燥方式如风干或日晒方式能耗低、设备投入少,但干燥时间长,产品性质变化较大[2]。近年较多采用的方式是热风干燥或热泵干燥,以及热风或热泵辅助其他方式干燥,这种方式干燥周期短,但能耗高、设备投入多。最近新兴起的真空冷冻干燥技术被广泛地应用到生物、医药和食品领域。Oddone等[3]研究表明真空冷冻干燥促进大冰晶的形成,加速了冰的升华并减缓了解吸过程。Dong等[4]发现真空冷冻干燥能够很好地保存咖啡豆有机酸和单不饱和脂肪酸。

目前粪污厌氧残余物常用干燥方式有风干干燥、热风干燥、微波冻干和真空冷冻干燥等[5],综合比较不同干燥方式对粪污厌氧残余物理化性质的研究还较少,而真空冷冻干燥方式对粪污厌氧残余物干燥效果也还未见报道。本文拟通过比较真空冷冻干燥、风干干燥和热风干燥等方式对粪污厌氧残余物理化性质差异,并在此基础上优化真空冷冻干燥预冻时长,从而提出粪污厌氧残余物最佳干燥方式,为更加准确地揭示粪污化学形态与含量,以及为科学研究开展和干燥方式的优选提供理论依据。

1 材料与方法

1.1 试验材料

粪污厌氧残余物采自天津宁河种猪场规模化养殖能源环境工程中全混式沼气发酵工程(CSTR),该工程有效反应容积500 m3,以猪粪和水为原料,日消耗粪便 10 t,粪污厌氧残余物产出量为 2.05 t·d-1,该沼气发酵工程长期稳定运行。粪污厌氧残余物基本理化性质为含水量88.84%,pH值8.84,铵态氮(NH+4-N)31 mg·g-1,全氮(TN)41.93 mg·g-1,溶解性有机碳(DOC)7.43 g·kg-1,总有机碳(TOC)507.68 g·kg-1,含盐量0.05%。

1.2 仪器与设备

FD系列冷真空冷冻干燥机;2XZ-4型旋片式真空泵;DGG-9240B型电热恒温鼓风干燥机;DELTA 320 pH 计;DDSJ-308A 电导率仪;KDY-9810凯氏定氮仪;VarioTOC测定仪。

1.3 试验设计

1.3.1 试验处理

1.3.1.1 不同干燥方式对粪污厌氧残余物理化性质的影响

真空冷冻干燥(Vacuum Freeze Drying,VFD):真空冷冻干燥机干燥。称取500 g新鲜均匀粪污厌氧残余物均匀覆盖在物料盘中,厚度不超过10 mm,放入冷阱预冻6 h之后,将冷冻的粪污厌氧残余物移入真空冷冻干燥室,腔内压强3~4 Pa,低温-80℃,连续干燥24 h至恒重。

风干干燥(Air Drying,AD):自然风干干燥。称取500 g新鲜均匀粪污厌氧残余物均匀平铺在物料盘中,放置在空旷遮光的板房内,平均室温8℃,连续干燥一周至恒重。

热风干燥(Heat Air Drying,HAD):电热干燥箱干燥。称取500 g新鲜均匀粪污厌氧残余物均匀平铺在铁盘中,热风温度80℃,连续干燥8 h至恒重。

3种不同干燥处理均设置3次重复。

1.3.1.2 VFD处理预冻时长对粪污厌氧残余物化学性质的影响

为进一步优化和探究VFD预冻时间对样品各指标的影响,根据真空冷冻干燥设备推荐参数设置了预冻 3 h(VFD3)和预冻 6 h(VFD6)。

VFD3:称取500 g新鲜均匀粪污厌氧残余物均匀覆盖在物料盘中,厚度不超过10 mm,放入冷阱预冻3 h之后,将冷冻的粪污厌氧残余物移入真空冷冻干燥室,腔内压强3~4 Pa,低温-80℃,连续干燥24 h至恒重。

VFD6:同上,但放入冷阱内预冻6 h。

两种预冻时长干燥处理均设置3次重复。

1.3.2 测定方法

含水率测定应用恒温箱热风干燥法[6-7]。pH值用(水∶样=1∶1)pH计直接测定。铵态氮的测定采用凯氏定氮法[8]。全氮在样品消煮后采用凯氏定氮法测定[9]。盐度应用电导率仪测定[10-12]。DOC采用TOC分析仪测定[13]。总有机碳选用重铬酸钾容量法-稀释热法测定[14]。

1.4 数据分析

用Excel 2010处理数据并作图,采用SPSS软件进行方差分析,应用Duncan方法分析各处理间数据在α=0.05水平的差异显著性。

2 结果与分析

2.1 干燥方式对粪污厌氧残余物物理性质的影响

2.1.1 粪污厌氧残余物含水率和pH值变化特征

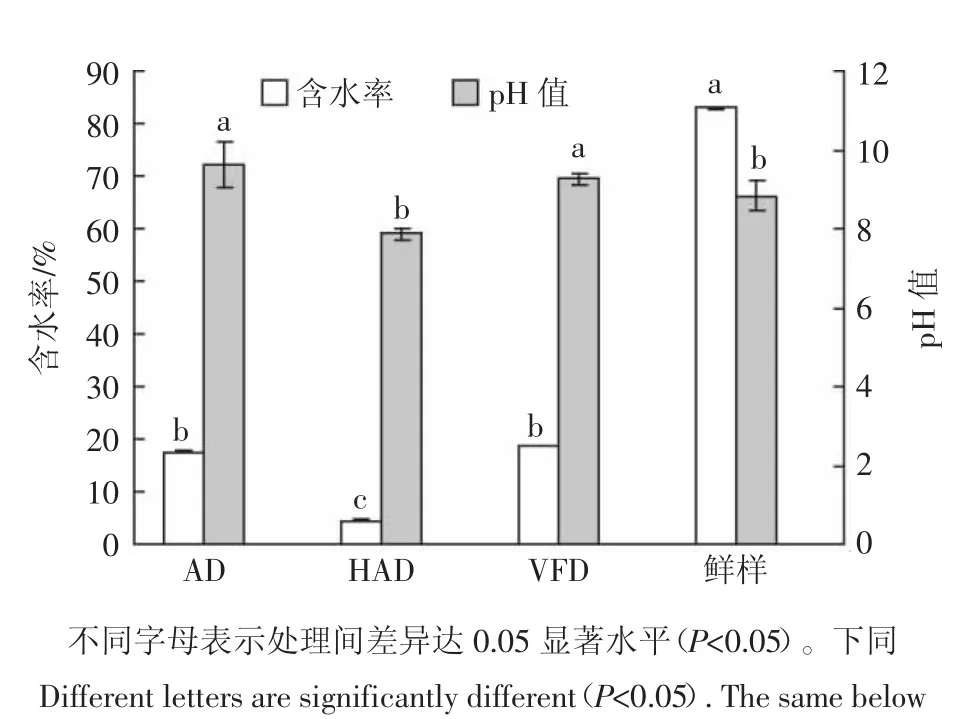

不同干燥方式下粪污厌氧残余物含水率和pH值见图1。3种干燥处理水分干燥效果总体呈现VFD、AD>HAD趋势,VFD处理样品含水率能够达到与AD处理接近的水平,处理间差异不显著,VFD处理样品含水率比鲜样降低了64个百分点;HAD处理样品的含水率最小,与各处理相比均达到显著差异水平,比AD和VFD处理约低了13~14个百分点。不同处理粪污厌氧残余物pH值呈现AD、VFD>鲜样>HAD趋势。AD处理pH值与VFD处理间差异不显著,分别比鲜样pH值有所升高,维持了鲜样较高的pH值特征。HAD处理pH值比鲜样降低了11%,朝向中性趋势降低,与AD和VFD处理相比差异达到显著水平(P<0.05)。

图1 不同干燥方式对粪污厌氧残余物含水率和pH值的影响Figure 1 Characteristics of moisture content and pH value under different drying methods

2.1.2 粪污厌氧残余物TN和NH+4-N含量变化特征

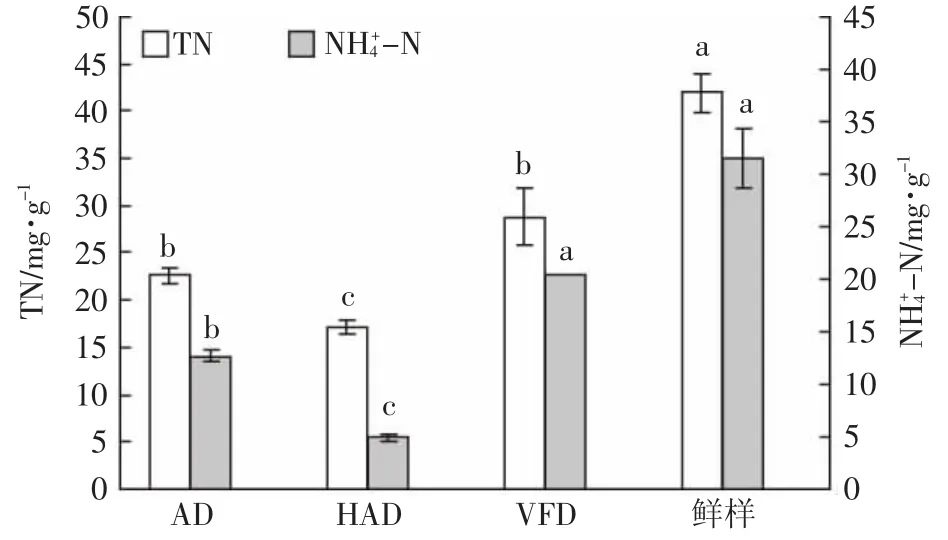

不同干燥方式下粪污厌氧残余物TN和NH+4-N见图2。3种干燥方式粪污厌氧残余物TN含量依次为VFD>AD>HAD。虽然VFD处理TN含量较鲜样降低了30%,但比AD和HAD处理分别高27%和69%,与HAD处理间差异达到显著水平(P<0.05)。总体来看,3种干燥处理NH+4-N含量趋势为VFD>AD>HAD,处理之间差异分别达到显著水平(P<0.05),VFD处理NH+4-N含量分别是AD处理和HAD处理的1.5倍和4倍。3种干燥处理NH+4-N含量均比新鲜样品有所损失,VFD处理NH+4-N含量比鲜样降低了35%左右,但处理间差异不显著,HAD处理NH+4-N含量比鲜样降低了84.44%,HAD处理和AD处理与鲜样之间差异达到显著水平(P<0.05)。

图2 不同干燥方式对粪污厌氧残余物TN和NH+4-N含量的影响Figure 2 Characteristics of TN and NH+4-N under different drying methods

2.1.3 粪污厌氧残余物TOC和DOC含量变化特征

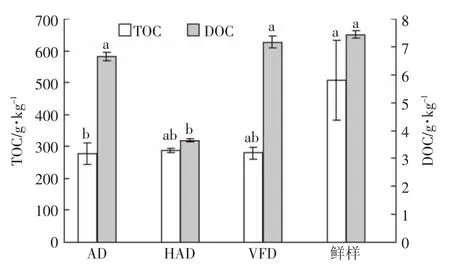

不同干燥方式下粪污厌氧残余物TOC和DOC含量见图3。粪污厌氧残余物TOC含量总体变化趋势为鲜样>HAD、AD、VFD。3种干燥处理TOC含量都较鲜样降低了40%,3个干燥处理之间TOC含量差异并不显著。粪污厌氧残余物DOC含量总体变化趋势为鲜样>VFD>AD>HAD。VFD和AD处理的DOC含量与鲜样间差异不显著,HAD处理DOC含量与其他处理间差异均达到显著水平(P<0.05)。

图3 不同干燥方式对粪污厌氧残余物TOC和DOC含量的影响Figure 3 Characteristics of TOC and DOC under different drying methods

2.1.4 粪污厌氧残余物全盐量变化特征

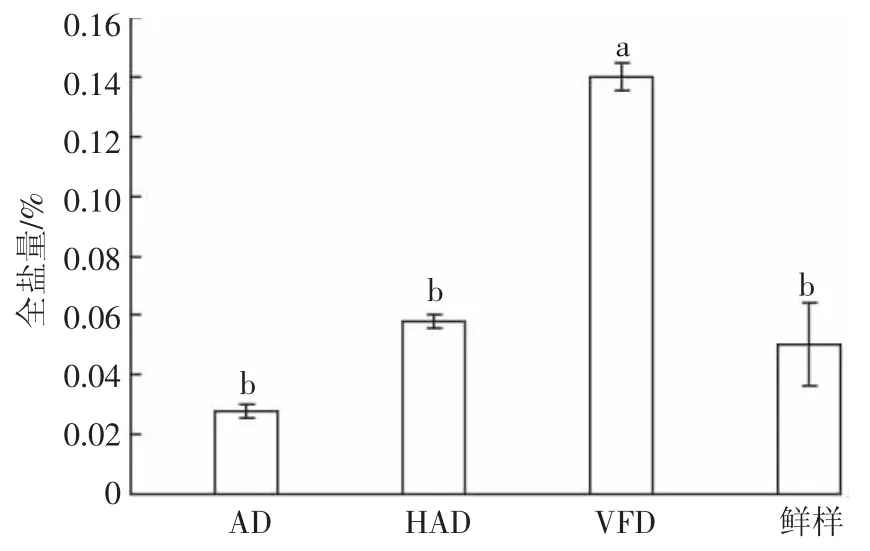

不同干燥方式下粪污厌氧残余物全盐量见图4。粪污厌氧残余物全盐量总体呈现VFD>HAD>鲜样>AD趋势。VFD处理全盐量比鲜样显著增加,分别是AD、鲜样和HAD的4.7、2.8倍和2.3倍,处理之间差异均达到显著水平。AD、HAD处理与鲜样间差异不显著。

图4 不同干燥方式对粪污厌氧残余物全盐量的影响Figure 4 Characteristics of total salinity under different drying methods

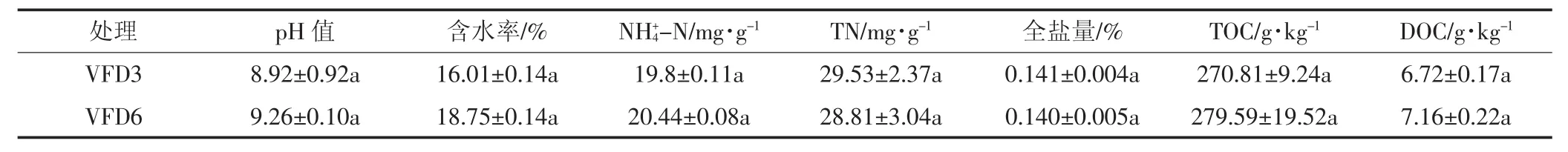

2.2 VFD处理预冻时长对粪污厌氧残余物化学性质的影响

预冻时长(预冻3 h和6 h)对粪污厌氧残余物化学性质的影响见表1。两个预冻时长处理含水率、NH+4-N、DOC、TOC、TN、全盐量等指标数值非常相近,所有指标处理之间差异均不显著,真空冻干预冻时长对粪污厌氧残余物理化性质的影响较小。预冻3 h既节约时间与能源,又可达到与预冻6 h相似的干燥效果和稳定的化学性质。

3 讨论

本研究比较了VFD、AD和HAD干燥方式对粪污厌氧残余物干燥效果与化学性质。结果表明VFD和AD干燥所得样品中TN和NH+4-N含量较高,HAD处理含量最低,主要因为高温条件下部分氮素以气体形式分解扩散,而VFD和AD干燥在相对低温条件下有效保持了NH+4-N含量[15-16]。DOC含量变化特征与NH+4-N相似,VFD和AD干燥处理中DOC含量较高,而HAD处理DOC含量相对较低,主要因为高温显著促进了粪污中易氧化碳和溶解性有机碳的分解[17],而VFD和AD干燥过程中抗氧化成分和性质得到较好保护[18],张雨婷等[19]和高炜等[20]发现冷冻干燥能够保持铁皮石斛较高的多糖含量,也从侧面给出了相似的研究启示。本研究发现3个干燥处理TOC含量差异不显著,表明非水溶性有机碳仍然是粪污厌氧残余物中主要形态,并且该部分成分对温度变化不明显。有研究发现与TOC相比,草地土壤DOC的变化更为迅速[21],并且土壤DOC含量在有机质中所占的比例很小[22]。VFD处理的粪污厌氧残余物全盐量不仅明显高于AD和HAD处理,甚至高于鲜样。这可能是因为VFD处理存在冻融过程,螯合的离子在冻融过程中被释放,同时有机物矿化率增大,这个推论在土壤的冻融过程中被广泛证实。常宗强等[23]发现冻融过程对土壤氮矿化有促进作用,罗金明等[24]研究得出冻融土壤中HCO-3、CO-3等离子含量显著增加。VFD、AD和HAD处理方式对粪污厌氧残余物理化性质均有较大的影响,但VFD方式与AD和HAD相比影响最小。HAD方式虽干燥时间短,但耗能高,干燥方法工业化应用具有一定局限性,在粪污规模化生产中使用较少[25-27]。VFD能够实现与AD相近的水分去除效果,本研究也证实VFD处理缩短干燥时间、保持样品化学组成等优势[28-34],对于了解和掌握粪污本身化学含量和形态具有一定的意义。

VFD干燥前需对样品进行预冻,目的是为了冻结样品中水分以进行真空升华[35]。预冻时间过长不仅浪费能源和时间,而且会影响样品中化学组成。本研究表明两组预冻时长处理对粪污厌氧残余物化学性质影响差异不显著,均可以获得较好的干燥效果和稳定的化学性质与组成,这与干燥物体的性质和尺寸有关。任红兵[36]研究发现预冻时间控制在3 h以内即可满足VFD升华过程,与本研究结果高度一致。因而推荐真空冷冻干燥且预冻3 h作为粪污厌氧残余物干燥方式。

4 结论

(1)真空冷冻干燥、风干干燥和热风干燥对粪污厌氧残余物的pH、NH+4-N、TN、含盐量、TOC和DOC均有较大的影响,但真空冷冻干燥与风干干燥和热风干燥相比影响最小。

(2)真空冷冻干燥6 h或3 h预冻时长对粪污厌氧残余物化学性质影响差异不显著。

表1 不同预冻时长对粪污厌氧残余物化学性质的影响Table 1 Chemical properties of bio-slurry under different pre-freezing periods

(3)预冻3 h的真空冷冻干燥处理方式对样品化学性质影响最小,干燥方便快捷、操作简便,推荐作为农业生产和科学研究使用的干燥处理方式。同时在生产上或科研上的应用还应综合考虑成本和研究目标。

[1]白莹莹.农业沼气在北方农业源减排中的应用浅析[J].环境科学导刊,2014,33(1):73-76.

BAI Ying-ying.Application of agricultural biogas in agricultural emission reduction in Northern China[J].Environmental Science Survey,2014,33(1):73-76.

[2]邓媛元,汤 琴,张瑞芬,等.不同干燥方式对苦瓜营养与品质特性的影响[J].中国农业科学,2017,50(2):362-371.

DENG Yuan-yuan,TANG Qin,ZHANG Rui-fen,et al.Effects of different drying methods on the nutrition and physical properties of momordicacharantia[J].Scientia Agricultura Sinica,2017,50(2):362-371.

[3]Oddone I,Antonello A B,Roberto P.Influence of controlled ice nucleation on the freeze-drying of pharmaceutical products:The secondary drying step[J].International Journal of Pharmaceutics,2017,524(1):134-140.

[4]Dong W J,Hu R S,Chu S,et al.Effect of different drying techniques on bioactive components,fatty acid composition,and volatile profile of robusta coffee beans[J].Food Chemistry,2017,23(4):121-130.

[5]吴景贵,孟安华,张振都,等.循环农业中畜禽粪便的资源化利用现状及展望[J].吉林农业大学学报,2011,33(3):237-242,259.

WU Jing-gui,MENG An-hua,ZHANG Zhen-du,et al.Present situations and prospects for resource utilization of livestock and poultry feces in recycling agriculture[J].Journal of Jilin Agricultural University,2011,33(3):237-242,259.

[6]张学礼,胡振琪,初士立.土壤含水量测定方法研究进展[J].土壤通报,2005,36(1):118-123.

ZHANG Xue-li,HU Zhen-qi,CHU Shi-li.Research advances in measuring method of soil water content[J].Chinese Journal of Soil Science,2005,36(1):118-123.

[7]时新玲,王国栋.土壤含水量测定方法研究进展[J].中国农村水利水电,2003,59(10):84-86.

SHIXin-ling,WANGGuo-dong.Researchadvancesinmeasuringmethod of soil water content[J].China Rural Water and Hydropower,2003,59(10):84-86.

[8]谢小玲,李海锋,李雪莹,等.土壤全氮半微量定氮法与自动定氮仪定氮法的比较分析[J].生态环境学报,2012,21(6):1071-1074.

XIE Xiao-ling,LI Hai-feng,LI Xue-ying,et al.Comparative analysis of nitrogen fixation method for semi-micro nitrogen fixation and automatic nitrogen fixation in soil[J].Ecology and Environmental Sciences,2012,21(6):1071-1074.

[9]胡子峰.凯氏定氮仪原理和校准的方法[J].上海计量测试,2011,223(3):49-50.

HU Zi-feng.The principle and calibration method of Kjeldahl nitrogen apparatus[J].Shanghai Measurement and Testing,2011,223(3):49-50.

[10]邱桂京.电导率仪检定原理的探讨[J].计量与测试技术,2005,32(11):14-16.

QIU Gui-jing.Electricity conductivity appraisal principle discussion[J].Measurement and Testing Techniques,2005,32(11):14-16.

[11]刘 峄,雷玲玲,刘慧芹,等.2265FS土壤原位电导仪测定结果与土壤含盐量的关系[J].湖北农业科学,2014,53(13):3167-3169.

LIU Yi,LEI Ling-ling,LIU Hui-qin,et al.Relationships between the soil in situ conductive meter measured by 2265FS and the soil salinity[J].Hubei Agricultural Sciences,2014,53(13):3167-3169.

[12]张 祯.影响土壤电导率的测定因素分析[C].中国环境科学学会,2008:1071-1073.

ZHANG Zhen.Analysis of determinants of soil conductivity[C].Chinese Society for Environmental Sciences,2008:1071-1073.

[13]盛 浩,宋迪思,王翠红,等.土壤溶解性有机碳四种测定方法的对比和转换[J].土壤,2015,47(6):1049-1053.

SHENG Hao,SONG Di-si,WANG Cui-hong,et al.Comparison and conversion of four methods for determination of soil soluble organic carbon[J].Soils,2015,47(6):1049-1053.

[14]鲍士旦.土壤农化分析[M].北京:中国农业科技出版社,1999:30-40.

BAO Shi-dan.Soil agricultural chemical analysis[M].Beijing:Agricultural Science and Technology Press of China,1999:30-40.

[15]邓宇杰,罗理勇,田小军,等.干燥方式对不同品种茶树花主要生化成分的影响[J].食品工业科技,2017,919(7):356-364.

DENG Yu-jie,LUO Li-yong,TIAN Xiao-jun,et al.Effects of drying methods on the principal biochemical components of different cultivars of tea flower[J].Science and Technology of Food Industry,2017,919(7):356-364.

[16]Argyropoulos D,Mvller J.Kinetics of change in colourandrosmarinic acid equivalents during convective drying of lemon balm(Melissa officinalis L.)[J].Journal of Applied Research on Medicinal and Aromatic Plants,2014,1(1):e15-e22.

[17]李 琪,薛红喜,王云龙,等.土壤温度和水分对克氏针茅草原生态系统碳通量的影响初探[J].农业环境科学学报,2011,30(3):605-610.

LI Qi,XUE Hong-xi,WANG Yun-long,et al.The preliminary study on the impact of soil temperature and moisture on carbon flux over Stipakrylovie ecosystem[J].Journal of Agro-Environment Science,2011,30(3):605-610.

[18]Jiang N,Liu C Q,Li D J.Evaluation of freeze drying combined with microwave vacuum drying for functional okra snacks:Antioxidant properties,sensoryquality,andenergyconsumption[J].LWT-Food Science and Technology,2017,82(4):216-226.

[19]张雨婷,郭 赛,张 莉,等.不同干燥方法对铁皮石斛多糖和甘露糖含量的影响[J].安徽中医药大学学报,2017,36(2):68-71.

ZHANG Yu-ting,GUO Sai,ZHANG Li,et al.Effects of different drying methods on polysaccharides and mannose content of dendrobium candidum[J].Journal of Anhui Traditional Chinese Medical Univer-sity,2017,36(2):68-71.

[20]高 炜,丁胜华,王蓉蓉,等.不同干燥方式对柠檬片品质的影响[J].食品科技,2017,42(2):114-119.

GAO Wei,DING Sheng-hua,WANG Rong-rong,et al.Effects of drying methods on the quality of lemon piece[J].Food Science and Technology,2017,42(2):114-119.

[21]齐玉春,彭 琴,董云社,等.温带典型草原土壤总有机碳及溶解性有机碳对模拟氮沉降的响应[J].环境科学,2014,35(8):3073-3082.

QI Yu-chun,PENG Qin,DONG Yun-she,et al.Reponses of soil total organic carbon and dissolved organic carbon to simulated nitrogen deposition in temperate typical steppe in Inner Mongolia,China[J].Environmental Science,2014,35(8):3073-3082.

[22]卫 东,戴万宏,汤 佳.不同利用方式下土壤溶解性有机碳含量研究[J].中国农学通报,2011,27(18):121-124.

WEI Dong,DAI Wan-hong,TANG Jia.Study of soils dissolved organic carbon in different land use[J].Chinese Agricultural Science Bulletin,2011,27(18):121-124.

[23]常宗强,马亚丽,刘 蔚,等.土壤冻融过程对祁连山森林土壤碳氮的影响[J].冰川冻土,2014,36(1):200-206.

CHANG Zong-qiang,MA Ya-li,LIU Wei,et al.Effect of soil freezing and thawing on the carbon and nitrogen in forest soil in the Qilian Mountains[J].Journal of Glaciology and Geocryology,2014,36(1):200-206.

[24]罗金明,邓 伟,张晓平,等.冻融季节苏打盐渍土的水盐变化规律[J].水科学进展,2008,19(4):559-566.

LUO Jin-ming,DENG Wei,ZHANG Xiao-ping,et al.Variation of water and salinity in sodic saline soil during frozen-thawing season[J].Advancesin Water Science,2008,19(4):559-566.

[25]Mghazli S,Ouhammou M,Hidar N,et al.Drying characteristics and kinetics solar drying of Moroccan rosemary leaves[J].Renewable Energy,2017,108(12):303-310.

[26]Onwude D I,Hashim N,Chen G G.Recent advances of novel thermal combined hot air drying of agricultural crops[J].Trends in Food Science&Technology,2016,57(9):132-145.

[27]Sebastiani A,Hirnet T,Antje J E.Comparison of speed-vacuum method and heat-drying method to measure brain water content of small brain samples[J].Journal of Neuroscience Methods,2017,276(11):73-78.

[28]Sette P,Salvatori D,Schebor C.Physical and mechanical properties of raspberries subjected to osmotic dehydration and further dehydration by air-and freeze-drying[J].Food and Bioproducts Processing,2016,100(7):156-171.

[29]Li Y H,Qi Y R,Wu Z F,et al.Comparative study of microwave-vacuum and vacuum drying on the drying characteristics,dissolution,physicochemical properties,and antioxidant capacity of Scutellaria extract powder[J].Powder Technology,2017,317(5):430-437.

[30]Rajkumar G,Shanmugam S,Galvao M S,et al.Comparative evaluation of physical properties and volatiles profile of cabbages subjected to hot air and freeze drying[J].LWT-Food Science and Technology,2017,80(3):501-509.

[31]Chen Q Q,Li Z L,Bi J F,et al.Effect of hybrid drying methods on physicochemical,nutritional and antioxidant properties of dried black mulberry[J].LWT-Food Science and Technology,2017,80(2):178-184.

[32]Schulze B,Hubbermann E M,Schwarz K.Stability of quercetin derivatives in vacuum impregnated apple slices after drying(microwave vacuum drying,air drying,freeze drying)and storage[J].LWT-Food Science and Technology,2014,57(11):426-433.

[33]Park H J,Lee Y,Eun J B.Physicochemical characteristics of kimchi powder manufactured by hot air drying and freeze drying[J].Biocatalysis and Agricultural Biotechnology,2016,5(2):193-198.

[34]Parniakov O,Bals O,Lebovka N,et al.Pulsed electric field assisted vacuum freeze-drying of apple tissue[J].Innovative Food Science and Emerging Technologies,2016,35(4):52-57.

[35]Ma J,Sun D W,Qu J H.Prediction of textural changes in grass carp fillets as affected by vacuum freeze drying using hyperspectral imaging based on integrated group wavelengths[J].LWT-Food Science and Technology,2017,82(4):377-385.

[36]任红兵.真空冷冻干燥技术及其在中药领域的应用[J].装备应用与研究,2016,482(20):12-21.

REN Hong-bing.Vacuum freeze drying technology and its application in traditional Chinese medicine[J].Equipment Application and Research,2016,482(20):12-21.

The effects of three kinds of drying methods on the chemical properties of fecal anaerobic residues

YANG Hou-hua1,2,ZHANG Ke-qiang2,3,YAN Lei1*,LI Jia-jia2,WANG Li-na4,SHEN Shi-zhou2,3,LAI Rui-te2,WANG Feng2,3*

(1.College of Resources and Environment,Northeast Agricultural University,Harbin 150030,China;2.Agro-Environmental Protection Institute,Ministry of Agriculture,Tianjin 300191,China;3.Dali Experimental Station of Agro-Environmental Science,Ministry of Agriculture,Dali 671004,China;4.College of Horticulture Landscape Architecture,Tianjin Agricultural University,Tianjin 300384,China)

This study was used to reveal the effects of different drying methods on the chemical properties of fecal anaerobic residues,which provided the theoretical basis for choosing suitable drying measures.After fecal anaerobic residues were dried by vacuum freeze-drying,airdrying,and hot air-drying,a series of evaluation indices was tested,which included pH value,ammonia nitrogen,total nitrogen,total salinity,total organic carbon(TOC),and dissolved organic carbon(DOC).The results showed that vacuum freeze-drying had the least loss of chemical components of the three methods,which indicated that the vacuum freeze-drying process could maintain high physical and chemical properties.In this study,the effects of different pre-freezing times on the chemical properties of fecal anaerobic residue were also analyzed.There was no significant difference between 3 hours of freeze-drying and 6 hours of freeze-drying in the characterizations of the fecal anaerobic residues.Thus,freeze-drying for 3 hours is suggested as the best pretreatment because of its easy operation and short time.

fecal anaerobic residue;vacuum freeze-drying;air-drying;hot air-drying;chemical property

2017-06-29 录用日期:2017-09-08

杨厚花(1990—),女,山东人,硕士研究生,从事污染防治研究。E-mail:houhua_yang0929@163.com

*通信作者:王 风 E-mail:wangfeng_530@163.com 闫 雷 E-mail:yanlei_74@163.com

国家重点研发计划项目(2017YFD0800403);天津市自然科学基金项目(16JCYBJC29700);948 项目(2014-S4,2016-X53);公益性行业(农业)科研专项基金(201503119-06-01)

Project supported:NationalKey Research and Development Program(2017YFD0800403);Natural Science Foundation of Tianjin,China(16JCYBJC29700);948Program(2014-S4,2016-X53);TheSpecial ScientificResearchFundof Agricultural PublicWelfareProfessionof China(201503119-06-01)

X713

A

1672-2043(2017)12-2515-06

10.11654/jaes.2017-0915

杨厚花,张克强,闫 雷,等.三种干燥方式对粪污厌氧残余物化学性质的影响[J].农业环境科学学报,2017,36(12):2515-2520.

YANG Hou-hua,ZHANG Ke-qiang,YAN Lei,et al.The effects of three kinds of drying methods on the chemical properties of fecal anaerobic residues[J].Journal of Agro-Environment Science,2017,36(12):2515-2520.