Effects of Nano PbZrO3 on the Decompositions of AP, RDX, HMX and the Combustion of (NG/NC) Propellant

2018-01-08WANGWeiminWEITaotaoGAOHongxuXIAOLibaiXUKangzhenZHAOFengqi

WANG Wei-min, WEI Tao-tao, GAO Hong-xu, XIAO Li-bai, XU Kang-zhen, ZHAO Feng-qi

(1. College of Chemical Engineering, Northwest University, Xi′an 710069, China;2. Xi′an Modern Chemistry Research Institute, Xi′an 710065, China)

Effects of Nano PbZrO3on the Decompositions of AP, RDX, HMX and the Combustion of (NG/NC) Propellant

WANG Wei-min1, WEI Tao-tao1, GAO Hong-xu2, XIAO Li-bai2, XU Kang-zhen1, ZHAO Feng-qi2

(1. College of Chemical Engineering, Northwest University, Xi′an 710069, China;2. Xi′an Modern Chemistry Research Institute, Xi′an 710065, China)

nano PbZrO3; NG/NC double-base propellant;metal composite oxide; solid propellant; thermal decomposition; catalytic combustion

Introduction

Solid propellant is the power source of solid rocket and missile engine, and the core technique of propellant is combustion. Based on the requirement of stability, the combustion of propellant is controllable, which can be adjusted by adding the combustion catalyst. A small amount of catalyst (mass fraction 2%-5%) can greatly improve the propellant combustion performance[1-2]. Metal oxides or nano metal oxides, such as CuO, α-MNO2, Co3O4and PbO, are often used as combustion catalysts in solid propellant[3-6]. And the physical mixtures of two metal oxides present better application properties than single metal oxides. However, the physical mixtures of two metal oxides often present bad compatibility with some acidic components of solid propellant, which limits their applications.

As a new type of functional materials, nano metal composite oxides have small size, large specific surface area and high stability(acid and alkali resistance), and two metals of metal composite oxides can form “synergetic effect”[7]. So many metal composite oxides have been largely reported in recent years, and they were used in many new fields, such as photocatalysis[8], thermoelectric materials[9]and Li ion batteries[10]. The metal composite oxides can improve the combustion parameters of the solid propellants, such as the burning rate[11], the pressure exponent[12]and energy properties of propellants[13], which have better application prospects than single metal oxides. In our work, we hope that metal composite oxides can be used as combustion catalysts of solid propellant, instead of metal oxides or their physical mixtures.

PbZrO3, a typical perovskite composite oxide (ABO3), is a novel inorganic material with unique physical and chemical properties, whose oxygen octahedron shares the same vertex and then forms a three-dimensional network. Metal composite oxide PbZrO3has been reported because of its ferroelectric, electronic and optical properties. For example, Nawanil et al. synthesized electrospun antiferroelectirc lead zirconate nanofibers[14]. Bjørheim et al. reported the combined conductivity and DFT study of protons in PbZrO3[15]. Nunes et al. prepared lead zirconate powders to study photoluminescent properties[16]. But nano PbZrO3as combustion catalyst is rarely reported. PbZrO3can be used as a good potential catalyst in solid propellant instead of common PbO, ZrO2and their physical mixtures, which will open up a new application field of nano PbZrO3.

In this study, we will firstly report the catalytic decomposition action of nano PbZrO3on AP, RDX and HMX, and explore its catalytic combustion properties in NG/NC solid propellant.

1 Experimental

1.1 Materials

Nano PbZrO3powders were synthesized by co-precipitation method[17-18]: Pb(NO3)2·(AR grade) was dissolved into distilled water. ZrO(NO3)2·2H2O was added to the Pb(NO3)2aqueous solution to form a stoichiometric equimolar aqueous solution (100mL) with a total cation concentration of 0.6mol/L, followed by the addition of H2O2(20mL,mass fraction of 30%) and formed solution (A). A solution (B) was the mixture of H2O2(80mL,mass fraction of 30%) and NH3·H2O (20mL,mass fraction of 28%). Then solution (A) was slowly dripped into the solution (B) in the ice-water bath under stirring, generating plenty of light yellow precipitate. After stirring for 2h, the precipitate was filtrated, washed and dried at 80℃ for 12h in the air. Finally, the precursor was calcined at different temperatures for different hours, and cooled to ambient temperature naturally.

NG/NC double-base propellant used in this research was prepared as follows: NG/NC double-base propellant was composed of 59% (mass fraction) of nitrocotton (NC), 30% of nitroglycerin (NG), 8.5% of diethyl phthalate (DEP), 2% of centralite II (C2) and 0.5% of other auxiliaries. The PbZrO3-DB propellant consisted of the above components (500g) and nano PbZrO3(15g, 40nm) was prepared by solventless extrusion technique, including slurry mixing, rolling and extruding[11].

1.2 Equipments and conditions

The X-ray diffraction patterns were recorded by a 6100 diffractometer (Shimadzu, Japan). Morphological and compositional observations were carried out by field emission scanning electron microscopy (SIGMA, Carl Zeiss, Germany), transmission electron microscope (HT-7700, Hitachi, Japan) and FE-SEM coupled EDS (Oxford, England). Thermal decomposition of samples was studied by a DSC 200F3 (Netzsch, Germany) under nitrogen atmosphere at a flow rate of 80mL/min. The crucible is a standard aluminium product and the condition of crucible is open. The burning rates of solid propellant were measured in a standard burner filled with nitrogen at different pressures, and the samples prepared were the Φ5mm×100mm cylinder coated with polyvinyl formal.

1.3 Characterization of nano PbZrO3

The crystalline and phases of PbZrO3with different preparation conditions (temperature and time) have been analyzed by XRD patterns and shown in Fig.1. When the precursor was subjected to thermal treatment at 400℃ or 500℃, the PbO phase can be observed, but the PbO phase disappears gradually with the rise of temperature (Fig.1(a)). The perovskite-type PbZrO3calcined at 600℃ becomes the predominant phase, and the traces of unreacted PbO and ZrO2have been also found. With calcination temperature over 650 ℃, a singe-phase perovskite PbZrO3was found and matched with JCPDS file number (35-0739)[17]. Fig. 1(b) shows that the effect of reaction time on phase formation is not obvious to the purity of product with the reaction time of 4h or more. Considering energy consumption, and ensuring product purity and good morphology, the optimal condition for preparation of nano PbZrO3is as follows: the reaction temperature of 700℃ and time of 6h.

Fig.1 XRD results for PbZrO3 powders at different temperatures and times

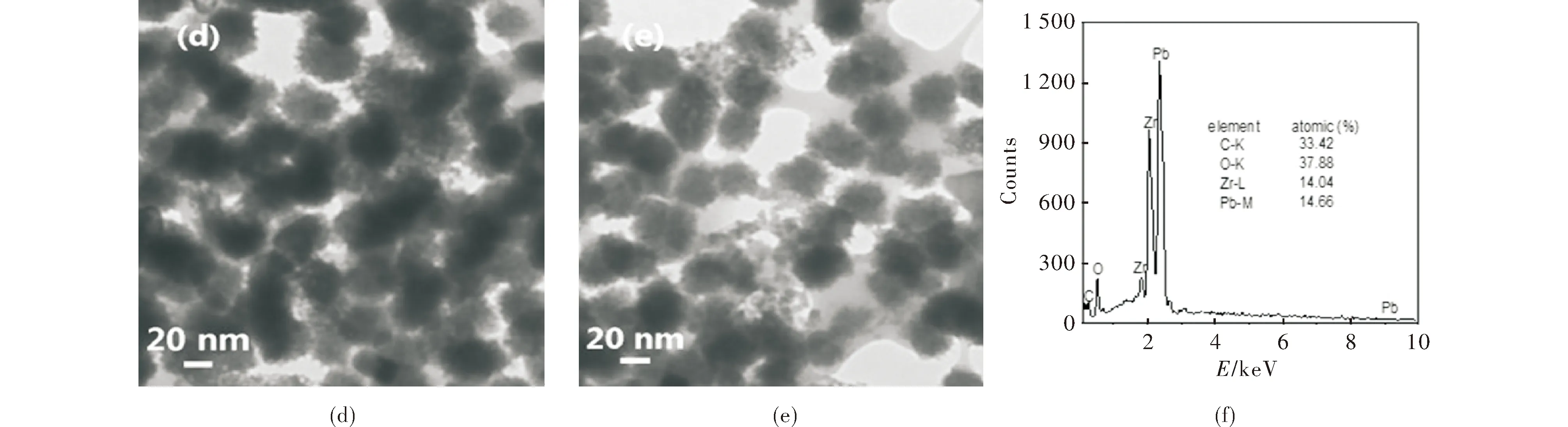

SEM images(Fig. 2(a),(b),(c)) show three microstructural features of PbZrO3prepared at 650, 700 and 800℃ for 6h, respectively. The powder prepared at 650℃ presents relatively large spherical particles. When the calcination temperature is higher than 700℃, the product particles are homogenous, spherical and uniformly distributed with an average particle size of 40nm. The powder calcined at 800℃ illustrates that a larger uniformly particle size is about 120nm and the particle agglomeration appears in partial section[17]. The TEM images of PbZrO3(Fig. 2(d),2(e)) further indicate that the powder calcined at 700℃ has a good dispersion and the average particle size is about 40 nm, which is consistent with the result of SEM (Fig. 2(b)). EDS result shows the typical signals of Pb and Zr elements, and the ratio of the two elements is about 1∶1, which further indicates that the sample is PbZrO3. The products prepared at 700℃ for 6h were used to the subsequent experimental studies.

Fig. 2 SEM images of the calcined powders at (a) 650℃, (b) 700℃, (c) 800 ℃ for 6 h, TEM graphs of the calcined powders at 700℃ (d, e) and EDS spectrum (f) of PbZrO3 powder

2 Results and discussion

2.1 Effects of PbZrO3 on thermal decomposition of AP, RDX and HMX

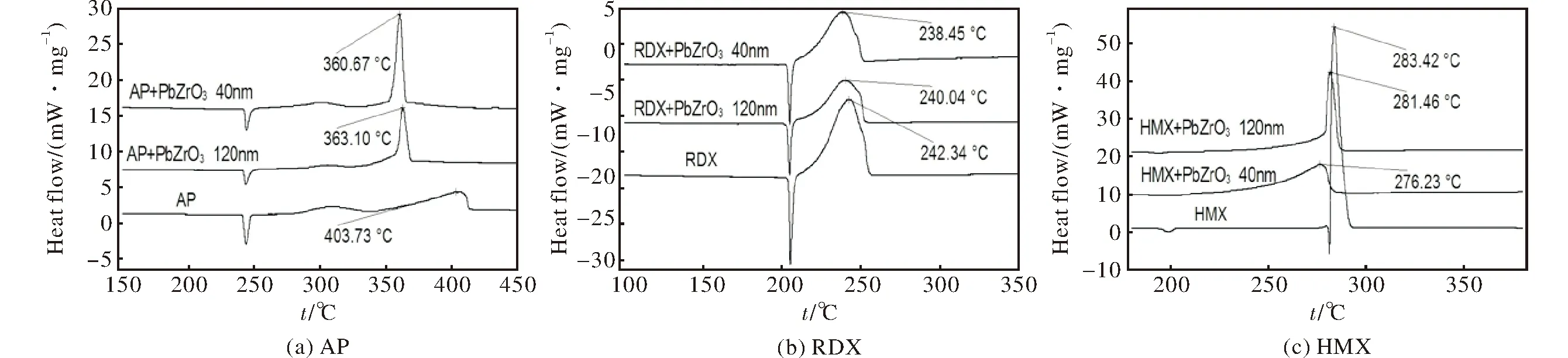

Two PbZrO3samples with two particle sizes (120 and 40nm) were used to explore the catalytic decomposition action on AP, RDX and HMX. The investigations were carried out with DSC method at a heating rate of 10℃/min. Nano PbZrO3and pure AP/RDX/HMX were mixed at a mass ratio of 1∶4, respectively[11]. The results (Fig.3) indicated that PbZrO3(40nm) has more obvious catalytic effect on the thermal decomposition of AP, RDX and HMX than PbZrO3(120nm). PbZrO3can obviously decrease the decomposition temperature of AP, while it weakly reduces the decomposition temperature of RDX. The main peak temperatures of exothermic decomposition for AP are ahead of 40.6℃ (120nm) and 43.1℃ (40nm), and the exothermic peak shape of AP changes greatly from a broad one to a sharp one[19]. The peak shape of HMX also changes greatly from a sharp one to a broad one in Fig. 3(c), and the melting process disappears. But nano PbZrO3has no obvious influence on the phase transitions of AP and RDX and the melting process of RDX. Moreover, compared with the effect of the particle size of PbZrO3, the smaller the particle size presents, the better catalytic decomposition effect.

Fig.3 DSC curves of the influence of different PbZrO3 powders on the thermal decomosition of AP, RDX and HMX

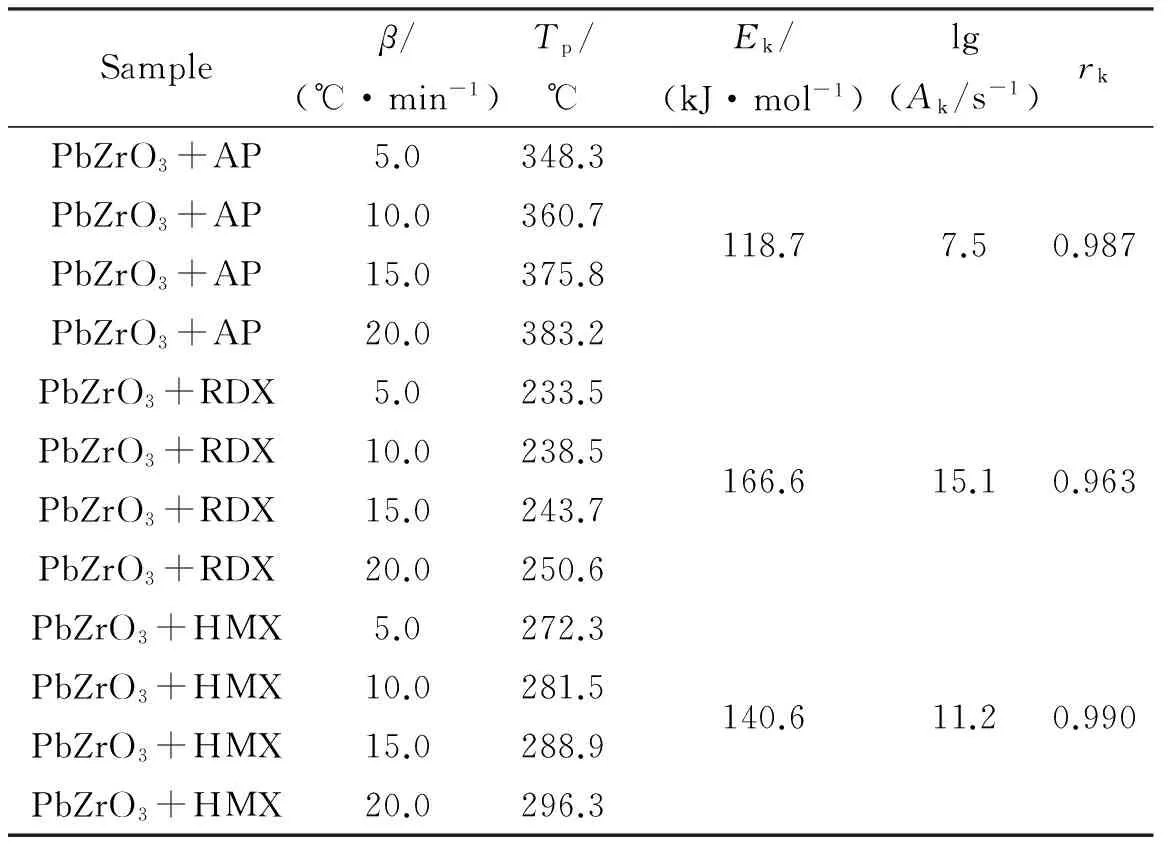

Apparent activation energy of the decomposition process was studied by Kissinger method[20]with DSC data from different heating rates(5, 10, 15 and 20℃/min), and the results of three mixture samples are listed in Table 1. Apparent activation energies of decomposition process for the three mixtures (PbZrO3+AP, PbZrO3+RDX and PbZrO3+HMX, PbZrO3with particle size of 40nm) were obtained to be 118.7, 166.6 and 140.6kJ/mol, respectively. Compared with the literature values of pure AP[19], RDX[21]and HMX[22], the apparent activation energies are decreased by about 21, 7.4 and 15kJ/mol respectively, indicating that nano PbZrO3possesses catalytic decomposition action on these three typical energy materials.

Table 1 DSC data and apparent activation energy of the exothermic decomposition of three mixtures

2.2 Thermal behaviors of PbZrO3-DB propellant

DSC curves (Fig. 4) at different heating rates indicate that the thermal decomposition behavior of PbZrO3-DB propellant presents a large exothermic process, which is in good consistent with the shape of peak of DB propellant without PbZrO3catalyst, but the peak temperature is ahead of about 5.2℃ from 208.8℃ to 203.6℃ at the heating rate of 10.0℃/min[23].

Fig.4 DSC curves of PbZrO3-DB propellant decomposition at different heating rates

From DSC datas at different heating rates, apparent activation energy (Ea) and the pre-exponential constant (A) of the exothermic decomposition process were obtained by Kissinger method[20]and Ozama method[24], and listed in Table 2.

Table 2 DSC data and kinetic parameters of the exothermic decomposition process of PbZrO3-DB propellant

Note:Subscript k, data obtained by Kissinger method; subscript o, data obtained by Ozawa method; r, the linear correlation coefficient.

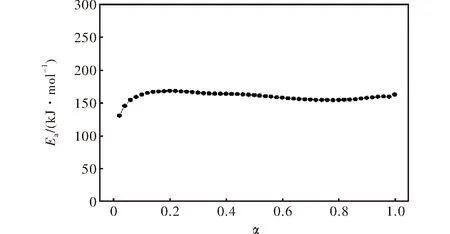

Substituting corresponding DSC data (βi,Tiandαi,i=1, 2, 3, …) into Ozawa equation, the values ofEafor any givenαwere obtained and shown in Fig.5. The values ofEadistribute from 154 to 169kJ/mol in theαrange of 0.1-0.9, and the average value ofEais 161kJ/mol, which is in good agreement with the results obtained by Kissinger method from only peak-temperature values. So the value was used to check the validity ofEaby other methods.

The most probable mechanism function was obtained by putting DSC data and 41 types of kinetic model functions into five integral equations (the general integral equation, the universal integral equation, MacCallum-Tanner equation,atava-esták equation and Agrawal equation) for calculating[25-27]. We found that these values ofEaand lgAobtained by the five equations are matched well with each other, and close to these values obtained by Kissinger method, Ozawa method and the equal conversion-degree method. The functionf(α)=2(1-α)1/2(contracting cylinder with phase boundary reaction) was found to be the best one in those forty-one functions according to the unanimity rule, though some differences exist in the four sets of calculated data as shown in Table 3[25, 27-28]. So the kinetic equation of the decomposition process for PbZrO3-DB propellant can be described as:

(1)

Fig.5 Ea-α curve obtained by Ozawa method

Method(eqtion)β/(℃·min-1)Ea/(kJ·mol-1)lg(A/s-1)rGeneralintegral5168.1916.030.9999Generalintegral10172.8416.570.9999Generalintegral15149.7313.990.9998Generalintegral20170.2716.240.9999MacCallum-Tanner5168.5616.020.9999MacCallum-Tanner10173.3716.880.9999MacCallum-Tanner15150.1613.980.9998MacCallum-Tanner20170.9216.260.9999Šatava-Šesták5167.3315.920.9999Šatava-Šesták10171.8716.460.9999Šatava-Šesták15149.9614.000.9998Šatava-Šesták20169.5616.150.9999Agrawal5168.1916.030.9999Agrawal10172.8416.570.9999Agrawal15149.7313.990.9998Agrawal20170.2716.240.9999Mean165.2415.71

The self-accelerating decomposition temperature (TSADT) and critical temperature of thermal explosion (Tb) are two important parameters required to ensure safe storage and process operations for energetic materials and to evaluate their thermal stabilities.TSADTandTbcan be obtained by Eq (2) and Eq (3)[27], respectively.

(2)

(3)

whereEois the apparent activation energy obtained by Ozawa method,aandbare coefficients.

SoTSADTandTbfor PbZrO3-DB propellant are 175.9 and 177.9℃, respectively, indicating that the thermal stability is good.

2.3 Combustion properties of PbZrO3-DB propellant

Burning rate (u) and pressure exponent (n) are two important factors to characterize the application performance of solid propellant[26, 29]. The relationship betweenu,nandp(test pressure) is shown in Eq (4).

(4)

wherecis a fitted coefficient, andiis the test point.

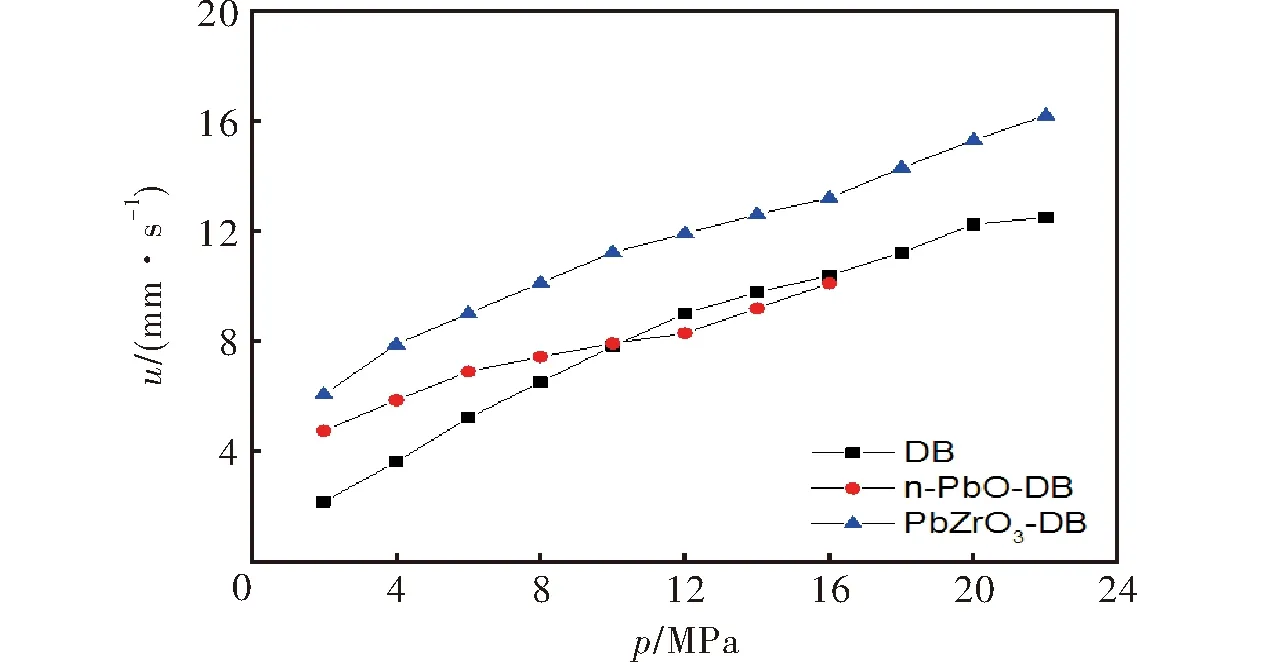

The determination results of burning rate for PbZrO3-DB propellant are shown in Fig.6, which also contains different DB propellants for comparison (DB: NG/NC double-base propellant with no any catalyst;n-PbO-DB∶NG/NC double-base propellant with nano PbO catalyst[6]; PbZrO3-DB∶NG/NC double-base propellant with nano PbZrO3catalyst). With the catalytic action of PbZrO3, the burning rate of PbZrO3-DB propellant is increased markedly, which can reach the double of NG/NC propellant without any catalyst. The values of burning rate of PbZrO3-DB propellant are much more than that of nano PbO-DB propellant at each pressure. PbZrO3exhibits better catalytic combustion effect than single nano PbO.

Fig.6 Burning rate curves of different DB propellants

The pressure exponent (n) for PbZrO3-DB propellant can be fitted at each pressure or pressure range, according to the burning rate value and Eq (4). Commonly, we divided the burning pressure into three ranges in the field of solid propellant, including low pressure range (2-8MPa), middle pressure range (8-14MPa) and high pressure range (16-22MPa). So the results at the three ranges were as follows:

at 2-8MPa,u=4.6995p0.3666,r=0.9992;

at 8-14MPa,u=4.5152p0.3903,r=0.9931;

at 16-22MPa,u=2.2195p0.6438,r=0.9992.

It can be seen that the pressure exponent of PbZrO3-DB propellant is 0.37 in the low pressure range of 2-8MPa, and 0.39 in the middle pressure range of 8-14MPa. Both are lower than the available value (0.6) of DB propellants. But the value of pressure exponent in the high pressure range of 16-22 MPa is beyond the available value. Nano PbZrO3can reduce the pressure exponent of NG/NC propellant greatly, and is more suitable to the application of middle-low-pressure burning solid propellant. All indicate that nano PbZrO3exhibits good application performance and can be a potential catalyst to replace PbO in solid propellant.

3 Conclusion

(1)In all, nano PbZrO3powders were prepared and characterized. Nano PbZrO3can reduce the thermal decomposition temperatures and the apparent activation energies (21, 7.4 and 15kJ/mol) of decomposition process for AP, RDX and HMX.

(3)Nano PbZrO3used as the combustion catalyst of NG/NC double-base propellant can increase the burning rate and reduce the pressure exponent greatly (0.37-0.39 in the pressure range of 2-14MPa). Nano PbZrO3exhibits a better catalytic combustion action than single nano PbO. Nano PbZrO3is suitable to the application of middle-low-pressure burning solid propellant.

[1] Armstrong R W, Baschung B, Booth D W, et al. Enhanced propellant combustion with nanoparticles[J]. Nano Letters, 2003, 3(2): 253-255.

[2] Styborski J A, Scorza M J, Smith M N, et al. Iron nanoparticle additives as burning rate enhancers in AP/HTPB composite propellants[J]. Propellants,Explosives,Pyrotechnics, 2015, 40(2): 253-259.

[3] Hao G Z,Liu J,Gao H,et al. Preparation of nano-sized CuO and its catalytic effect on the thermal decomposition of AP[J]. Chinese Journal of Explosives & Propellants(Huozhayao Xuebao), 2015, 38(4):18-21.

[4] Chen L J, Zhu D Y. The particle dimension controlling synthesis of α-MNO2nanowires with enhanced catalytic activity on the thermal decomposition of ammonium perchlorate[J]. Solid State Sciences, 2014, 27: 69-72.

[5] Jamil S, Janjua MRSA, Ahmad T. The synthesis of flower shaped microstructures of Co3O4by solvothermal approach and investigation of its catalytic activity[J]. Solid State Sciences, 2014, 36: 73-79.

[6] Zhang X H, Long C, Wang T C, et al. Study on the effects of nano-PbO on the combustion properties of double-base propellant[J]. Chinese Journal of Explosives & Propellants (Huozhayao Xuebao), 2002, 25(2): 39-41.

[7] Liu T, Wang L S, Yang P, et al. Preparation of nanometer CuFe2O4by auto-combustion and its catalytic activity on the thermal decomposition of ammonium perchlorate[J]. Materials Letters, 2008, 62(24): 4056-4058.

[8] Dong S S, Tian X D, Xu Z X, et al. Role of self-assembly coated Er3+: YAlO3/TiO2in intimate coupling of visible-light-responsive photocatalysis and biodegradation reactions[J]. Journal of Hazardous Materials, 2016, 302: 386-394.

[9] Delorme F, Diaz C P, Guilmeau E, et al. Thermoelectric properties of Ca3Co4O9-Co3O4composites[J]. Ceramics International, 2015, 41(8): 10038-10043.

[10] Petnikota S, Marka S K, Srikanth VVSS, et al. Elucidation of few layered graphene-complex metal oxide (A2Mo3O8, A=Co, Mn and Zn) composites as robust anode materials in Lin ion batteries[J]. Electrochimical Acta, 2015, 178: 699-708.

[11] Wei T T, Zhang Y, Xu K Z, et al. Catalytic action of nano BiWO6on thermal decompositions of AP, RDX, HMX and combustion of NG/NC propellant[J]. RSC Advances, 2015, 5(86): 70323-70328.

[12] Zhang Y, Wei T T, Xu K Z, et al. Catalytic decomposition action of hollow CuFe2O4nanospheres on RDX and FOX-7[J]. RSC Advances, 2015, 5(92): 75630-75635.

[13] Sanoop A P, Rajeev R, George B K. Synthesis and characterization of a novel copper chromite catalyst for the thermal decomposition of ammonium perchlorate[J]. Thermochimical Acta, 2015, 606: 34-40.

[14] Nawanil C, Boomchom B, Prachayawarakorn J, et al. Synthesis and phase evolution of electrospun antiferroelectric lead zirconate (PbZrO3) nanofibers[J]. Materials Science and Engineering B-Advanced Functional Solid-State Materials, 2012, 177(13): 1009-1016.

[15] Bjφrheim T S, Kuwabara A, Ahmed I, et al. A combined conductivity and DFT study of protons in PbZrO3and alkaline earth zirconate perovskites[J]. Solid State Ionics, 2010, 181(3/4): 130-137.

[16] Nunes J M A, Espinosa J W M, Gurgel M F C, et al. Photoluminescent properties of lead zirconate powders obtained by the polymeric percursor method[J]. Ceramic International, 2012, 38(6): 4593-4599.

[17] Khamman O, Chaisan W, Yimnirun R, et al. Effect of vibro-milling time on phase formation and particle size of lead zirconate nanopowders[J]. Materials Letters, 2007, 61(13): 2822-2826.

[18] Ko T, Hwang D. Preparation of nanocrystalline lead zirconate powder by homogeneous precipitation using hydrogen peroxide and urea[J]. Materials Letters, 2003, 57(16/17): 2472-2479.

[19] Hao G Z, Liu J, Liu H H, et al. Preparation of nano-sized copper chromite and its effect on thermal decomposition performances of ammonium perchlorate[J]. Chinese Journal of Explosives & Propellants(Huozhayao Xuebao), 2015, 38(1): 26-29.

[20] Kissinger H E. Reaction kinetics in differential thermal analysis[J]. Analytical Chemistry, 1957, 29(11): 1702-1706.

[21] Yang W T, Zhang Y C, Liu S W, et al. Thermodynamic properties, non-isothermal reaction kinetics and safety of RDX-based combustible materials[J]. Chinese Journal of Explosives & Propellants(Huozhayao Xuebao), 2017, 40(2): 19-23.

[22] Wei Z X, Xu Y Q, Liu H Y, et al. Preparation and catalytic activities of LaFeO3and Fe2O3for HMX thermal decomposition[J]. Journal of Hazardous Materials, 2009, 165(1/3): 1056-1061.

[23] Yi J H, Zhao F Q, Xu S Y, et al. Effect of pressures on decomposition reaction kinetics of double-base propellant catalyzed with cerium citrate[J]. Journal of Thermal Analysis and Calorimetry, 2009, 95(2): 381-385.

[24] Ozawa T. A new method of analyzing thermo-gravimetric data[J]. Bulletin of the Chemical Society of Japan, 1965, 38(11): 1881-1885.

[25] Vyazovkin S, Charles A W. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data[J]. Thermochimica Acta, 1999, 340/341: 53-68.

[26] Yi J H, Zhao F Q, Hong W L, et al. Effects of Bi-NTO complex on thermal behaviors, nonisothermal reaction kinetics and burning rates of NG/TEGDN/NC propellant[J]. Journal of Hazardous Materials, 2010, 176 (1/3): 257-261.

[27] Hu R Z, Gao S L, Zhao F Q, et al. Thermal Analysis Kinetics[M]. 2nd ed. Beijing (in Chinese): Science Press, 2008.

[28] Dey A, Athar J, Varma P, et al. Graphene-iron oxide nanocomposite (GINC): an efficient catalyst for ammonium perchlorate (AP) decomposition and burn rate enhancer for AP based composite propellant[J]. RSC Advances, 2015, 5(3): 1950-1960.

[29] Kohga M, Naya T. Thermal decomposition behaviors and burning characteristics of AN/RDX-based composite propellants supplemented with MNO2and Fe2O3[J]. Journal of Energetic Materials, 2015, 33(4): 288-304.

纳米PbZrO3对AP、RDX、HMX热分解和NG/NC双基推进剂燃烧性能的影响

王为民1,魏涛涛1,高红旭2,肖立柏2,徐抗震1,赵凤起2

(1.西北大学化工学院,陕西 西安 710069;2.西安近代化学研究所,陕西 西安 710065)

纳米PbZrO3;NG/NC双基推进剂;金属复合氧化物;固体推进剂;热分解;催化燃烧

10.14077/j.issn.1007-7812.2017.06.005

TJ55;O65 Document Code:A Article ID:1007-7812(2017)06-0029-07

date:2017-09-19; Revised date:2017-10-27

Project supported: The national defence key laboratory of propellant and explosive combustion (No.914*162) and postdoctoral science foundation of China (No.2014M552480).

Biography:WANG Wei-min (1992-), male, graduate, research fields: nano materials.E-mail:1633541139@qq.com

XU Kang-zhen (1976-), male, professor, research fields: the synthesis and properties of new energetic materials. E-mail: xukz@nwu.edu.cn