秸秆还田深松旋埋联合耕整机设计与试验

2017-12-15张居敏祝英豪张春岭Tahir夏俊芳

周 华,张居敏,祝英豪,张春岭,H.M.Tahir,夏俊芳

秸秆还田深松旋埋联合耕整机设计与试验

周 华,张居敏,祝英豪,张春岭,H.M.Tahir,夏俊芳※

(华中农业大学工学院,武汉 430070)

深松作业能有效打破犁底层,提高土壤蓄水保墒能力。秸秆还田是秸秆资源利用最为直接有效的方式,将2种保护性耕作方式结合在一起可大大提高作业效率。为了满足深松和秸秆还田同时作业的需求,设计了集土壤深松、破茬碎土、秸秆旋埋、平地等多功能于一体的深松旋埋联合耕整机。该机主要由自激振动深松装置和秸秆还田旋埋刀辊组成,自激振动深松装置可调节预紧力,不仅可以在一定程度上减少深松耕作阻力,还可以在遇到障碍物时有效保护深松铲,深松铲柄的设计利用了滑切原理,可有效切断秸秆和杂草,防止缠绕和堵塞深松铲,对旋埋刀辊进行了重新布置和优化,提高了工作稳定性和破土能力。田间试验表明深松作业可有效减小旋埋刀辊功率;在拖拉机1挡和2挡速度下深松旋埋组合作业总功率分别为单独深松和单独旋埋2项作业之和的85.0%和82.2%;深松旋埋组合作业下深松和旋埋的平均耕深分别为28.9和17.5 cm,耕深稳定性分别为93.5%和87.4%,秸秆埋覆率为92.0%,耕后地表平整度为1.0 cm,深松旋埋联合作业后的各项性能参数均超过质量评定指标,满足农艺要求。

农业机械;设计;土壤;深松;秸秆还田;滑切;旋埋;组合作业

0 引 言

传统的旋耕方式作业多年后对土壤压实严重,形成坚硬的犁底层,导致耕层变浅,作物根系发展空间受限[1-3]。深松作业可有效改善土壤耕层结构,提高蓄水保墒能力,利于作物根系发展,是作物增产的一项重要技术[4-7]。秸秆还田作为对秸秆资源最直接有效的利用方式,一方面减少了秸秆焚烧带来的环境污染问题[8-12],另一方面提高了土壤的有机质含量,是作物增产增收的另一技术措施[13]。深松作业与秸秆还田作业通常是2个单独的作业环节,增加了拖拉机的下地次数,不但不利于抢农时还对土壤进行了二次碾压,因此设计一种将深松与秸秆还田2种保护性耕作的方式结合在一起的机具非常必要。

为了实现保护性耕作的目的,国内外学者对深松和秸秆还田方式及相应机具进行了研究。Celik等[14]研究了不同作业情况下深松的功耗对比和对土壤的扰动情况。Amardeep等[15]针对不同材质的旋耕刀片工作后的磨损情况进行了试验分析,为节省刀片更换时间提供了参考。张丽等[16]研究了深松和秸秆还田对农田土壤物理特性的影响,确定了深松结合秸秆还田对土壤耕层的改善优于单独深松作业。赵伟等[17-18]设计了深松旋耕组合作业机,并对其进行了功率消耗和动力学分析。王瑞丽等[19]设计了秸秆深埋还田开沟灭茬机,并通过试验证明其具有较好的开沟、灭茬、碎土效果。韦丽娇等[20]通过甘蔗地深松旋耕和犁铧旋耕作业对比,证明深松旋耕可提高作业效率40%左右,且旋耕质量能达到作业要求。孙东霞等[21]设计了深松旋耕施肥联合整地机,可一次作业完成深松、旋耕、施肥、镇压作业,还可分解重组,达到较好的试验效果。田慎重等[22]研究了深松旋耕数年后土壤有机碳含量变化情况,证明其效果优于常规旋耕处理。国内外学者主要针对无秸秆田进行了深松和旋耕研究,或对秸秆单独还田作业进行了研究,但对深松和秸秆还田组合作业机具研究不多,尤其对有秸秆田深松作业研究更少。

为了实现深松和秸秆还田2种保护性耕作模式相结合,缓解保护性耕作条件下作物秸秆和杂草对深松铲的缠绕和堵塞现象,增加秸秆和土壤混埋程度,本文结合课题组已研发的秸秆还田旋埋刀辊[23-27]设计了深松旋埋联合耕整机,并对刀辊的刀具进行重新排布优化,该机能够一次完成土壤深松、破茬碎土、秸秆旋埋、平地等作业,可进行组合作业,也可拆分进行单项作业。对各作业工况的工作阻力、功率消耗以及耕前耕后土壤状况进行了田间对比试验研究,以期为研究保护性耕作模式提供参考。

1 整机结构设计

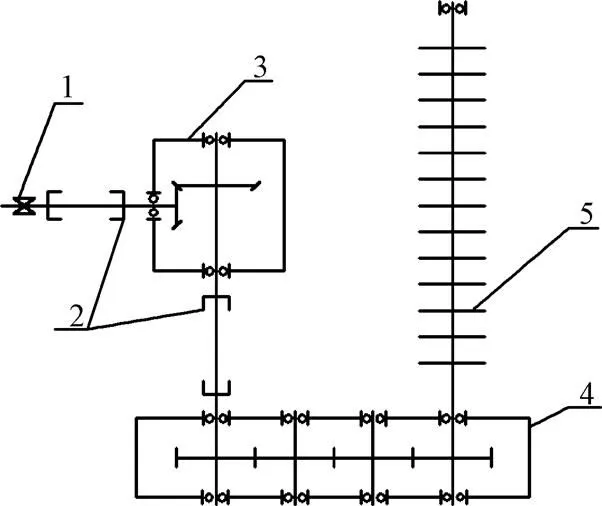

根据耕整地农艺要求,所设计的机具作业工序为深松→秸秆还田旋埋→平地。机具整体结构如图1所示,主要包括自激振动深松装置1、旋埋刀辊2、平土拖板3、中间变速箱4、侧边传动箱5、机架6和限深轮7等。

1.自激振动深松装置 2.旋埋刀辊 3.平土拖板 4.中间变速箱 5.侧边传动箱 6.机架 7.限深轮

1.1 工作原理

工作时,深松旋埋机悬挂于拖拉机后方,随拖拉机的前行,深松装置先入土进行深松作业,疏松土壤,为旋埋刀辊减轻作业阻力,并由限深轮控制其深松深度,然后旋埋刀辊入土,进一步破碎上层土壤,并对秸秆和杂草进行埋覆,最后由平土拖板将耕后地表拖压平整。

1.2 整机性能和结构参数设计

由于机具作业地为旱地,偏黏性土壤,因此土壤坚实度普遍较高,深松作业时牵引阻力较大,秸秆旋埋作业时旋埋刀辊功率消耗较大。深松旋埋联合耕整机结合了土壤深松和秸秆旋埋2项作业,与2项单独作业相比,其整机综合性能有助于改善以上问题。首先,深松作业使土壤松动,土壤坚实度大大降低,越靠近上层土壤扰动量越大,这种上松下实的土壤状况为旋埋刀辊改善了作业条件,可有效减小旋埋刀辊的旋埋功率,其次,旋埋刀辊旋转过程中受到土壤的反作用力,尤其是旋埋刀辊上的螺旋横刀横向切土使该力更为明显,该反作用力相当于给深松旋埋联合耕整机施加了一个主动推力,该主动推力可抵消部分深松作业的牵引阻力,减轻拖拉机的作业负荷。

深松旋埋联合耕整机的设计有效工作幅宽为2 m,而深松深度不应低于25 cm,由于深松作业的土壤扰动宽度约为深松深度的2倍,因此取两深松铲的横向安装距离为50 cm,配置4个深松铲,深松铲居中对称布置,两边各留25 cm,以完全覆盖后面的旋埋区间。秸秆和杂草埋覆在8~10 cm以下的比例越大越好,设计以10 cm为基准,增加40%为最小耕深,因此旋埋刀辊的耕深需在14 cm以上,旋埋刀辊的切土长度即为整机的有效工作幅宽2 m。深松旋埋联合耕整机的前后两部分下面由8个M18的U型螺栓连接固定,上面由一根长度可调的带螺纹的钢管连接,深松旋埋联合耕整机的主要结构参数如表1所示。

表1 深松旋埋联合耕整机主要结构参数 Table1 Main structural parameters of combined tillage machine for subsoiling and rotary burying

1.3 动力传递方式

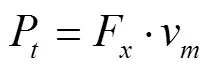

深松旋埋联合耕整机工作过程中,深松装置的驱动力由拖拉机牵引力提供,旋埋刀辊的驱动力由拖拉机动力输出轴提供,动力传递路线为拖拉机动力输出轴→万向节→中间变速箱→万向节→侧边传动箱→旋埋刀辊,如图2所示。

1.动力输出轴 2.万向节 3.中间变速箱 4.侧边传动箱 5.旋埋刀辊

1.4 机具受力分析

深松旋埋机在作业过程中受到来自于土壤的作用力,受力情况较为复杂,主要受力部件有拖板、旋埋刀辊、深松装置和限深轮等。以其前进方向地面为轴,以深松铲柄连接段方向为轴,建立坐标系,其各部件受力如图3所示。

作业过程中,在水平方向,除土壤对旋埋刀辊切土过程的反作用力F与前进方向相同外,其余的水平分力方向均与前进方向相反,而在垂直方向,除土壤对深松铲运动过程中产生的垂直分力F和机具自身重力为垂直地面向下,其余的垂直分力方向均向上,由此建立拖拉机牵引力方程

式中为机具质量,kg。

注:为拖拉机的瞬时牵引点,F为拖拉机的水平牵引合力,N;F为拖拉机的垂直牵引合力,N;F为拖拉机的牵引阻力,N;F为土壤对拖板的摩擦阻力,N;F为土壤对拖板的支持力,N;F为土壤对旋埋机的摩擦阻力,N;F为土壤对旋埋机的支持力,N;F为土壤对刀具切土过程反力的水平分力,N;F为土壤对刀具切土过程反力的垂直分力,N;F为土壤对深松铲的水平阻力,N;F为土壤对深松铲的垂直阻力,N;F为土壤对铲底的摩擦阻力,N;F为土壤对铲底的支持力,N;F为限深轮的滚动阻力,N;F为土壤对限深轮的支持力,N;为机具沿前进方向的加速度,m·s-2;为机具的重力,N。

Note:is instantaneous towing point of tractor,Fis horizontal traction force of tractor, N;Fis vertical traction force of tractor, N;Fis traction resistance of tractor, N;Fis frictional resistance of soil to the planker, N;Fis the supporting force of soil to the planker, N;Fis friction resistance of soil to rotary burying machine, N;Fis the supporting force of soil to rotary burying machine, N;Fis horizontal component force of soil reaction force during cutting soil, N;Fis vertical component force of soil reaction force during cutting soil, N;Fis horizontal resistance of soil to the subsoiling, N;Fis vertical resistance of soil to the subsoiling, N;Fis frictional resistance of soil to subsoiler bottom, N;Fis the supporting force of soil to subsoiler bottom, N;Fis rolling resistance of depth wheel, N;Fis the supporting force of soil to depth wheel, N;is the acceleration of the machine along the advancing direction, m·s-2;is gravity of machine, N.

图3 深松旋埋联合耕整机受力简图

Fig.3 Force diagram of combined tillage machine for subsoiling and rotary burying

由于机具正常工作时视为匀速运动,故为0,限深轮和拖板受土壤作用力相对于深松铲和旋埋机较小,可忽略不计,由此可得拖拉机牵引合力为

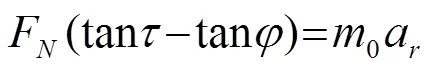

拖拉机牵引功率P为

由此可得机具所消耗总功率为

式中P为拖拉机牵引功率,kW;v为机具前进速度,m/s;为机具所消耗总功率,kW;P为旋埋刀辊所消耗驱动功率(即拖拉机动力输出轴功率),kW。

2 关键部件设计

2.1 自激振动深松装置设计

由于深松旋埋联合耕整机作业对象为秸秆残茬覆盖地,地表情况复杂,秸秆和杂草对深松作业影响较大,深松铲易产生秸秆缠绕和堵塞现象[28-29],传统的深松装置难以满足要求,增加切草装置又会增大机具空间,因此需要设计合理的深松装置。

2.1.1 滑切型深松铲设计

深松铲柄的设计是深松铲设计的关键,合理的铲型不但可以缓解工作过程中秸秆和杂草的缠绕,还可有效降低其工作阻力,为此设计了滑切型深松铲柄(图4)。深松铲柄由连接段、切土段和铲尖连接段三部分组成。

注:A为连接段,B为切土段,C为铲尖连接段,E为双翼深松铲,α为入土角,(°);β为铲尖连接段与水平面夹角,(°);τ为滑切角,(°);h为深松铲长度,mm。

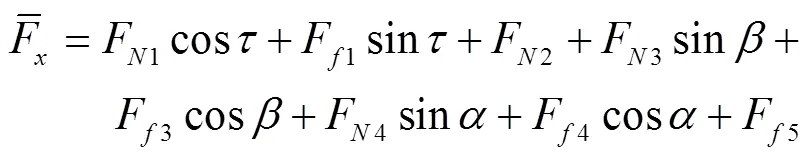

切土段利用滑切原理设计而成,滑切角越小,滑切阻力越大;滑切角越大,滑切阻力越小,滑切角的选择可根据以下公式[30]进行取值

式中F为滑切刃的正压力,N;为滑切角,(°);为滑切刃与土壤摩擦角,(°);0为被切割质点质量,kg;a为质点沿滑切刃切向加速度,m/s2。

由式(5)可知,在滑切刃正压力F>0时,要使被切割土壤与滑切刃产生滑切作用,必须令a>0,即>,由于滑切刃与土壤的摩擦系数范围大约在0.2~0.6之间,取最大摩擦系数0.6计算得约为31°,因此必须大于31°才能产生滑切作用。研究表明[31-33],当滑切角为35°~55°时滑切阻力较小,若滑切角取值过小,则滑切减阻和秸秆切断效果不明显,若滑切角取值过大,则铲柄长度过大,铲柄强度和稳定性降低,因此切土段设计滑切角取中间值为45°。切土刃口角也是影响切削性能的重要因素,切土刃口角取值过大会导致切削能力降低,工作阻力增大,过小会导致刃口偏薄,容易损坏,据文献[34]的设计要求设计切土刃口角为60°。

为防止切土段和铲尖连接段相交处土壤夹塞等问题,其角度变化不宜过大,即铲尖连接段与水平面的夹角不宜过小,因此设计其角度为45°,而深松铲的入土角对其牵引阻力和碎土效果有着重要影响,当入土角达到或超过40°时,牵引阻力会显著增加,一般入土角不超过25°,因此铲尖入土角度取为19°。深松装置后面的旋埋刀辊存在旱耕旋埋秸秆埋覆深度不足的现象,为扩大底层土壤扰动量而提高其作业质量,铲尖整体采用双翼型深松铲。深松铲其余尺寸设计要求按照文献[34]进行设计。

2.1.2 深松铲受力分析

深松铲在作业过程中受土壤作用力情况较为复杂,可将其划分为几个区域,受力情况如图5所示。

注:B1为铲柄切土区,B2为过渡区,E1为深松铲连接区,E2为铲面区,E3为铲底接触区,FN1,FN2,FN3,FN4为法向阻力,N;Ff1,Ff3,Ff4为切向阻力,N;FN5为土壤对铲底的支持力,N;Ff5为土壤对铲底的摩擦力,N。

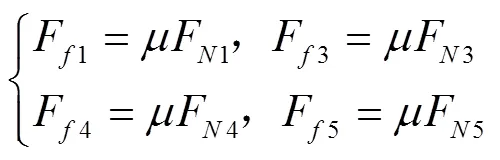

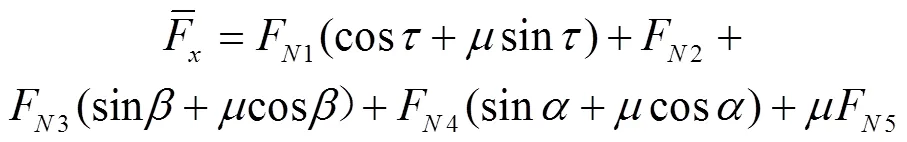

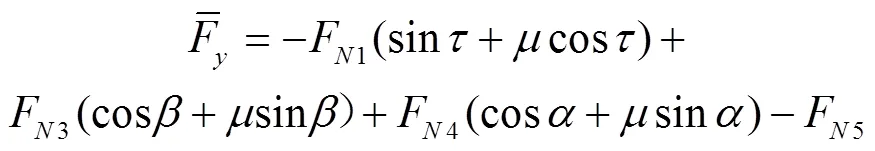

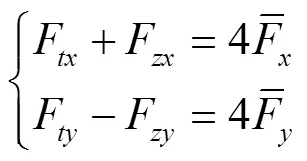

由于深松铲柄及双翼深松铲材质均为65Mn钢,土壤视为均匀体,故其具有相同的摩擦系数,由此可得式(7)。

式中为深松铲与土壤间的摩擦系数。将式(7)代入(6)可得

故深松装置所受水平合力与垂直合力分别为

2.1.3 自激振动和连接调节装置设计

传统的深松铲连接方式为通过铲座固连在机架横梁上,当作业过程中遇到障碍物(如石块等)时,会在瞬间产生较大的阻力,而深松铲只能强行通过,这也是深松铲容易损坏变形的主要原因之一。针对上述问题,设计了深松铲自激振动保护装置和与其相匹配的连接调节装置,如图6a所示。自激振动装置不但可以有效保护深松铲,还可在一定范围内降低深松铲的耕作阻力[35-37]。自激振动装置内部主要包括弹簧和滑块,外部主要包括弹簧套筒和预紧螺栓等,深松铲的顶端与其铰接在一起,通过调节预紧螺栓控制弹簧的预紧力,以便深松铲适应不同条件的土壤。连接调节装置主要包括前连接板和后连接板,前后连接板上均开有L型槽,L型槽对置装配,前连接板和深松铲柄夹在两块后连接板中间。当弹簧的预紧力调节完毕,对置的L型槽可以实现深松铲柄前后和上下的二维移动,使深松铲柄连接段在正常状态下始终垂直于水平面,而对置的L型槽间始终有2个交点,由螺栓连接。

1.自激振动装置 2.连接调节装置 3.深松铲柄

1.Self-excited vibration device 2.Connection adjustment device 3.Subsoiler handle

注:为铰接点,为铲尖位置,为转角,为地面,为障碍物。

Note:,arehinge points;,aresubsoiler tip position;is the angle of rotation;is ground;is obstacle.

图6 深松铲保护装置示意图

Fig.6 Diagram of subsoiler protection device

当深松装置在前进过程中遇到障碍物时,如图6b,弹簧在深松铲柄的杠杆作用下继续压缩,深松装置的3个铰接点发生相对位移,深松铲整体会沿铰接点产生一定的角度(即)转动,铰接点移动到′,而铲尖位置由移动到′,深松铲整体向上和向后移动,机具继续前行,由此跨过障碍物,保护深松铲,当铲尖完全跨过障碍物,其阻力又恢复至正常耕作状态,弹簧所受额外压力释放,深松铲自动恢复原有耕深,以保证其耕深稳定性。

2.2 旋埋刀辊设计

秸秆埋覆还田主要由旋埋刀辊完成,旋埋刀辊包括六段区间,每段区间均由弯刀、螺旋横刀、刀盘和IIT 245旋耕刀组成。主要参数包括:7个刀盘、36把弯刀、18把螺旋横刀和36把旋耕刀。螺旋横刀焊接在左右弯刀上,弯刀通过螺栓紧固在刀盘上,六段区间的刀具排布分为2种,1、3、5节相同,2、4、6节相同,第1、2节刀具排布如图7a所示,每节刀具螺旋横刀成3条螺旋线排布,旋耕刀均匀排布在螺旋横刀中间,成两边对称的3条螺旋线。旋埋作业时,螺旋横刀和旋耕刀对土壤均有轴向侧推效应,对应的螺旋横刀与旋耕刀的推土方向相反,使这2种效应相互抵消,保证作业后地表平整和秸秆均匀揉合于耕层土壤中。

螺旋横刀的结构由一个直角梯形沿一定螺旋线扫描而成,如图7b所示,主要结构参数有水平长度,轴向转角,最大切土半径,工作过程中,旋埋刀辊正转,旋转半径大于的旋耕刀先入土,进行切土和破茬作业,再由螺旋横刀进一步碎土并埋覆秸秆,这样既能发挥传统旋耕刀切土破茬的优势,又能发挥螺旋横刀秸秆埋覆的优势[12]。

注:图7a中,为左右弯刀;为螺旋横刀;为左右旋耕刀;为刀盘。图7b中,l为螺旋横刀水平长度,mm;r为螺旋横刀最大切土半径,mm;φ为螺旋横刀的轴向转角,(°);OO'为旋埋刀辊轴线。

3 田间试验

3.1 试验目的和试验条件

3.1.1 试验目的

试验主要检测深松旋埋联合作业机配置的合理性,探究整机工作的稳定性和适应性,测试整机的牵引阻力、功率消耗、耕作状况及秸秆埋覆情况,以及探讨不同作业方式下的功率消耗情况。

3.1.2 试验条件

2017年4月14至15日在华中农业大学现代农业科技试验基地选取了大豆收获后的闲置田进行试验,该田块为旱作区,土壤为偏黏性土,试验前田块长有杂草和秸秆残茬,土壤状况适耕,田块各处试验条件基本相同,试验田块面积满足测试要求。试验仪器主要包括东方红LX954拖拉机(中国一拖集团)、深松旋埋联合耕整机、CKY-810扭矩传感器(北京中航科仪测控技术有限公司,量程:0~3 000 N·m,精度为0.5%)、BK-5型牵引力负荷传感器(中国航天空气动力技术研究院,精度等级:0.3)、数据采集箱、带有动力学参数遥测软件的接收电脑、TJSD-750型土壤紧实度测定仪(浙江托普云农科技股份有限公司,精度:±0.5‰FS)、环刀、烘箱、电子秤、卷尺、直尺等,试验前田块各项参数状况如表2所示。

表2 试验前田块各项参数 Table 2 Field parameters before experiment

3.2 试验方法

本设计的深松旋埋联合耕整机为可拆卸式,可分别进行深松作业和旋埋作业。因此,分别对深松机单机作业、深松后旋埋作业、单独旋埋作业和深松旋埋组合作业4种情况进行性能试验,对机具的牵引阻力和功率消耗进行分析,其他性能参数有深松耕深、旋埋耕深、耕深稳定性、耕后地表平整度、耕后土壤坚实度、秸秆埋覆率等。

试验分8个工况进行:1)深松机单独作业,深松深度25~30 cm,分拖拉机1挡、2挡2个作业速度;2)在深松地上进行单独旋埋作业,旋埋刀辊转速300 r/min,旋埋深度14~18 cm,分拖拉机1挡、2挡2个作业速度;3)未耕地单独旋埋作业,旋埋刀辊转速300 r/min,旋埋深度14~18 cm,分拖拉机1挡、2挡2个作业速度;4)深松旋埋组合作业,旋埋刀辊转速300 r/min,深松深度25~30 cm,旋埋深度14~18 cm,分拖拉机1挡、2挡2个作业速度。试验田块长度为50 m,取中间20 m为拖拉机稳定工作区间,2头各留15 m作为拖拉机起步和掉头距离,每个工况重复3次,取其平均值作为该工况试验结果,田间试验情况如图8所示。

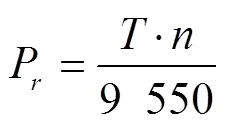

机具的牵引阻力和旋埋刀辊的功率测试分别采用牵引力负荷传感器和扭矩传感器。牵引力负荷传感器包括3个悬挂销,分别安装在拖拉机的三点悬挂处,每个传感器的输出为电信号4~20 mA,该电信号通过接收电脑进行实时采集,并经内部的处理软件将电信号转换为可直接读取的阻力数值,对应测量范围为0~30 kN,3个传感器可测量上拉杆和左右悬挂处机具的6个参数,即三点的水平受力和垂直受力。扭矩传感器将测得的拖拉机动力输出轴的扭矩和转速同样传递到电脑软件,并自动通过式(11)进行计算旋埋刀辊所消耗功率:

式中为拖拉机动力输出轴扭矩,N·m;为拖拉机动力输出轴转速,r/min。

3.3 试验结果和分析

各工况下三点悬挂所测水平和垂直分力以及其合力如表3所示,表4为各工况作业后试验数据。

表3 各工况下拖拉机牵引力

注:“-”代表受力方向与原规定受力正方向相反。

Note: “-” represents the force direction is opposite to the original force direction.

表4 作业后试验数据

由表3可知,单独深松时随前进速度的增加,拖拉机水平牵引合力F明显增加;而旋埋作业时其水平牵引合力F均很小,甚至为负值,说明旋埋刀辊正向旋转时产生的水平推力抵消了其水平阻力;深松旋埋组合作业时其水平牵引合力F与单独深松作业相比,在1挡时,分别为11 886和11 448 N,增加了3.8%,而在2挡时,分别为12 064和13 580 N,减小了11.2%,再次证明旋埋刀辊的水平推力抵消了机具部分水平阻力。

由表4可得,单独深松时当速度从0.52增加到0.84 m/s时,速度增加61.5%,总功率从5.95 增加到11.41 kW,总功率增加91.8%,说明速度对深松功率影响明显。深松后旋埋作业和单独旋埋作业牵引功率消耗均较小,仅为0.07~1.29 kW,主要消耗为旋埋功率,深松后旋埋作业相比于单独旋埋作业,在1挡速度下的旋埋功率分别为24.36和32.28 kW,减小24.5%,总功率分别为24.62和32.55 kW,减小24.4%;在2挡速度下的旋埋功率分别为30.74和38.23 kW,减小19.6%,总功率分别为30.81和39.52 kW,减小22.0%,因此,先进行深松作业可有效降低旋埋作业时的功率消耗。深松旋埋组合作业在1挡和2挡下的总功率分别为32.72和41.88 kW,略大于单独旋埋作业,但小于单独深松和单独旋埋作业功率消耗之和,在1挡和2挡速度下其总功率分别占2项作业之和的85.0%和82.2%。与传统的深松旋耕组合作业机相比,通过参阅文献[17,38],对比相近的作业参数,通过比例关系换算成相同的作业幅宽,得出其在2个挡位速度下的功率消耗分别为34.2~38.4和45.5~48.7 kW,功率减小范围分别在4.4%~14.8%和7.9%~14.0%,说明本文设计的深松旋埋联合耕整机比传统的深松旋耕组合作业机具有更好的功率利用率。

由于目前没有与深松旋埋联合耕整机相配套的作业性能评价指标,因此深松旋埋联合耕整机的作业性能按文献[39]来评定,结果如表5所示。从表5可知,进行深松旋埋联合作业后的深松和旋埋的平均耕深分别为28.9和17.5 cm,耕深稳定性分别为93.5%和87.4%,秸秆埋覆率为92.0%,耕后地表平整度为1.0 cm,均大于质量评定指标,说明深松旋埋联合耕整机一次作业可达到较好的作业深度、秸秆埋覆以及平整地表的目的,满足耕整地农艺要求。并且0~15 cm和15~30 cm的耕后土壤坚实度分别为437.6和951.8 kPa,分别比耕前减小了78.4%和67.4%;0~10和10~20 cm的耕后土壤容重分别为1.40和1.41 g/cm3,分别比耕前减小了6.7%和8.4%,达到了较好的疏松土壤效果。

表5 深松旋埋联合耕整机的作业性能

4 结论与讨论

1)深松旋埋联合耕整机能一次下田完成土壤深松、破茬碎土、秸秆旋埋、平地等作业,实现一机多用,减少了拖拉机的下田次数,减轻了拖拉机对土壤的压实,节约农时。

2)对深松和旋埋等关键部件进行了设计和优化,采用滑切原理设计的深松铲柄可有效切断秸秆和杂草,防止深松铲柄发生堵塞;设计的自激振动连接装置可有效保护深松铲,防止因耕作阻力过大导致的深松铲变形,还可在一定范围内减小耕作阻力;合理优化旋埋刀辊的排布方式,提高了耕作后的地表平整度。

3)通过田间试验表明,深松旋埋联合作业功率消耗小于单独深松和单独旋埋2项作业之和,说明深松作业改善了旋埋作业的作业条件,降低了旋埋作业的功率消耗,在拖拉机1挡和2挡速度下其总功率分别占2项作业之和的85.0%和82.2%,深松和旋埋的平均耕深分别为28.9和17.5 cm,耕深稳定性分别为93.5%和87.4%,秸秆埋覆率为92.0%,耕后地表平整度为1.0 cm,均大于质量评定指标,满足农艺要求。

本文设计的自激振动深松装置相对于传统深松装置的减阻效果和整机作业后的破茬碎土率、秸秆埋覆深度稳定性以及作业效率等问题还有待于进一步试验研究。

[1] 朱瑞祥,张军昌,薛少平,等. 保护性耕作条件下的深松技术试验[J]. 农业工程学报,2009,25(6):145-147. Zhu Ruixiang, Zhang Junchang, Xue Shaoping, et al. Experimentation about subsoiling technique for conservation tillage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(6): 145-147. (in Chinese with English abstract)

[2] 李洪文,陈君达,李问盈. 保护性耕作条件下深松技术研究[J]. 农业机械学报,2000,31(6):42-45. Li Hongwen, Chen Junda, Li Wenying. Study on subsoiling technique for conservation tillage field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2000, 31(6): 42-45. (in Chinese with English abstract)

[3] 张金波,佟金,马云海. 仿生减阻深松铲设计与试验[J]. 农业机械学报,2014,45(4):141-145. Zhang Jinbo,Tong Jin,Ma Yunhai. Design and experiment of bionic anti-drag subsoiler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(4): 141-145. (in Chinese with English abstract)

[4] Raper R L. In-row subsoilers that reduce soil compaction and residue disturbance[J]. Applied Engineering in Agriculture, 2007, 23(3): 253-258.

[5] 张瑞富,杨恒山,高聚林,等. 深松对春玉米根系形态特征和生理特性的影响[J]. 农业工程学报,2015,31(5):78-84. Zhang Ruifu, Yang Hengshan, Gao Julin, et al. Effect of subsoiling on root morphological and physiological characteristics of spring maize[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(5): 78-84. (in Chinese with English abstract)

[6] 张祥彩,李洪文,王庆杰,等. 我国北方地区机械化深松技术的研究现状[J]. 农机化研究,2015,37(8):261-264. Zhang Xiangcai, Li Hongwen, Wang Qingjie, et al. Research status on mechanized subsoiling technology in northern China[J]. Journal of Agricultural Mechanization Research, 2015, 37(8): 261-264. (in Chinese with English abstract)

[7] 刘俊安,王晓燕,李洪文,等. 基于土壤扰动与牵引阻力的深松铲结构参数优化[J]. 农业机械学报,2017,48(2):60-67.

Liu Jun’ an, Wang Xiaoyan, Li Hongwen, et al. Optimization of structural parameters of subsoiler based on soil disturbance and traction resistance[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(2): 60-67. (in Chinese with English abstract)

[8] 胡宏祥,程燕,马友华,等. 油菜秸秆还田腐解变化特征及其培肥土壤的作用[J]. 中国生态农业学报,2012,20(3):297-302.

Hu Hongxiang, Cheng Yan, Ma Youhua, et al. Decomposition characteristics of returned rapeseed straw in soil and effects on soil fertility[J]. Chinese Journal of Eco-Agriculture, 2012, 20(3): 297-302. (in Chinese with English abstract)

[9] Blazier M A, Patterson W B, Hotard S L. Straw harvesting, fertilization,and fertilizer type alter soil microbiological and

physical properties in a loblolly pine plantation in the mid-south USA[J]. Biology and Fertility of Soils, 2008, 45(2): 145-153.

[10] 曹国良,张小曳,郑方成,等. 中国大陆秸秆露天焚烧的量的估算[J]. 资源科学,2006,28(1):9-13.

Cao Guoliang, Zhang Xiaoye, Zheng Fangcheng, et al. Estimating the quantity of crop residues burnt in open field in China[J]. Resources Science, 2006, 28(1): 9-13. (in Chinese with English abstract)

[11] 窦森,陈光,关松,等. 秸秆焚烧的原因与秸秆深还技术模式研究[J]. 吉林农业大学学报,2016,38(5):1-8.

Dou Sen, Chen Guang, Guan Song, et al. Why burning of corn stover in fields and technical models studies of it’s deep incorporation to subsoil[J]. Journal of Jilin Agricultural University, 2016, 38(5): 1-8. (in Chinese with English abstract)

[12] 张秀梅,张居敏,夏俊芳,等. 水旱两用秸秆还田耕整机关键部件设计与试验[J]. 农业工程学报,2015,31(11):10-16.

Zhang Xiumei, Zhang Jumin, Xia Junfang, et al. Design andexperiment on critical component of cultivator for strawreturning in paddy field and dry land[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(11): 10-16. (in Chinese with Englishabstract)

[13] 王金武,王奇,唐汉,等. 水稻秸秆深埋整秆还田装置设计与试验[J]. 农业机械学报,2015,46(9):112-117.

Wang Jinwu, Wang Qi, Tang Han, et al. Design and experiment of rice straw deep buried and whole straw returning device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(9): 112-117. (in Chinese with English abstract)

[14] Celik A, Raper R L. Design and evaluation of ground-driven rotary subsoilers[J]. Soil and Tillage Research, 2012, 124(4): 203-210.

[15] Amardeep S K, Gurmeet S C, Shisli S. Wear behavior of hardfacings on rotary tiller blader[J]. Procedia Engineering, 2014, 97: 1442-1451.

[16] 张丽,张中东,郭正宇,等. 深松耕作和秸秆还田对农田土壤物理特性的影响[J]. 水土保持通报,2015,35(1):102-106,117.

Zhang Li, Zhang Zhongdong, Guo Zhengyu, et al. Effects of subsoiling tillage and straw returning to field on soil physical properties[J]. Bulletin of Soil and Water Conservation, 2015, 35(1): 102-106, 117. (in Chinese with English abstract)

[17] 赵伟,张文春,周志立,等. 深松旋耕组合作业机的研制与试验研究[J]. 农业工程学报,2007,23(1):125-128.

Zhao Wei, Zhang Wenchun, Zhou Zhili, et al. Development and experimental research of combined subsoiling and rotary tilling set[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(1): 125-128. (in Chinese with English abstract)

[18] 赵伟,周志立,牛毅,等. 深松与旋耕组合作业机具的开发[J]. 农业机械学报,2007,38(2):75,79-82.

Zhao Wei, Zhou Zhili, Niu Yi, et al. Development of subsoiling and rotary tilling unit[J]. Transactions of the Chinese Society for Agricultural Machinery, 2007, 38(2): 75, 79-82. (in Chinese with English abstract)

[19] 王瑞丽,杨鹏,Rabiu Falalu Jahun,等. 秸秆深埋还田开沟灭茬机设计与试验[J]. 农业工程学报,2017,33(5):40-47.

Wang Ruili, Yang Peng, Rabiu Falalu Jahun, et al. Design and experiment of combine machine for deep furrowing, stubble chopping,returning and burying of chopped straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(5): 40-47. (in Chinese with English abstract)

[20] 韦丽娇,董学虎,李明,等. 1SG-230型甘蔗地深松旋耕联合作业机的设计[J]. 广东农业科学,2013(13):177-179.

Wei Lijiao, Dong Xuehu, Li Ming, et al. Design of 1SG-230 typed sugarcane ripper cum rotary tiller[J]. Guangdong Agricultural Sciences, 2013(13): 177-179. (in Chinese with English abstract)

[21] 孙冬霞,张爱民,宫建勋. 1SZL-250A型深松旋耕施肥联合整地机的设计与试验[J]. 中国农机化学报,2016,37(4):1-6.

Sun Dongxia, Zhang Aimin, Gong Jianxun. Design and experiment on 1SZL-250A type sub soiling rotary tillage fertilizer combined soil working machine[J]. Journal of Chinese Agricultural Mechanization, 2016, 37(4): 1-6. (in Chinese with English abstract)

[22] 田慎重,王瑜,宁堂原,等. 转变耕作方式对长期旋免耕农田土壤有机碳库的影响[J]. 农业工程学报,2016,32(17):98-105.

Tian Shenzhong, Wang Yu, Ning Tangyuan, et al. Effect of tillage method changes on soil organic carbon pool in farmland under long-term rotary tillage and no tillage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(17): 98-105. (in Chinese with English abstract)

[23] 张居敏,周勇,夏俊芳,等. 旋耕埋草机螺旋横刀的数学建模与参数分析[J]. 农业工程学报,2013,29(1):18-25. Zhang Jumin, Zhou Yong, Xia Junfang, et al. Mathematical modeling and analysis of helical blade for stubble burying rotary tiller[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(1): 18-25. (in Chinese with English abstract)

[24] 王志山,夏俊芳,许绮川,等. 水田高茬秸秆旋耕埋覆装置功耗测试方法[J]. 农业工程学报,2011,27(2):119-123. Wang Zhishan, Xia Junfang, Xu Qichuan, et al. Power consumption testing system of high stubble buried device in paddy field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(2): 119-123. (in Chinese with English abstract)

[25] 张居敏,贺小伟,夏俊芳,等. 高茬秸秆还田耕整机功耗检测系统设计与试验[J]. 农业工程学报,2014,30(18):38-46.

Zhang Jumin, He Xiaowei, Xia Junfang, et al. Design and field experiment of power consumption measurement system for high stubble returning and tillage machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(18): 38-46. (in Chinese with English abstract)

[26] 夏俊芳,贺小伟,余水生,等. 基于ANSYS/LS-DYNA 的螺旋刀辊土壤切削有限元模拟[J]. 农业工程学报,2013,29(10):34-41.

Xia Junfang, He Xiaowei, Yu Shuisheng, et al. Finite element simulation of soil cutting with rotary knife roller based on ANSYS/LS-DYNA software[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(10): 34-41. (in Chinese with English abstract)

[27] 张秀梅,夏俊芳,张居敏,等. 水旱两用秸秆还田组合刀辊作业性能试验[J]. 农业工程学报,2016,32(9):9-15.

Zhang Xiumei, Xia Junfang, Zhang Jumin, et al. Working performance experiment of combination blade roller for straw returning in paddy field and dry land[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(9): 9-15. (in Chinese with English abstract)

[28] 郭新荣. 土壤深松技术的应用研究[J]. 山西农业大学学报,2005(1):74-77. Guo Xinrong. Application study oil technique of the soil deep loosening[J]. Journal of Shanxi Agricultural University, 2005(1): 74-77. (in Chinese with English abstract)

[29] 柴民杰,李洪文,何进,等. 秸秆覆盖地深松机的设计与试验研究[J]. 农机化研究,2006,28(7):136-138,142.

Chai Minjie, Li Hongwen, He Jin, et al. Design and experimental study on subsoiler for corn-cover field[J]. Journal of Agricultural Mechanization Research, 2006, 28(7): 136-138, 142. (in Chinese with English abstract)

[30] 权龙哲,佟金,曾百功,等. 玉米根茬铲切刀具的滑切刃曲线优化设计[J]. 农业工程学报,2011,27(12):13-17.

Quan Longzhe, Tong Jin, Zeng Baigong, et al. Optimization design of sliding cutting edge curve of corn rootstalk cutting tool[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(12): 13-17. (in Chinese with English abstract)

[31] 庞声海. 关于滑切理论与滑切角的选用[J]. 华中农学院学报,1982,6(1):64-69. Pang Shenghai. On the theory of sliding cutting and the choice of its angle[J]. Journal of Huazhong Agricultural College, 1982, 6(1): 64-69. (in Chinese with English abstract)

[32] 顾耀全,贾洪雷,郭慧,等. 滑刀式开沟器设计及试验[J]. 农业机械学报,2013,44(2):38-42. Gu Yaoquan, Jia Honglei, Guo Hui, et al. Design and experiment of sliding knife furrow opener[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(2): 38-42. (in Chinese with English abstract)

[33] 贾洪雷,郑嘉鑫,袁洪方,等. 仿形滑刀式开沟器设计与试验[J]. 农业工程学报,2017,33(4):16-24.

Jia Honglei, Zheng Jiaxin, Yuan Hongfang, et al. Design and experiment of profiling sliding-knife opener[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(4): 16-24. (in Chinese with English abstract)

[34] JB/T 9788-1999深松铲和深松铲柄[S]. 北京:全国农业机械标准化技术委员会,1999.

[35] 邱立春,李宝筏. 自激振动深松机减阻试验研究[J]. 农业工程学报,2000,16(6):72-76.

Qiu Lichun, Li Baofa. Experimental study on the self-excited vibration subsoiler for reducing draft force[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2000, 16(6): 72-76. (in Chinese with English abstract)

[36] 王雪艳. 振动深松技术与关键部件研究[D]. 北京:中国农业大学,2005.

Wang Xueyan. Study on Vibrating Subsoiling Technology and Its Parts[D]. Beijing: China Agricultural University, 2005. (in Chinese with English abstract)

[37] 张军昌,闫小丽,林泽坤,等. 自激式振动深松整地机设计与试验[J]. 农业机械学报,2016,47(9):44-49,72.

Zhang Junchang, Yan Xiaoli, Lin Zekun, et al. Design and experiment of self-exciting vibration deep-loosening and subsoiling machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(9): 44-49, 72. (in Chinese with English abstract)

[38] 许春林,李连豪,赵大勇. 北方大型联合整地机设计与试验[M]. 北京:中国农业大学版社,2014:134-141.

[39] JB/T 10295-2001深松整地联合作业机[S]. 北京:全国农业机械标准化技术委员会,2001.

周 华,张居敏,祝英豪,张春岭,H.M.Tahir,夏俊芳. 秸秆还田深松旋埋联合耕整机设计与试验[J]. 农业工程学报,2017,33(22):17-26. doi:10.11975/j.issn.1002-6819.2017.22.003 http://www.tcsae.org

Zhou Hua, Zhang Jumin, Zhu Yinghao, Zhang Chunling, H.M.Tahir, Xia Junfang. Design and experiment of combined tillage machine for subsoiling and rotary burying of straw incorporated into soil[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(22): 17-26. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.22.003 http://www.tcsae.org

Design and experiment of combined tillage machine for subsoiling and rotary burying of straw incorporated into soil

Zhou Hua, Zhang Jumin, Zhu Yinghao, Zhang Chunling, H.M.Tahir, Xia Junfang※

(430070,)

Soil compaction become very serious problem due to many years of traditional tillage practices which result in formation of hard plow pan, shallower rooting depth, decreased air and water permeability, and confined root system development. Subsoiling and straw incorporated into soil applied jointly result in good working efficiency, alleviation of plow pan by subsoiling, improved water holding capacity and buried crop residue. This is direct and effective way of improving organic matter contents and it can also effectively alleviate the environmental pollution caused by straw burning. This practice will not only reduce wheel traffic in field, it also will save busy time in farming season and will play an important role in increasing crops yield and farmer’s income. Through the study of relevant literature, in order to meet the needs of deep tillage and straw burying at the same time, a multifunctional machine for subsoiling and rotary burying have designed, which was capable of joint operations like subsoiling, stubbles cutting, soil crushing, residue burying and leveling. Subsoiling implement with self-excited vibration and adjustable pre-tightening force were devised in this machine which worked to reduce subsoiling resistance to certain degree and also protected the subsoiler when it encountered obstacles. The principle of sliding cutting was adopted in the design of the deep shovel bar which can cut off straw and weeds effectively and prevented winding and clogging to the subsoiler bar. The stress analysis of the subsoiling implement was carried out and the force formula was determined. Blades of rotary cutter were rearranged and optimized to improve working stability and soil cutting and crushing capacity. Subsoiling provided good condition for rotary burying and the depth of straw embedment was increased. Different field tests such as separate subsoiling, rotary burying after subsoiling, separate rotary burying and subsoiling with rotary burying as combined operation was carried out. The traction resistance and power consumption of implement under different working conditions were analyzed. Results showed that the traction resistance and power consumption of subsoiling operation was greatly affected by the working speed. In the rotary burying operation, the driving force of the positive rotation of the rotary cutter roll was opposite to the working resistance so that the cancel out and the traction power consumption of rotary burying operation were small, and power ratio for rotary burying was more. Under the 1st and 2nd gear speeds of the tractor, the total power respectively for the combined operation of subsoiling and rotary burying was 32.72 and 41.88 kW. They accounted for 85% and 82.2% of the total sum of individual subsoiling and rotary burying operations, respectively. Through consulting relevant documents, compared with the traditional machine for subsoiling and rotary tillage, the power consumption was reduced by 4.4% to 14.8% and 7.9% to 14.0%, respectively in the same working condition. Other parameters of experiment collected after combined operation of subsoiling and rotary burying and statistically analyzed included average depth of subsoiling. The results showed that rotary burying were 28.9 and 17.5 cm, respectively, subsoiling tillage stability was 93.5% and rotary burying tillage stability was 87.4%, the average vegetation cover rate was 92.0%, the surface evenness after tillage was 1.0 cm, and soil resistance of 0-15 and 15-30 cm after tillage were 437.6 and 951.8 kPa, which were 78.4% and 67.4% less than that before tillage, respectively. Soil bulk density of 0-10 and 10-20 cm after tillage were 1.40 and 1.41 g/cm3which decreased by 6.7% and 8.4%, respectively compared with that before tillage. The performance evaluation indexes of subsoiling field preparation combine machine were compared, and the measured values of the above parameters for combined operation of subsoiling and rotary burying exceeded the quality evaluation index and meet the agronomic requirements.

agricultural machinery; design; soils; subsoiling; straw returning; sliding cutting; rotary burying; combination operation

10.11975/j.issn.1002-6819.2017.22.003

S222.4

A

1002-6819(2017)-22-0017-10

2017-07-03

2017-10-08

公益性行业(农业)科研专项经费资助项目(201503136);湖北省科技支撑计划项目资助项目(2015BBA155);新进博士科研启动金(2662015BQ016)

周 华,博士生,主要从事现代农业装备设计及测控研究。Email:zhouhua688@163.com

夏俊芳,教授,博士生导师,主要从事现代农业装备设计及测控研究。Email:xjf@mail.hza.edu.cn