十水硫酸钠相变蓄冷保温箱保冷特性的试验研究

2017-12-15徐笑锋章学来JothamMuthokaMunyalo李玉洋陈启杨

徐笑锋,章学来,Jotham Muthoka Munyalo,李玉洋,陈 跃,陈启杨,刘 升

十水硫酸钠相变蓄冷保温箱保冷特性的试验研究

徐笑锋1,章学来1※,Jotham Muthoka Munyalo1,李玉洋1,陈 跃1,陈启杨1,刘 升2

(1. 上海海事大学蓄冷技术研究所,上海 201306; 2. 北京市农林科学院蔬菜研究中心,北京 100097)

针对果蔬保鲜冷链物流中2~8 ℃的运输温区要求,为了保证运输中果蔬等农产品的品质,研发一种经济性较高,相变温度为6.4 ℃,相变潜热为141 J/g的硫酸钠水合盐体系,其成分为(75.5%Na2SO4·10H2O+3%硼砂+1.25%聚丙烯酸钠+16%NH4Cl+4%KCl+0.25%去离子水)。相变材料封装于聚乙烯蓄冷板中,应用于发泡聚丙烯(expanded polypropylene)保温箱和真空绝热板(vacuum insulation panel)保温箱中,组成蓄冷式冷链运输装备。利用产品供应规范(good supply practice GSP)验证设备建立保温箱温度测试系统,得到箱内各点的升温曲线,通过平均保冷时间来评价保温箱的保冷效果,对比了保温箱载货与空载情况下箱内各点的温度变化。综合考虑保温箱内侧面布置、顶层布置等不同的摆放方式,聚丙烯发泡与真空绝热板不同保温箱体材质对保冷性能的影响。研究表明真空绝热板的保温效果优于发泡聚丙烯,可提高保冷时间13.31%;蓄冷剂在侧布形式下的保冷时间较侧布加顶布方式延长4.7%;在真空绝热板保温箱中分析了载货情况下的保冷性能较空载保冷时间减少0.77 h。研究结果为蓄冷保温箱在冷链物流中的进一步设计和优化提供支持,以及蓄冷技术在果蔬冷链物流中的应用提供参考。

水果;冷藏;相变材料;冷链物流;十水硫酸钠;蓄冷保温箱;蓄冷板

0 引 言

冷链物流要求食品在生产加工、储存运输以及销售消费的各个环节中必须处于食品所要求的温度区间内,以保证食品的质量[1-4]。中国每年有大量食品在没有冷链保障下运输销售,造成食品变质腐烂,损失率高达20%以上[5-8]。蓄冷技术在食品低温加工、低温贮藏、低温运输配送、低温销售等食品冷链的各环节中都具有广泛的应用背景和节能潜力[9-12]。相变蓄冷材料需要相变温区符合冷藏保鲜要求,潜热较高,导热性能较好,稳定性较强[13-14]。利用相变蓄冷原理[13-15],按冷链运输不同的温度需求将不同相变温度的蓄冷材料填充至蓄冷保温箱中,利用相变温度对果蔬精确控温[16],进行合理配置可达到食品冷链物流的要求[17-18]。

蓄冷保温箱是20世纪80年代初期从发达国家发展起来的一种高效物流技术[18-20],其耐冷耐热耐用,环保密封,尺寸灵活,保温性能优良以及配载形式灵活成为疫苗运输的一个优质的运输设备,是短途运送和保鲜果蔬的有效工具。蓄冷保温箱是一种绝热密封箱体,配备冰袋或冰盒等蓄冷材料来维持箱内的低温,无需制冷就能实现长时间保冷,完成果蔬的冷链配送[17]。张静荣等[21]针对韭黄的保鲜,对比研究3种运输箱体保冷效果,发现蓄冷保温箱抑制了韭黄变质,有效延长了保冷时间。宋海燕等[22]研究填充不同质量蓄冷材料时,蓄冷保温箱的保冷特性,验证了蓄冷保温箱能达到果蔬运输2~8 ℃的温区要求。

传统的蓄冷保温箱材质多为聚氨酯,其保温性能一般且污染较大[21]。刘翠娜等[23]利用真空绝热板与聚氨酯发泡组成复合保温材料,使蓄冷保温箱在保证有效体积的情况下冷负荷降低15.7%。阚安康等[24-26]研制了开孔聚氨酯为真空绝热板芯材,有效将导热系数降低到10 mW/(m·K)以下。保温箱中温度场分布不均匀也是一个不可忽视的问题。张哲等[27-28]研究了蓄冷式冷藏车中码货方式对车厢温度场的影响及温度场分布,发现空载与码货等不同工况下,车内温度场均匀性差异较大。武小娟等[29]研究了蓄冷板不同布置方式的冷藏车内温度场分布情况,发现不同冷板布置方式影响车厢内温度场的均匀性。陈文朴等[30]研制了一种甲酸钠低温蓄冷剂,并应用于聚氨酯和复合材料2种蓄冷箱中,发现蓄冷剂用量与保温材料对保冷特性影响较大。

本研究在前人研究的基础上,以果蔬保鲜温区2~8 ℃为标准,保证果蔬等农产品在运输中的品质为目的,自主研发一种低成本,高潜热,热稳定性高的相变蓄冷材料—硫酸钠水合盐体系。以硫酸钠水合盐体系为蓄冷剂,应用于发泡聚丙烯(expanded polypropylene,EPP)保温箱和真空绝热板(vacuum insulation panel,VIP)保温箱中,组成蓄冷式冷链运输装备并对其进行优化设计与试验研究。利用产品供应规范验证设备(good supply practice,GSP)建立保温箱温度测试系统,得到箱内各点的升温曲线,通过平均保冷时间来评价保温箱的保冷效果。综合考虑侧面布置与顶层布置等不同冷板摆放方式及聚丙烯发泡和真空绝热板不同保温箱体材质对保冷性能的影响,分析对比了保温箱载货与空载不同情况下箱内各点的温度变化。研究成果解决了在果蔬保鲜温区2~8 ℃内的保温运输问题,降低成本并精确控温,保证果蔬品质,为蓄冷保温箱的进一步优化和设计,以及蓄冷技术在果蔬冷链物流中的深入研究和应用提供参考。

1 材料与方法

1.1 试验材料

利用相变蓄冷技术,达到精确控温的目的。采用自主研发硫酸钠水合盐为蓄冷剂,成分为75.5%Na2SO4·10H2O+3%硼砂+1.25%PAAS+16%NH4Cl+ 4%KCl+0.25%去离子水(PAAS为聚丙烯酸钠)。其相变温度为6.4 ℃,满足果蔬冷链物流保鲜温度区间要求,相变潜热为141 J/g,导热系数为0.547 W/(m·K),如表1所示。

表1 蓄冷剂性能对比

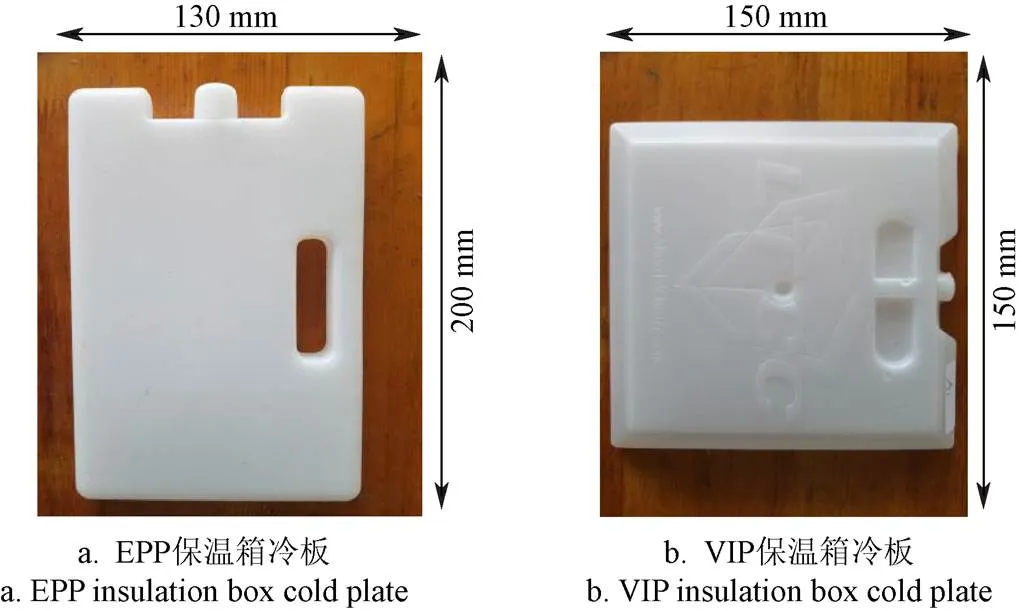

与同温区蓄冷材料相比,其具有储能潜热大,无过冷和相分离现象,热传导性、稳定性良好,可循环使用以及成本低廉等优点[31]。选用上海力统冷链科技有限公司生产的2种蓄冷保温箱作为试验对象,保温箱的技术参数如表2所示。其中一种采用发泡聚丙烯作为保温材料,EPP是一种高结晶型聚合物、气体复合材料,具有优良的耐热性能、化学稳定性好、绝热性、耐油性、质量轻、使用寿命长等优点,目前已成为市场上广泛应用的一种新型环保隔热材料。另外一种保温箱材质为真空绝热板,VIP是一种新型节能、高效的绝热保温材料,该材料通过提高板内真空度以及填充隔热芯材来达到保温效果。真空绝热板具有较低的导热系数、较小的厚度等优点。2种保温箱匹配不同形状尺寸的蓄冷板如图1所示,将自主研发硫酸钠蓄冷材料填充至蓄冷板内,对保温箱进行降温。

表2 保温箱的技术参数

图1 不同形状尺寸的蓄冷板

温度测试系统是由杭州泽大仪器有限公司生产的GSP验证设备,测试系统包括GSP验证仪主机、无线温湿度传感器(温湿度RFID卡片)、中继器以及验证云平台。验证仪主机通过中继器接收到无线温湿度传感器采集的数据并实时显示,方便用户在实际使用过程中能够实时看到温湿度并及时对其不合理的点位作出分析和调整。温湿度RFID卡片的测温范围为−40~80 ℃,精度±0.5 ℃;Agilent 34972A型数据采集仪,每次采集时间1 s;T型热电偶,精度±0.5 ℃,热响应时间为0.4 s;中继器可以增加无线传输距离;验证云平台可通过客户端转换采集到的数据并生成报告方便用户分析。

1.2 试验方法

1.2.1 不同冷板布置方式试验

试验选用EPP保温箱进行试验研究。由于保温箱与冷板结构设计原因,本试验采用两种蓄冷剂摆放形式进行研究,如图2所示。

图2 不同冷板布置方式

一种是侧布的方式,在箱四周分别放置一块蓄冷板;还有一种方式是在箱内顶部放置两块,在箱两边各放一块。将等量1 600 g硫酸钠相变蓄冷材料填充至4块蓄冷板,并利用超低温冷柜对其进行充冷。蓄冷板充冷时间为10 h,初始温度为−15 ℃如图3所示。将冷板按不同摆放方式放入EPP保温箱,用胶带固定温湿度RFID卡片对其各待测点温度进行监测,其中顶部利用胶带固定一块悬空温湿度RFID卡片测量箱体内部空间温度变化,重复进行5次试验,得出平均值。

1.2.2 不同材质蓄冷保温箱试验

在EPP保温箱与VIP保温箱中同样采用侧布加顶布冷板布置方式,布置5块蓄冷板。其中EPP保温箱与VIP保温箱容积为7 040 125 mm3,5 750 000 mm3。

EPP保温箱与VIP保温箱容积比为1.22。在VIP保温箱中充注2 000 g十水硫酸钠体系作为蓄冷剂。按照同体积蓄冷量相同原则,在EPP保温箱中充注2 440 g十水硫酸钠体系至5块蓄冷板中。布置两种保温箱的温度待测点,并用胶带固定温湿度RFID卡片如图3所示,其中用胶带固定一个温湿度RFID卡片悬空测量箱内空间温度;紧闭保温箱盖,打开GSP验证设备开始监测;当各测点温度上升至接近室温(21.5±1.5)℃时,测量结束,重复5次试验导出数据,分析研究2种不同材质保温箱保冷特性。

图3 不同材料的保温箱

1.2.3 果蔬保鲜试验

选用苹果作为载货应用试验对象,选用2 000 g硫酸钠蓄冷剂,VIP保温箱保冷。为防止试验过程中冷凝水的污染以及防止苹果由于呼吸作用产生乙烯的催熟现象,在试验前先将苹果用保鲜膜包裹。由于温湿度RFID卡片无法监测苹果表皮和苹果内部温度,因此采用热电偶进行温度测试。将热电偶分别固定在苹果内部和苹果表皮处,如图4所示。将总质量为1 500 g的苹果放入VIP保温箱中,并在保温箱内部布置温度测点,重复测试5次,分析平均值。

图4 苹果保鲜试验示意图

2 结果与分析

2.1 不同冷板布置方式对保温箱保冷特性的影响

图5与表3是不同冷板布置方式下各测点温度变化情况。由于保温箱盖直接暴露在室温下,冷量下沉,箱内顶部保冷时间较短,因此在试验中采用在保温箱顶部放置两块板和两侧各放一块蓄冷板的方式,同时与在保温箱四周放置蓄冷板的方式进行对比。蓄冷剂的相变温度为6.4 ℃,放置在保温箱短边的蓄冷板维持6~8 ℃时间最长。两种蓄冷剂不同摆放方式下,箱内的空间温度一致,都为7~9 ℃,但是侧布方式下的保冷时间较侧布加顶布方式长0.81 h。侧布方式下的保温箱平均保冷时间比顶布加侧布方式下的时间更长。在实际运输中,在不影响箱体内有效容积的情况下,可以考虑将蓄冷板布置成侧布的方式,以增强保冷效果。

图5 冷板不同布置方式下温度变化曲线

由表3可知,侧布方式顶部保冷温度9~11 ℃,而侧布加顶布方式顶部保冷温度在6~8 ℃,两种布置方式箱体内顶部最大仍存在3 ℃温差。由于短边侧板面积较小且每个边蓄冷剂质量一致,所以短边侧板温度较低,保冷时间长。侧布方式较顶布加侧布方式将平均保冷时间有效的提高了4.7%,但箱体顶部与底部温差较大,箱体内温度场分布不均匀。在顶部增加冷板后,由图5对比可得顶部温度明显下降2~3 ℃。顶布加侧布方式温度场分布更为均匀,更有利于果蔬的保鲜。

表3 不同布置方式测点的温度

2.2 不同材质蓄冷保温箱保冷特性研究

从图6可以看出,EPP和VIP保温箱内分别放入2 000、2 440 g的蓄冷剂,但是其保冷效果不一样。VIP保温箱内空间温度较EPP保温箱内空间温度低1 ℃,而且平均保冷时间较后者长1.24 h,提高了13.31%。各箱内蓄冷剂相变温度都为6.4 ℃,但是维持时间长短根据箱体材质各有不同。两种保温箱内各层蓄冷板的保冷时间变化趋势基本相同,由下至上保冷时间依次缩短,这是由于冷量向下传输的原因。VIP保温箱由于导热系数较低,各温度测点的温度变化更接近。其内置于箱顶的蓄冷板的保冷时间比箱底的保冷时间短3.19 h。且EPP保温箱底部的保冷时间仍长于顶部的保冷时间。保温箱的顶部是保温的最不利位置,因此在实际应用中可以考虑适当增加箱体内的顶部蓄冷量或者在保温箱顶部做附加的保温处理,以保证箱内均匀释放冷量,维持更长的保冷时间。

图6 不同材质保温箱温度变化曲线

由表4可直观看出,在室温环境为(21±1.5 )℃,箱内蓄冷板布置方式蓄冷剂种类、同容积蓄冷剂质量等外界因素相同的情况下,VIP保温箱的保冷效果更佳,温度分布也更加均匀稳定。但是VIP保温箱内体积较小,蓄冷板体积较大,使得箱内有效利用容积减少,因此在实际应用中也需考虑这方面因素带来的影响。

表4 不同保温材质测点的温度

2.3 果蔬保鲜温度场分布研究

分别对比了VIP保温箱空载和载货的保冷效果,试验结果如图7和表5所示。通过对比发现,载货的保温箱内升温至相变温度6.4 ℃的升温速率较空载的保温箱更快,这是因为保温箱内放入的是未经过预冷常温下的苹果,而苹果的比热容远大于空气,导致苹果吸收了更多蓄冷剂的固态显热,因此载货的升温速率大于空载的升温速率,而且蓄冷剂释冷阶段时间大大缩短。从表5可以看出,利用硫酸钠水合盐体系与真空绝热板蓄冷保温箱相结合,载货的平均保冷时间为9.63 h,证明比空载的平均保冷时间短0.77 h,但是蓄冷剂的相变温度仍在6~8 ℃范围内没有变化,可有效保鲜货物。

图7 保温箱空载与载货时的温度变化曲线

在实际应用过程中,要全方面考虑会对货物品质产生影响的各个因素,合理的选择被保冷货物的预冷温度、蓄冷剂的用量及预冷温度。蓄冷剂的预冷温度过低虽能延长保冷时间,但是会冻坏货物,损害货物的品质。

表5 载货与空载下测点的温度

3 结 论

针对应用于果蔬冷链物流的十水硫酸钠蓄冷保温箱,不同的冷板布置方式、不同的保温箱材质以及是否载货等都是影响其保冷性能的关键因素。本文通过试验研究主要得出以下结论:

1)侧布加顶布的冷板布置方式较仅侧布可提高箱体内温度场的均匀度,有效降低顶部温度3 ℃,利于保证果蔬的品质;冷板侧布布置可有效的提高保冷时间,较侧布加顶布方式可将箱体内保鲜时间延长4.7%。

2)将真空绝热板及其填充隔热芯等技术应用于蓄冷保温箱中,与普通EPP保温箱相比可有效延长保冷时间13.31%。且真空绝热板材质的蓄冷保温箱内温度场分布更加均匀,各温度测点间温差较小,但其质量较大,有效使用体积减小,经济性需要提高。

3)以苹果为保鲜对象,利用硫酸钠水合盐体系与真空绝热板蓄冷保温箱相结合,可有效的保鲜9.63 h左右,较空载保冷时间减少0.77 h。蓄冷保温箱可行性较高,保冷特性优良。

[1] Rathod M K, Banerjee J. Thermal stability of phase change materials used in latent energy storage systems: A review[J]. Renewable and Sustainable Energy Reviews, 2013, 18: 246-258.

[2] Sarier N, Onder E. Organic phase change materials and their textile applications: An overview[J]. Thermochimica Acta, 2012, 540: 7-60.

[3] 葛文杰,赵春江. 农业物联网研究与应用现状及发展对策研究[J]. 农业机械学报,2014,45(7):222-230,277.

Ge Wenjie, Zhao Chunjiang. State-of-the-art and developing strategies of agricultural internet of things[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(7): 222-230,277. (in Chinese with English abstract)

[4] 黄雪莲,于新,马永全. 蓄冷技术在果蔬保鲜中的研究与应用[J]. 仲恺农业技术学院学报,2010,23(2):67-71.

Huang Xuelian, Yu Xin, Ma Yongquan. Study and application of cool storage technology in fruits and vegetables preservation[J]. Journal of Zhongkai University of Agriculture and Engineering, 2010, 23(2): 67-71. (in Chinese with English abstract)

[5] 赵春江,韩佳伟,杨信廷,等. 冷链物流研究中的计算流体力学数值模拟技术[J]. 农业机械学报,2015,46(3):214-222.

Zhao Chunjiang, Han Jiawei, Yang Xinting, et al. Digital simulation technology of computational fluid dynamics in agricultural cold-chain logistics applications[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(3): 214-222. (in Chinese with English abstract)

[6] 邸倩倩,王亚会,刘斌,等. 风速对冷藏车内温度分布的影响[J]. 食品科技,2017,42(5):46-51.

Di Qianqian, Wang Yanhui, Liu Bin, et al. Effect of wind speed on the temperature of liquid nitrogen refrigerated vehicle[J]. Food Science and Technology 2017, 42(5): 46-51. (in Chinese with English abstract)

[7] 张东霞,吕恩利,陆华忠,等. 保鲜运输车温度场分布特性试验研究[J]. 农业工程学报,2012,28(11):254-260.

Zhang Dongxia, Lü Enli, Lu Huazhong, et al. Experimental study on temperature field distribution characteristics in fresh-keeping transportation[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2012, 28(11): 254-260. (in Chinese with English abstract)

[8] 翁卫兵,房殿军,李强,等. 冷藏运输厢内流场和温度场协同控制[J]. 农业机械学报,2014,45(6):260-265,290.

Weng Weibing, Fang Dianjun, Li Qiang, et al. Cooperative control of flow field and temperature field in refrigerated transport carriage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(6): 260-265, 290. (in Chinese with English abstract)

[9] 赵春江,韩佳伟,杨信廷,等. 基于CFD的冷藏车车厢内部温度场空间分布数值模拟[J]. 农业机械学报,2013,44(11):168-173.

Zhao Chunjiang, Han Jiawei, Yang Xinting, et al. Numerical simulation of temperature field distribution in refrigerated truck based on CFD[J]. Transactions of the Chinese Society of Agricultural Machinery, 2013, 44(11): 168-173. (in Chinese with English abstract)

[10] 韩佳伟,赵春江,杨信廷,等. 基于CFD数值模拟的冷藏车节能组合方式比较[J]. 农业工程学报,2013,29(19):55-62.

Han Jiawei, Zhao Chunjiang, Yang Xinting, et al. Comparison of combination mode of energy conservation for refrigerated car based on CFD numerical simulation[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2013, 29(19): 55-62. (in Chinese with English abstract)

[11] 郭嘉明,吕恩利,陆华忠,等. 保鲜运输车果蔬堆码方式对温度场影响的数值模拟[J]. 农业工程学报,2012,28(13):231-236.

Guo Jiaming, Lü Enli, Lu Huazhong, et al. Numerical simulation on temperature field effect of stack method of garden stuff for fresh-keeping transportation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of CSAE), 2012, 28(13): 231-236. (in Chinese with English abstract)

[12] 谢晶,瞿晓华,徐世琼. 冷藏库内气体流场数值模拟与验证[J]. 农业工程学报,2005,21(2):11-16.

Xie Jing, Qu Xiaohua, Xu Shiqiong. Numerical simulation and verification of airflow in cold-store[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2005, 21(2): 11-16. (in Chinese with English abstract)

[13] Gogou E, Katsaros G, Derens E, et al. Cold chain database development and application as a tool for the cold chain management and food quality evaluation[J]. International Journal of Refrigeration, 2015(52): 109-121.

[14] 应铁进,朱冰清,戚晓丽,等. 用于农产品保鲜的有机物水溶液相变蓄冷剂[J]. 农业机械学报,2015,46(2):208-212,207.

Ying Tiejin, Zhu Bingqing, Qi Xiaoli, et al. Development of organic solution phase change materials for preservation of agricultural products[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015,46(2): 208-212,207. (in Chinese with English abstract)

[15] 李晓燕,李凯娣,刘家庆,等. 相变蓄冷技术在食品冷链中的应用研究与进展[C]//武汉,2013中国制冷学会学术年会论文集.2013.

Li Xiaoyan, Li Kaidi, Liu Jiaqing, et al. Research and progress of phase change storage technology application inthe food cold chain[C]//Wuhan,2013 China Refrigeration Institute Academic Essays. 2013. (in Chinese with English abstract)

[16] 黄艳,章学来. 蓄冷技术在食品冷链物流中的研究进展[J]. 包装工程,2015(15):23-29.

Hunag Yan, Zhang Xuelai. Research progress of the application of cold storage technology in food cold chain logistics[J]. Packaging Engineering, 2015(15): 23-29. (in Chinese with English abstract)

[17] 洪乔荻,邹同华,宋晓燕,等. 疫苗运输用蓄冷材料性能研究[J]. 低温与超导,2013(8):59-62.

Hong Qiaodi, Zou Tonghua, Song Xiaoyan, et al. Study on the performance of cool storage material for vaccine transportation[J]. Cryogenics & Superconductivity, 2013(8): 59-62. (in Chinese with English abstract)

[18] Brosnan T, Sun D. Precooling techniques and applications for horticultural products a review[J]. International Journal of Refrigeration, 2001, 24(2): 154-170.

[19] 吴丽媛,宋文吉,高日新,等. 基于板式冰蓄冷的冷藏库恒温特性的试验研究[J]. 制冷学报,2012(33):66-69.

Wu Liyuan, Song Wenji, Gao Rixin, et al. Experimental study of plate ice storage cold storage temperature based on the characteristics of cold[J]. Journal of Refrigeration, 2012(33): 66-69. (in Chinese with English abstract)

[20] 刘秀娟,贺可太,冯爱兰. 蓄冷箱在疫苗运输中的应用研究[J]. 物流技术,2008(6):116-118,125.

Liu Xiujuan, He Ketai, Feng Ailan. Study on application of cold box in vaccine transportation[J]. Logistics Technology, 2008(6): 116-118,125. (in Chinese with English abstract)

[21] 张静荣,肖云茹,郁小森,等. 三种便携式蓄冷保温箱在韭黄保鲜应用中的效果比较[J]. 食品工业科技,2017,38(17):279-282,323.

Zhang Jingrong, Xiao Yunru, Yu Xiaosen, et al. A Comparison of application effects on three kinds of portable insulation incubator in fresh keepin[J]. Science and Technology of Food Industry, 2017, 38(17): 279-282, 323. (in Chinese with English abstract)

[22] 宋海燕,田萌萌,伍亚云. 蓄冷剂质量对挤塑聚苯乙烯保温箱温控效果的影响研究[J]. 包装工程,2016(7):56-60.

Song Haiyan, Tian Mengmeng, Wu Yayun. Influences of the coolant amount on temperature control effect of extruded polystyrene insulation box[J]. Packaging Engineering, 2016(7): 56-60. (in Chinese with English abstract)

[23] 刘翠娜,张双喜,周恒勤,等. 便携式蓄冷保温箱结构优化[J]. 吉林化工学院学报,2011(1):29-33.

Liu Cuina, Zhang Shuangxi, Zhou Hengqin, et al.Optimization of structure of portable cool storage incubator[J]. Journal of Jilin Institute of Chemical Technology, 2011(1): 29-33. (in Chinese with English abstract)

[24] 阚安康,韩厚德,曹丹,等. 开孔聚氨酯真空绝热板芯材的研究[J]. 绝缘材料,2008(2):45-48.

Kan An’kang, Han Houde, Cao Dan, et al. Research on open-cell rigid polyurethane formfor vacuum insulated panel core[J]. Insulating material, 2008(2): 45-48. (in Chinese with English abstract)

[25] 郭志鹏,阚安康,杨帆,等. 布置真空绝热板的冷藏集装箱内温度分布[J]. 南京航空航天大学学报,2017,49(1):29-33.

Guo Zhipeng, Kan An’kang, Yang Fan, et al. Temperature distribution inside reefer container equipped with vacuum insulation panels[J].Journal of Nanjing University of Aeronautics & Astronautics, 2017, 49(1): 29-33. (in Chinese with English abstract)

[26] 孟闯,阚安康,郭志鹏,等. 真空绝热板研究现状及其在建筑领域的应用[J]. 真空,2017,54(1):67-73.

Meng Chuang, Kan An’kang, Guo Zhipeng, et al. The research status of vacuum insulation panel and its application in the architecture field[J]. Vacuum, 2017, 54(1): 67-73. (in Chinese with English abstract)

[27] 张哲,郭永刚,田津津,等. 冷板冷藏汽车箱体内温度场的数值模拟及试验[J]. 农业工程学报,2013,29(增刊1):18-24.

Zhang Zhe, Guo Yonggang, Tian Jinjin, et al. Numerical simulation and experiment of temperature field distribution in box of cold plate refrigerated truck[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2013, 29(Supp.1): 18-24. (in Chinese with English abstract)

[28] 张哲,李立民,田津津,等. 冷藏车温度场不均匀度对蔬菜保鲜效果的影响[J]. 农业工程学报,2014,30(15):309-316.

Zhang Zhe, Li Limin, Tian Jinjin, et al. Effects of refrigerated truck temperature field uniformity on preservation of vegetables[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2014, 30(15): 309-316. (in Chinese with English abstract)

[29] 武小娟,王忠堂,梅瑞斌,等. 冷板的布置方式对冷板车车内温度场的影响[J]. 制冷与空调,2008(5):12-15.

Wu Xiaojuan, Wang Zhongtang, Mei Ruibin, et al. Temperature distribution of refrigerator truck influence by position of cooling source[J]. Refrigeration & Air-Conditioning, 2008(5): 12-15. (in Chinese with English abstract)

[30] 陈文朴,章学来,黄艳,等. 甲酸钠低温相变材料的研制及其在蓄冷箱中的应用[J]. 制冷学报,2017,38(1):68-72.

Chen Wenpu, Zhang Xuelai, Huang Yan,et al.Application Sodium formate as low temperature phase change materials in cold storage insulation box[J]. Journal of Refrigeration, 2017, 38(1): 68-72. (in Chinese with English abstract)

[31] 郭长华. 相变储热材料三水醋酸钠储热性能研究[D]. 兰州:兰州理工大学,2011.

Guo Changhua. Study on Heat Storage Performance of Sodium Acetate Trihydrate for Phase Change Thermal Storage Materials[D]. Lanzhou: Lanzhou University of Technology, 2011. (in Chinese with English abstract)

徐笑锋,章学来,Jotham Muthoka Munyalo,李玉洋,陈 跃,陈启杨,刘 升. 十水硫酸钠相变蓄冷保温箱保冷特性的试验研究[J]. 农业工程学报,2017,33(22):308-314. doi:10.11975/j.issn.1002-6819.2017.22.040 http://www.tcsae.org

Xu Xiaofeng, Zhang Xuelai, Jotham Muthoka Munyalo, Li Yuyang, Chen Yue, Chen Qiyang, Liu Sheng. Experimental study on cold retention characteristics of cold storage incubator using Na2SO4·10H2O as PCMs[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(22): 308-314. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.22.040 http://www.tcsae.org

Experimental study on cold retention characteristics of cold storage incubator using Na2SO4·10H2O as PCMs

Xu Xiaofeng1, Zhang Xuelai1※, Jotham Muthoka Munyalo1, Li Yuyang1, Chen Yue1, Chen Qiyang1, Liu Sheng2

(1,,201306,; 2.,100097,)

At present, cold chain in China is developing rapidly, especially in the cold chain market of agricultural products, it has huge market potential. But the cold chain transportation still faces serious constrains for its development. The shortage of cold chain capacity and frequent discontinuity in the process of transportation deteriorate the quality of agricultural products. Thermal storage cold chain transportation equipment currently used includes refrigerated transportation with cold storage technology and adiabatic thermal insulation technology from which thermal storage insulation boxes are mainly used. Thermal storage insulation box is composed of heat preservation box and thermal storage plate. Thermal storage insulation box has no refrigeration function, the temperature is controlled by putting thermal storage plates of different temperature in the box, and the temperature could be maintained for a long time. The temperature of fresh-keeping and cold chain transportation are requested in the range of 2 - 8 ℃, the thermal storage material (sodium sulfate salt hydrate system) is wrapped in polyethylene thermal storage plate. It is used in polypropylene (EPP) foaming thermal storage boxes and vacuum insulation plate (VIP) boxes, and constitutes the thermal storage cold chain transportation equipment. Good Supply Practice (GSP) was used in this study to verify equipment and built temperature test system of thermal storage insulation boxes. Temperature measuring points were distributed at different sites, as such, the heating curve of each point in the box was obtained. Heat preservation effect was evaluated by the average cooling time in box. The influence of the way of holding thermal storage plates and the insulating properties of the insulation box material were considered. Our study showed that the insulation property of vacuum insulation board was better than foamed PP, the cooling maintain time could be increased by 13.31% and the average cooling maintain time increased 1.24 h. The temperature distribution was more uniform and stable. However, if each wall in the vacuum insulated plate insulation box was arranged with a cooling board, the box capacity would be reduced effectively. So it was necessary to consider the influence of this factor in the practical application. The cooling maintaining time of the refrigerant under the modality of side-sway was extended by 4.7% than top-sway. But the temperature difference between top and bottom of the box was large. The temperature distribution is uneven. Adding of thermal storage board on the top made the temperature declined 3 ℃. The temperature distribution was more uniform when the modality of top and side were adopted, which was more conducive to the preservation of fruits and vegetables. The temperature of each point when the box was loaded and unloaded was compared, and the cooling maintaining property was analyzed, the cooling maintaining time of load decreased 0.77 h than unload. In the actual application process, all factors which affect the quality of the goods and reasonable selection of the pre-cooling temperature, the amount of refrigerant and pre-cooling temperature of the refrigerant should be considered.

fruits; cold storage; phase change materials; cold chain; Na2SO4·10H2O; cold storage incubator; cold plates

10.11975/j.issn.1002-6819.2017.22.040

TK02

A

1002-6819(2017)-22-0308-07

2017-08-07

2017-10-14

上海市科委项目(16040501600);上海海事大学博士创新基金项目(2017ycx081)

徐笑锋,博士生,研究方向:冷链物流、蓄冷技术。 Email:fxx_xu@163.com

章学来,教授,博导,研究方向:相变储能技术。 Email:xlzhang@shmtu.edu.cn