Pickering乳液在药物载体制备方面的研究进展

2017-12-14戈明亮汤微

戈明亮,汤微

Pickering乳液在药物载体制备方面的研究进展

戈明亮,汤微

(华南理工大学,聚合物成型加工工程教育部重点实验室,聚合物新型成型装备国家工程研究中心,广东广州510641)

Pickering乳液具有成本低、稳定性好、毒性小等优点,广泛应用于化妆品、食品、医药等方面。利用Pickering乳液制备药物载体操作简单,可改善难溶药物的溶出,对药物具有一定的缓释效果,其在药物载体方面具有广阔的发展前景。本文综述了近些年Pickering乳液在药物载体方面的研究进展,首先简要介绍了药物缓释技术及Pickering乳液性质;然后重点分析了不同固体粒子稳定的Pickering乳液在载药微球制备中的研究;还探讨了Pickering乳液在制备载药凝胶、载药多孔支架以及载药乳剂等方面的应用;最后对Pickering乳液制备药物载体方面作出展望,随着该技术相关研究的发展和成熟,药物载体的稳定性、生物相容性等问题的突破,利用Pickering乳液制备药物载体的方法技术将更有利于药物载药体系的发展。

Pickering乳液;固体粒子;药物载体;缓释

大多数药物不具备缓释特性,需多次给药才能保证血药浓度足量以发挥治疗效果,因此需要通过药物缓释技术来解决此问题[1]。药物缓释技术指通过载体以物理或化学方法装载药物,控制药物进入人体病变组织,将小分子药物以适当的浓度持续地释放出来[2-3]。药物缓释技术能够减少给药次数,增加药物治疗稳定性,延长药物作用时间,有利于提高药物疗效、降低毒副作用[4-8]。微球或胶囊、多孔支架因其比表面积大、密度低、孔隙率高等特性,而被广泛应用于药物载体领域[9]。以多孔支架、微球或胶囊为基体的药物载体制备方法主要有溶胶-凝胶法[10]、层-层自组装法[11]和乳液模板法[12]等,乳液模板法与溶胶-凝胶法和层-层自组装法相比,操作简便而得到广泛关注。根据乳液的类型,乳液模板法可分为传统乳液模板法和Pickering乳液模板法。传统乳液是指加入表面活性剂稳定的乳液,传统乳液模板制备的多孔材料具有连通的孔结构,但支架力学性能较差,表面活性剂用量较大,反应条件要求严格。

1903年RAMSDEN[13]研究发现水和悬浮有固体颗粒的石蜡混合搅拌,可得到由固体颗粒稳定的乳液,随后PICKERING[14]对其进行了进一步的研究,故称由固体颗粒稳定的乳液为Pickering乳液。固体粒子可被两相润湿吸附在液液界面上,由于其润湿性的不同可形成油包水(W/O)或水包油 (O/W)型乳液[15-16]。固体粒子包括无机粒子、有机粒子和其他粒子,如SiO2、黏土纳米粒子、苯乙烯(PS)、病毒等[17-20]。通过三相接触角来评价固体粒子的润湿性,一般<90°易得到O/W乳液,>90°易得到W/O乳液,但是不能太大或太小,否则粒子分散在水相或油相中,不能得到稳定的Pickering乳液[21]。目前,公认的Pickering乳液的稳定机理主要为固体颗粒在油水界面上形成固体颗粒膜,阻隔了乳液液滴之间的碰撞聚并,同时也增加了液滴之间的相互斥力,两者共同作用稳定乳 液[22-23]。利用Pickering乳液制备药物载体操作简便,孔隙比较均匀,可以有效地防止液滴的聚结,提高稳定性;界面微粒层可以提高对药物的保护和控制药物的释放,在改善难溶性药物的溶出方面具有巨大潜力。因此,利用Pickering乳液制备药物载体对药物进行缓释具有广阔的发展前景。

1 载药微球或胶囊

微球或胶囊作为药物载体,可以起到分散、保护和缓释药物的作用,尤其是具有生物相容性的微球或胶囊,在载药及控制释放方面具有广阔的应用空间[24-26]。当载药微球或胶囊进入人体后,体液由孔道渗入载体内部形成药液,使得微球或胶囊内外形成浓度差,导致内部药液不断向微球或胶囊外释放,实现药物的释放,通过控制例如载体孔径、壳层厚度等可达到对药物释放速度的调节。通过选择无机粒子、有机粒子或复合粒子稳定Pickering乳液可制备出不同种类不同结构的载药微球或胶囊。

1.1 无机粒子

利用无机粒子稳定的Pickering乳液制备载药微球或胶囊的制备方法可分为乳液干燥法、乳液聚合法等。

1.1.1 Pickering乳液干燥法

采用Pickering乳液干燥法制备载药微球或胶囊的过程是先将药物溶入到油相或水相中,再用无机粒子制备稳定的Pickering乳液,然后将油相或水相除去,得到载药微球或胶囊。载药微球或胶囊的载药性能与无机粒子性质、油相种类、油相与无机粒子比例等因素有关。SIMOVIC等[27]用带有正电荷或负电荷的脂质作为油相,亲水性多孔SiO2固体粒子作为稳定剂,制备O/W型Pickering乳液,再通过喷雾干燥将水相除去,使胶囊成为干粉状,提高难溶性药物的溶出率和生物利用度,得到多孔结构的吲哚美辛载药微囊;在大鼠的口服给药研究中,Pickering乳液所得到的载药微囊的绝对生物利用度优于普通乳液。WEI等[28]以溶有聚乳酸-羟基乙酸共聚物(PLGA)的CH2Cl2为油相,以SiO2粒子稳定O/W型Pickering乳液,通过溶剂蒸发将CH2Cl2除去和酸洗有效地将SiO2粒子除去,制备无毒、生物相容性好的PLGA微球,过程见图1;在缓冲溶液中(pH=7.2,5,3,1)测得布洛芬(IBU)的载药量为5.26%~29.49%,包封率为73.60%~97.76%,在pH为7.2时,9000min后仍有将近25%的IBU没有释放,PLGA微球对IBU有一定的缓释效果。此外,WEI等[29]用埃洛石稳定Pickering乳液,以类似的方法得到PLGA微球;但是药物的缓释性能比用SiO2稳定的Pickering乳液制备的微球的缓释性能差,pH=7.2、7000min后,IBU的释放量达到75%左右,IBU的装载量和包封率随pH的增大而减小。可将Pickering乳液与其它技术理论相结合,扩宽Pickering乳液的应用范围, ZHANG等[30]将溶于左旋聚乳酸(PLLA)的CH2Cl2作为油相,用疏水性SiO2稳定W/O型Pickering乳液,将该Pickering乳液逐滴注射到含有疏水性SiO2的培养皿中,使SiO2粒子覆盖在Pickering乳液的液滴表面,干燥后去除水相和油相得到多孔胶囊,该胶囊100h后释放了大约42%的模拟药物,对药物具有缓释效果,制备过程见图2。

图1 SiO2粒子包覆的PLGA微球和PLGA微球制备示意图[28]

图2 基于Pickering乳液的液珠和多孔胶囊的制备示意图[30]

通过选择不同的固体粒子,来制备具有靶向特性的药物载体,使药物在所需部位释药,提高药物有效浓度,降低药物毒性和不良反应,OKA等[31]利用氧化铁稳定Pickering乳液,将疏水性荧光性模型药物芘加入羟基烷基/二氯甲烷溶液中,以氧化铁为壳、生物降解高分子聚羟基烷基(PHAS)为核,制备磁性核壳复合粒子。荧光分析表明药物负载于核壳复合粒子中,通过PHAS生物降解可实现缓慢持续释放药物。王志琰等[32]采用共沉淀法制备纳米Fe3O4颗粒稳定O/W型Pickering乳液,聚甲基三乙氧基硅烷和IBU分散在油相中,乳液静置陈化、洗涤后得到以SiO2和磁性粒子为壳层的载药磁性空心球;载药磁性空心球经过大约40h,释放了80%以上的药物且释放过程较为平缓。

1.1.2 Pickering乳液聚合法

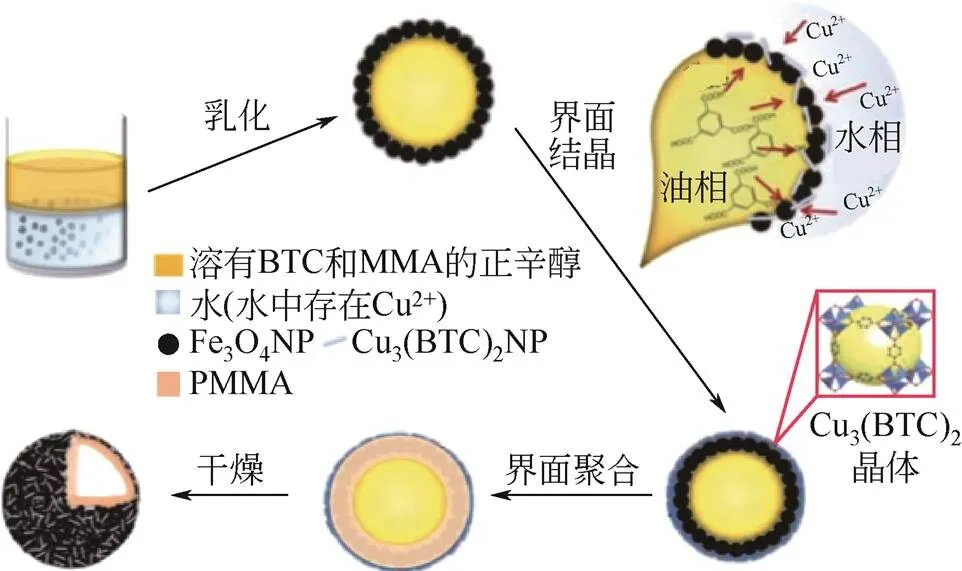

通过在Pickering乳液中发生聚合反应制备微球或胶囊,然后将微球或胶囊放入药物溶液中,得到载药微球或胶囊,其操作简单,可通过调节释放介质的温度来调节药物释放速率。ZHANG等[33]用甲基丙烯酰氧基丙基三甲氧基硅烷改性的二氧化硅稳定W/O型反相Pickering乳液,以-异丙基丙烯酰胺的水溶液为内相,以溶有二乙烯基苯和甲基丙烯酸甲酯的液态石蜡为外相,经乳液聚合得到温敏性聚-异丙基丙烯酰胺/聚甲基丙烯酸甲酯/二氧化硅复合微胶囊;将此微胶囊放入IBU的乙醇溶液,可制备具有药物缓释效果的载药微胶囊,可通过调节壁厚和释放介质的温度来调节药物释放速率。LU等[34]用坡缕石(PAL)稳定O/W型Pickering乳液,将甲基丙烯酸二乙基氨基乙酯(DEAEMA)单体、甲基丙烯酸甲酯(MMA)单体、交联剂二甲基丙烯酸乙二醇酯和引发剂偶氮二异丁腈(AIBN)溶于甲苯中作为油相,聚合后制备PDEAEMA/PAL复合微球,将该微球放入罗丹明B乙醇溶液中,制备载药微球。该微球对罗丹明B的包封率大约为13.5%,通过调节pH可调控药物释放速率。ZHU等[35]将均苯三甲酸(BTC)、单体MMA和引发剂AIBN溶于油相,Cu2+溶于水相,用Fe3O4纳米粒子稳定O/W型Pickering乳液,经Cu3(BTC)2纳米晶体在油水界面原位生长和聚甲基丙烯酸甲酯(PMMA)聚合作用得到超稳定中空微球,制备过程见图3,该微球具有很好的装载量和缓释特性,50℃、12h后测得该微球对IBU的装载能力为250mg/g,45℃时10mg微球的药物总释放时间为7h,装载量和释放特性受温度的影响。

1.1.3 其他方法

通过界面结晶或得到水凝胶制备载药微球或胶囊,WANG等[36]用碳酸钙稳定O/W型Pickering乳液,向乳液中通CO2气体以及加入CaCl2水溶液,通过碳酸钙结晶制备碳酸钙胶囊;胶囊的包封率达到60%,纯柠檬烯的释放时间少于5min,胶囊对柠檬烯的释放时间超过40min,具有一定的缓释效果。ZHOU等[37]以γ-甲基丙烯酰氧基丙基三甲氧基硅烷改性的SiO2纳米颗粒稳定W/O型Pickering乳液为模板,采用反复冻融法成功制备了聚乙烯醇水凝胶/二氧化硅复合微球,此中空复合微球对亚甲基蓝有良好的包覆能力和缓释作用;由于制备过程低温凝胶化,该微球特别适合装载温敏性药物。

图3 磁性中空微球的制备[35]

1.2 有机粒子及无机/有机复合粒子

也有研究者用有机粒子或无机/有机复合粒子作为稳定剂制备Pickering乳液载药微球或胶囊。LIU等[38]通过在Pickering乳液中发生交联反应来制备载药微球,预先将硫醇、三羟甲基丙烷三丙烯酸酯、光引发剂和IBU溶于油相中,以壳聚糖为稳定剂制备O/W型Pickering乳液,再紫外光照射乳液10min,得到壳聚糖/硫醇-烯微球,在壳聚糖/硫醇-烯微球中IBU的包封率均接近100%,缓释效果良好。LIU等[39]则通过在Pickering乳液中发生聚合反应来制备胶囊,具体做法是利用沸石咪唑酯骨架材料(ZIF-8)稳定W/O型Pickering乳液,水相包含丙烯酰胺、聚乙二醇和海藻酸钠(alginate),丙烯酰胺经聚合作用发生相分离,最后在ZIF-8的作用下海藻酸钠凝胶化制备yolk-shell型 ZIF-8/alginate微胶囊,该方法可形成一囊多核的微胶囊;将微胶囊放入罗丹明B溶液中,制备载药胶囊。该胶囊对罗丹明B具有缓释效果,70min释放率为55%。也有研究者[40]将Pickering乳液模板法和层层自主装法相结合制备载药胶囊,扩宽Pickering乳液在药物载体方面的应用。具体制备过程是用聚乙烯亚胺/锂皂石复合粒子稳定水包二甲苯Pickering乳液,在乳滴界面依次不断吸附海藻酸和壳聚糖天然聚电解质,通过层层自组装法制备海藻酸-壳聚糖微胶囊,加入异丙醇洗涤得到中空微胶囊,将其浸入含有IBU的磷酸缓冲溶液中,制备载药中空微胶囊;中空微胶囊对布洛芬的装载量为150mg/g,且聚电解质层数越多,IBU释放速度越慢。

2 载药凝胶、多孔支架及载药乳剂

Pickering乳液也可用于制备载药凝胶或载药多孔支架。ZHOU等[41]采用聚(-异丙基丙烯酰胺-甲基丙烯酸酯磺胺嘧啶)(PNS)纳米凝胶稳定O/W型Pickering乳液,预先将抗癌药物阿霉素(DOX)溶于油相中,将Pickering乳液溶剂蒸发后得到载药PNS纳米凝胶,结果表明DOX的包封率接近100%,载药量达到15%,具有较好的缓释效果,无突释现象产生。CHEN等[42]利用氧化石墨烯/聚乙烯醇(GO/PVA)稳定O/W型Pickering乳液,预先将丙烯酰胺、,'-亚甲基双丙烯酰胺和过硫酸钾加入水相中,经水相聚合作用得到多孔GO/PVA凝胶,将凝胶浸入DOX溶液中制备载药GO/PVA凝胶,该载药凝胶具有较好的抗癌性能和缓释作用。HU等[43]以聚乳酸疏水改性的羟基磷灰石(g-HAp)为稳定粒子,PLLA溶于CH2Cl2溶液为油相,将药物IBU加入油相中,制备Pickering乳液,再将CH2Cl2和水蒸发后得到结构可控的HAp/PLLA纳米复合载药多孔支架,其制备和药物释放过程见图4;研究显示IBU释放速度随着释放介质的pH和g-HAp纳米粒子浓度的增加而加快,多孔支架对IBU具有明显的缓释作用。该研究团队还制备了g- HAp/PLGA[44]和g-HAp/PCL[45]载药多孔支架,载药多孔支架均对IBU药物具有缓释作用。

图4 IBU-HAp/PLLA复合多孔支架的制备及其体外药物释放[43]

Pickering乳液还可以用于制备载药乳剂。SIMOVIC等[46]利用SiO2粒子稳定O/W 型Pickering 乳液,亲油性药物邻苯二甲酸二丁酯(DBP)溶于聚二甲基硅氧烷(PDMS),纳米SiO2包覆着载有药物的PDMS液滴,该方法有利于解决生物相容性低和难溶性药物方面的问题。FRELICHOWSKA等[47]利用疏水性SiO2稳定的水/硅油Pickering乳液来缓释咖啡因药物,通过与相同配比的表面活性剂稳定的乳液对比研究发现,药物在Pickering乳液中释放更慢,皮肤对Pickering乳液中药物的吸收速率更快。ANDREA等[48]采用淀粉粒子稳定O/W型Pickering乳液,含有百里酚或两性霉素B的乳液具有抗真菌性,该乳液在口腔抗真菌疏水性药物输送上具有一定的发展前景。LECLERCQ等[49]用环糊精稳定O/W型Pickering乳液,该乳液对硝酸益康唑盐药物具有一定的缓释效果。SHAH等[50]采用离子交联法得到壳聚糖-三聚磷酸盐粒子,用壳聚糖-三聚磷酸盐粒子稳定O/W型Pickering乳液,该乳液对姜黄素有一定的缓释效果。刘若林等[51]将层状金属氢氧化物(LDH)颗粒分别与改性海藻酸钠(DA)和传统表面活性剂(CTAB)稳定Pickering乳液,得到乳液液滴大小均匀,稳定性较好的Pickering乳液,研究表明,LDH-DA复配Pickering乳液体系释药速率低于LDH-CTAB复配Pickering乳液体系。

3 展望

Pickering乳液具有如下特点:①固体粒子用量少,成本低;②制备药物载体所用的大多数固体粒子无毒且制备结束后固体粒子易除去,安全性更高;③因为纳米粒子的物化性质比表面活性剂更稳定,不易受温度、油相种类和pH的影响,Pickering乳液稳定性更好;④可功能化改性,如Pickering乳液可加入磁性粒子,制备出磁性药物载体,在靶向给药方面具有应用价值;⑤Pickering乳液在外界刺激下发生破乳、相分离、相反转等,可制备环境响应型Pickering乳液(如温度敏感型、磁场敏感型、pH响应型)将其运用于药物载体方面。但是目前所使用的固体粒子种类少,需不断发现新型的具有特殊功能的固体粒子,并将Pickering乳液与新技术新理论相结合,扩展其在药物载体方面的应用,将Pickering乳液与其他制备药物载体的技术相结合。采用Pickering乳液制备药物载体具有操作简便、灵活可控、载药方便、环境友好以及可选择不同的固体粒子调节药物载体渗透性等优点,但存在药物载体在生物环境中的稳定性和相容性等问题,如何通过简便易控的方法改善药物载体的稳定性及相容性需要更深入的研究。随着Pickering乳液技术不断发展,利用Pickering乳液制备药物载体的方法也将会逐步趋于成熟,造福于广大 患者。

[1] 尤左祥,杨亲正,岳占国,等.抗肿瘤药物载体的主动靶向策略[J].中国组织工程研究,2012,16(25):4701-4705.

YOU Z X,YANG Q Z,YUE Z G,et al.Active targeting strategy of antitumor drug carrier[J].Chinese Journal of Tissue Engineering Research,2012,16(25):4701-4705.

[2] VALLETREGI M,BALAS F,ARCOS D.Mesoporous materials for drug delivery[J].Angewandte Chemie,2007,46(40):7548-7558.

[3] MANSOUR H M,SOHN M,ALGHANANEEM A,et al.Materials for pharmaceutical dosage forms:molecular pharmaceutics and controlled release drug delivery aspects[J].International Journal of Molecular Sciences,2010,11(9):3298-3322.

[4] PAQUETTE D W,RYAN M E,WILDER R S.Locally delivered antimicrobials:clinical evidence and relevance[J].Journal of Dental Hygiene,2008,82(s3):10-15.

[5] 孔墨奇.SiO2介孔材料的制备改性及在药物缓释领域的应用[D].长沙:中南大学,2014.

KONG M Q.The preparation of mesoporous silica,study on their functionalizations and application in the drug delivery field[D].Changsha:Central South University,2014.

[6] LANGER R,TIRRELL D A.Designing materials for biology and medicine[J].Nature,2004,428(6982):487-492.

[7] LAVAN D A,MCGUIRE T,LANGER R.Small-scale systems fordrug delivery[J].Nature Biotechnology,2003, 21(10):1184-1191.

[8] BROWN M B,MARTIN G P,JONES S A,et al.Dermal and transdermal drug delivery systems:current and future prospects[J].Drug Delivery,2006,13(3):175-187.

[9] KIMMINS S D,CAMERON N R.Functional porous polymers by emulsion templating:recent advances[J].Advanced Functional Materials,2011,21(2):211–225.

[10] HAN K,ZHAO Z H,XIANG Z,et al. The sol–gel preparation of ZnO/silica core–shell composites and hollow silica structure[J].Materials Letters,2007,61(2):363-368.

[11] WANG A H,CHENG T,YUE C,et al.Assembly of environmental sensitive microcapsules of PNIPAAm and alginate acid and their application in drug release[J].Journal of Colloid and Interface Science,2009,332(2):271–279.

[12] DINSMORE A D, MING F H, NIKOLAIDES M G,et al.Colloidosomes:selectively permeable capsules composed of colloidal particles[J].Science,2002,298(5595):1006–1009.

[13] RAMSDEN W.Separation of solids in the surface-layers of solutions and ‘suspensions’(observations on surface-membranes, bubbles,emulsions,and mechanical coagulation).——preliminary account[J].Proceedings of the Royal Society of London,1903,72(4):156-164.

[14] PICKERING S U.CXCVI——Emulsions[J].J.Chem.Soc.Trans.,1907,91:2001-2021.

[15] BINKS B P.Particles as surfactants-similarities and differences[J].Current Opinion in Colloid and Interface Science,2002,7(1/2):21-41.

[16] AVEYARD R,BINKS B P,CLINT J H.Emulsions stabilised solely by colloidal particles[J].Advances in Colloid and Interface Science,2003,100(2):503-546.

[17] FUJII S,READ E S,BINKS B P,et al.Stimulus-responsive emulsifiers based on nanocomposite microgel particles[J].Advanced Materials,2005,17(8):1014-1018.

[18] BON S A,COLVER P J.Pickering miniemulsion polymerization using Laponite clay as a stabilizer[J].Langmuir,2007,23(16):8316-8322.

[19] TARIMALA S,RANABOTHU S R,VERNETTI J P,et al.Mobility andaggregation of charged microparticles at oil-water interfaces[J].Langmuir,2004,20(13):5171-5173.

[20] KAUR G,HE J,XU J,et al.Interfacial assembly of turnip yellow mosaicnanoparticles[J].Langmuir,2009,25(9):5168-5176.

[21] AND B P B,LUMSDON S O.Influence of particle wettability on the type and stability of surfactant-free emulsions[J].Langmuir,2000,16(23):8622-8631.

[22] AND B P B,LUMSDON S O.Pickering emulsions stabilized by monodisperse latex particles:effects of particle size[J].Langmuir,2001,17(15):4540-4547.

[23] BINK B P,FLETCHER P D I.Particles adsorbed at the oil-water interface:a theoretical comparison between spheres of uniform wettability and janus particles[J]. Langmuir,2001,17(16):4708-4010.

[24] OLEDZKA E,KONG X,NARINE S S.Synthesis and characterization of novel lipid functionalized poly(-caprolactone)s[J]. Journal of Applied Polymer Science,2011,119(3):1848–1856.

[25] QI Y,LI N J,XU Q F,et al.Synthesis and characterization of a new amphiphilic copolymer containing multihydroxyl segments for drug carrier[J].Journal of Applied Polymer Science,2011,121(5):2843–2850.

[26] SAHOO S,SASMAL A,SAHOO D,et al.Synthesis and characterization of chitosan-polycaprolactone blended with organoclay for control release of doxycycline[J].Journal of Applied Polymer Science,2010,118(6):3167–3175.

[27] SIMOVIC S,HEARD P,HUI H,et al.Dry hybrid lipid-silica microcapsules engineered from submicron lipid droplets and nanoparticles as a novel delivery system for poorly soluble drugs[J].Molecular Pharmaceutics,2009,6(3):861-872.

[28] WEI Z J,WANG C Y,LIU H,et al.Facile fabrication of biocompatible PLGA drug-carrying microspheres by O/W Pickering emulsions[J]. Colloids and Surfaces B:Biointerfaces,2012,91(1):97-105.

[29] WEI Z J,WANG C Y,LIU H,et al.Halloysite nanotubes as particulate emulsifier:preparation of biocompatible drug-carrying PLGA microspheres based on Pickering emulsion[J].Journal of Applied Polymer Science,2012,125(s1):E358-E368.

[30] ZHANG G Z,WANG C Y.Pickering emulsion-based marbles for cellular capsules[J].Materials,2016,9(7).

[31] OKA C,USHIMARU K,HORIISHI N,et al.Core–shell composite particles composed of biodegradable polymer particles and magnetic iron oxide nanoparticles for targeted drug delivery[J].Journal of Magnetism and Magnetic Materials,2015,381:278-284.

[32] 王志琰,毋伟,张魁,等.Pickering乳液法原位制备载药磁性SiO2空心球及缓释性能[J].北京化工大学学报(自然科学版),2010(3):110-114.

WANG Z Y,WU W,ZHANG K,et al.preparation and characterizations of drug-loaded magnetic hollow silica microspheres by a Pickering emulsion based route[J].Journal of Beijing University of Chemical Technology(Natural Science Edition),2010(3):110-114.

[33] ZHANG K,WU W,GUO K,et al. Synthesis of temperature- responsive poly(-isopropyl acrylamide)/poly(methyl methacrylate)/ silica hybrid capsules from inverse Pickering emulsion polymerization and their application in controlled drug release[J]. Langmuir,2016,26(11):7971-7980.

[34] LU J,WU J,CHRN J,et al.Fabrication of pH‐sensitive poly(2‐(diethylamino)ethyl methacrylate)/palygorskite composite microspheresPickering emulsion polymerization and their release behavior[J]. Journal of Applied Polymer Science,2015,132(26):42179.

[35] ZHU X M,ZHANG S P,ZHANG L H,et al.Interfacial synthesis of magnetic PMMA@Fe3O4/Cu3(BTC)2hollow microspheres through one-pot Pickering emulsion and their application as drug delivery[J].RSC Advances,2016,6(63):58511-58515.

[36] WANG X L,ZHOU W Z,CAO J,et al.Preparation of core-shell CaCO3capsulesPickering emulsion templates[J].Journal of Colloid & Interface Science,2012,372(1):24-31.

[37] ZHOU H,SHI T,ZHOU X.Poly(vinyl alcohol)/SiO2composite microsphere based on Pickering emulsion and its application in

controlled drug release[J].Journal of Biomaterials Science Polymer Edition,2014,25(7):641-656.

[38] LIU H,WEI Z J,HU M,et al.Fabrication of degradable polymer microspherespH-responsive chitosan-based Pickering emulsion photopolymerization[J].RSC Advances,2014,4(55):29344-29351.

[39] LIU W,ZHAO Y J,ZENG C F,et al.Microfluidic preparation of yolk/shell ZIF-8/alginate hybrid microcapsules from Pickering emulsion[J].Chemical Engineering Journal,2016,307:408-417.

[40] LIU H,GU X,HU M,et al.Facile fabrication of nanocomposite microcapsules by combining layer-by-layer self-assembly and Pickering emulsion templating[J].RSC Advances,2014,4(32):16751-16758.

[41] ZHOU G F,ZHAO Y B,HU J D,et al.A new drug-loading technique with high efficiency and sustained-releasing abilitythe Pickering emulsion interfacial assembly of temperature/pH-sensitive nanogels[J]. Reactive and Functional Polymers,2013,73(11):1537–1543.

[42] CHEN Y H,WANG Y L,SHI X T,et al.Hierarchical and reversible assembly of graphene oxide/polyvinyl alcohol hybrid stabilized Pickering emulsions and their templating for macroporous composite hydrogels[J].Carbon,2016,111:38-47.

[43] HU Y,ZOU S W,CHEN W K,et al.Mineralization and drug release of hydroxyapatite/poly(l-lactic acid) nanocomposite scaffolds prepared by Pickering emulsion templating[J]. Colloids and Surfaces B:Biointerfaces,2014,122:559-565.

[44] YANG H,GU X Y,YANG Y,et al.Facile fabrication of poly(L-lactic acid)-grafted hydroxyapatite/poly(lactic--glycolic acid) scaffolds by Pickering high internal phase emulsion templates[J]. ACS Applied Materials & Interfaces,2014,6(19):17166-17175.

[45] HU Y,GAO H C,DU Z S,et al.Pickering high internal phase emulsion-based hydroxyapatite/poly(-caprolactone) nanocomposite scaffolds[J].Journal of Materials Chemistry B,2015,3(18):3848-3857.

[46] SIMOVIC S,PRESTIDGE C A.Nanoparticle layers controlling drug release from emulsions[J].European Journal of Pharmaceutics & Biopharmaceutics,2007,67(1):39-47.

[47] FRELICHOWSKA J,BOLZINGER M A,VALOUR J P,et al.Pickering W/O emulsions:drug release and topical delivery[J]. International Journal of Pharmaceutics,2009,368:7-15.

[48] ANDREA C,WANG M S,AMOL C,et al.Antifungal activity against Candida albicans of starch Pickering emulsion with thymol or amphotericin B in suspension and calcium alginate films[J]. International Journal of Pharmaceutics,2015,493(1/2):233-242.

[49] LECLERCQ L,NARDELLORATAJ V.Pickering emulsions based on cyclodextrins:a smart solution for antifungal azole derivatives topical delivery[J].European Journal of Pharmaceutical Sciences,2015,82:126-137.

[50] SHAH B R,LI Y,JIN W P,et al.Preparation and optimization of Pickering emulsion stabilized by chitosan-tripolyphosphate nanoparticles for curcumin encapsulation[J].Food Hydrocolloids,2015,52:369-377.

[51] 刘若林,李嘉诚,冯玉红,等.月桂醇基海藻酸钠与层状双金属纳米颗粒稳定载药Pickering乳液及其缓释性能[J].高分子材料科学与工程,2015(4):102-106.

LIU R L,LI J C,FENG Y H,et al.Drug-controlled release properties of stable Pickering emulsion prepared with dodecanol algiante and layer double hydroxide nanoparticles [J].Polymer Materials Science and Engineering,2015(4):102-106.

Progress in preparation of drug carriers based on Pickering emulsion

GE Mingliang,TANG Wei

(Key Laboratory of Polymer Processing Engineering of Ministry of Education,National Engineering Research Center of Novel Equipment for Polymer Processing,South China University of Technology,Guangzhou 510641, Guangdong,China)

Pickering emulsion is widely used in food,cosmetics and pharmaceutical fields due to its low cost,good stability and low toxicity. Preparation of drug carriers by Pickering emulsion offers great potential in the pharmaceutical industry since the preparation method is simple to operate,improved the dissolution of poorly soluble drugs,and sustained release property. Recent applications of Pickering emulsion in the field of drug carrier are outlined in this review. Firstly,drug delivery systems and properties of Pickering emulsion are briefly introduced. Then drug-carrying microspheres based on Pickering emulsion and stabilized by different solid particles are discussed in detail. In addition,the applications of Pickering emulsion in the preparation of drug-carrying gels,drug-carrying porous scaffolds and drug-carrying emulsions are also discussed. Finally,research directions of drug carriersthe Pickering emulsion are suggested. With the further studies of Pickering emulsion,the stability and biocompatibility of drug carriers can be improved.

Pickering emulsion;solid particles;drug carrier;sustained release

TQ460.1

A

1000–6613(2017)12–4586–06

10.16085/j.issn.1000-6613.2017-0522

2017-03-28;

2017-05-04。

广东省自然科学基金项目(2016A030313520)及2017年度广东水利科技创新项目(2017-24)。

戈明亮(1970—),男,副教授,研究方向为功能材料的研究和制备。E-mail:gml@scut.edu.cn。