Precise Dispensing Quantity Gaugingand System Design Using MassDifference and Ultra-InfinitesimalLead/Diameter Ratio of Screw Transmission

2017-11-28GULizhiGUOShuailiangHANJiaxingZHONGChen

GU Lizhi, GUO Shuailiang, HAN Jiaxing, ZHONG Chen

(College of Mechanical Engineering and Automation, Huaqiao University, Xiamen 361021, China)

PreciseDispensingQuantityGaugingandSystemDesignUsingMassDifferenceandUltra-InfinitesimalLead/DiameterRatioofScrewTransmission

GU Lizhi, GUO Shuailiang, HAN Jiaxing, ZHONG Chen

(College of Mechanical Engineering and Automation, Huaqiao University, Xiamen 361021, China)

Based on redundant method, a precise dispensing quantity gauging system was put forward, with coalescence of the dispensing part mass difference or the average corresponding value of the masses of the part before and after the glue dispensing and the ultra-infinitesimal lead/diameter ratio screw transmission to control the variation of glue barrel volume precisely. A self-lubricating double guide rail design was developed to ensure dispensing quantity and control the glue drop strictly within (0.200±0.001) g. By using modular design, a high precision dispensing machine was realized with moderate flexibility. Through modular simulating prototype, the spatial structure and the reliability of dispensing machine were optimized. Experimental study shows that the proposed solution can guarantee real-time controlling the dispensing quantity precisely,which meets the requirements of the production rhythm.

precise gauging; dispensing quantity; mass difference; ultra-infinitesimal lead/diameter ratio screw; redundant technology; linear error

Nowadays dispensing machine is becoming more and more widely used in the production of mechanical and electronic products, and the research and application of the dispensing technology and the methods are mainly concentrated in the control of the dispensing measurement, dispensing position, and the expansion of dispensing application scope. The quality of the dispensing machines largely relies upon the controlling precision of the dispensing quantity measurement and dispensing position of the glue. In the field of dispensing research and application, it is key and heart to improve the precision of the dispensing measurement and dispensing position of the glue. The higher precision of dispensing measurement and dispensing position of the glue will even expand the application scope of dispensing machine. In the aspect of dispensing precise measurement and control, choosing the appropriate mode of dispensing to adapt to different application will improve the efficiency of the contact dispensing.

Kipman[1]provided an innovative strobe-based drop analysis equipment for non-contact dispensing systems. Wang,etal[2]and Bustamante,etal[3]by using a vision location system in the glue dispensing robot for improvement of the location accuracy and programmable logic control. Sprovieri[4]developed a high-speed automatic dispensing system for both the locating and positioning precision. Kaburlasos,etal[5]adopted the Lattice-Computing ensemble for reasoning based on formal fusion of disparate data types in an industrial dispensing application. Shenify,etal[6]estimated precipitation via Support Vector Machine with discrete wavelet transform. Toh,etal[7]presented three dimensional adjustable cavity for flexible singulation of multiple medications in an automated medication dispenser.

Taylor[8]managed to predict defection for droplet-dispensed UV nanoimprint lithography through by fast simulation of resin flow at feature, droplet, and template scales. Zhao,etal[9]designed a gantry robot for dye dispense and analysis of vibration of its synchronous belt driven and positioning system. Kagerer,etal[10]improved drop-on-demand print head positioning with the analysis of influencing factors droplet characteristics. Genevra,etal[11]put forward an effective approach to designing and construction of microcontroller based self-dispense detecting liquid dispenser that was able to design and construct the dispensing process for dispensing a particular liquid.

Three-axis dispensing machine positioning control system based on machine vision now has presented with high performance and high precision by control system, which can greatly improve in linear and circular curve on the coating. A good solution was presented to the problem of low control precision and poor stability in the open-loop of traditional dispensing technology.Dutta,etal[12]developed an efficient system with the faucet device for both running mode and filling mode through embedding an algorithm that integrates functions including data acquisition and management in a microcontroller that dynamically computes and compares the amount of water being dispensed through the flow sensor. Shankaraiah,etal[13]discussed the development of an android based smart automated fluid dispensing and blending system through juice dispensing and blending application used in food processing with three layers[14]. Hartford,etal[15]after comparison with OEB5, put forward VBE, indicating the advantages of using an automated powder dispensing system in it for efficient handling and effective containment of potent compounds. Nouraei,etal[16]presented a novel modular liquid handling robot to simplify and standardize FTIR sample preparation procedure including 96-channel liquid dispenses head and input-output plates.

This paper takes the quality variation of the part or the average quality value of the dispensed part before and after the dispensing is done as a comparison signal, and ultra-infinitesimal lead/diameter ratio screw transmission controls the variation of glue barrel volume precisely. Based on redundancy principle, using the combination of the quality difference and ultra-infinitesimal lead/diameter ratio of Archimedes screw technology, with the self-lubricating double guide rail design, to realize the dispensing quantity control with the accuracy of the glue drop within (0.200±0.001) g. Meanwhile, the modular design is done to realize the performance of the high precision dispensing machine and the function of moderate flexibility. Through the modular manufacture simulation prototype, optimization is developed on the spatial structure and the reliability of the whole machine.

1 Dispensing Quantity Measurement and Control Theory Based on

RedundancyMethodSection

1.1BasicPhysicalPropertiesofEpoxyResinABGlues

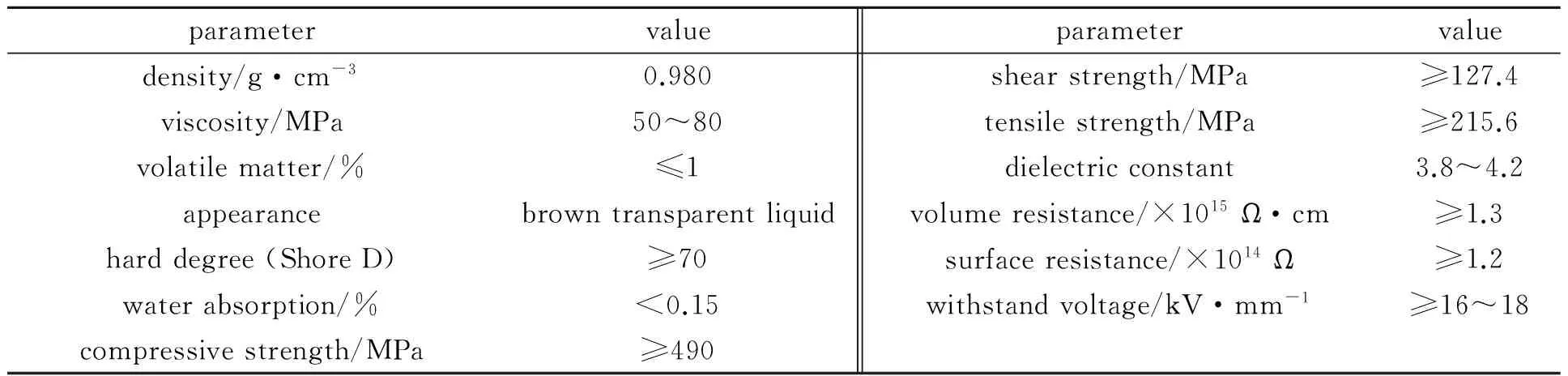

Epoxy resins are used as the glues with certain physical properties several basic physical properties are listed in table 1.

Tab.1 Basic physical properties of epoxy resin AB glue表1 环氧树脂胶的基本物理性能

Striving to control the glue drop is (0.200±0.001) g, glue point is a surrounding clean half spherical; production rhythm is a glue point production process use 1 second in total for a circulation, and the net dispensing time is 0.2 second.

1.2PrincipleofMassDifferenceofDispensedPart

In the process of dispensing, thanks to the properties of epoxy resin ab glue. In order to ensure the precise points of control and glue mass. It is difficult to measure the point glue directly, but indirect methods can.

Adopted the method of the dispensing parts mass variation before and after dispensing, cylindrical tube and the parts mass variation before and after dispensing as control factor. The basic algorithm is as follows

WhereMcbis the mass of the glue tube before dispensing;Mcais the mass of the glue tube after dispensing;Mpbis the mass of parts before dispensing;Mpais the mass of parts after dispensing. We take the glue mass

For calculating dispensing glue quantity, comparing it with the standard glue massMswe have

The mass difference is used as the input signal to the next drop dispensing control.

1.3TechniquesofUltra-InfinitesimalLead/DiameterRatio

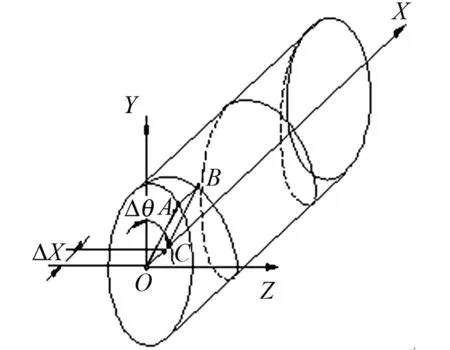

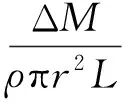

Using the technology of ultra-infinitesimal lead/diameter ratio screw mechanism to measure the dispensing quantity precisely. According to the screw axial displacement, we have

Where Δθis rotation angle, Δθ=2·Δs/d; Δsis the arc length corresponding to Δθ;Lis the lead of the screw.

Fig.1 Ultra-infinitesimal lead/diameter ratio screw图1 超小导程/直径比丝杠

Therefore, by controlling the arc length, the actual rotation angle is controlled, and still then the screw axial displacement is controlled. From equation (3) we know that if to control the dispending glue quantity is wanted to control precisely, one way may be used to the purpose: control the screw axial displacement. And the control of the screw axial displacement may be done by the control of the rotation angle of it. In engineering, it is of ease to manipulate the arc length instead of the control of the rotation angle. Therefore, we present and adopt the ultra-infinitesimal lead/diameter ratio screw mechanism, as shown in figure 1.

The screw of glue barrel driving screw is with the working diameter ofd, and lead ofL. Then we have the lead/diameter ratioL/d≤ε, whereεis a positive number, and the smaller the value of it, the more literal and elaborate the relative distance in axial direction when the nut moves with the same rotation angle of the screw.

Therefore, the axial relative movement between the nut and screw is more delicate with the same arc length when the working diameter is different. In general, mechanical transmissionε≥1/7. For the precise control of the dispensing glue quantity, and considering about the production rhythm,ε≤1/10 is taken as the ultra-infinitesimal lead/diameter ratio.

1.4IntegratedAlgorithmBasedonRedundancyMethods

With mechanical measurement, that is, through the controlling of the volume of cylindrical tube to realize indirectly the controlling of the dispensing glue quantity

At the same time, the mass difference of the parts measured by electronic scale before and after dispensing is used to ensure precisely control of the dispensing quantity. Specific algorithm isMpra=min{|Mi-Msta|}.In here,Mprameans the real dispensing mass actually used;Miis a measurement of the above methods; andMstais a preset ideal value.

2 Realization of Dispensing Precise Control and Systematical Analysis

2.1SelectionofLeadScrewParametersforUltra-SmallLead/DiameterRatio

According to actual needs, working diameter of glue cylinder is Ø8 mm, driving lead screw working diameter is Ø80 mm, lead/diameter=1/10, leadL=8 mm, single start.

According to requirements of production rhythm, metering and dispensing a drop is within 0.2 s in time and dispensing is 0.2 g in quality. Therefore, the distance that screw walks in the axial is as follows

The corresponding rotation angle and arc length are calculated below respectively

2.2DesignofDispensingNeedleWithTwo-ConstituentCompensation

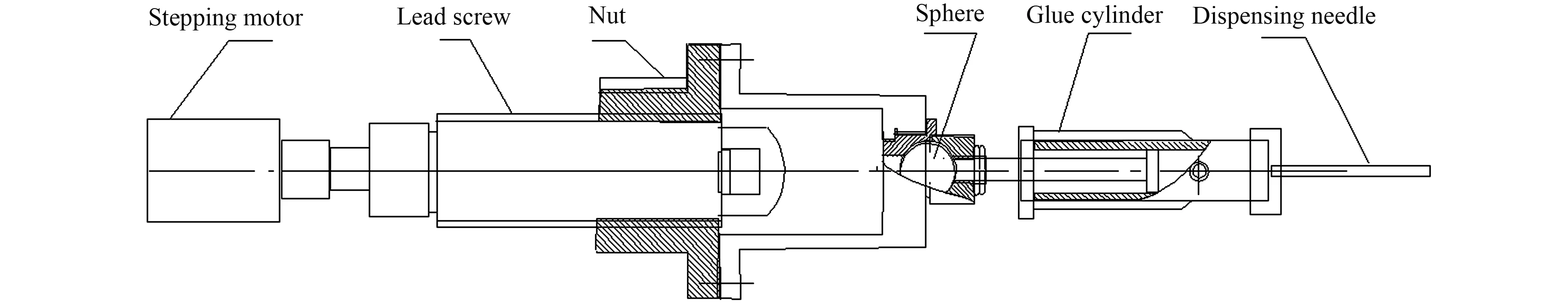

Under the piston working mode, the glue cylinder is designed with diameter of Ø8 mm, and ball hinge flexible connection is adopted between the driving lead screw and the needle cylinder piston. It is desirable to ensure the piston inside the cylinder being matched with the cylindrical surface, and then to drive the glue to work in the specified point. The basic structure of the needle is shown in figure 2.

Fig.2 Cylindrical dispensing needle structure with two-constituents compensation图2 圆柱形双组份补偿式点胶针管结构

2.3MmodularandOptimizationDesignofWholeDispensingMeasurementSystem

2.3.1 Driving Motor Stepping motor is adopted as the driving device for the movement of the screw. The lead of the screw is designed with the value of 8 mm. Choose the motor whose step angle is 1.8° and if it turns in a complete circle then the number of pulses is: 360°÷1.8°=200. Now the drive subdivision is done, and the step angle is equally divided into 8 parts, then each step of the motor is with 1.8°÷8=0.225°, and turning a circle needs 360°÷0.225°=1 600 pulses.

Determination of the motor parameter, the length of each step: lead screw with a lead of 8 mm will move 8 mm every turn, and in each step it may have a linear movement: 8÷1 600=0.005 mm/step.

2.3.2 Connection Between Dispensing Machine and Production Line In order to ensure the production rhythm and shorten the time of dispensing, as the production unit of circuit protector, dispensing machine complete dispensing independently, meanwhile, dispensing parts in conveying mechanism, and then conveying mechanism will move the parts to the next service position. For this purpose, a dedicated accompanying fixture is designed. Under the premise of basic structural features, ensuring the positioning and clamping of the parts, and then ensuring dedicated accompanying fixture in the order of any two work positions.

2.3.3 General Control Chart Selection the needle tube diameter of working cavity is Ø8 mm, driving lead screw working diameter is Ø40 mm, double heads, working system with a lead of 10 mm. From the formula (5), the distance of the needle cylinder along the axial direction is

Considering formula (4), we have

The corresponding arc length is

Wheredin the formula is the driving screw working diameter,Lis the lead of the screw.

3 Design of Mechanical Structure and Control System

3.1DesignofLeadScrewMechanismUsingUltra-SmallLead/DiameterRatio

Indeed, the parameters of the lead screw mechanism become the main parts in the design. In order to obtain the high precision of the glue quantity in dispensing, the following are chosen for the fundamental design parameters:

The screw diameter,d=80, the lead (here equal to pitch),L=8 number of the start, the range of the linear movement of the nut,D=30 (adjustable). Ratio of the lead to the working diameter:ε=1/10.

Self-lubrication guide is employed so as to improve the performance of the movement and the precision for the glue quantity in the screw driving mechanism.

3.2DesignofControlSystem

The control system also can guarantee the realization of all the functions of the whole machine, among them, the most important is to guarantee the dispensing mass and production rhythm. Figure 3 shows the basic functions of the control system and the logical order.

Fig.3 System function diagram图3 系统功能图

3.3OverallDesignofDispensingMachine

Dispensing machine is used for circuit protector package, therefore, in the production line requires the whole function is reliable, the action is quick and the structure is compact. For this purpose, applying system engineering principles in the basic function settings and the overall layout, and the single objective optimization design is used in the function module, meanwhile, considering the organic connection in functional modules, and realization of the overall dual optimization. Under the premise of ensuring basic production rhythm, realizing the measurement precision and dispensing position precision, and then to control the quantity of glue drop is (0.200±0.001) g.

3.3.1 Basic Function and Layout Based on System Engineering Principles In order to ensure the dispensing mass and dispensing operation, in addition to the mechanism and device that measurement of the dispensing mass and conveying glue to the designated space for dispensing, directly, it is also essential to ensure the relative position of each component, to provide movement and power, and to control all of the moving parts effectively. From the overall functional requirements, the dispensing machine is divided to 6 parts: the structure frame of Long men type, moving slide, beam guide, dispensing working cylinder, motion and power system, and control system.

Clamping on dispensing parts in mobile skateboards, movement the moving slide in the direction ofXaxis, and dispensing cylinder orthogonal installed in the beam guide, so it can makeYdirection linear motion along the cross beam. The dispensing work cylinder can also movement along with its own axial direction. The composite motion of sliding board, beam guide rail and the working cylinder dispensing, formed spatial instantaneous trajectory of the dispensing cylinder cusp and stagnation point. In the control system, when this stagnation point in the parts coincides with the predetermined dispensing point, the step motor will push the piston motion precisely in the working cylinder to realize the process of dispensing. When the dispensing ends, the stepping motor will reverse the movement, that is moving sliding board, beam guide and dispensing work cylinder back onto their initial positions. In the process of the piston reverse motion in the working cylinder, glue is fed into. Thus, a dispensing cycle is complete and ready for the next dispensing process.

3.3.2 Optimization Design of Function Modules Pertaining Glue Quantity The dispensing machine in discussion consists of sliding board, beam guide, working cylinder of the glue dispensing and transmission-controlling system installed on the gantry frame. Each function module is independent relatively, supporting and guaranteeing the dispensing glue quantity. Every functional module uses optimized design to ensure reliable function and quick reaction, according to the special task of its own in compact construction. For the beam guide module, for example, the optimal design of it is as follows with its basic function of supporting the dispensing glue screw mechanism and providing the accurate position of the working needle.

Objective function is minf(X)=α·W(X), constraints isg(X)≤a,h(X)≤b, and decision variables isX≥0. In here,αis the weighing factor array,W(X) is the quality vector of the components in each functional modulus,g(X) is the constraint of the stress condition,ais the limitation of the stress,h(X) is the constraint of the rigidity condition, andbis the limitation of the rigidity.

Then, the mass-minimized beam guide is obtained with the prerequisite of guaranteeing its proper function for the position ofYaxis of the needle and supporting the lead screw.When the optimization problem belongs to linear pro-gramming problem, the simplex method may be used for the solution. Otherwise, if the problem is nonlinear, then it may be solved by the penalty function method. The optimization design methods of other functional modules are similar and here we do not give the unnecessary details.

4 Experiment and Result Analysis

The number of the experiment sample is 100 and some of the results are listed in table 2. Quantities of the components, quality of the glue drop, and the corresponding arc lengths are also given in this table.

Table 2 shows that it is feasible to control the dispensing mass based on the algorithm of the redundancy technique. Single dispensing mass as feedback or comparison signal can reach requirements of the dispensing mass control, but there are also exceeded the situations, for example, using ΔMcor ΔMpalone, its dispensing mass extreme is beyond the permitted range. With the integrated algorithm, the re-quirements of dispensing mass can fully be met. The above discussion and analysis results are confirmed by experimental study and simulation analysis.

5 Conclusions

The precise measurement technique of dispensing glue quantity with redundant method has put forward, combining with the volume variation of cylindrical tube to control the quantity of the glue on the dispensing part before and after dispensing indirectly. The deviation of the glue quantity change is selected corresponding to the volume difference. The average value of both of the corresponding mass changes or each value of the part quality is taken as the comparison signal to adjust the dispensing glue quantity at any time, guaranteeing the dispensing quantity accuracy: (0.200±0.001) g.

If the glue quantity limitation is required even more restrict then the precision ball-roller screw mechanism may be used, instead.

The modular design technique is developed for the glue dispensing system as well as the whole machine. In order to adapt to the different shape of the dispensing head and the variation of the glue quantity, the dispensing machine carrier, dynamic system, control system and other structural function modules are optimally designed relatively independently. Then combined into the whole system, in order to realize the different function of dispensing applications, every module can be adjusted, with high reliability and high precision.

[1] KIPMAN Y.Innovative strobe-based drop analysis equip-ment for non-contact dispensing systems[C]∥Nanotechnology 2010: Electronics, Devices, Fabrication, MEMS, Fluidics and Computational.Washington D C:Image Xpert Inc,2010:488-491.

[2] WANG Nianfeng,LIU Jinghui,WEI Shuai,etal.A vision location system design of glue dispensing robot[C]∥Proceedings of the 8th International Conference on Intelligent Robotics and Applications.New York:Springer-Verlag,2015:536-551.

[3] BUSTAMANTE M,MORENO G,PELAEZ A,etal.Design and implementation of an automation didactic module focused to machine vision and programmable logic control[C]∥3rd International Congress of Engineering Mechatronics and Automation.Cartagena:IEEE Press,2014:1-5.

[4] JOHN S.Ammunition assemblers find a silver bullet in innovative sealants applied with a high-speed automatic dispensing system[J].Assembly,2011,54(7):34-36.

[5] KABURLASOS V G,PACHIDIS T.A lattice-computing ensemble for reasoning based on formal fusion of disparate data types, and an industrial dispensing application[J].Information Fusion,2014,16(1):68-83.

[6] SHENIFY M,DANESH A S,GOCI M,etal.Precipitation estimation using support vector machine with discrete wavelet transform[J].Water Resources Management,2015,30(2):1-12.

[7] TOH C K,NG S L J,TAN Y O.Three dimensional adjustable cavity for flexible singulation of multiple medications in an automated medication dispenser[C]∥IEEE International Conference on Automation Science and Engineering.Seoul:IEEE Press,2012:347-352.DOI:10.1109/CoASE.2012.6386353.

[8] TAYLOR H K.Defectivity prediction for droplet-dispensed UV nanoimprint lithography, enabled by fast simulation of resin flow at feature, droplet, and template scales[C]∥SPIE Advanced Lithography.San Jose:SPIE,2016:97770E.DOI:10.1117/12.2218757.

[9] ZHAO Zhenhong,JIANG Xiuming,DU Yuhong.Design of gantry robot for dye dispense and analysis of vibration of its synchronous belt driven and positioning system[J].Key Engineering Materials,2011,458:313-318.

[10] KAGERER M,MEEUW A,BERGER J,etal.Relevant influen-cing factors on droplet characteristics for a piezoelectrically driven drop-on-demand printhead[C]∥International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers.Montreal:ASME,2014:V007T09A055-V007T09A065.DOI:10.1115/IMECE2014-36199.

[11] GENEVRA E C,MBONU E S,OKAFOR K C.An effective approach to designing and construction of microcontroller based self-dispense detecting liquid dispenser[C]∥International Conference on Adaptive Science and Technology.Ota:IEEE Press,2015:1-7.

[12] DUTTA P,DONTIBOYINA U S G V.Faucet add-on water supply management system using smart sensors[C]∥International Conference on Computational Intelligence and Communication Technology.Ghaziabad:IEEE Press,2016:468-471.DOI:10.1109/CICT.2016.99.

[13] SHANKARAIAH G S,YELLAMPALLI S.Android based fluid dispensing and blending system automation[C]∥International Conference on Computational Intelligence and Computing Research.Coimbatore:IEEE Press,2015:1-5.DOI:10.1109/ICCIC.2014.7238467.

[14] 尤芳怡,朱德友.水泥道板砖骨料定量加料控制系统硬件设计[J].华侨大学学报(自然科学版),2004,25(2):172-175.DOI:10.3969/j.issn.1000-5013.2004.02.016.

[15] HARTFORD G,CHEUNG P,WHITAKER K,etal.Effective and efficient weighing of potent compounds[J].Pharmaceutical Technology Europe,2013,37(9):42-45.

[16] NOURAEI H,BEN-MRAD R,SINCLAIR A N.Development of a piezoelectric fuel injector[J].IEEE Transactions on Vehicular Technology,2016,65(3):1162-1170.

(责任编辑: 钱筠英文审校: 崔长彩)

采用质量差和超小导程/直径比丝杠传动的点胶量精细计量技术及系统设计(英文)

顾立志, 郭帅亮, 韩佳兴, 钟琛

(华侨大学 机电及自动化学院, 福建 厦门 361021)

基于冗余技术原理,采用制件点胶前后质量差和超小导程/直径比阿基米德丝杠技术组合,辅以自润滑双导轨设计,保证点胶量控制胶滴为(0.200±0.001) g;采用模块化设计,实现点胶机性能的高精度和功能的适度柔性,并通过模块化试制模拟样机,优化点胶机的空间结构及整机可靠性.研究结果表明:该方案保证了点胶量的实时精密控制且同时满足生产节拍的要求.

精细计量; 点胶量; 质量差; 超小导程/直径比丝杠; 冗余技术; 线性误差

2016-12-26

顾立志(1956-),男,教授,博士,主要从事数字化设计制造的研究.E-mail:gulizhi888@163.com.

福建省科技计划重点项目(20170034); 福建省厦门市科技计划项目(3502Z20153030)

10.11830/ISSN.1000-5013.201612057

U 491.17DocumentCodeAArticleNumber1000-5013(2017)06-0760-08