改性脲醛树脂粘合基质块性能及其对黄瓜幼苗生长的影响

2017-09-15赵永富夏礼如

曲 萍,赵永富,宋 婧,夏礼如

改性脲醛树脂粘合基质块性能及其对黄瓜幼苗生长的影响

曲 萍,赵永富,宋 婧,夏礼如※

(江苏省农业科学院,农业设施与装备研究所,农业部长江中下游设施农业工程重点实验室,南京 210014)

针对机械化移栽过程中,基质容易散落,造成根系损伤的问题,该研究采用了既具有粘合性又具有养分释放功能的生物降解胶黏剂粘合基质成块。测定了水解蛋白改性脲醛树脂的基本性能,基质块的孔隙度、EC值、pH值和抗压强度的变化规律,以及基质块对黄瓜幼苗生长的影响。试验结果表明,该改性脲醛树脂的氮素释放速率前期缓慢,后期较快,在第7周时养分释放率可达48%。添加50%改性脲醛树脂后,基质块的总孔隙度下降约8.4%,但还是能够满足黄瓜生长需要。然而添加改性脲醛树脂后基质块的EC由2.51 mS/cm下降到1 mS/cm左右,pH值基本保持不变。改性脲醛树脂在添加量50%时,抗压强度为0.14 MPa以上,能够满足机械手抓取的要求,也能够满足幼苗根系生长的要求。同时,叶面积、鲜质量、干质量比普通基质提高了89.86%、57.00%、79.2%。III-UF改性脲醛树脂的养分释放速率与黄瓜幼苗生长养分需求速率是一致的,该配方最有利于黄瓜幼苗的生长。添加胶黏剂后,每个颗苗只需增加0.0125元,从成本上看价格便宜,有利于推广应用。

基质;机械化;理化特性;水解蛋白;改性脲醛树脂;基质块;育苗;黄瓜

曲 萍,赵永富,宋 婧,夏礼如. 改性脲醛树脂粘合基质块性能及其对黄瓜幼苗生长的影响[J]. 农业工程学报,2017,33(15):253-259. doi:10.11975/j.issn.1002-6819.2017.15.032 http://www.tcsae.org

Qu Ping, Zhao Yongfu, Song Jing, Xia Liru. Performance of substrate blocks glued by modified urea formaldehyde resins and its effect on cucumber seedlings[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(15): 253-259. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.15.032 http://www.tcsae.org

0 引 言

育苗移栽能够使作物早熟、高产、优质、节省资源,大约有半数以上的设施作物需要进行育苗。传统的育苗移栽的种植方式主要依靠人工作业,费工费时,效率低下,因此机械化移栽技术得到了大力的发展。机械移栽能保证移栽的株距、行距、深度。然而,目前市场上的育苗基质在从育苗穴盘取出到移动到地面后覆土的机械化移栽过程中,由于机械手的抓取力度不当以及机械的物理振动,育苗基质会有不同程度的散落,从而造成根系的损伤、定植后作物缓苗时间长等现象。

为了解决机械化移栽过程中基质散落伤根的问题,很多学者做了大量的研究。有人研究利用生物降解的育苗钵避免移栽过程的伤根问题,Nechita等采用了木质的纤维、泥炭等制备了营养钵用于蔬菜的育苗[1],Prasanna Kumar等采用纸做育苗钵适用于机械化移栽[2],Qu等采用了秸秆和改性脲醛树脂制备生物降解的育苗容器[3],也有人采用压缩的基质块进行育苗,张凤银等研究了不同压缩回弹的有机育苗基质块对辣椒幼苗生长的影响,基质块的出苗时间长,但更有利于幼苗生长[4],葛桂民采用有机基质压缩成型并进行育苗技术的研究,发现复配后的基质块更有利于扦插和播种的幼苗后期的生长[5]。公开号为CN101781155A的专利文献公开了一种养分缓释型蔬菜育苗基质块,采用草炭、蛭石、珍珠岩、蘑菇渣、碎秸秆、包膜控释氮肥、包膜控释复合肥制得了养分缓释型育苗基质块,基质的养分由聚合物包膜控释肥提供,养分含量较普通基质提高10倍以上,实现苗期至生育前期不用追加肥料[6]。公开号为CN104761380A的专利公开了一种适用于水稻育苗基质块,将作物秸秆、营养剂、膨胀剂等采用热压成型,基质块培育的幼苗生长情况略差于普通基质[7]。袁巧霞等为优化蔬菜育苗成型基质的配方,提高成型基质蔬菜育苗效果,分别以牛粪好氧堆肥腐熟料和牛粪蚯蚓堆肥腐熟料为主料,草炭为辅料,吸水树脂为膨胀剂,木醋液为调节剂,黄瓜为指示植物,研究不同配方对成型基质块成型及育苗效果的影响,基质块的存活率和茎粗株高不及牛粪蚯蚓堆肥腐熟料[8]。采用育苗钵育苗,钵体的降解周期难控制,基质块一般都需要压缩成型,而且利用土坨育苗,由粘性较大的土壤压制而成,其通透性差,成活率低,在浇水以及移栽过程中容易破碎伤根。目前,采用既具有粘合性又具有养分释放功能的生物降解胶黏剂来辅助基质成块的研究尚未见报道。

本研究以可生物降解的改性脲醛树脂为粘合剂,加入传统的基质调节育苗方块的酸碱性、物理化学吸收能力、缓冲能力、营养物质等。通过分析改性脲醛树脂对普通基质的理化性质、抗压强度的变化规律,以及该新型基质块养分释放规律对黄瓜幼苗生长的影响,为育苗生产应用该产品提供理论和适用性支持。

1 材料与方法

1.1 供试材料

供试作物为津春4号(天津科润农业科技股份有限公司黄瓜研究所),供试基质为优佳育苗基质(木薯渣∶珍珠岩∶蛭石=2∶1∶1,淮安市中园园艺发展有限公司生产)。大豆分离蛋白(蛋白纯度90%,河南安阳市得天力食品有限公司);尿素(分析纯,≥99.0%,西陇化工股份有限公司);甲醛溶液(分析纯,37.0%~40.0%,西陇化工股份有限公司);磷酸(分析纯,≥85.0%,天津市科密欧化学试剂有限公司);氢氧化钾(分析纯,≥85.0%,西陇化工股份有限公司)。

1.2 方法

1.2.1 改性脲醛树脂的制备

在三口烧瓶中加入水解蛋白、尿素和甲醛,用氢氧化钾溶液调节pH值为7.8,升温至50 ℃后停止加热,当温度不再继续上升时,再升温至90 ℃,保温半小时。用磷酸溶液调节pH值至4.5~5,到雾点后,再用氢氧化钾溶液调pH值至7.5;加入剩余尿素,降温至75℃,保温半小时后降温放料。其中甲醛与当量尿素的摩尔比为1.2∶1,水解蛋白替代尿素的摩尔数分别为2%、4%、6%、8%,分别用I-UF、II-UF、III-UF、IV-UF表示。

1.2.2 基质块的制备

将无养分添加的基质与改性脲醛树脂进行混合,其中改性脲醛树脂添加量为基质质量的50%。将混合后的材料放入穴盘中,在60℃的烘箱中烘干4 h成型,即获得所述具有养分控释功能的育苗基质块。基质块初始含水率约为31%,终态含水率约为4%。I-UF,II-UF,III-UF,IV-UF与基质混合制得的基质块分别用T1、T2、T3、T4表示。当III-UF添加量为基质的0、40%、50%、60%、70%时制备的基质块分别用T5、T6、T7、T8和T9表示。

1.2.3 孔隙度的测定

取基质块,浸泡在水中24 h 后称质量W1,将水分自由沥干24 h 后称质量W2,最后将基质放入烘箱内烘至质量恒定后称质量W3,按以下公式计算:

式中W1为浸泡24 h后质量,g;W2为控水24 h后质量,g;W3为烘干后质量,g;V为体积,mL。

1.2.4 播种及苗期管理

育苗在2016年9月份进行,选用72孔的穴盘,将黄瓜种子播于穴盘内,每穴一粒种子,在江苏省农业科学院温室内进行育苗试验,内部的温度、湿度、二氧化碳、光照强度等参数如图1所示。

图1 温室内环境Fig.1 Environment in greenhouse

1.2.5 幼苗综合指标的测定

幼苗生长30 d时进行测定,形态指标:用直尺(0.1 mm)测量从生长点到基质表面之间的距离为株高;用游标卡尺(0.01 mm)测量幼苗子叶节下1 cm处为幼苗茎粗;在茎基部将幼苗地上部分和根系分开,用水洗净,吸水纸吸干水分,置于烘箱内105 ℃杀青15 min,80 ℃烘干至恒质量,该质量为干质量;壮苗指数=(径粗/株高)×全株干质量;叶绿素的测定采用CCM-200 PLUS叶绿素测定仪(美国OPTI-sciences)。

1.2.6 基质块的基本性能

pH值和EC值的测定:将基质块粉碎后,用去离子水润湿(含水率50%~60%)平衡24小时后称取10 g样品于100 mL烧杯中,加入50 mL去离子水,在180 r/min下振荡40 min,静置24 h过滤后,采用德国Lovibond SensoDirect 150测定仪测定pH值和EC值。抗压强度的测定:样品基质块直接在5 cm×5 cm×5 cm的立方体容器中成型。采用万能力学试验机(HY-0580,上海衡翼精密仪器有限公司)测定立方体的抗压强度。

1.2.7 氮素释放

用PVC管封底做成淋洗柱,以石英砂为淋洗介质,基质块添加量按氮与石英砂质量比为3∶1000添加;同时以未加样品的处理为空白,设3个重复的处理。每隔7 d取出土柱淋洗,淋洗液消煮后,用凯氏定氮仪测定总氮含量。

1.2.8 数据分析

使用Excel20l0和SPSS19.0软件进行数据统计分析,使用最小显著差异法(least significant difference, LSD)检验进行多重比较。

2 结果与讨论

2.1 改性脲醛树脂的基本性能

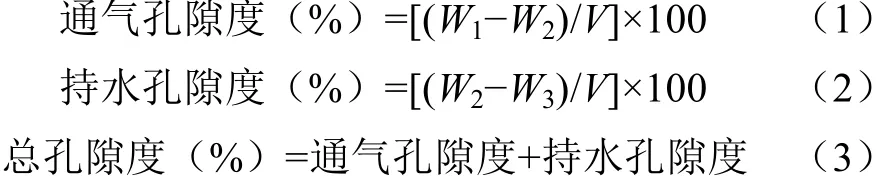

表1为水解蛋白改性脲醛树脂的初始基本性质。从表中可以看出,不同配方的改性脲醛树脂pH值和密度差别不大。然而,随着替代率的增大改性脲醛树脂的黏度明显提高,固含量下降,固化时间延长,游离甲醛降低。黏度增大是因为蛋白水解物本身的黏度就很大,在改性脲醛树脂中蛋白水解物添加越多,改性脲醛树脂黏度越大。改性后脲醛树脂的固含量也有所下降是因为蛋白水解物的固含量很低,改性脲醛树脂的固含量随着水解蛋白的添加量的增大而降低。通过测定改性脲醛树脂的固化时间可以得出改性脲醛树脂的反应活性,随着替代率的增大,水解蛋白添加量的增多,改性脲醛树脂的固化时间变长。说明添加蛋白水解物后,由于水解蛋白链段的空间阻隔以及单位体积内的活性基团减少,改性脲醛树脂的反应活性下降了[9]。由于水解蛋白中的活性氨基与甲醛反应形成的羟甲基较尿素和甲醛形成的羟甲基稳定,因此改性脲醛树脂中的游离甲醛随着替代率的增大而减少[10]。

表1 改性脲醛树脂的基本性能Table 1 Basic performance of modified urea formaldehyde

2.2 改性脲醛树脂的养分释放

水解蛋白改性脲醛树脂的生物降解性即养分释性能是基质块的重要指标。采用土柱淋洗的方法测定基质块中添加的改性脲醛树脂的养分释放率,该氮素释放率已扣除空白土柱中的氮素释放。从图2中可以看出,前3周内,改性脲醛树脂的氮素释放速率较为缓慢,原因是在初期改性脲醛树脂比表面积小,能降解并释放养分的分子链段少,微生物需要时间产生相应的酶降解该树脂。在第4周到第7周养分释放速率明显增加,这是因为随着降解时间的延长,改性脲醛树脂的比表面积增大,能分解利用改性脲醛树脂的微生物越来越多,分解速率加快[11]。第7周时,IV-UF养分释放率为48%。并且氮素释放速率随着水解蛋白添加量的增加而提高,水解蛋白越多,改性脲醛树脂中的分子结构相对疏松,酶更容易进入,因而分解速率快[12]。根系的健康生长与基质中的养分密切相关[13],因此可以通过调控水解蛋白的含量来调控改性脲醛树脂的结构,进而调控养分释放速率,与幼苗的养分需求规律基本一致,使其有利于黄瓜根系的生长。

图2 改性脲醛树脂中的氮素释放速率Fig.2 Nitrogen release rate of modified urea formaldeh yde

2.3 改性脲醛树脂对基质块理化性状的影响

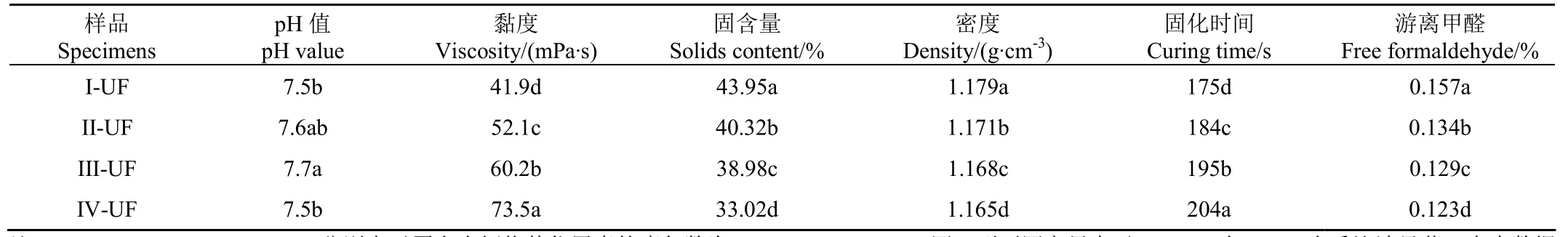

栽培基质的大小孔隙比要适宜,具有适宜的通气孔隙,能保证空气交换,还要有适宜的持水孔隙保持水分,供植物吸收利用,大小孔隙比要适宜[14-15]。理想的基质要求总孔隙度为54%~96%,大小孔隙比在(0.25~0.5):1之间[16-17]。从表2中可以看出,普通基质的总孔隙度为72.9%。添加改性脲醛树脂后,通气孔隙度和持水孔隙度均减少。以III为例,和普通基质相比,基质块的通气孔隙度、持水孔隙度和总孔隙度分别下降6.6%,9.0%和8.4%。原因是粘合剂在粘合基质的同时,基质本身的孔隙被部分堵塞,基质颗粒与基质颗粒间的部分孔隙也被改性脲醛树脂填充。此外,基质表面丰富的吸水性基团羟基也被改性脲醛树脂给包裹起来,而不能发挥吸水保水的作用。而在改性脲醛树脂与基质质量比为1:2时,通气孔隙度随着蛋白水解物替代尿素的摩尔数的增加而增加,原因是改性脲醛树脂的固含量随着蛋白水解物替代量的增大而减少。孔隙度大说明基质较轻、疏松,容纳空气和水的量大,有利于根系生长。不同的改性脲醛树脂粘合基质块中大小空隙比基本不变。

电导率是基质浸提液中可溶性盐浓度指标,反映基质当中可溶性养分总量,电导率过高则构成渗透逆境,会导致植物盐害,须通过淋洗降低盐分,电导率过低则营养不足以维持植物正常生长[18-19]。有研究认为作物生长安全电导率范围为750~2 600 μS/cm[20]。从表2中可以看出,普通基质的EC值为2.51 mS/cm,而添加改性脲醛树脂后基质块的EC值明显降低至1 mS/cm左右,原因是改性脲醛树脂在基质颗粒表面形成了一层包覆膜,阻碍了部分离子溶解到水中,从而使得基质块的EC值偏低。而随着蛋白水解物替代尿素的摩尔数的增大,EC值有增大的趋势,一方面原因是替代率越大,改性脲醛树脂的固含量越多,基质颗粒的包覆率越低,另外一个原因可能是蛋白水解物越多,其固化后的改性脲醛树脂的分子链结构越疏松,部分离子能够穿过包覆膜到水溶液中。从表中可以看出,改性脲醛树脂粘合基质成块的pH值与普通基质差异不显著。

表2 不同改性脲醛树脂粘合基质块的孔隙度Table 2 Porosity of substrate block bonded with different kind of modified urea formaldehyde

2.4 改性脲醛树脂对基质块抗压强度的影响

机械化移栽的核心部件是机械手,是直接与苗坨接触的工作部件,夹持指在夹持的过程中,基质块的抗压强度是一个重要的指标[21-24]。基质块的强度直接决定穴苗损伤率和苗坨破碎率。传统的基质中,抗压强度与各成分间接触的紧密程度、基质配方、填充量、根系、水分密切相关[25]。测定结果显示(图3)在添加不同质量百分比的改性脲醛树脂后,随着改性脲醛树脂添加比例的增大,基质块的抗压强度也随着增大,并且在添加同样含量的改性脲醛树脂时,随着水解蛋白替代尿素的增大,基质块的抗压强度越小,其原因是替代率越大,改性脲醛树脂的固含量越低,有效胶合的分子越少,从而使得基质块强度变小。然而添加量越大,基质块孔隙度显著下降,不利于作物根系的生长。综合考虑诸因素,改性脲醛树脂在添加量50%时,抗压强度为0.14 MPa以上,能够满足机械手抓取的要求,也能够满足幼苗根系生长对孔隙度的要求。

图3 不同改性脲醛树脂粘合基质块的抗压强度Fig.3 Compressive strength of substrate block bonded with different kind of modified urea formaldehyde resins

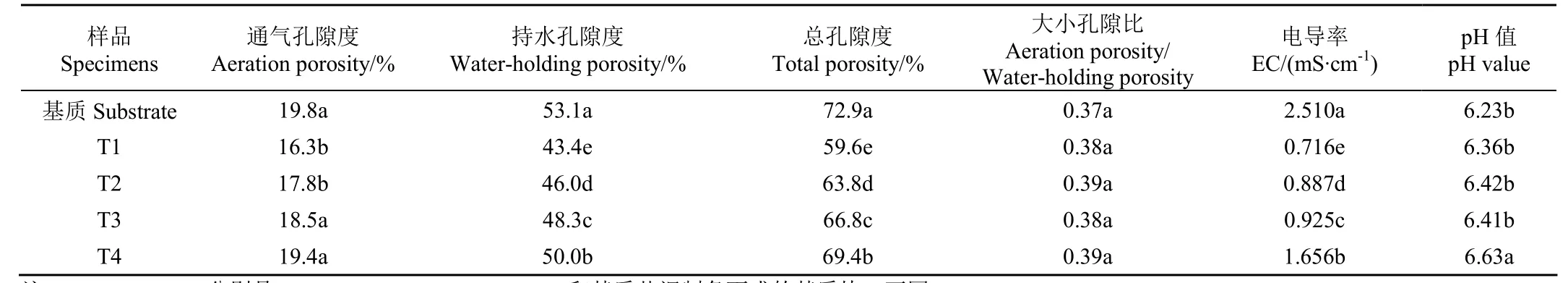

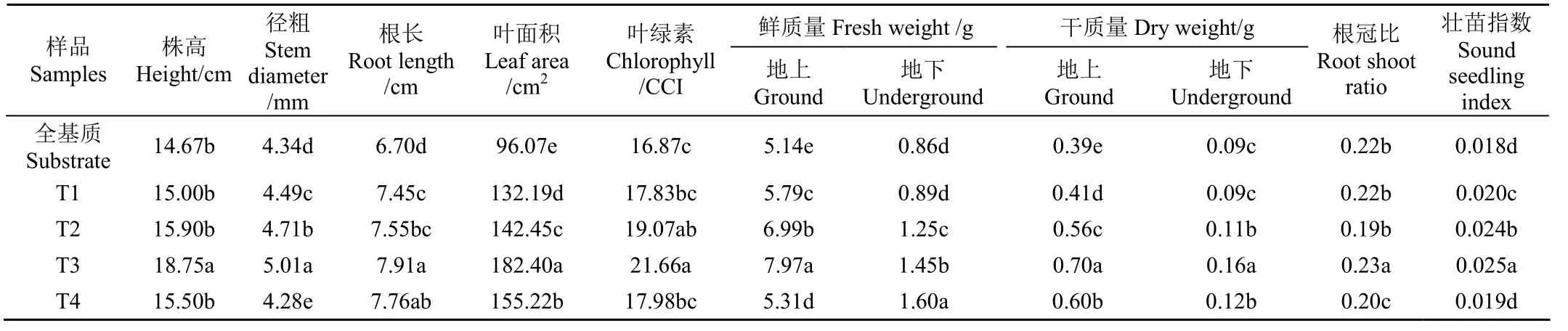

2.5 基质块对黄瓜幼苗生长的影响

基质块T3培育的黄瓜幼苗在一叶一心时的图片如图4所示,黄瓜根系能够很好地穿透基质块,并且在一片真叶的时候也能很好的成块,不散坨。从表3中可以看出,T1,T2和T4和全基质相比在株高上没有显著差异。在茎粗和叶面积上,T1,T2,T3,T4和全基质彼此之间均差异显著。T1,T2,T4和全基质相比在根长上存在显著差异,叶绿素则是II和III与全基质有显著差异,T1和T4与全基质没有显著差异。地上部分鲜质量和干质量彼此之间差异明显,地下部分鲜质量除了T1和全基质差异不明显外,T2,T3,T4均差异显著,地下干质量则是T2,T3和T4与全基质差异显著。总的来说,改性脲醛树脂粘合基质制备的基质块III和全基质培育的黄瓜幼苗的各项指标均有显著差异,黄瓜幼苗的各项指标和对照相比均有不同程度的提高,株高、径粗、根长比普通基质分别提高了27.81%,15.40%,18.10%。叶面积、鲜质量、干质量比普通基质提高了89.86%,57.00%,79.2%。壮苗指数提高了38.89%。然而,根冠比确有所下降,原因可能是添加胶黏剂后,基质块的孔隙度有所下降,导致了根系生长艰难,速率变慢,也可能是该树脂促进根和冠的生长,促进冠生长的更多[26]。其中,III-UF/基质培育出的黄瓜幼苗的壮苗指数优于其他几种基质块。也就是说,III-UF改性脲醛树脂的养分释放速率与黄瓜幼苗生长养分需求速率是比较一致的,该配方适宜于黄瓜幼苗的生长。

图4 一叶一心的黄瓜幼苗Fig.4 Cucumber seedlings with one leaf

表3 不同基质块培育的黄瓜幼苗生长状况Table 3 Growth conditions of cucumber seedlings in different substrate block

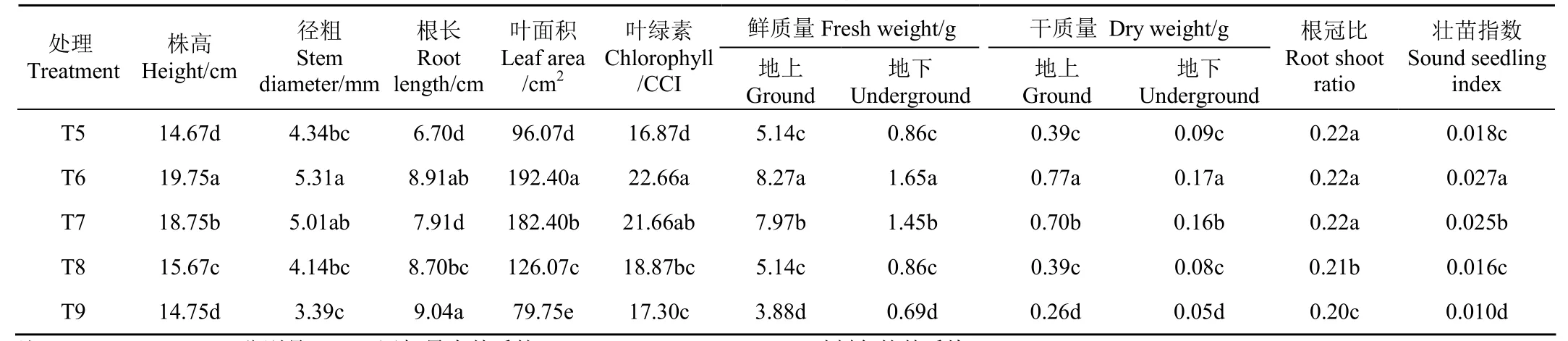

表4为不同胶黏剂(III-UF)添加量对黄瓜幼苗生长的影响,从表6中可以看出,鲜质量干质量随着基质中胶黏剂的添加量由40%增加到70%,黄瓜幼苗的各项指标呈现下降的趋势。一方面是因为粘合剂添加量越多直接导致孔隙度显著下降,另一方面是由于具有养分释放功能的胶黏剂太多,养分供应大于黄瓜幼苗所需的养分,反而不利于黄瓜幼苗的生长[27-30]。但是在胶黏剂添加量为50%时,各项指标还是优于未加胶黏剂的普通基质。为了保证基质块的强度,同时有利于黄瓜幼苗的生长,粘合剂添加量为50%时,最适宜于黄瓜幼苗的生长。

表4 不同胶黏剂(III-UF)添加量的黄瓜幼苗生长状况Table 4 Growth conditions of cucumber seedlings with different resins (III-UF) content

2.6 成本分析及应用前景

自主研发改性脲醛树脂2 300元/t。以72孔穴盘为例,改性脲醛树脂添加量为50%时,每个穴盘所需胶黏剂的成本为0.9元,每个孔所需的胶黏剂成本为0.012 5元。此外,该脲醛树脂属于生物降解材料,该改性胶黏剂在具备粘合功能的同时,能够缓慢释放养分,在苗期无需施用水溶肥,减少了苗期施用肥料的成本。而且,在定植后也能继续为植株提供养分。该胶黏剂主要成分为氮磷钾,不会对作物和土壤造成二次污染,并且该胶黏剂的合成所需的设备与木材工业中所用的胶黏剂基本一致,无论设备还是工艺都很成熟,因此有良好的应用前景。

3 结 论

本文中合成了一种适宜于粘合基质成块的改性脲醛树脂,该改性脲醛树脂的养分释放速率可以由水解蛋白进行调控,水解蛋白添加量越多,养分释放速率越快。添加改性脲醛树脂后,基质块的EC值有所降低,pH值基本保持不变。基质块的持水孔隙度和通气孔隙度有所下降,但从幼苗的综合指标看,还是能够满足黄瓜幼苗的生长需要。III-UF改性脲醛树脂在添加50%时,抗压强度为0.14 MPa以上,能够满足机械手抓取的要求,且鲜质量干质量养分释放速率与黄瓜幼苗生长养分需求速率基本一致,适宜黄瓜幼苗的生长。该基质块免除了常规育苗后期需要施肥的问题,并且基质块有一定的强度,解决了机械无损抓取的难题。重要的是,该改性脲醛树脂价格适中,在农业中有良好的应用前景。

[1] Nechita P, Dobrin E, Ciolacu F, et al. The biodegradability and mechanical strength of nutritive pots for vegetable planting based on lignocellulose composite materials[J]. Bioresources, 2010, 5(2): 1102-1113.

[2] Prasanna Kumar G V, Raheman H. Identification of optimum combination of proportion of vermicompost in the soil-based potting mix and pot volume for the production of paper pot seedlings of vegetables[J]. Journal of Plant Nutrition, 2012, 35(9): 1277-1289.

[3] Qu P, Huang H, Wu G, et al. Preparation and degradation of seedling containers made from straw and hydrolyzed soy protein isolate modified urea-formaldehyde resins[J]. BioResources, 2015, 10(4): 7946-7957.

[4] 张凤银,魏传斌,张光梅,等. 有机育苗基质块对辣椒幼苗生长的影响[J]. 农学学报,2012,2(3):41-43.

Zhang Fengyin, Wei Chuanbin, Zhang Guangmei, et al. Effects of organic substrate block on the growth of hot pepper seedling[J]. Journal of Agriculture, 2012, 2(3): 41-43. (in Chinese with English abstract)

[5] 葛桂民. 玉米秸秆发酵有机基质压缩成型及育苗技术研究[D]. 郑州:河南农业大学,2009.

Ge Guimin. Study on Selection Organic Matrix Formulation of Corn Straw Compression Molding and Breeding Technology[D]. Zhengzhou: Henan Agricultural University, 2009. (in Chinese with English abstract)

[6] 北京市农林科学院. 养分缓释型蔬菜育苗基质块:201010112173.4 [P]. 2010-02-11

[7] 杭州烨霖农业科技有限责任公司. 一种水稻育苗基质块及其制备工艺:201510154468.0 [P]. 2015-04-02

[8] 杨龙元,袁巧霞,刘志刚,等. 牛粪好氧和蚯蚓堆肥腐熟料成型基质块制备及育苗试验[J]. 农业工程学报,2016,32(24):226-233.

Yang Longyuan, Yuan Qiaoxia, Liu Zhigang, et al. Experiment on seedling of compressed substrates with cow dung aerobic composting and earthworm cow dung composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(24): 226-233. (in Chinese with English abstract)

[9] Lorenz L F, Conner A H, Christiansen A W. The effect of soy protein additions on the reactivity and formaldehyde emission of urea-formaldehyde adhesive resins[J]. Forest Products Journal, 1999, 49(3): 73-78.

[10] Qu P, Huang H, Wu G, et al. Effects of hydrolysis degree of soy protein isolate on the structure and performance of hydrolyzed soy protein isolate_urea_formaldehyde copolymerresin[J]. Journal of Applied Polymer Science, 2015, 132(7). DOI: 10.1002/app.41469

[11] 曲萍,常志州,赵永富,等. 蛋白水解物改性脲甲醛缓释肥的结构及氮素释放特征[J]. 农业工程学报,2016,32(21):240-245.

Qu Ping, Chang Zhizhou, Zhao Yongfu, et al. The structure of hydrolyzed soy protein modified urea formaldehyde and its nitrogen release characteristic[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(21): 240-245. (in Chinese with English abstract)

[12] Qu P, Huang H, Wu G, et al. Hydrolyzed soy protein isolates modified urea-formaldehyde resins as adhesives and its biodegradability[J]. Journal of Adhesion Science and Technology, 2015, 29(21): 2381-2398.

[13] Krasowski M J, Owens J N, Tackaberry L E, et al. Aboveand below-ground growth of white spruce seedlings with roots divided into different substrates with or without controlled-release fertilizer[J]. Plant and Soil, 1999, 217(1): 131-143.

[14] 戴小红,孙伟生,樊权,等. 农林废弃物混配基质的理化性质及其对油茶幼苗生长效应的综合评价[J]. 植物资源与环境学报,2016,25(1):54-61.

Dai Xiaohong, Sun Weisheng, Fan Quan, et al. Physicochemical property of mixed substrates with agricultural and forestry wastes and comprehensive evaluation of their effect on growth of Camellia oleifera seedlings[J]. Journal of Plant Resources and Environment. 2016, 25(1): 54-61. (in Chinese with English abstract)

[15] 张舒玄,常江杰,李辉信,等. 奶牛粪蚯蚓堆肥的基质配方及对草莓育苗的影响[J]. 土 壤, 2016, 48(1): 59—64

Zhang Shuxuan, Chang Jiangjie, Li Huixin, et al. Substrate formula of cow manure vermicompost and its effects on strawberry seedling[J]. Soils, 2016, 48(1): 59—64.

[16] 张硕,余宏军,蒋卫杰. 发酵玉米芯或甘蔗渣基质的黄瓜育苗效果[J]. 农业工程学报,2015,31(11):236-242.

Zhang Shuo, Yu Hongjun, Jiang Weijie. Seedling effects of corncob and bagasse composting substrates in cucumber[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(11): 236-242. (in Chinese with English abstract)

[17] 郭世荣. 固体栽培基质研究、开发现状及发展趋势[J]. 农业工程学报,2005,21(14):1-4.

Guo Shirong. Research progress current exploitations and developing trends of solid cultivation medium[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(14): 1-4. (in Chinese with English abstract)

[18] 胡亚利,孙向阳,龚小强,等. 混合改良剂改善园林废弃物堆肥基质品质提高育苗效果[J]. 农业工程学报,2014,30(18):198-204.

Hu Yali, Sun Xiangyang, Gong Xiaoqiang, et al. Mix-ameliorant improving substrates quality of waste compost from garden and seedling effect[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(18): 198-204. (in Chinese with English abstract)

[19] 赵海涛,李天鹏,姚旭,等. 堆置与添加蛭石对污泥蚓粪培育茄子幼苗的影响[J]. 中国农业科学,2014,47(23):4668-4679.

Zhao Haitao, Li Tianpeng, Yaoxu, et al. Effects of the potting media produced by activated sludge vermicompost stacked and added vermiculite on eggplant seedlings[J]. Scientia Agricultura Sinica, 2014, 47(23): 4668-4679. (in Chinese with English abstract)

[20] 刘方春,马海林,马丙尧,等. 菇渣用作无纺布容器育苗成型机配套基质的研究[J]. 生态与农村环境学报,2010,26(5):477-481.

Liu Fangchun, Ma Hailin, Ma Bingyao, et al. Use of used mushroom cultivation medium as raw material in making seedling pots of non-woven fabric[J]. Journal of Ecology and Rural Enviroment, 2010, 26(5): 477-481. (in Chinese with English abstract)

[21] 缪小花,毛罕平,韩绿化,等. 黄瓜穴盘苗拉拔力及钵体抗压性能影响因素分析[J]. 农业机械学报,2013,44(s1):27-32.

Miao Xiaohua, Mao Hanping, Han Lvhua. Analysis of influencing factors on force of picking plug seedlings and pressure resistance of plug seedlings[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(s1): 27-32. (in Chinese with English abstract)

[22] 赵雄,沈明,陈建能,等. 棉花移栽机旋转式取苗机构的运动学分析及虚拟试验[J]. 农业工程学报,2014,30(8):13-20.

Zhao Xiong, Shen Ming, Chen Jianneng, et al. Kinematic analysis and virtual experiment of rotary pick-up mechanism on cotton transplanter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(8): 13-20. (in Chinese with English abstract)

[23] 田昆鹏,毛罕平,胡建平,等. 自动移栽机门形取苗装置设计与试验研究[J]. 农机化研究,2014(2):168-172.

Tian Kunpeng, Mao Hanping, Hu Jianping, et al. Design and experimental study on the door-shaped picking seedling mechanism of auto-transplanter[J]. Agricultural Mechanization Research, 2014(2): 168-172. (in Chinese with English abstract)

[24] 褚群,董春娟,尚庆茂. γ-聚谷氨酸对番茄穴盘育苗基质矿质养分供应及幼苗生长发育的影响[J]. 植物营养与肥料学报,2016,22(3):855-862.

Chu Qun, Dong Chunjuan, Shang Qingmao. Effects of γ-poly glutamic acid on substrate mineral nutrient supply and growth of tomato plug seedlings[J]. Journal of Plant Nutrition and Fertilizer, 2016, 22(3): 855-862. (in Chinese with English abstract)

[25] 张冕,姬江涛,杜新武. 国内外移栽机研究现状与展望[J].农业工程,2012,2(2):21-23.

Zhang Mian, Ji Jiangtao, Du Xinwu. Status and prospect of transplanter at home and abroad[J]. Agricultural Engineering, 2012, 2(2): 21-23. (in Chinese with English abstract)

[26] 王吉庆,赵月平,刘超杰. 水浸泡玉米秸基质对番茄育苗效果的影响[J]. 农业工程学报,2011,27(3):276-281.

Wang Jiqing, Zhao Yueping, Liu Chaojie. Effects of water-soaked corn stalk substrate on tomato seedling culture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(3): 276-281. (in Chinese with English abstract)

[27] 林育炯,张均华,胡继杰,等. 不同类型基质对机插水稻秧苗生理特征及产量的影响[J]. 农业工程学报,2016,32(8):18-26.

Lin Yujiong, Zhang Junhua, Hu Jijie, et al. Effects of different seedling substrates on physiological characters and grain yield of mechanized-transplanted rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(8): 18-26. (in Chinese with English abstract)

[28] 陈世昌,周士锋,徐明辉,等. 促腐剂对菇渣发酵过程的影响及育苗基质优化研究[J]. 北方园艺,2011(17):177-180.

Chen Shichang, Zhou Shifeng, Xu Minghui, et al. Effect of transformation promoter addition on processing fermentation of mushroom residue and medium optimization for seeding[J]. Northern Horticulture, 2011(17): 177-180. (in Chinese with English abstract)

[29] Hartwigsen J A, Evans M R. Humic acid seed and substrate treatments promote seedling root development[J]. Hortscience, 2000, 35(7): 1231-1233.

[30] Carmona E, Moreno M T, Avilés M, et al. Use of grape marc compost as substrate for vegetable seedlings[J]. Scientia Horticulturae, 2012, 137(4): 69-74.

Performance of substrate blocks glued by modified urea formaldehyde resins and its effect on cucumber seedlings

Qu Ping, Zhao Yongfu, Song Jing, Xia Liru※

(Key Laboratory of Agricultural Engineering in the Middle and Lower Reaches of Yangtze river, Institute of Agricultural Facilities and Equipment, Jiangsu Academy of Agricultural Science, Nanjing 210014, China)

In order to solve the problem of scattering substrates and the damaged root during the process of mechanized transplanting, the hydrolyzed soy protein modified urea formaldehyde resins were applied to glue the substrates together. The properties of modified resins, such as pH value, viscosity, solid content, density, curing time, and free formaldehyde, were characterized. The nutrient release rate of modified urea formaldehyde resins was characterized. The aeration porosity, water-holding porosity, EC, pH value, and compressive strength of the substrate blocks were also tested; the effect of the substrate block on the cucumber seedling was measured. The results show that the hydrolyzed soy protein modified urea formaldehyde resins can meet requirements of gluing the substrates together. The viscosity and curing time increase obviously. And, the solid content and free formaldehyde decrease a little. The reason is that the viscosity of hydrolyzed soy protein is higher than urea formaldehyde resins, and the solid content is lower than urea formaldehyde resins. The active groups in modified urea formaldehyde resins are fewer than unmodified urea formaldehyde resins. In addition, the space barrier from the soy protein causes the increased curing time, because the hydroxymethyl groups formed from active amino groups of hydrolyzed soy protein and formaldehyde are more stable than that formed from urea and formaldehyde. The nutrient release rate is an important indicator of the substrate block. Soil column leaching method was applied to characterize the nitrogen release rate. The nitrogen release rate in the first 3 weeks is slower. Then the nitrogen release rate is improved in the later time, and the release rate can reach 48% in the 7thweek. The reason is the specific surface area increases as the time goes on. The aeration porosity, water-holding porosity, and total porosity of the substrate blocks are decreased by 6.6%, 9.0%, and 8.4% compared with the traditional substrate. The reason is that the porosity and the hydrophilic groups of the substrate are covered by modified urea formaldehyde resins. However, the porosity can meet the growth requirement of the cucumber seedling when the modified urea formaldehyde resins are added in the substrates in the proportion of 1:2. The EC of substrate block decreases from 2.5 to 1 mS/cm. The pH value of the substrate block remains unchanged. The compress strength of the substrate block is above 0.14 MPa, which can meet the requirement of grabbing of manipulator during the transplanting process. When the modified urea formaldehyde is added, the height, stem diameter, root length are improved by 27.81%, 15.40%, and 18.10%, respectively. And the leaf area, fresh and dry weight are improved by 89.86%, 57.00%, and 79.2%, respectively. In addition, the substrate blocks with 50% resins are suitable for the root growth of cucumber seedlings. III-H-UF is the best resins that the nutrient release rate is in accordance with the nutrient requirement characteristics of the cucumber seedlings. The formula of the substrate blocks is suitable for the cucumber seedlings growth. Every seedling tray increases by 0.9 yuan when blended with modified urea formaldehyde resins. And every seedling increases by 0.0125 yuan for seedling tray with 72 holes.

substrates; mechanization; physichemical properties; hydrolyzed soy protein; modified urea formaldehyde; substrate block; grow seedlings; cucumber

10.11975/j.issn.1002-6819.2017.15.032

S216; X71

A

1002-6819(2017)-15-0253-07

2017-02-15

2017-05-31

江苏省农业科技自主创新基金(CX(16)1002);国家自然基金(11605077)

曲萍,博士,副研究员,主要从事农用生物降解材料的研究。南京 江苏省农业科学院,农业设施与装备研究所,农业部长江中下游设施农业工程重点实验室,210014。Email:qupinghappy@163.com

※通信作者:夏礼如,硕士,研究员,主要从事设施农业技术与装备的研究。南京 江苏省农业科学院,农业设施与装备研究所,农业部长江中下游设施农业工程重点实验室,210014。Email:liruxiajaas@126.com