Preparation and performance of PSA nanofiber filtration membrane

2017-04-20XuHaoChenLongSunJunfenPanDanWangXiaofeng

Xu Hao, Chen Long*, Sun Junfen, Pan Dan,Wang Xiaofeng

(1.State Key Laboratory for Modification of Chemical Fibers and Polymer Materials,College of Materials Science and Engineering,Donghua University,Shanghai 201620; 2. Shanghai Tanlon Fiber Co., Ltd.,Shanghai,201419)

Preparation and performance of PSA nanofiber filtration membrane

Xu Hao1, Chen Long1*, Sun Junfen1, Pan Dan1,Wang Xiaofeng2

(1.State Key Laboratory for Modification of Chemical Fibers and Polymer Materials,College of Materials Science and Engineering,Donghua University,Shanghai 201620; 2. Shanghai Tanlon Fiber Co., Ltd.,Shanghai,201419)

A polysulfonamide(PSA) nanofiber membrane was prepared with PSA nonwoven as a support layer by electrospinning process and was applied in high-temperature and high-efficiency air filtration field. The effects of the environmental humidity, spinning time, spinning voltage and tip-collector distance on the nanofiber morphology, diameter, pore size and mechanical properties of the nanofibers membrane were discussed. The influence of the nanofiber packing density on the filtration performance and pressure drop was studied. The results showed that the nanofiber was well-distributed when the environmental humidity was 30%; the nanofiber packing density was 6.78 g/m2, and the filtration efficiency, pressure drop and quality factor of nanofibers membrane were 99.93%, 754 Pa and 9.63×10-3, respectively, when the spinning voltage was 22 kV, the tip-collector distance 16 cm and spinning time 23 h; and the PSA nanofibers membrane reached the requirement of PM2.5 filtration and was expected to be widely used in the high-temperature filtration field.

polysulfonamide fiber; electrospinning; nanofiber; filtration efficiency; filtration pressure drop

At present, industrial dust is mainly removed by traditional filtration fabric, but its collection efficiency is only 45% for PM2.5 and cannot reach the requirement of catching PM2.5. The nanofibers are used widely in high-efficiency filtration field due to their advantages of low diameter, high specific surface area and small pore size[1-6].

Polysulfonamide (PSA) fiber is a high-temperature resistant fiber developed by China independently, which is mainly spun by dry and wet spinning process. PSA fiber has been widely used in industrial filter field due to excellent chemical stability, thermal resistance, flame retardant property and mechanical properties. However, the research on PSA nanofibers[7-8]is still at the starting stage now. Chen Wenjie studied the influence of spinning parameters on the morphology of composite nanofiber prepared by adding inorganic particles into PSA solution. There are many research efforts in the electrospinning process of PSA nanofiber,but no literature on the influence of environmental humidity on the fiber morphology and the influence of PSA nanofiber structure on the filtration performance.

The authors studied the influence of environmental humidity on PSA nanofiber formation and the influences of spinning parameters such as voltage, tip-collector distance and spinning time on nanofiber morphology. The influences of the PSA nanofiber morphology on the filtration performance were analyzed. This work lays the foundation for the research and application of PSA nanofiber.

1 Experimental

1.1 Materials and reagents

PSA spinning solution:solid content 12%,purchased from Shanghai Tanlon Fiber Co., LTD.; dimethylacetamide(DMAc):analytical purity,supplied by Shanghai Tanlon Fiber Co., LTD.; PSA non-woven:supplied by Shanghai Tanlon Fiber Co., LTD.; epoxy resin embedding medium:supplied by SPI Co., LTD., USA.

1.2 Preparation of PSA nanofibers membrane

DMAc was added into a PSA solution with 12% solid content to prepare a 10% PSA solution by mass fraction, which was taken with a 5-milliliter syringe for the electrospinning process. The spinning parameters are illustrated in Tab.1. PSA nanofibers were prepared by controlling the environmental humidity as 50%, 40% and 30% based on the process conditions for sample 1#and the change of pore size with the spinnning time (1, 2, 3, 4 h) was observed at the given environmental humidity under process conditions for sample 1#.

Tab.1 PSA electrospinning parameters

Note:The flow rate was 1.6 μL/min and the rotation velocity of the cylinder was 100 r/min.

1.3 Preparation of PSA nanofiber filter

PSA nanofibers membrane was prepared with PSA non-woven as a support layer under the process conditions for sample 1#. PSA nanofibers membrane with different thickness were obtained by controlling the spinning time as 7, 11, 15, 19, 23 and 25 h. The dependence of filtration efficiency and filtration pressure drop of PSA nanofibers membrane on the spinning time was studied.

1.4 Measurement and Characterization

Fiber diameter (d)andporesize(D)ofnanofibersmembrane:ThemicrostructureofPSAnanofibersmembranewascharacterizedbyaJMS-5600LVscanningelectronmicroscope.dandDweremeasuredbyintroducingtheSEMimagesintoImage-proplussoftwareafterbinaryprocessing[9-10].

Nanofibersmembranethickness(S):ThecrosssectionmorphologyofPSAnanofibersmembranewascharacterizedbyscanningelectronmicroscopy.Softhenonofibersmembranewasmeasured.

Mechanicalproperties:ThemechanicalpropertiesofthenanofibersweremeasuredwithanXS(08)XG-3fibertensilestrengthtester.Eachfibersamplewiththelengthof20mmandthewidthof10mmwasmeasured8timestoacquiretheaveragevalue.

Porosity(n):Theequation(1)isusedtocalculatetheporosityofPSAnanofibriousmembrane.

n=1-(Wg)/ρH

(1)

WhereWgisthepackingdensityofthenanofibersmembrane, ρisthedensityofPSAandHisthethicknessofnanofibersmembrane.

Filtrationperformance:ThefiltrationperformanceofPSAnanofiberfilterwascharacterizedbyaLzc-Hfiltertester.Thesizeofaerosolparticleswas0.3μmandthecross-flowvelocitywas32L/min.Thefiltrationefficiency(η)isexpressedastheratiooftrappeddustamounttodustamountinunfilteredair.

Pressuredrop(∆P)isthestaticpressuredifferencebeforeandafterfiltration.Itisalsocalledpressurelossandfiltrationresistance.

Qualityfactor(QF)representstherelationshipbetweenfiltrationefficiencyandpressuredrop.ThehigherQFis,thebetterqualitythefilterposseses. QFcanbecalculatedwithequation(2).

QF=-ln(1-η)/∆P

(2)

2 Results and discussion

2.1 Effect of environmental humidity on fiber morphology

It can be seen from Fig.1 that the adhesion and combination of PSA nanofibers were depressed while decreasing the relative environmental humidity. The nanofibers exhibited smooth surface,even thickness and uniform distribution as the relative environmental humidity was 30%. Therefore, the relative environmental humidity was properly controlled as 30%in the experiment.

Fig.1 Surface morphology of PSA nanofibers under different relative environmental humidity Spinning time, 4 h.

2.2 Effect of spinning time on pore size of PSA nanofibers membrane

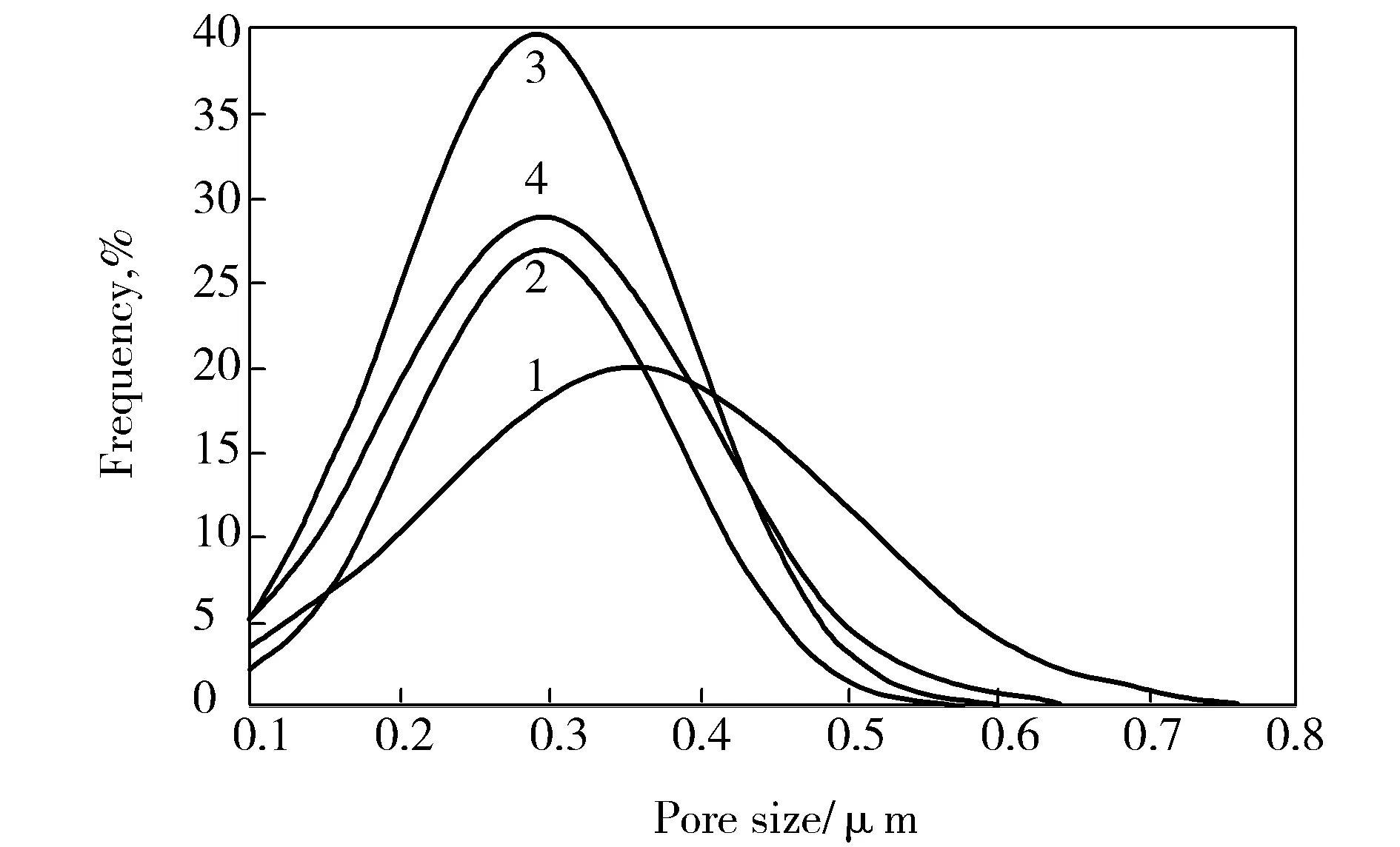

It can be seen from Fig.2 that the pore size of the nanofibers membrane was stable at about 0.3 μm and the distribution became narrow when the spinning time was more than 2 h. Therefore, the spinning time was properly controlled as more than 2 h in the experiment.

Fig.2 Pore size distributions of PSA nanofibers membrane at different spinning time Relative environmental humidity, 30%. 1—1 h;2—2 h;3—3 h;4—4 h

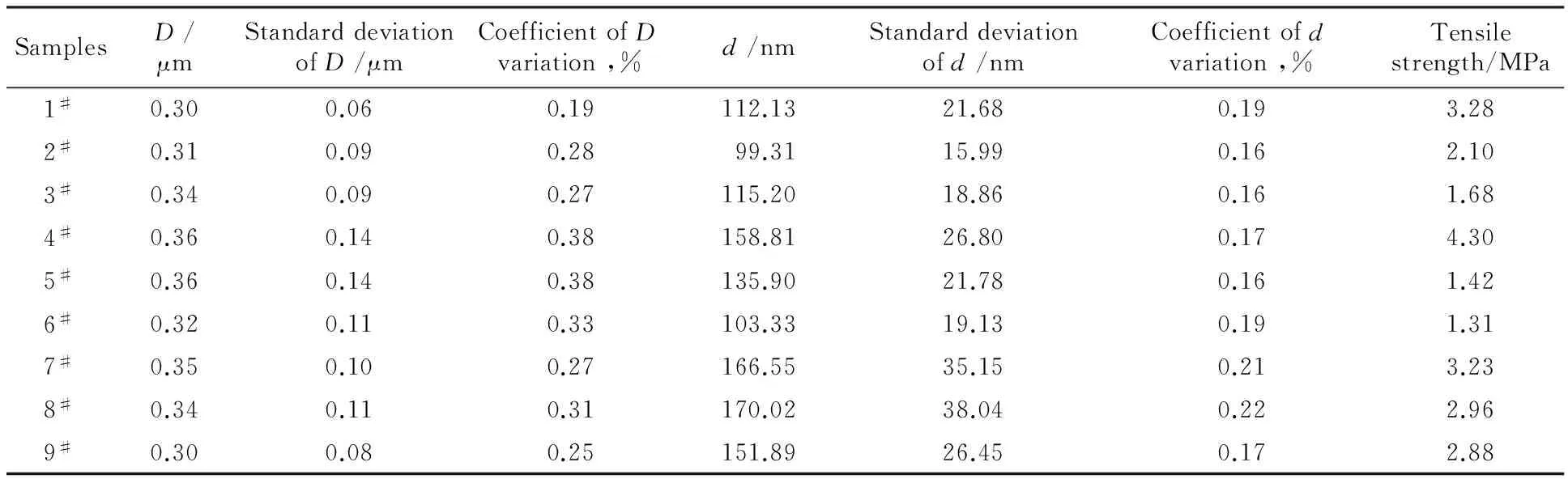

2.3 Effect of spinning voltage and tip-collector distance onDofPSAnanofibersmembrance

As shown in Tab.2, the tip-collector distance affected the fiber diameter in different way. The flying time of the jet increased with the tip-collector distance under the same electrospinning process, which would make the stretching time prolong andddecreaselikesamples4#, 5#, 6#andsamples8#, 9#.Ontheotherhand,theincreaseoftip-collectordistanceledtothereductionofelectricfieldintensity,whichwoulddecreasethestretchingforceonthejetandincreasethefiberdiameterlikesamples1#, 2#,3#,orsamples7#,8#.Theincreaseofvoltagecouldshortentheflyingtimeofthejetunderthesameelectrospinningprocess,whichwoulddecreasethestretchingdegreeandincreasedlikesamples1#, 4#, 7#,or2#, 5#, 8#,or3#, 6#, 9#.Amongthesefibersamples,samples1#and3#hadthelowerstandarddeviationandvariationcoefficientofd,narrowerdiameterdistributionandmoreuniformthickness.

Tab.2 d and D of PSA nanofibers membrane

Note:The spinning time was 4 h and the relative environmental humidity was 30%.

The pore size and distribution of PSA nanofibers membrane were mainly related to the fiber diameter and packing density. TheDofsamples1#-9#was0.3μmorso.ThestandarddeviationandvariationcoefficientofDwererelativelylowforsamples1#, 2#, 3#, 7#, 9#.

Thetensilestrengthofthenanofibersmembranewasmainlyrelatedtofiberpackingdensityandd.ItalsocanbeseenfromTab.2thattheincreaseoftip-collectordistancecouldleadtothereductionofthestrengthofPSAnanofibersmembraneunderthesameelectrospinningprocessbecausetheflyingtimeofthejetwasincreasedandtheresidualsolventsofsolidifiedfiberweredecreased,thusthefiberadhesionreduced.Thetensilestrengthofsamples1#, 4#, 7#,8#and9#washigherthanthoseofotherfibersamples.Samples1#hadtheuniformdandDandexcellentmechanicalproperties.

2.4 Effect of spinning time on filtration performance of PSA nanofiber filter

As illustrated in Tab.3,ηrosefrom11.760%to99.952%and∆Palsorosefrom73Pato797Pawiththeextensionofspinningtime.becausetheincreaseofpackingdensityofthenanofibersmembraneelevatedthecollisionprobabilitybetweenfibersandparticles.Atthesametime, ∆PofPSAnanofiberfilterwasincreasedastheporositywasincreased.ThecomprehensiveperformanceofPSAnanofibersmembranewasoptimizedwiththeQFof9.63×10-3whenthespinningtimewas23h.

Tab.3 Air filtration performance of PSA nanofiber filter

Note:The spinning voltage was 22 kV,the tip-collector distance 16 cm, and the relative environmental humidity 30%.

3 Conclusion

a. The PSA nanofibers were well-distributed and had smooth suface when the environmental humidity was 30%. The pore size and distribution of the nanofibers membrane tended to be stable and narrow when the spinning time was more than 2 h.

b. The PSA nanofibers membrane exhibited uniform thickness,narrow pore size distributeion and high tensile strength when the environmental humidity was 30%, the spinning voltage 22 kV, the spinning time 23 h, and tip-collector distance 16 cm.

c.ηand∆PofPSAfilterwere99.93%and754Pa,respectively,QFwasmaximizedandthefiltrationperformancewasoptimizedwhenthepackingdensityofPSAfibersmembranewas6.78g/m2.

[1] Wang Han, Zheng Gaofeng, Sun Daoheng. Electrospun nanofibrous membrane for air filtration[C]//Proceedings of the 7th IEEE International Conference on Nanotechnology, 2007:1255-1258.

[2] Yoon K,Hsiao B S,Chu B. Functional nanofibers for environmental applications[J]. J Mater Chem, 2008,18(44):5326-5334.

[3] Qin Xiaohong, Wang Shanyuan. Filtration properties of electrospinning nanofibers[J]. J Appl Polym Sci, 2006,102(2):1285-1290.

[4] Bhardwaj N,Kundu S C.Electrospinning: A fascinating fiber fabrication technique[J].Biotech Adv,2010,28(3):325-347.

[5] Wang Xianfeng, Ding Bin, Sun Gang, et al. Electro-spinning/netting: A strategy for the fabrication of three-dimensional polymer nano-fiber/nets[J]. Prog Mater Sci, 2013, 58(8):1173-1243.

[6] Huang Zhengming, Zhang Yanzhong, Kotaki M, et al. A review on polymer nanofibers by electrospinning and their applications in nanocomposites[J]. Comp Sci Tech, 2003, 63(15):2223-2253.

[7] Liu Li, Shi Ying, Jiao Qinghua, et al. Preparation of polysulfoneamide electrospinning nanofibers[C]//Electronic Packaging Technology & High Density Packaging, 2008 International Conference on IEEE,2008:1-4.

[8] Chen Wenjie, Xin Binjie, Wu Xiangji. Fabrication and characterization of PSA nanofibers via electrospinning[J]. J Ind Text, 2014, 44(1):159-179.

[9] Ziabari M, Mottaghitalab V, Haghi A K. Evaluation of electrospun nanofiber pore structure parameters[J]. Korean J Chem Eng, 2008, 25(4):923-932.

[10] Sambaer W,Zatloukal M,Kimmer D.The use of novel digital image analysis technique and rheological tools to characterize nanofiber nonwovens[J].Polym Test,2010,29(1):82-94.

PSA纳米纤维毡的制备和性能

徐 浩,陈 龙,孙俊芬,潘 丹,汪晓峰

(1.东华大学材料科学与工程学院纤维材料改性国家重点实验室,上海 201620;2.上海特安纶纤维有限公司,上海 201419)

以聚砜酰胺(PSA)无纺布为支撑层,采用静电纺丝法制备了PSA纳米纤维毡,并用于高温高效空气过滤领域;研究了环境湿度对PSA纤维成形的影响规律,探讨了纺丝时间、纺丝电压、接收距离对纳米纤维毡形貌、孔径、纤维直径及其力学性能的影响,以及纳米纤维毡面密度对滤材过滤效率和压阻的影响。结果表明:当环境相对湿度达到30%时,纳米纤维成形良好;当纺丝电压为22 kV,纺丝时间23 h,接收距离为16 cm时,制备的纳米纤维毡面密度为6.78 g·m-2,滤材过滤效率达到99.93%,过滤压阻为754 Pa,纳米纤维毡质量因子为9.63×10-3;PSA纳米纤维毡达到了PM2.5过滤的要求,有望在高温过滤领域得到广泛应用。

聚砜酰胺纤维 静电纺丝 纳米纤维过滤效率 过滤压阻

Foundation item: National Key Technologies R & D Program of China during the 13th Fier-Year Plan Period(2016YFB0302600). * Corresponding author: happyjack@dhu.eud.cn.

TQ342+.31 Document code:A Article ID: 1001- 0041(2017)02- 0042- 04

Received date:27-10-2016; revised date: 15- 02- 2017.

Biography: Xu Hao(1991-),male,master canditate, is engaged in the preparation of electrospun PSA naaofiber. E-mail:fightingxuhao@163.com.