预制工艺

2017-02-08马尔科索尔

马尔科·索尔

司马蕾 译

预制工艺

马尔科·索尔

司马蕾 译

节选自马丁·劳奇的《优雅的泥土——夯土建筑与设计》, 奥托·卡普芬格和马尔科·索尔(编著),细部出版社,慕尼黑,2015年, 第118-121页。由细部出版社再版。

预制工艺为夯土建筑提供了一种新范式,这种技术无论从定性还是定量的角度来说都是一次巨大的飞跃。它让夯土建筑的建造达到了一个新水平,也让更多的项目可以考虑使用夯土。这种分离建筑的生产和安装过程的做法更为经济,因为在施工现场的作业中,相比雇佣一群工人在现场夯土、慢慢地垒起建筑的做法,起重机能够在工期很紧的情况下很快地把成品部件搭建好。因为部件在造好时已经是干的了,整合分包出去的各项工种时可以做到无缝衔接,这也大大地缩短了建造所需的时间。虽然生产这些墙仍然是一项时间密集型的工作,但生产和安装的时间变得更容易规划和协调了。

因为过去几乎没有离开现场在别处进行夯土的先例,夯土建筑中的预制工艺几乎是个未知的领域,但现在已经开始出现了这方面的尝试。相关的技术和结构要求变得更为细致,并开始通过优化设计来探索解决方案。在这座最初的预制夯土建筑的大体部分基本完工之后,后续的修整的工作也进化了很多,这让由各种部件组成的墙体看上去就和在现场建造的夯土墙一模一样。

但施工过程的规划仍需要继续进行改进,例如在工程的初期阶段,尽管很难,仍要快速明确对这些夯土部件的要求。这涉及到施工的管理和生产间的密切配合,而其中对预制影响最大的要素是制造和冲压的工艺。例如,在决定了墙的厚度之后,下一步要做的是调整部件的尺度以适应不同的空间高度。而部件的长度还要考虑到把部件搬送就位的起重机的荷载限制,这一长度是由起重机允许的最大重量、墙的高度和宽度共同决定的。这种在规划和生产的交接中会出现的交互问题都需要仔细地进行评估。

为了尽量控制部件的数量以实现较低的造价和较短的工期,甚至连起重机的摆放位置、根据机械臂外展距离确定的最大负荷都需要进行考虑:靠起重机近的部件可以相对重些,也可以设计的长一些。位于森帕赫的瑞士鸟类研究所的项目就仔细地评估了这些方面的要素。

但同时,这也让建造的技术也变得简单多了:预制部件的细部都是标准化的,即使非熟练工人也可以来施工。建造工作也可以分配给多个实施方来分担,这对夯土建筑行业整体也是有益的。

生产优势

世界上第一个预制夯土部件是在1997年由Lehm Ton Erde Baukunst GmbHi设计的一面起居室里的墙。这面墙被安装在木结构的建筑中,乍看之下在施工上几乎不可能实现: 屋架的建造工期有限,进度很紧,此外,工程计划在一月份进行,这个时期因为霜冻的关系不可能在场地上进行夯土。因此才出现了想通过起重机在建造木构架的同时把夯土墙吊装进去的解决方案,也催化了土质建材的预制化进程。

这一时期的第一个大规模项目是古格勒打印机公司位于奥地利皮拉赫的一个办公楼项目。项目中构成建筑内墙的标准化的部件被互相堆叠在一起,再把节点连接起来。这一墙体部件里包含了用地源热泵供能的通风管道,夯土墙的功能则类似于地暖,利用其触感特点,创造出舒适的室内环境。

制造古格勒项目中所需的160个部件花了3个月时间,但之后将其安装到位只花了不到两周时间。最新采用了预制夯土部件的项目则是位于瑞典劳芬的利口乐草药中心项目和位于森帕赫的瑞士鸟类研究所项目。由于改良了制造流程,现在的部件生产速度比1990年代有了提升,生产和安装部件所需的时间比大约为3:1。

1 机械预制能减少劳动力的需求,并加快了生产过程。这台机器由Lehm Ton Erde Baukunst GmbHi研发/Mechanical prefabrication alleviates physically strenuous labor and expedites the production process. The machine was developed by Lehm Ton Erde.

Excerpt of Martin Rauch Refined Earth -Construction and design with Rammed Earth, Otto Kapfinger and Marko Sauer (eds.), Edition detail, Munich 2015, p. 118 - 121.

Reprint by courtesy of Edition detail, Munich.

2 由于墙体部件不抗拉,必须开发悬挂系统来进行装吊。这种系统也能让部件实现垂直放置/As the elements cannot be subjected to tensile loading, a suspension system had to be developed. This also allows the elements to be set in place vertically.

Prefabrication represents a new paradigm in rammed earth construction, as it is a quantum leap both in a quantitative and in a qualitative sense. It takes the practice to a new level and gives more options for finding projects that can be executed with rammed earth. Economic considerations support the argument for separating the processes of production and installation, primarily due to on-site logistics: rather than employing a team of laborers to ram the earth in situ, gradually putting up the building over time, cranes can quickly mount the finished elements in accordance with the demands of a tight schedule. As the elements are already dry when they are erected, integrating the remaining building trades of other subcontractors is seamless, which significantly shortens the duration of the construction work. Fabricating the walls is still just as time intensive a process, but the production and mounting phases can be more easily planned and coordinated.

As there are virtually no historical precedents for earth being rammed offsite rather than in situ, prefabrication in earth construction is largely unexplored territory, although experience is now beginning to emerge in this field. Its technical and structural requirements are becoming more refined - as are the solutions in matters of design. While the rudimentary joints of the first prefabricated buildings were roughly finished, retouching has become considerably more advanced, such that walls made up of compound elements are as homogeneous in appearance as walls rammed on site.

Improvements needed to be made in the planning process, as defining the earth elements requires hard and fast decisions to be made at an early stage. This involves a close collaboration between construction documentation and production, as often factors only tangentially related to the manufacturing and ramming process can be crucial to their fabrication. For example, once the wall thickness has been decided, the next step is to adjust the size of the elements to match the room height. The length is dependent on the load limitation of the crane that lifts the elements into place. Thus, the length is a product of the maximum permissible for weight, height, and wall width. These interdependencies, at the interface between planning and production, must be carefully evaluated.

In order to limit the number of elements as much as possible, which in the end results in a lower price and a shorter construction schedule, even details such as the location of the crane and the maximum load capacity relative to its outreach are considered: elements nearer to the crane can be proportionally heavier and therefore longer in design. In constructing the Swiss Ornithological Institute in Sempach, strict attention was paid to each of these aspects.

In contrast, technical implementation has become much simpler: prefabricated details are standardized and can even be put in practice by unskilled labor. The task can be dispensed to multiple actors, which is of overall benefit to the earth building trade.

Production Advantages

The first prefabricated element completed by Lehm Ton Erde was a living room wall in 1997. It was to be installed in a timber-frame construction, which at first appeared to be logistically impossible: the schedule of the framing was extremely tight in a fixed window of time, and, moreover, planned for January, when the earth could not be stamped onsite due to frost. A solution was thus sought that would allow the wall to be installed with a crane simultaneously with the timber construction process. This was the catalyst for prefabrication.

The first larger-scale project from this period was an office building for Gugler Printers in Pielach. The standardized elements, which were also interior walls, were stacked on top of one another and the joints then sealed. The modules contain flues for ventilation powered by a geothermal heat

使用预制材料来进行建造的项目数量也有了显著的增长:预制墙体可以快速地进行生产而不用考虑天气情况,这让工程进度的调整变得容易多了。此外,现在的成品运输也变得更容易了,这也有利于推广室内预制工艺。即使是采用本地材料来进行建造的需求也可以被满足,例如位于劳芬的草药中心项目使用的土就是基地本身的土方,生产预制品的工厂距离工地还不到3km。对这种大型项目来说,在当地直接设工厂往往更为经济,既可以利用当地的材料,也能减少运输的距离。

机械预制

正如上文所说,夯土建筑的预制领域基本是片处女地,为了发展预制的工艺、进一步提高其生产效率,也应需求出现了一些新的发明。在工艺上的改进主要体现在减少生产部件所需的人力。而人力劳动中最艰苦的部分就是用原材料填满模具并把填料压实。

为此,马丁发明了一台机器,专门用来把土自动分配到模具里,再用一个运动的锤子来夯实它(图1)。这一工作还是需要不少人力来参与,但这个送料机已经能完成其中的大部分工作了。因为已经不需要让一个人来站在模具里面夯土,这种机器也能用来直接生产比较薄的墙体。此外,也能使用比较长的模具,通过一片片地连续堆叠水平土层来生产整面墙体,之后根据需要的尺寸把墙体切割开,再在现场按同一顺序安装起来。

悬挂和运输

因为夯土部件的抗拉能力很弱,就像没法从两头提起没有加固过的土一样,在安装过程中,底面上的受力必须要非常均匀。对于较为轻薄的部件,通过加设木梁和几条捆带能帮助分散重量。但是对更大和更重的部件来说,就需要订制开发专业的机械运输系统,以便在放置它时实现3个维度上的同时调整。为了从下方托住部件,冲压制造墙体的第一层时在墙底加装了由圆形的管道和钢筋构成的阶梯状构件。安装时在管道下面铺设锚杆,再用两个钢片把它安装到吊升用的齿轮上去(图2)。采用这样的辅助工艺的缺点是在部件安装完后,金属件会露出来一部分。为了减少工艺的复杂性,也减少材料的浪费,这种钢质构件现在已经用木楔来代替了。木楔在制造墙体时先嵌入其中,脱模时则可以拆除掉。这样,楔子形成的孔洞就可以让吊装用的捆带直接绑在部件上了。

墙体部件通过每隔60cm的捆带固定到梁上,体块和梁间的绳索系统能帮助荷载分布均匀,之后再通过两个吊链让墙体竖立起来(图3)。

安装过程

墙体部件被放在由纯粘土砂浆构成的约1cm厚的垫层上。部件之间利用自身重量通过摩擦粘合,上部的部件会嵌入到砂浆中去。连接面四周的粘土砂浆必须涌出来,这样才能保证砂浆包裹住了整个面。在部件正确地放置到砂浆上了之后,要用木楔子把它的位置固定住。在砂浆干燥之后,整个部件的重量会传导到下部的部件上。因为夯土不能承受拉力,这一步骤对于夯土部件来说比对钢筋混凝土部件重要得多。

各个部件之间的连接件和节点都会在装配时或者完工之后再次封实。然而准备的工作在生产部件的时候就开始了:各个面的垂直角和水平的向上面上都已经切开了槽口,在装配完工之后,这些槽口以最小1cm左右的间隙被填入石灰砂浆。因为石灰比土硬,并且和土的形变特性不同,要先在槽的底部垫一层软粘土。当石灰块变硬并且发生形变之后,就会胀开到软土的位置上。

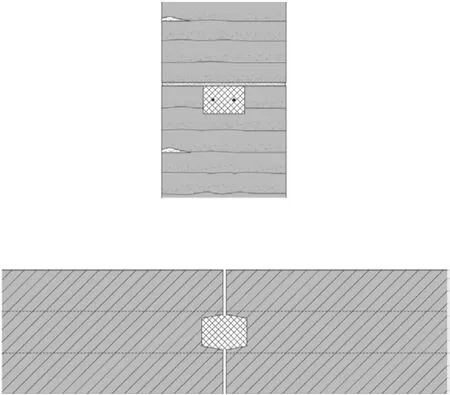

3 部件间用石灰砂浆进行接合。钢筋在结构上水平放置。水平剖面(上图)与1:20竖向剖面(下图)/The elements are joined with trass-lime mortar. Rebar is laid into the structure horizontally. Horizontal section (above) and vertical section (below) at 1:20 scale.

部件之间的水平连接则是通过在水平的凹槽上放置两个相连的钢构件,再用石灰砂浆嵌入构件中完成的。这相当于在现场浇筑的夯土墙中使用的圈梁的效果。因为构件要伸入两侧的墙体的凹槽大约15cm,45cm宽的墙中构件外的部分就只有15cm,35cm宽的墙则只有5cm了。凹槽嵌入的深度大约为6cm。

如果夯土墙不是承重墙的话,它需要通过背面连接到建筑的结构体系中。可以通过在水平方向抹灰浆来连接墙体部件,再用一个包含钢筋的Z字型托架来把墙装配到建筑结构中去。因为土墙的变形较大,托架需要形成一种具有活动性的连接。因为使用了铁质的垫片,结构体系和土墙立面都可以保持各自原来的保温性。

最后,在完成了部件之间的定位和连接之后,还要小心地接合好接缝部分,让墙面的纹理能保持整体上的节奏感。预制技术只有在完善了这一修饰工艺之后才能说真正地实现了技术突破,因为这意味着夯土墙视觉上的复古效果可以通过高效的建造方法来实现了(图5-10)。

绝缘元素

4 相关工艺的最新发展:绝缘预制部件。这种工艺能造出两面都有夯土图案的土墙立面/The most recent step in development: insulated prefabricated elements. These make it possible to create an earth facade where the ramming pattern is visible on both sides.

到目前为止,还只有单层的墙能够被预制。但为了生产中空墙而做的初步实验已经在进行了,这种墙体会在两片夯土墙之间夹一层轻质的绝缘层。这样,墙的两面就都能够保持外观的美感和土墙的物理特性了,还有一个另外的好处就是能在中空层里面装配进制冷或制热的管道。□collector: the earth walls function like hypocausts, capitalizing on their haptic properties while creating a comfortable indoor climate.

It took three months to finish the 160 pieces required for the Gugler project - these were then put in place over the course of a mere two weeks. The most recent projects completed with prefabricated elements are the Kräuterzentrum in Laufen and the Swiss Ornithological Institute's visitor center in Sempach. due to improved workflow and increased production speed compared to the 1990s, the current ratio of production to installation in prefabricated parts is approximately 3:1.

The number of projects constructed with prefabricated materials has grown significantly: walls can be produced efficiently regardless of weather conditions and schedules are simpler to coordinate. In addition, transportation of commodities has become much easier - which also favours an indoor fabrication process. Even the demand for building with local materials can be fulfilled; for example, the elements of the Ricola Kräuterzentrum were made of earth from an area in the vicinity of the building site. The distance from the production hall to the construction site was less than 3km. For large projects, it is often expedient to set up the production facilities locally, in order to utilize regional materials while decreasing transportation distances.

Mechanical Prefabrication

Since, as we mentioned above, this is largely a virgin territory, in order to develop prefabrication and further improve its efficiency, several new inventions have been required. Progress has primarily targeted at a reduction in the amount of physical labor required. The most strenuous task is filling the formwork with the material and compacting the mixture.

A machine was therefore developed to address this particular challenge by automatically distributing the earth within the formwork and mechanically compacting it with a moving rammer (fig.1). There is still a good deal of manual labor involved but a major part of it can be accomplished by this feeder mechanism. The machine also allows for the production of thinner walls, since the process no longer requires a person to be able to stand inside the form boards to ram the material. Long formworks enable the production of entire walls in a single segment with continuous horizontal layering. Afterwards, the elements can be cut to the appropriate size and installed in the same order on the building site.

5-7 生产及安装过程示意/Schematic of production and installation process

8-10 生产及安装过程示意/Schematic of production and installation process (5-10 图片来源/Copyright: Ricola AG,摄影/Photos: Markus Bühler-Rasom)

Suspension and Transportation

Since the elements have very low tensile strength, forces must be evenly distributed along the lowest edge of the element during the installation process - blocks of unreinforced earth cannot be suspended from two points. With thinner and therefore lighter pieces, a wooden beam and several lifting straps suffice to distribute the weight. However, with larger and heavier elements, a specialized and custom-developed transport mechanism must be employed to allow adjustments on all three axes while setting the piece. To support the blocks from below, the first round of stamping includes a ladder-like structure made of round piping and iron rebar at the bottom. Anchor rods are then laid into these pipes and attached directly to the lifting gear with two steel plates (fig.2). The disadvantage of utilizing such an auxiliary construction is that it remains a part of the wall after placement. To reduce the complexity and avoid material waste, these steel constructions were replaced with wooden wedges, which could be stamped into the walls and driven through them after removing the formwork. As a result, the suspension straps can be attached directly through these gaps.

The straps attach the element to the lifting beam every 60 cm. The load is distributed through a system of cables between the block and the beams. The element is then aligned vertically onsite using two chain hoists (fig.3).

Installation Process

The element is placed on a bed of clay mortar approximately 1 cm thick, composed of the same materials. The friction-fit joining of the elements is actuated by their own weight, as the block embeds itself into the mortar. Clay must well out of the gap on all sides - this is the only way to ensure that the entire cavity has been filled. Once the block has been correctly placed on the mortar, its position is fixed with wooden wedges. After the mortar has dried, the entire load will bear down flat onto the element below. This is particularly important with rammed earth as compared with reinforced concrete, because

10 it cannot withstand tensile forces.

All the connections and joints between the individual elements are sealed during or just after the mounting process. However, preparation for this begins during production: a groove is notched into the vertical edges of the sides as well as the upwardfacing horizontal aspect. After the elements have been set, with a minimum gap of 1cm, the vertical grooves are filled with trass-lime mortar. Since these columns of trass-lime are stiffer than the earth and have different movement characteristics, the bottom of the groove is pitched with a trowel of soft clay. When the columns harden and then deform, they can expand into the softer clay.

The elements are horizontally connected by placing two contiguous iron rebar pieces in the horizontal grooves and embed them with trass-lime mortar. This functions similarly to the use of a ring beam for in situ rammed walls. Since there must be approximately 15cm covering the groove on both sides of the wall, it can be 15 cm wide in a 45cm thick wall, whereas a 35cm wall leaves only 5cm to play with. The groove is milled to a depth of about 6cm.

If the earth wall is not load bearing, it must be attached to the structural system on its inner façade. Reinforcing the horizontal grouting in between the elements is well suited to this purpose. A Z-shaped bracket enclosing the rebar can be used to friction-fit the element to the building’s loadbearing structure. Due to the relatively strong creep deformation exhibited by earth, it should be executed as a movable connection. Due to the use of iron spacers, the structural system and the façade retain their separate thermal envelopes.

Finally, after positioning and joining the elements, the seams are meticulously sealed and integrated into the rhythm of the striation. The breakthrough in prefabrication has only truly occurred since perfecting this retouching method, as this meant that the optical and archaic qualities of rammed earth could then be combined with an efficient fabrication process (fig.5-10).

Insulated Elements

So far, only single-leaf walls have been prefabricated. Preliminary tests for the production of cavity-wall modules have been conducted, in which a lightweight earth insulation layer is sandwiched between two rammed earth wythes. They can thus retain their aesthetic appearance and technical properties on both sides. As an additional benefit, the middle segment can be outfitted with heating and cooling conduits.□

编注/Editor's Note

i 德语Lehm Ton Erde (Loam Clay Earth) Baukunst GmbH译为壤土-粘土-泥土建筑艺术股份有限公司

Prefabrication

Marko Sauer

Translated by SIMA Lei

作家、建筑评论家

2016-09-09