碱金属氯化物二元熔盐密度的分子动力学模拟研究

2017-01-18路贵民于建国

王 佳, 孙 泽, 路贵民, 于建国

(华东理工大学资源与环境工程学院,上海 200237)

碱金属氯化物二元熔盐密度的分子动力学模拟研究

王 佳, 孙 泽, 路贵民, 于建国

(华东理工大学资源与环境工程学院,上海 200237)

采用分子动力学模拟方法,计算了LiCl-NaCl、LiCl-KCl、LiCl-RbCl、LiCl-CsCl、NaCl-KCl、NaCl-RbCl以及NaCl-CsCl等碱金属氯化物二元混合熔盐在不同温度和不同组分下的密度,证实了添加LiCl能够降低NaCl、KCl、RbCl以及CsCl熔盐的密度,添加NaCl则仅能够降低RbCl和CsCl熔盐的密度,而增大KCl熔盐的密度。随着温度的逐渐升高,各混合熔盐的密度逐渐减小。根据不同温度、不同组分下的密度数据,拟合得出了各混合熔盐的密度关于温度和组分含量的表达式。

碱金属氯化物二元混合熔盐; 密度; 分子动力学模拟

熔盐在工业生产中具有广泛的应用,如熔盐反应堆[1]、核反应中的冷却剂[2]、金属生产中或电沉积中的电解质[3]以及传热蓄热介质[4]等。密度是熔盐体系的一大重要性质,制约着熔盐的实际应用。在电解法生产金属工艺过程中,金属产物以及槽渣与电解质熔盐之间的分离效果受电解质熔盐的密度影响,在实际生产中常常会添加某种助剂来调整和改善电解质熔盐的密度。

碱金属氯化物熔盐是一类简单的熔盐,对该体系的研究比较广泛,但是还不够全面深入。有关碱金属氯化物纯熔盐的密度,已经有了较为丰富的实验数据[5],但关于碱金属氯化物二元混合熔盐密度的研究则相对比较离散,仅有少数的几个体系在特定的温度和组分下有相关的数据报道[5]。系统地研究碱金属氯化物二元混合熔盐的密度具有十分重要的理论价值和实际意义。

密度的实验测定通常采用阿基米德法[6],由于熔盐的腐蚀性以及高温实验的难操作性,测定各温度、各组分下熔盐的密度成本较高,因而较难实现。采用计算机模拟技术计算熔盐的密度,成本低,操作简便,还能实现任意温度、任意组分下熔盐密度的计算。本文采用分子动力学方法计算了不同温度、不同组分下LiCl-NaCl、LiCl-KCl、LiCl-RbCl、LiCl-CsCl、NaCl-KCl、NaCl-RbCl与NaCl-CsCl等碱金属氯化物二元混合熔盐的密度,以完善碱金属氯化物熔盐密度数据库,同时满足工程实际应用的需求。

1 计算方法

采用Fumi-Tosi势函数[7]来描述离子之间的相互作用,前期研究表明,Fumi-Tosi势函数可以准确地预测碱金属氯化物体系熔盐的密度[8-9]。Fumi-Tosi势函数的具体形式如下:

(1)

采用开源软件LAMMPS进行分子动力学计算。计算元胞取为立方体,粒子数取1 024个,其中阴离子为512个,阳离子数目则按物质的量之比分配,初始结构为粒子随机分布。粒子的初始速度设置为随机分布,并符合高斯分布。为了消除边界效应,计算采用周期性边界条件。势函数的截断半径设为L/2,其中L为体系弛豫平衡后模拟盒子的长度。为了消除截断误差,采用Ewald求和法处理长程作用力,即截断半径以内的作用力直接计算,而截断半径以外的作用力则在倒易空间内进行计算,Ewald求和法的计算精度设为1.0×10-6。用Verlet算法数值求解牛顿运动方程,时间步长设为1 fs。

体系首先在等温等压(NPT)系综下平衡弛豫104步,采用Nose-Hoover控温法和控压法,恒温和恒压参数均设置为0.1 ps。待体系达到平衡后,在NPT系综下进行计算,计算时间为5×105步,收集不同时刻下体系的体积信息,以计算体系的密度:

(2)

其中n是某种碱金属氯化物“分子”的数目,M为分子的摩尔质量,VE为模拟体系的平衡体积,NA为阿伏伽德罗常数,其值为6.02×1023。

对所有的碱金属氯化物二元混合熔盐而言,密度计算的温度范围选取为近熔点处至1 500 K,计算间隔为20 K,计算温度的下限根据体系的平衡相图确定,组分质量分数为0~100%,计算间隔为6.25%。

2 结果与讨论

2.1 LiCl-NaCl混合熔盐

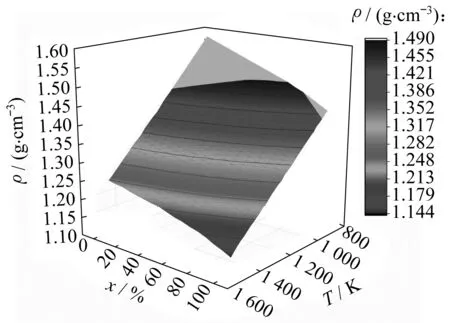

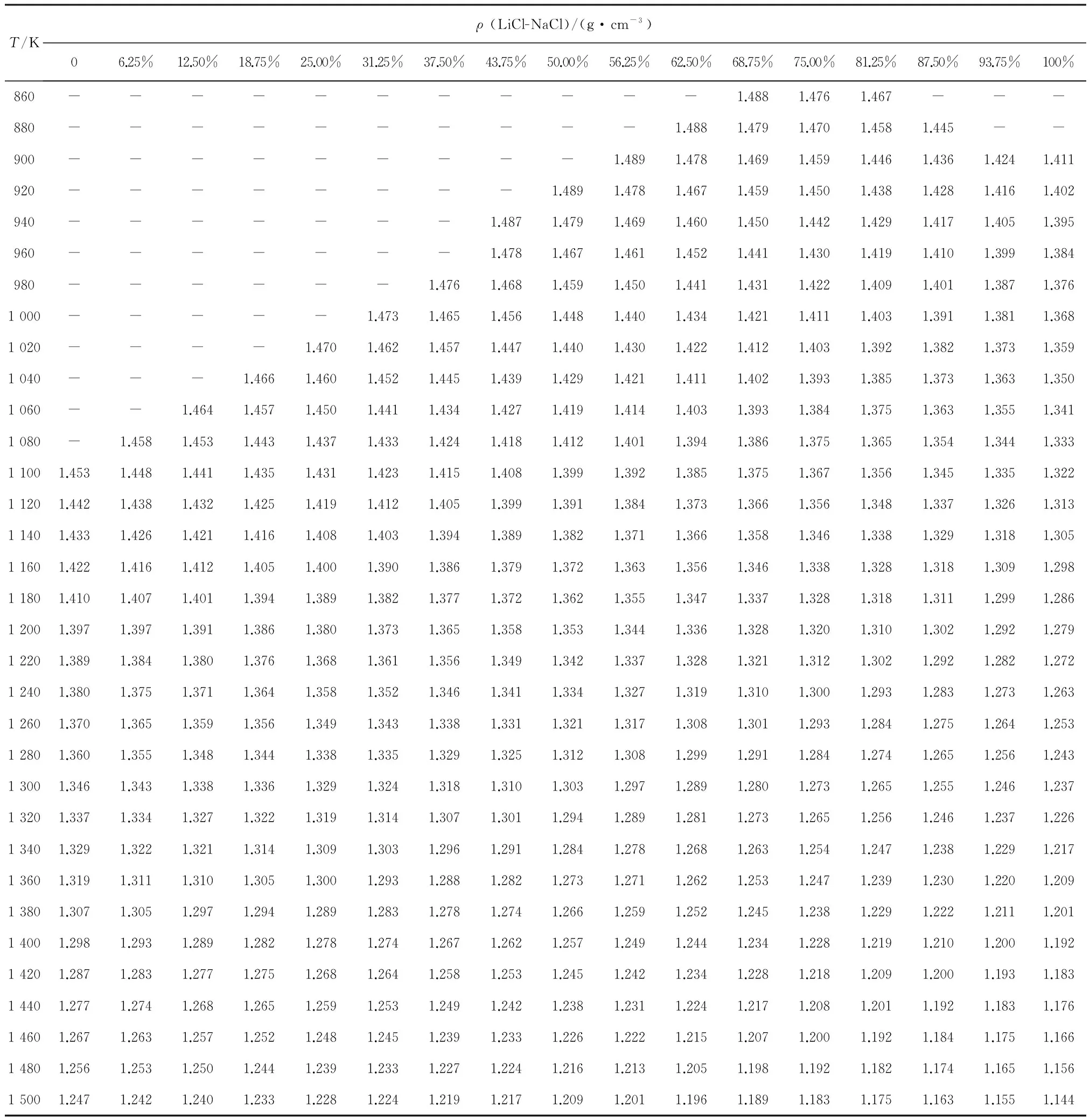

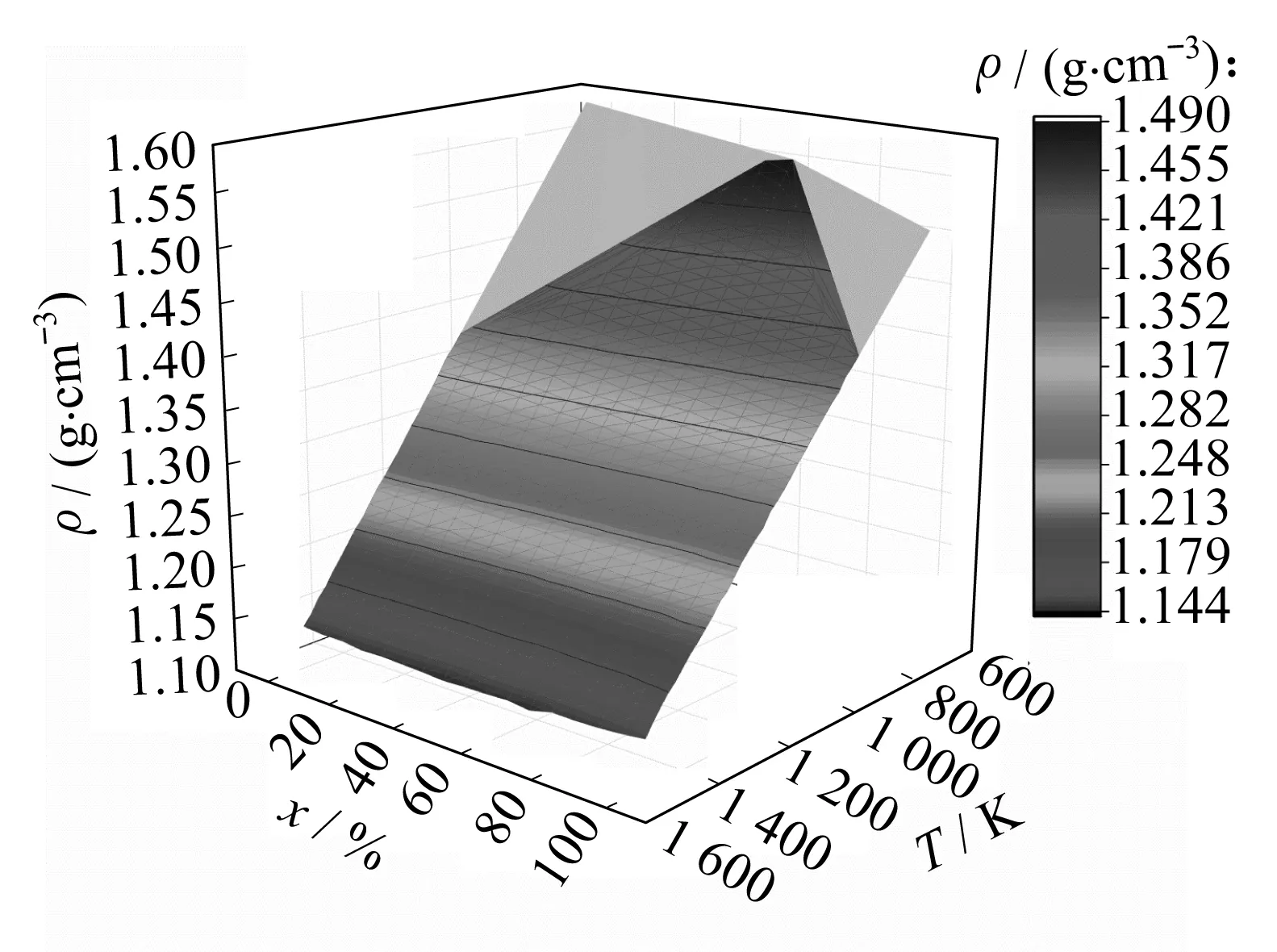

不同温度、不同组分下LiCl-NaCl混合熔盐的密度-温度-组分关系如图1所示。随着LiCl摩尔分数(x)的增加或者温度的升高,LiCl-NaCl熔盐的密度逐渐降低。不同温度、不同组分下LiCl-NaCl混合熔盐的密度值见表1。根据LiCl-NaCl混合熔盐在不同温度、不同组分下的密度,初始假设密度与温度以及组分的一次项和二次项相关,拟合得到LiCl-NaCl熔盐的密度表达式为:

ρ(LiCl-NaCl)=1.907 5-3.797 5×10-4T-

5.662 1×10-4x-3.841 3×10-8T2-

5.866 8×10-6x2

(3)

式中:T表示温度,单位为K;x为LiCl的摩尔分数。由式(3)可以看出,温度和组分的二次项在密度表达式中所占的比重很小,故舍弃二次项重新进行拟合,得到LiCl-NaCl熔盐在860~1 500 K以及相应组分范围内密度的表达式为:

ρ(LiCl-NaCl)=1.976 3-4.751 3×10-4T-

1.178 5×10-3x

(4)

图1 不同温度下LiCl-NaCl混合熔盐的密度Fig.1 Densities of molten LiCl-NaCl at different temperatures表1 不同温度下LiCl-NaCl混合熔盐的密度Table 1 Densities of molten LiCl-NaCl at different temperatures

T/Kρ(LiCl-NaCl)/(g·cm-3)06.25%12.50%18.75%25.00%31.25%37.50%43.75%50.00%56.25%62.50%68.75%75.00%81.25%87.50%93.75%100%860-----------1.4881.4761.467---880----------1.4881.4791.4701.4581.445--900---------1.4891.4781.4691.4591.4461.4361.4241.411920--------1.4891.4781.4671.4591.4501.4381.4281.4161.402940-------1.4871.4791.4691.4601.4501.4421.4291.4171.4051.395960-------1.4781.4671.4611.4521.4411.4301.4191.4101.3991.384980------1.4761.4681.4591.4501.4411.4311.4221.4091.4011.3871.3761000-----1.4731.4651.4561.4481.4401.4341.4211.4111.4031.3911.3811.3681020----1.4701.4621.4571.4471.4401.4301.4221.4121.4031.3921.3821.3731.3591040---1.4661.4601.4521.4451.4391.4291.4211.4111.4021.3931.3851.3731.3631.3501060--1.4641.4571.4501.4411.4341.4271.4191.4141.4031.3931.3841.3751.3631.3551.3411080-1.4581.4531.4431.4371.4331.4241.4181.4121.4011.3941.3861.3751.3651.3541.3441.33311001.4531.4481.4411.4351.4311.4231.4151.4081.3991.3921.3851.3751.3671.3561.3451.3351.32211201.4421.4381.4321.4251.4191.4121.4051.3991.3911.3841.3731.3661.3561.3481.3371.3261.31311401.4331.4261.4211.4161.4081.4031.3941.3891.3821.3711.3661.3581.3461.3381.3291.3181.30511601.4221.4161.4121.4051.4001.3901.3861.3791.3721.3631.3561.3461.3381.3281.3181.3091.29811801.4101.4071.4011.3941.3891.3821.3771.3721.3621.3551.3471.3371.3281.3181.3111.2991.28612001.3971.3971.3911.3861.3801.3731.3651.3581.3531.3441.3361.3281.3201.3101.3021.2921.27912201.3891.3841.3801.3761.3681.3611.3561.3491.3421.3371.3281.3211.3121.3021.2921.2821.27212401.3801.3751.3711.3641.3581.3521.3461.3411.3341.3271.3191.3101.3001.2931.2831.2731.26312601.3701.3651.3591.3561.3491.3431.3381.3311.3211.3171.3081.3011.2931.2841.2751.2641.25312801.3601.3551.3481.3441.3381.3351.3291.3251.3121.3081.2991.2911.2841.2741.2651.2561.24313001.3461.3431.3381.3361.3291.3241.3181.3101.3031.2971.2891.2801.2731.2651.2551.2461.23713201.3371.3341.3271.3221.3191.3141.3071.3011.2941.2891.2811.2731.2651.2561.2461.2371.22613401.3291.3221.3211.3141.3091.3031.2961.2911.2841.2781.2681.2631.2541.2471.2381.2291.21713601.3191.3111.3101.3051.3001.2931.2881.2821.2731.2711.2621.2531.2471.2391.2301.2201.20913801.3071.3051.2971.2941.2891.2831.2781.2741.2661.2591.2521.2451.2381.2291.2221.2111.20114001.2981.2931.2891.2821.2781.2741.2671.2621.2571.2491.2441.2341.2281.2191.2101.2001.19214201.2871.2831.2771.2751.2681.2641.2581.2531.2451.2421.2341.2281.2181.2091.2001.1931.18314401.2771.2741.2681.2651.2591.2531.2491.2421.2381.2311.2241.2171.2081.2011.1921.1831.17614601.2671.2631.2571.2521.2481.2451.2391.2331.2261.2221.2151.2071.2001.1921.1841.1751.16614801.2561.2531.2501.2441.2391.2331.2271.2241.2161.2131.2051.1981.1921.1821.1741.1651.15615001.2471.2421.2401.2331.2281.2241.2191.2171.2091.2011.1961.1891.1831.1751.1631.1551.144

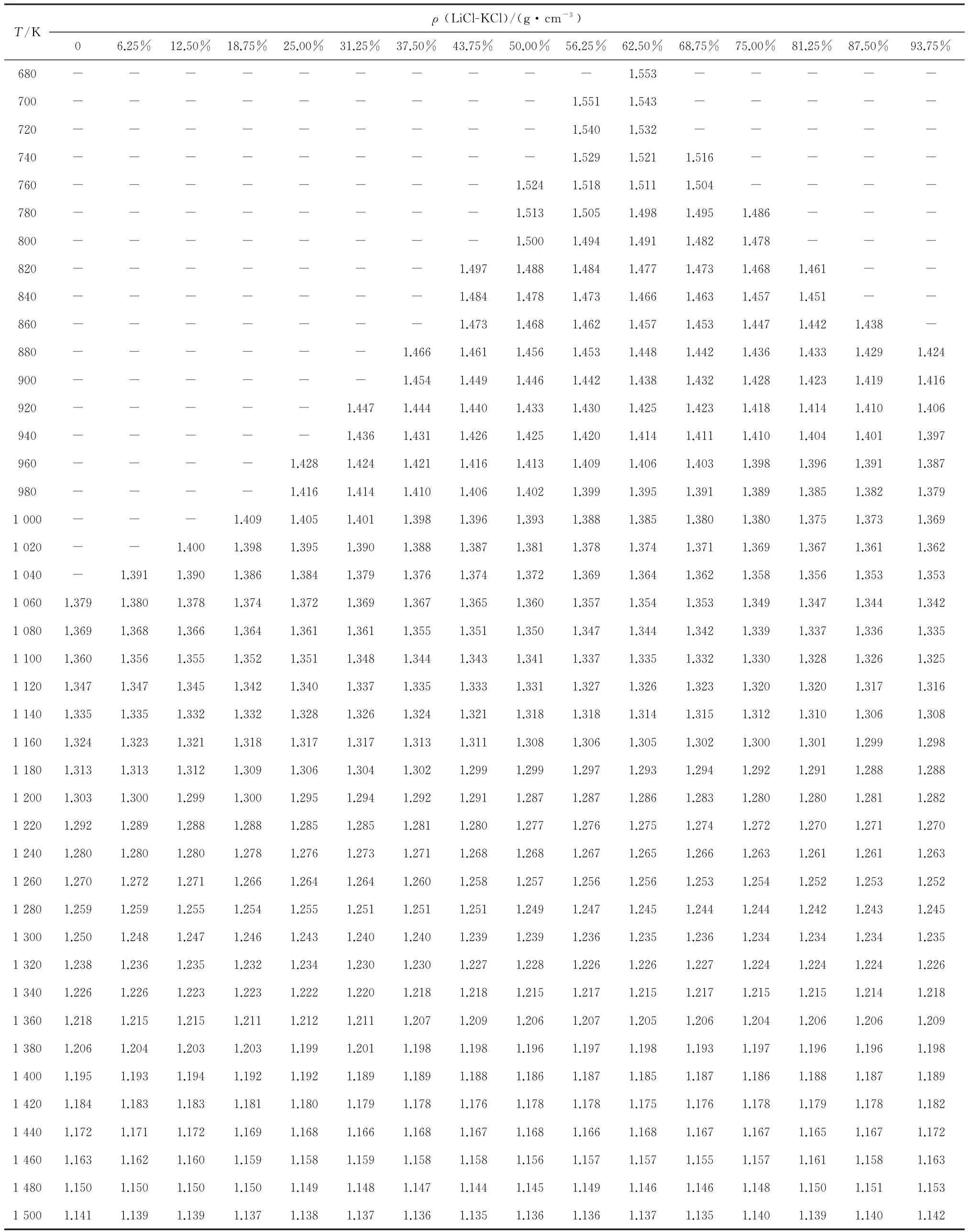

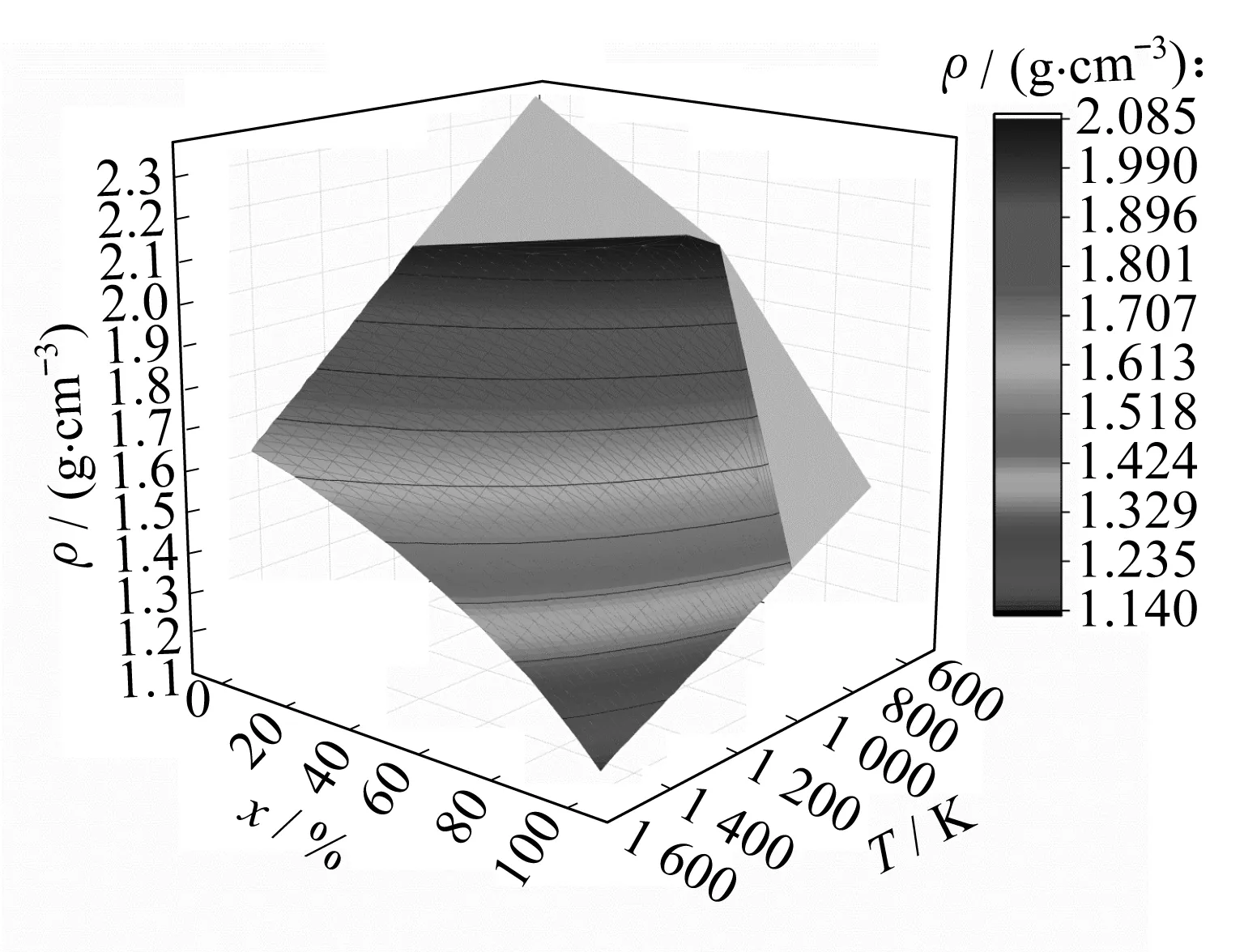

2.2 LiCl-KCl混合熔盐

不同温度、不同组分下LiCl-KCl混合熔盐的温度-组分-密度关系如图2所示,具体的密度值见表2。随着LiCl摩尔分数的增加或者温度的升高,LiCl-KCl熔盐的密度逐渐减小。根据LiCl-KCl混合熔盐在不同温度、不同组分下的密度值,初步拟合得到LiCl-KCl熔盐密度的表达式为:

ρ(LiCl-KCl)=1.915 1-5.213 7×10-4T-

2.231 9×10-4x+8.127 3×10-9T2-

2.347 5×10-7x2

(5)

图2 不同温度下LiCl-KCl混合熔盐的密度Fig.2 Densities of molten LiCl-KCl at different temperatures表2 不同温度下LiCl-KCl混合熔盐的密度Table 2 Densities of molten LiCl-KCl at different temperatures

T/Kρ(LiCl-KCl)/(g·cm-3)06.25%12.50%18.75%25.00%31.25%37.50%43.75%50.00%56.25%62.50%68.75%75.00%81.25%87.50%93.75%680----------1.553-----700---------1.5511.543-----720---------1.5401.532-----740---------1.5291.5211.516----760--------1.5241.5181.5111.504----780--------1.5131.5051.4981.4951.486---800--------1.5001.4941.4911.4821.478---820-------1.4971.4881.4841.4771.4731.4681.461--840-------1.4841.4781.4731.4661.4631.4571.451--860-------1.4731.4681.4621.4571.4531.4471.4421.438-880------1.4661.4611.4561.4531.4481.4421.4361.4331.4291.424900------1.4541.4491.4461.4421.4381.4321.4281.4231.4191.416920-----1.4471.4441.4401.4331.4301.4251.4231.4181.4141.4101.406940-----1.4361.4311.4261.4251.4201.4141.4111.4101.4041.4011.397960----1.4281.4241.4211.4161.4131.4091.4061.4031.3981.3961.3911.387980----1.4161.4141.4101.4061.4021.3991.3951.3911.3891.3851.3821.3791000---1.4091.4051.4011.3981.3961.3931.3881.3851.3801.3801.3751.3731.3691020--1.4001.3981.3951.3901.3881.3871.3811.3781.3741.3711.3691.3671.3611.3621040-1.3911.3901.3861.3841.3791.3761.3741.3721.3691.3641.3621.3581.3561.3531.35310601.3791.3801.3781.3741.3721.3691.3671.3651.3601.3571.3541.3531.3491.3471.3441.34210801.3691.3681.3661.3641.3611.3611.3551.3511.3501.3471.3441.3421.3391.3371.3361.33511001.3601.3561.3551.3521.3511.3481.3441.3431.3411.3371.3351.3321.3301.3281.3261.32511201.3471.3471.3451.3421.3401.3371.3351.3331.3311.3271.3261.3231.3201.3201.3171.31611401.3351.3351.3321.3321.3281.3261.3241.3211.3181.3181.3141.3151.3121.3101.3061.30811601.3241.3231.3211.3181.3171.3171.3131.3111.3081.3061.3051.3021.3001.3011.2991.29811801.3131.3131.3121.3091.3061.3041.3021.2991.2991.2971.2931.2941.2921.2911.2881.28812001.3031.3001.2991.3001.2951.2941.2921.2911.2871.2871.2861.2831.2801.2801.2811.28212201.2921.2891.2881.2881.2851.2851.2811.2801.2771.2761.2751.2741.2721.2701.2711.27012401.2801.2801.2801.2781.2761.2731.2711.2681.2681.2671.2651.2661.2631.2611.2611.26312601.2701.2721.2711.2661.2641.2641.2601.2581.2571.2561.2561.2531.2541.2521.2531.25212801.2591.2591.2551.2541.2551.2511.2511.2511.2491.2471.2451.2441.2441.2421.2431.24513001.2501.2481.2471.2461.2431.2401.2401.2391.2391.2361.2351.2361.2341.2341.2341.23513201.2381.2361.2351.2321.2341.2301.2301.2271.2281.2261.2261.2271.2241.2241.2241.22613401.2261.2261.2231.2231.2221.2201.2181.2181.2151.2171.2151.2171.2151.2151.2141.21813601.2181.2151.2151.2111.2121.2111.2071.2091.2061.2071.2051.2061.2041.2061.2061.20913801.2061.2041.2031.2031.1991.2011.1981.1981.1961.1971.1981.1931.1971.1961.1961.19814001.1951.1931.1941.1921.1921.1891.1891.1881.1861.1871.1851.1871.1861.1881.1871.18914201.1841.1831.1831.1811.1801.1791.1781.1761.1781.1781.1751.1761.1781.1791.1781.18214401.1721.1711.1721.1691.1681.1661.1681.1671.1681.1661.1681.1671.1671.1651.1671.17214601.1631.1621.1601.1591.1581.1591.1581.1581.1561.1571.1571.1551.1571.1611.1581.16314801.1501.1501.1501.1501.1491.1481.1471.1441.1451.1491.1461.1461.1481.1501.1511.15315001.1411.1391.1391.1371.1381.1371.1361.1351.1361.1361.1371.1351.1401.1391.1401.142

由式(5)可以看出,温度和组分的二次项在密度表达式中所占的比重很小,故舍弃二次项重新进行拟合,得到LiCl-KCl熔盐在680~1 500 K温度区间以及相应组分范围内的密度的表达式为:

ρ(LiCl-KCl)=1.905 3-5.028 3×10-4T-

2.465 4×10-4x

(6)

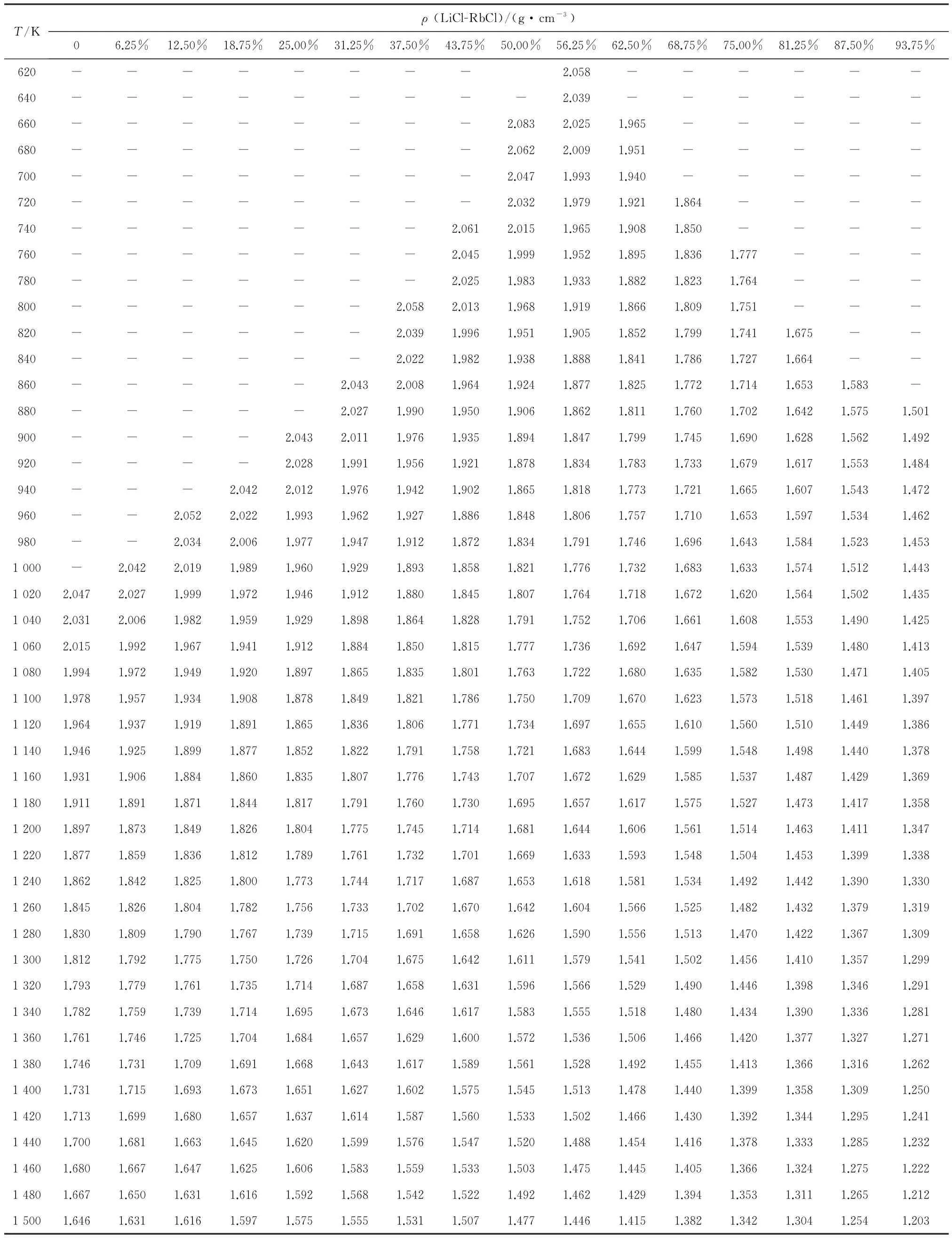

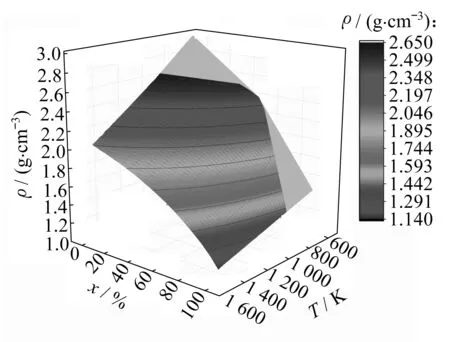

2.3 LiCl-RbCl混合熔盐

不同温度不同组分下LiCl-RbCl混合熔盐的温度-组分-密度关系如图3所示,具体的密度值见表3。

表3 不同温度下LiCl-RbCl混合熔盐的密度Table 3 Densities of molten LiCl-RbCl at different temperatures

图3 不同温度下LiCl-RbCl混合熔盐的密度Fig.3 Densities of molten LiCl-RbCl at different temperatures

随着LiCl摩尔分数的增加或温度的升高,体系的密度逐渐减小。根据计算结果,初步拟合得到LiCl-RbCl熔盐密度的表达式为:

ρ(LiCl-RbCl)=2.723 6-7.474 8×10-4T-

1.851 4×10-3x+3.691 4×10-8T2-

4.122 2×10-5x2

(7)

由式(7)可以看出,温度的二次项在密度表达式中所占的比重很小,故舍弃温度的二次项,增加组分的三次项,重新进行拟合,得到的表达式为:

ρ(LiCl-RbCl)=2.680 3-6.634 0×10-4T-

2.291 2×10-3x-2.949 3×10-5x2-

7.998 7×10-8x3

(8)

由式(8)则可以看出,组分的三次项所占的比重也很小,故舍弃组分的三次项,再次拟合,得到LiCl-RbCl混合熔盐在620~1 500 K温度区间以及相应组分范围内密度的表达式为:

ρ(LiCl-RbCl)=2.677 1-6.638 1×10-4T-

1.808 2×10-3x-4.161 9×10-5x2

(9)

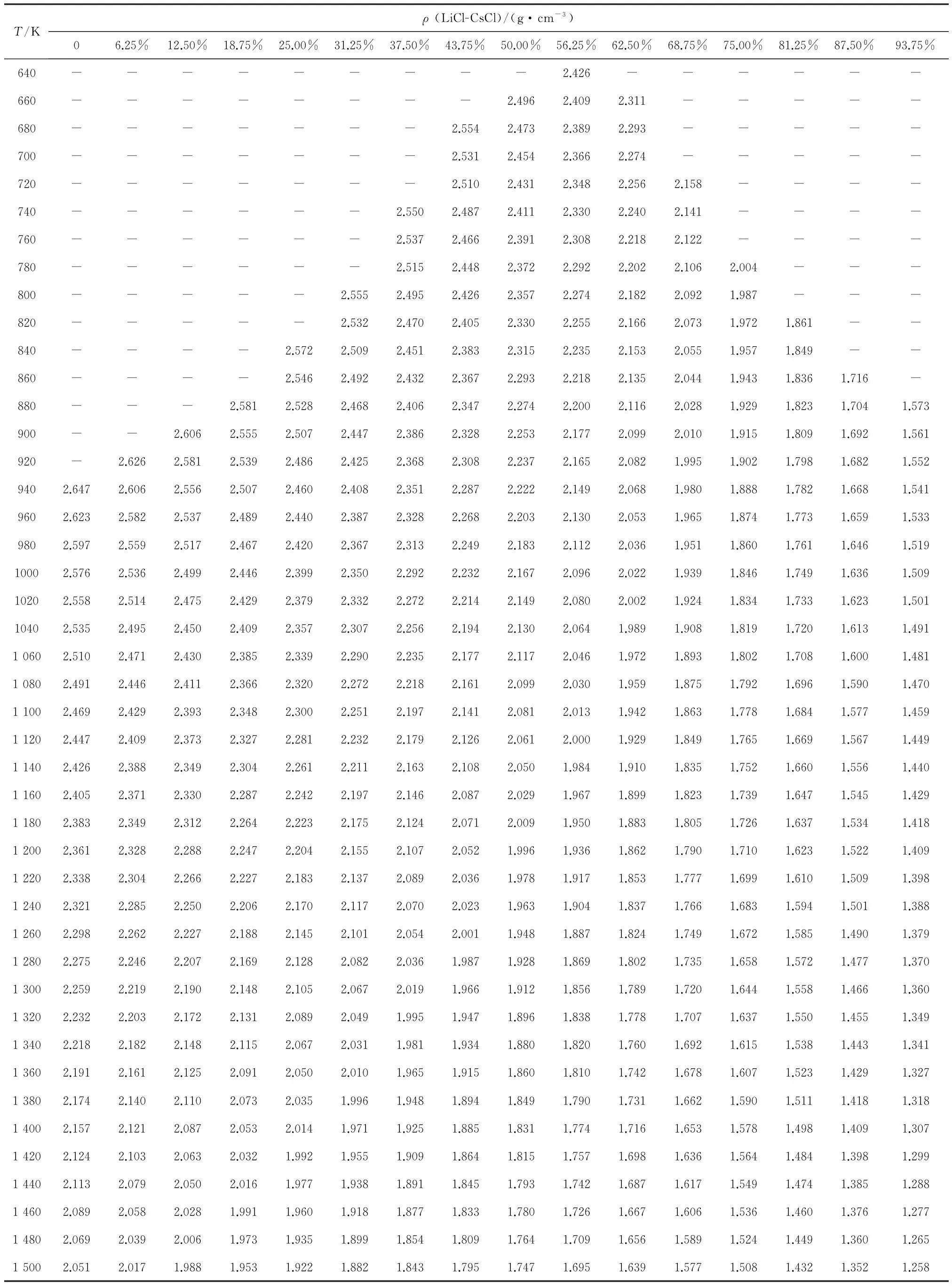

2.4 LiCl-CsCl混合熔盐

计算得到不同温度、不同组分下LiCl-CsCl混合熔盐的密度,其温度-组分-密度关系如图4所示,具体的密度值见表4。

图4 不同温度下LiCl-CsCl混合熔盐的密度Fig.4 Densities of molten LiCl-CsCl at different temperatures

由图4可以看出,随着LiCl摩尔分数的增加或者温度的升高,LiCl-CsCl熔盐的密度逐渐减小。此外,还可以看到,与LiCl-NaCl和LiCl-KCl等熔盐不同,LiCl-CsCl混合熔盐的温度-组分-密度关系图明显呈曲面,说明该混合熔盐的密度与温度或者组分的高次项相关。根据LiCl-CsCl混合熔盐在不同温度、不同组分下的密度,初步拟合得到LiCl-CsCl熔盐密度的表达式为:

ρ(LiCl-CsCl)=3.461 2-1.056 0×10-3T-

3.226 2×10-3x+1.028 9×10-7T2-

7.246 0×10-5x2

(10)

由式(10)可以看出,温度的二次项在密度表达式中所占的比重很小,故舍弃温度的二次项,同时增加组分的三次项,重新进行拟合得到的表达式为:

ρ(LiCl-CsCl)=3.345 4-8.226 3×10-4T-

4.961 5×10-3x-2.645 2×10-5x2-

3.132 8×10-7x3

(11)

由式(11)则可以看出,组分的三次项所占的比重也很小,故舍弃组分的三次项,再次拟合得到LiCl-CsCl混合熔盐在640~1 500 K温度区间以及相应组分范围内密度的表达式为:

ρ(LiCl-CsCl)=3.332 7-8.236 1×10-4T-

3.105 3×10-3x-7.360 9×10-5x2

(12)

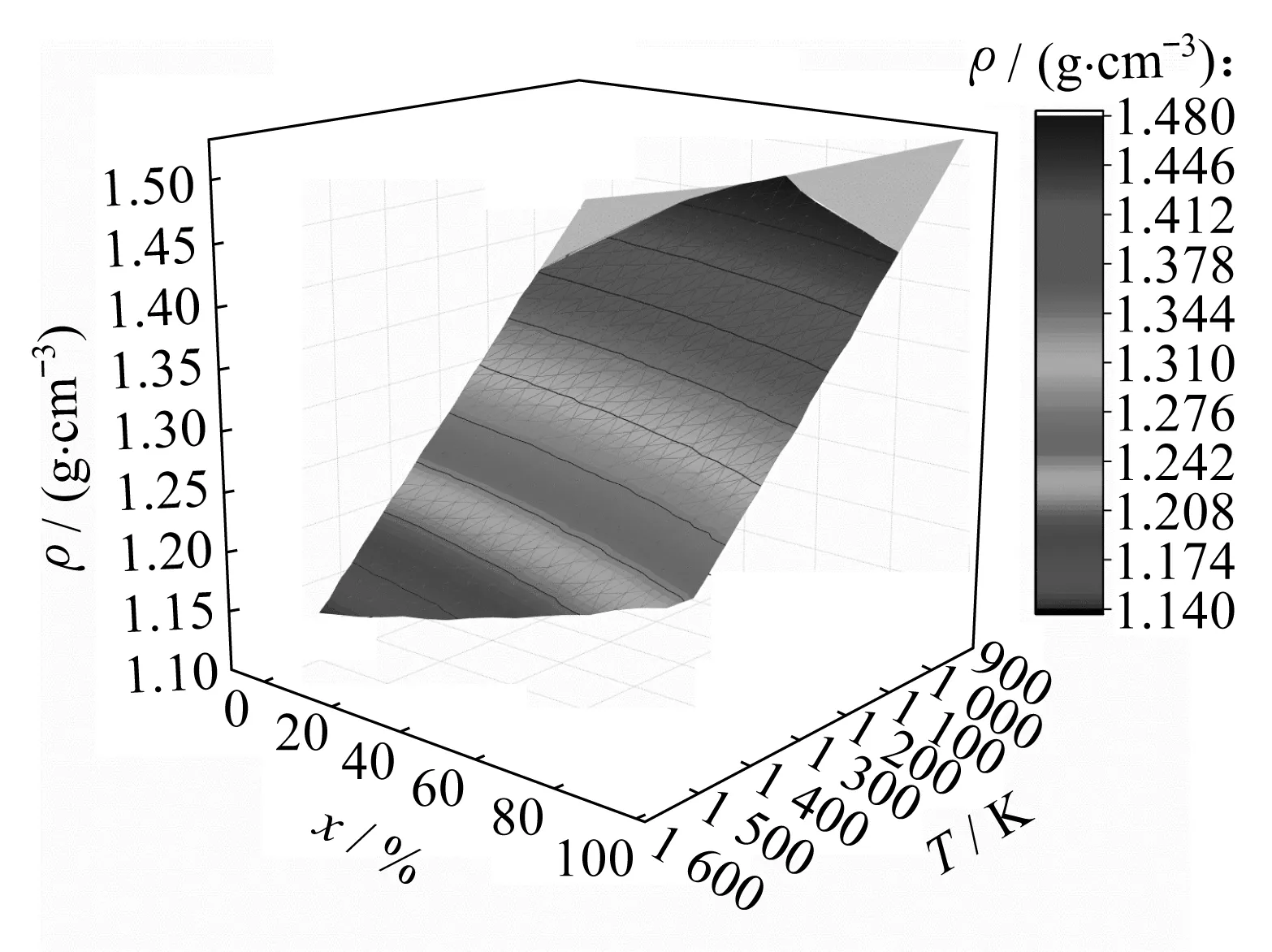

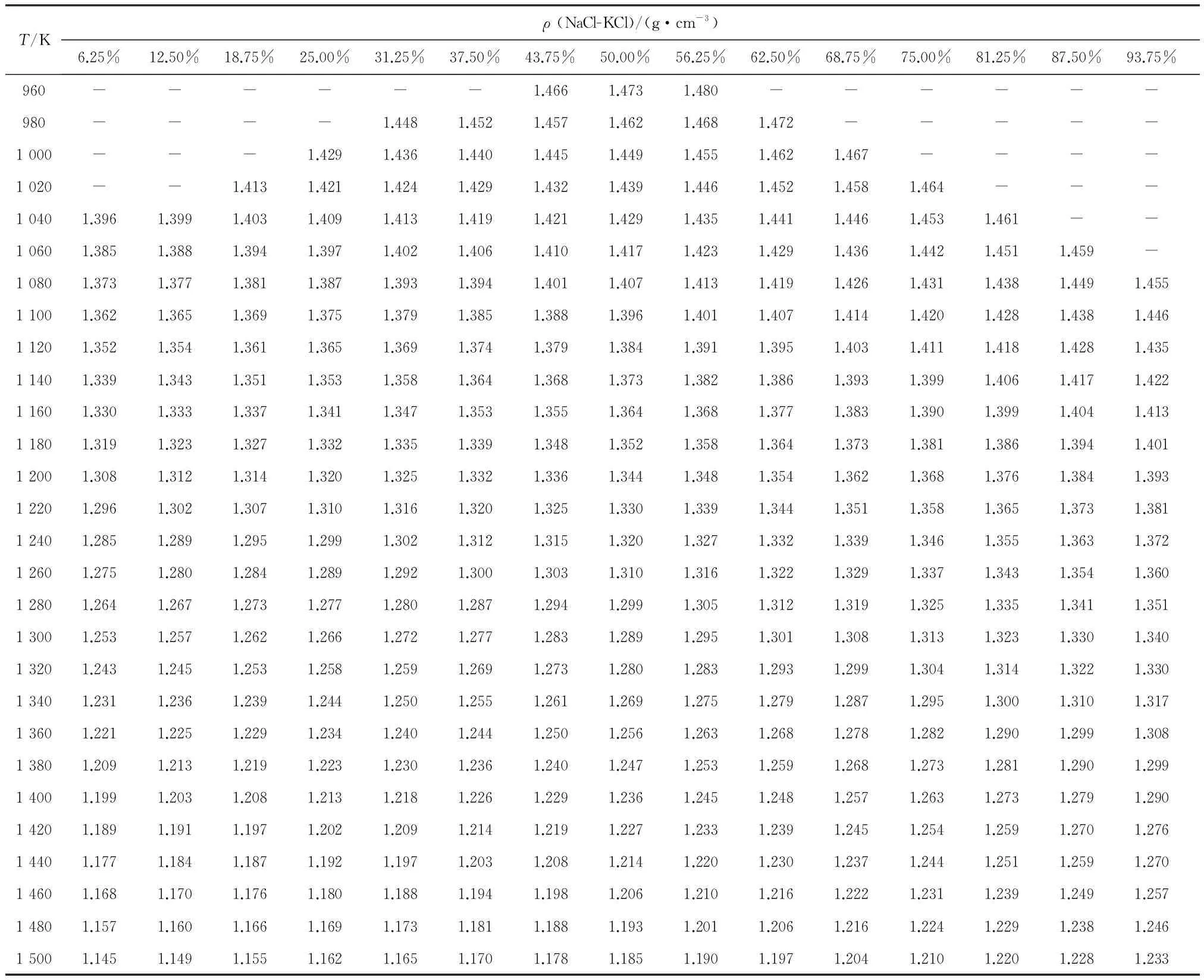

2.5 NaCl-KCl混合熔盐

不同温度、不同组分下NaCl-KCl混合熔盐的温度-组分-密度关系如图5所示,其详细密度值见表5。

图5 不同温度下NaCl-KCl混合熔盐的密度Fig.5 Densities of molten NaCl-KCl at different temperatures

随着NaCl摩尔分数的降低或者温度的升高,NaCl-KCl熔盐的密度逐渐减小。根据计算结果初步拟合得到NaCl-KCl熔盐密度的表达式为:

ρ(NaCl-KCl)=1.990 7-6.097 3×10-4T+

5.797 0×10-4x+3.035 5×10-8T2+

4.038 5×10-6x2

(13)

表4 不同温度下LiCl-CsCl混合熔盐的密度Table 4 Densities of molten LiCl-CsCl at different temperatures

表5 不同温度下NaCl-KCl混合熔盐的密度Table 5 Densities of molten NaCl-KCl at different temperatures

其中,x为NaCl的摩尔分数。由式(13)可以看出,温度和组分的二次项在密度表达式中所占的比重均很小,故舍弃二次项,重新进行拟合,得到NaCl-KCl混合熔盐在960~1 500 K温度区间以及相应组分范围内密度的表达式为:

ρ(NaCl-KCl)=1.933 7-5.307 8×10-4T+

9.796 7×10-4x

(14)

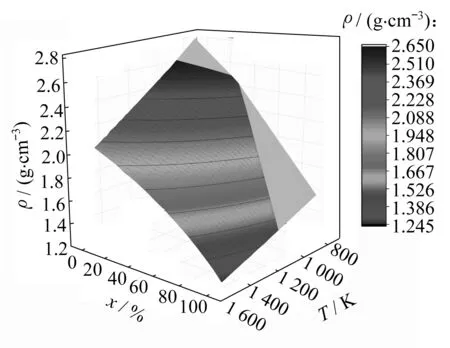

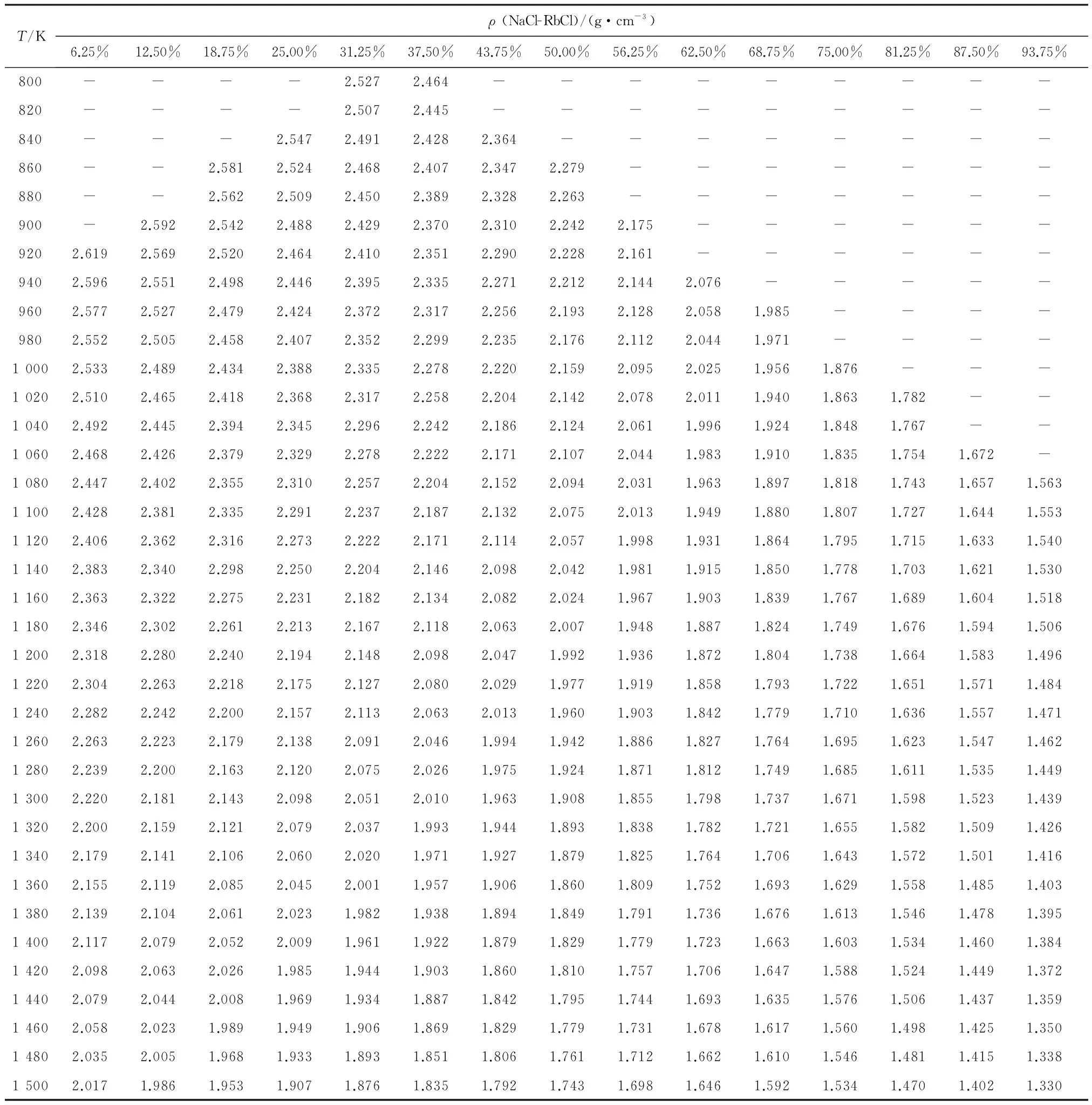

2.6 NaCl-RbCl混合熔盐

不同温度、不同组分下NaCl-RbCl混合熔盐的温度-组分-密度关系如图6所示,详细的密度值见表6。随着NaCl摩尔分数的增加或者温度的升高,NaCl-RbCl混合熔盐的密度逐渐降低。根据NaCl-RbCl混合熔盐在不同温度、不同组分下的密度,初步拟合得到NaCl-RbCl熔盐的密度表达式为:

ρ(NaCl-RbCl)=2.903 1-9.890 0×10-4T-

3.094 8×10-3x+1.178 8×10-7T2-

1.582 4×10-5x2

(15)

图6 不同温度下NaCl-RbCl混合熔盐的密度Fig.6 Densities of molten NaCl-RbCl at different temperatures

由式(15)可以看出,温度的二次项在密度表达式中所占的比重均很小,故舍弃温度的二次项,同时添加组分的三次项,重新进行拟合,得到的密度表达式为:

ρ(NaCl-RbCl)=2.729 5-7.009 6×10-4T-

由式(16)可以看出,组分的三次项在密度表达式中所占的比重也很小,故舍弃组分的三次项,再次拟合,得到NaCl-RbCl混合熔盐在860~1 500 K温度区间以及相应组分范围内密度的表达式为:

ρ(NaCl-RbCl)=2.729 7-7.009 7×10-4T-

3.037 3×10-3x-1.646 9×10-5x2

(17)表6 不同温度下NaCl-RbCl混合熔盐的密度Table 6 Densities of molten NaCl-RbCl at different temperatures

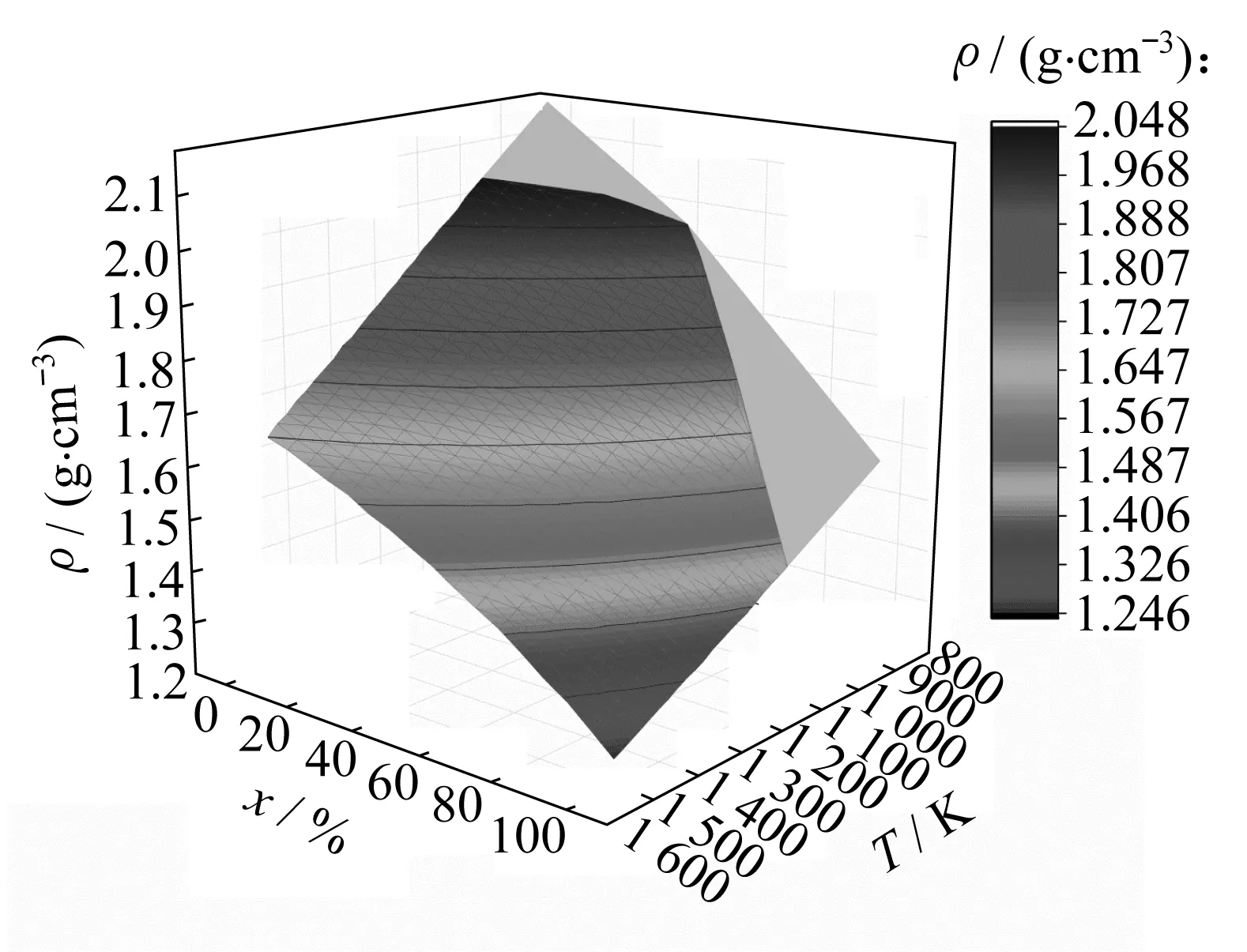

2.7 NaCl-CsCl混合熔盐

不同温度、不同组分下NaCl-CsCl熔盐的温度-组分-密度关系如图7所示,详细的密度值见表7。随着NaCl摩尔分数的增加或者温度的升高,NaCl-CsCl熔盐的密度降低。此外,与LiCl-CsCl相似,NaCl-CsCl混合熔盐的温度-组分-密度关系图明显呈曲面,说明该混合熔盐的密度与温度或者组分的高次项相关。根据密度数据初步拟合得到NaCl-CsCl熔盐的密度表达式为:

ρ(NaCl-CsCl)=3.744 8-1.460 3×10-3T-

5.465 6×10-3x+2.481 1×10-7T2-

3.634 1×10-5x2

(18)

由式(18)可以看出,温度的二次项在密度表达式中所占的比重均很小,故舍弃温度的二次项,同时添加组分的三次项,重新进行拟合,得到的密度表达式为:

ρ(NaCl-CsCl)=3.403 0-8.679 9×10-4T-

5.910 2×10-3x-2.357 5×10-5x2-

9.469 3×10-8x3

(19)

图7 不同温度下NaCl-CsCl混合熔盐的密度Fig.7 Densities of molten NaCl-CsCl at different temperatures表7 不同温度下NaCl-CsCl混合熔盐的密度Table 7 Densities of molten NaCl-CsCl at different temperatures

T/Kρ(NaCl-RbCl)/(g·cm-3)6.25%12.50%18.75%25.00%31.25%37.50%43.75%50.00%56.25%62.50%68.75%75.00%81.25%87.50%93.75%800----2.5272.464---------820----2.5072.445---------840---2.5472.4912.4282.364--------860--2.5812.5242.4682.4072.3472.279-------880--2.5622.5092.4502.3892.3282.263-------900-2.5922.5422.4882.4292.3702.3102.2422.175------9202.6192.5692.5202.4642.4102.3512.2902.2282.161------9402.5962.5512.4982.4462.3952.3352.2712.2122.1442.076-----9602.5772.5272.4792.4242.3722.3172.2562.1932.1282.0581.985----9802.5522.5052.4582.4072.3522.2992.2352.1762.1122.0441.971----10002.5332.4892.4342.3882.3352.2782.2202.1592.0952.0251.9561.876---10202.5102.4652.4182.3682.3172.2582.2042.1422.0782.0111.9401.8631.782--10402.4922.4452.3942.3452.2962.2422.1862.1242.0611.9961.9241.8481.767--10602.4682.4262.3792.3292.2782.2222.1712.1072.0441.9831.9101.8351.7541.672-10802.4472.4022.3552.3102.2572.2042.1522.0942.0311.9631.8971.8181.7431.6571.56311002.4282.3812.3352.2912.2372.1872.1322.0752.0131.9491.8801.8071.7271.6441.55311202.4062.3622.3162.2732.2222.1712.1142.0571.9981.9311.8641.7951.7151.6331.54011402.3832.3402.2982.2502.2042.1462.0982.0421.9811.9151.8501.7781.7031.6211.53011602.3632.3222.2752.2312.1822.1342.0822.0241.9671.9031.8391.7671.6891.6041.51811802.3462.3022.2612.2132.1672.1182.0632.0071.9481.8871.8241.7491.6761.5941.50612002.3182.2802.2402.1942.1482.0982.0471.9921.9361.8721.8041.7381.6641.5831.49612202.3042.2632.2182.1752.1272.0802.0291.9771.9191.8581.7931.7221.6511.5711.48412402.2822.2422.2002.1572.1132.0632.0131.9601.9031.8421.7791.7101.6361.5571.47112602.2632.2232.1792.1382.0912.0461.9941.9421.8861.8271.7641.6951.6231.5471.46212802.2392.2002.1632.1202.0752.0261.9751.9241.8711.8121.7491.6851.6111.5351.44913002.2202.1812.1432.0982.0512.0101.9631.9081.8551.7981.7371.6711.5981.5231.43913202.2002.1592.1212.0792.0371.9931.9441.8931.8381.7821.7211.6551.5821.5091.42613402.1792.1412.1062.0602.0201.9711.9271.8791.8251.7641.7061.6431.5721.5011.41613602.1552.1192.0852.0452.0011.9571.9061.8601.8091.7521.6931.6291.5581.4851.40313802.1392.1042.0612.0231.9821.9381.8941.8491.7911.7361.6761.6131.5461.4781.39514002.1172.0792.0522.0091.9611.9221.8791.8291.7791.7231.6631.6031.5341.4601.38414202.0982.0632.0261.9851.9441.9031.8601.8101.7571.7061.6471.5881.5241.4491.37214402.0792.0442.0081.9691.9341.8871.8421.7951.7441.6931.6351.5761.5061.4371.35914602.0582.0231.9891.9491.9061.8691.8291.7791.7311.6781.6171.5601.4981.4251.35014802.0352.0051.9681.9331.8931.8511.8061.7611.7121.6621.6101.5461.4811.4151.33815002.0171.9861.9531.9071.8761.8351.7921.7431.6981.6461.5921.5341.4701.4021.330

由式(19)可以看出,组分的三次项在密度表达式中所占的比重也很小,故舍弃组分的三次项,再次拟合,得到NaCl-CsCl混合熔盐在800~1 500 K温度区间以及相应组分范围内密度的表达式为:

ρ(NaCl-CsCl)=3.398 3-8.672 8×10-4T-

5.377 3×10-3x-3.754 9×10-5x2

(20)

碱金属氯化物二元混合熔盐的密度随着组分的变化关系与其微观结构的变化密切相关。以LiCl-NaCl为例,前期研究表明[9],随着LiCl摩尔分数的增加,混合熔盐中Na-Cl和Na-Na离子对之间的相互作用逐渐减弱,离子趋向于分散分布,因而LiCl-NaCl体系的宏观密度逐渐降低。对于NaCl-KCl体系而言,随着NaCl摩尔分数的增加,熔盐中离子对之间的相互作用亦逐渐减弱,但程度轻微,而离子间的紧密堆积度逐渐增大,即原子的排列更加趋于紧凑,因此体系的密度逐渐增大。

3 结 论

本文采用分子动力学方法,计算了不同温度、不同组分下LiCl-NaCl、LiCl-KCl、LiCl-RbCl、LiCl-CsCl、NaCl-KCl、NaCl-RbCl以及NaCl-CsCl等碱金属氯化物二元混合熔盐体系的密度,同时根据计算结果,拟合得到了LiCl-NaCl、LiCl-KCl、LiCl-RbCl、LiCl-CsCl、NaCl-KCl、NaCl-RbCl以及NaCl-CsCl等体系熔盐的密度表达式。计算结果表明,随着温度的逐渐升高,各混合熔盐的密度逐渐减小;随着LiCl摩尔分数的增加,LiCl-NaCl,LiCl-KCl,LiCl-RbCl和LiCl-CsCl等混合熔盐的密度逐渐下降;随着NaCl摩尔分数的增加,NaCl-KCl熔盐的密度逐渐增大,而NaCl-RbCl和NaCl-CsCl体系熔盐的密度逐渐减小。

[1] BRUN C L.Molten salts and nuclear energy production [J].Journal of Nuclear Materials,2007,360(1):1-5.

[2] WALDROP M M.Nuclear energy:Radical reactors [J].Nature,2012,492(7427):26-34.

[3] GROULT H,BARHOUN A,BRIOT E,etal.Electrode-position of Zr on graphite in molten fluorides [J].Journal of Fluorine Chemistry,2011,132(12):1122-1126.

[4] BRADWELL D J,KIM H,SIRK A H,etal.Magnesium-antimony liquid metal battery for stationary energy storage [J].Journal of the American Chemical Society,2012,134(4):1895-1901.

[5] JANZ G J,TOMKINS R P T,Allen C B,etal.Molten salts:Chlorides and mixtures-electrical conductance,density,viscosity,and surface tension data [J].Journal of Physical and Chemical Reference Data,1975,4(4):871-1178.

[6] KUBIKOVA B,DANIELIK V,ROBERT E,etal.Phase equilibrium and density investigation of the molten LiCl + NaCl + ZnCl2system [J].Journal of Chemical and Engineering Data,2014,59(8):2408-2412.

[7] SANGSTER M J L,DIXON M.Interionic potentials in alkali halides and their use in simulations of the molten salts [J].Advances in Physics,1976,25(3):247-342.

[8] WANG Jia,SUN Ze,LU Guimin,etal.Molecular dynamics simulations of the local structures and transport coefficients of molten alkali chlorides [J].The Journal of Physical Chemistry B,2014,118:10196-10206.

[9] WANG Jia,WU Jie,SUN Ze,etal.Molecular dynamics study of the transport properties and local structures of molten binary systems (Li,Na)Cl,(Li,K)Cl and (Na,K)Cl[J].Journal of Molecular Liquids,2015,209:498-507.

[10] PAULING L.The sizes of ions and their influence on the properties of salt-like compounds [J].Zeitschrift fur Kristallographie-Crystalline Materials,1928,67(1):377-404.

[11] PAULING L.The influence of relative ionic sizes on the properties of ionic compounds [J].Journal of the American Chemical Society,1928,50(4):1036-1045.

Molecular Dynamics Simulation for the Densities of Molten Binary Alkali Metal Chlorides

WANG Jia, SUN Ze, LU Gui-min, YU Jian-guo

(School of Resources and Environmental Engineering,East China University of Science and Technology,Shanghai 200237,China)

The densities of molten LiCl-NaCl,LiCl-KCl,LiCl-RbCl,LiCl-CsCl,NaCl-KCl,NaCl-RbCl and NaCl-CsCl at different temperatures were calculated by molecular dynamics simulation within the full composition range.The addition of LiCl could reduce the densities of molten NaCl,KCl,RbCl and CsCl.NaCl could also reduce the densities of molten RbCl and CsCl,but increase the density of molten KCl.The densities of these mixtures all reduced with the increasing of temperature.In addition,the expression of density on temperatune and composition for these melts were fitted according to the calculated results.

molten binary alkali metal chlorides; densities; molecular dynamics simulation

1006-3080(2016)06-0771-11

10.14135/j.cnki.1006-3080.2016.06.005

2016-09-18

国家自然科学基金(U1407202)

王 佳(1989-),女,江苏人,博士生,主要从事氯化物熔盐的相关模拟计算。 E-mail:10072157@mail.ecust.edu.cn

路贵民,E-mail:gmlu@ecust.edu.cn

O552

A