乙醇浸渍对切片茄子干燥特性和品质的影响

2016-12-19赵海燕方小明巨浩羽张月敬陈兴付刘嫣红高振江肖红伟

赵海燕,方小明,王 军,巨浩羽,张月敬,陈兴付,张 茜,刘嫣红,高振江,肖红伟※

(1. 中国农业大学工学院,北京 100083;2. 中国农业科学院蜜蜂研究所100093;3. 石河子大学机械电气工程学院,石河子 832000)

乙醇浸渍对切片茄子干燥特性和品质的影响

赵海燕1,方小明2,王 军1,巨浩羽1,张月敬1,陈兴付1,张 茜3,刘嫣红1,高振江1,肖红伟1※

(1. 中国农业大学工学院,北京 100083;2. 中国农业科学院蜜蜂研究所100093;3. 石河子大学机械电气工程学院,石河子 832000)

为了提高切片茄子的干制品质、缩短干燥时间,对热风干燥前的切片茄子进行了乙醇浸渍处理。以不同干燥温度(45、55、65℃)、预处理乙醇体积分数(0、5%、15%)和茄子切片厚度(1.0、1.5、2.0 cm)为试验因素,以干燥时间及干燥后产品的干燥速率、色泽、复水比和微观结构为评价指标进行正交试验。试验结果表明:干燥温度、乙醇体积分数和切片厚度对干燥时间均有显著影响(P<0.05);综合评价的影响顺序由大到小依次为:切片厚度>干燥温度>乙醇体积分数;切片茄子的干燥过程属于降速干燥,通过费克第二定律得到切片茄子的水分有效扩散系数在2.74×10-9~7.75×10-9m2/s;切片厚度对干燥后茄子片的复水比有显著影响(P<0.05),复水比随着切片厚度的增加而减少;乙醇体积分数对干燥后茄子片的色泽具有显著影响(P<0.05),而且可以改变干燥后茄子的微观结构改善物料外观品质。当乙醇体积分数为15%、干燥温度为65℃、切片厚度为1.0 cm时,干燥时间为225 min,复水比为4.93,明亮度为88.24,既有较快的干燥速率又能够得到比较好的色泽。研究表明适宜体积分数的乙醇浸渍预处理能够提高切片茄子的干燥速率、改善色泽,为高品质切片茄子快速干燥提供了理论依据。

干燥;优化;品质控制;切片茄子;乙醇浸渍;复水比;色泽;微观结构

0 引言

茄子(eggplant)是茄科茄属一年生草本植物,是餐桌上常见的家常菜[1]。茄子营养丰富,具有防治高血压、冠心病、动脉硬化和出血性紫癜等功效[2]。茄子在全国各地广为种植,但由于新鲜茄子含水率较高、呼吸作用强,在采收后不耐储藏,货架期短。所以在茄子收获后,对其进行及时食用和加工处理是减少经济损失的重要方式。

干燥脱水是茄子加工的主要方式之一[3]。然而,干燥时间长、干燥后产品色泽差是切片茄子干燥中存在的主要问题。茄子中含有大量的过氧化物酶[4],切片茄子在空气中极易发生酶促褐变,导致干制品色泽差,影响其感官品质。同时,目前茄子干燥大多采用自然晾晒方式,干燥时间长,一般需要3~4 d,干燥过程中易受天气、灰尘、虫鸟、微生物等因素的影响,干燥品质差。Zhang 等[5]和Ertekin等[6]对茄子干燥特性和品质进行了相关研究,然而均未得到干燥速率快且品质较优的干燥茄子片。因此,提高切片茄子的干燥速率、改善干燥品质尤其是色泽势在必行。

干燥前的预处理是加快果蔬干燥速率、改善品质的重要工艺环节,如果处理不当,不但不能提高干燥速率,而且会造成营养成分的损失、有害物质的残留、不良化学反应的发生等[7-10]。常见的果蔬预处理方法包括烫漂、熏硫、乙醇溶液等化学物质浸渍[11-13]处理方式。研究表明,烫漂会极大改变物料的组织结构状态,进而改变物料的干燥速率[14-15],但是会造成一些水溶性色素、维生素、多糖等的严重流失和降解,甚至完全损失,这使干燥后产品的营养价值大打折扣[16-17]。熏硫可以达到护色、提高营养物质特别是维生素C的保留率,而且使用方便、成本低,但制成品中SO2残留是个不容忽视的问题[18-19]。

乙醇具有渗透快、易蒸发、无残留及对人体无害等优点,已有将其应用于果蔬预处理的报道[20-22]。结果发现,乙醇浸渍处理能够显著提高果蔬干燥速率、改善干燥后色泽的现象,这可能是因为乙醇的沸点比水低,易挥发,干燥时受热迅速气化,体积膨胀对于扩充物料内部孔隙结构促进水分迁移具有一定作用,较高的干燥温度又促进了其挥发,挥发过程中带走物料内部的部分自由水,达到了作用时间短,作用效率高的目的;另外乙醇气化后形成的惰性环境有助于物料隔绝氧气,降低了氧化反应发生的机率,有助于物料色泽的保持,起到了护色作用。然而,将乙醇浸渍处理应用于切片茄子的促干与护色是否可行,国内外尚无相关报道。

因此,为解决茄子干燥过程中存在的干燥时间长、色泽劣变等突出问题,本研究将乙醇浸渍处理应用于切片茄子的促干和护色。在前期单因素研究的基础上,结合热风干燥技术,研究了不同干燥温度(45、55、65℃)、乙醇预处理体积分数(0、5%、15%)和切片厚度(1.0、1.5、2.0 cm)对切片茄子干燥特性、色泽和复水比的影响,以期为茄子干燥加工新技术的研究开发提供理论依据。

1 材料与方法

1.1 试验装置及工作原理

基于温湿度控制的箱式热风干燥试验装置(中国农业大学工学院农产品加工技术与装备试验室自制)如图1所示。其主要由电加热管、干燥室、排湿风机、加湿湿帘、内循环风扇以及自动控制部分组成。当干燥室温度小于预设值时,电加热管工作当;干燥室温度大于预设值时,电加热管停止工作。干燥室相对湿度小于设定相对湿度范围值时,加湿电磁阀打开,湿帘对干燥室加湿;相对湿度大于设定相对湿度范围时,排湿离心风机打开,对干燥室排湿。

图1 温湿度控制内循环热风干燥机总体结构示意图Fig.1 Schematic diagram of hot air internal recycle dryer based on being controlled temperature and humidity

其他仪器设备:YP型电子天平(上海精科天平,0.1 g),FZQ-400/2D型真空包装机(北京市天月缘包装机械有限公司),DHG-9140A型电热恒温鼓风干燥箱(上海一恒科技有限公司);SMY-2000SF型色差仪;干燥器、培养皿、烧杯若干。

1.2 试验原料

试验所用原料是新鲜的紫色长茄子(品种:朗高),购于北京当地农贸市场,平均长度(20±1)cm,直径(4.5±0.5)cm,平均质量(190±5)g/个,平均湿基含水率94%(含水率用105℃、24 h烘干法测定)。试验前将紫色长茄放入聚乙烯袋内并置于(5±1)℃下保存。

1.3 试验方法

根据前期试验及相关文献[23-24]报道,选择干燥温度(45、55、65℃)、乙醇浸渍体积分数(0、5%、15%)、切片厚度(1.0、1.5、2.5 cm)3个因素,进行正交试验设计。浸渍过程中切片茄子完全没入乙醇溶液中,且浸渍时间均为5 min。将物料切成所需厚度的片状物料,按照试验方案,对茄子片定时称量,直至茄子片湿基含水率降低到6%时结束试验,取出冷却后装袋并密封保存。每组试验重复3次,取平均值作为结果。选择L9(33)正交表,各因素水平及试验设计见表1所示。

表1 正交试验因素水平设计Table 1 Factors and levels of orthogonal test L9(33)

1.4 试验参数的获取方法

茄子片热风干燥过程中的干燥曲线采用水分比MR (moisture ratio)随干燥时间的变化曲线。不同干燥时间茄子片的水分比[25-26](MR)计算方式如公式(1)所示

式中Mo为茄子片的初始干基含水率,g/g;Me为茄子片干燥到平衡时的干基含水率,g/g;Mt为茄子片干燥到t时刻的干基含水率,g/g。

由于茄子片的平衡干基含水率Me远小于Mo和Mt,公式(1)可以简化为如下公式[27-28]

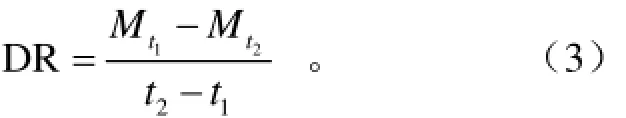

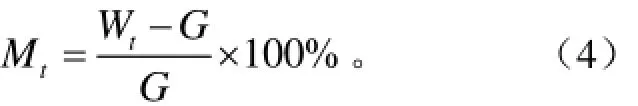

干燥速率(drying rate)[29]的计算采用如下公式:

式中DR为干燥过程中时间在t1和t2之间的茄子片干燥速率,g/(g·h);Mt1和Mt2为干燥过程中时间为t1和t2时茄子片的干基含水率,g/g。

干基含水率[30]Mt(moisture content on dry basis)计算采用下式

式中Wt为茄子片在干燥t时刻的总质量,g;G为茄子片干物质质量,g。

干燥过程中水分的扩散规律[31-33]可以用费克第二定律来描述。即

式中Deff为水分有效扩散系数,m2/s;L为茄子片的厚度,m;t为干燥时间,s。对公式(6)的两边取自然对数得到如下方程

因此可以画出lnMR关于t的关系曲线,通过线性回归计算出斜率k,就可以得出水分有效扩散系数。

1.5 复水比的测定方法

茄子干后的复水特性采用复水比RR(rehydration ratio)作为评价指标。复水试验的方法是:将5 g干燥后的茄子片置入200 mL温度为90℃的热水中,30 min后捞出用吸水纸吸干其表面水分并称量[34]。复水比RR采用公式(5)计算

式中RR为复水比;Ww为复水后茄子片的质量,g;Wd为复水前茄子片的质量,g。

1.6 色泽的测定方法

茄子干燥后去掉边缘的紫皮磨成粉,采用SMY-2000SF型色差仪,以仪器白板色泽和黑板色泽为标准,依据CIELAB表色系统测量茄子粉的明度值L。L*为明亮度,范围是0(黑色)~100(白色),L*越大,产品颜色越好。

1.7 微观结构的观测方法

茄子片干燥后,将干燥茄子片处理成3 mm×3 mm× 3 mm的小立方体样品,然后,样品首先被安装在磁控溅射仪(英国Quorum科技有限公司,SC7640)上,进行5 min喷金处理以固定组织结构,并在10 kV加速电压下对其表面组织微观结构用扫描电子显微镜(日本东京日立集团,S3400)进行观察[35-36]。重复观看不同区域的组织结构,并选择具有代表性图片进行保存与进一步分析。

1.8 综合评价方法

为使数据具有统一性,需对评价指标进行归一化。正向指标(复水率RR,明亮度L*)和负向指标(干燥时间t)归一化公式分别如下[30]

式中yi为归一值,xi为指标实际值,xmax和xmin分别为指标最大值和最小值。

由按照公式(14)进行加权得到干燥条件的综合评分Y[30]

式中y1、y2、y3分别为复水率、明亮度和干燥时间归一化后的结果,l1、l2、l3分别对应其权重。在保证干燥品质明亮度L*,复水比RR良好条件下,使得干燥时间t减小,采用层次分析方法[30],得出明亮度L*、复水比RR、干燥时间t的权重分别为0.35、0.35、0.30。

2 结果与分析

2.1 不同干燥条件对茄子片干燥特性的影响

茄子片在不同干燥条件下的干燥曲线以及正交试验结果极差分析表见图2和表2所示。由图2可知,茄子片的水分比随着干燥时间的增加而减少。这与南瓜片[37]、李子[38]干燥以及杏子[39]和胡萝卜丁[40]的干燥研究结果相一致。茄子片的湿基含水率从94%降低到6%的各干燥条件下的干燥时间如表2所示。从图2可以看出当干燥温度为45℃、预处理乙醇体积分数为5%、切片厚度为2.0 cm时所用的干燥时间最长,为660 min;而当切片厚度为1.0 cm,干燥温度为65℃、预处理乙醇体积分数为15%或干燥温度为55℃、预处理乙醇体积分数为5%时,所用的干燥时间最短,为225 min。

图2 茄子片不同干燥条件下的干燥动力学曲线Fig.2 Drying kinetic curves of eggplant slices under different drying conditions

由表2极差分析结果表明,在试验参数范围内,三个干燥因素对干燥时间影响的大小依次为切片厚度>干燥温度>乙醇预处理体积分数,干燥温度、乙醇体积分数和切片厚度对干燥时间均有显著影响(P<0.05)。对切片茄子进行乙醇预处理有利于提高切片茄子的干燥速率。这与Silva[20]在乙醇对水果干燥中的研究结论相一致。这是由于乙醇具有易挥发的特性,茄子经低浓度的乙醇浸渍后,在干燥时水分蒸发较快且带出茄子内部的部分自由水,提高了干燥速率;而茄子经高浓度的乙醇浸渍后,乙醇使茄子内部的营养成分产生变化,使其组织结构更加致密,在干燥过程中,阻碍了水分的迁移。

试验5和试验9的处理切片厚度一致,试验9的温度和乙醇浓度均比试验5高,但2个试验组干燥时间一致,这可能是因为高温促进了茄子内部的水分迁移,提高干燥速率[25],而高体积分数15%的乙醇又阻碍了水分的迁移,降低了干燥速率,造成2个试验组呈现出一致的干燥时间。在只考虑干燥时间的情况下,试验5和试验9的试验条件下干燥时间最短,为225 min。

表2 试验数据的正交分析Table 2 Experiment were analyzed by orthogonal design method

2.2 不同干燥条件对茄子片干燥后复水特性的影响

由极差分析结果可知,3个因素对复水比的影响顺序为:预处理乙醇体积分数>切片厚度>干燥温度。茄子切片厚度对干燥茄子片的复水比影响显著(P<0.05),随厚度增加,干燥后茄子片的复水比减少。这可能是由于茄子的组织结构特殊,厚度越厚收缩越小。温度和预处理乙醇浓度对茄子片的复水比影响不显著(P>0.05),然而,适当的温度和适宜的预处理乙醇浓度会改善干燥茄子片的复水特性。这可能是由于较大切片厚度会使茄子片失水不至于过快,避免了表面的结壳现象。温度升高复水比降低可能是由于高温导致茄子片快速失水导致表面硬化结壳,致使组织内部孔道皱缩[41]。适宜的预处理乙醇浓度可以改善干燥后茄子片的复水比可能是由于乙醇预处理强化了茄子片内部的微观结构,使其不至于干燥过程发生孔道坍塌等变化,而浓度过高又会破坏水分迁移孔道。这与Corrêa和Braga对香蕉[22]干燥和Braga对菠萝[42]干燥的研究结论一致。

2.3 不同干燥条件对茄子片色泽变化的影响

由表2正交试验的极差分析可知,3个因素对明亮度影响顺序为预处理切片厚度>乙醇体积分数>干燥温度;乙醇体积分数对干燥后茄子片的色泽有显著影响(P<0.05)。茄子干燥过程中色泽的改变反映了其褐变的程度[6],这可能是由于茄子中的糖分在干燥过程中发生美拉德反应所导致的[5]。而乙醇处理对其色泽起到改善作用,可能是因为乙醇气化后形成的惰性环境有助于物料隔绝氧气,降低了氧化反应发生的几率,有助于物料色泽的保持。这与Silva[20]在研究乙醇预处理对果蔬干燥的影响的结论一致,Correa和Braga[22]研究也发现乙醇处理可以改善菠萝干制品的色泽。

2.4 不同干燥条件下对茄子片综合评分的影响

由表2极差分析可知,3个因素对干燥后茄子片的综合评分的影响顺序为:切片厚度>干燥温度>预处理乙醇体积分数。最佳干燥工艺为切片厚度为1.0 cm,干燥温度为65 ℃,预处理乙醇浓度为15%,验证试验表明此条件下,干燥时间t为225 min,复水比RR为4.93,明亮度L*为88.24。

2.5 茄子片在不同干燥条件下的有效扩散系数

由图3可知,茄子在干燥过程中没有恒速干燥段,整个干燥过程属于降速干燥。这说明,茄子片的干燥过程是由内部水分扩散控制的[41]。不同干燥条件下的水分有效扩散系数Deff计算结果如表3所示。

图3 茄子片在不同干燥条件下的干燥速率曲线Fig.3 Drying rate curves of eggplant slices under different drying conditions

表3 线性回归拟合公式和水分有效扩散系数Table 3 Linear regression formulas and effective moisture diffusion coefficients of eggplant slices

由表3可以看出,茄子片的水分有效扩散系数范围在(2.74~7.75)×10-9m2/s。由表2极差分析结果可知,切片厚度的极差值最大,因此,切片厚度是影响茄子片干燥的主要决定因素,可以得到水分有效扩散系数随切片厚度的增加整体呈增加趋势。这可能是因为切片越厚,水分的迁移路径增加导致的结果[38]。

2.6 茄子片在不同干燥条件下的微观结构

不同干燥条件下干燥茄子切片的表面组织结构如图4所示。从图4中可以看出,乙醇处理的茄子切片干燥后其微观结构出现较多蜂窝状结构;温度较高时,干燥后茄子切片表面的蜂窝状结构更多且微孔直径也增大。这可能是因为乙醇处理后,茄子内部组织中的水分由于乙醇与水的替换而且乙醇易挥发,干燥时受热迅速气化,体积膨胀,使物料内部孔隙结构扩充,而使茄子内部组织的微孔变大[20];而干燥温度较高时,切片茄子表面由于快速失水而结壳硬化,随着干燥的进行物料温度逐渐升高物料内外的蒸汽压力梯度也逐渐增大,当茄子切片内部水分的蒸汽压力大于其组织的结合应力时,就会将原来的组织破坏而产生新的结构致使其组织微孔增大。这一结论与之前的研究有相似之处。同时,进一步佐证了经高温处理的干制茄子片复水比低的特性。Deng和Zhao[43]认为干燥过程中物料不同组织结构的温度梯度、压力梯度、溶质浓度梯度以及化学反应(如淀粉糊化或凝胶)均可破坏物料的组织结构。Musielak[44]研究发现干燥失水会导致组织结构变形,引起局部应力,当应力积累到超过组织结构之间的结合力时,组织就会被撕裂或产生变形,尤其是干燥速度较快时比较明显。

图4 不同干燥条件下茄子的微观结构Fig.4 Microstructure of eggplant under different drying conditions

3 结论

1)茄子切片厚度、干燥温度、预处理乙醇体积分数3个因素对干燥时间的影响顺序由大到小依次为:切片厚度>干燥温度>预处理乙醇体积分数;对复水比的影响顺序为:预处理乙醇体积分数>切片厚度>干燥温度;对明亮度影响顺序为:切片厚度>预处理乙醇体积分数>干燥温度。

2)综合考虑各指标因素,温度为65℃,预处理乙醇体积分数为15%时,切片厚度为1.0 cm时,干燥茄子片的干燥时间为225 min,复水比RR为4.93,明亮度为88.24,其干燥速率较高、品质较好。

3)茄子片干燥属于降速干燥,可以通过费克第二定律得出茄子片的水分有效扩散系数范围在(2.74~7.75)×10-9m2/s。

4)乙醇处理对干燥后茄子片的微观结构有较大影响,将乙醇用于干燥前的预处理可以改善干后物料的外观品质。

[1] Gramazio P, Prohens J, Plazas M, et al. Location of chlorogenic acid biosynthesis pathway and polyphenol oxidasegenes in a new interspecific anchored linkage map of eggplant[J]. BMC PlantBiology, 2014, 14(1): 350-365.

[2] 魏好程,汤凤霞,沈塞群. 茄子多酚氧化酶特性及控制研究[J]. 食品研究与开发,2009,30(6):48-52. Wei Haocheng, Tang Fengxia, Shen Saiqun. Study on the activity and the inhibitor of the polyhenol oxidase from eggplant[J]. Food Research and Development, 2009, 30(6): 48-52.

[3] 张慜,王成芝,李春丽,等. 茄子脱水工艺及模型研究[J].东北农业大学学报,1993,24(4):366-370. ZhangMin, Wang Chengzhi, Li Chunli, et al. Research on drying technology and model of eggplant[J]. Journal of Northeast Agriculture College, 1993, 24(4): 366-370. (in Chinese with English abstract)

[4] 刘春丽,陈欲云. 鲜切茄子酶促褐变的过氧化物酶的特性研究[J]. 四川理工学院学报:自然科学版,2012,25(2):8-11. Liu Chunli, Chen Yuyun. Study on the characteristics of enzyme browning of peroxidase in fresh-cut eggplant[J]. Journal of Sichuan University of Science & Engineering (Natural Science Edition), 2012, 25(2): 8-11. (in Chinese with English abstract)

[5] Zhang Lili, Wang Xiangyou, Yu Long, et al.Drying characteristics and color changes of infrared drying eggplant[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(Supp 2): 291-296.

[6] Ertekin C, Yaldiz O. Drying of eggplant and selection of a suitable thin layer drying model[J]. Journal of Food Engineering, 2004, 63(3): 349-359.

[7] Xiao Hongwei, Yao Xuedong, Lin Hai, et al. Effect of SSB (superheated steam blanching) time and drying temperature on hot air impingement drying kinetics and quality attributes of yam slices[J]. Journal of Food Process Engineering, 2012, 35(3): 370-390.

[8] 毕金峰,方芳,丁媛媛,等. 预处理对哈密瓜变温压差膨化干燥产品品质的影响[J]. 食品与机械,2010,26(2):15-18. Bi Jinfeng, Fang Fang, Ding Yuanyuan, et al. Effect of different pretreatments on the product quality ofexplosion puffing drying for hami-melon[J]. Food and Machinery, 2010, 26(2): 15-18. (in Chinese with English abstract)

[9] 徐新风,张英丽,陈计峦,等. 不同干燥方式对无核紫葡萄干品质的影响[J]. 农产品加工:创新版,2010(10):48-50. Xu Xinfeng, Zhang Yingli, Chen Jiluan, et al. The effect of quality for seedless purple raisins by different drying methods[J]. Innovational Edition of Farm Products Processing, 2010(10): 48-50. (in Chinese with English abstract)

[10] Pahlavanzadeh H, Basiri A, Zarrabi M. Determination of parameters and pretreatment solution for grape drying[J]. Drying technology, 2001, 19(1): 217-226

[11] 张慜,王成芝,李春丽. 茄子渗透脱水及渗后干燥的研究[J].农业工程学报,1992,8(4):97-101. Zhang Min, Wang Chengzhi, Li Chunli. Study on osmoite dehydration and osmosed drying of eggplant[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1992, 8(4): 97-101. (in Chinese with English abstract)

[12] 刘春菊,王海鸥,刘春泉,等. 预处理对气流膨化干燥黄桃丁品质的影响[J]. 食品工业科技,2016,37(3):251-255. Liu Chunju, Wang Haiou, Liu Chunquan, et al. Effect of pretreatment on product quality ofexplosion puffing drying yellow peach[J]. Science and Technology of Food Industry, 2016, 37(3): 251-255. (in Chinese with English abstract)

[13] Vásquez-Parra J E, Ochoa-Martínez C I, Bustos-Parra M. Effect of chemical and physical pretreatments on the convective drying of cape gooseberry fruits(Physalis peruviana)[J]. Journal of Food Engineering, 2013, 119(3): 648-654.

[14] Falade K O, Solademi O J. Modelling of air drying of fresh and blanched sweet potato slices[J]. International Journal of Food Science and Technology, 2010, 45(2): 278-288.

[15] Demirel D, Turhan M. Air-drying behavior of Dwarf Cavendish and Gros Michel banana slices[J]. Journal of Food Engineering, 2003, 59(1): 1-11.

[16] 邓云,吴颖,李云飞. 黄花菜烫漂过程中维生素C降解动力学研究[J]. 食品工业科技,2006,27(12):53-54. Deng Yun, Wu Ying, Li Yunfei. Study on the degradation kinetics of Vc in Hemarocalliscitrina Baroni during blanching[J]. Science and Technology of Food Industry, 2006, 27(12): 53-54. (in Chinese with English abstract)

[17] Xin Y, Zhang M, Xu B, et al. Research trends in selected blanching pretreatments and quick freezing technologies as applied in fruits and vegetables: A review[J]. International Journal of Refrigeration, 2015, 57(9): 11-25.

[18] 辛爱玲,崔援军. 硫磺熏制对山药中二氧化硫残留量的影响[J]. 安徽医药,2008,12(5):421-422. Xin Ailing, Cui Yuanjun. The influence of sulphur fuming on the Sulphur dioxide’s remaining quantity in dioscoreaopposita thumb[J]. Anhui Medical and Pharmaceutical Journal, 2008, 12(5): 421-422. (in Chinese with English abstract)

[19] 杨春城,古能平,侯文贤. 硫处理在果蔬保鲜与加工中的利与弊[J]. 保鲜与加工,2004,4(4):37-38. Yang Chuncheng, GuNengping, HouWenxian. Action and application of sulphur treatment preservation and processing of fruit and vegetable[J]. Storage and Process, 2004, 4(4): 37-38. (in Chinese with English abstract)

[20] Silva M A, Braga AMP, Santos P H S. Enhancement of fruit drying the ethanol effect[C]//18th International Drying Symposium, Xiamen, 2012(11): 11-15.

[21] Santos PHS,Silva MA. Kinetics of L-ascorbic acid degradation in pineapple drying under ethanolic atmosphere[J]. Drying Technology, 2009, 27(9): 947-954.

[22] CorrêaJ LG,Braga AMP. The influence of ethanol on the convective drying of unripe, ripe, and overripe bananas[J]. Drying Technology, 2012, 30(8): 817-826.

[23] Azimi A, Tavakoli T, Beheshti H K, et al. Experimental study on eggplant drying by an indirect solar dryer and open sun drying[J]. Iranica Journal of Energy & Environment, 2012, 3(4): 348-354.

[24] Brasiello A, Adiletta G, Russo P, et al. Mathematical modeling of eggplant drying: shrinkage effect[J]. Journal of Food Engineering, 2013, 114(1): 99-105.

[25] 张茜,肖红伟,代建武,等. 哈密瓜片气体射流冲击干燥特性和干燥模型[J]. 农业工程学报,2011,27(增刊1):382-388. Zhang Qian, Xiao Hongwei,DaiJianwu, et al. Air impingement drying characteristics and drying model of Hami melon flake[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(Supp.1): 382-388. (in Chinese with English abstract)

[26] Xiao Hongwei, Law C L, Sun Dawen, et al. Color change kinetics of american ginseng (panaxquinquefolium) slices during air impingement drying[J]. Drying Technology, 2014, 32(4): 418-427.

[27] Doymaz İ. An Experimental study on drying of green apples[J]. Drying Technology, 2009, 27: 478-485.

[28] Xiao Hongwei, Pang Changle, Wang Lihong,et al. Drying kinetics and quality of Monukka Seedless grapes dried in an air-impingement jet dryer[J]. Biosystems Engineering, 2010, 105(2): 233-240.

[29] 娄正,高振江,肖红伟,等. 板栗气体射流冲击干燥特性和工艺优化[J]. 农业工程学报,2010,26(11):368-373. Lou Zheng, Gao Zhenjiang, Xiao Hongwei, et al. Air impingement drying characteristics and process optimization of chestnut[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(11): 368-373. (in Chinese with English abstract)

[30] 张卫鹏,高振江,肖红伟,等. 基于Weibull 函数不同干燥方式下的茯苓干燥特性[J]. 农业工程学报,2015,31(5):317-324. Zhang Weipeng, Gao Zhenjiang, Xiao Hongwei, et al. Drying characteristics of poriacocos with different drying methods basedon Weibull distribution[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(5): 317-324. (in Chinese with English abstract)

[31] Doyamz I. Air-drying characteristics of tomtoes[J]. Journal of Food Engineering, 2007, 78(4) : 1291-1297.

[32] Di Matteo M, Cinquanta L, Galiero G, et al. Effect of a novel physical pretreatment process on the dryingkinetics of seedless grapes[J]. Journal of Food Engineering, 2000, 46(2): 83-89.

[33] Srikiatden J, Roberts JS. Measuring moisture diffusivity of potato and carrot (core and cortex) during convective hot air and isothermal drying[J]. Journal of Food Engineering, 2006, 74(1): 143-152.

[34] Xiao Hongwei, Bai Junwen, Xie Long, et al. Thin-layer air impingement drying enhances drying rate of American ginseng (Panaxquinquefolium L.) slices with quality attributes considered[J]. Food and Bioproducts Processing, 2015, 94(2): 581-591.

[35] Dai Jianwu, Rao Junquan, Wang Dong, et al. Process-based drying temperature and humidity integration control enhances drying kinetics of apricot halves[J]. Drying Technology, 2015, 33(3): 365-376.

[36] Xiao Hongwei, Lin Hai, Yao Xuedong, et al. Effects of different pretreatments on drying kinetics and quality of sweet potato bars undergoing air impingement drying[J]. International Journal of Food Engineering, 2009, 5(5): 1-17.

[37] Doyamz I. Air-drying characteristics of tomtoes[J]. Journal of Food Engineering, 2007, 78(4) : 1291-1297.

[38] Doymaz I. Effect of dipping treatment on air drying of plums[J]. Journal of Food Engineering, 2004, 64(6): 465-470.

[39] 肖红伟,张世湘,白竣文,等. 杏子的气体射流冲击干燥特性[J]. 农业工程学报,2010,26(7):318-323. Xiao Hongwei, Zhang Shixiang, Bai Junwen, et al. Air impingement drying characteristics of apricot[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(7): 318-323.

[40] Xiao Hongwei, Gao Zhenjiang,Lin Hai, et al. Air impingement drying characteristics and quality of carrot cubes[J]. Journal of Food Process Engineering, 2010, 33(5): 899-918.

[41] 巨浩羽,肖红伟,白竣文,等. 苹果片的中短波红外干燥特性和色泽变化研究[J]. 农业机械学报,2013,44(增刊2):186-191. Ju Haoyu, Xiao Hongwei, Bai Junwen, et al. Medium and short wave infrared drying characteristics and color changing of apple slices[J]. Transactions of the ChineseSociety for Agricultural Machinery, 2013, 44(Supp.2): 186-191. (in Chinese with English abstract)

[42] Braga A M P, Pedroso M P, Augusto F, et al. Volatiles identification in pineapple submitted to drying in an ethanolic atmosphere[J]. Drying Technology, 2009, 27(2): 248-257.

[43] Deng Yun, Zhao Yanyun.Effect of pulsed vacuum and ultrasound osmopretreatments on glass transitiontemperature, texture, microstructure and calcium penetrationof dried apples (Fuji)[J]. LWT-FoodScience and Technology, 2008, 41(9): 1575-1585.

[44] Musielak G. International stresses caused by outflow of moisture and phase change inside driedmaterial[J]. Drying Technology, 1996, 14(2): 289-306.

Effect of ethanol dipping pretreatment on drying characteristics and quality of eggplant slices

Zhao Haiyan1, Fang Xiaoming2, Wang Jun1, Ju Haoyu1, Zhang Yuejing1, Chen Xingfu1, Zhang Qian3, Liu Yanhong1, Gao Zhenjiang1, Xiao Hongwei1※

(1. College of Engineering, China Agricultural University, Beijing 100083, China; 2. Bee Research Institute of Chinese Academy of Agricultural Sciences, Beijing 100093, China; 3. College of Mechanical and Electric Engineering, Shihezi University, Shihezi 832000, China)

Because the eggplant is widely planted all over the country, but the moisture content of fresh eggplant is high and the shelf life is short, so harvested eggplants should be dried and dehydrated in time. How to achieve high-quality dried products is one of the important directions in drying research. Chemical impregnation process is a novel pretreatment technology, and ethanol is chosen as a chemical, which has many advantages, such as fast penetration, easy to evaporate, no chemical residues and harmless to human body, and has been applied to the pretreatment of fruit and vegetable. In order to improve the drying quality of eggplant slices and shorten the drying time, the eggplant slices were dipped in ethanol before hot air drying. The effects of different drying temperature (45, 55 and 65℃), ethanol concentration (0, 5% and 15%) in pretreatment and slice thickness (1.0, 1.5 and 2.0 cm) on drying rate, color, rehydration ratio and microscopic structure were investigated through the orthogonal experiments in this paper. Results showed that drying temperature, ethanol concentration in pretreatment and sample thickness had significant (P<0.05) effects on the drying processing. In addition, the sample thickness was most significant, followed by drying temperature and ethanol concentration in pretreatment. The drying time decreased with the increase of temperature, increased with the increase of slice thickness of the eggplant, and decreased first and then increased with the increase of alcohol concentration in pretreatment. The whole drying process was a kind of falling-rate drying. According to Fick’s Second Law, the water effective diffusion coefficient was determined, which ranged from 2.74×10-9to 7.75×10-9m2/s. The sample thickness had greater impact (P<0.05) on the rehydration ratio compared with the drying temperature and ethanol concentration, and the rehydration ratio decreased as the sample thickness increased. The ethanol concentration in pretreatment had important influence (P<0.05) on color parameters of dried eggplant slices, but the effects of eggplant thickness and drying temperature on the color and lustre were not significant, which were far less than that of ethanol concentration in pretreatment on the color and lustre. And the pretreatment with ethanol also could change the microstructure and appearance quality of the dried samples. After eggplant was dipped in ethanol with low concentration, its moisture would be faster evaporated and the internal free water would be sent out in the drying process, and the drying rate was improved. And after eggplant was impregnated with high-concentration ethanol, ethanol made eggplant’s internal nutrient composition change, which resulted in its structure more compact, and prevented moisture migration in the process of drying. Taking account of the drying rate and quality attributes, drying at 55℃, with ethanol concentration of 15% and sample thickness of 1.5 cm were recommended as the most favorable conditions for eggplant slice drying. In this drying condition, drying time, rehydration ratio and lightness was 225 min, 4.93 and 88.24, respectively. The present findings indicate that ethanol dipping pretreatment can not only enhance drying rate but also improve color attributes of dried products. The results provide a theoretical reference for the rapid drying of high-quality eggplant slices.

drying; optimization; quality control; eggplant slice; ethanol dipping pretreatment; rehydration ratio; color parameters; microstructure

10.11975/j.issn.1002-6819.2016.09.033

TS255.36; TS255.52

A

1002-6819(2016)-09-0233-08

赵海燕,方小明,王 军,巨浩羽,张月敬,陈兴付,张 茜,刘嫣红,高振江,肖红伟. 乙醇浸渍对切片茄子干燥特性和品质的影响[J]. 农业工程学报,2016,32(9):233-240.

10.11975/j.issn.1002-6819.2016.09.033 http://www.tcsae.org

Zhao Haiyan, Fang Xiaoming, Wang Jun, Ju Haoyu, Zhang Yuejing, Chen Xingfu, Zhang Qian, Liu Yanhong, Gao Zhenjiang, Xiao Hongwei. Effect of ethanol dipping pretreatment on drying characteristics and quality of eggplant slices[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(9): 233-240. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.09.033 http://www.tcsae.org

2015-12-25

2016-03-22

国家自然科学基金项目(31501548,31360399,31201436)和国家科技支撑项目(2015BAD19B010201)。

赵海燕,女(汉),河南洛阳人,主要从事农产品加工及贮藏的研究。北京 中国农业大学工学院,100083。Email:zzhaohaiyann@163.com

※通信作者:肖红伟,男(汉),河南商丘人,副教授,博士,博士生导师,主要从事农产品加工技术和装备的研究。北京 中国农业大学工学院,100083。Email:xhwcaugxy@163.com