基于同心轴圆筒式电容传感器的花生仁水分无损检测技术

2016-12-19赵丽清尚书旗高连兴胡修慧殷元元龚丽农

赵丽清,尚书旗,高连兴,胡修慧,殷元元,龚丽农

(1. 沈阳农业大学工程学院,沈阳 110161; 2. 青岛农业大学机电工程学院,青岛 266109)

基于同心轴圆筒式电容传感器的花生仁水分无损检测技术

赵丽清1,2,尚书旗2,高连兴1※,胡修慧2,殷元元2,龚丽农2

(1. 沈阳农业大学工程学院,沈阳 110161; 2. 青岛农业大学机电工程学院,青岛 266109)

为了实现花生仁含水率的快速准确检测,设计了以MSP430单片机为控制芯片的花生仁含水率检测仪,利用圆筒式电容传感器、温度传感器和称质量传感器分别检测花生仁的电容、温度和容积密度,通过信号检测调理电路进行测量信号电容到频率的转换,单片机进行数据处理后计算出花生仁含水率,在液晶屏上显示检测结果,并将检测数据存储到内存卡中。进一步研究了含水率、温度和容积密度对频率的影响规律,建立了描述含水率与差频、温度的数学模型,并验证了基于电容法检测花生含水率的可行性和模型的可靠性。试验表明,在含水率6.4%~18.2%、温度10~40℃范围内,该检测仪的测量相对误差绝对值小于0.5%。该研究为快速无损检测花生仁含水率提供了参考。

电容法;含水率;温度;花生仁;温度补偿;容积密度

0 引言

花生是我国的重要油料与经济作物。我国花生常年种植面积约500万hm2,总产1 400万t,分别占世界20% 和40%。刚收获的花生仁含水率达45%~50%,而储藏时要求含水率要低于10.5%[1-4]。含水率对花生收获过程中的晾晒与摘果、收后干燥、储藏、脱壳和贸易等多个环节有极其重要的影响。花生仁含水率过高,不但影响测得的花生质量,而且造成脱壳时的花生仁损伤与损失,同时花生荚果或花生仁存放与储藏过程中容易霉变。花生干燥、加工、储藏和贸易过程中需要频繁、快速、精确地进行水分检测。

测量花生仁水分常用的方法有传统烘干法、近红外光谱检测法、微波法、电容法等。

花生仁水分检测的国标法是烘干法。通过手摇切片机或小刀将花生仁切成0.5 mm以下的薄片或剪碎[5],然后进行烘干通过质量损失率检测水分含量,该方法过程繁琐,且需花费几个小时的时间烘干;K.N.Govindarajan 等[6]采用近红外反射比方法检测整粒花生仁含水率,但其更适宜于花生仁表面含水率检测;S. Trabelsi等[7]采用微波技术检测花生仁含水率,并通过试验研究进行了温度和容积密度校正补偿,但该技术成本极高。

电容法粮食水分测量传感器因其结构简单、动态响应快、性价比高,仍是目前粮食水分测量的研究热点。Chari V. K. Kandala等[8]采用射频阻抗法设计了一种平行极板式电容水分检测仪来检测花生仁含水率,使用射频阻抗仪测量并计算不同频率下样本电容值、相角值及损耗因子,但平行板电容器由边界效应导致的测量误差较大;翟宝峰等[9]采用交流法将电容变化转变成电压变化后检测粮食含水率;郭文川等[10]利用直流充/放电电路,分析了影响小杂粮介电特性的因素;刘志壮等[11]利用电容数字转换芯片AD7150检测稻谷含水率;滕召胜等[12]研究了稻谷、小麦及大米的导电浴盆效应。美国DICKEY-John公司的GAC2500型水分仪和日本PM8188水分仪在国内有一定的市场。前者精度高,但体积较大,不方便移动,且价格极高;后者是手持式水分仪,精度比前者低。国内个别厂家在深入研究PM8188的基础上,研发了自己的产品,比较有代表性的是上海青浦绿洲LDS系列谷物水分测定仪,但因其测量精度和重复率较低,未得到行业广泛认同,特别是对于花生仁等大籽粒粮食作物,精度问题更加显著。本文基于电容法测量原理,优选了边界效应最小的圆筒式电容器作为传感器核心、采用电容-差频转换方法,设计了相应的硬件电路,研究了温度和容积密度对花生仁水分测试的影响关系,对数据进行了温度补偿,首次在国内进行了花生仁无损水分检测系统的试验研究。

1 系统的构成与工作原理

1.1 花生仁水分检测系统构成

图1为花生仁水分检测系统的总体构成框图,该系统主要由电容、温度和称质量传感器模块、单片机模块、A/D转换模块、电源模块、显示模块、存储模块及按键等模块组成。选用MSP430单片机作为主控芯片,其功耗低、信号处理速度快,用于实现数据的采集、计算及人机交互的功能;键盘由测量按键和存储按键组成,完成对样品的测量和采集信息的存储;液晶显示屏使用的是薄膜晶体管(thin film transistor,TFT)液晶模块,用于显示测量频率、质量、温度及含水率等。

图1 水分检测系统结构图Fig.1 Structure diagram of moisture content detection system

接通电源后,系统开始进入水分检测状态,将花生仁放入定量容器内,由固定高度落入电容传感器内,按检测按键进行检测。电容、称质量传感器和温度分别检测花生仁的电容、质量、温度信号;信号经过检测调理电路和模数转换电路传送到MSP430单片机,由单片机完成对花生仁电容到频率的采集及转换、温度和质量数据的采集;然后计算出差频和容积密度;再通过对数据建模、计算得到水分值,最后各数据信息由显示模块显示,并按下存储按键由存储模块进行数据信息存储。

1.2 工作原理

电容式水分仪的工作原理[13-16]是通过放入极板间的物料的含水率不同,其介电常数不同,导致电容值发生改变,通过测量电容值的变化,间接测出物料的含水率。设计的花生仁水分检测仪采用高频电容式原理进行含水率的检测。

检测微小电容的方法通常是在激励信号的作用下,连续对被测电容充放电,将电容转换成与之成一定比例关系的电压或频率信号,还有的将其转换成脉冲宽度信号或电流信号,常用的2种电容转换方式是电容-频率法和电容-电压法[17-21]。

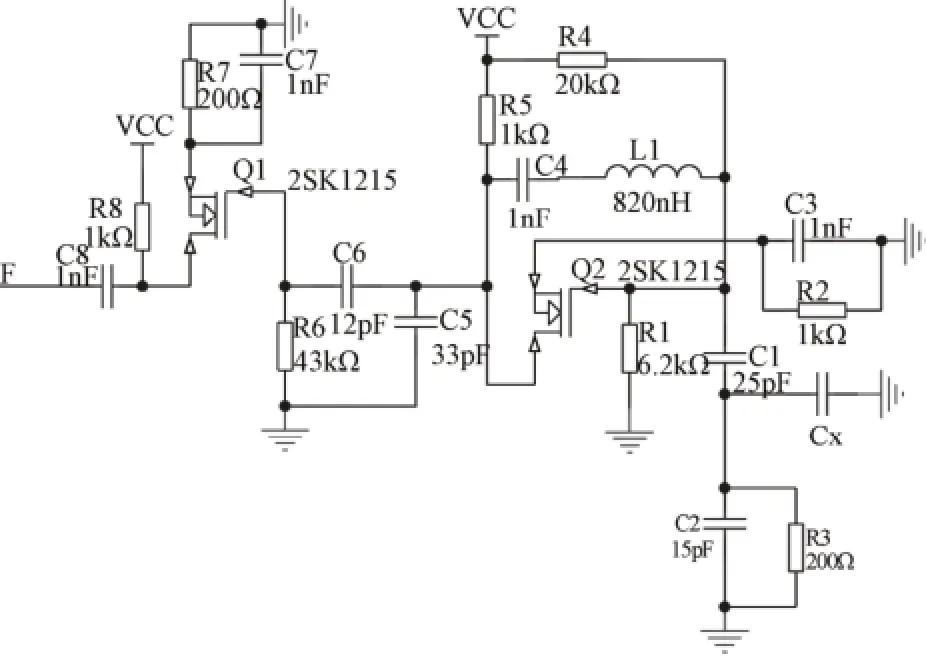

本设计采用的方法是将电容值的大小转换为频率值输出,由于仪器电容值的变化很小,而且易受到杂散电容及外界温湿度的影响。为此本文采用了差频式检测方法,差频式检测方法具有精度高、稳定性好等优点,设计的检测转换电路如图2所示。通过将电容传感器Cx接入振荡电路,分别测量未放入样本空筒时电路产生的振荡频率和装满样品时的频率,将电容量的改变转变成频率的改变输出,依据频率的改变量,计算得出花生仁样本的水分值。

图2 电容检测转换电路Fig.2 Capacitance detection and conversion circuit

2 系统结构与软件设计

2.1 花生仁水分检测仪结构设计

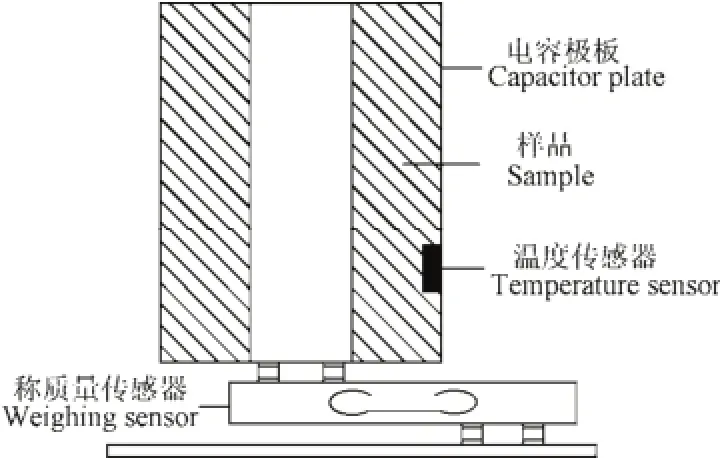

图3为检测花生仁含水率仪器的结构。整个检测装置主要包括电容、温度和称质量传感器以及底座等。电容传感器采用同心轴圆筒式结构。极板材料选用铝合金,外直径为8.4 cm,内直径为5 cm,柱高11 cm。温度传感器选用的南京时恒集团生产的MF58 NTC热敏电阻,其体积小、精度高、抗干扰能力强,能在−55~+250℃下正常工作。平行梁式称质量传感器选用的上海天贺自动化仪表有限公司生产的LCS-D1,精度为±0.02%,灵敏度为(2.0±0.1)mV/V。底座使用亚克力板支撑整个检测装置。图4为所设计检测仪的实物图。

图3 检测仪结构Fig.3 Structure of detector

图4 检测仪器实物图Fig.4 Picture of real detector

2.2 软件设计

图5为测量仪软件系统的设计框图。软件系统由主程序完成对各模块的初始化,子程序包括频率、温度和质量的采集程序,差频、容积密度和含水率的计算程序,以及按键识别、液晶显示等程序。可以实现对频率、温度、质量的采集,以及完成差频、容积密度和最终水分值的计算与显示。

图5 软件系统框图Fig.5 Block diagram of software system

3 材料与方法

3.1 试验材料

花生仁:品种为四粒红,产自吉林省吉林市。带壳花生:品种为四粒红,产自山东省临沂市。对花生仁和带壳花生分别进行处理,除去杂质及破碎不完整的籽粒,只选用籽粒完好、形状大小较均匀的花生仁作为试验样品。

3.2 试验仪器

DHG-9140A型电热鼓风干燥箱:杭州得聚仪器设备有限公司;YH-A型电子天平:瑞安市乐祺有限公司;FA2004电子分析天平:上海舜宇恒平科学仪器有限公司。

3.3 试验方法

3.3.1 样品的制备

采用2种样品制备方法进行对比试验,分别是往花生仁和带壳花生喷洒水来获得不同含水率梯度花生仁样品[22-28],带壳花生剥壳后检测花生仁含水率。根据国家标准GB 5497-1985方法,采用130℃干燥法,测得花生仁和带壳花生样品初始含水率分别约为6%和7%,两组花生分别称取7份样品,将7份样品放入密封袋中。为配制不同含水率的花生样品,分别对每份样品加入不同量的水,样品水分高于15%时,分多次、每次少量加入水。将配置好的花生样品放在2℃的冰箱中3 d,在此期间对各样品袋进行晃动,使样品水分吸收均匀。在每次测量前,将样品放在不同温度的环境下20 h,使其与外界环境达到温度平衡。试验前,用烘干法获得2组样品的湿基含水率分别为6.4%、8.4%、10.5%、12.6%、14.5%、16.3%、18.2%和5.4%、7.5%、9.5%、11.4%、13.3%、15.5%、17.7%,配制的样品用于仪器的标定与检验。

3.3.2 测量方法

每次样品水分的标定都采用国标法,将花生仁样品置于130℃的电热鼓风干燥箱中烘干,直至质量不再改变,根据烘干前后花生仁的质量变化计算出并记录下各组的水分值,作为标准值,含水率采用湿基表示法。将花生仁在固定高度(距容器底部约13 cm)以自由落体方式落到固定容器内测得无压实花生仁质量,然后对花生仁施加不同大小的压力或采取振动容器的方式,改变容器内所放花生仁的质量,用花生仁质量除以所使用容器的体积,得到不同容积密度的花生仁样品。分别在不同温度环境下进行试验,每组样品进行5次试验取平均值,记录各组数据。

4 结果与分析

4.1 不同含水率、温度和差频试验

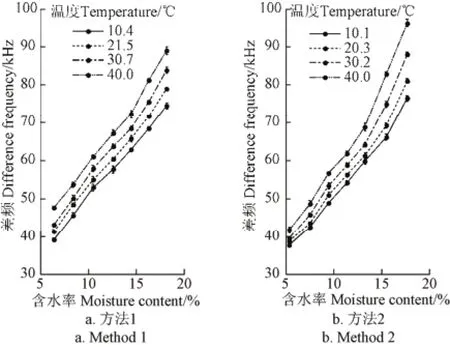

采用自由落体方式,不同含水率和温度与所测花生仁差频的关系如图6所示。

图6 花生仁含水率、温度与差频的关系Fig.6 Relationship of moisture content, temperature and difference frequency of peanut kernels

从图6可以看出,2种方法得到的花生仁样品的差频值随含水率的增大成上升的趋势,随温度的升高也成增大的趋势,在高水分和高温度情况下增长更快。

4.2 容积密度和差频试验

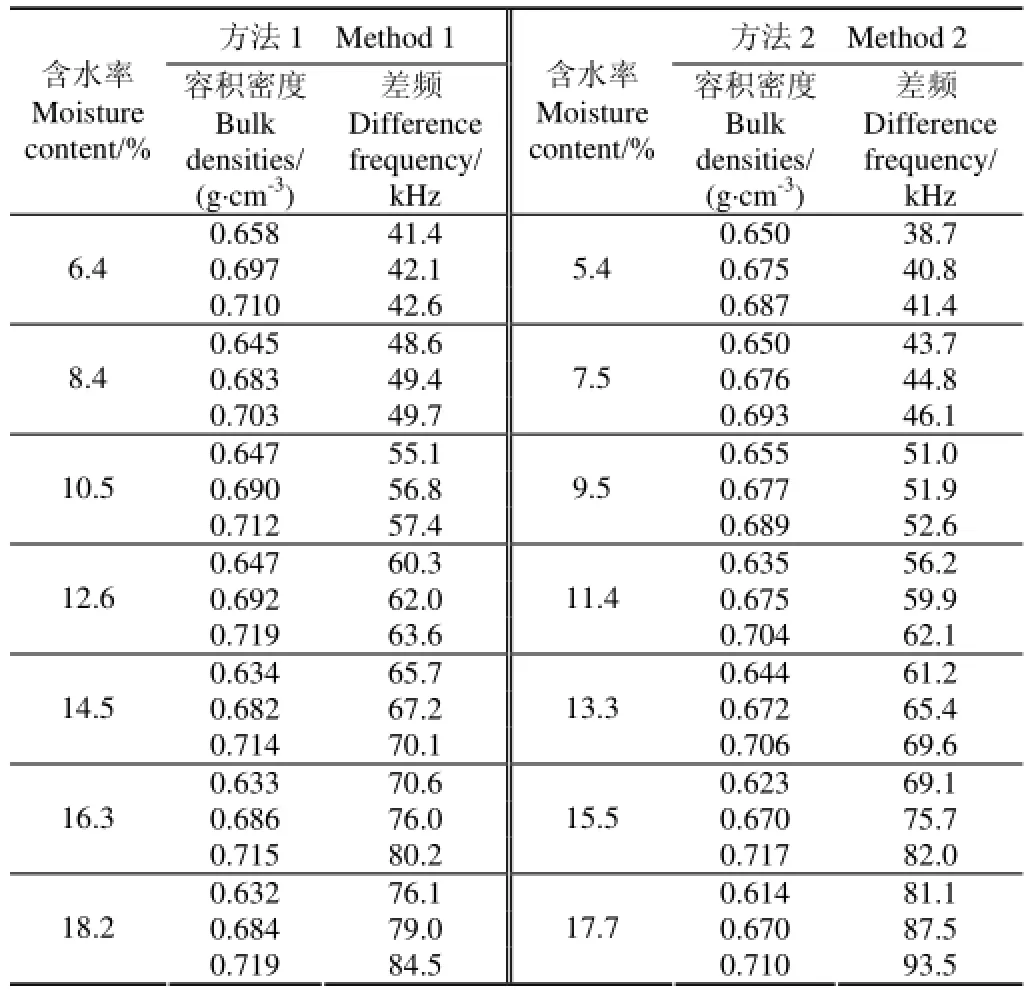

表1为室温20℃左右下,不同含水率花生仁在不同容积密度下测得的差频值。分析表中数据可知,对于同一水分含量的花生仁,容积密度增大,差频值也随之增大。低含水率阶段,差频值变化较小,高含水率阶段,差频值变化较大。

4.3 含水率模型的建立与验证

4.3.1 模型建立检验

测量时采用定容积取样法,花生仁在一定高度自由落体,如果不人为振动电容传感器或改变其体积,由表1可知花生仁的容积密度变化不大,对结果影响不显著;由图6可知,温度对花生仁水分检测的结果有很大影响,同一含水率花生仁样品,温度越高,花生仁内部自由水的布朗运动速度越快,介电常数增大,电容量越大,频率差值越大。因此在自由落体条件下,采取对含水率、频率和温度3个变量进行建模。分析2种方法得到的数据可知,影响规律和参数对比结果具有一致性,所以采用国际通用的样品制备方法1所得数据建立数学模型。含水率值作为输出值,频率和温度为输入值,用MATLAB软件进行多元二次建模,可采用的模型有线性、纯二次、交叉和完全二次模型[29-31],通过比较分析4种模型的参数,选择最佳拟合方程。

表1 不同含水率和容积密度的花生仁差频值Table 1 Difference frequency values of peanut kernels under different moisture contents and bulk densities

表2为4种回归模型的拟合参数。由表2可知,完全二次模型的数据剩余标准差最小,说明数据较集中,建立的模型显著性最好;残差平方和最小,且复相关系数R2=0.9959最大,说明拟合程度最好。因此可采用完全二次模型建立花生仁含水率检测模型。各模型方程为:

线性模型方程

纯二次模型方程

交叉模型方程

完全二次模型方程

式中M为含水率,%;F为差频,kHz;T为温度,℃。

为验证模型可靠性,随机配制多份不同含水率的花生仁,在不同温度下测得差频,用上述4个模型的计算值与实际水分值进行比较,比较结果如图7所示。由图7模型验证数据可知,完全二次模型的相关系数R2最高,该模型优于其他3个模型,说明完全二次模型能准确地描述含水率、差频和温度之间的关系,即最佳数学模型为模型(4)。

表2 拟合方程参数对比Table 2 Comparison of parameters for fitting equations

图7 计算值和实际值对比Fig.7 Comparing calculated values with actual values of moisture content

4.3.2 含水率预测试验验证

将表示花生仁含水率与差频、温度的关系的方程(4)编写程序写入单片机,用随机配制的12份不同含水率花生仁样品检验测量仪测量的精确度。用本文设计的花生仁含水率检测仪进行检测,每个样品进行3次测量,结果取3次测量的平均值。表3是检测仪测量值与标准值的比较结果。

表3 含水率测量值和实际值对比Table 3 Comparing measured values with actual values of moisture content %

由表3可以看出,测量结果与烘箱法结果相比,测量相对误差的绝对值小于0.5%。因此,设计的花生仁含水率测量仪检测结果较好的满足设计要求,能够实现花生仁含水率的快速准确检测。

5 结论

1)本文设计了一种圆筒式花生仁水分测量仪。检测硬件电路采用高频电容测量技术,其可将料筒电容变化转换成频率变化。由于被测料筒电容为皮法级,为避免杂散电容的引入,影响测量精度,试验数据采用差频法获得。即试验数据取自空料桶和装满物料料桶分别接入电路后测量频率之差。由于圆桶边界效应小,差频法又能尽可能的减小引入误差,因此该仪器精度高、重复率好。

2)研究了温度10~40℃、花生仁含水率6.4%~18.2%、容积密度0.632~0.719 g/cm3范围内,差频与含水率、温度和容积密度的关系,建立了含水率、差频和温度的三元二次方程,并对回归模型的准确性进行了验证,在容积密度基本保持不变的情况下,该模型可以准确地描述花生仁差频与含水率、温度的关系。

3)验证了所设计的花生仁含水率检测仪的测量结果,试验结果表明,该水分仪测量的水分值与实际水分值误差在±0.5%范围内。

[1] 关萌,沈永哲,高连兴,等. 花生起挖晾晒后的果柄机械特性[J]. 农业工程学报,2014,30(2):87-93. Guan Meng, Shen Yongzhe, Gao Lianxing, et al. Mechanical properties of peanut peg after digging and drying[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(2): 87-93. (in Chinese with English abstract)

[2] 高连兴,李飞,张新伟,等. 含水率对种子玉米脱粒性能的影响机理[J]. 农业机械学报,2011,42(12):92-96,42. Gao Lianxing, Li Fei, Zhang Xinwei, et al. Mechanism of moisture content affect on corn seed threshing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(12): 92-96, 42. (in Chinese with English abstract)

[3] Trabelsi S, Nelson S O. Microwave dielectric properties of shelled and unshelled peanuts[J]. Transactions of the ASAE, 2004, 47(4): 1215-1222.

[4] 彭三河,刘洋. 影响新收带壳花生含水率的参数研究[J].长江大学学报:自然科学版农学卷,2009,6(2):75-77. Peng Sanhe, Liu Yang. Study on influence parameters of water content of newly harvested peanuts[J]. Journal of Yangtze University: Nat Sci Edit Agri Sci, 2009, 6(2): 75-77. (in Chinese with English abstract)

[5] GB/T 5497-1985 粮食、油料检验水分测定法[S]. 1985. GB/T 5497-1985 Inspection of grain and oilseeds-methods for determination of moisture content[S]. 1985. (in Chinese with English abstract)

[6] Govindarajan K N, Kandala C V K., Subbiah J. NIR reflectance spectroscopy for nondestructive moisture content determination in peanut kernels[J]. Transactions of the ASABE, 2009, 52(5): 1661-1665.

[7] Trabelsi S, Nelson S O, Lewis M A. Microwave nondestructive sensing of moisture content in shelled peanuts independent of bulk density and with temperature compensation[J]. Sensing & Instrumentation for Food Quality & Safety, 2009, 3(2): 114-121.

[8] Kandala C V K, Butts C L, Nelson S O. Capacitance sensor for nondestructive measurement of moisture content in nuts and grain[J]. IEEE Transactions on Instrumentation and Measurement, 2007, 56(5): 1809-1813.

[9] 翟宝峰,白媛. 电容式粮食水分检测仪的设计[J]. 辽宁工学院学报,2003,23(1):34-39. Zhai Baofeng, BaiYuan. Design of capacitor moisture detector for cereal[J]. Journal of LiaoNing Institute of Technology, 2003, 23(1): 34-39. (in Chinese with English abstract)

[10] 郭文川,赵志翔,杨沉陈. 基于介电特性的小杂粮含水率检测仪设计与试验[J]. 农业机械学报,2013,44(5):188-193. Guo Wenchuan, Zhao Zhixiang, Yang Chenchen. Moisture meter for coarse cereals based on dielectric properties[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(5): 188-193. (in Chinese with English abstract)

[11] 刘志壮,吕贵勇. 基于电容法的稻谷含水率检测[J]. 农业机械学报,2013,44(7):179-182. Liu Zhizhuang, Lü Guiyong. Moisture content detection of paddy rice based on capacitance approach[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(7): 179-182. (in Chinese with English abstract)

[12] 滕召胜,周光俊,童调生. 粮食的导电浴盆效应与新型水分检测方法研究[J]. 中国粮油学报,1999,14(1):59-62. Teng Zhaosheng, Zhou Guangjun, Tong Tiaosheng. Electric conductivity bathtub effect of grain and a new method of measuring moisture content[J]. Journal of the Chinese Cereals and Oils Association, 1999, 14(1): 59-62. (in Chinese with English abstract)

[13] Nelson S O. Factors affecting the dielectric properties of Grain[J]. Transactions of the ASAE, 1982, 25(4): 1045-1049.

[14] Nelson S O, Trabelsi S. Principles for microwave moisture and density measurement in grain and seed[J]. Journal of Microwave Power and Electromagnetic Energy, 2004, 39(2): 107-117.

[15] 郭文川,朱新华. 国外农产品及食品介电特性测量技术及应用[J]. 农业工程学报,2009,25(2):308-312. Guo Wenchuan, Zhu Xinhua. Foreign dielectric property measurement techniques and their applications in agricultural products and food materials[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(2): 308-312. (in Chinese with English abstract)

[16] 付鹤翔,张利凤,郭文川. 电容式粮食含水率测量仪的设计[J]. 农机化研究,2011,33(11):131-134. Fu Hexiang, Zhang Lifeng, Guo Wenchuan. Research on capacitive grain moisture content meter[J]. Journal of Agricultural Mechanization Research, 2011, 33(11): 131-134. (in Chinese with English abstract)

[17] 张文昭,刘志壮,周文真. 电容法猪肉含水率快速检测的研究[J]. 农业工程学报,2012,28(20):272-275. Zhang Wenzhao, Liu Zhizhuang, Zhou Wenzhen. Quick detection of water content for pork by capacitance method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(20): 272-275. (in Chinese with English abstract)

[18] 杨柳,毛志怀,董兰兰. 电容式谷物水分传感器平面探头的研制[J]. 农业工程学报,2010,26(2):185-189. Yang Liu, Mao Zhihuai, Dong Lanlan. Development of plane polar probe of capacitive grain moisture sensor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(2): 185-189. (in Chinese with English abstract)

[19] 杨柳,杨明皓,董兰兰. 主动屏蔽式平面探头水分在线传感器研究[J]. 农业机械学报,2010,41(1):77-80. Yang Liu, Yang Minghao, Dong Lanlan. Development of a coplanar electrode capacitance moisture sensor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(1): 77-80. (in Chinese with English abstract)

[20] 杨王凡,黄磊,吴素萍,等. 多路数据采集与处理模型的设计及水分传感器埋设位置优化[J]. 农业工程学报,2015,31(21):148-153. Wang Fan, Huang Lei, Wu Suping, et al. Design of multi-channel data acquisition and processing model and optimization of moisture sensor buried position[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(21): 148-153. (in Chinese with English abstract)

[21] 刘贺,赵燕东. 基于驻波原理的短探针小麦茎水分传感器[J].农业工程学报,2011,27(11):140-144. Liu He, Zhao Yandong. Wheat stem moisture sensor using short probes based on SWR principle[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(11):140-144. (in Chinese with English abstract)

[22] 郭文川,王婧,刘驰. 基于介电特性的薏米含水率检测方法[J]. 农业机械学报,2012,43(3):113-117. Guo Wenchuan, Wang Jing, Liu Chi. Predicating moisture content of pearl barley based on dielectric properties[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(3): 113-117. (in Chinese with English abstract)

[23] 郭文川,王婧,朱新华. 基于介电特性的燕麦含水率预测[J]. 农业工程学报,2012,28(24):272-279. Guo Wenchuan, Wang Jing, Zhu Xinhua. Moisture content prediction of oat seeds based on dielectric property[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(24): 272-279. (in Chinese with English abstract)

[24] Casada M E, Armstrong P R. Wheat moisture measurement with a fringing field capacitive sensor[J]. Transactions of the ASABE, 2009, 52(5):1785-1791.

[25] 郭文川,刘驰,杨军. 小麦秸秆含水率测量仪的设计与试验[J]. 农业工程学报,2013,29(1):33-40. Guo Wenchuan, Liu Chi, Yang Jun. Design and experiment on wheat straw moisture content meter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(1): 33-40. (in Chinese with English abstract)

[26] Guo Wenchuan, Wang Shaojin, Tiwari Gopal et al. Temperature and moisture dependent dielectric properties of legume flour associated with dielectric heating[J]. LWT-Food Science and Technology, 2010, 43(2): 193-201.

[27] Kandala C V, Sundaram J. Nondestructive measurement of moisture content using a parallel-plate capacitance sensor for grain and nuts[J]. Sensors Journal, IEEE, 2010, 10(7):1282-1287.

[28] McIntosh R B, Casada M E. Fringing field capacitance sensor for measuring the moisture content of agricultural commodities[J]. Sensors Journal, IEEE, 2008, 8(3): 240-247.

[29] 黄操军,田芳明,刘坤,等. 基于DSP的谷物含水率在线测量方法[J]. 农业机械学报,2009,40(Z1):61-64. Huang Caojun, Tian Fangming, Liu Kun, et al. Universal online measuring method of grain moisture content based on DSP[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(Z1): 61-64. (in Chinese with English abstract)

[30] 黄操军,段玉波,李爱传,等. 基于DSP和单片机的谷物含水率准动态检测技术研究[J]. 农业工程学报,2008,24(5):127-130. Huang Caojun, Duan Yubo, Li Aichuan, et al. Quasi-dynamic measurement technology for grain moisture content based on DSP and MPU[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(5): 127-130. (in Chinese with English abstract)

[31] 张永林,王旺平,郑长征,等. 谷物干燥实时在线智能水分测量系统[J]. 农业工程学报,2007,23(9):137-140. Zhang Yonglin, Wang Wangping, Zheng Changzheng, et al. Intelligent real-time on-line measuring system for moisture content during grain drying[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(9): 137-140. (in Chinese with English abstract)

Nondestructive measurement of moisture content of peanut kernels based on concentric cylindrical capacitance

Zhao Liqing1,2, Shang Shuqi2, Gao Lianxing1※, Hu Xiuhui2, Yin Yuanyuan2, Gong Linong2

(1. College of Engineering, Shenyang Agricultural University, Shenyang 110161, China; 2. College of Mechanical and Electrical Engineering, Qingdao Agricultural University, Qingdao 266109, China)

Peanut is an important oil and economic crop, and also a major export product in China. Peanut industries manufacture many types of peanut-based products for human’s life. The moisture content of peanuts is in the range of 45%-50% when peanuts are freshly harvested, and the moisture content has to be below 10.5% in storage. High moisture content in peanut kernels can make them moldy, which mainly produces the toxic aflatoxins and causes huge waste and jeopardizes human’s health. Therefore it is necessary to keep proper moisture content in every treating process of peanuts. The detection of moisture content plays an important role in harvesting, drying, storage and trade of peanuts. Although the traditional oven-drying method has high precision, it is cumbersome and takes a lot of time. In addition to the oven-drying method and the microwave method, the near infrared method and the capacitance method are also common methods of moisture content detection. Comparing to other methods, the capacitance method has advantages of simple structure and low cost. In order to develop a rapid and accurate moisture content detection method for peanut kernels, the capacitance method was adopted to measure moisture content by using dielectric properties of grain. A peanut kernel moisture content detector was designed; MSP430 single chip microcomputer was taken as its control chip, and cylindrical capacitance sensor, temperature sensor and weighing sensor were used to detect capacitance, temperature and bulk density of peanut kernels respectively. Capacitance was converted to frequency through the signal detection and conditioning circuit, and frequency was detected when the capacitance sensor was empty or full of peanut kernels samples. The difference frequency values were processed and calculated by the single chip microcomputer. Subsequently an equation of measured difference frequency, temperature and moisture content values was established by the oven-drying method, and the detection results were displayed on the liquid crystal display (LCD) screen and all detected data were saved in a memory card. To investigate the influence of moisture content, temperature and bulk density on difference frequency, the tests were conducted at 7 moisture content levels from 6.4% to 18.2% and 4 temperature levels from 10 to 40℃ . The results indicated that there was a good linear relationship between moisture content and difference frequency, as the difference frequency values increased with the elevation of moisture content, temperature and bulk density. In the test, because peanut kernels fell into the capacitance sensor from fixed height, the bulk density was not changed, which caused little effect on measurement. Therefore a mathematical model of 3 parameters of moisture content, temperature and difference frequency was established based on the MATLAB 7.10.0 software by using a multi-variation binomial regression method. Linear model, pure quadratic model, interaction model and full quadratic model were compared and the results suggested that the full quadratic model described the relationship of moisture content, temperature and difference frequency more accurately. In the validation test, the results showed the absolute value of relative error measured by the moisture content detector was below 0.5%. Therefore the feasibility of detecting the moisture content of peanut kernels based on the capacitance method was verified, as well as the reliability of the multi-linear regression model. This investigation provides a useful tool for the rapid and nondestructive measurement of moisture content for peanut kernels.

capacitance; moisture content; temperature; peanut kernel; temperature compensation; bulk density

10.11975/j.issn.1002-6819.2016.09.030

S237

A

1002-6819(2016)-09-0212-07

赵丽清,尚书旗,高连兴,胡修慧,殷元元,龚丽农. 基于同心轴圆筒式电容传感器的花生仁水分无损检测技术[J]. 农业工程学报,2016,32(9):212-218.

10.11975/j.issn.1002-6819.2016.09.030 http://www.tcsae.org

Zhao Liqing, Shang Shuqi, Gao Lianxing, Hu Xiuhui, Yin Yuanyuan, Gong Linong. Nondestructive measurement of moisture content of peanut kernels based on concentric cylindrical capacitance[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(9): 212-218. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.09.030 http://www.tcsae.org

2015-11-16

2016-03-02

国家自然科学基金资助项目(51575367);国家公益性行业(农业)科研专项(200903053);山东省农机局农机技术提升项目(2015YH106);山东省自主创新专项(2013CXC90205-1);山东省自然基金(ZR2011FM034)

赵丽清,女(蒙古族),内蒙古呼和浩特人,副教授,博士,硕士生导师,主要从事农业智能装备及测试技术研究。青岛 青岛农业大学机电工程学院,266109。Email:zhlq017214@163.com

※通信作者:高连兴,男,教授,博士生导师,主要从事农产品加工与收获机械研究。沈阳 沈阳农业大学工程学院,110866。Email:lianxing_gao@126.com