高温快速盐浴渗氮提高拖拉机曲轴性能

2016-12-19戴明阳

戴明阳,唐 威,孙 斐,胡 静,2※

(1. 常州大学材料科学与工程学院江苏省表面工程科学与技术重点实验室,常州 213164;2. 常州大学江苏省光伏科学与工程协同创新中心,常州 213164;3. 常州轻工技术职业学院机械工程系,常州 213164)

高温快速盐浴渗氮提高拖拉机曲轴性能

戴明阳1,唐 威1,孙 斐2,3,胡 静1,2※

(1. 常州大学材料科学与工程学院江苏省表面工程科学与技术重点实验室,常州 213164;2. 常州大学江苏省光伏科学与工程协同创新中心,常州 213164;3. 常州轻工技术职业学院机械工程系,常州 213164)

为提高拖拉机曲轴盐浴渗氮效率,选择用于生产拖拉机曲轴的常用材料45钢,分别进行不同保温时间的高温快速盐浴渗氮和常规盐浴渗氮。利用光学显微镜、X射线衍射仪、显微硬度计和电化学工作站对渗层的显微组织、物相、硬度和耐蚀性进行了测试和分析。研究结果表明:经过660℃×20 min高温盐浴渗氮处理后化合物层的厚度与560℃×140 min常规盐浴渗氮相近,表明高温盐浴渗氮可以显著缩短渗氮的时间。在化合物层厚度相近的情况下,高温盐浴渗氮处理后渗层中γ'-Fe4N相含量从常规盐浴渗氮的0.46增加到0.61,同时,截面最高硬度从常规盐浴渗氮的702提高到784 HV0.01,并且耐蚀性能也获得了提高。该研究可为提升盐浴渗氮技术应用于45钢拖拉机曲轴表面改性工艺方案提供参考。

拖拉机;温度;试验;曲轴;盐浴氮化;硬度

0 引言

目前,随着农业机械化的迅速发展,拖拉机已经在农业生产方面获得了非常广泛的应用[1-2]。曲轴作为拖拉机中传递动力的关键零件[3-4],在工业中常选用45钢为生产材料[5]。由于曲轴在工作过程中常产生较大磨损[6-7],同时在一些腐蚀环境中还存在曲轴表面腐蚀问题[8-9]。故为了提高45钢拖拉机曲轴的使用寿命,通常需要对其进行表面改性处理来提高其表面硬度和耐磨性等综合性能。目前,曲轴的表面强化一般采用高频淬火[10],但高频淬火存在工艺复杂,处理后材料变形较大且耐蚀性不高等缺点[11-13]。

与拖拉机曲轴常用的表面强化方法高频淬火相比,盐浴渗氮具有工艺简单,处理后材料变形小且材料表面硬度和耐蚀性更高[14]。因此可以被用来取代高频淬火来提高45钢曲轴的表面硬度和耐蚀性。但常规盐浴渗氮对于要求有良好耐磨性和耐蚀性的曲轴,渗氮时间通常需要2 h以上[15],而曲轴的高频淬火处理时间仅为十几分钟[16]。对比可以看出盐浴渗氮处理后曲轴虽然性能更好,但是由于渗氮时间过长降低了曲轴生产效率,从而在工业生产上无法替代高频淬火。

为了提高渗氮效率,国内外的相关研究已经报道了添加稀土或外加电场这2种方法[17-18],但是由于稀土价格较高而电场催渗工艺复杂,虽然降低了渗氮时间,但却使盐浴渗氮成本提高,工艺操作复杂。因此,本研究旨在保持盐浴渗氮工艺操作简单、成本低和性能好等优势的前提下,通过适当提高渗氮温度来显著缩短盐浴渗氮处理拖拉机曲轴的时间。

为此,选用拖拉机曲轴常用材料45钢为试验材料,通过适当的提高盐浴渗氮的渗氮温度实现高温盐浴渗氮。对比分析高温盐浴渗氮和常规盐浴渗氮处理后,45钢的截面组织、物相、硬度和耐蚀性,同时分析相关机理,以期为高温快速盐浴渗氮应用于拖拉机曲轴的表面强化提供一定的参考。

1 试验材料与方法

1.1 试验材料

试验选用拖拉机曲轴常用材料调质态的45钢,其化学成分(质量分数,%)为C:0.46,Si:0.17,Mn:0.52,S:0.031,P:0.032,其余为Fe[19]。采用线切割制成尺寸为10 mm×10 mm×10 mm样品,并依次用240-2000#的砂纸打磨至镜面,最后放入无水乙醇中用超声波清洗干净,吹干,待用。本试验渗剂为氮化盐浴,其中的CNO-含量约为34%[20]。

1 .2 试验方法

45钢试样在350 ℃的空气炉中预氧化25 min。首先选取曲轴常用的一组常规盐浴渗氮(normal salt bath nitriding,NM)工艺参数为560 ℃×140 min,然后在640、660和680℃分别进行不同保温时间的高温盐浴渗氮(higher temperature salt bath nitriding,HT)获得与曲轴常用的氮化工艺参数相同的化合物层厚度,同时在此保温时间条件下进行560℃常规盐浴渗氮,最后进行水冷。

将不同盐浴渗氮处理后的试样先用4%的硝酸酒精溶液腐蚀其截面,用DMI3000M型金相显微镜(徕卡公司生产)观察试样的截面的显微组织和化合物层厚度;用D/max-2500型X 射线衍射仪XRD(X-ray diffractometer,日本理学公司生产)分析试样表层的物相结构;用HXD-1000TMC型维氏硬度计(上海光学仪器公司生产)测量硬度,加载载荷为10 g,保压时间为15 s。采用CS 350电化学测试系统(武汉科斯特仪器有限公司生产)在3.5% NaCl溶液中测量试样在室温下的极化曲线,参比电极为饱和甘汞电极SCE(saturated calomel electrode),辅助电极为Pt电极,扫描速率为10 mV/s。

2 试验结果与分析

2.1 显微组织和渗层厚度分析

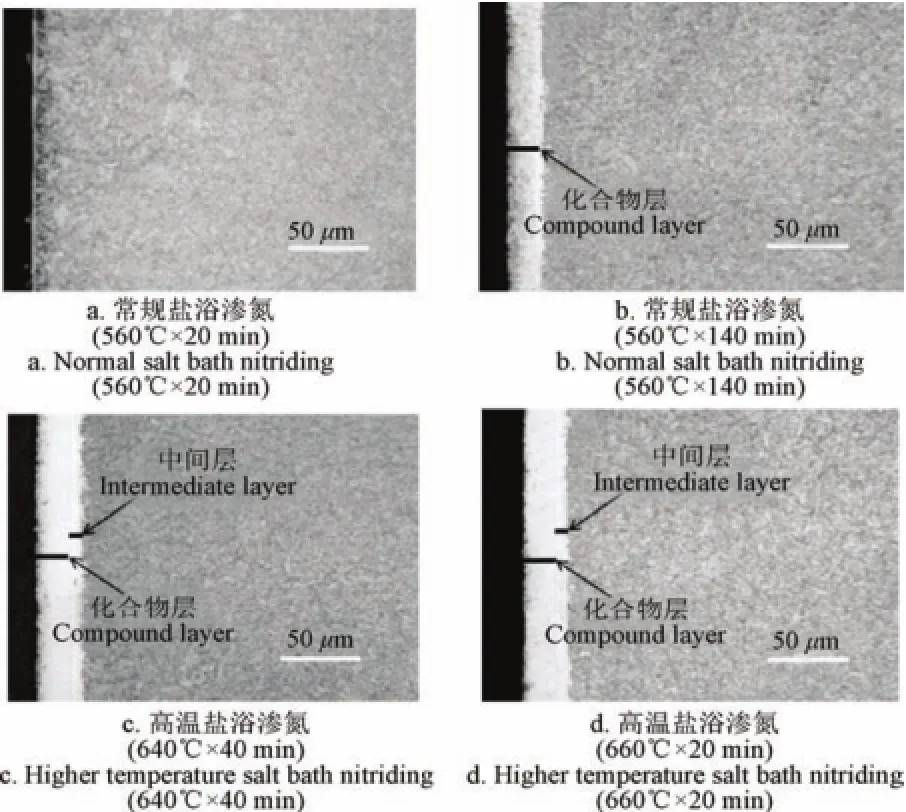

图1为不同盐浴渗氮工艺条件下45钢盐浴渗氮处理后的截面组织。

图1 不同盐浴渗氮工艺处理后45钢的截面组织Fig.1 Cross sectional microstructure of 45 steel after salt bath nitriding under different conditions

由图1可知,常规和高温盐浴渗氮处理后45钢的表面都会形成一层化合物层(也称为白亮层[21])。经560℃× 20 min盐浴渗氮处理后化合物层的厚度仅为3.8 μm,说明短时间常规盐浴渗氮获得的化合物层厚度很薄,无法满足45钢拖拉机曲轴性能的要求。而在相同保温时间条件下经660℃高温盐浴渗氮处理后的化合物层为17.1 μm,与经560℃×140 min获得的化合物层厚度相近,表明高温盐浴渗氮具有高效快速的特点,在代替常规盐浴渗氮用于曲轴工业生产时能显著的缩短渗氮时间,提高生产效率。此外,对比图1c和图1d可知,当高温盐浴渗氮的温度从660降低到640℃时,在相近化合物层厚度条件下,盐浴渗氮的保温时间增加到40 min,表明660℃高温盐浴渗氮时效率更高。继续将渗氮温度提高到680℃时,发现渗氮所用的氮化盐分解太快,已经不适合进行渗氮处理。因此660℃×20 min 是一个比较理想的工艺参数。同时高温盐浴渗氮处理后在化合层与扩散层之间形成了白亮色的中间层,亦称为奥氏体层,其实质为氮在奥氏体中的固溶体[22]。此外,对比图1b和1d可以看出,经660℃×20 min高温盐浴渗氮工艺处理后45钢基体组织与560℃×140 min常规盐浴渗氮基本一致。表明经660℃×20 min高温盐浴渗氮工艺处理后对基体组织没有影响。

2.2 物相分析

图2是白亮层层深相近的情况下,不同工艺盐浴渗氮处理后45钢渗层的X射线衍射图谱。由图2可知,虽然高温快速盐浴渗氮和常规盐浴渗氮处理后渗层物相都由ε-Fe2-3N和γ′-Fe4N相组成,但两者γ′-Fe4N与ε-Fe2-3N的最强峰比值[23]分别为(Iγ′Iε)NT=0.61和(Iγ′Iε)NM=0.46。从γ′-Fe4N和ε-Fe2-3N最强峰比值可判断,高温快速盐浴渗氮后γ′-Fe4N相对含量较高。可见,高温盐浴渗氮有利于N元素向基体内扩散,渗层中富N相-Fe2-3N较少,γ′-Fe4N较多。

图2 不同盐浴渗氮工艺处理后45钢的X射线衍射图谱Fig.2 X-Ray diffraction patterns of 45 steel after salt bath nitriding under different conditions

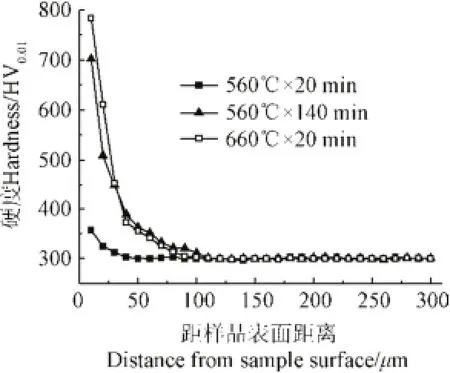

2.3 硬度分析

图3为45钢经不同盐浴渗氮处理后的截面硬度曲线。从图中可以看出,经560℃×20 min短时间常规盐浴渗氮处理后的截面硬度最低,因此不能满足曲轴耐磨性的要求。而经过660℃×20 min短时高温盐浴渗氮处理后的截面硬度不仅要远远大于相同渗氮时间处理后的常规盐浴渗氮,并且还大于经560℃×140 min常规盐浴渗氮处理后的截面硬度,截面最高硬度从常规盐浴渗氮的702提高到784 HV0.01。这是因为高温盐浴渗氮处理后化合物层中高硬度γ′-Fe4N相的含量相对较高,从而进一步提高了渗层的截面硬度。因此,快速高温盐浴渗氮处理后的45钢拖拉机曲轴的耐磨性会更高。此外,由图3可知,高温盐浴渗氮和常规盐浴渗氮处理后的基体硬度基本相同,均为300 HV0.01左右。因此,经过660℃×20 min高温盐浴渗氮处理后对基体硬度没有影响。

图3 不同盐浴渗氮工艺处理后45钢的截面硬度曲线Fig.3 Micro-hardness profile of 45 steel after salt bath nitriding under different conditions

2.4 耐蚀性分析

图4为不同工艺盐浴渗氮处理后45钢的动电位极化曲线。使用CS 350电化学工作站自带软件CView2,应用Tafel方法对图4进行数据拟合得到了试样的腐蚀电位Ecorr和腐蚀电流Icorr如表1所示。

图4 不同盐浴渗氮工艺处理后45钢的动电位极化曲线Fig.4 Potentiodynamic polarization curve of 45 steel after salt bath nitriding under different conditions

表1 不同工艺处理后45钢极化曲线拟合获得的电化学参数Table 1 Electrochemistry parameters fitted by potentiodynamic polarization curve under different conditions

由表1可知,在化合物层厚度相近的条件下,高温快速盐浴渗氮处理后45钢的腐蚀电位Ecorr大于常规盐浴渗氮,由−1 090提高至−1 053 mV。同时腐蚀电流Icorr由0.302降低到0.214 μA/cm2。由此表明高温盐浴渗氮处理后45钢耐蚀性比常规盐浴渗氮进一步提高。这是因为高温快速盐浴渗氮处理形成的中间层(图1d)有利于进一步提高45钢的耐蚀性。因此高温盐浴渗氮处理后的45钢耐蚀性更好,所以高温盐浴渗氮处理45钢拖拉机曲轴耐蚀更好。

2.5 机理分析

通过对试验数据处理和分析,表明相比于常规盐浴渗氮,高温盐浴渗氮工艺可以显著的缩短盐浴氮化的时间,应用于曲轴的工业生产时能显著提高生产效率。而产生这种有利作用的原因主要有以下2个方面。

1)在盐浴渗氮过程中,活性氮原子是通过CNO−的分解产生的,主要的化学反应如下[23]

而在常规盐浴渗氮工艺中,由于盐浴氮化的温度较低。CNO−分解的速度较慢且不完全,从而导致活性氮原子浓度较低。因此,常规盐浴渗氮工艺中化合物层增长的速度较慢。而在高温盐浴氮化工艺中,由于提高了盐浴氮化的温度,从而有效的提高了CNO−的分解速度。因此使活性氮原子的浓度提高。同时在高的盐浴氮化温度下,活性氮原子的运动的速度加快,从而加快了盐浴氮化的速度。

2)45 钢中的空位浓度[24]

式中C为空位浓度;A为常数,通常取1;Qf为Fe形成1 mol空位所需做的功,本文取176 000 J/mol;R为气体常数,8.314 J/(mol·K);T为温度,K。

由式(1)可知,常规盐浴渗氮在560℃时45钢中的空位浓度约为9.2×10-10%,而高温盐浴渗氮在660℃时45钢中的空位浓度约为1.4×10-8%,高温盐浴渗氮处理时45钢中的空位浓度约为常规盐浴渗氮的5倍以上。而空位浓度的增加为氮原子扩散进入基体中提供了更多的空间,并且减少了活性氮原子的扩散阻力,因此,会有更多的氮原子进入基体中,从而有效的缩短盐浴渗氮的时间,提高生产效率。

3 结论

1)高温快速盐浴渗氮显著缩短渗氮时间,45钢经660℃×20 min盐浴渗氮处理后化合物层厚度与560℃×140 min基本相同;同时高温盐浴渗氮后化合层与扩散层之间形成了中间层。

2)高温盐浴渗氮不改变45钢渗层物相,与常规盐浴渗氮处理一样,由ε-Fe2-3N和γ'-Fe4N相组成,但前者γ'-Fe4N相的相对含量从常规盐浴渗氮的0.46增加到0.61。

3)高温盐浴渗氮提高45钢表面硬度,最高截面硬度从常规盐浴渗氮的702提高到784 HV0.01。

4)高温盐浴渗氮提高45钢耐蚀性,自腐蚀电位从常规盐浴渗氮的−1 090提高到−1 053 mV,自腐蚀电流由0.302降低到0.214 μA/cm2。

[1] 赵剡水,杨为民. 农业拖拉机技术发展观察[J]. 农业机械学报,2010,41(6):42-48. Zhao Yanshui, Yang Weimin. Technological development of agricultural tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(6):42-48. (in Chinese with English abstract)

[2] 罗锡文,张智刚,赵祚喜,等. 东方红X-804 拖拉机的DGPS 自动导航控制系统[J]. 农业工程学报,2009,25(11):139-145. Luo Xiwen, Zhang Zhigang, Zhao Zuoxi, et al. Design of DGPS navigation control system for Dong fang hong X-804 tractor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(11): 139-145. (in Chinese with English abstract)

[3] 李继山,廖日东,陈国华. 42CrMo 钢曲轴电磁感应加热过程奥氏体化[J]. 材料热处理学报,2015,36(1):217-222. Li Jishan, Liao Ridong, Chen Guohua. Austenite formulation of 42CrMo steel induction heating crankshaft[J]. Transactions of Materials and Heat Treatment, 2015, 36(1): 217-222. (in Chinese with English abstract)

[4] 马跃进,张建华,刘淑霞,等. 干喷钢砂在电弧喷涂修复曲轴中的应用[J]. 农业工程学报,2000,16(1):71-74. Ma Yuejin, Zhang Jianhua, Liu Shuxia, et al. Application of dry blasting steel grit on repairing crankshaft with arc spraying[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2000, 16(1): 71-74. (in Chinese with English abstract)

[5] 韩存仓. 45钢拖拉机曲轴断裂分析[J]. 金属热处理,2010,35(3):104-107. Han Cuncang. Fracture analysis of 45 steel crankshaft for tractor[J]. Heat Treatment of Metals, 2010, 35(3): 104-107. (in Chinese with English abstract)

[6] Li Wei, Yan Qing, Xue Jianhua. Analysis of a crankshaft fatigue failure[J]. Engineering Failure Analysis, 2015, 55: 139-147.

[7] Fonte M, Duarte P, Anes V, et al. On the assessment of fatigue life of marine diesel engine crankshafts[J]. Engineering Failure Analysis, 2015, 56: 51-57.

[8] 黄邦戈,陆宇衡,谢德锦. 发动机曲轴再制造工艺研究[J].装备制造技术,2011(5):10-12. Huang Bangge, Lu Yuheng, Xie Dejin. Study on engine crankshaft remanufacturing process[J]. Equipment Manufactring Technology, 2011(5): 10-12. (in Chinese with English abstract)

[9] 常建,徐兆坤. 国外发动机曲轴连杆轴承材料分析[J]. 汽车与配件,1997(3):26-27.

[10] 方华,高峥,袁兆成,等. 淬火强化曲轴的弯曲疲劳分析[J].内燃机学报,2002,21(6):465-472. Fang Hua, Gao Zhen, Yuan Zhaocheng, et al. Research on bending fatigue of quenching strengthened crankshaft[J]. Transactions of Csice, 2002, 21(6): 465-472. (in Chinese with English abstract)

[11] 李军迎,陈学富,杨钊,等. 45钢曲轴的感应淬火工艺[J].金属热处理,2013,38(4):67-68. Li Junying, Chen Xuefu, Yang Zhao, et al. Induction hardening process of 45 steel crankshaft[J]. Heat Treatment of Metals, 2013, 38(4): 67-68. (in Chinese with English abstract)

[12] 周建忠,花银群,杨继昌,等. 球铁曲轴激光淬火强化技术研究[J]. 农业机械学报,2001,32(3):109-112. Zhou Jianzhong, Hua Yinqun, Yang Jichang, et al. Study on the laser hardening technology for a crankshaft of nodular iron[J]. Transactions of the Chinese Society for Agricultural Machinery, 2001, 32(3): 109-112. (in Chinese with English abstract)

[13] 鲁金忠,孙益飞,张雷洪,等. 激光斜冲击对S1100型曲轴疲劳强度的影响[J]. 农业机械学报,2007,38(11):167-169. Lu Jinzhong, Sun Yifei, Zhang Leihong, et al. Effect of oblique laser shock processing on fatigue strength of S1100 crankshaft[J]. Transactions of the Chinese Society for Agricultural Machinery, 2007, 38(11): 167-169. (in Chinese with English abstract)

[14] 李惠友,罗德福,吴少旭. QPQ技术的原理与应用[M]. 北京:机械工业出版社,2008.

[15] 周鼎华. QPQ处理工艺及其质量控制[J]. 热处理技术与装备,2006,27(1):28-30. Zhou Dinghua. QPQ technology and quality control[J]. Heat Treatment Technology and Equipment, 2006, 27(1): 28-30. (in Chinese with English abstract)

[16] 徐洪波. 重卡曲轴热处理工艺性能分析[D]. 青岛:山东大学,2009. Xu Hongbo. Heavy Truck Crankshaft Performance Analysis of Heat Treatment Process[D]. Qingdao: Shangdong University, 2009. (in Chinese with English abstract)

[17] Zhou Zhengshou, Dai Mingyang, Shen Zhiyuan, et al. Effect of D.C. electric field on salt bath nitriding for 35 steel and kinetics analysis[J]. Journal of Alloys and Compounds, 2015, 623: 261-265.

[18] Cleugh D, Blawert C, Steinbach J, et al. Effects of rare earth additions on nitriding of EN40B by plasma immersion ion implantation[J]. Surface and Coatings Technology, 2001, 142: 392-396.

[19] 刘传博,汤文彬,刘琎. 35钢45钢化学成分与机械性能的关系[J]. 钢铁研究,1995(2):20-23. Liu Chuanbo, Tang Wenbin, Liu Jin. Dependence of mechanical properties on chemical compositions of No.35 & No.45 steel[J]. Research on Iron & Steel, 1995(2): 20-23. (in Chinese with English abstract)

[20] Cai Wei, Meng Fanna, Hu Jing, et al. Effect of QPQ nitriding time on wear and corrosion behavior of 45 carbon steel[J]. Applied Surface Science, 2012, 261: 411-414.

[21] 戴明阳,周正寿,胡静,等. 35钢稀土快速盐浴渗氮技术及动力学分析[J]. 材料热处理学报,2015,36(9):197-201. Dai Mingyang, Zhou Zhengshou, Hu Jing, et al. Rapid rare earth salt bath nitriding of 35 steel and kinetics analysis[J]. Transactions of Materials and Heat Treatment, 2015, 36(9): 197-201. (in Chinese with English abstract)

[22] Balikci E, Yaman O. Investigation on liquid bath nitriding of selected steels[J]. Surface Engineering, 2011, 27(8): 609-615.

[23] Wang Jun, Lin Yuanhua, Yan Jing, et al. Influence of time on the microstructure of AISI 321 austenitic stainless steel in salt bath nitriding[J]. Surface and Coatings Technology, 2012, 206(25): 3399-3404.

[24] Luo Heng, Shin Y, Yu Yang, et al. Predicting oxygen vacancy non-stoichiometric concentration in perovskites from first principles[J]. Applied Surface Science, 2014, 323: 65-70.

Improvement of tractor crankshaft properties by rapid high temperature salt bath nitriding

Dai Mingyang1, Tang Wei1, Sun Fei2,3, Hu Jing1,2※

(1. Jiangsu Key Laboratory of Materials Surface Science and Technology, School of Materials Science and Engineering, Changzhou University, Changzhou 213164, China; 2. Jiangsu Collaborative Innovation Center of Photovolatic Science and Engineering, Changzhou University, Changzhou, 213164, China; 3. Department of Mechanical Engineering, Changzhou Institute of Light Industry Technology, Changzhou, 213164, China)

Salt bath nitriding is one of the most popular surface modification technologies to treat tractor’s crankshaft for obtaining the required properties. Generally, several hours is needed to acquire the required layer depth in normal salt bath nitriding, and especially, it is almost impossible to get the required qualified deep layer depth due to the loose outermost surface layer formed at longer duration. Therefore, it is of significant value to improve its efficiency and get the required layer depth with good quality. In order to enhance the nitriding efficiency of tractor’s crankshaft, AISI 1045 carbon steel, which is a type of common material used to produce tractor’s crankshaft in industrial production, was selected as the testing material. Rapid salt bath nitriding was conducted at higher temperature of 660℃ instead of normally used 560℃ .Then we compared normal salt bath nitriding with higher temperature salt bath nitriding for different nitriding time. Optical microscopy (OM), X-ray diffraction (XRD), micro-hardness testing and electrochemical workstation were employed for analyzing the microstructure, phase, micro-hardness and corrosion resistance of the tested material, respectively. The results show that compound layer (also called white layer) is formed at the outermost surface after salt bath nitriding under all conditions. The thickness of compound layer is only 3.8 μm nitrided at 560℃ for 20 min, which is too thin to effectively improve the surface hardness and corrosion resistance of AISI 1045 steel, and it is increased to 17.1 μm treated at higher temperature of 660℃ for 20 min, which is the same thickness as that nitrided at 560℃ for140 min. Therefore, it can be concluded that higher temperature salt bath nitriding is much more efficient than normal salt bath nitriding. Meanwhile the main phases of compound layer are composed of ε-Fe2-3N and γ'-Fe4N nitrided under different conditions. But the relative contents of ε-Fe2-3N and γ'-Fe4N are different, which can be obtained by calculating the ratio of the strongest peak of γ'-Fe4N to the strongest peak of ε-Fe2-3N. The ratio of γ'-Fe4N to ε-Fe2-3N is 0.61 and 0.46 for higher temperature salt bath nitriding and normal temperature salt bath nitriding, respectively, which clearly shows that the relative content of γ'-Fe4N is more at higher temperature salt bath nitriding. Higher surface hardness and modestly higher sub-surface hardness are obtained with the same compound layer thickness after higher temperature salt bath nitriding. The maximum cross-sectional micro hardness of the AISI 1045 steel is increased from 702 to 784 HV0.01, which implies that the tractor’s crankshaft made of AISI 1045 steel treated by higher temperature salt bath nitriding may have better wear resistance. Moreover, AISI 1045 steel treated by higher temperature salt bath nitriding shows higher corrosion potential of -993 mV and lower corrosion current of 0.302l A/cm2compared with that treated by normal temperature salt bath nitriding, which indicates that AISI 1045 steel treated by higher temperature salt bath nitriding has better corrosion resistance. The mechanism of high temperature salt bath nitriding process is that the decomposition rate of CNO−is greatly accelerated, and thus much more active nitrogen atoms can be produced in the salt bath media, plus the vacancy concentration in AISI 1045 steel is significantly increased at higher temperature. Therefore, a conclusion can be drawn that high temperature salt bath nitriding is possible to replace normal salt bath nitriding to further enhance the tractor’s crankshaft made of AISI 1045 steel, since high temperature salt bath nitriding can not only shorten salt bath nitriding time, but also enhance the combined properties of tractor’s crankshafts.

tractors; temperature; experiments; crankshaft; salt bath nitriding; hardness

10.11975/j.issn.1002-6819.2016.09.006

TG156.8

A

1002-6819(2016)-09-0040-05

戴明阳,唐 威,孙 斐,胡 静. 高温快速盐浴渗氮提高拖拉机曲轴性能[J]. 农业工程学报,2016,32(9):40-44.

10.11975/j.issn.1002-6819.2016.09.006 http://www.tcsae.org

Dai Mingyang, Tang Wei, Sun Fei, Hu Jing. Improvement of tractor crankshaft properties by rapid high temperature salt bath nitriding[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(9): 40-44. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.09.006 http://www.tcsae.org

2015-09-08

2016-03-23

江苏省科技成果转化项目(BA2013078);江苏省研究生创新基金项目(SCZ100431322)

戴明阳,男,研究方向为金属表面化学热处理。常州 常州大学江苏省表面工程科学与技术重点实验室,213164。Email:dmy9304@126.com※通信作者:胡 静,博士,教授,从事金属材料表面改性研究。常州 常州大学江苏省表面工程科学与技术重点实验室,213164。

Email:jinghoo@126.com