荔枝收获切割器果梗锯切功耗影响因素试验

2016-12-19赵润茂王红军唐之富张炳超邹湘军

赵润茂,王红军,唐之富,张炳超,邹湘军,叶 敏

(华南农业大学南方农业机械与装备关键技术教育部重点实验室,广州 510642)

荔枝收获切割器果梗锯切功耗影响因素试验

赵润茂,王红军※,唐之富,张炳超,邹湘军,叶 敏

(华南农业大学南方农业机械与装备关键技术教育部重点实验室,广州 510642)

为合理设计荔枝收获装备切割部件,获得理想荔枝果、树分离效果,在确定以回转锯切为切割方式的基础上,搭建果梗锯切功耗测定平台并进行荔枝果梗锯切试验。研究了锯齿前面斜磨角、锯片齿数、进锯速度、锯切转速对果梗锯切实时功耗的影响;以单因素试验结果为依据,选定三因素三水平进行正交试验,得到各因素对锯切实时功耗峰值影响的主次顺序为锯切转速、进锯速度、齿前面斜磨角、锯片齿数;同时得到在给定因素水平下的最佳组合是采用25°齿前面斜磨锯片、进锯速度为60 mm/min、锯切转速为550 r/min,此时电机瞬时功耗峰值最小为0.488 J。该研究为荔枝机械化收获装备切割部件的设计提供了参考。

机械化;切割;试验;荔枝收获;切割器;果梗锯切;影响因素

0 引言

对荔枝产后采收环节实施机械化作业是推动荔枝产业发展的有效途径。依据人工采摘方式,荔枝采摘装备执行机构应具备稳固夹持与切割分离的基本功能,其中,切割机构是该装备的关键行为部件,更为直接影响果实采摘周期、采摘成功率、果枝分离断面平整度等,因此本文对荔枝果梗切割的影响因素进行试验研究。

目前针对农林作物茎秆切割特性的研究有:Igathinathane C等[1-3]利用扭力扳手、树剪、万能材料试验机搭建了玉米茎秆切割能测定台,研究切入角对玉米秆粉碎能耗的影响,并得到其切割力—位移特性;Senthilkumar T等[4]设计多因素试验研究刀片数量、圆周速度、刃厚、刀前角对棉花秸秆粉碎长度的影响;刘庆庭等在自制单刀切割试验台上对影响根茬破坏的因素进行研究[5],并通过甘蔗茎秆切割力试验,得到滑切角、刀盘倾角、切割速度对单位切割力及最大切割力的影响效应[6];其他还有针对油菜[7]、甘蓝[8]、龙须草[9]、龙眼[10]、灌木[11-12]等。然而农林作物生长环境各异、不同物种间物料参数不尽相同,其加工特性无法直接迁移使用,因此需对荔枝果梗进行独立试验研究。

对于荔枝果梗切割,陈燕等[13]建立了切割速度、切割角度、刃口形式与峰值切割力、切割强度之间的关系;吴良军等[14]通过试验测定其剪切强度、剪切功,并说明峰值剪切力、剪切功与果梗横截面积呈正相关。但其二者研究时采用的往复式割刀不适于荔枝果体单点悬挂、成串采摘的特点,且需要较复杂传动机构,因此更宜选用圆锯片作为果梗切割刀具,但直接选用标准化工业锯片无法最佳贴合荔枝收获的农艺要求,且目前未见有针对荔枝采摘锯片选用设计与功耗分析相关的研究。

本文在搭建低成本果梗锯切功耗测定试验平台的基础上,依据木材切削原理,对荔枝切割器锯片结构、运动参数进行单因素及多因素试验,获得各因素对试验指标的影响效应及既定因素水平下的最佳组合,以期为荔枝机械化采摘切割方案的制定提供参考。

1 果梗锯切试验台结构与原理

1.1 试验材料

试样采自华南农业大学热带亚热带果树种质资源圃,树种桂味,采样时间2015年7月8日。所采果梗尽可能通直、无病虫害和少分枝,试样直径为5~6 mm,长度剪裁为100 mm左右,采后将果梗编号用小枝叶分层覆盖保存,并保证所有试验在试样采后12 h内完成。依照标准规定(GB/1931-2009)实测含水率范围为53.48%~65.32%。

1.2 试验用锯片

在进行荔枝的机械化采收时,农艺学要求果梗应沿垂直于纤维方向的截面被切断且不留茬;结合木材切削原理,该切断方式为横向锯切,应选择横截圆锯片作为切割刀具。由于荔枝挂果果梗横截面积小、起支撑作用的木质部含量较少、抗弯能力差,所以必须选用厚度较小的超薄圆锯片,同时采用一定的拨料量以减少切削过程中锯片与锯路壁的摩擦,防止夹锯。据此确定选用图1所示锯片,其结构尺寸参数见表1。

图1 试验用硬质合金圆锯片Fig.1 Carbide saw blade for experimentation

表1 横截锯结构参数Table 1 Parameters of cross-cut saw

1.3 试验设备及工作原理

自行搭建的锯切力试验台总体结构如图2所示,主要包括:广州广材试验仪器有限公司生产的WD-20KE型精密微控电子式万能试验机,精度±0.5%,分辨率±1/120 000;胜利DM6234P+电机转速仪,精度±(0.05%+1),分辨力0.1;胜利VC86B数字万用表,精度±(1.0%+10),采样频率3次/S;正科ZGA60FM-G(24 V,600 r/min)型永磁直流减速电机,固纬直流电源供应器(变动率≤0.01%+3 mV),呼和浩特环众(集团)有限责任公司生产的K01-50三爪卡盘,广州美默通电子科技有限公司生产的CCM5D数显直流电机调速器等。

图2 锯切试验台结构示意图Fig.2 Structure schematic of test bed for sawing

如图2所示,试验在电子式万能材料试验机上进行,选用K01-50型三爪卡盘作为物料夹具,卡盘装配于万能试验机上压头处;锯片通过可拆卸法兰连接杆与电机主轴配合;直流电机与电机调速器、万用表连接,由直流电源供应器提供稳定电压,固定于万能试验机机架下侧平台,数字万用表通过RS232串口与计算机实时通讯。试验时,首先利用电机转速仪与电机调速器配合调节电机至设计转速,再控制万能试验机上压头带动所夹持物料以设定速度竖直向下进给靠近锯片直至完成一次切割。该试验台实现锯片可更换、进锯速度与切割转速可调并可测;另利用通讯万用表实时获得电机电流,以研究锯切过程中的切割功耗。

2 试验方法

2.1 试验指标的确定

果梗切割过程中锯片受到的切割阻力及产生的能量消耗是进行采摘器动力匹配及锯片结构优化设计所依据的主要参数,且对延长刀具寿命、提高采摘机械户外工作时长有重要意义。在实际锯切过程中,圆锯片受到的径向力、切向力大小方向实时变化,传统的测力方法难以满足需要,为便于测量分析,以主电机功耗来衡量果梗被切断的难易程度。果梗锯切时主电机能量消耗可分解为[15]

式中W为锯切过程切割电机所做总功,J;W0为电机空载状态下维持自身运行所需的基本能量,J;W'为锯断果梗的能量消耗,J。

直流电机在负载条件下,输入电压值恒定,电流值依据动载大小而增减,故锯切电机所做总功为

式中U为电机输入电压,恒值24.0,V;I为电机电流值,可利用万用表实时测定,A;t为做功时长,s。

2.2 试验因素的确定

本研究涉及的荔枝果树是典型的木本植物,其果梗宏观力学表现为正交各向异性[16],根据切削刃和主运动相对木材纤维方向的不同,木材直角自由切削分为纵向、横向和端向3个主要切削方向[17],显然,荔枝采摘时的切削为横向锯切,如图3所示。

图3 果梗锯切截面Fig.3 Sawing direction of litchi stem

在农业机械研究中,按支撑条件不同将切割分为有支撑切割与无支撑切割,对于荔枝收获,需在切割工序前利用夹持机构将果梗夹持,以防果实跌落,即切割刀片是以单端支撑切割原理工作的,因此,齿刃最小线速度的大小及其与进锯速度的匹配程度将直接决定果梗割茬是否产生撕裂。而锯齿线速度的选择与茎秆纤维组织的刚柔度有关[18],为控制生物特性的差异,试验样本同批次选自特定果树同一高度、直径在5~6 mm范围内的光滑果梗。

在进锯过程中,锯齿侧刃必须先于主刃切断果梗纤维,因此侧刃的锋利程度,即锯齿前面斜磨角在一定范围内增加,可减小切削功率[19];其次,每齿进给量表征锯片单个齿切削体积的大小,切削量过大导致果柄被锯片压倒歪斜、不能完全切断、断面倾斜及不平整等现象,切削量太小会降低采摘器的工作效率,每齿进给量为

式中Vz为每齿进给量,mm;v为进锯速度,m/min;n为锯片转速,r/min;z为圆锯片齿数。

由式(3)可知,齿数、进锯速度、锯片转速对锯片切削性能有一定影响,且锯片齿数、锯片转速与每齿进给量成反比[20],进锯速度与每齿进给量成正比。

2.3 单因素试验设计

综上所述,选取锯片齿前面斜磨角、齿数、进锯速度、锯切转速进行单因素试验,每个因素取3水平,每个水平重复3次。为排除果梗直径、含水率对试验结果的影响,每组因素试验在同一果梗上完成。果梗直径使用广陆数显游标卡尺(分辨率0.01 mm,误差±0.03 mm)测量,在锯切位置的不同方向上测量4次并求均值。

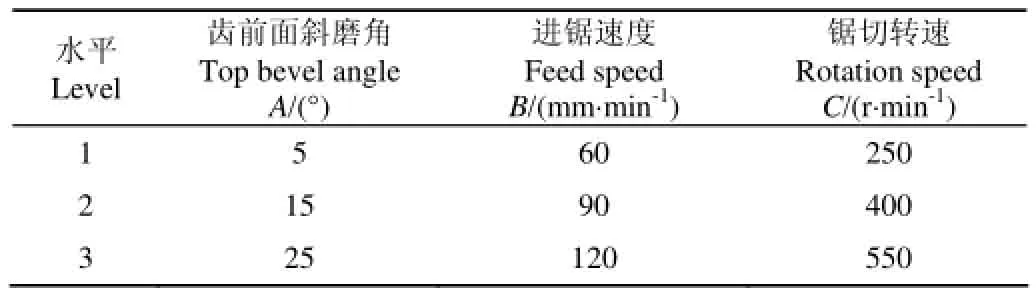

2.4 正交试验设计

在单因素试验结果分析的基础上选取齿前面斜磨角、进锯速度、锯切转速进行正交试验,以寻求最优化的参数组合。根据正交试验“尽可能选用小号正交表”的原则,选择L9(34)正交表进行试验,并对试验结果进行方差分析,因素水平如表2所示。

表2 正交试验因素水平表Table 2 Factors and levels graph for orthogonal test

3 结果与分析

图4是一次试验中万用表获取的电机电流—时间曲线。电流峰值Imax可以反映锯切过程中电机瞬时功耗极值,功耗极值通过在锯切时段对峰值电流的积分获得。

式中Wc为电机瞬时功耗计算值,J;t1为电流峰值出现时刻,s;t2为电流峰值终止时刻;T为万用表采样周期,恒值1/3,s;Imax为果梗锯切阶段电机电流峰值,A。

由图4可知,随着进锯时间(进给量)的增加,电机瞬时功耗逐渐上升,在进给行至果梗直径一半处到达峰值;继续进给,电机瞬时功耗则逐步减小直至果梗被完全锯断。曲线的形成原因是:在锯片对果梗的切入段,锯片进给引起果梗与锯片的当量接触弧长增加,即单位时间内锯齿侧刃需承担更多的切削量,则电机瞬时功耗增大;在切出段,果梗与锯片的接触情况与切入段恰为相反,则电机瞬时功耗逐步下降。

3.1 单因素试验

3.1.1 齿前面斜磨角

依据文献[17],一般情况下,硬质合金圆锯片齿前面斜磨范围为10°~20°,试验时拉开水平区间[21],定制齿前面斜磨角为5°、15°、25°的横截锯片锯切荔枝果梗,每个水平进行3次重复试验。记录电机电流峰值,以此计算电机功耗峰值并取均值,计算结果见表3,分析数据得出:电机功耗峰值随齿前面斜磨角的增大而减小,齿前面25°斜磨的锯片锯切效果最好,此时功耗峰值为0.637 J。对数据结果进行方差分析,F=9.949> F0.05(2,6)=5.14,表明锯片齿前面斜磨角对电机功耗峰值有显著影响。

3.1.2 锯片齿数

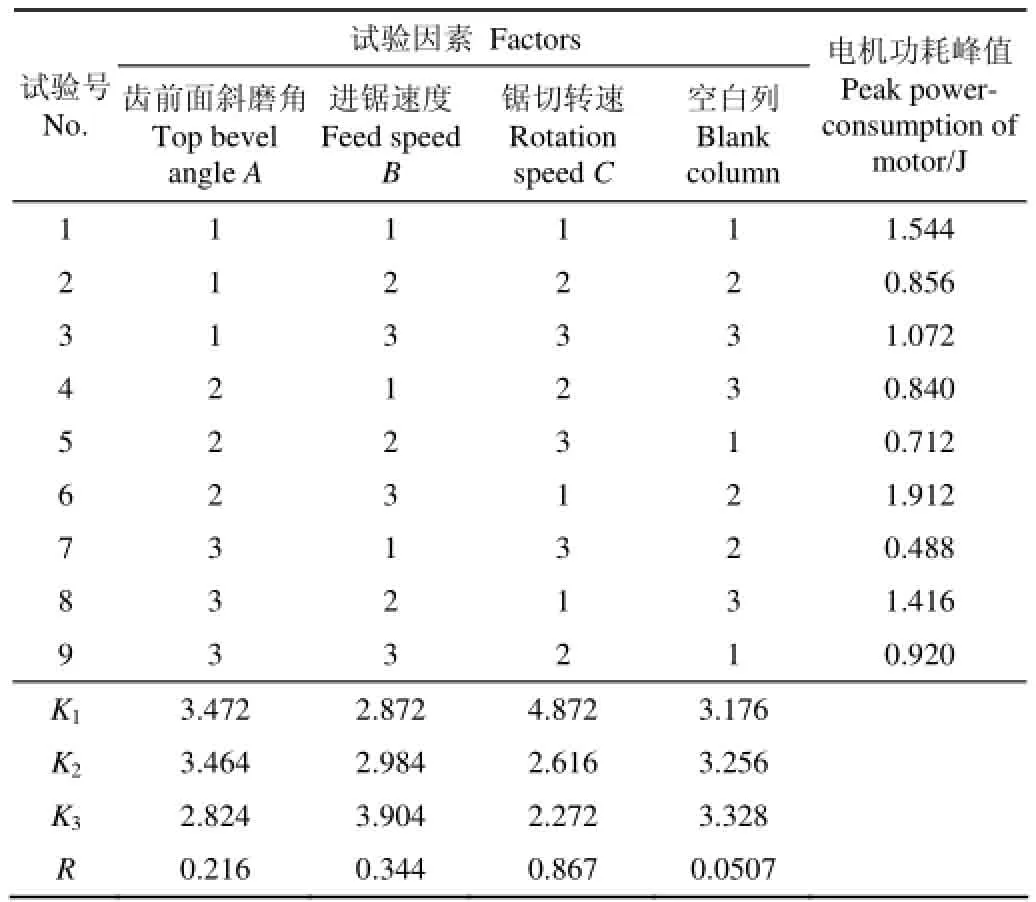

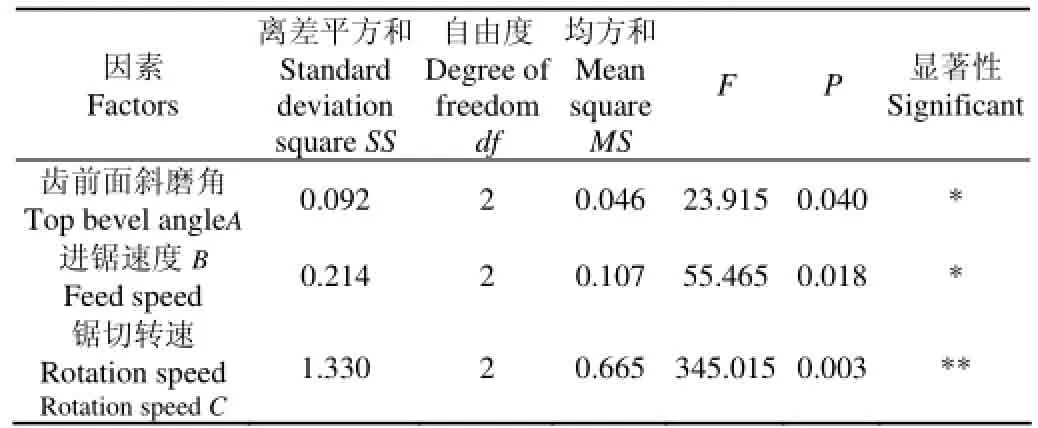

为避免过大的齿距造成卡锯现象,锯片齿数不宜过少,且又考虑到锯片周长尺寸限制及经济因素,锯片齿数有上限。分别试制30、40、50齿横截锯片锯切果梗,各水平试验重复3次。计算电机功耗峰值及其均值,结果见表3,分析得出:电机功耗峰值随锯片齿数增加而减小,50齿锯片功耗峰值最小为0.795 J。对其进行方差分析,F=1.803 3.1.3 进锯速度 控制万能材料试验机以不同的进给速度带动锯片锯切果梗,各水平试验重复3次。进行电机功耗峰值及其均值计算,结果见表3,可见随着进锯速度的增大,电机功耗峰值逐渐增大,速度为60 mm/min时,锯切功耗峰值最小为0.525 J。对数据结果进行方差分析,F=69.959>F0.01(2,6)= 10.93,因此进锯速度对电机功耗峰值有极显著影响。 表3 单因素试验方案及结果Table 3 Results of single factor experiment 3.1.4 锯切转速 对荔枝果梗的切断,存在一个临界锯切转速(锯齿线速度),实际工作时若低于这个临界速度,锯齿则无法割断所切削部分的木纤维,即会造成果梗歪斜切断、歪斜不断或劈裂现象[22]。据此,通过预试验测得9把锯片均能顺利切断果梗的最低转速约为230 r/min(此时进锯速度为120 mm/min),故取250 r/min为正式试验中锯切转速的水平下限。调节电机调速器使锯片以设定转速锯切荔枝果梗,每组试验重复3次,表3为试验中电机功耗峰值与峰值均值,可知:锯片转速增加,电机功耗降低,当锯片转速为550 r/min时,电机功耗峰值最小为0.603 J。进行单因素方差分析,F=271.879>F0.01(2,6)= 10.93,表明锯切转速对电机功耗峰值有极显著影响。 3.2 正交试验 根据表2进行9组多因素试验,并对结果进行直观分析,数据如表4所示。 表4 正交试验方案及结果Table 4 Results of orthogonal test 由表4可以看出,1、6、8号试验锯切功耗明显高于其他组,6号试验最高为1.912 J,7号试验最低为0.488 J。根据极差R值比较,锯切转速>进锯速度>齿前面斜磨角,可见C因素是最重要因素,取3水平为好;其次为B因素,取1水平为好;而A因素对结果的影响较小,取3水平为好,即A3B1C3是给定水平下的最佳试验组合。对正交试验数据进行方差分析,结果如表5所示。 表5 正交试验方差分析Table 5 Variance analysis of orthogonal test 方差分析表明:因素“齿前面斜磨角”、“进锯速度”对锯切功耗均有显著影响(P<0.05),但进锯速度较齿前面斜磨角影响更为显著;因素“锯切转速”对锯切功耗有极显著影响(P<0.01),这与极差分析的主次因素结论一致。 A3B1C3恰是表4中7号试验,其电机功耗峰值在9组试验中最小,为0.488 J,即直观分析结论验证了单因素试验、正交试验数据结果。 搭建了果梗锯切功耗测定平台,并对含水率为53.48%~65.32%、直径为(5±0.2)mm的“桂味”种荔枝果梗进行锯切试验。 1)单因素试验结果表明:锯片齿前面斜磨角对电机瞬时功耗峰值有显著影响,且随齿前面斜磨角的增大,电机功耗峰值降低;锯片齿数对电机瞬时功耗峰值无显著影响;进锯速度对电机瞬时功耗峰值有极显著影响,功耗峰值随进锯速度的增大而增加;锯切转速对电机瞬时功耗峰值有极显著影响,功耗峰值随锯切转速的增加而减小,在120 mm/min的进锯速度下,所选锯片能实现顺利锯切的临界转速为230 r/min。 2)正交试验结果表明:影响锯切电机瞬时功耗峰值的主次因素依次为:锯切转速、进锯速度、锯片齿前面斜磨角、锯片齿数;既定水平下,采用25°齿前面斜磨的锯片,在60 mm/min进锯速度、550 r/min锯切转速下电机功耗峰值最小为0.488 J。 3)单因素试验结果与多因素试验及其直观分析、方差分析结果一致,可为荔枝收获装备切割器的设计提供理论依据。 [1] Igathinathane C, Womac A R, Sokhansanj S. Effect of angle of cut on com stalks mechanical cutting strength and energy[C]//Phoenix: American Society of Agricultural and Biological Engineers, 2010. [2] Igathinathane C, Pordesimo L O, Schilling M W, et al. Fast and simple measurement of energy requirements for plant stalk cutting[C] //Providence: American Society of Agricultural and Biological Engineers, 2008. [3] Igathinathane C, Pordesimo L O, Schilling M W, et al. Fast and simple measurement of cutting energy requirement of plant stalk and prediction model development[J]. Industrial Crops and Products, 2011, 33(2): 518-523. [4] Senthilkumar T, Manian R, Kathirvel K. Effect of blade and operational parameters on shredding efficiency of an experimental cotton stalk shredder[J]. Agricultural Mechanization in Asia, Africa and Latin America, 2011, 42(3): 9-13. [5] 刘庆庭,区颖刚,卿上乐,等. 甘蔗茎秆在光刃刀片切割下根茬破坏试验[J]. 农业工程学报,2007,23(3):103-107. Liu Qingting, Ou Yinggang, Qing Shangle, et al. Stubble damage of sugarcane stalks in cutting test by smooth-edge blade[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(3): 103-107. (in Chinese with English abstract) [6] 刘庆庭,区颖刚,卿上乐,等. 甘蔗茎秆切割力试验[J]. 农业工程学报,2007,23(7):90-94. Liu Qingting, Ou Yinggang, Qing Shangle, et al. Cutting force test of sugarcane stalk[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(7): 90-94. (in Chinese with English abstract) [7] 吴明亮,管春运,汤楚宙,等. 油菜茎秆切割力影响因素试验[J]. 农业工程学报,2009,25(6):141-144. Wu Mingliang, Guan Chunyun, Tang Chuzhou, et al. Experiments on influencing factors of cutting force of rape stem[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(6): 141-144. (in Chinese with English abstract) [8] 李小强,王芬娥,郭玮俊,等. 甘蓝根茎切割力影响因素分析[J]. 农业工程学报,2013,29(10):42-48. Li Xiaoqiang, Wang Fen’e, Guo Weijun, et al. Influencing factor analysis of cabbage root cutting force based on orthogonal test[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(10): 42-48. (in Chinese with English abstract) [9] 罗海峰,汤楚宙,邹冬生,等. 龙须草茎秆往复式切割试验研究[J]. 农业工程学报,2012,28(2):13-17. Luo Haifeng, Tang Chuzhou, Zou Dongsheng, et al. Experiment on reciprocating cutting of eulaliopsis binate stem[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(2): 13-17. (in Chinese with English abstract) [10] 吴良军,杨洲,段洁丽,等. 龙眼树枝修剪机具刀片切割力的影响因素试验[J]. 农业工程学报,2012,28(24):8-14. Wu Liangjun, Yang Zhou, Duan Jieli, et al. Experiment on influencing factors of cutting force of blades of trim tool for longan branch[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(24): 8-14. (in Chinese with English abstract) [11] 陈昕. 四倍体刺槐饲料收获机往复切割器切割性能研究[D].北京:北京林业大学,2011. Chen Xin. The Research of Reciprocating Knife Cutting Performance Used for Tetraploid Robinia Pseudoacacia Harvester[D]. Beijing: Beijing Forestry University, 2011. (in Chinese with English abstract) [12] 刘志刚,王德成,翟改霞,等. 往复式双动刀灌木收割机设计与试验[J]. 农业机械学报,2013(增刊2):102-106. Liu Zhigang, Wang Decheng, Zhai Gaixia, et al. Design and experiment on reciprocating double knife shrub harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013(Supp.2): 102-106. (in Chinese with English abstract) [13] 陈燕,蔡伟亮,向和平,等. 面向机器人采摘的荔枝果梗力学特性[J]. 农业工程学报,2012,28(21):53-58. Chen Yan, Cai Weiliang, Xiang Heping, et al. Mechanical properties of litchi stem for harvesting robots[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(21): 53-58. (in Chinese with English abstract) [14] 吴良军,杨洲,洪添胜,等. 荔枝树枝力学特性的试验研究[J]. 农业工程学报,2012,28(16):68-73. Wu Liangjun, Yang Zhou, Hong Tiansheng, et al. Experimental study on mechanical properties of litchi branches[J]. Transactions of the Chinese Society of Agricultural Engineering, (Transactions of the CSAE), 2012, 28(16): 68-73. (in Chinese with English abstract) [15] 唐进元,林学杰,唐健杰,等. 基于DEFORM-3D的金属锯切过程力能仿真研究[J]. 制造技术与机床,2012(8):99-103. Tang Jinyuan, Lin Xuejie, Tang Jianjie, et al. Force theory simulation research of metal cutting process based on DEFORM-3D software[J]. Design and Research, 2012(8): 99-103. (in Chinese with English abstract) [16] 陈诚. 往复切割器式灌木平茬机切割力的研究[D]. 北京:北京林业大学,2011. Chen Cheng. Research of Cutting Force for Reciprocating Knife Bush Harvester[D]. Beijing: Beijing Forestry University, 2011. (in Chinese with English abstract) [17] 曹平祥,郭晓磊. 木材切削原理与刀具[M]. 北京:中国林业出版社,2010. [18] 梁建平. 2GP—100灌木平茬机研究设计[J]. 内蒙古林业科技,1994(4):25-28. Liang Jianping. Study on the design of 2GP-100 bush harvester[J]. Inner Mongolia Forestry Science & Technology, 1994(4): 25-28. (in Chinese with English abstract) [19] 金维洙. 木材切削与木工刀具[M]. 哈尔滨:东北林业大学出版社,2005. [20] 李黎. 木材切削原理与刀具[M]. 北京:中国林业出版社,1983. [21] 王颉. 试验设计与SPSS应用[M]. 北京:化学工业出版社,2007. [22] 王飞. 沙生灌木圆锯片平茬锯切性能研究[D]. 北京:北京林业大学,2009. Wang Fei. Cutting Research for Desert Shurb Regenerating Harvesting with Circular Saw[D]. Beijing: Beijing Forestry University, 2009. (in Chinese with English abstract) Experiment on influencing factors of power consumption for sawing stem in cutting device of litchi harvester Zhao Runmao, Wang Hongjun※, Tang Zhifu, Zhang Bingchao, Zou Xiangjun, Ye Min There are 3 main forms of cutter commonly assembled into agricultural harvesters, which are reciprocating cutter, cutter disks and saw blade. Given the fact that the litchi fruits grow in bunches and hang from the bearing shoots, as well as the bionic principle that the cutting-section of the litchi stem must be smooth and unsplit when litchi is picked, it is more suitable to choose the saw blade when the litchi harvester is designed. However, directly using standardized industrial saw blade could not be best in agronomy. Meanwhile, it is indispensable to focus on the studies on the relationship between structure parameters and power consumption of main motor as well as the relationship between motion parameters and power consumption of main motor. After all, the harvester works in outdoor environment. Applying the principles of wood processing and cutting tool technology, the structure and motion parameters were experimentally studied. The experiment was carried out using an universal testing machine, with a 3-jaw chuck mounted on the upper pressure head and the saw blade -motor system installed at the bottom platform. The motor speed, whose current value was real-time measured during the sawing process by a communication multimeter, was controlled by a speed governor. The samples were taken from the Germplasm Collections of Tropical and Subtropical Fruit Species, South China Agricultural University. It was assured that these samples had a length of about 10 mm and a diameter between 5-6 mm, and the branches were straight, with no divergence and free of diseases. Each group of test was conducted on the same stem so as to lower the impact of the diameter and moisture content between different samples. Experiments were designed by using the single-factor method in the study, and 9 kinds of circular saw blades were trial-manufactured, with the combination of 3 kinds of teeth numbers and 3 kinds of face bevel angles. Besides, 3 rotation speed levels were set respectively. There existed a critical rotation speed in the process of stem sawing. If operating speed was lower than the critical speed, stem fibers would not be cut off thoroughly and even cause stem splitting. Therefore, the critical speed of each saw blade was measured by preliminary tests. Finally, a 250 r/min rotation speed was set as the lowest level over the whole experimental process. After all, the results showed that: 1) The instantaneous power consumption of the sawing motor was significantly affected by the face bevel angle (P<0.05), and the rotation speed (P<0.01), but was not affected by the number of teeth; 2) The instantaneous power consumption of the sawing motor increased with the rise of the feeding speed, while decreased with the rise of the face bevel angle and rotation speed. Based on the single-factor experiment, the L9(34) orthogonal experiment was carried out. The results showed that: 1) The order from high to low for the effect of each factor on instantaneous power consumption peak was rotation speed, feeding speed, face bevel angle and number of teeth; 2) At given levels, the lowest instantaneous power consumption of the cutting motor was 0.488 J, which was detected under the optimal combination of parameters, i.e. the face bevel angle was 25°, the feeding speed was 60 mm/min, and the rotation speed was 550 r/min. The study may provide theoretical basis for the design of cutting device of litchi harvester. mechanization; cutting; experiments; litchi harvesting; cutting device; stem-sawing; influencing factors 10.11975/j.issn.1002-6819.2016.09.003 S225.93;S667.1 A 1002-6819(2016)-09-0016-06 赵润茂,王红军,唐之富,张炳超,邹湘军,叶 敏. 荔枝收获切割器果梗锯切功耗影响因素试验[J]. 农业工程学报,2016,32(9):16-21. 10.11975/j.issn.1002-6819.2016.09.003 http://www.tcsae.org Zhao Runmao, Wang Hongjun, Tang Zhifu, Zhang Bingchao, Zou Xiangjun, Ye Min. Experiment on influencing factors of power consumption for sawing stem in cutting device of litchi harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(9): 16-21. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.09.003 http://www.tcsae.org 2015-09-09 2016-01-13 国家自然科学基金资助项目(51175189) 赵润茂,男,陕西乾县人,博士生,主要从事农业机械装备的研究。广州 华南农业大学南方农业机械与装备关键技术教育部重点实验室,510642。Email:Zhrm_2007@163.com ※通信作者:王红军,女,重庆人,教授,博士,主要从事智能设计、农业机械装备的教学和研究。广州 华南农业大学南方农业机械与装备关键技术教育部重点实验室,510642。Email:xtwhj@scau.edu.cn

4 结论

(Key Laboratory of Key Technology on Agricultural Machine and Equipment, Ministry of Education, South China Agricultural University, Guangzhou 510642, China)