联合循环机组热经济学H&S方法建模及性能评价

2016-12-12李鸿坤陈坚红盛德仁

李鸿坤,陈坚红,盛德仁,李 蔚

(浙江大学 热工与动力系统研究所,浙江 杭州 310027)

联合循环机组热经济学H&S方法建模及性能评价

李鸿坤,陈坚红,盛德仁,李 蔚

(浙江大学 热工与动力系统研究所,浙江 杭州 310027)

联合循环;H&S模型;热经济学成本;耗散性组件;评价指标

众所周知,燃气-蒸汽联合循环发电已成为当前火力发电的主要发展方向之一[1].在能源-经济-环境协调发展的要求下,较高的发电成本是制约联合循环电厂的重要因素.合理的成本计算与分析是寻求复杂能量系统的节能潜力和优化方向的基础.联合循环发电的成本计算及效益分析成为研究领域的热点.

1 H&S理论

按照设备的功能,可以将机组中的组件分为生产性组件和耗散性组件.凝汽器、烟囱等都属于耗散性组件,该类组件没有明确的产品,工作流体在该类组件中恢复至初始状态.很多学者将负熵作为耗散性组件的产品.E&S模型解决了耗散组件的燃料及产品定义的问题,使得耗散组件能够被独立出来进行讨论和分析.E&S模型存在相应的问题,对于耗散组件,在数量上,产品的量远远大于燃料的量[13-14],即生产效率大于1,这不符合热力学规律,导致了不能对耗散组件进行有效的评价.

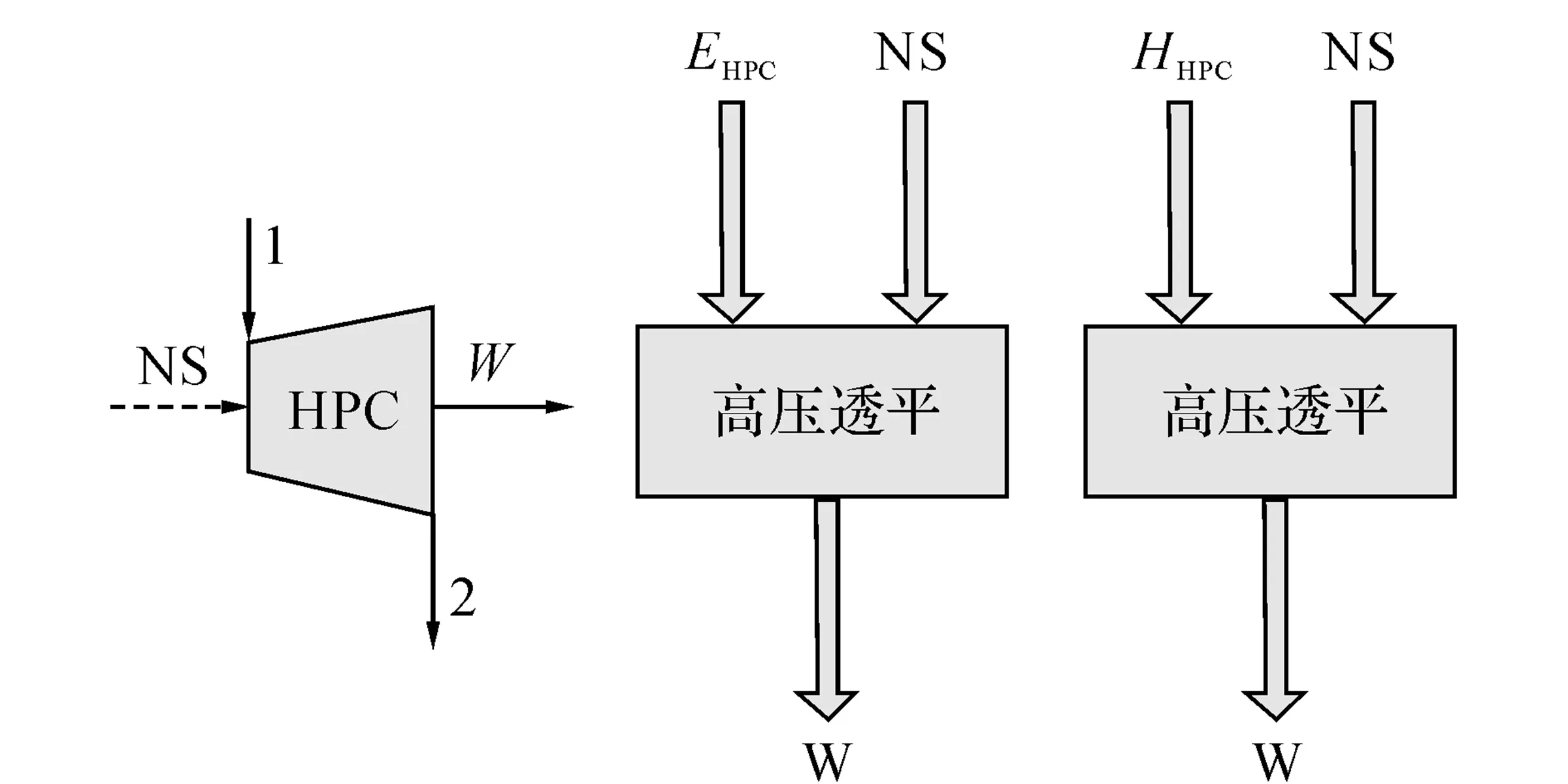

图1 高压透平的E&S模型与H&S模型Fig.1 E&S model and H&S model of high pressure turbine

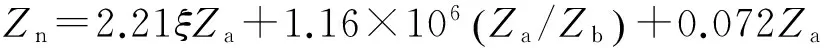

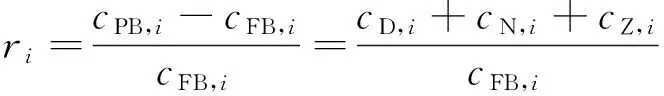

(1)

(2)

(3)

HHPC=qm(h1-h2).

(4)

(6)

(7)

传统的热量法计算分析只能反映能量转换过程中各股物流和能流的能量数量,无法反映能量传递的方向以及评价能量品质.与传统的热量法计算分析不同,尽管包含热力参数焓,从式(7)可知,H&S模型本质上是热力学第二定律与经济学规律相结合而来,属于热经济学方法的范畴,致力于分析能量系统中产品成本的形成过程.

2 热经济学成本模型的构建

以某典型的GE单轴9FA型燃气轮机联合循环机组为例建立热经济学模型进行分析.主要设备燃气轮机型号为PG9351,压气机压比为15.4,汽轮机型号为D10(按国内命名规则为LN137-9.65/2.18/0.30/565/565/300),配置国产三压余热锅炉.

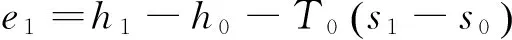

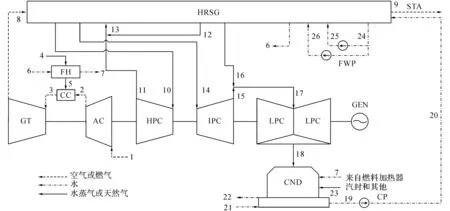

2.1 物理及生产结构图

物理结构图是将所研究的热力系统在某一集成度下重新划分得到的.如图2所示,为了方便计算,将余热锅炉和余热锅炉中的换热器看作是一个组件,记为HRSG.高压给水泵和低压给水泵看作一个组件,记为FWP.汽轮机的高压缸、中压缸和低压缸被拆分开作为单独的组件,记为HPC、IPC和LPC.为了系统的完整性和结果的精确性,考虑了烟囱(STA)和燃料加热器(FH)等组件.其他组件还有压气机(AC)、燃气透平(GT)、燃烧室(CC)、凝结水泵(CP)、凝汽器(CND)以及发电机(GEN)等.系统中的物流在物理结构图中用箭头表示.采用燃料-产品(fuel-product)的概念定义各设备的功能,基于H&S理论可知,燃料和产品都可以分为2种:焓和负熵.用焓或负熵量化的某一组件的生产目的被称为产品,其他为副产品.为了获得该产品所消耗的焓或者负熵被称为燃料.

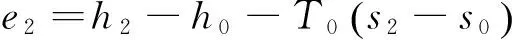

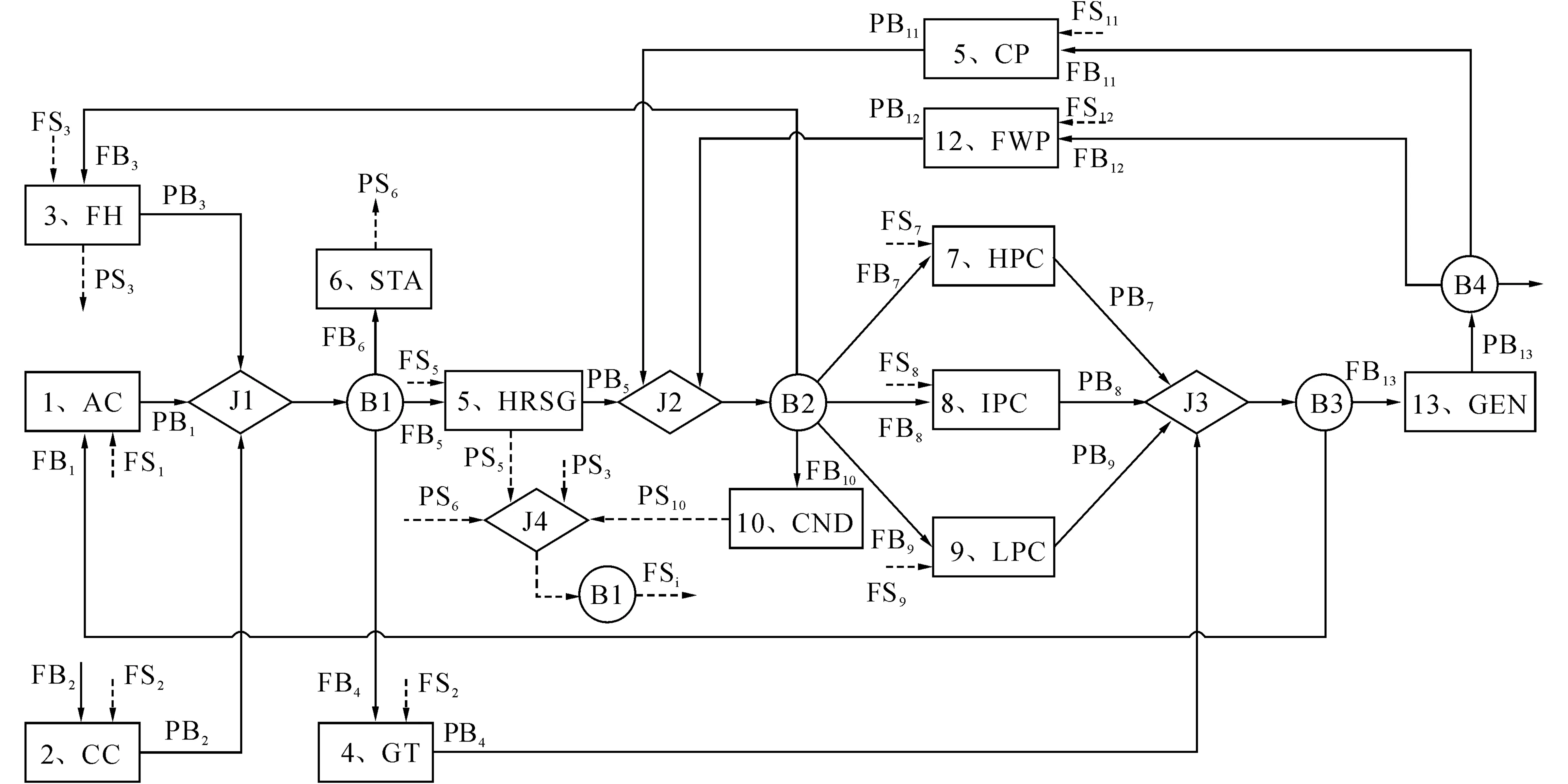

根据燃料-产品的定义,可以将物理结构图转化为生产结构图.图3中,矩形表示生产或者耗散性组件,菱形(J)、圆形(B)表示汇集组件和分支组件.这2类组件为虚拟组件,在汇集组件中,2个或者多个组件的产品汇合形成其他组件的燃料,该燃料通过分支组件分发给其他组件.各物理组件的箭头 FBi和PBi分别表示该单元所消耗的焓能燃料和焓能产品(包含热能、机械能及电能),箭头 FSi和PSi分别表示该组件所产生的负熵燃料和负熵产品.在汇集和分支组件中,入口和出口的焓或负熵保持守恒.图3的生产结构图中只考虑了内部的能量流动,组件的投资和维护成本可以认为是一种外部资源,由系统的外部环境直接输入到对应的组件中.

图2 燃气-蒸汽联合循环物理结构图Fig.2 Physical structure of gas-stream CCPP

图3 燃气-蒸汽联合循环生产结构图Fig.3 Productive structure of gas-stream CCPP

2.2 非能量费用计算

热经济学成本不仅包含上述的能量成本,还需计算组件的投资、运行和维护成本,即非能量费用.很多学者通常采用成本计算方程(costing equations)来完成设备投资成本的估算,本文所使用的成本计算方程参考文献[15]和[16].对于在以往的文献中没有涉及到的烟囱和燃料加热器的成本估算,采用下式[17]进行估算:

ZSTA=αZHRSG,0.03≤α≤0.06;

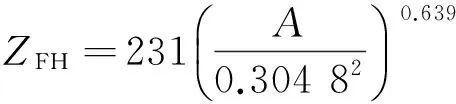

(8)

(9)式中:α为比例系数,A为燃料加热器的有效换热面积.

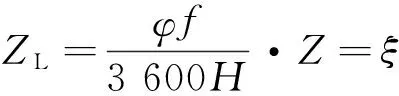

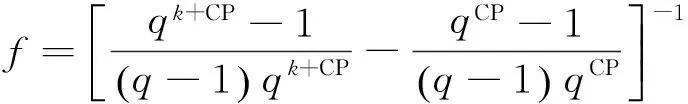

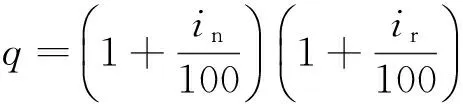

在热经济学成本计算中,需要将系统的投资成本Z,在经济寿命周期内,等额折算为每年的偿还成本ZL.该成本称为等额年度化分期偿还成本[18].

(10)

(11)

(12)式中:φ为系统维护因子,f为年度化因子,H为系统年运行小时数,ξ为分期偿还因子,CP为系统建设周期,k为分期偿还周期,in为利率,ir为通货膨胀率.

考虑到组件每年的运行维护费用,得到子系统的年非能量费用成本[19]如下:

(13)

式中:Za为某一组件的投资费用,Zb为系统的总投资费用.

2.3 热经济学成本方程

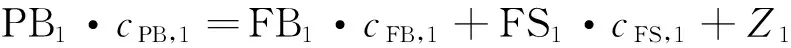

将联合循环系统中的所有组件的成本方程分为以下3类:第一类为单一产品的生产性组件(如透平、泵);第二类为多产品的生产性组件(如余热锅炉、燃料加热器等换热器型组件);第三类为耗散性组件(如凝汽器、烟囱).以压气机、余热锅炉、烟囱为例,3类成本方程分别为

(15)

(16)

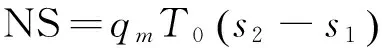

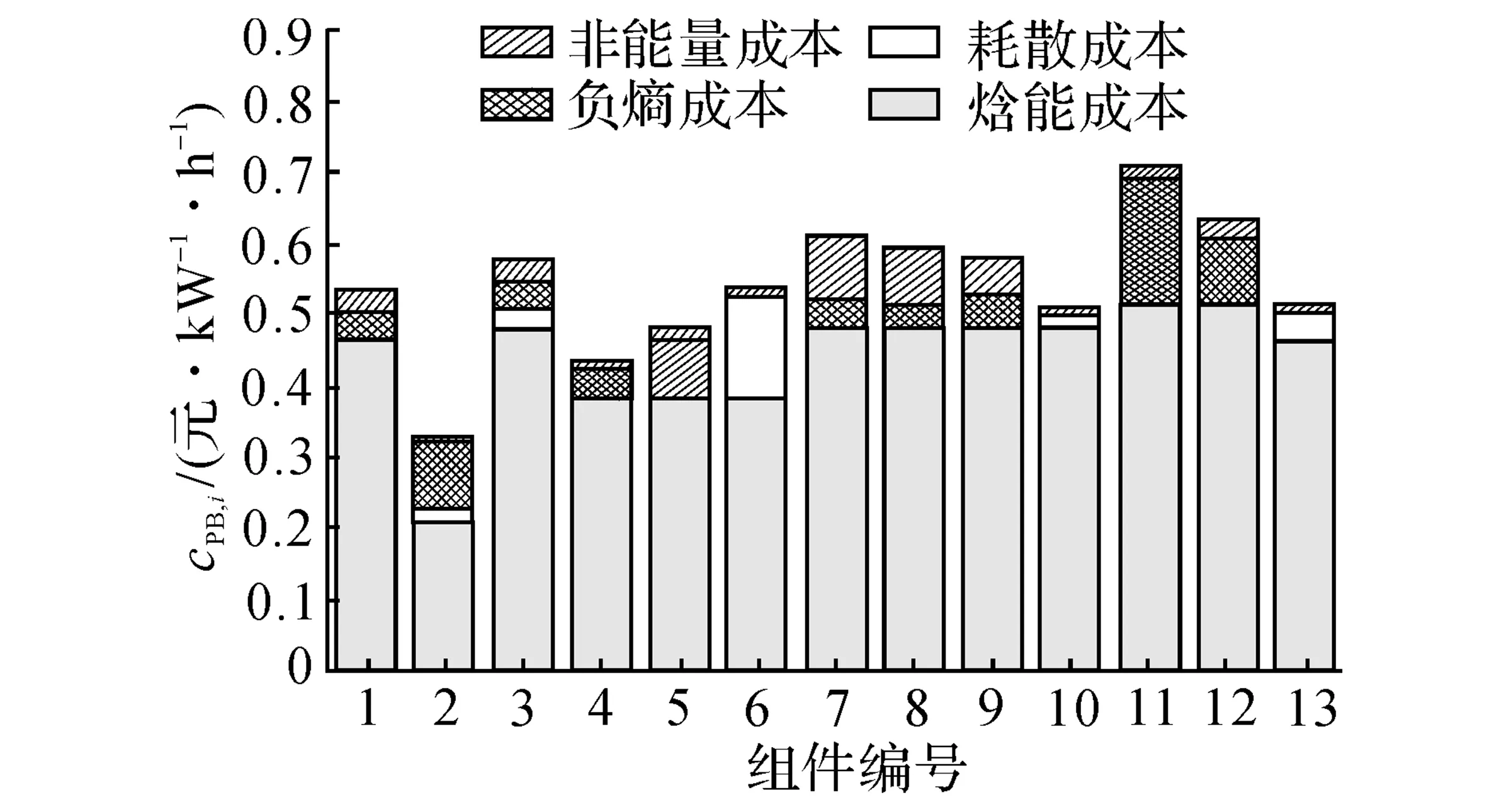

2.4 热经济学成本组成

组件的一般性热经济学成本表达式可以写作如下形式:

cPB,i=kFBicFB,i+kFSicFS,i+kZi= cFB,i+kDicFB,i+kFSicFS,i+kZi,

(17)

cPB,i=cFB,i+cD,i+cN,i+cZ,i.

(18)

式中:kFBi、kFSi和kZi分别为生产单位焓能产品所需的能量消耗、负熵消耗和非能量消耗.cD,i、cN,i、cZ,i分别为耗散成本、负熵成本和非能量成本,

cD,i=kDicFB,i=(kFBi-1)cFB,i,

cN,i=kFSicFS,i,cZ,i=kZi.

焓能成本是得到相应焓能产品所需的最少能量.耗散成本是由于散热、机械损耗所引起的能量损失成本,对于第一类组件,可以看作绝热过程,不存在机械损耗,所以耗散成本为0.负熵成本是由于热力过程的不可逆性而引起的,对于第三类组件,负熵是作为其产品,所以负熵成本为0.非能量成本是设备投资、运行以及维护所需的费用.

3 结果分析及性能评价

3.1 模型验证

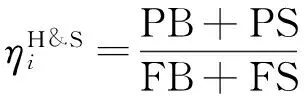

(19)

表1 100%设计大气环境基本负荷工况每股能量流的基本热力参数

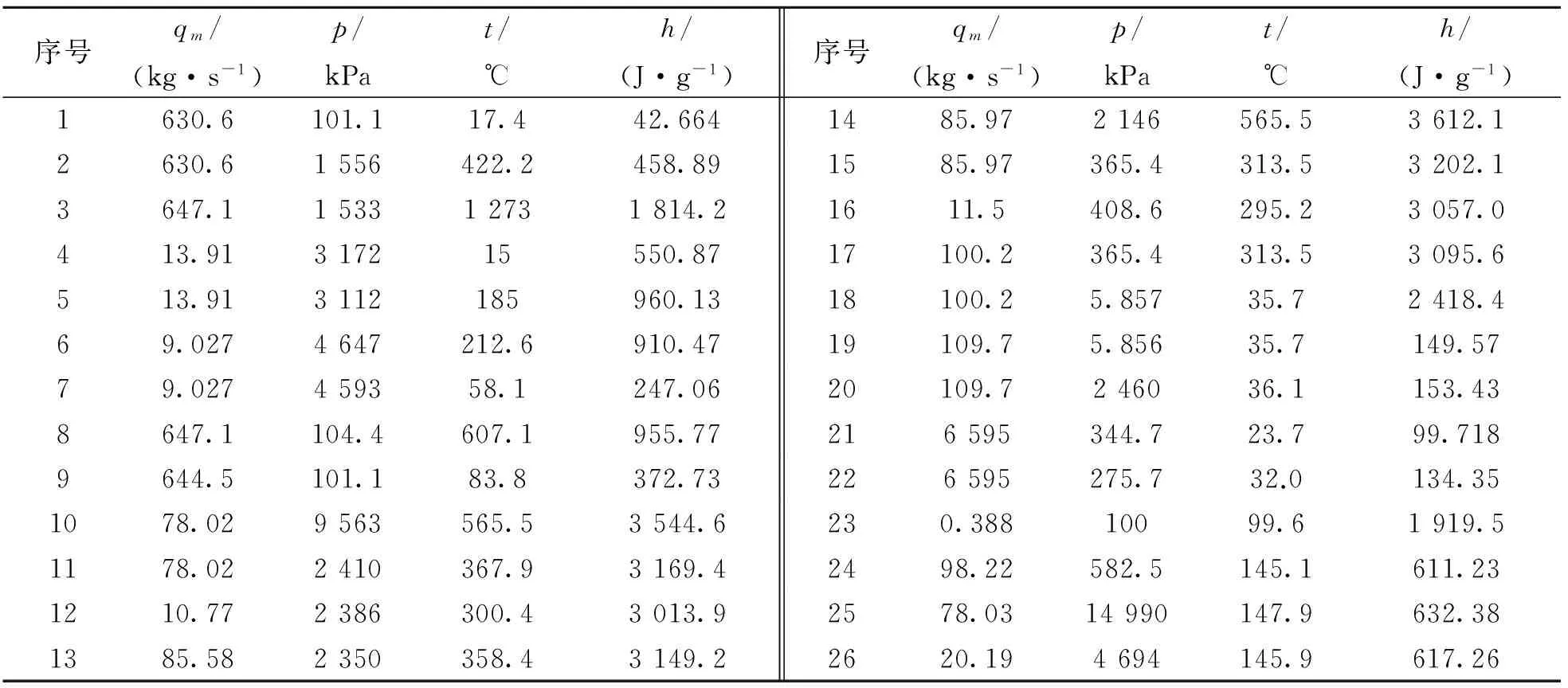

表2 燃气-蒸汽联合循环各组件生产效率

3.2 热经济学成本分析

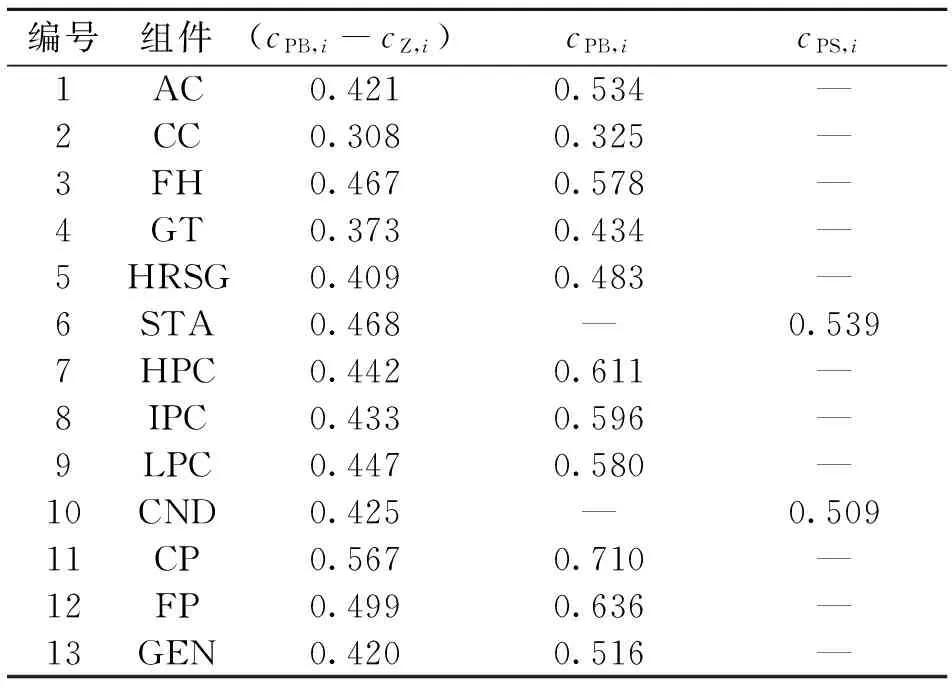

表3 燃气-蒸汽联合循环各组件热经济学成本

从表3可以看出,最终电能的热经济学成本为0.516元/(kW·h).根据目前市场电价分析可知,该价位偏高,这是当前燃气-蒸汽联合循环电厂发电经济性压力大的原因.

图4 燃气-蒸汽联合循环单位热经济学成本组成Fig.4 Composition of unit thermoeconomic cost in gas-stream CCPP

3.3 联合循环系统性能评价

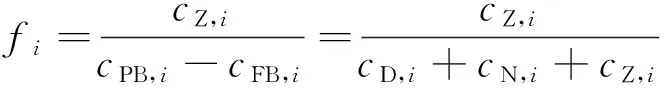

(20)

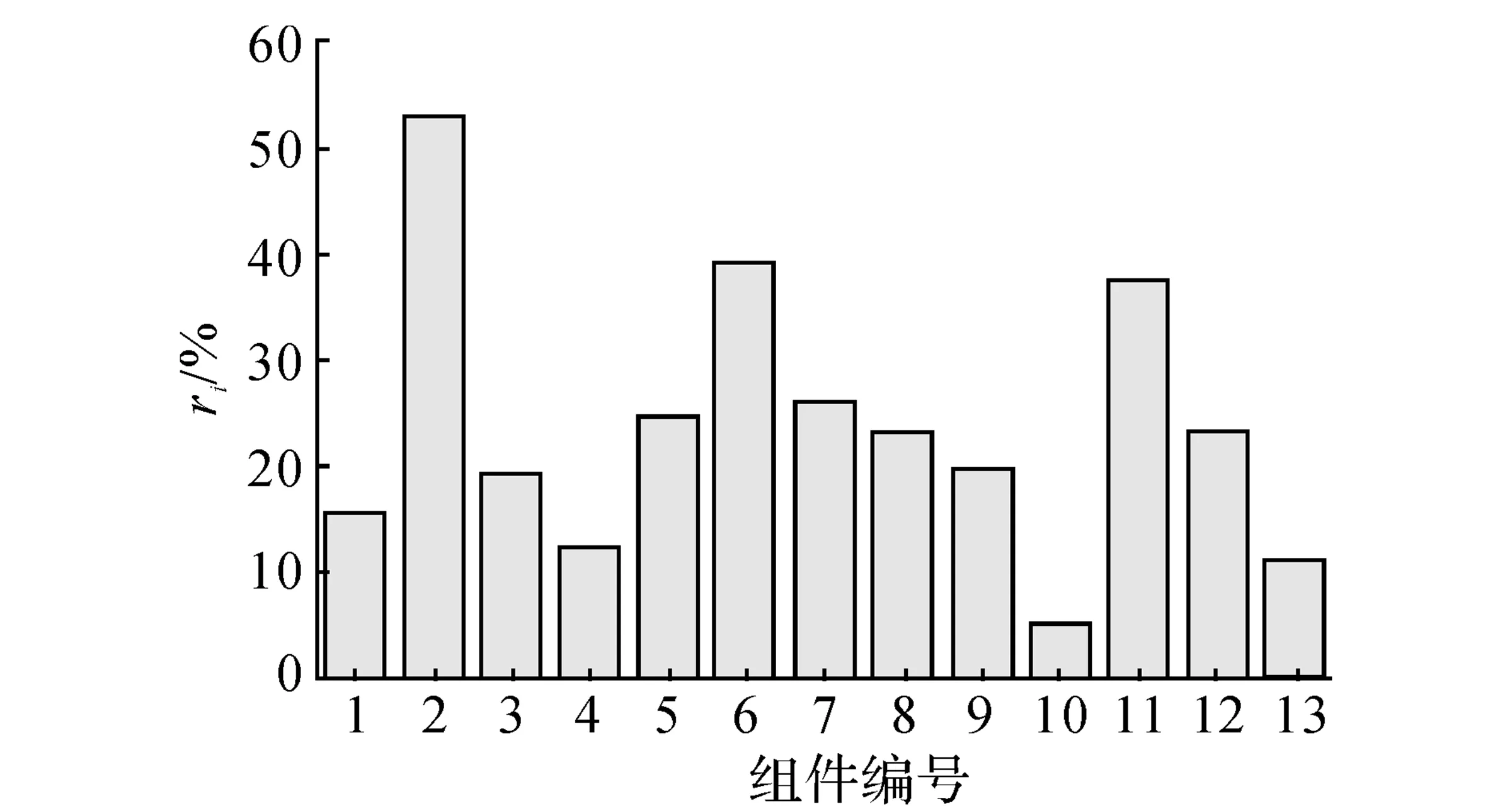

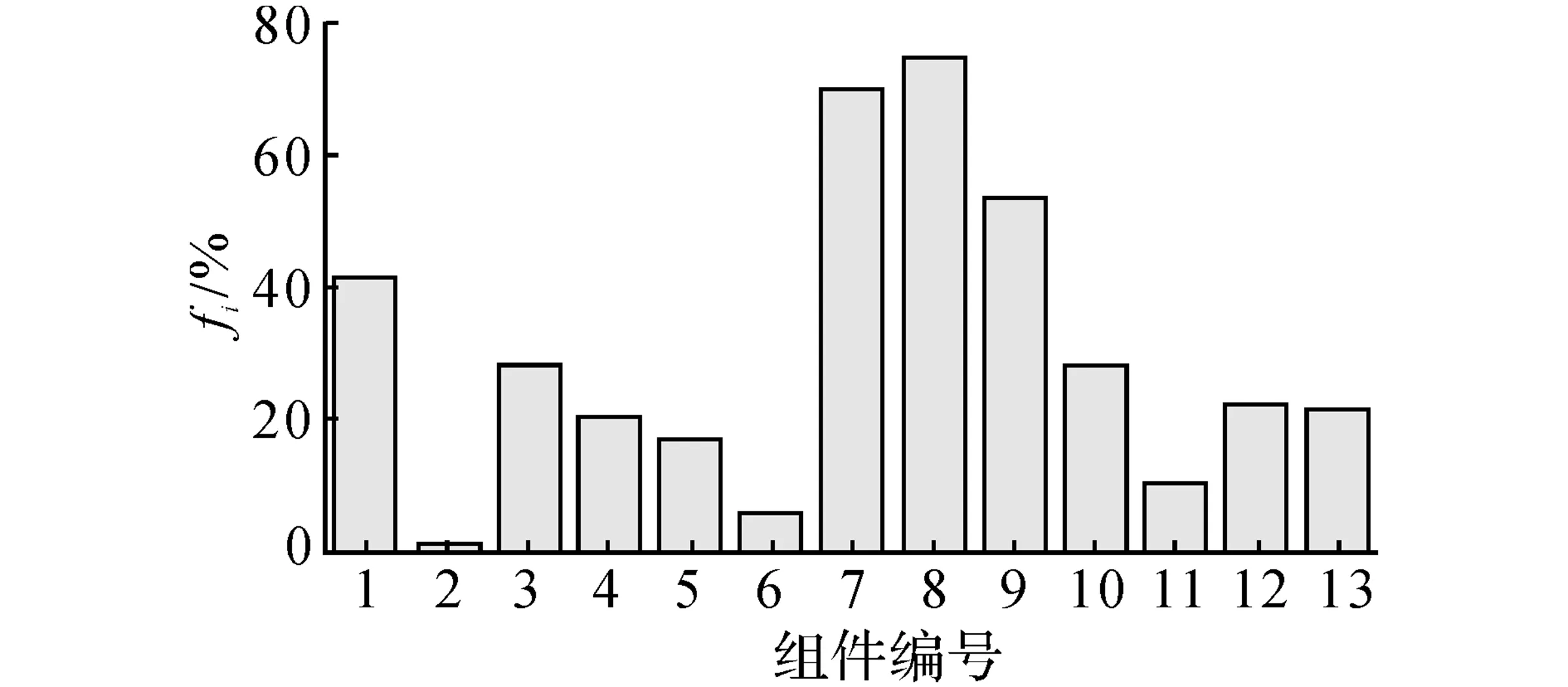

(21)式中:(cPB,i-cFB,i)为产品的成本差,由耗散成本、负熵成本和非能量成本组成.通过改进的指标可以对耗散组件进行评价.每个组件的计算结果如图5、6所示.

图5 各个组件的相对成本差Fig.5 Improved relative cost difference of each component

图6 各个组件的经济系数Fig.6 Exergoeconomic coefficient of each component

4 结 论

(1)建立基于H&S理论的燃气蒸汽联合循环发电机组的热经济学成本模型,解决了E&S模型计算结果中组件生产效率与热力学规律不符的矛盾.

(2)提出耗散成本的概念,将热经济学成本分为焓能成本、耗散成本、负熵成本和非能量成本,从本质上将热力学第二定律与经济学相结合.

(3)采用改进的评价指标对燃气蒸汽联合循环发电机组进行评价.结果显示:对于凝结水泵和燃烧室,需要减少由于不可逆引起的负熵成本;对于压气机和汽轮机组,改进的方向是降低投资成本.

[1] KEHLHOFER R, BACHMANN R, NIELSON H, et al. Combined-cycle gas and steam turbine power plants [M]. Tulsa (Oklahoma): Pennwell, 2009.

[2] WADE N M. Energy and cost allocation in dual-purpose power and desalination plants [J]. Desalination, 1999, 123(2): 115-125.

[3] EL-SAYED Y M. Application of exergy to design [J]. Energy Conversion and Management, 2002, 43(9): 1165-1185.

[4] VALERO A, CORREAS L, ZALETA A, et al. On the thermoeconomic approach to the diagnosis of energy system malfunctions: Part 1: the TADEUS problem [J]. Energy, 2004, 29(12): 1875-1887.

[5] PETRAKOPOULOU F, BOYANO A, CABRERA M, et al. Exergoeconomic and exergoenvironmental analyses of a combined cycle power plant with chemical looping technology [J]. International Journal of Greenhouse Gas Control, 2011, 5(3): 475-482.

[6] AHMADI P, DINCER I. Exergoenvironmental analysis and optimization of a cogeneration plant system using multimodal genetic algorithm (MGA) [J]. Energy, 2010, 35(12): 5161-5172.

[7] SANTOS J, NASCIMENTO M, LORA E, et al. On The negentropy application in thermoeconomics: a fictitious or an exergy component flow? [J]. International Journal of Thermodynamics, 2009, 12(4): 163-176.

[8] VALERO A, SERRA L, UCHE J. Fundamentals of exergy cost accounting and thermoeconomics. Part I: theory [J]. Journal of Energy Resources Technology, 2006, 128(1): 1-8.

[9] VALERO A, SERRA L, UCHE J. Fundamentals of exergy cost accounting and thermoeconomics Part II: applications [J]. Journal of Energy Resources Technology, 2006, 128(1): 9-15.

[10] LOURENÇO A B, SANTOS J J C S, DONATELLI J L M. Exergy analysis and fuel exergy allocation in a HTGR direct combined cycle [C]//2012 20th International Conference on Nuclear Engineering and the ASME 2012 Power Conference. Anaheim: ASME, 2012: 137-144. [11] LOURENÇO A B, SANTOS J J C S, DONATELLI J L M. Thermoeconomic modeling of a simple heat pump cycle: an alternative approach for valve isolation [C]// Proceedings of the 15th Symposium on Thermal Science and Engineering of Serbia. Sokobanja:[s.n.], 2011: 446-453.

[12] LOURENÇO A B, NEBRA S A, SANTOS J J C S, et al. Application of an alternative thermoeconomic approach to a two-stage vapour compression refrigeration cascade cycle [J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2015, 37(3): 903-913.

[13] ZHANG C, WANG Y, ZHENG C, et al. Exergy cost analysis of a coal fired power plant based on structural theory of thermoeconomics [J]. Energy Conversion and Management, 2006, 47(7): 817-843.

[14] YAO H, SHENG D, CHEN J, et al. Exergoeconomic analysis of a combined cycle system utilizing associated gases from steel production process based on structural theory of thermoeconomics [J]. Applied Thermal Engineering, 2013, 51(1): 476-489.

[15] XIONG J, ZHAO H, ZHANG C, et al. Thermoeconomic operation optimization of a coal-fired power plant [J]. Energy, 2012, 42(1): 486-496.[16] 赵春, 王培红. 燃气-蒸汽联合循环热经济学分析评价指标研究[J]. 中国电机工程学报, 2013, 33(23): 44-50. ZHAO Chun, WANG Pei-hong. Investigation on the evaluation indices for thermoeconomic analysis of combined cycle power plants [J]. Proceedings of the CSEE, 2013, 33(23): 44-50.

[17] TAAL M, BULATOV I, KLEMEJ, et al. Cost estimation and energy price forecasts for economic evaluation of retrofit projects [J]. Applied Thermal Engineering, 2003, 23(14): 1819-1835.

[18] AHMADI P, DINCER I, ROSEN M A. Exergy, exergoeconomic and environmental analyses and evolutionary algorithm based multi-objective optimization of combined cycle power plants [J]. Energy, 2011, 36(10): 5886-5898.

[19] 白兰.基于 GTCC 发电成本分析的矩阵模式热经济学方法研究[D].保定:华北电力大学,2007. BAI Lan. Research of matrix model thermoeconomics based on the analysis of GTCC power cost [D].Baoding: North China Electric Power University, 2007.

[20] 张超. 复杂能量系统的热经济学分析与优化[D]. 武汉: 华中科技大学, 2006. ZHANG Chao. Thermoeconomic analysis and optimization of complex energy systems [D].Wuhan: Huazhong University of Science and Technology, 2006.

Thermoeconomic analysis and performance evaluation of gas-steam combined cycle power plant based on H&S model

LI Hong-kun, CHEN Jian-hong, SHENG De-ren, LI Wei

(InstituteofThermalScienceandPowerSystems,ZhejiangUniversity,Hangzhou310027,China)

Traditional E&S model could not define the fuel and product of dissipative components conceivably in thermodynamics viewpoint. The productive components were overcharged. A new model was established for gas-steam combined cycle power plant based on structure theory of thermoeconomics and H&S theory in order to conduct the cost calculation and performance analysis of energy systems more reasonably and effectively. The composition of each component’s thermoeconomic cost was analyzed and the concept of dissipative cost was proposed. The traditional evaluation indexes of relative cost difference and exergyeconomic coefficient were improved based on the H&S model. The typical 9FA single shaft gas-steam combined cycle generating unit was used to verify the effectiveness and accuracy of the model. Results show that the structure theory of thermoeconomics based on H&S model can reasonably deal with dissipative components’ definition of fuel and product. The productive components can be fairly evaluated. For the condensate pump and the combustion chamber, it is necessary to reduce negentropy cost caused by irreversibility. For the air compressor and the steam turbine, the direction of improvement is to reduce non-energy cost.

combined cycle power plant; H&S model; thermoeconomic cost; dissipative component; evaluation index

2015-08-21. 浙江大学学报(工学版)网址: www.journals.zju.edu.cn/eng

李鸿坤(1991-),男,硕士生,从事电厂故障诊断和热力系统优化的研究. ORCID: 0000-0001-7094-4793. E-mail:lhk@zju.edu.cn 通信联系人:陈坚红,男,副教授. ORCID: 0000-0003-0957-6914. E-mail:power@zju.edu.cn

10.3785/j.issn.1008-973X.2016.01.017

TM 611

A

1008-973X(2016)01-0116-07