筛板塔细颗粒物协同脱除特性实验

2016-12-06李存杰郑成航翁卫国朱松强王丁振岑可法

张 军, 李存杰, 郑成航, 翁卫国, 朱松强,王丁振, 高 翔, 岑可法

(1.浙江大学 能源清洁利用国家重点实验室,浙江 杭州 310027; 2. 浙江能源集团有限公司,浙江 杭州310006)

筛板塔细颗粒物协同脱除特性实验

张 军1, 李存杰1, 郑成航1, 翁卫国1, 朱松强2,王丁振1, 高 翔1, 岑可法1

(1.浙江大学 能源清洁利用国家重点实验室,浙江 杭州 310027; 2. 浙江能源集团有限公司,浙江 杭州310006)

针对常规喷淋空塔无法满足颗粒物协同控制的难题,提出筛板塔强化传质实现协同脱除的方法.基于湿法烟气脱硫中试试验平台,考察湿法烟气脱硫关键工艺参数,包括烟气流速、浆液喷淋量、飞灰浓度、颗粒粒径等对细颗粒物脱除效率的影响规律,并与喷淋空塔脱除特性进行对比.结果表明,在实验工况下,细颗粒物脱除效率大于90%,最高超过95%;脱除效率随烟气流速、颗粒物浓度及浆液喷淋量的增大而提高.颗粒物分级脱除效率曲线呈“V”形分布特性,在0.2~1.0 μm粒径范围内脱除效率最低;在相同条件下,筛板塔细颗粒物脱除效果显著优于喷淋塔,在0.2~1.0 μm粒径段的脱除效率与总脱除效率较喷淋塔分别提高11%和5%以上.

筛板塔;燃煤电厂;细颗粒物;协同控制;排放特性

近年来,大气污染排放形势日趋严峻,煤炭燃烧会产生大量的粉尘、SO2及NOx等污染物,会对人体健康及自然环境带来巨大危害[1-2],是我国大气污染的主要来源之一.目前,我国燃煤电站普遍在除尘系统后加装湿法烟气脱硫(wet flue gas desulfurization, WFGD)系统,据统计,90%以上采用了石灰石-石膏湿法脱硫工艺,WFGD系统在高效脱硫的同时,由于脱硫浆液的洗涤作用,还能够协同脱除一部分飞灰颗粒,但对PM2.5的捕集效率较低[3];另外,因为脱硫浆液雾化夹带、石膏晶体析出,以及形成了可凝结颗粒物[4-5],脱硫塔出口Ca、S元素含量大幅增加[6],也在一定程度上制约了WFGD对细颗粒物的控制效果.

国内外学者针对湿法脱硫塔协同控制细颗粒物开展了大量研究.鲍静静等[7-8]发现应用蒸汽相变技术后WFGD内细颗粒物数浓度显著降低.熊桂龙等[9]采用蒸汽相变和撞击流耦合的方法,实验研究了撞击流相变室中应用蒸汽相变促进细颗粒脱除的效果.赵汶等[10]的试验结果表明化学团聚技术可使细颗粒物平均粒径增大约4倍,数浓度降低40%以上.Kim等[11]电喷射系统引入湿法喷淋洗涤器中,实验发现系统产生的带电液滴能够有效地捕集气体中的细颗粒.除此之外,陈海林等[12]研制了一种中试规模的螺旋型垂直筛板布气的喷射鼓泡脱硫除尘装置,除尘效率可达91%以上.Wang等[13]通过理论分析与实验研究了浮阀塔板的飞灰脱除特性.通过WFGD实现高效脱硫同时实现低成本的颗粒物控制具有重要意义,筛板塔具有成本低、传质效果强[14-16]等优点,在湿法烟气脱硫领域已有部分工程应用,但针对不同工况下筛板塔细颗粒物脱除效率的变化规律,筛板对细颗粒物强化脱除特性,以及筛板塔对颗粒物的协同控制作用等亟待解决的课题目前尚无研究.

本文基于湿法烟气脱硫中试试验平台,开展了筛板塔强化细颗粒物脱除特性的实验研究.研究了湿法烟气脱硫关键工艺参数,包括烟气流速、浆液喷淋量、飞灰浓度、颗粒粒径等,对颗粒物脱除特性的影响,对脱除效率及分级脱除效率进行分析,并与喷淋塔脱除特性对比,为进一步降低WFGD系统细颗粒的排放提供技术支撑.

1 实验系统及方法

1.1 实验系统

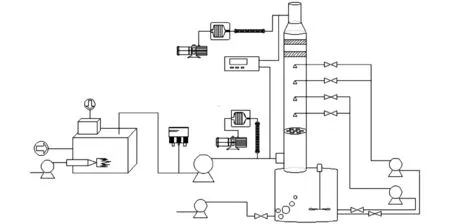

图1 筛板塔中试实验系统示意图Fig.1 Schematic of sieve tray spray scrubber experimental system

实验系统流程图如图1所示,从图1可以看出系统主要由污染物发生系统、烟气系统、吸收系统和测量系统组成.脱硫塔为喷淋塔结构,塔出口设置有2层折板式除雾器,下方设有4层喷淋层,在脱硫塔烟气入口与最下层喷淋之间安装有一层筛板,筛板塔主要设计参数qV-fluegas为烟气流量;qV-spray为喷嘴流量;qV-slurry为浆液量;ρB-flyash为烟尘浓度;wslurry为洗涤浆液含固量;H为脱硫塔塔高;D为脱硫塔塔径;d为筛板孔径;O为筛板开孔率;Δ为筛板孔间距,如表1所示,表中:在实验过程中,由热风炉燃烧产生热烟气,热风炉出口烟道处开有给料口,可变频给料机以一定频率向热烟气中送入电厂灰,飞灰与烟气在进入脱硫塔前充分混合,经增压风机增压进入脱硫塔,烟气经过筛板、喷淋层,与浆液逆向接触,至塔顶排出.

表1 筛板塔主要设计参数Tab.1 Main design parameters of sieve tray spray scrubber

1.2 试验测试方法

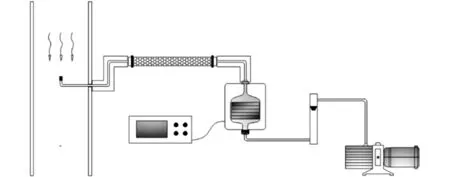

图2 DGI颗粒物采集系统图Fig.2 DGI particle matter sampling system

采样系统如图2所示,系统连接完毕后,开启保温装置(包括保温套和采样管伴热带),打开旁路并启动真空泵,将采样体积流量设置为70 L/min,在70 L/min的烟气流速下,细颗粒物会被DGI切割成5个粒径段:>2.5 μm、1.0~2.5 μm、0.5~1.0 μm、0.2~0.5 μm、<0.2 μm,大流量颗粒撞击式采集器(dekati gravimetric impactor, DGI)的收集盘会采集前4个粒径段的颗粒物;待保温装置温度升高至150 ℃,关闭旁路开始采样.入口与出口采样时间分别为10和15 min.采样后,将采样仪拆解,每级将收集到的颗粒物称重,计算其质量浓度.

分级细颗粒物脱除效率(简称“分级效率”)计算公式如下:

(1)

式中:ηi为第i级细颗粒脱除效率,ρin,i,ρout,i分别为脱硫塔入口与出口第i级细颗粒物质量浓度(mg/m3).

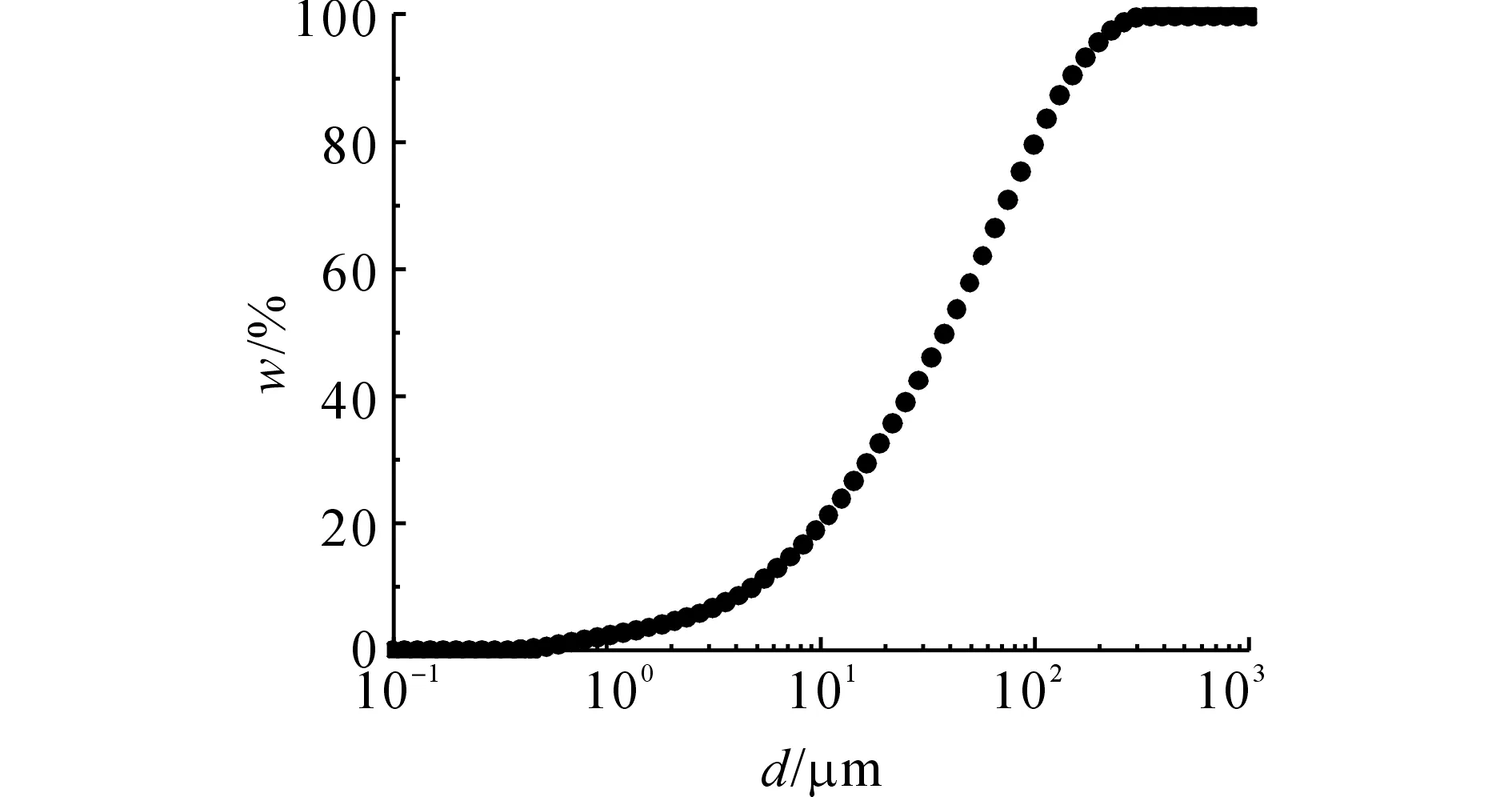

1.3 试验飞灰

中试试验所用的飞灰取自浙江省某电厂电除尘器第4级电场.如图3所示为使用Mastersizer 2000测得电厂飞灰的累积粒径分布,w为累积质量分数.从图3中可看出,飞灰颗粒粒径d在0.339 5~389.973 μm之间,以粗颗粒为主.PM2.5所占质量比重小于6%,PM10质量分数约为20%.飞灰颗粒质量分数中位粒径为38.0 μm.可吸入颗粒物(PM10)占飞灰颗粒总质量的21%,PM2.5占PM10总质量的30%.

图3 实验飞灰累积粒径分布Fig.3 Cumulative particle size distribution of coal-fired fly-ash particles

2 结果与讨论

2.1 烟气流速对脱除效率的影响

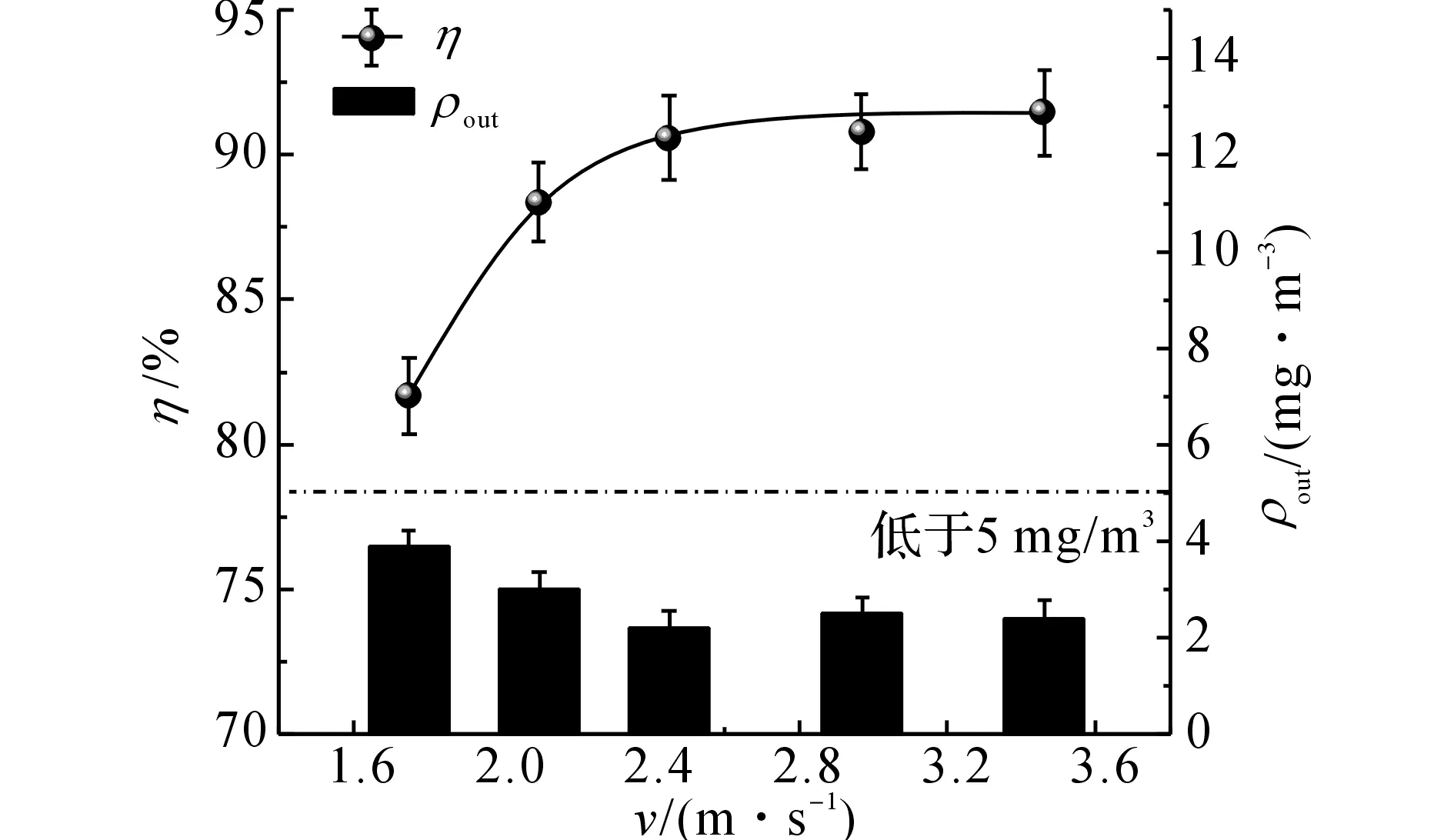

图4 烟气流速对飞灰颗粒脱除效率的影响Fig.4 Effect of gas flow rate on removal efficiency of fly-ash particle

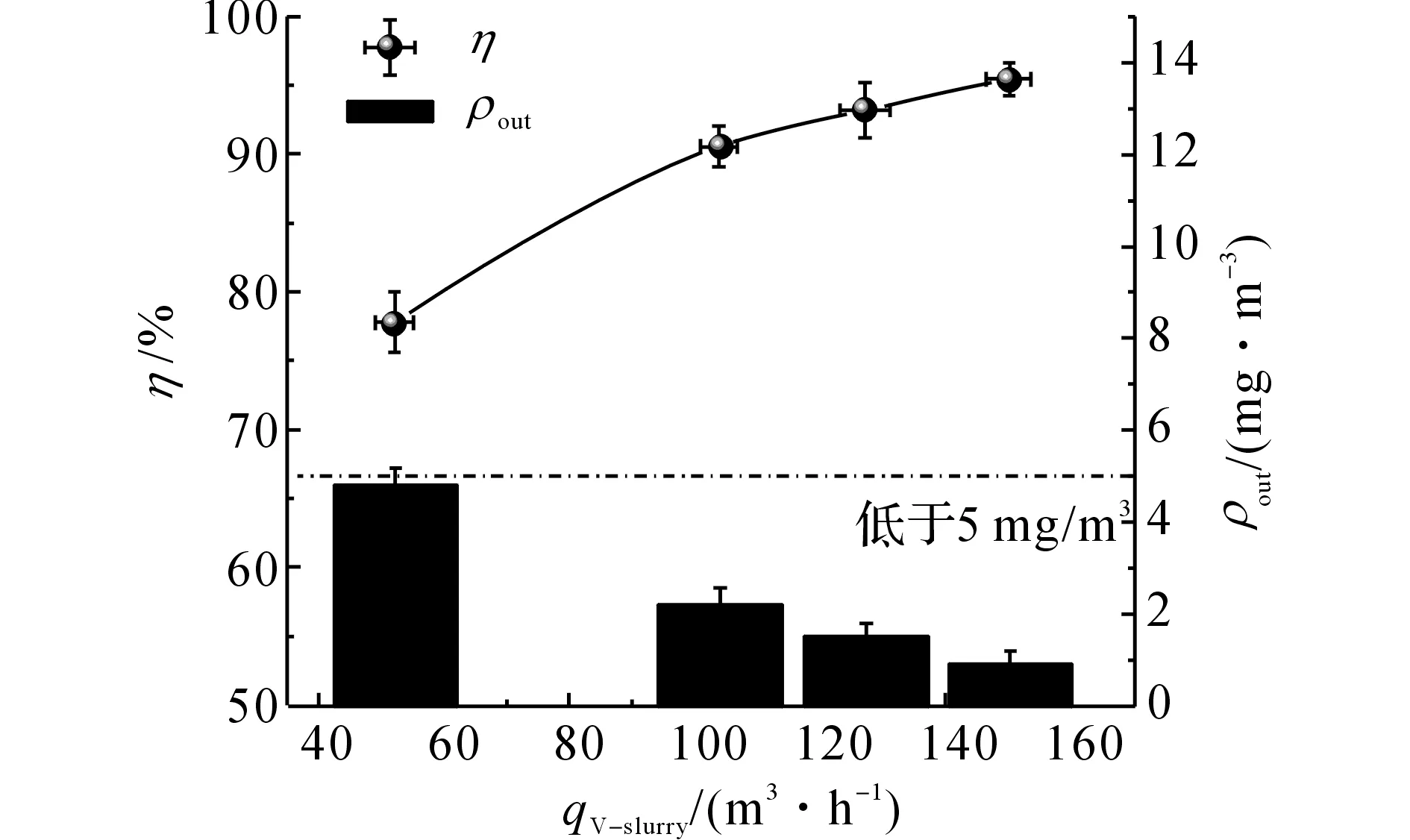

如图4所示为筛板塔颗粒物总脱除效率η随塔内烟气流速v的变化曲线,其中ρout为出口飞灰浓度.实验采用2层喷淋,入口飞灰浓度ρin=25±3 mg/m3.从图3中可看出,当v<2.45 m/s时,随着烟气流速的增加,系统对细颗粒物的脱除效率显著增加;当v=2.45 m/s时,脱除效率可达90%以上;当2.45 m/s 2.2 浆液喷淋量对脱除效率的影响 图5 浆液喷淋量对飞灰颗粒脱除效率的影响Fig.5 Effect of liquid flow rate on removal efficiency of fly-ash particle 在v=2.45 m/s时,ρin=22±2 mg/m3的工况条件下,考察了浆液喷淋量对颗粒物脱除的影响规律,如图5所示为浆液喷淋量对飞灰颗粒脱除效率的影响.从图5中可看出,颗粒物脱除效率随着浆液喷淋量的增加逐渐增大.其主要原因是浆液喷淋量增加使得气液接触界面增大[20];此外,在具有足够大的接触界面时,细颗粒分割粒径主要取决于单个气泡的液膜捕集效率[21],增大浆液喷淋量虽不能增加气泡数量但提高了单个气泡的脱除效率[22]. 2.3 粉尘浓度对脱除效率的影响 如图6所示为细颗粒物总脱除效率与入口飞灰浓度关系的测试结果.实验采用三层喷淋,烟气流速为2.45 m/s.从图6中可看出,随着入口飞灰浓度的增加,脱除效率先增大后趋于稳定.这是因为增加入口飞灰颗粒物浓度提高了细颗粒物间碰撞概率[23],强化了颗粒的间团聚,形成了部分大颗粒[19],进而显著提高了细颗粒的脱除效率;在入口飞灰颗粒浓度较高的情况下,液滴表面会形成不稳定的小尺度的团聚体,这些新形成的团聚体容易从液滴表面脱落[24],难以在洗涤塔内有效的脱除. 图6 入口飞灰浓度对颗粒脱除效率的影响Fig.6 Effect of fly-ash loading on removal efficiency of fly-ash particle 图7 粒径对颗粒脱除效率的影响Fig.7 Effect of particle size on removal efficiency of fly-ash particle 2.4 颗粒物粒径对脱除效率的影响 如图7所示为细颗粒物分级脱除效率变化曲线.烟气流速为2.45 m/s,3层喷淋,ρ为飞灰浓度.从图7中可看出,随着飞灰颗粒粒径减小,脱除效率先迅速降低随后再次回升,最低脱除效率出现在0.2~1.0 μm粒径区间,脱除效率呈“V”型分布.这是因为对于0.2 μm 以下的颗粒主要通过扩散作用捕集,随粒径的减小,扩散作用加剧,脱除效率提高;对于大于 1.0 μm 以上的颗粒,惯性碰撞机理起主要作用,随粒径的增加,捕集效率提高[25].而0.2~1.0 μm粒径段处于扩散作用与惯性碰撞作用的交叉区域[26],颗粒不能有效扩散,同时不具备足够的惯性脱离气流[27],因此该段颗粒脱除效率相对较低. 2.5 筛板塔与喷淋塔细颗粒物控制效果对比 如图8所示为筛板塔与喷淋塔的分级脱除效率与总脱除效率.实验采用2层喷淋,入口颗粒物浓度为26±2 mg/m3.从图8中可看出,筛板塔细颗粒物分级脱除效率与总脱除效率均高于喷淋塔,尤其是对0.2~1.0 μm粒径段颗粒的脱除效率较喷淋塔有大幅提升.笔者认为,这是因为在同一工况下,相对于喷淋空塔,筛板喷淋塔由于形成了持液层而具有更大的气液接触面积;另外,筛板持液层近似鼓泡,气液扰动强烈,促进了部分颗粒的团聚长大,强化了细颗粒的脱除. 图8 加装筛板前后颗粒物脱除效果对比Fig.8 Removal efficiency of different scrubbers (1)筛板塔烟气流速、浆液喷淋量、入口飞灰浓度对细颗粒物的脱除效果存在较大影响,脱除效率随浆液喷淋量的增大而提高,在一定范围内,随烟气流速、入口飞灰浓度的增加先增大后趋于稳定. (2)筛板塔细颗粒脱除效率随粒径增加先降低后升高,分级脱除效率曲线呈“V”形分布,0.2~1.0 μm粒径段的脱除效率最低. (3)相对喷淋塔,筛板塔具有更强的细颗粒物脱除能力,对粒径在0.2~1.0 μm左右细颗粒的脱除效率比喷淋塔高11%以上,而总脱除效率相对增加了5%左右. [1] GILMOUR P S, BROWN D M, LINDSAY T G, et al. Adverse health effects of PM10particles: involvement of iron in generation of hydroxyl radical [J]. Occupational and Environmental Medicine, 1996, 53(12): 817-822. [2] 高翔鹏,徐明厚,姚洪,等. 燃煤锅炉可吸入颗粒物排放特性及其形成机理的试验研究[J]. 中国电机工程学报,2007,27(17): 11-17. GAO Xiang-peng, XU Ming-hou, YAO Hong, et al. Experimental study on emission characteristics and formation mechanisms of PM10from a coal-fired boiler [J]. Proceedings of the CSEE, 2007,27(17): 11-17. [3] 王珲,宋蔷,姚强,等. 电厂湿法脱硫系统对烟气中细颗粒物脱除作用的实验研究[J]. 中国电机工程学报,2008,28(05): 1-7. WANG Hui, SONG Qiang, YAO Qiang, et al. Experimental study on removal effect of wet flue gas desulfurization system on fine particles from a coal-fired power plant[J]. Proceedings of the CSEE, 2008,28(05): 1-7. [4] BRACHERT L, KOCHENBURGER T, SCHABER K. Facing the sulfuric acid aerosol problem in flue gas cleaning: pilot plant experiments and simulation [J]. Aerosol Science and Technology, 2013, 47(10): 1083-1091. [5] SRIVASTAVA R K, MILLER C A, ERICKSON C, et al. Emissions of sulfur trioxide from coal-fired power plants [J]. Journal of the Air & Waste Management Association, 2004, 54(6): 750-762. [6] MEIJ R, TE WINKEL B. The emissions and environmental impact of PM10and trace elements from a modern coal-fired power plant equipped with ESP and wet FGD [J].Fuel Processing Technology, 2004, 85(6): 641-656. [7] BAO Jing-jing, YANG Lin-jun, YAN Jin-pei, et al. Experimental study of fine particles removal in the desulfurated scrubbed flue gas [J]. Fuel, 2013, 108(11): 73-79. [8] 鲍静静,杨林军,颜金培,等. 湿法烟气脱硫系统对细颗粒脱除性能的实验研究[J]. 化工学报,2009,60(05): 126-1267. BAO Jing-jing, YANG Lin-jun, YAN Jin-pei, et al. Performance of removal of fine particles by WFGD system [J]. CIESC Journal, 2009,60(05): 1260-1267. [9] 熊桂龙,杨林军,颜金培,等.蒸汽相变与撞击流耦合促进细颗粒物脱除[J]. 东南大学学报:自然科学版,2011,41(4): 761-766. XIONG Gui-long, YANG Lin-jun, YAN Jin-pei, et al. Improving removal of fine particles by coupling heterogeneous condensation with impinging streams [J]. Journal of southeast university :Natural Science Edition, 2011,41(4): 761-766. [10] 赵汶,刘勇,鲍静静,等. 化学团聚促进燃煤细颗粒物脱除的试验研究[J]. 中国电机工程学报,2013,33(20): 52-58+11. ZHAO Wen, LIU Yong, BAO Jing-jing, et al. Experimental research on fine particles removal from flue gas by chemical agglomeration [J]. Proceedings of the CSEE, 2013,33(20): 52-58+11. [11] KIM H G, KIM H J, LEE M H, et al. Experimental study on the enhancement of particle removal efficiency in spray tower scrubber using electrospray [J]. Asian Journal of Atmospheric Environment, 2014, 8(2): 89-95. [12] 陈海林,杨春平,甘海明,等. 螺旋型垂直筛板布气的喷射鼓泡脱硫除尘塔的研制和性能[J]. 环境科学学报,2010,30(2): 294-301. CHEN Hai-lin, YANG Chun-ping, GAN Hai-ming, et al. Development and evaluation of a jet bubble reactor using vertical sieves in a spiral housing as a gas in jet device for dust removal and desulfurization [J]. Acta Scientiae Circumstantiae, 2010, 30(2): 294-301. [13] WANG Q, CHEN X, GONG X. Theoretical and experimental investigation on the characteristics of fly‐ash scrubbing in a fixed valve tray column [J]. AIChE Journal, 2013, 59(6): 2168-2178. [14] GARCIA J A, FAIR J R. Distillation sieve trays without downcomers: prediction of performance characteristics [J]. Industrial & Engineering Chemistry Research, 2002, 41(6): 1632-1640. [15] KRISHNA R, VAN BATEN J M. Modelling sieve tray hydraulics using computational fluid dynamics [J]. Chemical Engineering Research and Design, 2003, 81(1): 27-38.[16] VAN BATEN J M, KRISHNA R. Modelling sieve tray hydraulics using computational fluid dynamics [J]. Chemical Engineering Journal, 2000, 77(3): 143-151. [17] WANG Q, CHEN X, GONG X. The particle removing characteristics in a fixed valve tray column [J]. Industrial & Engineering Chemistry Research, 2013, 52(9): 3441-3452. [18] LEE B K, MOHAN B R, BYEON S H, et al. Evaluating the performance of a turbulent wet scrubber for scrubbing particulate matter [J]. Journal of the Air & Waste Management Association, 2013, 63(5): 499-506. [19] MEIKAP B C, BISWAS M N. Fly-ash removal efficiency in a modified multi-stage bubble column scrubber [J]. Separation and Purification Technology, 2004, 36(3): 177-190. [20] MEIKAP B C, KUNDU G, BISWAS M N. Prediction of the interfacial area of contact in a variable-area multistage bubble column [J]. Industrial & Engineering Chemistry Research, 2001, 40(26): 6194-6200. [21] COUGHLIN, ROBERT W. Recent advances in air pollution control [M]. American Institute of Chemical Engineers。 [S.l.]. [s.n.]. 1974. [22] DW C. Theoretical comparison of efficiency and power for single-stage and multiple-stage particulate scrubbing [J] Atmos Environ, 1967, 10 (11): 1001-1004. [23] MOO-JOUNG M, FARQUHAR G J. Waste treatment and utilization: theory and practice of waste management[M]. Aids, 2015, 29(9): 1119-1120. [24] CHYLEK P, VIDEEN G, NGO D, et al. Effect of black carbon on the optical properties and climate forcing of sulfate aerosols [J]. Journal of Geophysical Research: Atmospheres, 1995, 1001(D8): 16325-16332. [25] PARK S H, JUNG C H, JUNG K R, et al. Wet scrubbing of polydisperse aerosols by freely falling droplets [J]. Journal of Aerosol Science, 2005, 36(12): 1444-1458. [26] KALDOR T G, PHILLIPS C R. Aerosol scrubbing by foam [J]. Industrial & Engineering Chemistry Process Design and Development, 1976, 15(1): 199-206. [27] KIM H T, JUNG C H, OH S N, et al. Particle removal efficiency of gravitational wet scrubber considering diffusion, interception, and impaction [J]. Environmental Engineering Science, 2001, 18(2): 125-136. Experimental of enhancement of simultaneous removing fine particle by sieve tray spray scrubber ZHANG Jun1, LI Cun-jie1, ZHENG Cheng-hang1, WENG Wei-guo1, ZHU Song-qiang2,WANG Ding-zhen1, GAO Xiang1, CEN Ke-fa1 (1.StateKeyLaboratoryofCleanEnergyUtilization,ZhejiangUniversity,Hangzhou310027,China;2.ZhejiangProvincialEnergyGroupCompanyCo.,Ltd.Hangzhou310006,China) A new sieve stray spray scrubber, which can promote the mass transfer of gas-liquid-solid system, was proposed in order to improve the fine particle removal efficiency in wet flue gas desulfurization (FGD) system.A pilot-scale wet FGD system was developed to study the removal characteristics of fine particles.The effects of flue gas flow rate, liquid flow rate, fly-ash loading and particle size on the fine particle removal efficiency were investigated.Results show that the fine particle removal efficiency is higher than 90% under typical working condition, of which the maximum exceeds 95%. The removal efficiency increases with the increase of flue gas flow rate, liquid flow rate and the concentration of particles.The fractional removal efficiency is a V-shaped curve with a minimum at 0.2 to 1.0 μm. The sieve tray spray scrubber has a better performance than the ordinary spray scrubber under the same conditions; the total removal efficiency and removal efficiency at 0.2-1.0 μm can be improved more than 5% and 11%, respectively. sieve tray scrubber; coal-fired power plant; fine particle; synergetic control; emission characteristics 2015-11-05. 浙江省重大科技专项计划资助项目(2014C03018); 国家杰出青年科学基金资助项目(51125025). 张军(1990—), 男, 博士生, 从事燃煤电厂大气污染物控制技术等研究. ORCID: 0000-0001-7096-0064. E-mail: stenpher@zju.edu.cn 高翔,男,教授.ORCID: 0000-0002-1732-2132. E-mail: xgao1@zju.edu.cn 10.3785/j.issn.1008-973X.2016.08.013 X 511 A 1008-973X(2016)08-1516-05 浙江大学学报(工学版)网址: www.journals.zju.edu.cn/eng

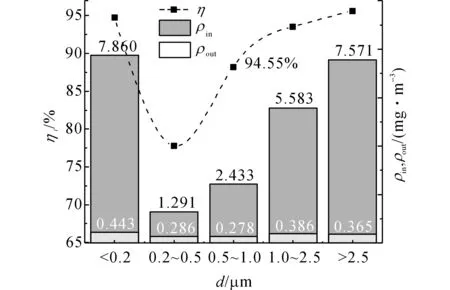

3 结 论