连续油管拖动均匀酸化分支水平井

2016-06-06张合文崔明月鄢雪梅赫安乐蒋卫东

张合文,崔明月,鄢雪梅,赫安乐,蒋卫东,梁 冲,晏 军

中国石油勘探开发研究院廊坊分院, 河北廊坊 065007

连续油管拖动均匀酸化分支水平井

张合文,崔明月,鄢雪梅,赫安乐,蒋卫东,梁冲,晏军

中国石油勘探开发研究院廊坊分院, 河北廊坊 065007

摘要:针对深层碳酸盐岩油气藏埋藏深、非均质性强、钻井周期长和成本高等特点,为进一步发挥水平井“少井高产”的优势,扩大单井控制面积,提高储层动用程度以及增加单井产量,在哈萨克斯坦K油田开展一口4级完井的分支水平井现场试验.通过室内实验确定了清洁自转向酸液配方,并对其暂堵转向、缓速和低伤害等性能进行室内测试.两分支都采用“直-增-稳”3段制井身剖面和筛管完井方式,并在完井后对侧分支进行了氮气泡沫暂堵转向酸化,主分支采用连续油管拖动水力喷射酸化技术解堵,措施实施后两分支合采投产.根据该油田储层、岩性和物性等特征,对施工压力、排量和连续油管拖动速度参数进行了优化,并计算了酸化后的表皮系数.结果显示,两个分支都达到了酸化解堵和恢复产能的目的,说明双分支水平井酸化工艺在该油田取得了较好的应用效果,具有广阔的应用前景.

关键词:采油工程;酸化;碳酸盐岩储层;少井高产;连续油管;分支水平井;暂堵;转向

分支井技术可以大幅降低油气开发成本,充分挖掘油田生产能力,提高油气采收率和油气开发综合经济效益[1-3].对于低渗透油气藏开发,分支井虽然能满足“密井网”的要求,但严重的油层伤害所导致的产能下降将使水平井失去经济价值[4-6],为恢复和提高油气井产量,需要有针对性地对分支井进行各种改造的措施,酸化是其中最重要的增产措施之一[7-11].

分支井酸化的关键包括如何准确进入要改造的分支,如何有效封隔距离很近的射孔段以及如何均匀改造各段储层.本研究优选确定了清洁自转向酸体系,并对其各项性能指标进行验证,创新性地将连续油管和水力喷射相结合,达到最大程度解除污染和释放产能的目的.通过对完井方式和酸化施工参数的优化,完成了该双分支水平井酸化作业,并取得了良好的增产效果.

1清洁自转向酸液体系

针对水平井段长、碳酸盐岩储层物性差异大和非均质性强等特点,本研究提出了使用具有暂堵、转向和低伤害等功能的清洁自转向酸液体系.当酸液进入高渗透储层并与岩石反应后,其pH值逐渐升高,小分子胶团数目迅速增加并形成凝胶,酸液在高渗透储层的流动阻力增大,被迫流向阻力相对较小的孔道,起到转向的作用.完成酸化作业并开始返排后,地层中的烃类开始流向井筒与残酸凝胶相遇,烃类的破胶作用使残酸黏度迅速降低,并低至接近水的黏度.

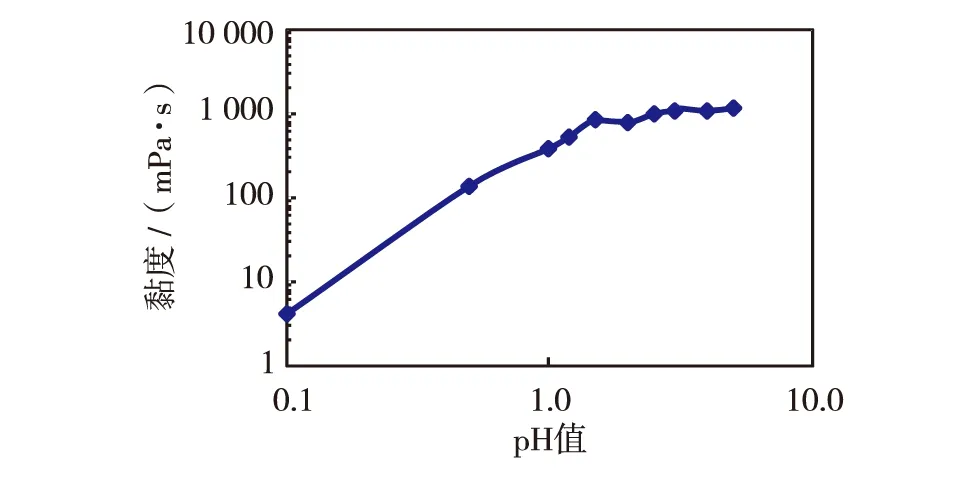

为确定自转向剂的最佳体积分数,分别向体积分数为20%的盐酸溶液中的加入不同体积的清洁自转向剂,使清洁自转向剂体积分数分别为1%、2%、3%、4%、5%和6%.使用碳酸钙粉末将pH值统一调至6,在65 ℃、剪切速率为170 s-1时其黏度如图1.由图1可见,当转向剂体积分数大于4%时,残酸黏度达到800 mPa·s以上,具有良好的转向性能;继续增加转向剂体积分数,黏度增加变缓.因此,确定转向酸体系中清洁自转向剂的最佳体积分数范围为5%~6%.

图1 转向剂体积分数确定实验Fig.1 Measurement of diverting agent concentration

同样,根据行业标准[12],对铁离子稳定能力、破乳率、腐蚀速度和酸渣量等参数进行实验,确定清洁自转向酸液配方,该清洁自转向酸液体系外观:红棕色,90 ℃时腐蚀速度≤5 g/(m2·h),稳定Fe3+性能≥1 000 mg/g,破乳率≥95%,无酸渣级别,界面张力≤1 mN/m,溶蚀率=97.9%,防膨率≥80%,65 ℃、100 s-1时,酸液黏度≥600 mPa·s,65 ℃、100 s-1时,破胶后黏度≤5 mPa·s.实验结果显示,该清洁自转向酸体系除了具有常规酸液体系的性能外,还具备自转向、缓速、遇烃破胶和保护储层等性能.

自转向酸的转向性能主要依靠酸液黏度的变化,实验测定了酸液不同pH值时黏度的变化,结果如图2.从图2可见,随着酸液与岩石反应的进行,pH值升高,反应后残酸基本维持高黏度,从而起到增加酸液向高渗层的流动阻力和改变流动方向的目的.

图2 60 ℃时pH与酸液黏度的关系Fig.2 Relationship between pH and residual acid concentration at 60 ℃

图3 岩芯流动实验装置Fig.3 Experimental apparatus of core flow tests

为进一步直观评价该酸液体系的转向性能,将岩芯并联实验装置(图3).所用岩芯为油井取芯后制成的直径为2.5 cm、长为6 cm的石灰岩柱体,方解石体积分数约为97%.相邻岩芯渗透率级差为2.实验首先用盐水饱和岩芯,维持回压约0.5 MPa不变的条件下,使盐水分别流过3块岩芯,待排量和注入压力稳定后,同时打开3个岩芯液体控制阀门,在统一的压力系统下注入酸液,待岩芯被酸液突破、出现压力骤降时止.

图4 不同酸液注入压力实验结果Fig.4 Results of different acid injection pressure test

实验过程中,提取出入口两端的压差Δp数据,见图4.结果显示,随着酸液与岩石反应的进行,优先进入高渗透率岩芯的酸液黏度增加,泵注压差也不断上升,转向酸液较常规酸液表现出了极好的暂堵性能.

为了对岩心溶蚀情况进行分析,对酸液处理过的岩芯进行核磁切片并成像分析,如图5.结果显示,常规酸只在渗透率最高的岩芯中形成了贯通孔,符合酸液易于向大孔隙中流动的规律,但两组自转向酸实验的所有岩芯都形成了较长的酸蚀蚓孔,表明自转向酸具有很好的暂堵转向和均匀改造的作用.

图5 酸蚀蚓洞形状和长度核磁照片Fig.5 Nuclear magnetic photos of wormhole shape and length

此外,清洁自转向酸还具有良好的缓速效果.图6为自转向酸缓速实验结果,可以看出,与普通盐酸相比,加入转向剂可明显减缓酸液与岩石的反应速度,为实现深度酸化提供了可能.

图6 自转向酸缓速试验结果Fig.6 Experimental results of retarding performance of self-diverting acid

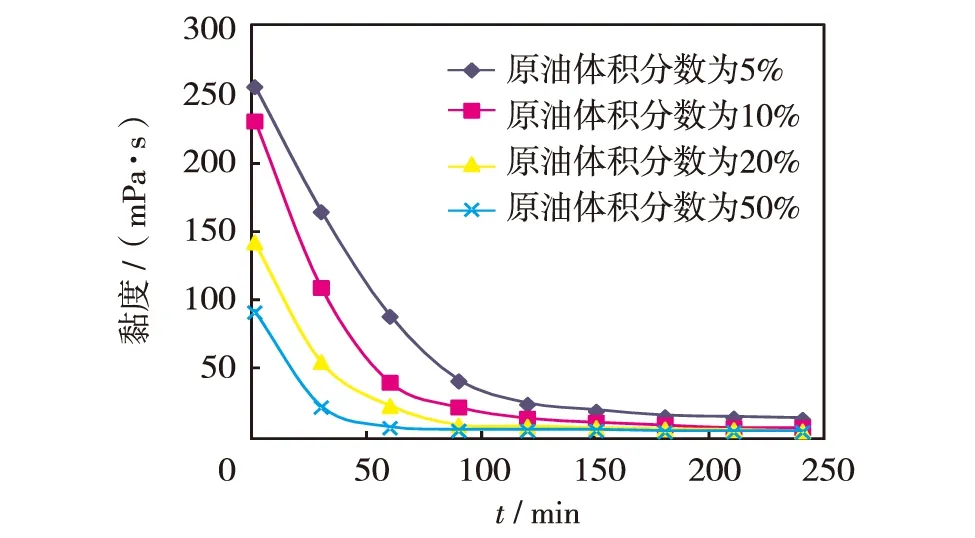

为验证清洁自转向酸的破胶降黏效果,向转向酸残酸凝胶中加入不同体积的轻质原油并将其混合,在170 s-1剪切速率下测得不同混合时间残酸凝胶的黏度,如图7,可以看到自转向酸破胶后黏度很低,极易返排.

图7 与不同体积原油混合后残酸凝胶黏度随时间变化Fig.7 Variation of residual acid viscosity with time after being mixed with different quantity of crude oil

2双分支井完井及酸化技术

2.1油田概况

哈萨克斯坦K油田埋藏较深,平均深度为4 335 m,最深达6 000 m.灰岩含量高,方解石平均体积分数为97%,物性差,平均孔隙度为7.2%,平均渗透率为0.098×10-3μm2,属于低孔、特低渗储层.微观孔隙结构主要是小微喉道,含天然裂缝.储层原始地层温度78~91 ℃,属于中温地层.原始地层压力系数较高,为1.7~1.8,但下降较快[13].

由于储层物性差,储层间和储层内的非均质性较强,且因储层横向和纵向联通性差导致油井供液能力弱,产量和压力在生产初期即呈快速下降趋势,稳产期短.双分支水平井可有效提高单井控制面积,降低储层流体渗流阻力,且可大大降低钻井成本[14-15].因水平井段长,钻井液浸泡时间长,污染相对严重,且物性差异导致污染分布不均匀,所以酸化改造势在必行[16-17].

2.2酸化策略

鉴于水平段伤害带形状特殊,因此有必要采取针对性措施,达到均匀布酸和最大程度动用储层的目的.连续油管拖动酸化技术具有如下优势:① 可以替出全井段内的压井液;② 可以实现全井段布酸;③ 液氮气举排液技术,可大大提高酸液返排速度和返排率[18-20].

为实现替净井筒内的压井液和酸液定向流动的目的,在连续油管端部布置喷射嘴.射流的增压作用源于射流动压向静压的转化,即伯努利方程

v2/2+p/ρ=C

(1)

其中, C为常数; p为驻点压力; v为射流速度(单位:m/s); ρ为介质密度(单位:kg/m3).

2.3双分支井钻完井方式

为实现分别酸化然后合采的目的,分支井设计采用4级完井方式.分支1的水平位移为750 m,分支2的水平位移为675 m,井眼轨迹都采用“直-增-稳”3段制井身剖面,稳斜段长分别为501.60 m和432.66 m.

生产管柱上,两分支都在技术套管内下入悬挂封隔器,其下悬挂油管到油层段,作为产层内流体流出和井口注入流体流入的通道.主井筒内则下入88.9 mm油管,通过插管封隔器与第1分支井眼内的油管相连通,并在下部油管上安装可开关的生产滑套,作为第2分支和上部油管连通的通道.

2.4第2分支施工参数优化

考虑到分支井眼重入的复杂性和技术不完善性,为提高施工作业的成功率,考虑对重入难度较大的第2分支进行笼统酸化,对第1分支进行连续油管拖动均匀酸化,两分支都完成改造作业后合层生产.

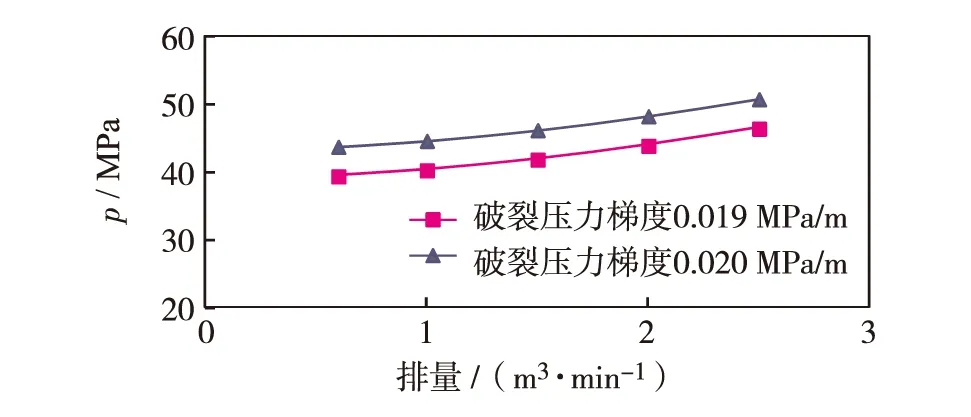

第2分支酸化利用氮气和自转向酸中的表面活性剂等形成的泡沫再次暂堵高渗层和已酸化层.同时,氮气的注入也可起到增加酸化后返排速度、减少二次污染的作用[13].图8给出了不同施工排量下地层破裂所需的井口压力,为了不压开地层,井口应限压40~45 MPa,优化的最大排量为1~2 m3/min.

图8 第2分支施工排量与压力关系曲线Fig.8 Relationship between pumping rate and pressure of the second branch

2.5第1分支施工参数优化

由于第1分支不存在重入难题,采用布酸效果较好的连续油管拖动酸化方式.连续油管摩阻压力损失Δp[21-23]为

(2)

其中, ρ为流体密度; v为流体平均流速(单位:m/s); d为连续油管内径; f为摩擦因数; L为连续油管长度.

对于螺旋管,在管内流体为牛顿流体条件下,雷诺数Re可表示为

(3)

其中, μ为流体动力黏度(单位:Pa·s).

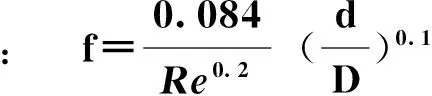

牛顿流体在直管段的摩擦因数f为

(4)

对于层流: a=16, b=1.0; 对于紊流: a=0.079, b=0.25.

牛顿流体通过螺旋管段的摩擦因数f的计算公式为

其中, D为滚筒心轴直径.

摩阻计算结果见图9.按照井口最高限压45 MPa,最大施工排量约为4 L/s,喷射速度可以达到12 m/s.拖动速度随排量的变化情况见图10.

图9 连续油管摩阻随排量变化Fig.9 Friction of coiled tubing with different pumping rate

图10 不同排量下连续油管回抽速度Fig.10 Drawing back velocity in coiled tubing under different pumping rate

3现场实施及效果分析

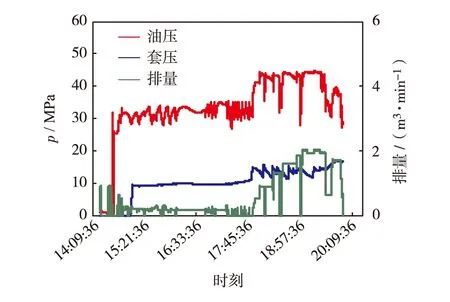

根据酸化策略和优化后的施工参数,分别于2013年1月和4月完成侧分支和主分支的酸化施工作业,施工曲线分别见图11和图12.

图11 第2分支施工曲线Fig.11 Treating curve of the second branch

图12 第1分支施工曲线Fig.12 Treating curve of the first branch

根据实际施工数据,计算表皮系数,结果见图13和图14.结果显示,两分支酸化后的表皮系数均降至0以下,说明酸化作业起到了解堵和增产的双重作用.

图13 第2分支表皮系数 Fig.13 Skin factor of the second branch

图14 第1分支表皮系数Fig.14 Skin factor of the first branch

增产效果方面,第2分支初期平均日产油量是酸化前产量的1.42倍,是该分支相邻水平井,产量的1.6~2.2倍.第1分支的初期平均产量与该分支临近水平井的产量相当.该井当年累计产油31 935 t,平均日产油102 t/d,取得了明显的增产效果和经济效益.且这是一口成功完钻并作业投产的分支井,具有一定的借鉴意义.

4结论

1)本实验确定的清洁自转向酸具有较好的转向、缓速和低伤害等性能,满足水平井均匀酸化所需的暂堵和转向等方面的要求.

2)优选的连续油管拖动喷射酸化是分支井解除污染的针对性措施,通过优化施工参数和引入水力喷射,保证了整个水平段的均匀改造和最大程度解除污染的实现.

3)分析结果显示,两个分支井眼的酸化都达到了解除污染的目的,并取得了良好的增产效果,为该类油藏提供了一种新的开发和增产方式.

参考文献/References:

[1] Mcdaniel B W, Loyd E, Vance H. Overview of stimulation technology for horizontal completions without cemented casing in the lateral[C]// SPE Asia Pacific Oil and Gas Conference and Exhibition. Melbourne, Australia:[s.n.], 2002: SPE 77825. doi: 10.2118/77825-MS.

[2] 范珊珊, 刘启国, 熊景明.多分支井技术发展综述[J].国外油田工程,2010,26(12): 42-45.

Fan Shanshan, Liu Qiguo, Xiong Jingming. Review of multilateral well technology[J]. Foreign Oilfield Engineering. 2010, 26(12): 42-45.(in Chinese)

[3] Chang F, Qu Q, Wayne F, et al. A novel self-diverting-acid developed for matrix simulation of carbonate reservoirs [C]// SPE International Symposium on Oilfield Chemistry. Huston, Texas:[s.n.], 2001: SPE 65033. doi: 10.2118/65033-MS.

[4] 朱世琰,李海涛,孙正丽,等.低渗透气藏分段压裂水平井非稳态产能模型[J].深圳大学学报理工版,2014,31(3) : 266-272.

Zhu Shiyan, Li Haitao, Sun Zhengli, et al. Unsteady productivity model of multi-stage fractured horizontal well in low permeability gas reservoir[J]. Journal of Shenzhen University Science and Engineering, 2014, 31(3) : 266-272.(in Chinese).

[5] 袁彬,苏玉亮,丰子泰,等.体积压裂水平井缝网渗流特征与产能分布研究[J].深圳大学学报理工版,2013,30(5) : 545-550.

Yuan Bin, Su Yuliang, Feng Zitai, et al. Productivity distribution and flow characteristics of volume-fractured horizontal wells[J]. Journal of Shenzhen University Science and Engineering, 2013, 30(5) : 545-550.(in Chinese)

[6] Frick T P, Economides M J. State of the art in the matrix stimulation of horizontal wells[J]. SPE Advanced Technology, 1996, 4(1):94-102.

[7] Stanley Rick, Portman L N, Diaz J D, et al. Global application of coiled-tubing acid tunneling yields effective carbonate stimulation[C]// SPE Annual Technical Conference andExibition. Florence, Italy:[s.n.], 2010: SPE 135604. doi: 10.2118/135604-MS.

[8] Alzaid M R, Al-Ghazal M A, Al-Driweesh S. Dual lateral open hole coiled tubing acid stimulation in deep HPHT sour gas producer wells-field experience and lessons learned from Ghawar field[C]// SPE Middle East Oil and Gas Show and Conference. Manama, Bahrain:[s.n.], 2013: SPE 164326. doi: 10.2118/164326-MS.

[9] 王永胜,付申,王永康.连续油管技术在定向井酸化中的应用[J].吐哈油气,2009,12(4): 379-382.

Wang Yongsheng, Fu Shen, Wang Yongkang. Application of coiled tubing technology in acidization of directional well[J]. Tuha Oil and Gas, 2009,12(4): 379-382.(in Chinese)

[10] 邹鸿江, 袁学芳, 杨向同, 等.连续油管拖动喷射酸压工艺在田河气田的应用[J].钻采工艺, 2012, 35(3):44-45.

Zou Hongjiang, Yuan Xuefang, Yang Xiangtong, et al. Coiled tubing drawing back acidizing technology and its application in Tianhe gasfield[J]. Drilling & Production Technology, 2012, 35(3): 44-45.(in Chinese)

[11] 杨旭,何冶,李长忠,等.水平井连续油管酸化及效果评价[J].天然气工业,2004, 24(7): 45-48.

Yang Xu, He Ye, Li Changzhong, et al. Horizontal well coiled tubing acidizing and its effect evaluation[J]. Natural Gas Industry, 2004, 24(7): 45-48.(in Chinese)

[12] SY/T5405-1996. 酸化用缓蚀剂性能试验方法及评价指标[S].

SY/T5405-1996. Test method and evaluation index for performance of corrosion inhibitor for acid[S].(in Chinese)

[13] 张合文,丁云宏,赫安乐,等.双分支水平井酸化技术在碳酸盐岩储层中的应用[J].石油钻采工艺,2014,36(4):84-87.

Zhang Hewen, Ding Yunhong, He Anle, et al. Application of acidizing in bi-lateral horizontal well in carbonate reservoir[J].Oil Drilling & Production Technology, 2014, 36(4): 84-87.(in chinese)

[14] Bernhard L, Chris F, Mark B, et al. Diversion and cleanup studies of viscoelastic surfactant-based self-diverting acid[J]. SPE Production & Operations, 2007, 22(1):121-127.

[15] 艾昆, 李谦定,袁志平,等.清洁转向酸酸压技术在塔河油田的应用[J].石油钻采工艺,2008,30(4):71-74.

Ai Kun, LI Qianding, Yuan Zhiping, et al. Application of acid fracturing technology with visco-elastic surfactant acid in Tahe oilfield[J]. Oil Drilling & Production Technology, 2008, 30(4): 71-74.(in Chinese)

[16] Furui K, Zhu D, Hill A D. A rigorous formation damage skin factor and reservoir inflow model for a horizontal well[J]. SPE Production & Facilities, 2002, 18(18):151-157.

[17] Furui K, Zhu D, Hill A D. A new skin factor model for perforated horizontal wells[C]// SPE Annual Technical Conference and Exhibition. Antonio, Texas:[s.n.], 2002: SPE 77363. doi: 10.2118/77363-MS

[18] 王峻乔.连续油管技术分析与研究[J].石油矿场机械,2005,34(5):34-36.

Wang Junqiao. Technical analysis and research of coiled tubing[J]. Oil Field Equipment, 2005, 34(5):34-36. (in chiese)

[19] 马发明, 桑宇.连续油管水力喷射压裂关键参数优化研究[J]. 天然气工业, 2008, 28(1): 76-78.

Ma Faming, Sang Yu. Optimized key parameters of hydraulic fracturing combined with coiled tubings[J]. Natural Gas Industry. 2008, 28(1): 76-78.(in Chinese)

[20] 田守嶒,李根生,黄中伟,等.连续油管水力喷射压裂技术[J].天然气工业, 2008, 28(8): 61-63.

Tian Shouceng, Li Gensheng, Huang Zhongwei, et al. Hydrojet fracturing technology with coiled tubing[J]. Natural Gas Industry, 2008, 28(8): 61-63.(in Chinese)

[21] 张晋凯,李根生,黄中伟,等.连续油管螺旋段摩阻压耗数值模拟[J].中国石油大学学报自然科学版,2012,36(2):115-119.

Zhang Jinkai, Li Gensheng, Huang Zhongwei, et al. Numerical simulation on friction pressure loss in helical coiled tubing[J]. Journal of China University of Petroleum Edition of Natural Science, 2012, 36(2): 115-119.(in Chinese)

[22] Kamel A H A, Shah S N. Friction pressure losses of surfactant-based fluids flowing in coiled tubing[C]// SPE Production and Operations Conference and Exhibition. Tunis, Tunisia: Society of Petroleum Engineers, 2010: SPE135826. doi: 10.2118/135826-MS.

[23] Zhou Yunxu, Shah S N. New friction factor correlations of non-newtonian fluid flow in coiled tubing[J]. SPE Drilling & Completion, 2006, 21(1):68-76.

【中文责编:晨兮;英文责编:天澜】

Uniformly acidized lateral horizontal well with drawing coiled tubing

Zhang Hewen, Cui Mingyue†, Yan Xuemei, He Anle, Jiang Weidong,Liang Chong, and Yan Jun Research Institute of Petroleum Exploration & Development-Langfang, Langfang 065007, Hebei Province, P.R.China

Abstract:As for deeply buried and heterogeneous carbonate reservoirs, which require long well-drilling periods with high cost, we carried a pilot test for lateral horizontal well with 4th-level well completion in Kazakhstan K oilfield in order to increase the well-controlled area and production rate of horizontal wells. Meanwhile, the process also aimed to enhance the degree of formation development and take full advantage of the idea of "fewer wells and higher production". Firstly, according to in-room laboratory test results, a clean self-diverting acid system was determined. The performance of the self-diverting acid in temporary blocking, retarding and low damage was tested. In practice, well trajectories of the two laterals were drilled in the pattern of three sections: vertical, angle increasing, and deviated. After the completion of the well, the secondary lateral was acidized by the diverting acid mixed with nitrogen, and the primary lateral was treated by drawing back coiled tubing. Subsequently, the two laterals went into operation at the same time. We optimize the treating pressure, the pumping rate, and coiled tubing drawing back velocity based on the formation, rock properties and physical properties of this oilfield. We calculate the skin factor after acidization. Results indicate that both of these two branches are acidized successfully thus restoring the productivity significantly, which implies broad application prospects of the lateral horizontal well drilling with acidizing technology in the oilfield.

Key words:oil production; acidizing; carbonate reservoir; fewer wells and higher production; coiled tubing; lateral horizontal well; temporary plugging; diverting

基金项目:国家“十二五”科技重大专项资助项目(2008ZX05031)

作者简介:张合文(1982—),男,中国石油勘探开发研究院工程师、博士. 研究方向:油气藏增产改造. E-mail: etczhanghw@163.com

中图分类号:TE 357.2

文献标志码:A

doi:10.3724/SP.J.1249.2016.03234

【环境与能源/Environment and Energy】

Received:2015-11-18;Accepted:2016-03-11

Foundation:National Science and Technology Support Program for the 12th Five-Year Plan of China (2008ZX05031)

† Corresponding author:Senior engineer Cui Mingyue. E-mail: cmy69@petrochina.com.cn

Citation:Zhang Hewen, Cui Mingyue, Yan Xuemei, et al.Uniformly acidized lateral horizontal well with drawing coiled tubing[J]. Journal of Shenzhen University Science and Engineering, 2016, 33(3): 234-240.(in Chinese)

引文:张合文,崔明月,鄢雪梅,等.连续油管拖动均匀酸化分支水平井[J]. 深圳大学学报理工版,2016,33(3):234-240.