Coalescence behaviour ofwater droplets in water-oilinterface under pulsatile electric fields

2016-05-30MortezaHosseini

Morteza Hosseini

Faculty ofchemicalengineering,BabolNoshirvaniUniversity of Technology,Babol,Iran

1.Introduction

The formation of an emulsion is either desirable or undesirable in many chemicalindustries.Therefore the coalescence phenomenon for separation(oily wastewater treatment)on one hand and the stability of the emulsion for example in food industry on the other hand are very importantfactors.However itis necessary to study the coalescence behavior ofdroplets and it is very important to investigate the stability ofan emulsion under electric field.

During crude oil production both oil and water phases are coproduced[1].Nowadays,there are many techniques for enhancing the separation ofwater-in-oilemulsions,such as the addition ofchemical demulsi fier,gravity or centrifugalsettling,heat treatment and electrostatic demulsi fication[2].Electric field is extensively used in the chemical,petroleum and biochemicalindustries.In a non-uniform electric field(DEP=di-electrophorese),the polarized particles experience a force causing them to move to those regions thathave high orlow electric field[3].Because ofeconomicalreason and particularly because of environmentalaspects,the related technique is very suitable and because of the simplicity of the apparatus and process for demulsi fication,the electricalway would be one of the bestway ofdestroying o/w emulsions.The separation ofemulsion with non-uniform electric field(DEP)has been studied and the effects oftemperature,time,voltage and differenttypes ofelectricalcurrentwere considered[4,5].

In this study,drop-interface coalescence(water drop in oil/water-interface)under non-uniform electric field with differentcondition ofwaveform types,different voltages,and different frequencies have been considered.In this kind of demulsi fier,one electrode is settled inside the cylindrical emulsion container and the other electrode is copper formic cylinder jacket(Fig.1).By passing electricalcurrent through the two electrodes,the field is created in a radial fashion towards the electrode[3,6].

Iftwo water droplets located in insulating oilare subjected to an externalelectric field E0,a dipole moment is induced at the droplets center.The magnitude of the dipole moment,p,depends on the electric field intensity,the drop size and permittivity[7].

2.Mechanisms of Non-uniform Electric Field on Drop Interface Coalescence

When a waterdropletis suspended in a non-uniform electrical field,the interaction of the applied field and induced dipole generates a force on the particle.This force termed di-electrophoresis[8].

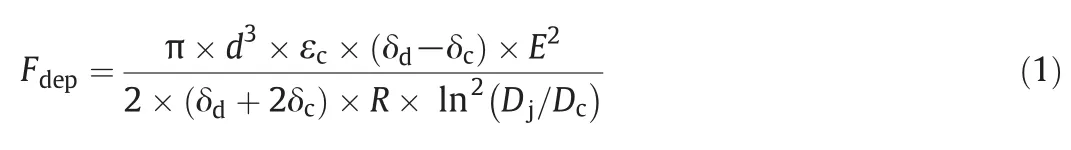

According to the Eq.(1),DEP force magnitude(Fdep)for cylindrical container has been estimated as the following formula:

Fig.1.Schematic diagram of the non-uniform electricalseparation instrument.

According to Eq.(1),the amount of Fdepdepends on the following parameters:

1.The ratio of the copper jacketdiameter,Dj,to the Perspex cylinder diameter Dc(emulsion container)(Fig.1).Eq.(1)shows that the force of DEP willbe weaker when the above-mentioned ratio is increased,so a higher electric field strength is required.

2.Dielectric constant,εc,which in continuous phase depends on the kind of emulsion.

3.The smaller the droplets diameters(d)are,the lower the DEP force required.

4.When the distance(R)between the center of the water drop and the centralelectrode increased,the effectofelectrical field intensity from the centralelectrode to farther droplets would be decreased.

3.Objectives of the Present Work

In general,three types of drop coalescence may occur:complete coalescence,incomplete coalescence,and no-coalescence.The incomplete coalescence,because of producing smaller droplets(secondary droplets),which becomes more dif ficult to be removed,is undesirable.

The no-coalescence process is caused by very fast and energetic coalescence between water droplets and interface.In this case,the water droplets push intensively to continuous phase and lead to an extreme droplets elongation.

When two water droplets approach to each other,a film ofoilphase is formed between them.In this work the investigation on the formation ofdroplets during the electro-coalescence of the primary droplets are reported.

4.Experimental Methodology

A schematic diagram of the system used in this study was shown in Fig.1.The non-uniform electric field apparatus involves a Perspex cylinder with a copper jacket.The diameter and the height of Perspex cylinder were 2 cm and 34 cm,respectively,and the diameter and height of copper jacketwere 2.2 cmand 32 cm,respectively.In the frontand back of the jacket,a smallhole was made to facilitate visualization of the coalescence phenomenon and the diameter of this hole was 1.9 cm approximately.A high voltage was attached to the middle electrode(brass electrode),and the lower one(cooper jacket)was earthed.

To produce high voltages,a positive polarity high-voltage direct current power ampli fier(TREK20/20C)was used.A high-speed digital video camera(Photon FAST CAMS A5),equipped with a micro lens(NAVITAR12_Zoom Lens),was used to observe the phenomena within the batch cylinder with a framing rate of20000 fps(frame per second).It was focused on the area limited to coalescing dropinterface.The lower part of the electro-coalescence cylinder was filled with the aqueous phase and its top part was filled with sunflower oilto form an interface between the two phases and proceed with the drop–interface coalescence experiments.The top ofthis cylinder has a very smallhole to allow a needle to be inserted to introduce the water drops by a syringe falling in oil to create a drop–interface coalescence.In the experiments conducted,sun flower oil was used(prepared from Morrisons Ltd.,UK).A halogen cold lamp(veritas,constellation 60,6650 K)was used for lighting.The intensity of the lighting was accurately adjusted to facilitate focusing.Deionized water was used as the dispersed phase.The properties of the liquids used are presented in Table 1.

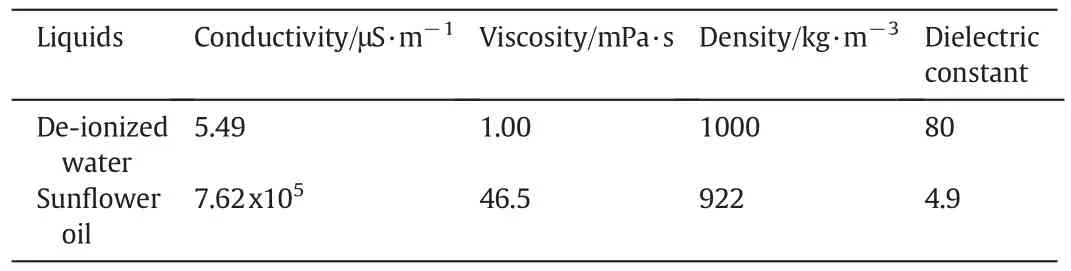

Table.1 This table shows the properties of the liquid used in the experiments

The diameter of the water droplets was in the range between 576 and 1196μm,which was measured by Image-Pro software using the images obtained by Photron Fast cam SA5.

Four waveform types were used to study the effect of them on the secondary dropletformation.The experimentswere performed approximately at a temperature of23°C.

5.Results and Discussions

In this study,first,the effect of four different waveform types(ramp-ac,puls-ac,sinusoidaland square-ac)on the behavior ofcoalescence using various voltages and frequencies was investigated.The coalescence processes ofwater droplets atan oil/water interface were recorded at20000 fps(frame per second)and were shown in the sequence ofimages and movies.When the dropletwas allowed to settle on the interface,the high strength electric field between the dropletand interface caused to clamp between them.There are two phenomena that dominate:(i)pumping of droplet into its bulk phase(due to surface tension)and(ii)the necking process(the dropletpush into continuousphase leading to increasing the dropletsize).Whethera secondary droplet is formed depends on the process which is dominating[9].In this area,the following major results were found:

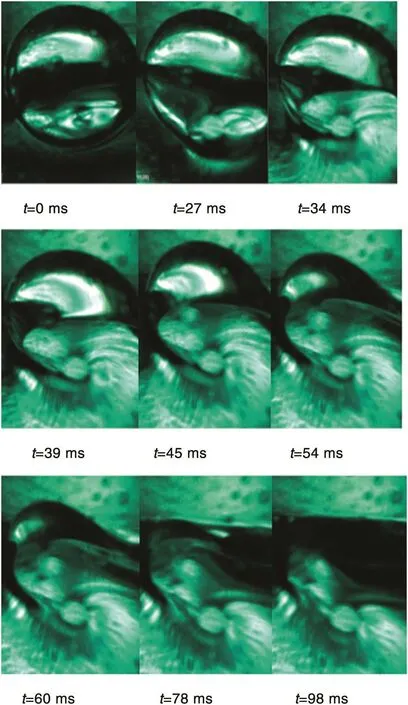

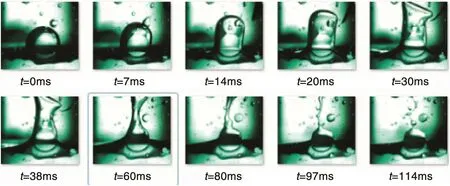

(a)complete coalescence:Itcan be seen from Fig.2 and Movie 1(see Supplementary materials)thatdropletwas pumped into its bulk phase and no necking occurred leading to a complete coalescence because the pumping process was faster than the necking process.The droplet experiences a repelling Columbic force by the adjacent electrode,this force is not suf ficiently strong(in the case ofcomplete coalescence)to help the occurrence ofnecking process[9].

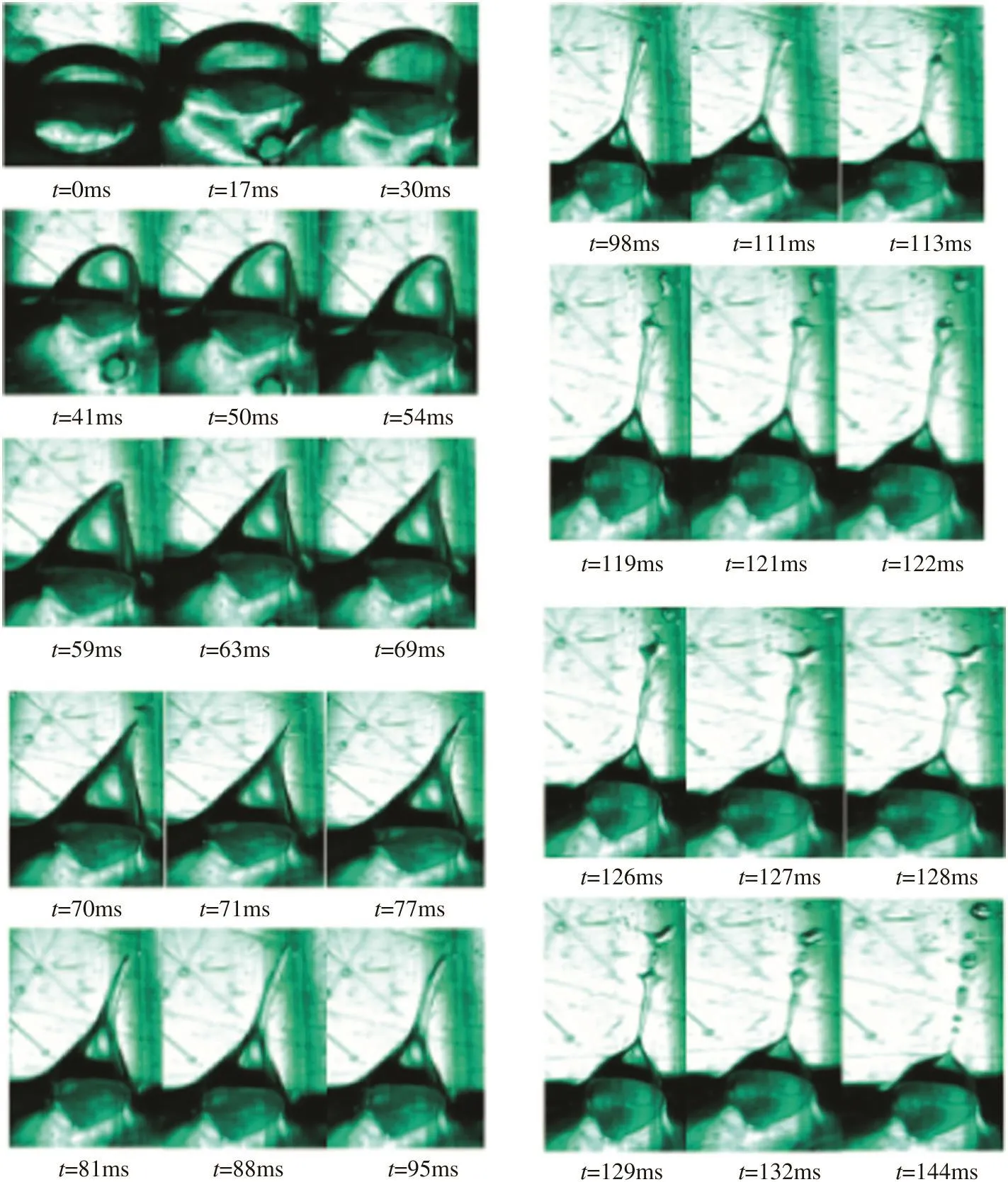

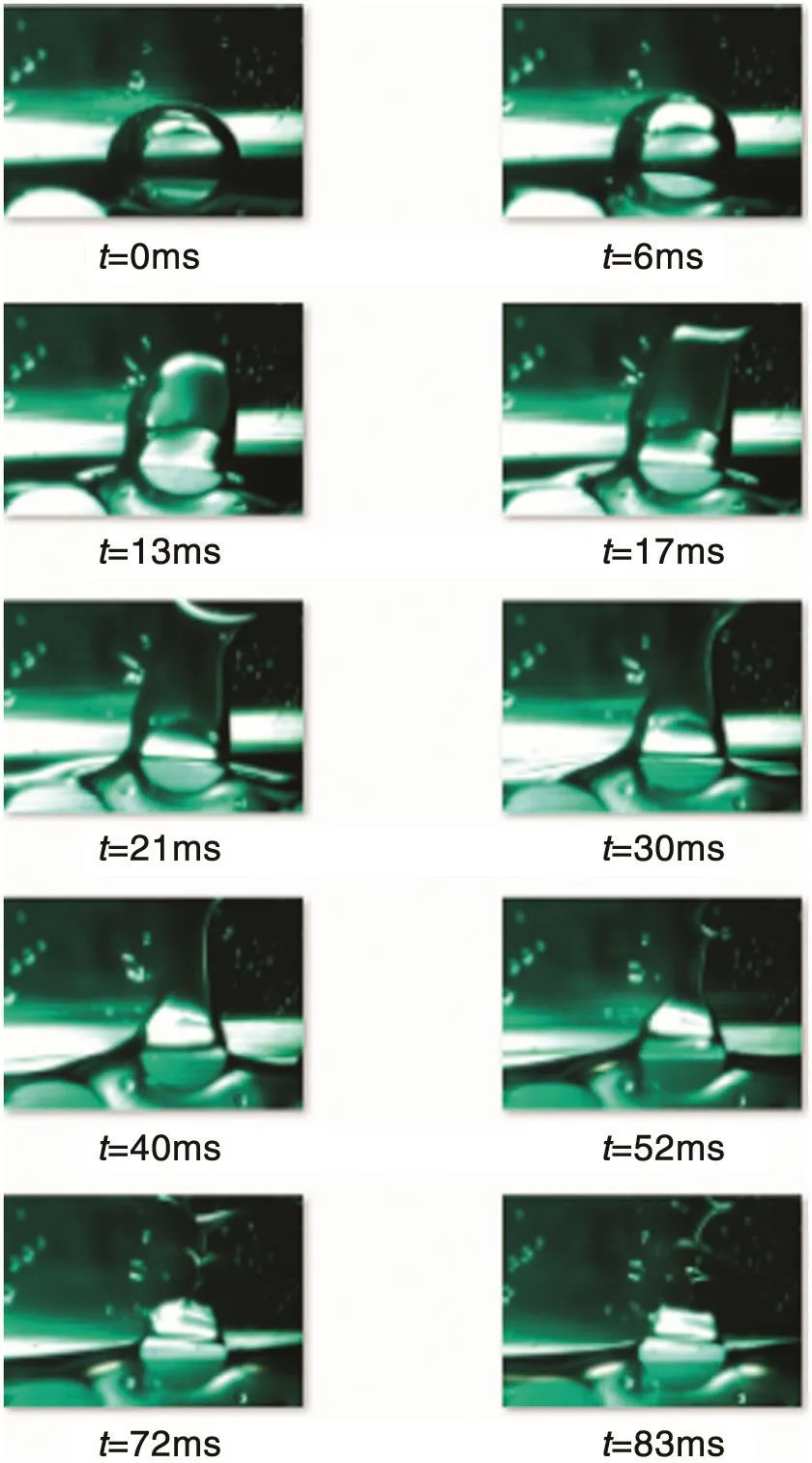

(b)incomplete coalescence:As shown in Fig.3(Movie 2,see Supplementary materials),the necking process was faster than the pumping process and finally led to an incomplete coalescence.The necking process and the pumping process were constantly in competition with each other.

Fig.2.This figure shows the water droplet coalescence in oil–water interface under nonuniform electric field in ramp-ac waveform type by applying amplitude and frequency of150 V·mm-1 and 60 Hz,respectively.

(c)no coalescence:The no-coalescence was caused by a very fastcoalescence and an extensive pushing ofdroplet into the continuous phase.The predominance of each of these processes depends on some parameters and willbe discussed here.

The effect of operational parameters such as electric field strength,waveform types and frequency on behavior of coalescence process was investigated.No secondary droplet for drop-interface coalescence was observed using amplitude less than 90 V·mm-1for all of four mentioned waveform types.The effect of frequency on the behavior of the coalescence was negligible using electric field strength lower than 90 V·mm-1.The application of high electric field up to 150 V·mm-1caused secondary droplets in all the mentioned waveform types,except in ramp-ac waveform.Secondary droplets were produced even by using ramp waveform by applying low frequency between 1 Hz and 50 Hz and amplitude up to 150 V·mm-1.However,no secondary droplet was observed by applying ramp waveform and frequency between 60 and 70 Hz and using the same amplitude,namely 150 V·mm-1(Fig.2 and Supplementary Video 1).Therefore,the effect offrequency was signi ficant in higher amplitude magnitudes.

In electric field strengths higher than 150 V·mm-1,the video camera showed that the complete coalescence could only be made with ramp-ac waveform types(producing no secondary droplets)(Fig.1).

A complete coalescence is demonstrated by Fig.2 using a ramp waveform because there were no any secondary droplets observed.There was a pumping process dominated.

5.1.Ramp-ac waveform in comparison to the sinusoidalwaveform

As it was seen in Fig.3,under the sinusoidal waveform,a dropinterface coalescence by applying amplitude of 150 V·mm-1and frequency of 60 Hz was an incomplete coalescence;because necking process was dominated and some secondary droplets were produced at the end of coalescence.Therefore the effect of waveform type was very signi ficant and the advantage of the ramp waveform in comparison to the sinusoidal waveform type was very clear(Fig.2).The waveform type was the key factor that played major role avoiding the production ofsecondary droplets.

5.2.Ramp-ac waveform in comparison to the pulse-ac waveform

Fig.4 showed a drop-interface coalescence using pulse-ac and applying amplitude of150 V·mm-1and frequency of60 Hz in comparison to the ramp waveform(Fig.2).The application of pulse-ac and using amplitude of 150 V·mm-1and frequency of 60 Hz led to a situation even close to the no-coalescence because the rupture between the droplet and the interface was very strong,leading to increase the primary droplet size.In this case,the droplet was pushed strongly into continuous phase and finally some bigger secondary droplets were detached from primary droplet.

However,using ramp-ac waveform with the same circumstancesled to a complete coalescence(Fig.2).

5.3.Ramp-ac waveform compare to the square-ac waveform

Fig.5 showed a drop-interface coalescence using square-ac waveformand applying amplitude of150 V·mm-1and frequency of60 Hz in comparison to the ramp-ac waveform(Fig.2),led to a situation close to the pulse-ac waveform and no-coalescence because the rupture between the droplet and the interface was very strong.In this case,like the pulse waveform,the droplet was pushed strongly into continuous phase and finally some bigger secondary droplets were detached from primary droplet too.

Fig.3.This figure demonstrates an incomplete drop-interface coalescence,sinusoidalwaveform,150 V·mm-1,60 Hz.

5.4.The effectof the frequency on coalescence behavior

The frequency played an important role in amplitude magnitudes higher than 90 V·mm-1.Despite using similar waveform(ramp-ac)and the similar amplitude amount(150 V·mm-1),applying different frequencies caused different results.Lower frequency magnitudes led to an incomplete coalescence due to some secondary droplets produced(necking process was dominated).

Fig.4.This figure shows the water droplet coalescence in oil–water interface.Here the pattern is no coalescence under non-uniform electric field by using pulse-ac waveform type.The amplitude and frequency were 150 V·mm-1 and 60 Hz,respectively.

Fig.5.This figure shows the water dropletcoalescence in oil–water interface as pattern of no-coalescence under non-uniform electric field by using square-ac waveform type.The amplitude and frequency were 150 V·mm-1 and 60 Hz respectively.

As it was observed,under the ramp-ac waveform,a dropinterface coalescence by applying amplitude of 150 V·mm-1was an incomplete coalescence because some secondary droplets were produced at the end of coalescence due to low frequency(20 Hz)(Fig.6 in comparison to Fig.1).It led to an incomplete coalescence due to occurrence ofnecking process.Itmeans that,the necking process was faster than the pumping process.

5.5.Using high amplitude up to 250 V·mm-1

Fig 7 shows,how two drops reactwith interface and how two drops react to each other and with interface simultaneously in comparison to single drop(see Supplementary Movie 6).Fig.7 shows a pattern ofnocoalescence of two water droplets coalescence in oil–water interface using pulse-ac waveformtype by applying the amplitude and frequency of250 V·mm-1and 60 Hz,respectively.This figure could be considered as a pattern for the no-coalescence situation which has been caused by elongation of water droplets in oil–water interface.The rupture between the droplets and the interface was very strong,leading to an increment of the primary droplet sizes.In this case,the droplets were pushed strongly into continuous phase and therefore some bigger secondary droplets were detached and finally led to a no-coalescence.

Table 2 shows the range of the electric field in which a complete coalescence for all four different waveform types is predictable.In this work,the pulse waveform was reacting by applying lower amplitude than the other waveform types but the range of the amplitude for a complete coalescence was short namely between 20 V·mm-1and 90 V·mm-1.If an o/w emulsion is placed in a non-uniform electric field(DEP),the higher the amplitude,the more particles would coalesce to each other.Therefore,the ramp-ac waveform could be more suitable fordemulsi fication ofwaterin oilemulsion due to a widerrange ofelectric field strength.

6.Conclusions

Fig.7.This figure shows the water drop coalescence in oil–water interface under non-uniform electric field using pule-ac waveform type by applying amplitude and frequency of 250 V·mm-1 and 60 Hz,respectively.

Different frequencies and different amplitudes were experimented and finally,it was found out that the magnitudes of 60 Hz and 150 V·mm-1were the optimum frequency and amplitude,respectively.Amplitude over 150 V·mm-1occurs mostly in the non-coalescence and lower amplitude than 150 V·mm-1achieved a weaker electric field and itcould notbe suitable for demulsi fication ofwater in oilemulsion due to low electric field strength.When the dropletwas allowed to settle on the interface,the high strength electric field between the droplet and interface caused to clamp between them.There are two phenomena that dominate:(i)pumping of droplet into its bulk phase(due to surface tension)and(ii)the necking process(the droplet push into continuous phase leading to increasing the droplet size).The necking process and the pumping process were constantly in competition with each other.If the pumping process(due to surface tension,the dropletwillpush into its bulk phase)is faster than the necking process,it willlead to a complete coalescence and conversely willlead to an incomplete coalescence(necking process act faster).In the nocoalescence process,the rupture between the droplet and the interface was very strong,leading to increase the primary droplet size.In this case,the dropletwas pushed strongly into continuous phase and finally some bigger secondary droplets were detached from primary droplet.The effect of frequency could be negligible in amplitudes lesser than 90 V·mm-1.In amplitude magnitude higher than 90 V·mm-1,the frequency had a signi ficant effect on coalescence process.Ramp-ac waveform could be applied to electric field strength up to 150 V·mm-1without observing any secondary droplets.The application ofhigh amplitudes up to 250 V·mm-1led to an extreme elongation ofdroplets.Consequently,larger secondary droplets were detached from the primary drop while coalescing.The waveform type was the key factor that played a major role in avoiding secondary droplets.It was foundthatthe ramp-ac waveformwas the bestwaveformand the magnitudes of60 Hz and 150 V·mm-1were the optimum frequency and amplitude,respectively.

Table 2 The range of the electric field in which a complete coalescence for allfour differentwaveform types

Nomenclature

Supplementary data to this article can be found online at http://dx.doi.org/10.1016/j.cjche.2016.04.007.

Acknowledgements

The authorwould like to thank a large number ofmembers of the Institute of Particle Science and Engineering,University of Leeds,UK for providing research facilities and for the helpfulcomments.Thanks are especially due to Professor Mojtaba Ghadirifor the helpfulcomments and support.The author is grateful for the generous help of Dr.Vincenzino Vicqua,Dr.DonghaiYang,and Dr.AliHassanpour.This research work was financially supported by Babol Noshirvani University of Technology,Iran.

[1]G.Berg,E.Lars,L.E.Lundgaard,N.Nicolas Abi-Chebel,Electrically stressed water drops in oil,Chem.Eng.Process.Process Intensif.49(2010)1229–1240.

[2]C.Guo,L.He,Coalescence behaviour of two large water-drops in viscous oilunder a DC electric field,J.Electrost.72(2014)470–476.

[3]H.Flavio,F.Morales,J.Duart,J.Samitier-Marti,Bacterialhandling under the in fluence ofnon-uniform electric fields:dielectrophoretic and electrohydrodynamic effects,An.Ann.Braz.Acad.Sci.80(2008)627–638.

[4]M.Hosseini,M.H.Shahavi,Electrostatic enhancement of coalescence of oil droplets(in nanometer scale)in water emulsion,Chin.J.Chem.Eng.20(4)(2012)654-–6658.

[5]K.Alinezhad,M.Hosseini,K.Mowagharnegad,M.Salehi,Exprimentaland modeling approach to separation of water in crude oilemulsion under non-uniform electrical field,Korean J.Chem.Eng.27(2010)198–205.

[6]J.Draxler,Fluessige Membranen fuer die Abwasserreinigung,dbv-Verlag,Graz,1992.

[7]M.Mohammadi,S.Shahhosseini,M.Bayat,Electrocoalescence ofbinary water droplets falling in oil:experimental study,Chem.Eng.Res.Des.92(2014)2694–2704.

[8]M.Hughes,H.Morgan,Dielectrophoretic trapping of single sub-micrometre scale bioparticles,J.Phys.D.Appl.Phys.31(1998)2205–2210.

[9]M.Mousavichoubeh,M.Ghadiri,M.Shariaty-Niassarb,Electro-coalescence of an aqueous droplet at an oil–water interface,Chem.Eng.Process.50(2011)338–344.

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Heat transfer ofnano fluidics in hydrophilic pores:Insights from molecular dynamics simulations☆

- Numericalsimulation ofstirred tanks using a hybrid immersed-boundary method☆

- Numericalsimulation ofmicromixing effect on the reactive flow in a co-rotating twin screw extruder☆

- Effects of Sn residue on the high temperature stability of the H2-permeable palladium membranes prepared by electroless plating on Al2O3 substrate after SnCl2–PdCl2 process:A case study☆

- Application ofdiffusive transport modelfor better insight into retardation mechanisms involved in ion-imprinted membrane transport

- Highly selective synthesis for 4,4′-bisphenol F from phenoland formaldehyde catalyzed with[C4mim][HSO4]ionic liquid☆