Improvement of Magnetic Field on Tribological Properties of Lubricating Oils with Zinc Butyloctyldithiophosphate

2016-03-22

(Department of Military Oil Application & Management Engineering, Logistical Engineering University, Chongqing 401311)

Improvement of Magnetic Field on Tribological Properties of Lubricating Oils with Zinc Butyloctyldithiophosphate

Jiang Zeqi; Fang Jianhua; Chen Boshui; Wu Jiang; Wang Jiu; Zheng Zhe

(Department of Military Oil Application & Management Engineering, Logistical Engineering University, Chongqing 401311)

Tribological properties of 150 SN mineral oil and the oils doped with different contents of zinc butyloctyldithiophosphate (T202) under magnetic feld or non-magnetic feld were evaluated on a four-ball tribotester by applying an external magnetic feld around the friction region. Moreover, the morphology and the tribochemical characteristics of worn surfaces were examined by a scanning electron microscope (SEM) and an X-ray photoelectron spectrometer (XPS). Then the lubrication mechanisms were discussed. The tribological test results indicated that the wear scar diameters (WSDs) of steel balls lubricated by the T202-containing lubricating oils and the friction coeffcients of the corresponding oil under magnetic feld were smaller than those without magnetic affection. The worn surface lubricated with the T202-formulated oils in a magnetic feld was smoother than that obtained under the normal condition. Furthermore, the results of XPS analysis indicated that tribochemical flms on the surfaces lubricated with T202-doped oils were mainly composed of compounds such as FeSO4, FeS and ZnS. The atomic concentrations of oxygen, sulfur, iron, zinc and phosphorus species identifed in T202 under magnetic feld were higher than those without magnetic impact. It can be inferred that the improved anti-wear and friction-reducing ability of T202-doped oils was attributed to the promoted tribochemical reactions and the modifcation of the worn surfaces induced by magnetic feld.

magnetic feld; zinc butyloctyldithiophosphate; improvement; lubrication

1 Introduction

In modern sophisticated machines, many sliding units generally work in electric and magnetic surroundings such as the motor brush, the rotating shaft, the magnetic cylinder and piston[1-3], and the diversifed and complicated working conditions of tribomates raise higher requirements for lubricants and additives. On the other hand, it has been demonstrated that self generated potential would be motivated because of the relative motion of tribo-pairs, and the voltage would constantly change due to the irregular micro-convex on the frictional surface, which could excite magnetic felds[4]. Magnetism, a form of substance possessing energy and momentum, will certainly bring about physical and chemical effect during friction process[5-8]. Yamamoto demonstrated the activation effect of magnetic feld on the surfaces of tribomates[9]. Campbell S. D. reported that the electrically charged tribo-surfaces could help to form physically/chemically absorbed flms or chemical reaction films that function as a low shear strength interface[10]. He found that the friction and wear properties of charged tribo-pair in ionic surfactant solutions would be changed as a consequence of the adsorption or desorption of ions induced by polarization potential[11].

It has been known that much of the improvement of industrial lubricants was ascribed to the application of additives in the late 1930s[12]. Zinc dithiophosphate (ZDDP), one of the most successful additives that have been applied for more than 50 years, is widely used in transmission fuid, hydraulic fuid, gear oil and other lubrication felds[13-14]. Lubrication mechanisms of ZDDP have been investigated in terms of various aspects such as temperature and chemical bonds[15-16]. Unfortunately, the influence of electromagnetic effect on the behavior of ZDDP is usually not taken into consideration. It is thus of greatsignifcance to compare tribological properties of ZDDP with and without magnetic feld affection to help realize the design of lubricant additives molecules and the active control on friction and wear performance for sliding parts working under electromagnetic conditions.

The present paper describes a method to determine the effect of magnetic feld on the tribological properties of lubricating oils containing zinc butyloctyldithiophosphate (T202, a typical kind of ZDDP). Moreover, the worn surfaces were analyzed to explore the mechanisms of antiwear and friction-reducing properties under the magnetic feld conditions.

2 Experimental

2.1 Preparation of oil samples

Prior to the friction and wear tests, five lubricants were prepared with different contents of T202, viz.: 0%, 0.5%, 1.0%, 1.5% and 2.0%, being incorporated into 150SN base oil, respectively. 150 SN base oil: a non-polarized paraffinic lubricating base oil obtained from the Shenzhen Lubricating Oil Industry Company, with its kinematic viscosity at 40℃ equating to 31.85 mm2/s.

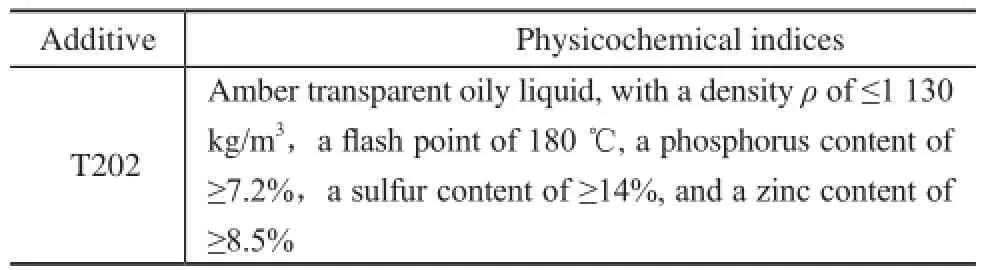

Additive: zinc butyloctyldithiophosphate (T202), obtained from the Beijing Benzene Ring Fine Chemicals Co., Ltd. The physicochemical indices of T202 are shown in Table 1.

Table 1 Physicochemical indices of T202

2.2 Friction and wear tests

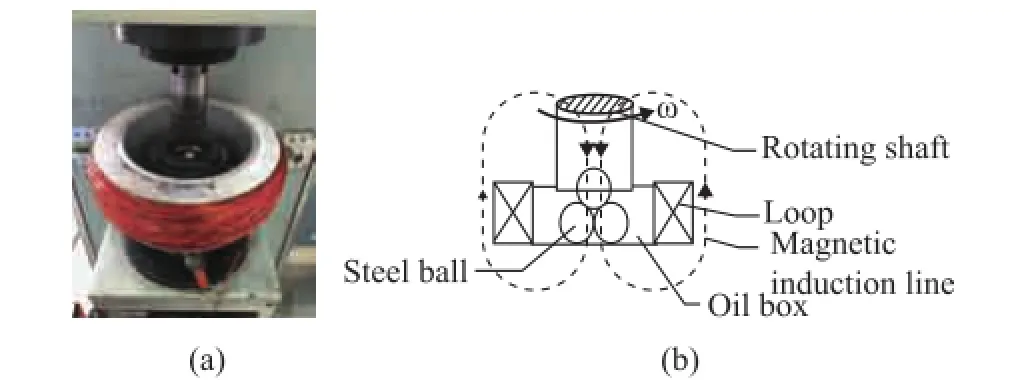

The tribological tests were carried out on a MMW-1 universal four ball tribotester following the procedures of SH/T 0189—1992, a Chinese standard method for testing the friction and wear properties of lubricants[17]. The tribotester consisted of a loaded rotating ball which glided on three fxed balls under a selected load, and the balls used in the tests were made of GCr15 standard steel balls with a diameter of 12.7 mm, a hardness of 59—61 HRC and a surface roughnessRaof 0.040 mm. To investigate the effect of magnetic feld on tribological performance of the lubricants, a copper loop of 800 windings was assembled on an aluminium alloy sleeve and then was set around the friction region as shown in Figure 1(a). During the friction test duration, the loop was electrified to produce a specifc intensity of magnetic feld by controlling the direct current intensity of 1 amp (1A), with magnetic induction lines being mostly perpendicular to the frictional contact surfaces, as shown in Figure 1(b). The friction and wear tests were conducted under a magnetic feld intensity of 0.1 T and a load of 392 N at a rotary speed of 1 200 r/min for 30 minutes. The magnetic intensity was measured by a HT201 portable digital Tesla meter. The performance of T202-formulated oils under the non-magnetic field was investigated under the same test parameters.

Figure 1 Assembly of tribotester

Prior to the tests, the steel balls were ultrasonically cleaned in petroleum ether for 10 minutes and then dried with a hair dryer. After each test run, the wear scar diameters (WSDs) were measured with an optical microscope, and additional tests should be duplicated if the three WSDs showed a relative error of greater than 10%. The friction coeffcients were recorded on the system continually and automatically. Then the average of the WSDs and the friction coeffcients were cited as the reported value. It is remarkable that units of the tester should be electrifed with a reverse DC current to demagnetize the equipment in order to avoid the infuence of residual magnetism.

2.3 Surface analysis

Prior to analysis, the steel balls lubricated with the oil doped with 2.0% of T202 under the impact of magnetic or non-magnetic felds were again ultrasonically rinsed in petroleum ether for 10 minutes, respectively. The surface morphology was observed by a ZEISS EVO18 scanning electron microscope (SEM). The tribochemical species on the worn surfaces were analyzed by an ESCALab 250 X-ray photoelectron spectrometer (exciting source: Al Kαradiation; reference: contaminated carbon (C1s:284.80 eV)).

3 Results and Discussion

3.1 Anti-wear properties

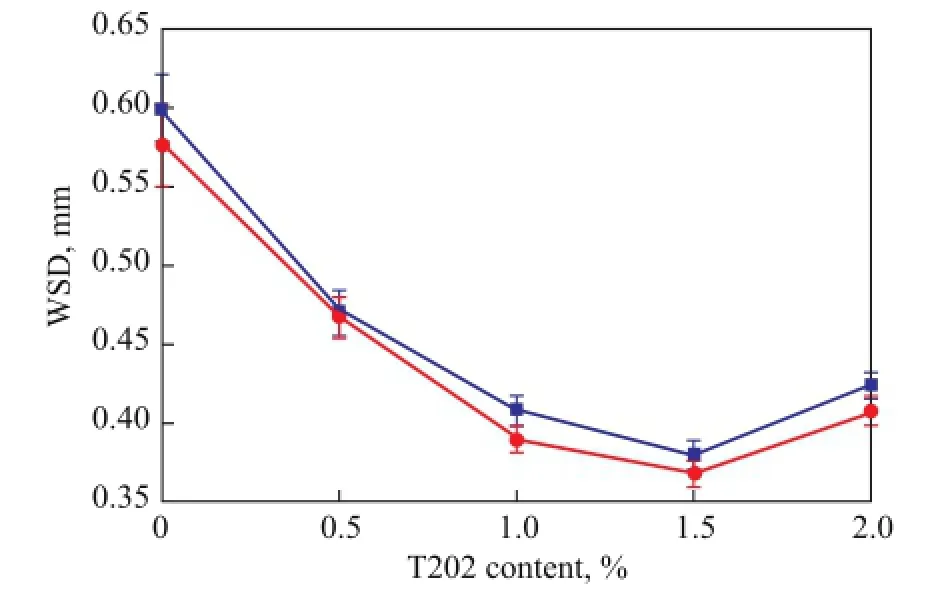

Figure 2 shows the variation of wear scar diameters (WSDs) with the mass fraction of T202 under a load of 392 N and a rotary speed of 1 200 r/min for 30 minutes under magnetic or non-magnetic field conditions. It can be obviously observed from Figure 2 that T202, when it was incorporated into the 150 SN mineral oil, could to a great extent improve the anti-wear properties of the base oil by providing lower WSDs than those of the neat mineral oil, indicating that T202 acted as an excellent anti-wear reducer in the 150 SN mineral oil. The WSDs decreased with an increasing content of T202 up to about 1.5%, beyond which an increase of WSDs was detected both under magnetic and non-magnetic conditions. Remarkably, it is interesting to know that the WSDs of worn surfaces lubricated with the oil containing T202 with magnetic affection were smaller than those without magnetic impact, which demonstrated that the magnetic feld had an ability to fortify the anti-wear properties of lubricating oils formulated with T202.

Figure 2 Variation of WSDs with mass fraction of T202 under magnetic or non-magnetic fi eld conditions

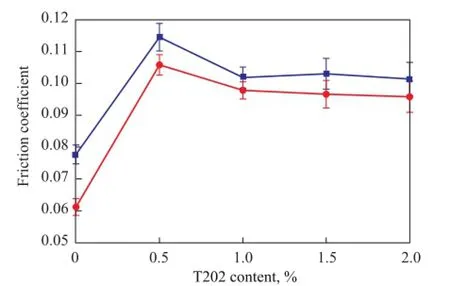

3.2 Friction-reducing properties

The variation of friction coeffcients with the weight percentage of T202 under a load of 392 N and a rotary speed of 1 200 r/min for 30 minutes in the magnetic field or non-magnetic feld environments are shown in Figure 3. It can be seen from Figure 3 that the friction-reducing ability of 150 SN neat oil were obviously impaired by T202, possibly partly because of the bad effect of T202 on the lipophilicity in 150 SN mineral oil. Furthermore, the friction coefficients of the lubricating oils formulated with T202 under the magnetic feld were lower than those obtained in non-magnetic condition, attesting to the positive effect of magnetic feld on the friction-reducing properties of lubricating oils doped with T202.

Figure 3 Variation of friction coef fi cients with mass fraction of T202 under magnetic or non-magnetic fi eld conditions

Figure 4 shows the variation of friction coeffcients with the test duration for the oils doped with 2.0% of T202 under a load of 392 N for 30 minutes. It is clear that the friction coefficients obtained with magnetic affection presented a more obvious fluctuation than that without magnetic field, indicating that the surface films were continually influenced by magnetism. Tang pointed out that electronic clouds inside the molecules would deform temporarily under magnetic fields, thus changing the intermolecular forces and influencing the physical andchemical properties of substances[18]. In terms of kinetics, the magnetic feld might help to enhance the structure of surface flm by adjusting the movement order of additive molecules with active structure.

Figure 4 Variation of friction coef fi cients with test time under magnetic fi eld and non-magnetic fi eld conditions

3.3 SEM analysis

The SEM morphology of the worn surfaces lubricated with the oils containing 2.0% of T202 under a load of 392 N for 30 minutes with and without magnetic field affection is shown in Figure 5. All the pictures on the left side are magnifed by 200 times and the right ones are the same samples magnifed by 1000 times. It can be obviously observed that the worn surface obtained under magnetic field affection (Figure 5(b)) was much shallower and smoother than that obtained without the impact of magnetic feld (Figure 5(a)). The results of SEM analysis confrmed that the magnetic feld could promote electro-chemical reactions between the T202 decomposition products and the steel surface to form a protection coating, thus enhancing the anti-wear and frictionreducing performance of the T202-formulated oils.

Figure 5 SEM morphology of worn surfaces lubricated with lubricants containing 2.0 wt% of T202 under magnetic or non-magnetic fi eld conditions

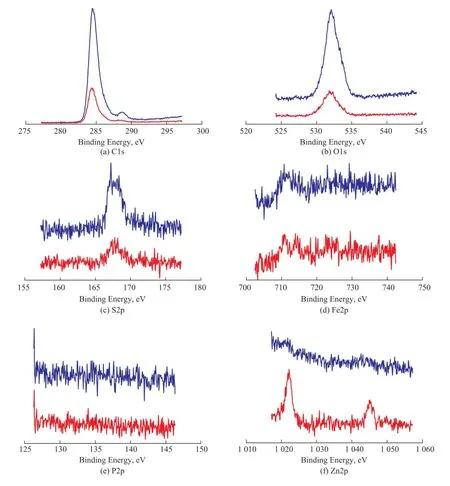

3.4 XPS analysis

Figure 6 shows the XPS spectra of worn surfaces lubricated with base oil containing 2.0% of T202 under a load of 392 N and a rotary speed of 1 200 r/min under magnetic or non-magnetic field conditions. The binding energy of C1s (Figure 6a) showed a peak in the range of 284.5—288.4 eV, which was ascribed to organic species of C—C, but the different intensity of the peak indicated a different degree of absorption with and without magnetic affection. The peak of O1s around a binding energy of 532.0 eV (Figure 6b) might be ascribed to iron oxide, indicating that oxide films were generated on the worn surfaces. In the spectrum of S2p (Figure 6c), the peak at a binding energy of 168.2 eV might correspond to FeSO4, FeS or other sulfur-containing compounds. In Figure 6d, the Fe2p peak at a binding energy of 711.0 eV implied that iron was oxidized into Fe2O3and ferric-containing chemical compounds. The peaks of P2p (Figure 6e) at a binding energy of 133.5 eV might be attributed to FePO4and other phosphorus-containing compounds. In Figure 6f, the peak of Zn2p at a binding energy of 1 022.0 eV revealed the existence of zinc sulfde and zinc[15], which demonstrated that the transformation from Zn2+to Zn occurred on the rubbed surfaces. The XPS analysis showed that complicated boundary lubrication film had been formed on the worn surfaces of lubricating oils with T202 under the investigated conditions.

The above detailed surface analysis results in Sections 3.3 and 3.4 are well consistent with the results of the tribological tests presented in Figure 2 and Figure 3.

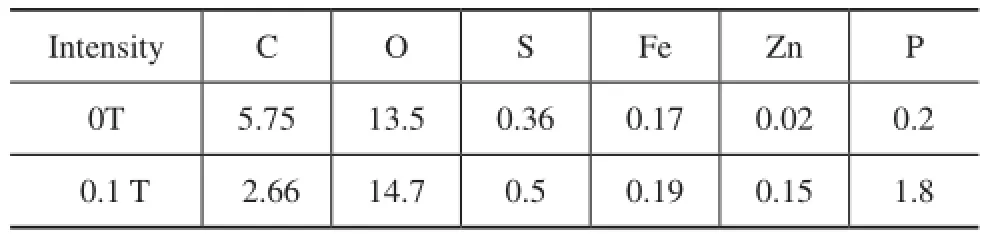

3.5 Mechanism analysis

To further explore the effect of magnetic field on the enhanced lubrication performance of the lubricating oils formulated with T202, the elemental composition and atomic content under a magnetic intensity of 0T or 0.1T was determined by XPS, with the details listed in Table 2. It can be clearly seen that the atomic percentage of functional elements involved in T202 (namely, oxygen, sulfur, iron, zinc and phosphorus) under a magnetic feld of 0.1 T were higher than those obtained under nonmagnetic feld, indicating that tribochemical reaction has been promoted by magnetic feld. The atomic percentage of oxygen (14.7% under magnetic feld and 13.5% in normal condition) well corresponds to the phenomenon that oxygen tends to gather around the magnetic feld because of its paramagnetic property[19]. The higher concentration of oxygen may be a factor for the improved lubrication effect, just as reported by Wang indicating that oxygenplays an important role in promoting the decomposition of ZDDP[20]. In addition, it has been demonstrated that there would be more electrons on the moving tribomates under the impact of electromagnetic feld[21]. The higher contents of zinc provided a proof that the worn surface under the magnetic impact would positively excite the transformation of Zn2++2e-→Zn(tribo), which could help to modify and strengthen the surface by forming the Zn-Fe alloy. Upon comparing Figure 5(a) and Figure 5(b), it can be inferred that the smoother surface under a magnetic intensity of 0.1 T (Figure 5b) might also be attributed to the modifcation of the worn surfaces induced by magnetism.

Figure 6 XPS spectra of worn surfaces lubricated with lubricating oils containing 2.0% of T202 under magnetic or non-magnetic fi eld conditions

Table 2 Elemental composition and atomic percentage

4 Conclusions

By applying an external magnetic feld to four-ball tribological test specimens, the improvement brought about by magnetic feld on the anti-wear and friction-reducing ability of the lubricating oils doped with zinc butyloctyldithiophosphate (T202) was demonstrated by providing smaller WSDs and lower friction coeffcients as compared to the case without magnetic impact. The worn surface lubricated with T202-doped oils under magnetic feld was characterized by slighter and smoother wear scars due to the formation of boundary lubrication flm which was mainly composed of tribochemical species such as FeSO4, FeS and ZnS that could be promoted by magnetism. The improved anti-wear and friction-reducing properties with the infuence of magnetic feld might be attributed to the positive effect of magnetism on tribochemical reactions and the fortifed modifcation of the worn surfaces, which could be confrmed by the XPS analysis results that the atomic concentrations of oxygen, sulfur, iron, zinc and phosphorus on the worn surface lubricated with the oils containing T202 under magnetic field affection were higher than those without magnetic affection.

Acknowledgements: The authors gratefully acknowledge the fnancial support provided by the National Natural Science Foundation of China (Project No. 51375491) and the Natural Science Foundation of Chongqing (Project No. CSTC, 2014JCYJAA50021) and the Innovation Fund of Logistical Engineering University (Project No. YZ13-43703).

[1] Han H B, Gao Y K, Zhang Y Z, et al. The magnetic flux density and magnetic attraction force on the contact surface of pin-disk friction pair under DC magnetic field[J]. Chinese Mechanical Engineering, 2015, 26(4): 503-507. (in Chinese)

[2] Jiang Z Q, Zheng Z, Fang J H, et al. Effect of Magnetic feld on Frictional and Wearing Properties[J]. Synthetic Lubricants, 2016, 43(1): 23-25. (in Chinese)

[3] Hu B, Meng Y g, Wen S Z. A Preliminary Experimental Study on Voltage-Controlled Friction Clutch[J]. Tribology, 2004, 24(1): 46-49. (in Chinese)

[4] Argibay N, Sawyer WG. Frictional voltammetry with copper[J]. Tribology Letters, 2012, 46: 337-342

[5] Jiang Z Q, Fang J H, Chen B S, et al. Tribological properties of base oil and lubricants with ammonium thiophosphate in magnetic field[J]. Petroleum Processing and Petrochemicals, 2016, 47(12): 78-81(in Chinese)

[6] Iida Y, Stolarski T A, Sato K. Surface damage resulted from rolling contact operating in magnetic fled[J]. Applied Physics, 2007, 40(24): 7629-7637

[7] Jiang Z Q, Fang J H, Chen B S, et al. Effect of magnetic feld on tribological properties of lubricating oils with and without tricresyl phosphate[J]. China Petroleum Processing and Petrochemical Technology, 2016, 18(3): 119-124

[8] Kumagai K., Suzuki K, Kamiya O. Study on reduction in wear due to magnetization[J]. Wear, 1993, 163-164: 196-201

[9] Yamamoto Y, Hirano F. Scuffing resistance of phosphate esters.Ⅱ: Effect of applied voltage[J]. Wear, 1981, 66: 77-86

[10] Campbell S D, Hillier A C. Nanometer-scale probing of potential-dependent electrostatic forces, adhesion, and interfacial friction at the electrode/electrolyte interface[J]. Langmuir, 1999, 15: 891-899

[11] He S Q, Meng Y G, Tian Y, et al. Response characteristics of the potential-controlled friction of ZrO2/stainless steel tribopairs in sodium dodecyl sulfate aqueous lubricant[J]. Tribology Letters, 2010, 38: 169-178.

[12] Spikes H. The history and mechanisms of ZDDP[J]. Tribology Letters, 2004, 17(3): 469-489

[13] Peng L L, Li J C, Ren T H, et al. The tribological behaviour of a novel triazine derivative and its combination with ZDDP as additive in mineral oil[J]. Industry Lubrication and Tribology, 2011, 63: 217-221

[14] Yin Z F, Kasrai M, Bancroft G M, et al. Chemical characterization of antiwear flms generated on steel by zinc dialkyldithiphosphate using X-ray absorption spectroscopy[J]. Tribology International, 1993, 26(6): 383-387

[15] Wen X H, Wang X Y, Liu W Q, et al. Anti-wear property of zinc dialkyldithiophosphate[J]. The Chinese Journal of Nonferrous Metals, 2005(15): 1306-1309. (in Chinese)

[16] Barnes A M, Bartle K D, Thibon V R A. A Review of Zinc Dialkyldithiophosphates(ZDDPs): Characterisation and Role in the Lubricating Oil[J]. Tribology International, 2001, 34: 389-395

[17] Song S Y, Li Z C, Qin Z N, et al. Oil Simulation Bench Test[M]. Beijing: China Petrochemical Press. 2001. 152-169. (in Chinese)

[18] Tang H B, Zhang M Q. Effect of magnetic felds on viscosity of alkane and alcohol[J]. Journal of Shengyang University of Technology, 2000, 22(5): 448-449. (in Chinese)

[19] Han H B, Liu H, Zhang Y Z, et al. The Electromagnetic Induction Phenomena in Friction Contact Area of Pin and Disk under DC Magnetic Field[J]. Tribology, 2015, 35(5): 557-562.

[20] Wang S S, Tung S C. The nature of electro-chemical reaction between several zinc organo-dithiophosphate antiwear additives and cast iron surfaces[J]. Tribology Transactions, 1989, 32: 1

[21] Liu J Y. Study on Tribological Properties of P-extreme Press Anti-wear Additives to Environmental Lubricant Base[D]. Xi’an: Chang’an University, 2004. (in Chinese)

Received date: 2016-05-30; Accepted date: 2016-09-01.

Prof. Fang Jianhua, Telephone: +86-23-86731410; E-mail:fangjianhua71225@sina.com.

杂志排行

中国炼油与石油化工的其它文章

- Effect of NH4F and Nano-SiO2on Morphological Control of α-Al2O3Platelets via Solid-state Reaction

- Desulfurization of Petroleum Coke by Calcination in Ammonia Atmosphere below 1 000 ℃

- Synthesis of Nano-ZSM-5 in Ultra-Concentrated System and Its Performance in Diesel Hydrodewaxing

- Effect of Mixed Oxide Support for Ni/ZnO in Reactive Adsorption Desulfurization

- Methodology for Design of Reactive Distillation Column and Kinetics for Isoamylene Etheri fi cation Catalysed by Amberlyst 35

- Effects of Coexisting Substances on Nitrobenzene Degradation with O3/H2O2Process in High-Gravity Fields