Research of Composite oil displacement effect of M20

2015-11-28邵识远

邵识远

Abstract: This paper selects the Daqing Refining & Chemical relativemolecular mass of 1900×104, the concentration of polymer solution of 1500mg/L,by simulation of physics,the SS (petroleum sulfonate)alkali free two system system,sodium carbonate three system toachieve ultra-low interfacial tension is a component concentration,and on this basis the viscoelastic properties,viscosity and oil displacement experiment.Research shows that,three element system in the surfactant concentration is 0.3%,the alkali concentration is 1.2%,the interfacial tension can reach 10-3mN/m,two system of surfactant concentration of 0.3% can reach 10-3mN/m;because of absence of alkali,the viscoelastic properties of monomers was higher than that of the composite system,in the composite system,elastic properties two system to more than three system system.Artificial heterogeneous oil displacement experiment results,SS alkali free two system system recovery rate reached 30.1%,6.7 percentage points higher than the single poly,2.7 percentage points higher than thethree element composite system.

Keywords: interfacial tension;viscoelasticity;surfactant/polymer system;displacement characteristics

Introduction

The Ma 20 fault block in the development, in 1973 September to the present, which lasted 37 years, has experienced 4 stages of development: natural energy development stage; in general, the commingled water injection development stage; the whole subdivision of layer series, comprehensive adjustment stage; high water cut development stage, the current has entered the late waterflooding oilfield, in order to maintain production, improve the oil ultimate recovery, restricted edge bottom water coning and heterogeneity caused by injected water fingering, carry out chemical flooding to enhance oil recovery technology research is necessary[1-4].

1.flooding system performance evaluation

This experiment selected polymer relative molecular mass is 1900 × 104, the concentration is 1500mg/L, surface active agent for petroleum sulfonate SS (called SS), alkali using Na2CO3, the composite system of surfactant SS and alkali concentration[5] acquired by the experiments.

1.1 interfacial tension stability study

Alkali / surfactant / polymer three system flooding EOR technology, its essence is the alkali and surfactant synergistic effect, greatly reduce the oil-water interfacial tension, in addition, the addition of alkali greatly reduces the surfactant and polymer adsorption on rock surface of the retention amount, improve the effective utilization rate of chemical reagents[6]. Therefore, study on the interfacial tension of alkaline / surfactant / polymer composite system of three system and two system of surfactant and polymer composites, often become the important parameters to evaluate the performance index of indoor chemical flooding.The range is wide, the in this region of alkali and surfactant achieved optimal synergistic effect, can further reduce the oil-water interfacial tension, significantly enhance the remaining oil in the reservoir oil displacement efficiency and the ability of [7].

Fig. 1-2 shows is the two element system 1900× 104 1500mg/l polymers, between different concentrations of SS and Ma 20 crude oil interfacial tension, as can be seen from the graph , water and rock interface between three phases to achieve dynamic balance, if continue to increase the concentration of surfactant, the concentration in rock interface on the surfactant molecules increases, the dynamic balance of rock interface was disrupted, interface tension rising trend.

1.2 Study on viscoelastic properties of system

Displacement of viscoelastic oil system to enhance oil displacement system of the swept volume and oil displacement efficiency plays a major role, is an important index to evaluate the displacement effect and for EOR contribution can not be ignored .

1.2.1 elastic experiment and results

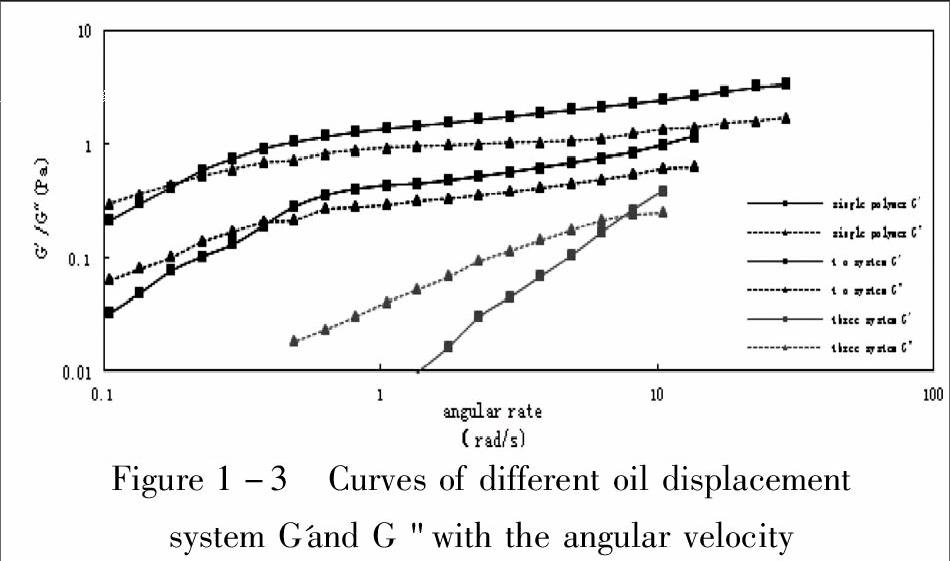

The interfacial tension test results shows the binary system in the surfactant concentration is 0.3%, also can achieve the best of the super low interfacial tension. The experimental results as shown in figure 1-3.

Figure 1-3 shows the dynamic rheological curves of 1900×104 1500mg/L polymer solution and two system, three system of the composite system, as can be seen from the graph, with increasing angular velocity, three kinds of oil displacement system storage modulus(G ') and loss modulus (G) increased gradually, and the angular velocity of a certain next, the storage modulus (G') and loss modulus (G ") were higher than two system and three system, three system exhibit poor viscoelastic properties, this is because part of the negative charge of alkali and polymer molecular chain in three system of neutralization, molecular chain to curl and adhesion, resulting in three t system of viscoelastic properties variation; for the same oil displacement system, storage modulus and loss modulus and curve has a point of intersection, when the angular frequency is lower than that of the intersection angle frequency, loss modulus greater than the storage modulus, the viscous effect solution is greater than the elastic effect; on the other hand, the storage modulus higher than the loss modulus.

1.2.2Analysis of oil displacement system viscosity test and results

The Brookfield DV-Ⅱ Bush viscometer, the shear rate of 6 r/min, the oil displacement system viscosity test temperature of 73 ℃, table 1 shows that the polymer molecular weight and concentration of 1900×104, 1500mg/L, petroleum sulfonate concentration 0.3%, Na2CO3 concentration is 1.2%, the viscosity of oil displacement test system.

From the test results can be seen in the destructive effects of viscosity, three system higher than the two system.

The experimental evaluation of oil displacement system performance, how specific the oil displacement effect, will be in the subordinate oil displacement experiment verified.

2 Evaluation of flooding oil displacement effect

2.1 experimental materials

The experimental model: the model size is 4.5cm × 4.5cm × 30cm, gas permeability is about 270md.

The experimental simulation of oil: oil of Liaohe Oilfield crude oil and kerosene dehydrated Ma 20 configured.

Experimental water: water saturated model based on artificial synthetic saline Ma 20 original formation ion content, mineralization degree is 5000mg/L. Preparation of polymer solution with water and water flooding, water flooding into the Ma 20 on-site sewage.

The experimental agent: polymer produced by Daqing Petrochemical Company, the relative molecular weight of 1900×104, 100% purity; surface active agent for petroleum sulfonate SS (SS), alkali using Na2CO3.

2.2 experimental equipment

The main 80-B2 type constant temperature box (manufacturing Jiangsu Wuxi petroleum equipment factory), ZX-4 type rotary vane vacuum pump in the United States of America Validyne Engineering CO. manufacturing, DV-II type rotary viscometer (American Brookfield company), Texas-500 type spinning drop interfacial tension instrument (the United States of America Kenuo Industrial Co. Ltd.), JB-3 type hand pump, AR1530/C electronic balance (the United States of America OHAUS company, the resolution of 0.001g), magnetic stirrer, the United States RUSK pump, HAAKE RS150 rheometer, electronic balance and other commonly used glass instrument etc..

2.3 test procedure

1) vacuum casting model after 4 hours, the saturation degree of mineralization of synthetic saline 5000mg/L, measuring porosity;

2) the saturated brine well synthetic model are arranged in the thermostat temperature 12 hours (73 ℃);

3) water drive oil to no water model, determination of the original oil saturation;

4) according to the provisions of the displacement rate of water flooding to the model export water more than 98%, the calculation of water flooding recovery;

5) put into three system, when the pore volume reaches the prescribed, transfer follow-up protection plug;

6) slug all after injection, continue to water flooding to the outlet water more than 98%, the calculation of chemical flooding.

2.4 experimental results and analysis

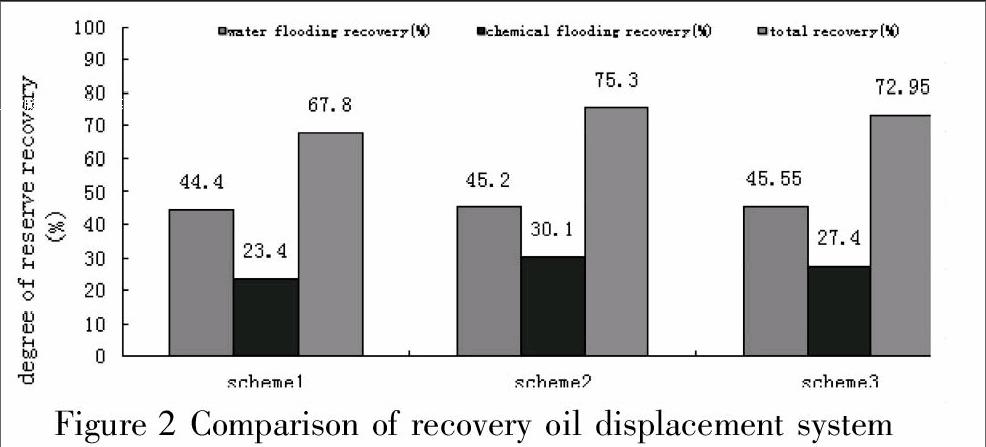

As can be seen from Figure 2, chemical scheme 2 alkali free two element composite flooding recovery is highest, the recovery rate reached 30.1%, more than scheme 1 single polymer higher than 6.7 percentage points, 2.7 percentage points higher than the scheme 3 three composite system, comparing the three kinds of oil displacement scheme, in the water flooding recovery are basically the same circumstances, the interfacial tension of scheme 2 two element composite system is low, with strong cleaning ability, viscosity, in the oil layer mobility control ability, enlarge the sweep volume markedly, from the storage modulus and loss modulus also can be seen, the viscoelastic properties of good performance of two system, coupled with low interfacial tension, can greatly the residual oil, the blind end water flooding and its spread to the area of flooding, these aspects together, the two element system of chemical flooding is highest . The three system swept volume enlargement effect than two system slightly low, but its cleaning ability is better than single poly, so the recovery in the two element system and monomeric intermediate values of .

Conclusion

(1) SS two system without alkali surfactant concentration of 0.3% is to achieve ultra-low interfacial tension, SS and Na2CO3 in the alkali concentration of 1.2% can achieve ultra-low interfacial tension, has a strong cleaning ability.

(2) compared with three system, two system SS alkali free system of storage modulus and loss modulus are large, good viscoelasticity, expand its reservoir sweep volume, the ability to improve cleaning efficiency are better than three system. Single polymer viscosity value is the highest, can keep the water oil mobility is lower than the total reservoir flow.

(3) SS alkali free two system syste not only has high expanding the volume of reservoir sweep capability and cleaning ability, thus the chemical flooding recovery is higher than three system, higher than 2.7 percentage points, 6.7 percentage points higher than the single polymer.

(4) flooding system with expanding swept volume ,at the same time,must have strong cleaning ability.

References

[1] WANG Qi min , JI Bao fa ,SUI Jun,GUO Wan kui. Practice and Knowledge of Tertiary RecoveryTechnique in DaQing Oilfield [J]. Petroleum Geology & Oilfield Deuelopment In Daqing,2001,20(2):1-8,16.

[2]Mou Jianhai,Li Ganzuo. Development status and Prospect of the three oil extraction technology [J]. Chemial Technology Market,2000,23(7):17-20.

[3]Yang Chengzhi.Chemical flooding to enhance oil recovery.BeiJing:Petroleum Industry Press,1999,132~145.

[4] Pan Feng. Mobility of A New Functional Polymer in Low Permeability Oil Layers [J]. Science Technology and Engineering,2011,11(34).

[5] Wu Zanxiao,Shi Zhicheng,Hou Xiaomei et al.. Application of resistance coefficient to optimizing parameters in polymer flooding[J]. Petroleum Geology and Recovery Efficiency,2006,13(1):92-94.

[6] WU Ting - ting,HOU Ya - wei,ZHANG Shao - hui. Determination of polymer flooding parameters for low permeable reservoirs [J]. Special Oil & Gas Reservoirs,2009,16(3):59-61.

[7] ZHANG Li-juan, YUE Xiang-an. Comparison Betw een the Binary/ Tertiary Compound Systems Flooding in Cores [J]. Journal of Petrochemical Universities,2010,23(3):17-20,31.