Engineering properties for high kitchen waste content municipal solid waste

2015-10-09WuGaoYunminChenLiangtongZhanXuechengBian

Wu Gao,Yunmin Chen,Liangtong Zhan,Xuecheng Bian

MOE Key Laboratory of Soft Soils and Geoenvironmental Engineering,Institute of Civil Engineering,Zhejiang University,Hangzhou,310058,China

Engineering properties for high kitchen waste content municipal solid waste

Wu Gao,Yunmin Chen*,Liangtong Zhan,Xuecheng Bian

MOE Key Laboratory of Soft Soils and Geoenvironmental Engineering,Institute of Civil Engineering,Zhejiang University,Hangzhou,310058,China

A R T I C L E I N F O

Article history:

High kitchen waste content(HKWC)

Municipal solid waste(MSW)

Landfill

Engineering properties

Leachate

MSW management

A B S T R A C T

Engineering properties of municipal solid waste(MSW)depend largely on the waste's initial composition and degree of degradation.MSWs in developing countries usually have a high kitchen waste content(called HKWC MSW).After comparing and analyzing the laboratory and field test results of physical composition,hydraulic properties,gas generation and gas permeability,and mechanical properties for HKWC MSW and low kitchen waste content MSW(called LKWC MSW),the following findings were obtained:(1)HKWC MSW has a higher initial water content(IWC)than LKWC MSW,but the field capacities of decomposed HKWC and LKWC MSWs are similar;(2)the hydraulic conductivity and gas permeability for HKWC MSW are both an order of magnitude smaller than those for LKWC MSW;(3)compared with LKWC MSW,HKWC MSW has a higher landfill gas(LFG)generation rate but a shorter duration and a lower potential capacity;(4)the primary compression feature for decomposed HKWC MSW is similar to that of decomposed LKWC MSW,but the compression induced by degradation of HKWC MSW is greater than that of LKWC MSW;and(5)the shear strength of HKWC MSW changes significantly with time and strain.Based on the differences of engineering properties between these two kinds of MSWs,the geo-environmental issues in HKWC MSW landfills were analyzed,including high leachate production,high leachate mounds,low LFG collection efficiency,large settlement and slope stability problem,and corresponding advice for the management and design of HKWC MSW landfills was recommended.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by

Elsevier B.V.All rights reserved.

1.Introduction

Landfill is the principal treatment of municipal solid waste(MSW)because it is both low cost and sorting-free(Chen et al., 2010a;EPA,2013).The design and security service of landfills have been challenged due to the complicated behaviors and unknown aspects of MSW's geotechnical properties(Machado et al., 2010).The design and stability assessment of slopes relate to the shear strength,hydraulic conductivity and vertical compressibility of the MSW.The leachate collecting system design is influenced by water content,field capacity,and hydraulic conductivity of the MSW.Additionally,the design of the landfill gas(LFG)collection and air injection system depends on the gas permeability of the MSW and the potential LFG capacity.It is difficult to fully characterize the engineering properties of MSW as the heterogeneous ones,but it is important to understand the basic behaviors and key engineering properties of MSW to enable the effective management and design of MSW landfills(Dixon and Jones,2005).

DevelopedcountrieshaveperformednumerousstudiesonMSW engineering properties.Landva and Clark(1990)carried out a research on the stability of landfills and explored the behaviors of MSW,includingcomposition,unitweight,permeability, compressibility and shear strength.Gabr and Valero(1995)conducted a geotechnical testing program to evaluate the waste properties(such as specific gravity of solids,water and organic contents, and composition)and the engineering properties such as permeability,compressibility and shear strength of aged MSW retrieved from the Pioneer Crossing Landfill located in Pennsylvania,USA.

In terms of hydraulic conductivity of MSW,Powrie and Beaven(1999)and Beaven(2000)used a large-scale compression cell to study the relationships between MSW's hydraulic conductivity and density,effective porosity,and effective stress.Many researchers(Landva and Clark,1990;Shank,1993;Jain et al.,2005;Reddy et al., 2009a,b,c;Beaven et al.,2011)implemented field tests to measure the field hydraulic conductivity of MSW.

With respect to MSW's gas permeability,a short-term air injection test was conducted by Jain et al.(2005)at New River Regional Landfill in Florida,USA to investigate and evaluate the impact of waste depth and the effect of leachate recirculation on airpermeability.Additionally,gas flow and transport models were used to estimate the gas diffusivity and permeability of MSW(Jung et al.,2011;Larson et al.,2012).

Considering the difference of compressibility between MSWand soil,Wall and Zeiss(1995)studied the effects of MSW's biodegradation on settlements.They also constructed landfill test cells to model both compression and decomposition over extended periods.Manassero et al.(1996)summarized the mechanisms resulting in the compression of MSW and analyzed the factors affecting the magnitude of settlement.Researchers maintained substantial interests in the compressibility of MSW and conducted various laboratory tests or numerical modeling(Landva et al.,2000;Hossain et al.,2003;Reddy et al.,2009b,d;Bareither et al.,2012a).

To gain insight into the shear strength of MSW,direct simple shear,direct shear and triaxial tests were conducted,and the effects of waste composition,confining stress,loading rate,degradation, samples size and strain on shear strength were explored in the past several years(Vilar and Carvalho,2004;Harris et al.,2006;Kavazanjian,2008;Zekkos et al.,2010;Reddy et al.,2009a,d;Bareither et al.,2012b).

Researchers in developing countries also conducted a vast number of studies on MSW.Based on the drilled MSW samples originating fromthe Qizishan Landfill in China,Zhan et al.(2008a,b)and Chen et al.(2009)measured WSM parameters such as composition,unit weight and void ratio,and explored engineering properties of MSW such as shear strength and compressibility.Wu et al.(2012a,b)conducted short-term air and water injection tests at a landfill in Beijing,and obtained the field air permeability and hydraulic conductivity of MSW.Machado et al.(2010)conducted a number of tests at two Brazilian landfills,and evaluated the parameters such as water and organic contents,composition, permeability and shear strength.

These studies revealed that the engineering properties of MSW depend not only on the waste's composition,but also on its degree of degradation(Dixon and Langer,2006;Zhan et al.,2008a;Chen et al.,2009;Machado et al.,2010;Zekkos et al.,2010;Bareither et al.,2012a,b).MSWs from developed and developing countries are significantly different;for example,Chinese MSW contains largely kitchen waste with the content of over 50%(Chen et al., 2010a),which is called high kitchen waste content(HKWC)MSW. However,kitchen waste only accounts for 20%or less of the USA MSW(Staley and Barlaz,2009),which belongs to the low kitchen waste content(LKWC)MSW.Furthermore,the kitchen waste degrades faster than the other compositions of MSW,which contributes to the differences of engineering properties between HKWC and LKWC MSWs.

Because the HKWC MSWs in developing countries are different from the LKWC MSWs in developed countries,the management or design principles used in developed countries may not be entirely applicable to landfills in developing countries.Therefore,a systematic comparison of the engineering properties between HKWC and LKWC MSWs should be performed,which is valuable for the design of HKWC MSW landfills.

In this paper,laboratory and field testing results of physical composition,hydraulic properties,gas generation,gas permeability,and mechanical properties for HKWC and LKWC MSWs are compared and analyzed.This work reveals the differences of engineering properties between HKWC and LKWC MSWs.Based on these findings,geo-environmental issues in HKWC MSW landfills are analyzed,and corresponding advice for the management and design of HKWC MSW landfills is recommended.

Table 1 Physical compositions of fresh MSWs and their initial water content(by wet basis,%).

2.Physical and chemical components of fresh MSW

2.1.Physical composition of fresh MSW

Physical compositions of fresh MSWs from landfills in China, Brazil,USA and Canada are summarized in Table 1,as well as thetypical compositions of MSWs from UK and France.Herein physical compositions include organic fractions and inorganic fractions.

SQL,CCL and SLL are representatives of Chinese landfills in warm and humid climates.As shown in Table 1,kitchen waste content of MSWs from these three Chinese landfills exceeds 50%, and the average value in China is as high as 55%,followed by the content of plastics,which is generally more than 12%.Machado et al.(2010)reported on two Brazilian landfills,BL in Sao Paulo and MCL in Salvador.Similar to the Chinese MSWs,MSWs from these two Brazilian landfills contained most kitchen waste,which made up over 40%of MSWs,with a plastics content of over 18%.

However,the physical compositions of MSWs from developed countries are different.MSWs from typical USA landfills,such as OHL in Illinois and NJL consist primarily of paper and cardboard, comprising over 24%.The kitchen waste content is less than 19%, which is about one-third the content of MSWs from Chinese and Brazilian landfills;instead,the contentof wood is higher(over 11%). The paper and cardboard content of MSW from SSL,a Canadian landfill,is even greaterthan that of MSWs fromUSAlandfills,which reaches as high as 58%.In regard to the scale of the country,the paper and cardboard content of USA MSW is over 35%,while the kitchen waste content is only 13.6%.The contents of paper and cardboard of MSWs from Canada,UK and France are similar, ranging from 26%to 31%,and the kitchen waste content ranges from 25%to 28.6%,which is approximately one-half the content of Chinese and Brazilian MSWs.

As listed in Table 1,the contents of kitchen waste in MSWs from both China and Brazil are over 40%,while the contents of kitchen waste in MSWs from USA,Canada,UK and France are less than 40%. According to the statistical results,the kitchen waste comprises 40%-85%of the MSWs in developing countries,while it accounts for 6%-30%of the MSWs in developed countries(Chen et al.,2010a, 2014).In this paper,based on the content of kitchen waste,the MSW has been divided into two categories,which are HKWC and LKWC MSWs,and 40%is suggested as the threshold value of the kitchen waste content.The engineering properties of MSWs that belong to a certain category exhibit a similar trend,which will be discussed in more details in the following sections.

The difference of the IWC between HKWC and LKWC MSWs is great,due to the differences in physical compositions.Table 2 shows the water content of organic fractions.As the typical water content of kitchen waste is 70%,the water in MSW comes largely from the kitchen waste,thus the IWC of HKWC MSWs is higher than that of the LKWC MSW as shown in Table 1.For instance,the average IWC of MSWs from the three Chinese landfills in Table 1 is 58.3%,which is at least three times the average value of the MSWs from OHL,NJL and SSL.

2.2.Chemical components of fresh MSW

Cellulose,lignin,fat,sugar,and protein are the primary degradablecomponentsoforganicfractionsinMSW.The proportion of individual chemical components in each organic fraction is given inTable 3(Barlaz,1998;He et al.,2003;IPCC,2006;Chen et al.,2014).Sugar is the primary chemical component of kitchen waste,which accounts for 60%by dry basis.For paper,its major chemical component is rapidly and slowly degradable cellulose,with a total content of 68%.The main chemical components of wood are slowly degradable cellulose and lignin,and their total content is 71.4%.Textiles have the same chemical components as wood.

Table 2 Water contents of organic fractions(by wet basis,%).

Table 3 Chemical components of organic fractions in freshMSW(bydry basis,%)(Chen et al., 2014).

On the basis of the typical water contents in Table 2,the organic fractions in Table 1 and chemical components in Table 3,the individual chemical component proportion in the fresh MSW is the sum of chemical component proportion in each organic fraction:

where mjis the wet proportion of individual chemical components in MSW(%),j is the number of chemical components,Miis the wet proportion of individual physical compositions in MSW(%),i is the number of physical compositions,Wiis the water content of individual physical compositions(%),andξiis the dry proportion of individual chemical components in each physical composition(%).

Fig.1.Chemical components of different MSWs.

Fig.1 shows the proportions of chemical components of fresh HKWC and LKWC MSWs by the same wet basis.The total average proportion of rapidly degradable components in fresh HKWC MSWs is 18.6%,higher than the average value in fresh LKWC MSWs, which is 15.35%.As a rapidly degradable component,sugar is the main substance in fresh HKWC MSW.The average proportion reaches 9.92%in fresh HKWC MSW,but is only 2.16%in fresh LKWCMSW.By contrast,the proportion of fast cellulose in fresh LKWC MSW is as high as 12.83%,higher than that in HKWC MSW,which is 7.03%.Compared with sugar,for which the primary metabolite is acetic acid during the hydrolysis and acidification stages,the anaerobic degradation of cellulose is more complex and slower.The anaerobic degradation processes in HKWC and LKWC MSWs are influenced by the proportion and degradation characteristic of each chemical component.Rapid accumulation of organic acid may be thus induced in the HKWC MSW landfill.

It takes a longertime for slowcellulose and lignin todecompose. The total average proportion of these two substances in LKWC MSWs is 27.01%,higher than that in HKWC MSWs,which is 10.45%. The average proportion of slow cellulose in LKWC MSWs is 17.62%, but it is only 6.59%in HKWC MSWs.

It is noted that the total average proportion of rapidly degradable components is higher than that of slowly degradable components for HKWC MSW;however,the total average proportion of slowly degradable components is higher than that of rapidly degradable components for LKWC MSW.Hence,there are differences in gas generation and settlement between HKWC and LKWC MSWs.

3.Hydraulic properties of MSW

Hydraulic properties of MSW are important for landfill design. The IWC of MSW and its water-holding capacity determine the leachate production and thus the design of an effective leachate collecting system(Oweis et al.,1990).Waste hydraulic conductivity influences leachate pressure distribution in the waste body,which in turn affects the magnitude and distribution of effective stresses and shear strength(Dixon and Jones,2005).

3.1.Water content of MSW

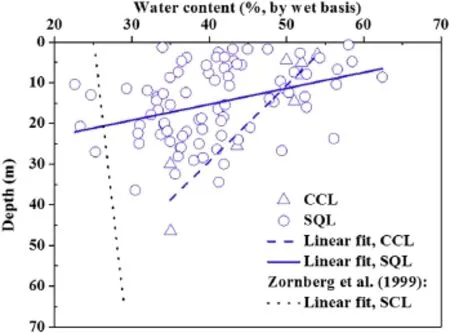

Ten boreholes in the diameterof 150 mmweredrilled in the first phase waste body at CCL,with depths ranging from 19.5 m to 58.5 m.Nine MSW samples were taken from depths of 3.1-46.5 m, and the corresponding fill age was 1-16 years.In order to represent all ages of waste deposited with landfill,5 boreholes in the diameter of 90-130 mm were drilled to the bottom of the first phase waste body at SQL,with depths ranging from 25 m to 38 m,and the corresponding fill age was 0.1-10.8 years.A total of 84 MSW samples were taken using heavy-wall samplers at an interval of 1 m or 2 m(Zhan et al.,2008a).The fill ages of MSW samples were determined according to the borehole logs and the records of the landfill operation.MSW samples were dried in an oven at a temperature of 60-70°C until the weight kept stable.The water content(by wet basis)of each sample was then calculated.

The water content of MSW samples from CCL changed from 35% to 54%,and from 22.6%to 62.4%for MSW samples from SQL.As shown in Fig.2,the water content of the MSW samples from CCL and SQL decreases with the overburden depth.It is noted that the IWC of fresh MSW from CCL and SQL is 58%and 61%,respectively. The water content of decomposed HKWC MSW is much lower than the IWC.A similar trend occurred in the Brazilian landfill.Machado et al.(2010)obtained 4-9 year-old MSW samples using excavators and drilling machines from MCL,a HKWC MSW landfill in Brazil. The samples were dried in an oven at a temperature of 70°C.The water content was then measured,which ranged from 38.9%to 47.4%,lower than its IWC(50%).

On the contrary,an increasing tendency of water content with increasing depths occurs in the LKWC MSW landfill,as observed by Zornberg et al.(1999)at a Southern California Landfill(called SCL, Fig.2).Additionally,the water content of decomposed LKWC MSW is relatively higher than its IWC.Hull et al.(2005)selected 13 boreholes with diameter of 91 mm at a Burlington County Landfill(called BCL)in New Jersey and MSW samples of 0.75-11.5 years old wereexcavated.Compared with the IWC(18%),thewatercontentof the individual sample was higher,changing from 18.8%to 41.6%.

Fig.2.In-situ water content of different MSWs.

3.2.Field capacity of MSWs

Based on the water retention curve(WRC)of the MSW,the field capacity(FC)is defined as the volumetric water content corresponding to a suction of 10 kPa,suggested by Qian et al.(2001a,b). For HKWC MSW,Zhan et al.(2008b)used the pressure plate method to obtain the WRC for landfill wastes from SQL at depths from3 m to 28 mwith the fill ages of 3-10 years.The MSW samples were shredded to a size less than 20 mm and recompacted to a dry density close to the corresponding in-situ dry density.Wu et al.(2012b)excavated MSW samples from a Beijing Landfill at depth between 1 m and 25 m,with the fill ages of 3-10 years old;large rocks(greater than 40 mm in diameter)were taken out and recompacted to achievethe WRC using modified Tempe cells.Based on the typical composition of fresh MSW in Hangzhou,Wei(2007)measured the WRCs of fresh artificial MSW samples using the pressure plate method and the Tempe cell method;and the samples were then recompacted to different void ratios.For LKWC MSW,Breitmeyer and Benson(2011)utilized the pressure plate method to obtain the WRC of 4 month-old MSW samples derived from an operating landfill in Southern Wisconsin.The waste was shredded to a size less than 25 mm and recompacted with different compaction energies to three different densities.

The FC of HKWC and LKWC MSWs obtained through laboratory tests is summarized in Table 4.As shown in the table,the degree of compaction,overburden loading and waste composition all influence the FC of WSWs.In particular,the degradation of organics has a significant effect on the FC of HKWC MSW because it increases with the fill age.

Some researchers utilized larger lysimeters with loading devices to measure the FC of MSW directly(Zornberg et al.,1999;De Velásquezetal.,2003;Lan,2012).Zornbergetal.(1999)measured the FC of relatively older waste from a landfill in Los Angeles County,USA;the equivalent depth ranged from 15.2 m to 61 m,and the FC of MSW changed from 47.4%to 53%using volumetric relationships.

Based onthe statistics,the FC of decomposed HKWC MSW lies in the range of decomposed LKWC MSW FC.It should be pointed out that the FC of decomposed HKWC MSW is less than its IWC;on the contrary,the FC of decomposed LKWC MSW is greater than its IWC.Hence,there is a difference of leachate production between HKWC and LKWC MSWs.

Table 4 Field capacity of MSWs based on the WRC.

3.3.Permeability coefficient of MSW

The permeability coefficient of MSW is one of the key parameters in the design of a leachate control system,a gas collection system and a leachate recirculation system particularly for bioreactor landfills.A number of researchers have conducted laboratory tests(triaxial permeability test and constant head test)and field tests(water injection test,infiltrating test and pumping test)to determine the permeability coefficient of MSW.

TheprimaryfactorsthataffectthehydraulicconductivityofMSW include waste composition,degree of compaction and overburden pressure.Fig.3illustratesthreerepresentativeMSWbulkunitweight profiles,suggested by Zekkos et al.(2006)from the hyperbolic MSW unit weight model;the recommended curves present low,typical, and high compaction efforts in landfills from left to right,respectively.On the basis of weight and dimensions(i.e.diameter and height)ofeachMSWsample,thebulkunitweightofMSWsfromCCL and SQL is determined and summarized in Fig.3.According to the distribution of the bulk unit weight along the depth,it can be observed that the compaction efforts of these two Chinese landfills are mostly in the range of low and typical compaction efforts.

Fig.3.Variation of bulk unit weight with depth.

Triaxial permeability tests and pumping tests were performed to measure the permeability coefficients of MSWs from SQL and CCL.Four MSW specimens from CCL and three from SQL were carefullycut fromintegral,undisturbed MSWs.The size of the MSW specimens used in the laboratory test was 160 mm in height and 100 mm in diameter.The corresponding burial depth ranged from 4.2 m to 29.2 m for MSW specimens from CCL,and from 5.5 m to 26 m for MSW specimens from SQL.Loads were later applied to the MSW specimens to simulate the in-situ overburden pressure after they were saturated.

The permeability coefficient obtained through laboratory tests on MSW specimens from SQL ranged from 3.56×10-8m/s to 4.81×10-6m/s and from 8.09×10-8m/s to 3.92×10-6m/s for MSW specimens from CCL.A pumping test was also conducted at SQL,and the permeability coefficient of 2.4×10-6-5.5×10-6m/s was obtained for MSW at depths between 15.5 m and 17.5 m Machado et al.(2010)also performed infiltration tests to measure the permeability coefficient of MSWat BL,a Brazilian landfill.It was found that the magnitude of permeability coefficient ranged from 10-5m/s to 10-8m/s betweenplacement and buried depth of 30 m.

Permeability coefficients of HKWC and LKWC MSWs have been collected and shown in Fig.4.Comparing the results of laboratory tests with those of field tests at SQL,the permeability coefficient obtained through the laboratory tests was an order of magnitude smaller than that from the field test at a similar depth,which was caused by the anisotropy of MSWand the advantaged stream in the landfills(Zhan et al.,2014).The magnitude of the permeability coefficient of the HKWC MSWs ranged from 10-5m/s to 10-8m/s between placement and buried depth of 30 m,while it was from 10-3m/s to 10-8m/s for LKWC MSWs at the same depth range. Compared to LKWC MSWs,the permeability coefficient of the HKWC MSWs is lower by over an order of magnitude.

Fig.4.Variation of permeability coefficient with depth(Bleiker et al.,1993;Jain et al., 2006;Olivier et al.,2009).

Table 5 Potential CH4generation capacity of fresh MSWs,L0(by wet basis).

Table 6 CH4generation rate of fresh MSWs,k(yr-1),recommended by EPA.

4.Gas generation and gas permeability of MSW

The LFG generated by the degradation of organics in MSW is a source of energy that consists of methane(CH4),carbon dioxide(CO2),and various toxic trace components(Allen et al.,1997;Eklund et al.,1998),the emission reduction and utilization of which have recently attracted researchers'attention.

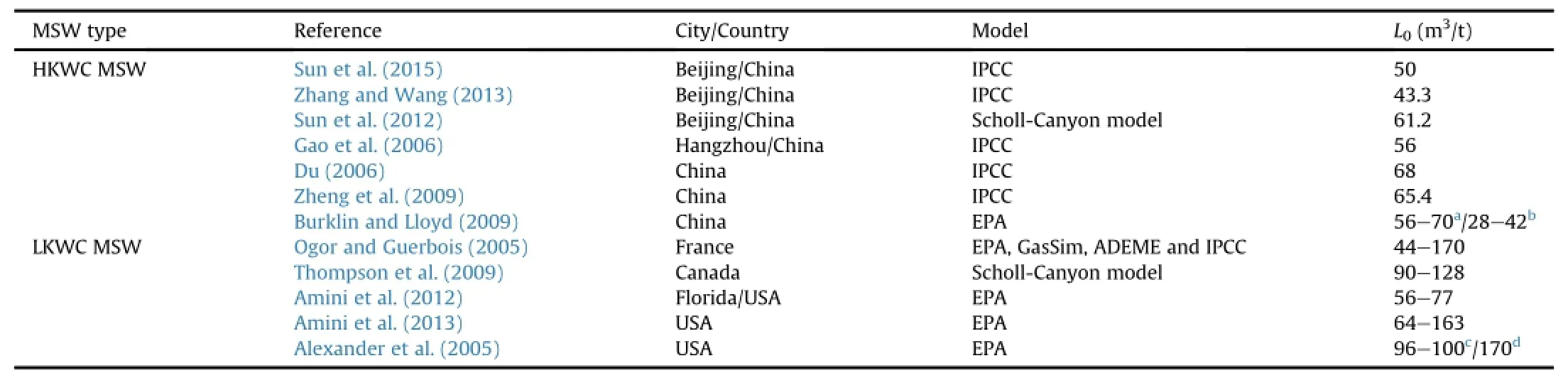

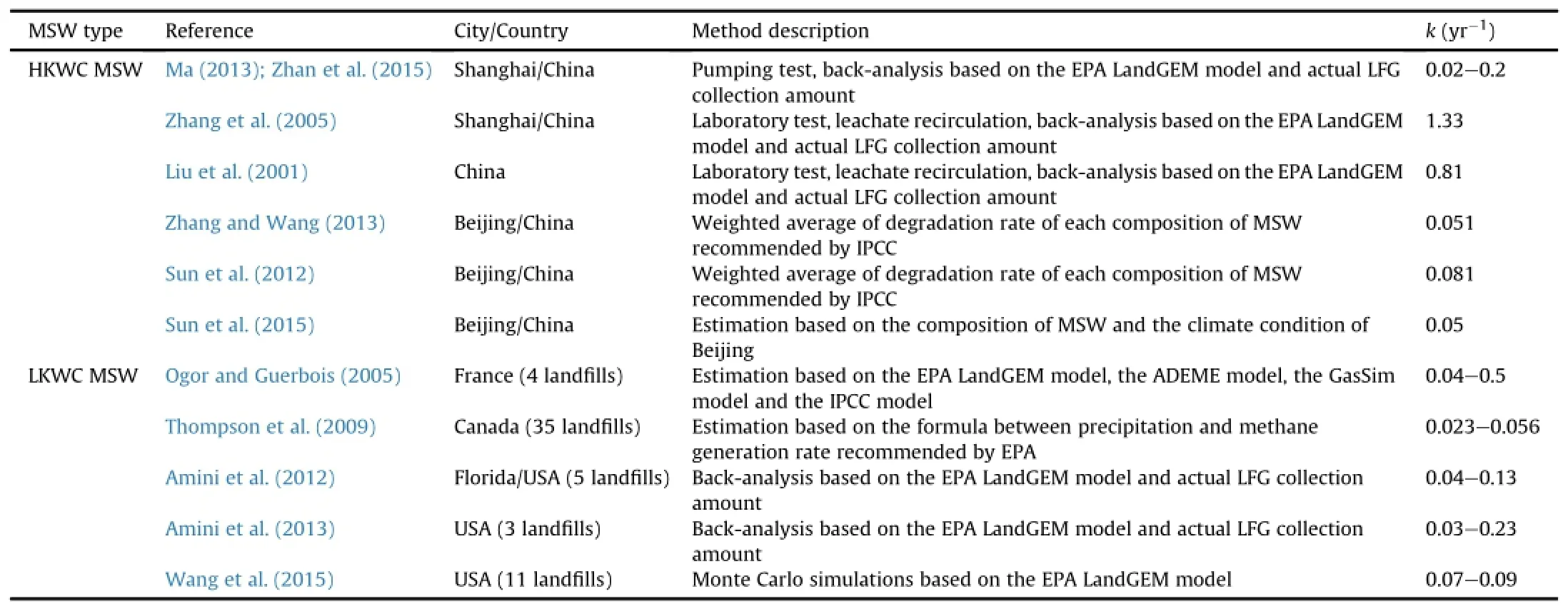

4.1.Potential CH4generation capacity and CH4generation rate

The potential CH4generation capacity(L0)and CH4generation rate(k)are two key parameters for LFG control and collection. Tables 5 and 6 list the values of L0and k recommended by the EPA, respectively.The EPA LandGEM default value of L0(by the wet basis)for fresh Chinese MSW is 56-70 m3/t,which is much lower than the value recommended by the EPA for fresh USA MSW.In addition,values of L0of HKWC and LKWC MSWs in the literature have also been included in Table 5.Similar to default values,L0values of fresh HKWC MSWs from China are basically lower than those of fresh LWKC MSW.

Values of k recommended by the EPA have been provided in Table 6.The default value of k for the fresh Chinese MSW is generally higher than that of the fresh USA MSW under the same conditions except in thewet climate or bioreactor.In addition,k can be obtained through a back-analysis based on the LFG collection amounts in laboratory tests and pumping tests,or estimated by the degradation rate and the proportion of each composition.As listed in Table 7,the range of k obtained by pumping tests varies widely from 0.02 yr-1to 0.2 yr-1,due to the different stages of MSW degradation.Moreover,the k value obtained in the laboratory is greater than that from landfills because the recirculation of leachate has accelerated the degradation of MSW.Values of k estimated by models such as the EPA LandGEM model,the IPCC model,the ADEME model and the GasSim model are also included in Table 7.The range of k varies with the composition of MSW, climate condition,region and analysis model.

Table 7 CH4generation rate of MSWs in the literature.

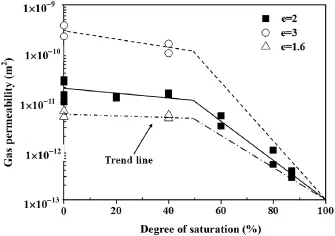

Fig.5.Gas permeability of HKWC MSW(after Wei et al.,2007).

4.2.Gas permeability of MSW

LFG transportation in MSW can be described by the Darcy's law as follows:

where vGis the velocity of LFG(m/s);kGis the gas permeability(m2);μGis the gas viscosities(kg m-1s-1),which equals 1.8×10-5kg/(m s)at the temperature of 20°C;uGis the gas pressure(Pa);and z is the depth(m).

kGis an input parameter for the design of LFG collection system and air injection system for aerobic bioreactors(Larson et al.,2012). Using a permeater with an inner diameter of 10 cm and a length of 60 m,Wei et al.(2007)and Wei(2007)carried out gas permeability tests to measure the kGvalues of MSW samples excavated from SQL with various degrees of saturation and porosities(e),as shown in Fig.5.The measured kGvalues in the laboratory decline with the decreasing porosity.In addition,kGfalls as the MSW degree of saturation increases and the trend turns down rapidly when the degree of saturation is over an inflection point.

Generally,MSW is unsaturated and kGof MSW is dependent on the intrinsic permeability and relative permeability of the landfill gas(Bear,1972):

kG=kikrG(3)

wherekiis the intrinsic permeability(m2),and krGis the relative gas permeability.kiis a fluid flow property related to the nature of a porous media and is independent of fluid properties,and it can be measured by injecting water or air through the porous media.For a completely dry porous media,kGis equal to kias krG=1.Thus,as shown in Fig.5,when e equals 1.6,2 and 3,respectively,the range of kiof HKWC MSWobtained through gas permeability tests is(5.04-6.6)×10-12m2,(1.01-2.92)×10-11m2,and(2.26-3.81)× 10-10m2,respectively.

Jain et al.(2005)conducted a short-term air injection test at New River Regional Landfill in Florida,USA;the Baehr and Huit model was used to estimate the kGvalue of waste at different depths.Wu et al.(2012a)performed a similar test at a landfill in Beijing,and calculated the kGvalue of waste using the Baehr and Joss model.The results have been summarized in Table 8.The field kGvalue of MSW decreases as the depth increases(or degradation increases)due to the overburden pressure and finer waste particles in the deeper layers.Additionally,the kGvalue of MSW in the Beijing Landfill is lower than that in the New River Regional Landfill by about an order of magnitude,caused by higher degree of saturation in the HWKC MSW landfill(Wu et al.,2012a).

5.Compression of MSW

The vertical compression of MSW is a focus of attention.The settlement during the active life of a landfill will enlarge the storage capacity of landfill,but will also have an adverse impact on the integrity of the cover system and the service performances of the leachate drainage system and the landfill gas collection system(Qian and Guo,1995a,b;Oweis,2006).In a soil mechanics approach,the instantaneous compression and rapid consolidation of MSW are defined as the primary compression,and mechanical creep and compression due to degradation can be combined as the secondary compression(Manassero et al.,1996).

Table 8 Gas permeability,kG,of MSWs in the literature.

5.1.Primary compression of MSW

Three MSW specimens were taken at depths from 9.2 m to 28.2 m from the CCL.The diameter was 98 mm for two of the specimens,and 82 mm for the rest one.The height of specimens was 200 mm.A total of 62 MSW specimens with diameters ranging from 79.5 mm to 95 mm and a height of 200 mm were taken from SQL,and the corresponding depth was 2.5-32.4 m(Chen et al., 2009).Compression tests were conducted to obtain the modified primary compression index(Cc′)of the MSW specimens.After the compression test,the organic content of each specimen from SQL was determined by weighting the mass loss afterhaving been dried in an oven at a temperature of 300°C.It takes about 2 years for organic content(by the dry basis)to decrease from over 30%to about 17%,and the Cc′value of HKWC MSW drops gradually to a stable value(Zhan et al.,2008a).

Many studies have been performed to measure Cc′of various MSWs,and the values of Cc′are then dispersed.Based on the fill age and the kitchen waste content,MSWs are divided into four categories:fresh LKWC MSW,aged LKWC MSW,fresh HKWC MSW and aged HKWC MSW.The distribution of Cc′in each kind of MSW is shown in Fig.6.As the fill age increases,the ranges of Cc′for both LKWC and HKWC MSWs shorten.The average value of C′cfor the fresh HKWC MSW is 0.295,but it drops to 0.204 for the aged HKWC MSW.The average value of C′cfor the fresh LKWC MSW is 0.217, reducing to 0.186 for the aged LKWC MSW,which is close to that ofthe aged HKWC MSW.The range of C′cfor the fresh LKWC MSW extends from 0.045 to 0.389,and the range of that of fresh HKWC MSW is relatively larger,from 0.13 to 0.46.But the range of C′cfor the aged HKWC MSW(0.082-0.325)is similar to that of the aged LKWC MSW(0.091-0.28).

Fig.6.Range of C′cof MSWs in the literature(Beaven and Powrie,1995;Chen and Ke, 2003;Liu et al.,2003;Oliver,2003;Oliver and Gourc,2007;Rao et al.,1977;Stoltz and Gourc,2007;Stoltz et al.,2011).

5.2.Secondary compression of MSW

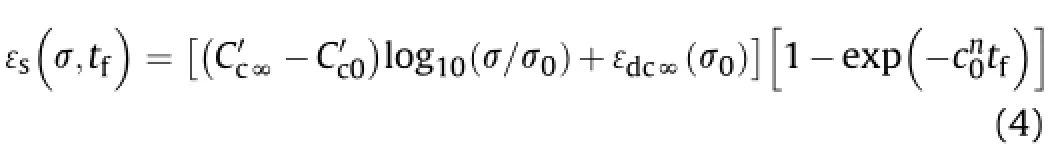

Compression generated by degradation is an important feature of MSW that differs from soil.The secondary compression can be calculated from the model proposed by Chen et al.(2010b)as follows:

where 3s(σ,tf)is the secondary strain of the MSW at a fill age of tfunder the applied load ofσ;σ0is the pre-consolidation pressure, which can be chosen as 30 kPa when no test data are available(CJJ 176-2012,2012);andare the modified primary compression indices of the fresh MSW and the fully decomposed MSWs respectively,which can be obtained through compression tests of fresh and fully decomposed MSWs.Based on the data in Fig.6 and this model,the modified primary compression index(tf)for the MSW with a fill age of tfcan be calculated using the following formula:

In Eq.(4),3dc∞(σ0)is the sum of the ultimate vertical strains of decomposition compression and mechanical creep underσ0.The value of3dc∞(σ0)can be obtained by subtracting the compressive vertical strain of the fully decomposed MSWunder the applied load ofσ0from that of the fresh MSW.Chen et al.(2010b)conducted a compression test using HKWC MSW,which lasted for 235 days;and the strain as a result of decomposition and creep was 20.7%,which reached the same magnitude as the primary compression(33.6%). China's technical code(CJJ 176-2012,2012)recommends that the 3dc∞(σ0)value of HKWC MSW is 20%-30%.It is possible that the long-term settlement could exceed the primary settlement under a higher content of organics and a suitable biodegradation condition for the HKWC MSW.For the LKWC MSW,the total decomposition strain can be in the same order of magnitude as the mechanical strain during filling and post filling periods(Oweis,2006),but that takes longer time to achieve.

In Eq.(4),c0is the MSW decomposition rate.The c0value can be obtained from degradation compression tests performed under a decomposition condition similar to that in the landfill,and can also be estimated using the back-analysis of measured long-term settlement data on similar landfills.The value of c0for HKWC MSW is generally greater than that for LKWC MSW.The recommended value using China's technical code(CJJ 176-2012,2012)is 0.06-0.18 yr-1for HKWC MSW.The higher the organic content and the more suitable the biodegradation conditions,the higher the value of c0.

6.Shear strength of MSW

The MSW shear strength is important for evaluating the stability of landfill slopes.The MSW is considered to be a frictional material, which often gives an increase in shear strength with increasing stress levels,thus the shear strength of MSW is usually defined by using the Coulomb failure criterion with two shear strength indices:the cohesion(c)and the friction angle(φ)(Dixon and Jones, 2005).

The shear behavior of MSW typically displays a progressive increase in shear stress with increasing shear displacement,referred to as the strain-hardening effect of the MSW(Kavazanjian et al., 1999;Vilar and Carvalho,2004;Harris et al.,2006;Zhan et al., 2008a;Bareither et al.,2012a).Additionally,waste compositions and material properties change as MSW decomposes,which has a significant influence on shear strength of MSW.

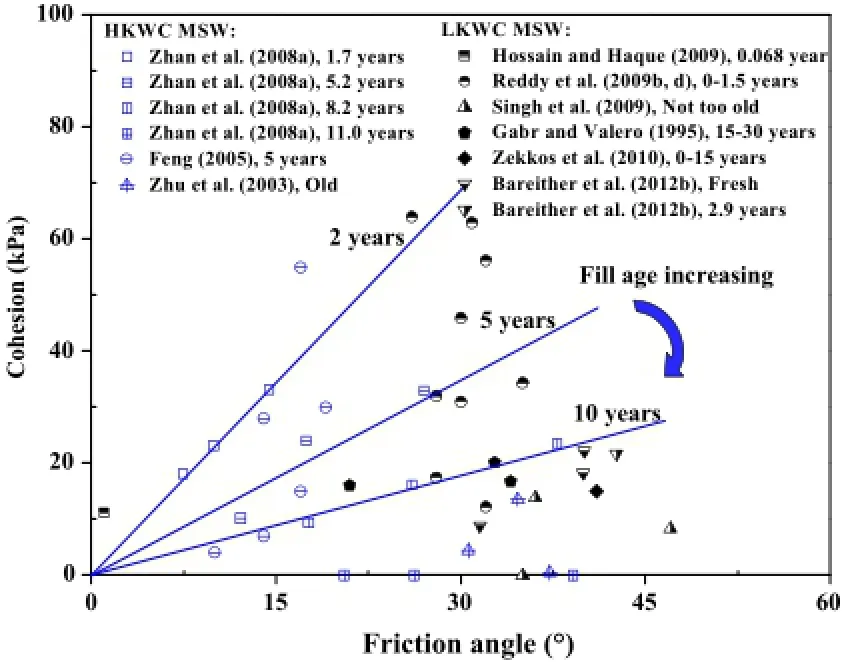

Ten laboratory study cases were selected,of which three cases were based on Chinese MSW and the rest were based on USA or Canadian MSWs.The shear strength indices were used in terms of total stress as MSW is generally unsaturated.Based on the current data,the friction angle of HKWC MSW is relativelysmaller than that of the LKWC MSW,but the range of cohesion of the HKWC MSW is similar to that of the LKWC MSW.Shear strength indices of HKWC and LKWC MSWs in consideration of the effects of strain and fill age are shown in Figs.7 and 8,respectively.

6.1.Influence of strain on the shear strength of MSW

As shown in Fig.7,the quadrant has been divided into different zones using elliptic loci with the same strain level.As the strain increases,the elliptic locus expands outwards,and both the friction angle and the cohesion of the HKWC MSWs increase.According to the results of Gabr and Valero(1995)and Singh et al.(2009), increasing stain also leads toan increase in the shear strength index of the LKWC MSWs.

Fig.7.Variation of shear strength indices with strain(Feng,2005;Hossain and Haque, 2009;Zhu et al.,2003).

Fig.8.Variation of shear strength indices with fill age(Feng,2005;Hossain and Haque,2009;Zhu et al.,2003).

6.2.Influence of aging on the shear strength of MSW

In Fig.8,the quadrant has been divided into different zones using the radial loci with the same fill age.As the fill age increases, the radial locus rotates clockwise.For HKWC MSW,the friction angle increases while the cohesion decreases,but the shear strength indices of LKWC MSWs do not match this pattern.Reddy et al.(2011)conducted direct shear tests and triaxial tests under the consolidated undrained(CU)condition to determine the shear strength of synthetic MSW at different phases of degradation.The synthetic MSW was prepared based on the composition of USA MSW and was degraded in bioreactors with leachate recirculation. It was observed that an increase in cohesion and a slight decrease in friction angle present as the waste degrades.The trend is opposite to that of HKWC MSW herein.

7.Analyses and discussions

As shown in Fig.1,the proportions of chemical components in HKWC and LKWC MSWs are quite different,which results in distinct engineering properties.Eventually,the differences in engineeringpropertiesofHKWCMSWleadtouniquegeoenvironmental issues in HKWC MSW landfills,such as high leachate production,high leachate mound,low LFG collection efficiency,large settlement and slope stability problem.The causes of these geo-environmental issues are analyzed and their effects on the HKWC MSW landfill management are discussed in the following sections.

7.1.Leachate production in HKWC MSW landfills

Given the high content of kitchen waste(more than 40%)and the high water content in kitchen waste(about 70%),the IWC of fresh HKWC MSW can be over 50%,which is higher than that of LKWC MSW(less than 35%).Paper,cardboard and fine particles are easilyabsorbable materials that can absorb substantial quantities of water from precipitation and from other materials,such as kitchen waste(Hull et al.,2005).The total proportion of compositions in HKWC MSW is less than that in LKWC MSW,as shown in Table 1. Therefore,the FC of HKWC MSW is smaller than its IWC,but the FC of LKWC MSW is higher than its IWC,which indicates that more intracellular water in kitchen waste can be released in HKWC MSW than that in LKWC MSW.Furthermore,the leachate release process is quicker for HKWC MSW due to the rapid degradation of kitchen waste.As a result,leachate production is significant in HKWC MSW landfills.A large quantity of leachate is produced in a HKWC MSW landfill in Tunisia,despite the negative water balance of the site(Zairi et al.,2014).According to the pilot-scale landfill experimental results,a leachate production rate of HKWC MSW can reach as high as 30%in the first two months(Xu et al.,2014).And field results show that leachate production for HKWC MSW landfills increases during the peak rainy seasons(Kularatne,2015).

Leaching coefficient method is usually used to predict leachate production in LKWC MSW landfills(Geng and Zheng,2009;He and Wu,2013).However,it will underestimate the production of leachate in HKWC MSW landfills because it does not consider the leachate generated from the waste due to compression and degradation(Pantini et al.,2014).It is especially significant for the HKWC MSW landfills to predict the leachate production accurately. Lan et al.(2012)proposed a modified method to consider that compared with the leaching coefficient method,the modified method gave a better prediction of leachate production.

7.2.Leachate mounds in HKWC MSW landfills

It can be seen from Fig.4 that the permeability coefficient of HKWC MSW(10-5-10-8m/s)is lower by an order of magnitude than that of LKWC MSW(10-3-10-8m/s),and declines sharply with the overburden depth.Given that the compaction effect is minor,as shown in Fig.3,the higher kitchen waste content in HKWC MSW causes the permeability coefficient difference between HKWC and LKWC MSWs.The pores between solid particles are compressed and the drainage channel is blocked with organic degradation.In addition,humus generated by organic degradation, a material with low permeability,fills the voids in the waste and decreases the hydraulic conductivity of HKWC MSW.

The low permeability coefficient,which decreases with overburden depth,leads to leachate mounds more easily,affecting the distribution of effective stresses in HKWC MSW landfills.Significant leachate production for the HKWC MSW and the clogging of the leachate collection and drainage system(LCDS)also contribute to high leachate mounds in HKWC MSW landfills.Along with the landfillprocess,theleachatelevelincreasesandthesaturationareain thewastealsoenlarges.Highleachatemoundsnotonlyaggravatethe leakageofleachate,butalsothreatenthestabilityofthelandfillslope.

The level of the leachate mound depends on a dynamic equilibrium between water input and output.Measures to control the water input include reducing the water content of waste through pre-compression before it is buried,covering the landfill surface to prevent precipitation infiltration,ensuring the integrity of the liner system to shield the inflow from the sides and bottom(He et al., 2010).A more efficient LCDS,such as a three-dimensional drainage configuration,is needed to guarantee the output of leachate for the normal operation of HKWC MSW landfills. Ensuring the performance of LCDS is critically important to reduce the adverse effects induced by high leachate production of the HKWC MSW.

7.3.LFG collection efficiency in HKWC MSW landfills

The potential CH4generation capacity,L0,is influenced by waste type and composition;the higher the waste cellulose content,the higher the value of L0(Alexanderet al.,2005).As shown in Fig.1,the average proportion of cellulose in LKWC MSW is higher than that in HKWC MSW,thus the L0value of LKWC MSW is larger than that of the HKWC MSW.Nutrients and water are two factors that affect the CH4generation rate(k)(Alexander et al.,2005).The ratio of total organic carbon to total nitrogen(C/N)ranging from 22 to 35 in organic fractions is believed to be the optimal range for anaerobic digester operation(Kayhanian and Hardy,1994;Ma et al.,2007). For LKWC MSW,the typical value of the C/N ratio is 49,which islarger than the optimal range as a result of higher proportions of paper,while the C/N ratio of HKWC MSW is about 20(Li and Guo, 2005;Sun,2008).In addition,the water from the HKWC MSW is sufficient for anaerobic degradation,which leads to a higher k value for HKWC MSW than that for LKWC MSW.

Since the organic degradation and the overlying loads decrease the void ratio,and release more leachate for HKWC MSW,a higher degree of saturation of HKWC MSW can be more easily achieved, resulting in disconnected travel paths of LFG,thus the field kGvalue of HKWC MSW is an order of magnitude smaller than that of LKWC MSW.The value of kGchanges from 10-11m2to 10-13m2when the degree of saturation of MSW increases from 0%to 87%based on Table 8.

In 2012,the MSW quantity treated by landfills in China was as much as 1.05×108t(National Bureau of Statistics of the People's Republic of China,2013).The potential production of LFG is still staggering,though the L0value of HKWC MSW is lower than that of the LKWC MSW.According to statistic data,before the end of 2008, 26 LFG power projects have been built and put into operation with the total power capacity of around 56.8 MW,and 2.234 million tons of carbon dioxide equivalent abatement has been achieved annually by all of these LFG projects(Chen et al.,2010c).Environmental impacts decrease significantly in landfills with the utilization of LFG owing to the combined effects of greenhouse gas(GHG)emission reduction and electricity generation(Dong et al.,2014).However, the LFG collection efficiency in most HKWC MSW landfills is low(Zairi et al.,2014).Zhao et al.(2009)evaluated the current MSW management with respect to GHG emissions in Tianjin,and concluded that the release of LFG from landfill contributed 68%to the total GHG emissions.On one hand,the LFG in the shallow layer may escape before the waste is covered due to a higher k value for HKWC MSW;on the other hand,a lower kGvalue makes it much more difficult to collect LFG.Increasing the LFG collection efficiency will reduce the magnitudes of GHG emissions(Niskanen et al., 2013;Yang et al.,2013).

Applying an enhanced temporary cover will prevent the precipitation infiltration and LFG leakage,and the LFG collection system(LFGCS)is needed soon after MSW is buried.The design of the final cover layer and its geotechnical and biological behaviors have an important role in minimizing gas emissions to the atmosphere. Capillary and methanotrophic final cover layers present lower CH4flux rates than the conventional layer(Maciel and Jucá,2011). Implementing an active drainage system,such as pumping wells, can lower the leachate level,which is conductive to the flow of LFG, increase the influence radius of LFG extraction wells and therefore increase the LFG collection efficiency in HKWC MSW landfills.The leachate level is suggested to be controlled to be less than 30%of the total waste thickness to achieve a high LFG collection efficiency(Zhan et al.,2015).

7.4.Settlement in HKWC MSW landfills

As expected,the primary compression of fresh HKWC MSW is greater than that of LKWC MSW because of the larger initial void ratio(Li et al.,2013);the Cc′value of fresh HKWC MSW ranges from 0.13 to 0.46 as shown in Fig.6.Given the rapid degradation of organic fractions in the HKWC MSW,the relative content of rigid materials like glass and brick is increased,and thus the mechanical compressibility of decomposed HKWC MSW is similar to that of the decomposed LKWC MSW.

Organic degradation also makes a great contribution to the total compression of MSWand is influenced by the mass of organics and the decomposition conditions.Although the total content of degradable components in LKWC MSW is generally higher than that of the HKWC MSW,as shown in Fig.1,compositions such as paper,wood and textiles remain for 18 years in absence of water(Zekkos et al.,2010).In comparison,the compression induced by degradation of HKWC MSW can reach 20%-30%of the initial fill height,and may exceed the magnitude of primary compression in more suitable degradation conditions.

According tothe long-term settlement measurements,the effect of degradation on the development of secondary settlement is changing.In a short time period,there is no significant increase in the settlement rate due to biodegradation;however,in a long time the settlement rate will increase as the effects of decomposition become more significant(Bjarngard and Edgers,1990;Wall and Zeiss,1995;Hossain and Gabr,2005;Bareither et al.,2013;Xu et al.,2015).

The total settlement in HKWC MSW landfills is considerably large and it can result in an advantageous increase in storage capacity under effective management,which includes the improvement of initial compaction,preferential decomposition conditions and leachate mound reduction,which would increase the effective overburden stress(Li et al.,2013).

7.5.Slope stability in HKWC MSW landfills

MSW is a type of strain-hardening material.Despite the fact that the values of shear strength indices vary widely,an increase in the shear strength of both the HKWC and the LKWC MSWs can be observed as shear strain continues to rise.Nonetheless,organics in HKWC MSW decrease rapidly and the proportions of inert particles increase,such as glass,ash and cinder.The shear strength property of HKWC MSW tends to be similar to that of sand in the process of degradation,thus the effect of fill age on the shear behavior of HKWC MSW is more significant than that for the LKWC MSW.A landfill slope could become unstable tens of years after its formation.

An evaluation of the shear strength taking into account strainhardening effects and aging effects will significantly affect the design of a safe HKWC landfill slope over both the short and long time.

In addition,landfill stability can be affected byleachate(Koerner and Soong,2000a,b):(1)making the waste heavier;(2)imposing a hydrostatic head;(3)generating excess pore pressure due to leachate recirculation;and(4)wetting the interfaces between the geosynthetic materials and MSW.Several serious landfill slope instability accidents are related to the leachate within landfills(Koelsch et al.,2005;Merry et al.,2005;Blight,2008).Chen et al.(2010a)calculated that the safety factor for non-lined landfills reduces as the ratio of the leachate mound height to the maximum MSW thickness increases.Decreasing the leachate mound is absolutely necessary.

8.Conclusions

In this paper,based on the content of kitchenwaste,MSWs were divided into HKWC and LKWC MSWs.Keyengineering properties of HKWC and LKWC MSWs were analyzed and compared,corresponding management and design principles for HKWC MSW landfills were proposed:

(1)Discrepancies in engineering properties between HKWC and LKWC MSWs essentially come from different compositions of fresh MSWs.

(2)Higher IWC but similar FC quantities result in higher leachate

production for HKWC MSW than that for LKWC MSW.Due to the occurrence of early and higher leachate production and lower hydraulic conductivity of MSW in HKWC MSW landfills,an effective performance of LCDS is necessary toavoid leachateinduced issues.

(3)HKWC MSW has a faster generation rate but a shorter duration and lower potential capacity of LFG than LKWC MSW.The lower gas permeability of HKWC MSWopposed to that of LKWC MSW exacerbates the difficulties of LFG collection in HKWC MSW landfills.An enhanced temporary cover and a timely LFGCS are necessary to prevent the LFG emission.

(4)The primary compression of decomposed HKWC MSW is similar to that of decomposed LKWC MSW,but compression induced by the degradation of HKWC MSW can be greater than that of LKWC MSW.Correct management,such as improvement of initial compaction,preferential decomposition conditions and leachate level reduction,will help to increase the capacity of HKWC MSW landfills.

(5)MSW shear strength changes with time and strain,which is particularly significant for HKWC MSW.It is necessary to take the aging effect and strain-hardening effect into consideration in order to assess HKWC MSW landfill slope stabilityand design for safe landfills.

(6)Based on the engineering properties of HKWC MSW,quantitative calculation methods and the corresponding design requirements need to be developed.

Conflict of interest

The authors wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Acknowledgments

Financial support provided by the National Basic Research Program of China(973 Project)(Grant No.2012CB719806)is gratefully acknowledged.

References

Alexander A,Burklin CE,Singleton A.Landfill gas emissions model(LandGEM)version 3.02 user's guide.US Environmental Protection Agency(EPA);2005.

Allen MR,Braithwaite A,Hills CC.Trace organic compounds in landfill gas at seven UK waste disposal sites.Environmental Science&Technology 1997;31(4):1054-61.

Amini HR,Reinhart DR,Mackie KR.Determination of first-order landfill gas modeling parameters and uncertainties.Waste Management 2012;32(2):305-16.

Amini HR,Reinhart DR,Niskanen A.Comparison of first-order-decay modeled and actual field measured municipal solid waste landfill methane data.Waste Management 2013;33(12):2720-8.

Assamoi B,Lawryshyn Y.The environmental comparison of landfilling vs.incineration of MSW accounting for waste diversion.Waste Management 2012;32(5):1019-30.

Bareither C,Benson C,Edil T.Compression behavior of municipal solid waste:immediate compression.Journal of Geotechnical and Geoenvironmental Engineering 2012a;138(9):1047-62.

Bareither C,Benson C,Edil T.Effects of waste composition and decomposition on the shear strength of municipal solid waste.Journal of Geotechnical and Geoenvironmental Engineering 2012b;138(10):1161-74.

Bareither C,Benson C,Edil T.Compression of municipal solid waste in bioreactor landfills:mechanical creep and biocompression.Journal of Geotechnical and Geoenvironmental Engineering 2013;139(7):1007-21.

Barlaz MA.Carbon storage during biodegradation of municipal solid waste components in laboratory-scale landfills.Global Biogeochemical Cycles 1998;12(2):373-80.

Bear J.Dynamics of fluids in porous media.New York:American Elsevier Pub.Co.;1972.

Beaven RP,Powrie W.Hydrogeological properties of refuse using a large scale compression cell.In:Proceedings Sardinia,the 5th International Waste Management and Landfill Symposium.Cagliari;1995.p.745-60.

Beaven R,Powrie W,Zardava K.Hydraulic properties of MSW.In:Geotechnical characterization,field measurement and laboratory testing of municipal solid waste,Proceedings of the 2008 International Symposium on Waste Mechanics. American Society of Civil Engineers(ASCE);2011.p.1-43.

Beaven RP.The hydrogeological and geotechnical properties of household waste in relation to sustainable landfilling.PhD Thesis.London:University of London;2000.

Bjarngard A,Edgers L.Settlement of municipal solid waste landfills.In:Proceedings of the 13th Annual Madison Waste Conference.Madison,USA:University of Wisconsin;1990.p.192-205.

Bleiker DE,McBean E,Farquhar G.Refuse sampling and permeability testing at the Brock West and Keele Valley landfills.In:Proceedings of the 16th International Madison Waste Conference:Municipal and Industrial Waste.Madison,USA:Department of Engineering Professional Development;1993.p.548-67.

Blight G.Slope failures in municipal solid waste dumps and landfills:a review. Waste Management and Research 2008;26(5):448-63.

Breitmeyer RJ,Benson CH.Measurement of unsaturated hydraulic properties of municipal solid waste.In:Geo-frontiers 2011:Advances in geotechnical engineering.ASCE;2011.p.1433-42.

Burklin C,Lloyd B.User's manual,China landfill gas model,version 1.1.Washington, D.C.:US EPA;2009.

Chen YM,Ke H.Compression characteristics of MSW and analysis of capacity for landfills.Acta Scientiae Circumstantiae 2003;23(5):694-8(in Chinese).

Chen YM,Ke H,Fredlund DG,Zhan LT.Xie Yan.Secondary compression of municipal solid wastes and a compression model for predicting settlement of municipal solid waste landfills.Journal of Geotechnical and Geoenvironmental Engineering 2010b;136(5):706-17.

Chen YM,Zhan LT,Li YC.Biochemical,hydraulic and mechanical behaviours of landfills with high-kitchen-waste-content MSW.In:The 7th International Congress on Environmental Geotechnics,Melbourne;2014.p.232-59.

Chen YM,Zhan LT,Li YC.Development of leachate mounds and control of leachaterelated failures at MSW landfills in humid regions.In:The 6th International Congress on Environmental Geotechnics,New Delhi;2010.p.76-98.

Chen YM,Zhan LT,Wei HY,Ke H.Aging and compressibility of municipal solid wastes.Waste Management 2009;29(1):86-95.

Chen ZZ,Gong HJ,Jiang R,Qin J,Wu WL.Overview on LFG projects in China.Waste Management 2010c;30(6):1006-10.

CJJ 176-2012.Technical code for geotechnical engineering of municipal solid waste sanitary landfill.Beijing:China Architecture and Building Press;2012(in Chinese).

De Velásquez MTO,Cruz-Rivera R,Rojas-Valencia N,Monje-RamíRez I,SáN-chez-GóMez J.Determination of field capacity of municipal solid waste with surcharge simulation.Waste Management and Research 2003;21(2):137-44.

Dixon N,Jones DRV.Engineering properties of municipal solid waste.Geotextiles and Geomembranes 2005;23(3):205-33.

Dixon N,Langer U.Development of a MSW classification system for the evaluation of mechanical properties.Waste Management 2006;26(3):220-32.

Dong J,Chi Y,Zou DA,Fu C,Huang QX,Ni MJ.Comparison of municipal solid waste treatment technologies from a life cycle perspective in China.Waste Management and Research 2014;32(1):13-23.

Du WP.Primary study on greenhouse gas-CH4 emission from MSW landfill.MS Thesis.Nanjing:Nanjing University of Information Science and Technology;2006(in Chinese).

Eklund B,Anderson EP,Walker BL,Burrows DB.Characterization of landfill gas composition at the fresh kills municipal solid-waste landfill.Environmental Science and Technology 1998;32(15):2233-7.

EPA.Municipal solid waste generation,recycling,and disposal in the United States:Facts and figures for 2011.Washington D.C.:EPA;2013.www.epa.gov/waste.

Feng SJ.Static and dynamic strength properties of municipal solid waste and stability analyses of landfill.PhD Thesis.Hangzhou:Zhejiang University;2005(in Chinese).

Francois V,Feuillade G,Matejka G,Lagier T,Skhiri N.Leachate recirculation effects on waste degradation:study on columns.Waste Management 2007;27(9):1259-72.

Gabr MA,Valero SN.Geotechnical properties of municipal solid waste.ASTM Geotechnical Testing Journal 1995;18(2):241-51.

Gao G,Dong YW,Jin HB,Huang W.Researches on counter measures of municipal waste disposal and management.Urban Environment and Urban Ecology 2000;13(2):39-41(in Chinese).

Gao ZW,He PJ,Shao LM,Li GJ,Yu JY,Chen ZF.Methane emission from active terrace of municipal solid waste landfills.Acta Scientiae Circumstantiae 2006;26(2):236-40(in Chinese).

Geng GJ,Zheng SY.Prediction for waste leachate quantity.Journal of Water Resources and Water Engineering 2009;20(2):95-9(in Chinese).

Harris JM,Shafer AL,DeGroff W,Hater GR,Gabr M,Barlaz MA.Shear strength of degraded reconstituted municipal solid waste.Geotechnical Testing Journal 2006;29(2):141-8.

He J,Wu N.Discussion on application of leachate generation calculation formula-Rainfallparametersselection.EnvironmentalScienceandManagement 2013;38(4):16-20(in Chinese).

He PJ,Feng SW,Shao LM.Municipal solid waste management.Beijing:Science Press;2003(in Chinese).

He PJ.Solid waste disposal and recycling technology.Beijing:Higher Education Press;2011(in Chinese).

He S,Lan JW,Zhan LT.Control measures for leachate generation rate and leachate level at valley-type landfills in South China.China Water and Wastewater 2010;26(8):1-5(in Chinese).

Hossain MDS,Haque MA.The effects of daily cover soils on shear strength of municipal solid waste in bioreactor landfills.Waste Management 2009;29(5):1568-76.

Hossain MS,Gabr MA,Barlaz MA.Relationship of compressibility parameters to municipal solid waste decomposition.Journal of Geotechnical and Geoenvironmental Engineering 2003;129:1151-8.

Hossain MS,Gabr MA.Prediction of municipal solid waste landfill settlement with leachate recirculation.In:Waste containment and remediation,Proceedings of Sessions of the Geo-Frontiers 2005 Congress.ASCE;2005.p.1-14.

Hull R,Krogmann U,Strom P.Composition and characteristics of excavated materials from a New Jersey landfill.Journal of Environmental Engineering 2005;131(3):478-90.

Intergovernmental Panel on Climate Change(IPCC).2006 IPCC guidelines for national greenhouse gas inventories.IPCC 2006.

Jain P,Powell J,Townsend T,Reinhart D.Air permeability of waste in a municipal solid waste landfill.Journal of Environmental Engineering 2005;131(11):1565-73.

Jain P,Powell J,Townsend T,Reinhart D.Estimating the hydraulic conductivity of landfilled municipal solid waste using the borehole permeameter test.Journal of Environmental Engineering 2006;132(6):645-52.

Jung Y,Imhoff P,Finsterle S.Estimation of landfill gas generation rate and gas permeability field of refuse using inverse modeling.Transport in Porous Media 2011;90(1):41-58.

Kavazanjian E,Matasovic N,Bachus RC.Large-diameter static and cyclic laboratory testing of municipal solid waste.In:Proceedings Sardinia,the 7th International Waste Management and Landfill Symposium,Cagliari;1999.p.437-44.

Kavazanjian E.The impact of degradation on MSW shear strength.In:GeoCongress 2008:geotechnicsofwastemanagementandremediation.ASCE;2008.p.224-31.

Kayhanian M,Hardy S.The impact of four design parameters on the performance of a high-solids anaerobic digestion of municipal solid waste for fuel gas production.Environmental Technology 1994;15(6):557-67.

Koelsch F,Fricke K,Mahler C,Damanhuri E.Stability of landfills-the Bandung dump site disaster.In:Proceedings of the 10th International Waste Management and Landfill Symposium.Sardinia,Italy;2005.

Koerner RM,Soong TY.Leachate in landfills:the stability issues.Geotextiles and Geomembranes 2000a;18(5):293-309.

Koerner RM,Soong TY.Stability assessment of ten large landfill failures.In:Proceedings of Sessions of Geo-Denver 2000,Advances in transportation and geoenvironmental systems using geosynthetics.ASCE;2000b.p.1-38.

Kularatne RKA.A case study on anticipated leachate generation from a semi-aerobic sanitary landfill at Aruwakkalu(Puttalam District)and its impacts.Environmental Earth Sciences 2015;73(11):7255-74.

Lan JW,Zhan LT,Li YC,Chen YM.Impacts of initial moisture content of MSW waste on leachate generation and modified formula for predicting leachate generation.Environmental Science 2012;33(4):1389-96(in Chinese).

Lan JW.Mechanism of leachate generation,transport and mound in MSW landfills and control of leachate level.PhD Thesis.Hangzhou:Zhejiang University;2012(in Chinese).

Landva AO,Clark JI.Geotechnics of waste fill.In:Geotechnics of waste fills-Theory and practice.ASTM International;1990.p.86-103.

Landva AO,Valsangkar AJ,Pelkey SG.Lateral earth pressure at rest and compressibility of municipal solid waste.Canadian Geotechnical Journal 2000;37(6):1157-65.

Larson J,Kumar S,Gale SA,Jain P,Townsend T.A field study to estimate the vertical gas diffusivity and permeability of compacted MSW using a barometric pumping analytical model.Waste Management and Research 2012;30(3):276-84.

Li Y,Guo AJ.Municipal solid waste sanitary landfill design guide.Beijing:China Environment Science Press;2005(in Chinese).

Li YC,Liu HL,Cleall PJ,Ke H,Bian XC.Influences of operational practices on municipal solid waste landfill storage capacity.Waste Management and Research 2013;31(3):273-82.

Liu FQ,Tang W,Nie YF.Study on the generation process of landfill gas by laboratory simulation.China Biogas 2001;19(1):22-6(in Chinese).

Liu R,Shi JY,Peng GX.Study on the settlement parameters of municipal solid waste. Geotechnical Engineering Technique 2003;(2):90-4(in Chinese).

Ma L,Wang DH,Zeng CM.Dry anaerobic digestion process for treating food waste. China Biogas 2007;25(1):27-30(in Chinese).

Ma XF.Extraction test and evaluation method of landfill gas for municipal solid waste landfills.MS Thesis.Hangzhou:Zhejiang University;2013(in Chinese).

Machado SL,Karimpour-Fard M,Shariatmadari N,Carvalho MF,do Nascimento JCF. Evaluation of the geotechnical properties of MSW in two Brazilian landfills. Waste Management 2010;30(12):2579-91.

Maciel FJ,Jucá JFT.Evaluation of landfill gas production and emissions in a MSW large-scale experimental cell in Brazil.Waste Management 2011;31(5):966-77.

Manassero M,Van Impe WF,Bouazza A.Waste disposal and containment.In:Proceedings of the 2nd International Congress on Environmental Geotechnics, Osaka,Japan;1996.p.193-242.

Merry SM,Kavazanjian Jr E,Fritz WU.Reconnaissance of the July 10,2000,Payatas landfill failure.Journal of Performance of Constructed Facilities 2005;19(2):100-7.

National Bureau of Statistics of the People's Republic of China.China statistical yearbook.Beijing:China Statistics Press;2013(in Chinese).

Niskanen A,Värri H,Havukainen J,Uusitalo V,Horttanaien M.Enhancing landfill gas recovery.Journal of Cleaner Production 2013;55:67-71.

Ogor Y,Guerbois M.Comparison of landfill methane emission models:a case study. In:Proceedings of the 10th International Waste Management and Landfill Symposium.Sardinia,Italy;2005.

Oliver F.Tassement des déchets en CSD de classe II:du site au modèle.PhD Thesis. Grenoble:Université Joseph-Fourier-Grenoble I;2003(in French).

Oliver F,Gourc JP.Hydro-mechanical behavior of municipal solid waste subject to leachate recirculation in a large-scale compression reactor cell.Waste Management 2007;27(1):44-58.

Olivier F,Oxarango L,Mugnier V,Tinet AJ,Marcoux MC.Estimating the drawdown of leachate in a saturated landfill:3D modeling based on field pumping tests. In:The 12th International Waste Management and Landfill Symposium.Sardinia,Italy;2009.

Oweis IS,Smith DA,Brian Ellwood R,Greene DS.Hydraulic characteristics of municipal refuse.Journal of Geotechnical Engineering 1990;116(4):539-53.

Oweis IS.Estimate of landfill settlements due to mechanical and decompositional processes.JournalofGeotechnicalandGeoenvironmentalEngineering 2006;132(5):644-50.

Pantini S,Verginelli I,Lombardi F.A new screening model for leachate production assessment at landfill sites.International Journal of Environmental Science and Technology 2014;11(6):1503-16.

Patumsawad S,Cliffe KR.Experimental study on fluidised bed combustion of high moisturemunicipalsolidwaste.EnergyConversionandManagement 2002;43(17):2329-40.

Powrie W,Beaven RP.Hydraulic properties of household waste and implications for landfills.Geotechnical Engineering 1999;137(4):235-47.

Qian XD,Guo ZP.Modern sanitary landfill engineering in the United States.part 1. Advances in Science and Technology of Water Resources 1995a;15(5):8-12(in Chinese).

Qian XD,Guo ZP.Modern sanitary landfill engineering in the United States.part 2. Advances in Science and Technology of Water Resources 1995b;15(6):27-31(in Chinese).

Qian XD,Koerner RM,Gray DH.Geotechnical aspects of landfill construction and design.Prentice Hall;2001a.

Qian XD,Shi JQ,Liu XD.Design and construction of modern sanitary landfills. Beijing:China Architecture and Building Press;2001b(in Chinese).

Rao SK,Moulton LK,Seals RK.Settlement of refuse landfills.In:Proceedings of the Conference on Geotechnical Practices for Disposal of Solid Waste Materials.Ann Arbor,Michigan:University of Michigan;1977.p.574-99.

Reddy KR,Hettiarachchi H,Parakalla NS,Gangathulasi J,Bogner JE.Geotechnical properties of fresh municipal solid waste at orchard hills landfill,USA.Waste Management 2009a;29(2):952-9.

Reddy KR,Gangathulasi J,Parakalla NS,Hettiarachchi H,Bogner JE,Lagier T. Compressibility and shear strength of municipal solid waste under short-term leachaterecirculationoperations.WasteManagementandResearch 2009d;27(6):578-87.

Reddy KR,Hettiarachchi H,Gangathulasi J,Bogner JE,Lagier T.Geotechnical properties of synthetic municipal solid waste.International Journal of Geotechnical Engineering 2009b;3(3):429-38.

Reddy KR,Hettiarachchi H,Parakalla N,Gangathulasi J,Bogner JE,Lagier T.Hydraulic conductivity of MSW in landfills.Journal of Environmental Engineering 2009c;135(8):677-83.

Reddy KR,Hettiarachchi H,Gangathulasi J,Bogner JE.Geotechnical properties of municipal solid waste at different phases of biodegradation.Waste Management 2011;31(11):2275-86.

Saint-Fort R.Assessing sanitary landfill stabilization using winter and summer waste streams in simulated landfill cells.Journal of Environmental Science and Health,Part A:Toxic/Hazardous Substances and Environmental Engineering 2002;37(2):237-59.

Shank KL.Determination of the hydraulic conductivity of the Alachua County southwest landfill.MS Thesis.Gainesville:University of Florida;1993.

Singh MK,Sharma JS,Fleming IR.Shear strength testing of intact and recompacted samples of municipal solid waste.Canadian Geotechnical Journal 2009;46(10):1133-45.

Staley BF,Barlaz MA.Composition of municipal solid waste in the United States and implications for carbon sequestration and methane yield.Journal of Environmental Engineering 2009;135(10):901-9.

Stoltz G,Gourc JP.Influence of compressibility of domestic waste on fluid conductivity.In:Proceedings Sardinia,the 11th International Waste Management and Landfill Symposium,Cagliari;2007.p.1-8.

Stoltz G,Tinet AJ,Staub MJ,Oxarango L,Gourc JP.Moisture retention properties of municipal solid waste in relation to compression.Journal of Geotechnical and Geoenvironmental Engineering 2011;138(4):535-43.

Sun SC,Lu HW,Ren LX,He L,Zhang JQ.Analysis on landfill gas emission and CDM projects in Beijing.Chinese Journal of Environmental Engineering 2015;9(7):3361-7(in Chinese).

Sun YJ.Investigation and anaerobic digestion feasibility of food waste in Hangzhou. MS Thesis.Hangzhou:Zhejiang University;2008(in Chinese).

Sun YQ,Wang CM,Zhang J,Lun XX,Wang H.Application of models for estimating landfill gas generation in China.Environmental Engineering 2012;30(Suppl.2):392-5(in Chinese).

Tchobanoglous G,Theisen H,Vigil SA.Integrated solid waste management.1st ed. New York:McGraw-Hill;1993.

Thompson S,Sawyer J,Bonam R,Valdivia JE.Building a better methane generation model:validating models with methane recovery rates from 35 Canadian landfills.Waste Management 2009;29(7):2085-91.

Vilar OM,Carvalho M.Mechanical properties of municipal solid waste.Journal of Testing and Evaluation 2004;32(6):438-49.

Wall DK,Zeiss C.Municipal landfill biodegradation and settlement.Journal of Environmental Engineering 1995;121(3):214-24.

Wang X,Nagpure AS,DeCarolis JF,Barlaz MA.Characterization of uncertainty in estimation of methane collection from select US landfills.Environmental Science and Technology 2015;49(3):1545-51.

Wei HY,Zhan LT,Chen YM.Experimental study on gas permeability of municipal solid waste.Chinese Journal of Rock Mechanics and Engineering 2007;26(7):1408-15(in Chinese).

Wei HY.Experimental and numerical study on gas migration in landfill of municipal solid waste.PhD Thesis.Hangzhou:Zhejiang University;2007(in Chinese).

Wu H,Chen T,Wang H,Lu W.Field air permeability and hydraulic conductivity of landfilled municipal solid waste in China.Journal of Environmental Management 2012a;98:15-22.

Wu H,Wang H,Zhao Y,Chen T,Lu W.Evolution of unsaturated hydraulic properties of municipal solid waste with landfill depth and age.Waste Management 2012b;32(3):463-70.

Xu H,Zhan LT,Guo RY,Shen SL,Lin WA,Chen P,Chen YM.Large-scale model experiments on multi-field interactions in landfill of municipal solid waste.In:The 7th International Congress on Environmental Geotechnics,Melbourne;2014.p.810-7.

Xu XB,Zhan LT,Chen YM,Guo QG.Parameter determination of a compression model for landfilled municipal solid waste:an experimental study.Waste Management and Research 2015;33(2):199-210.

Xue DD,Liu D,Yang M,Luo DN,Song XQ.The present situation of municipal waste disposal in Chengdu and sustainable development countermeasures.Guangdong Agricultural Sciences 2008;(11):100-2(in Chinese).

Yang N,Zhang H,Shao LM,Lü F,He PJ.Greenhouse gas emissions during MSW landfilling in China:influence of waste characteristics and LFG treatment measures.Journal of Environmental Management 2013;129:510-21.

Zairi M,Aydi A,Dhia HB.Leachate generation and biogas energy recovery in the Jebel Chakir municipal solid waste landfill,Tunisia.Journal of Material Cycles and Waste Management 2014;16(1):141-50.

Zekkos D,Bray JD,Kavazanjian E,Matasovic N,Rathje EM,Riemer MF,Stokoe KH. Unit weight of municipal solid waste.Journal of Geotechnical and Geoenvironmental Engineering 2006;132(10):1250-61.

Zekkos D,Kavazanjian E,Bray JD,Matasovic N,Riemer MF.Physical characterization of municipal solid waste for geotechnical purposes.Journal of Geotechnical and Geoenvironmental Engineering 2010;136(9):1231-41.

Zhan LT,Chen YM,Ling WA.Shear strength characterization of municipal solid waste at the Suzhou landfill,China.Engineering Geology 2008a;97(3-4):97-111.

Zhan LT,Ling D,Zhang WJ,Chen Y.Hydrogeological characterization of Suzhou landfill of municipal solid wastes.In:Proceedings of GeoCongress 2008,Geotechnics of Waste Management and Remediation.ASCE;2008b.p.248-55.

Zhan LT,Xu H,Lan JW,Liu Z,Chen YM.Field and laboratory study on hydraulic characteristics of MSWs.Journal of Zhejiang University(Engineering Science)2014;48(3):478-86(in Chinese).

Zhan LT,Xu XB,Chen YM,Ma XF,Lan JW.Dependence of gas collection efficiency on leachate level at wet municipal solid waste landfills and its improvement methods in China.Journal of Geotechnical and Geoenvironmental Engineering 2015;141(4):04015002.

Zhang J,Wang CM.Estimation of landfill gas generation based on the LandGEM modelinBeijinglandfillsites.EnvironmentalScienceandTechnology 2013;36(9):144-8(in Chinese).

Zhang WJ.Experimental and numerical study on water/leachate transport in landfill of municipal solid waste.PhD Thesis.Hangzhou:Zhejiang University;2007(in Chinese).

Zhang XX,He PJ,Shao LM,Li GJ.Effects of leachate recirculation on landfill gas production.Acta Scientiae Circumstantiae 2005;25(2):264-8(in Chinese).

Zhao W,van der Voet E,Zhang YF,Huppes G.Life cycle assessment of municipal solid waste management with regard to greenhouse gas emissions:case study of Tianjin,China.Science of the Total Environment 2009;407(5):1517-26.

Zheng X,Yang Y,Lei Y.Biogas power generation potential analysis of China's urban landfill.Environmental Protection 2009;4(4):19-22(in Chinese).

Zhu JG,Shi JY,Yan Y.Research on the strength performance of solid waste.In:Proceedings of the 1st National Conference on Environmental Geotechnical and Geosynthetic Material,Hangzhou;2003.p.192-6(in Chinese).

Zornberg JG,Jernigan BL,Sanglerat TR,Cooley BH.Retention of free liquids in landfills undergoing vertical expansion.Journal of Geotechnical and Geoenvironmental Engineering 1999;125(7):583-94.

Dr.Yunmin Chen is a professor of Department of Civil Engineering in Zhejiang University,and has been acting as head of the Institute of Geotechnical Engineering in Zhejiang University since 2002 and head of the MOE Key Laboratory of Soft Soils and Geo-environmental Engineering since 2007.He is also the Changjiang Scholar Professor and the Dean,Faculty of Engineering,Zhejiang University. His major research fields include soil dynamics,foundation engineering and geo-environmental engineering.He had achieved 7 research projects from National Natural Science Foundation of China,including one key project and one outstanding young scientist award.He was in charge of several large consultant projects in China,including the first airport built on thick soft clay in China,Shanghai Shibobian deep excavation(33 m depth),Hangzhou sanitary landfill of MSW(120 m height)etc.He is now conducting one National Basic Research Program of China(“973”Project)and acting as the leading scientist.To date,Dr.Chen has published over 200 journal papers and 3 books.His research outcomes have received 3 national-level awards and 10 province-level awards in China.He had been elected as keynote speaker,technical committee member or chairman of organizing committee for several international conferences or symposiums(e.g.,the chairman/co-chairman of ISEV series).He also serves as a member of TC5(Environmental Geotechnics)under ISSMGE and a council member of IGS(International Geosynthetics Society).

15 May 2015

in revised form 28 July 2015

*Corresponding author.Tel.:+86 571 88208776.

E-mail address:chenyunmin@zju.edu.cn(Y.Chen).

Peer review under responsibility of Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.

1674-7755©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.08.007

Accepted 10 August 2015 Available online xxx

杂志排行

Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Characterizing the influence of stress-induced microcracks on the laboratory strength and fracture development in brittle rocks using a finite-discrete element method-micro discrete fracture network FDEM-μDFN approach

- Effects of fracture distribution and length scale on the equivalent continuum elastic compliance of fractured rock masses

- Shear strength behavior of geotextile/geomembrane interfaces Belén M.Bacasa,*,Jorge Cañizalb,Heinz Konietzkyc

- Effects of spatial variation in cohesion over the concrete-rock interface on dam sliding stability

- Evaluation of the effect of sodium silicate addition to mine backfill, Gelfill-Part 2:Effects of mixing time and curing temperature

- Studies on the key parameters in segmental lining design